Page 1

Manitowoc Flake or Chiplet Ice Machines

Rebuild Instructions

Disassembly

Verify that no ice is in the auger/barrel (refer to Figure 1 on Sheet 2.

1. Remove splined hub.

2. Remove key stock. Sand shaft smooth where setscrew contacted shaft.

3. Remove evaporator top cap and grease from top of evaporator.

4. Remove top snap ring (big clip). (QF2300 only - also remove spring shim.)

5. Drive auger shaft out through top of evaporator by placing a wooden 2 x 4 on the floor and tapping the auger shaft

on the 2 x 4.

6. Remove run-out collar (remove from bottom, or run-out collar will be on the auger).

7. Remove bottom shaft seal.

8. Remove lower bearing snap ring. (QF2300 only - also remove bearing shim.)

9. Drive out bottom bearing (QF2300 only - also drive out second bearing shim) with bearing removal tool (top to

bottom).

10. Remove water seal snap ring.

11. Remove water seal (top to bottom).

12. Remove snap ring from top of auger.

13. Remove top bearing with a bearing puller.

14. Remove top seal.

Cleaning after Disassembly

Inspect auger and check for damage to the following areas:

Top bearing seat

Top shaft seal area

Bottom bearing seat

Bottom seal area

Remove contamination from auger:

Clean the following with 460 grit emery cloths:

Auger shaft

Auger flights (both sides - top and bottom)

Do not clean the cutting head with sandpaper (flakers only):

The cutting head self-cleans due to ice shear - emery cloth will dull the cutting edge.

Sand the auger with emery cloth until all scale is removed.

Evaporator barrel cleaning:

Assemble wheel stack on mandrel.

Drill and shaft extension are required:

Use speeds less than 200 rpm, slower = better.

Keep moving up and down; do not stop in one spot.

Scotch-Brite disc for cleaning:

Disc must be larger than inside diameter of barrel for even contact:

2" disc used on models QF0400, QC0700, and QF0800

4" disc used on models QF2300

Clean thoroughly with multiple passes of disc and clean cloths.

Thoroughly clean water inlet and ice outlet to complete the cleaning of the barrel.

Manitowoc Ice, Inc.

2110 South 26th Street, P.O. Box 1720, Manitowoc, WI 54221-1720 USA 8014373

Telephone 920-682-0161, Fax - Sales: 920-683-7589, Service/Parts: 920-683-7585, Other: 920-683-7879 Sheet 1 of 2

Web Site - www.manitowocice.com Rev. 06/30/04

Page 2

Reassembly

Note: Upper bearing has dust seal. Bottom bearing does not have dust seal. Bearing seating tool and grease are included

with kit.

1. Grease top shaft seal and install on auger.

2. Imprinted text on bearing must face up. Install top bearing and press on both inner/outer bearing race with special

tool to seat.

3. Install run-on sleeve onto bottom of auger (taper must face seal).

4. Grease top and bottom bearing race.

5. Install auger into barrel from top down.

6. Install inner and outer snap rings at the top bearing.

7. Seat upper bearing using dead-blow hammer to drive auger up and seat upper bearing on snap rings.

8. Install water seal using special tool to apply even pressure.

9. Install water seal snap ring using special tool to compress seal and seat snap ring.

10. Bottom bearing assembly: (QF2300 only - one bearing shim must be installed before bearing.) Roller thrust

bearing is directional. Imprinted text on bearing race must face down, towards bottom of evaporator. The wider

of the two races must face up, towards the evaporator.

11. Hand-pack bearing in grease and drive in place with special tool.

12. Install snap ring in bottom. (QF2300 only - before installing snap ring, install bearing backup spring.)

13. Pack top cover with grease and install.

14. Install bottom seal. Work any air out from under the seal being careful not to cut the seal or score the shaft.

15. Hand-turn auger to check operation. You can see the first shoulder of the auger, when it is correctly installed.

16. Install key stock.

17. Install splined hub (must be flush with shaft).

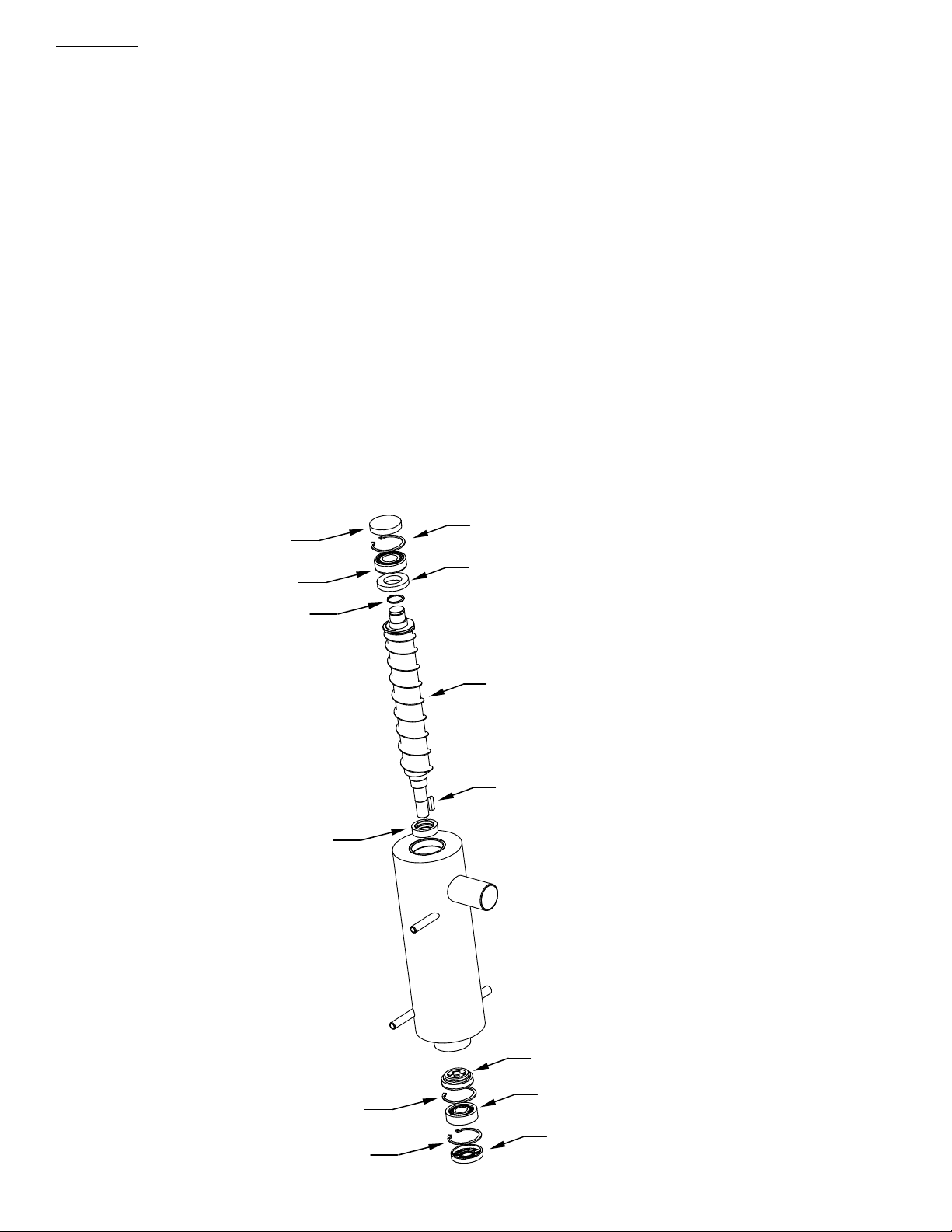

Evaporator Top Cap

Top Bearing

Auger Snap Ring

Run-Out Collar

Water Seal Snap Ring

Bearing Snap Ring

Top Bearing Snap Ring

Top Seal

Auger (optional)

Key Stock

Water Seal

Bottom Shaft Seal

Bottom Cap

Figure 1

8014373

Sheet 2 of 2

Rev. 06/30/04

Loading...

Loading...