Page 1

Marine

Q800

Ice Machine

Service Manual

Thank you for selecting a Manitowoc Ice Machine, the dependability leader in ice making equipment and

related products. With proper installation, care and maintenance, your new Manitowoc Ice Machine will

provide you with many years of reliable and economical performance.

Part Number 80-1216-3

2/2001

Page 2

Safety Notices

Procedural Notices

When using or servicing a Q Model Ice Machine, be

sure to pay close attention to the safety notices in this

manual. Disregarding the notices may lead to serious

injury and/or damage to the ice machine.

Throughout this manual, you will see the following

types of safety notices:

WARNING

Text in a Warning box alerts you to a potential

personal injury situation. Be sure to read the

Warning statement, and then proceed carefully.

CAUTION

Text in a Caution box alerts you to a situation in

which you could damage the ice machine. Be sure

to read the Caution statement, and then proceed

carefully.

When using or servicing a Q Model Ice Machine, be

sure to read the procedural notices in this manual.

These notices supply helpful and important

information.

Throughout this manual, you will see the following

types of procedural notices:

Important

Important boxes serve two functions.

They call the operator’s attention to important

information.

They also provide the service technician with

information that may help perform a procedure

more efficiently. Disregarding this information may

slow down the work.

NOTE: Text set off as a Note provides you with

simple, but useful, extra information.

CAUTION

Proper installation, care and maintenance are

essential for maximum ice production and troublefree operation of your Manitowoc Ice Machine.

Read and understand this manual. It contains

valuable care and maintenance information. If you

encounter problems not covered by this manual,

feel free to contact Manitowoc Ice, Inc. We will be

happy to provide assistance.

Important

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the

warranty.

Page 3

Table of Contents

Electrical System

Energized Parts Charts

Self-Contained Water-Cooled Models...........................................................................................................1

Wiring Diagram Sequence of Operation

Self-Contained Models.....................................................................................................................................2

Wiring Diagrams

Wiring Diagram Legend..................................................................................................................................9

Self-Contained – Q800 - 1 Phase ..................................................................................................................10

Component Specifications and Diagnostics

Main Fuse .......................................................................................................................................................11

Bin Switch.......................................................................................................................................................11

Compressor Electrical Diagnostics...............................................................................................................13

PTCR Diagnostics..........................................................................................................................................14

Ice/Off/Clean Toggle Switch .........................................................................................................................17

Control Board Relays....................................................................................................................................17

Electronic Control Board..............................................................................................................................18

Ice Thickness Probe (Harvest Initiation)

How the Probe Works ...................................................................................................................................20

Harvest/Safety Limit Light ...........................................................................................................................20

Freeze Time Lock-In Feature.......................................................................................................................20

Maximum Freeze Time..................................................................................................................................20

Diagnosing Ice Thickness Control Circuitry

Ice Machine Does Not Cycle Into Harvest When Water Contacts The Ice Thickness Probe...........21

Ice Machine Cycles Into Harvest Before Water Contact With The Ice Thickness Probe................22

Diagnosing Ice Machine That Will Not Run..........................................................................................23

Page 4

Table of Contents (cont.)

Refrigeration System

Sequence of Operation

Self-Contained Water-Cooled Models.........................................................................................................25

Operational Analysis (Diagnostics)

General............................................................................................................................................................27

Before Beginning Service ..............................................................................................................................28

Ice Production Check ....................................................................................................................................28

Installation/Visual Inspection Checklist......................................................................................................29

Water System Checklist ................................................................................................................................29

Ice Formation Pattern ...................................................................................................................................30

Safety Limits...................................................................................................................................................32

Comparing Evaporator Inlet and Outlet Temperatures............................................................................35

Hot Gas Valve Temperature Check.............................................................................................................36

Analyzing Discharge Pressure During Freeze or Harvest Cycle

Procedure..................................................................................................................................................37

Freeze Cycle Discharge Pressure High Checklist.................................................................................37

Freeze Cycle Discharge Pressure Low Checklist..................................................................................37

Analyzing Suction Pressure During Freeze Cycle

Procedure..................................................................................................................................................38

Freeze Cycle Suction Pressure High Checklist .....................................................................................39

Freeze Cycle Suction Pressure Low Checklist......................................................................................39

How to Use the Refrigeration System Operational Analysis Tables.........................................................40

Refrigeration System Operational Analysis Table

Single TXV................................................................................................................................................41

Pressure Control Specifications and Diagnostics

High Pressure Cutout (HPCO) Control.......................................................................................................42

Cycle Time/24 Hour Ice Production/Refrigerant Pressure Charts

Q800 ................................................................................................................................................................43

Refrigerant Recovery/Evacuating and Recharging

Normal Self-Contained Model Procedures..................................................................................................44

System Contamination Cleanup...................................................................................................................45

Replacing Pressure Controls Without Removing Refrigerant Charge ....................................................48

Filter-Driers....................................................................................................................................................50

Total System Refrigerant Charges...............................................................................................................50

Refrigerant Definitions..................................................................................................................................51

Refrigerant Re-Use Policy.............................................................................................................................52

HFC Refrigerant Questions and Answers...................................................................................................53

Page 5

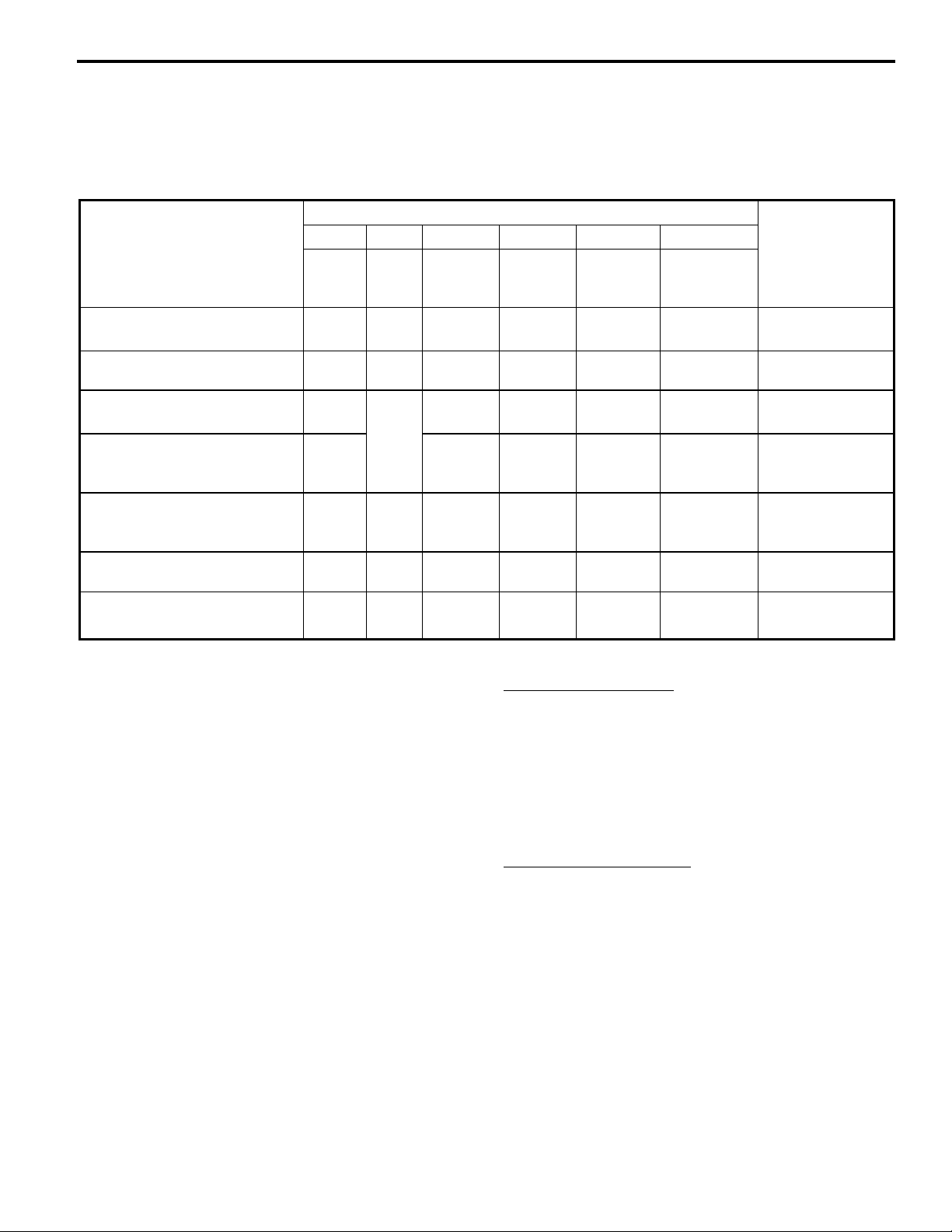

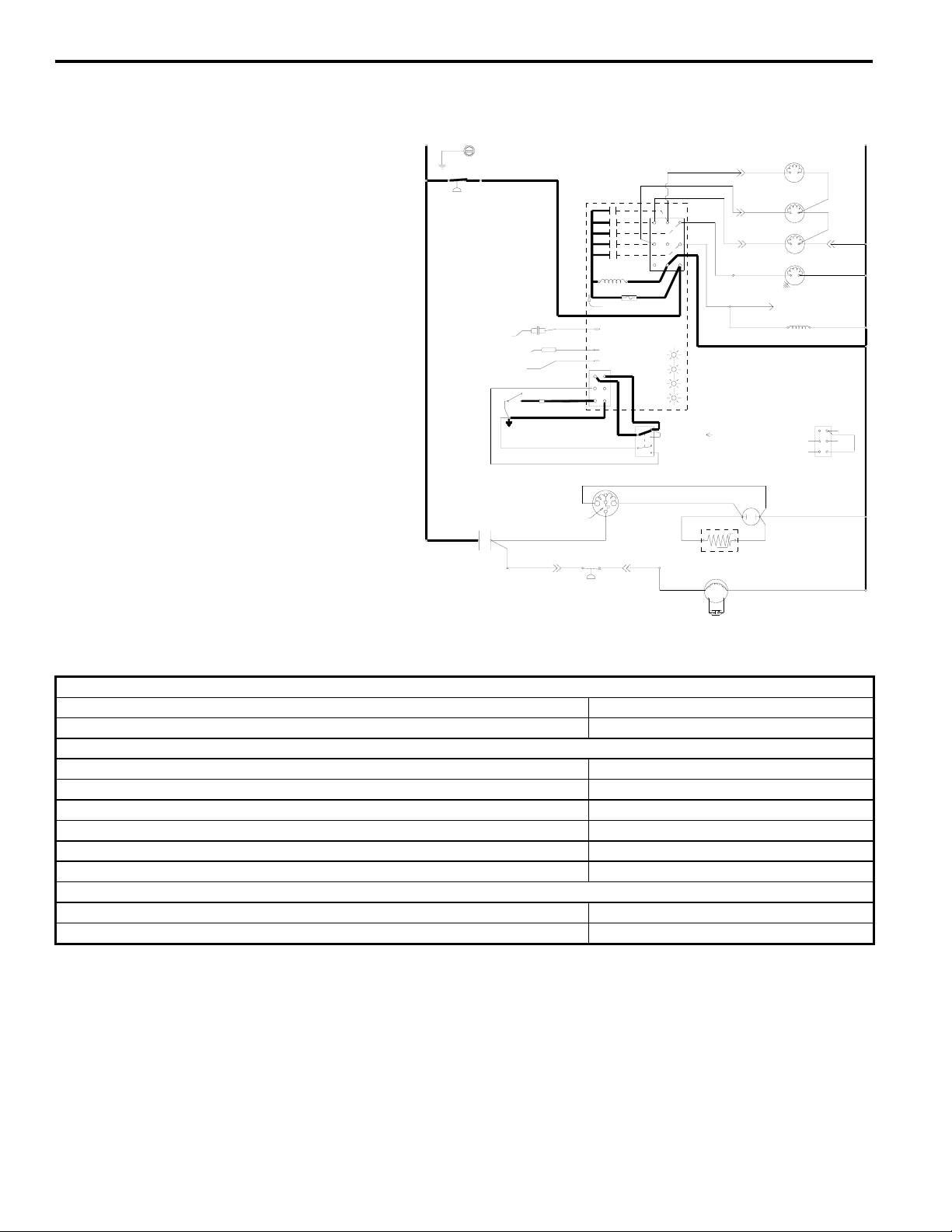

Electrical System

Energized Parts Charts

SELF-CONTAINED WATER-COOLED MODELS

Ice Making Control Board Relays

Sequence

Of

Operation

Start-Up

1. Water Purge

2. Refrigeration System

1

Start-Up

Freeze Sequence

3. Pre-Chill

Freeze

Harvest Sequence

5. Water Purge

6. Harvest

7. Automatic

Shut-Off

1

Initial Start-Up or Start-Up After Automatic Shut-Off

Harvest Water Purge

The circuit board has an adjustable water purge in

the harvest cycle. This permits a 15, 30 or 45

second purge cycle.

Auto Shut-Off

The ice machine remains off for 3 minutes before it

can automatically restart. The ice machine restarts

(steps 1-2) immediately after the delay period, if the

bin switch re-closes prior to 3 minutes.

Safety Timers

The control board has the following non-adjustable

safety timers:

1 2 3 4 5 5A Length

Water

Pump

On

Off

Off

On

On

Off

Off

Hot Gas

Valve(s)

On

On

Off

Off

On

On

Off

Electrical System

Water

Dump

Valve

On

Off

Off

Off

On

Off

Off

Contactor

Coil

Off

On

On

On

On

On

Off

FREEZE SEQUENCE

• The ice machine is locked into the freeze cycle

for the first 6 minutes, not allowing the ice

thickness probe to initiate a harvest sequence.

• The maximum freeze time is 60 minutes, at

which time the control board automatically

initiates a harvest sequence (steps 5-6).

HARVEST SEQUENCE

The maximum harvest time is 3-1/2 minutes, at

which time the control board automatically

terminates the harvest sequence. If the bin switch is

open, the ice machine will go to automatic shut-off

(step7). If the bin switch is closed, the ice machine

will go to the freeze sequence (steps 3-4).

Compressor

Off

On

On

On

On

On

Off

Of

Time

45 Seconds

5 Seconds

30 Seconds

Until 7 sec. water

contact with ice

thickness probe

Factory-set at

45 Seconds

Bin switch

activation

Until bin switch

re-closes

1

Page 6

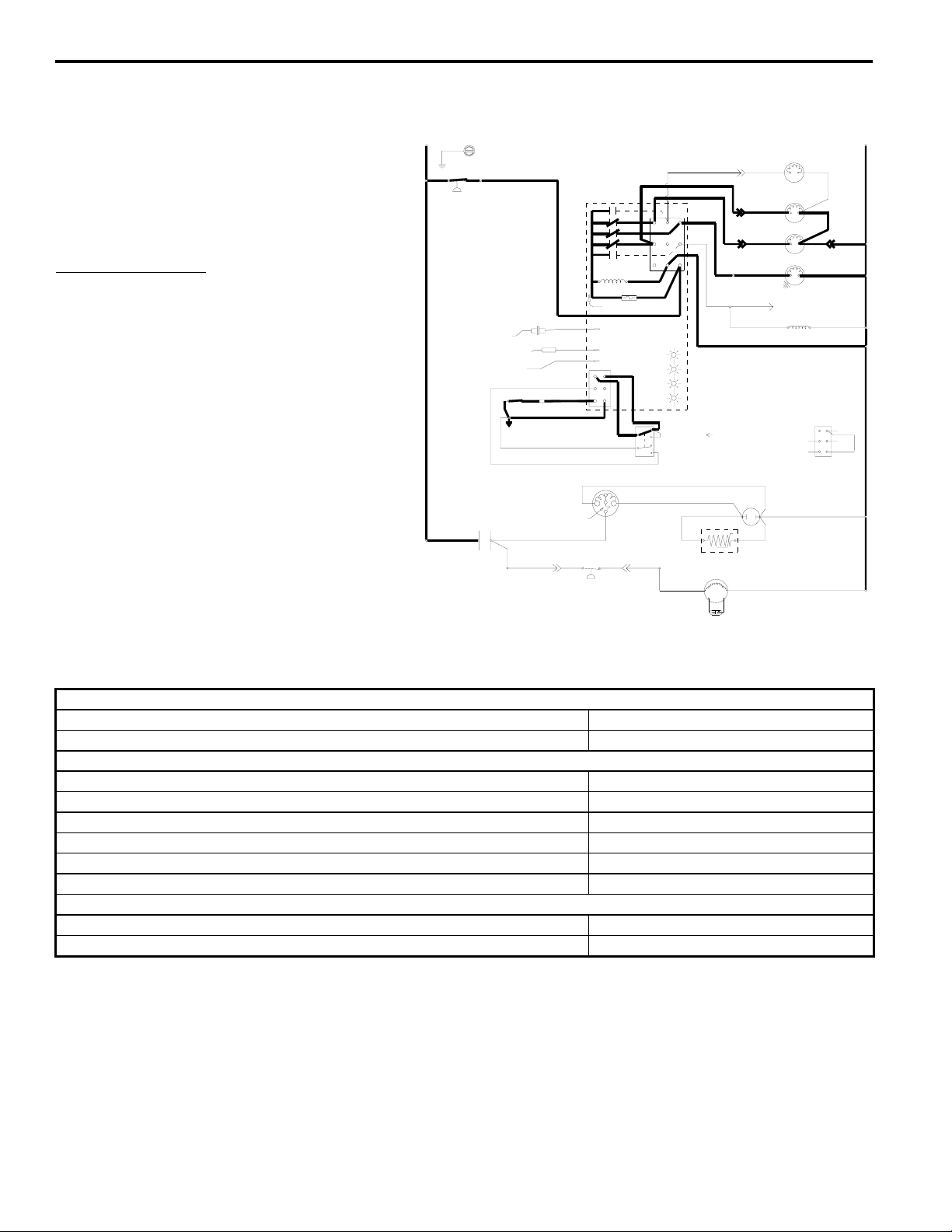

Electrical System

T

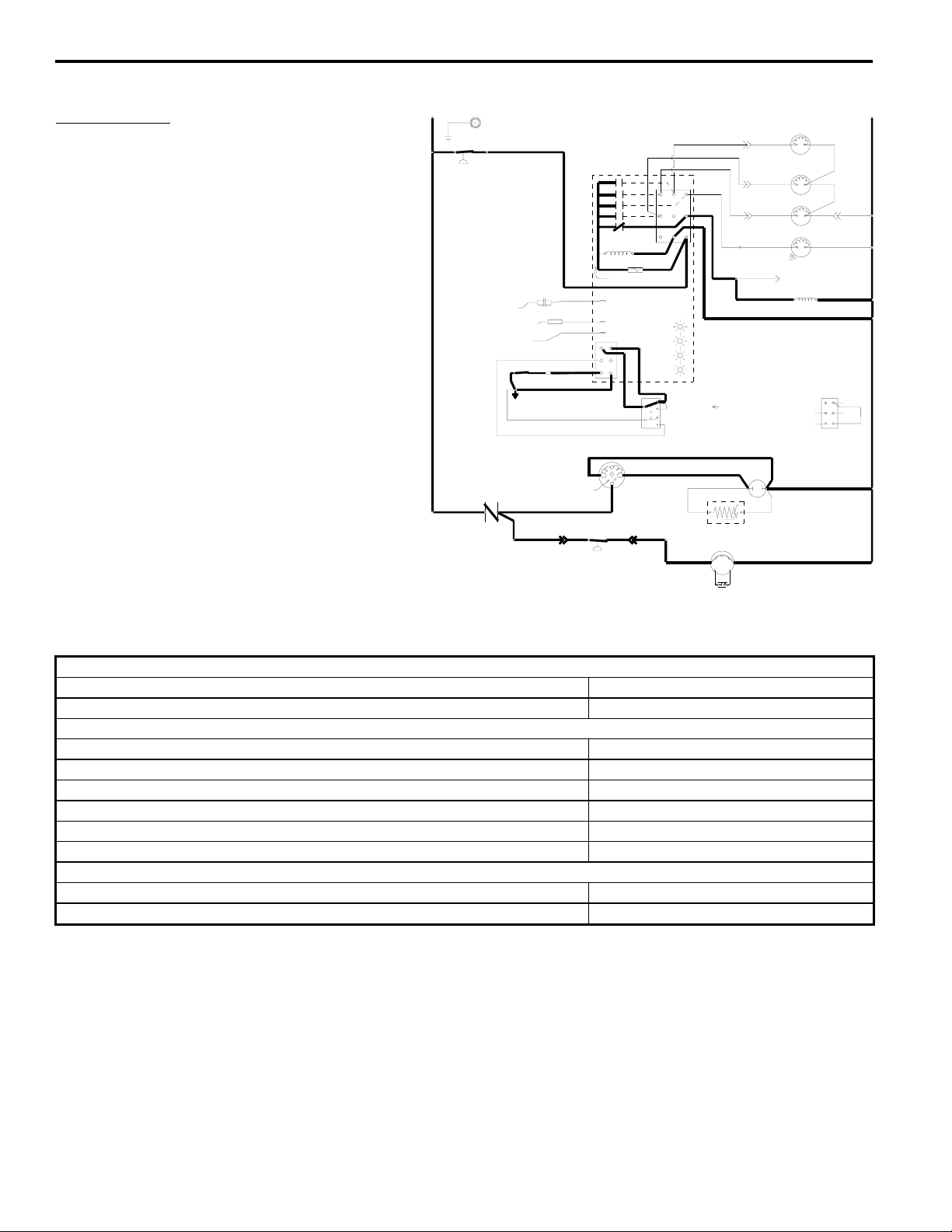

Wiring Diagram Sequence of Operation

SELF-CONTAINED MODELS

Initial Start-Up or Start-Up After Automatic Shut-Off

1. WATER PURGE

Before the compressor starts, the water

pump and water dump solenoid are

energized for 45 seconds to purge old water

from the ice machine. This ensures that the

ice-making cycle starts with fresh water.

The hot gas valve(s) is also energized

during the water purge. In the case of an

initial refrigeration start-up, it stays on for

an additional 5 seconds (50 seconds total).

L1

TB35

TB35

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

CONTACTOR

CONTACTS

(42)

L1

TB33

(64)

(66)

(51)

(55)

BIN SWITCH

(52)

(62)

(63)

(65)

*OVERLOAD

(48)

R

(85) (86)

FAN CYCLE CONTROL

2

4

1

3

5

TRANS.

1C

1F

1G

C

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

(68)

(69)

(62)

(49)

(47)

(53)

TB34

RUN CAPACITOR**

SEE SERIAL PLATE FOR VOLTAGE

(61)

(60)

(58)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

ICE

OFF

CLEAN

RUN CAPACITOR

(46) (50)

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

(57)

TB31

TB37

(59)

(73)

(56)

TOGGLE SWITCH

INTERNAL WORKING

VIEW

R

(45)

PTCR

FAN MOTOR

(AIR COOLED ONLY)

(98)

TERMINATES AT

PIN CONNECTION

CONTACTOR

COIL

VIEW FOR WIRING

R

66

62

(22)

(80)

(81)

WATER

PUMP

L2 (N)

(75)

(99)

(74)

68

67

69

SV1646-1

TB30

TB30

TB30

TB30

B30

TB30

Self-Contained Models

1. Water Purge (45 Seconds)

Toggle Switch

Bin Switch

Control Board Relays

#1 Water Pump Closed / ON

#2

#3 Hot Gas Solenoid Closed / ON

#4 Water Dump Valve Closed / ON

#5 Contactor Coil Open / OFF

Compressor OFF

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

ICE

Closed

2

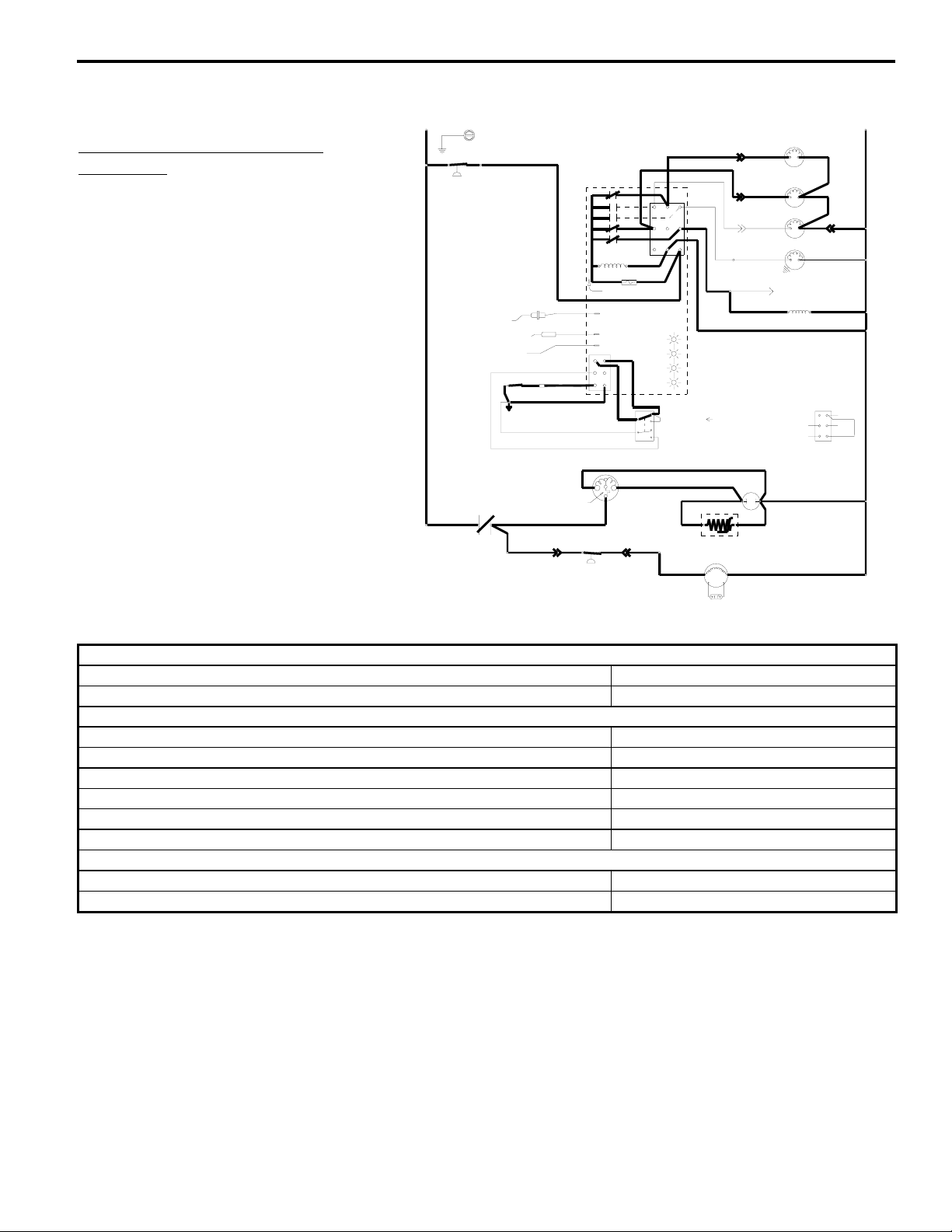

Page 7

T

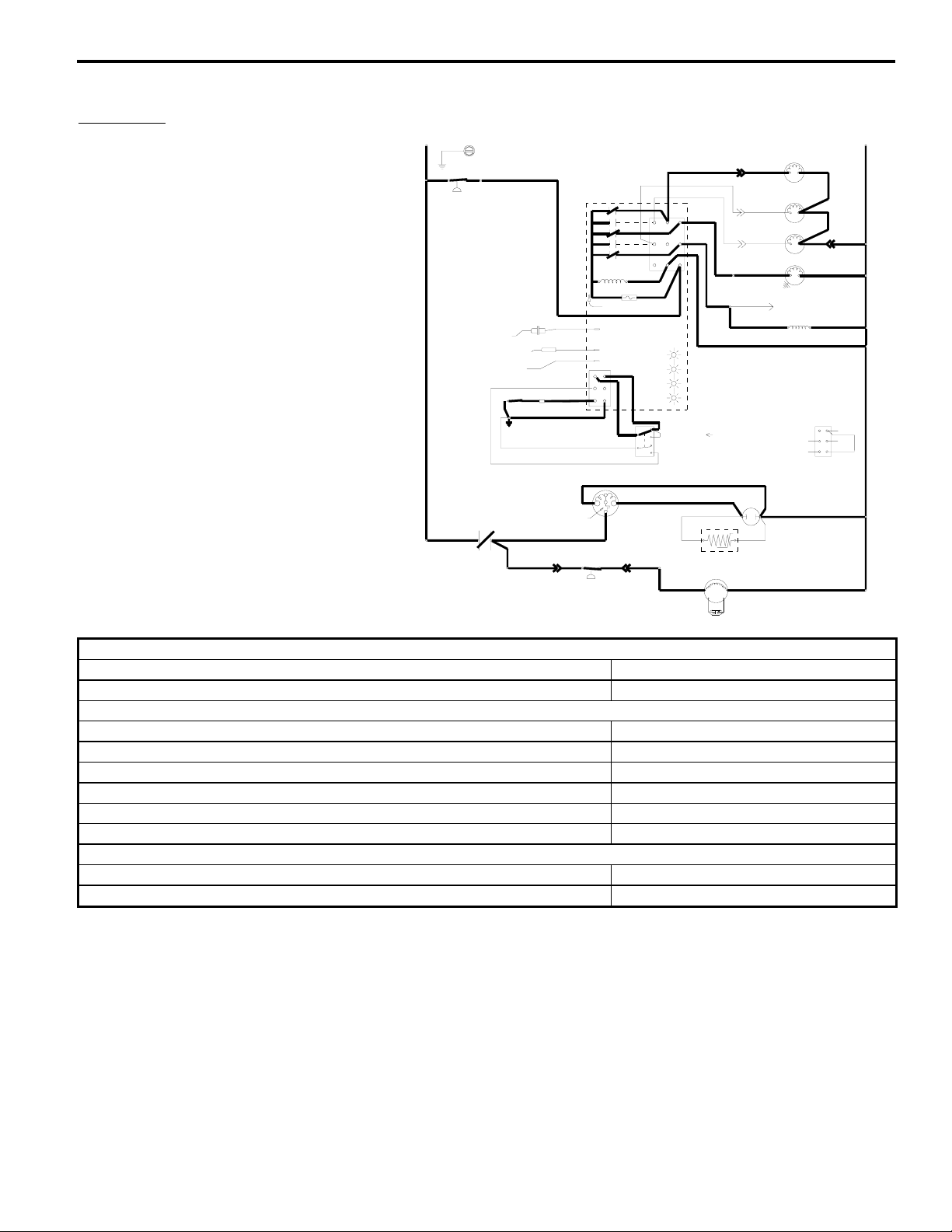

Initial Start-Up Or Start-Up After Automatic Shut-Off (cont.)

2. REFRIGERATION SYSTEM

START-UP

The compressor starts after the 45second water purge, and it remains on

throughout the Freeze and Harvest

cycles.

The hot gas valve(s) remains on for

the first 5 seconds of the initial

compressor start-up.

L1

TB35

TB35

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

CONTACTOR

CONTACTS

(42)

L1

TB33

(64)

(66)

(51)

(55)

BIN SWITCH

(52)

(62)

(63)

(65)

*OVERLOAD

(48)

R

(85) (86)

FAN CYCLE CONTROL

2

4

1

3

5

TRANS.

1C

1F

1G

C

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

(68)

(62)

(53)

RUN CAPACITOR**

Self-Contained Models

2. Refrigeration System Start-Up (5 Seconds)

Toggle Switch

Bin Switch

Control Board Relays

#1 Water Pump Open / OFF

#2

#3 Hot Gas Solenoid Closed / ON

#4 Water Dump Valve Open / OFF

#5 Contactor Coil Closed / ON

Compressor ON

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

ICE

Closed

Electrical System

(61)

(60)

(57)

(58)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

TOGGLE SWITCH

ICE

(69)

INTERNAL WORKING

OFF

VIEW

CLEAN

(49)

RUN CAPACITOR

(47)

(46) (50)

PTCR

TB34

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

TB31

TB37

(59)

(73)

(56)

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

(98)

TERMINATES AT

PIN CONNECTION

CONTACTOR

COIL

VIEW FOR WIRING

R

(80)

66

62

(22)

(81)

WATER

PUMP

L2 (N)

(75)

(99)

(74)

68

67

69

SV1646-2

TB30

TB30

TB30

TB30

B30

TB30

3

Page 8

Electrical System

T

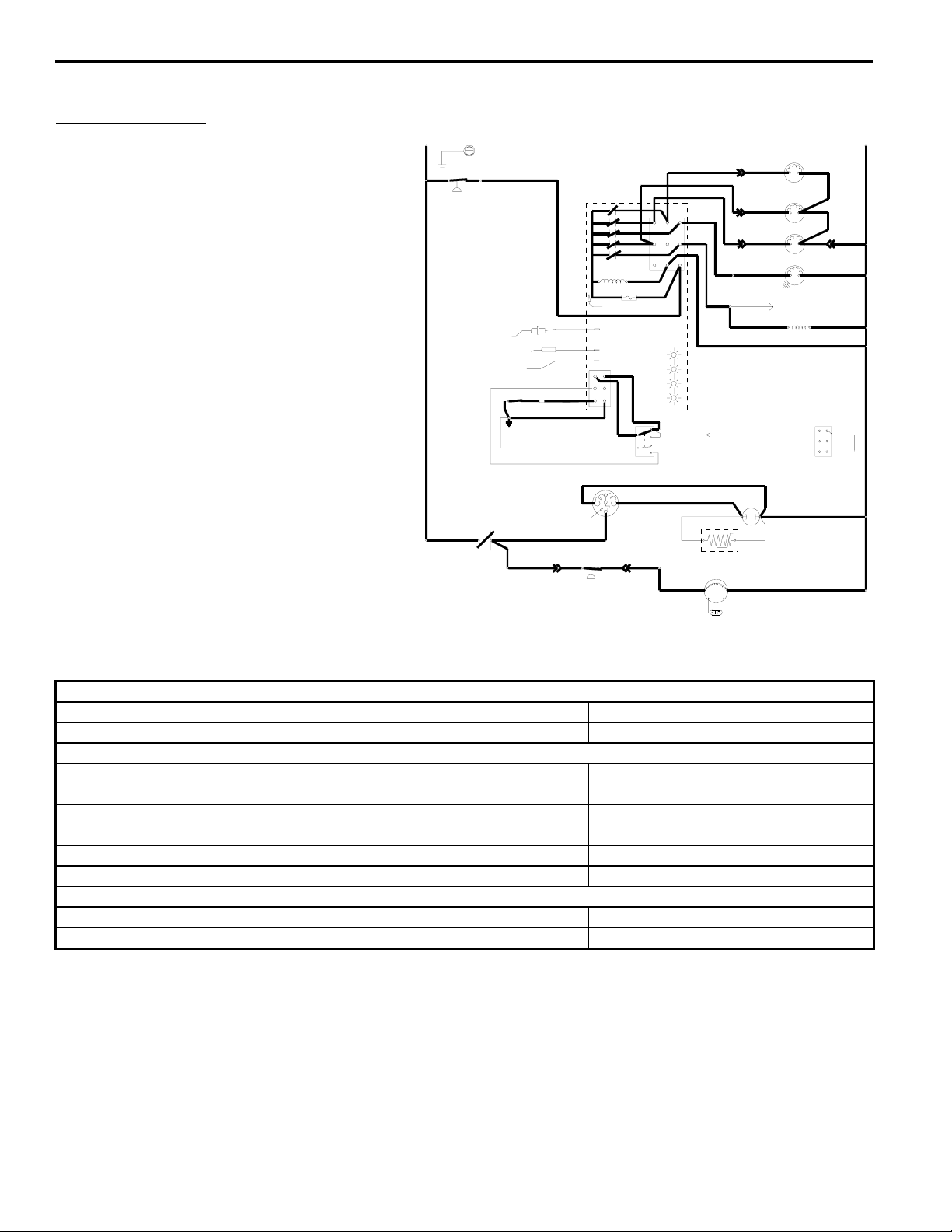

Freeze Sequence

3. PRE-CHILL

To pre-chill the evaporator, the compressor

runs for 30 seconds prior to water flow.

L1

TB35

TB35

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

CONTACTOR

CONTACTS

(42)

L1

TB33

(64)

(66)

(51)

(55)

BIN SWITCH

(52)

(62)

(63)

(65)

*OVERLOAD

(48)

R

(85) (86)

FAN CYCLE CONTROL

2

4

1

3

5

TRANS.

1C

1F

1G

C

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

RUN CAPACITOR**

Self-Contained Models

3. Pre-Chill (30 Seconds)

Toggle Switch

Bin Switch

Control Board Relays

#1 Water Pump Open / OFF

#2

#3 Hot Gas Solenoid Open / OFF

#4 Water Dump Valve Open / OFF

#5 Contactor Coil Closed / ON

Compressor ON

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

ICE

Closed

(53)

(61)

(60)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(68)

ICE

(69)

OFF

CLEAN

(62)

(49)

RUN CAPACITOR

(47)

TB34

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

(57)

(58)

TOGGLE SWITCH

INTERNAL WORKING

VIEW

(46) (50)

PTCR

(98)

TB31

TB37

(59)

TERMINATES AT

PIN CONNECTION

(73)

(56)

R

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

CONTACTOR

COIL

VIEW FOR WIRING

66

62

(22)

(80)

(81)

WATER

PUMP

(99)

(74)

68

67

(75)

69

L2 (N)

TB30

TB30

TB30

TB30

B30

TB30

4

Page 9

T

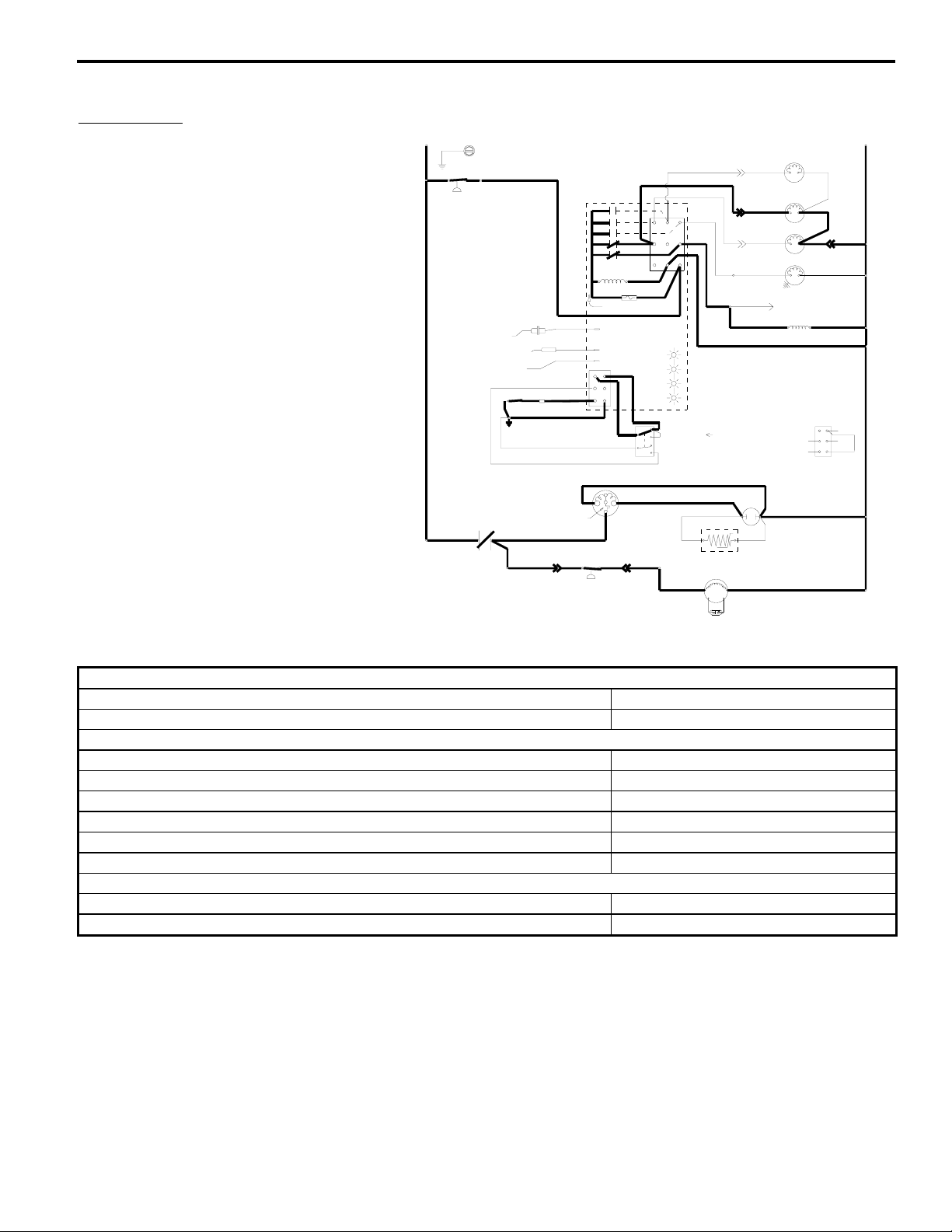

Freeze Sequence (cont.)

4. FREEZE

The water pump starts after the 30second pre-chill. An even flow of

water is directed across the evaporator

and into each cube cell, where it

freezes.

When sufficient ice has formed, the

water flow (not the ice) contacts the

ice thickness probes. After

approximately 7 seconds of continual

contact, a harvest cycle is initiated.

NOTE: The ice machine cannot

initiate a harvest cycle until a 6minute freeze lock has expired.

Self-Contained Models

Electrical System

L1

(55)

TB35

TB35

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

CONTACTOR

CONTACTS

(42)

L1

TB33

(64)

(66)

(51)

BIN SWITCH

(52)

(62)

(63)

(65)

*OVERLOAD

(48)

R

(85) (86)

FAN CYCLE CONTROL

2

4

1

3

5

TRANS.

1C

1F

1G

C

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

RUN CAPACITOR**

(53)

(61)

(60)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(68)

ICE

(69)

OFF

CLEAN

(62)

(49)

(47)

TB34

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

(57)

(58)

TOGGLE SWITCH

INTERNAL WORKING

VIEW

RUN CAPACITOR

(46) (50)

PTCR

(98)

TB31

TB37

(59)

TERMINATES AT

PIN CONNECTION

(73)

(56)

R

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

CONTACTOR

COIL

VIEW FOR WIRING

66

62

(22)

(80)

(81)

WATER

PUMP

L2 (N)

(75)

(99)

(74)

68

67

69

SV1646-4

TB30

TB30

TB30

TB30

B30

TB30

4. Freeze (Until 7 Seconds of Water Contact with Ice Thickness Probe)

Toggle Switch

Bin Switch

ICE

Closed

Control Board Relays

#1 Water Pump Closed / ON

#2

#3 Hot Gas Solenoid Open / OFF

#4 Water Dump Valve Open / OFF

#5 Contactor Coil Closed / ON

Compressor ON

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

5

Page 10

Electrical System

T

2

4

1

3

5

TRANS.

FUSE (7A)

Harvest Sequence

5. WATER PURGE

The water pump continues to run, and

the water dump valve energizes for 45

seconds to purge the water in the sump

trough.

After the 45 second water purge, the

water pump and dump valve de-

L1

(55)

TB35

HIGH PRES

CUTOUT

TB32

energize. The hot gas valve also

opens at the beginning of the water

purge to divert hot refrigerant gas into

the evaporator.

TB35

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

(64)

(66)

CONTACTOR

CONTACTS

(42)

L1

(51)

TB33

BIN SWITCH

*OVERLOAD

(48)

(52)

FAN CYCLE CONTROL

1C

1F

1G

(62)

(63)

(65)

R

C

(85) (86)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

(53)

RUN CAPACITOR**

Self-Contained Models

5. Water Purge (45 Seconds)

Toggle Switch

Bin Switch

ICE

Closed

Control Board Relays

#1 Water Pump Closed / ON

#2

#3 Hot Gas Solenoid Closed / ON

#4 Water Dump Valve Closed / ON

#5 Contactor Coil Closed / ON

Compressor ON

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

(61)

(60)

(58)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(68)

(69)

(62)

TOGGLE SWITCH

ICE

INTERNAL WORKING

OFF

VIEW

CLEAN

(49)

RUN CAPACITOR

(47)

(46) (50)

PTCR

TB34

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

(57)

(98)

TB31

TB37

(59)

TERMINATES AT

PIN CONNECTION

(73)

(56)

R

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

CONTACTOR

COIL

VIEW FOR WIRING

66

62

(22)

(80)

(81)

WATER

PUMP

L2 (N)

(75)

(99)

(74)

68

67

69

SV1646-5

TB30

TB30

TB30

TB30

B30

TB30

6

Page 11

T

Harvest Sequence (cont.)

6. HARVEST

The hot gas valve(s) remains open,

allowing refrigerant gas to warm the

evaporator. This causes the cubes to

slide, as a sheet, off the evaporator and

into the storage bin.

The sliding sheet of cubes swings the

water curtain out, opening the bin

switch. This momentary opening and

closing of the bin switch terminates

the Harvest Cycle and returns the ice

machine to the Freeze Cycle (steps 3-

4).

L1

TB35

TB35

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

CONTACTOR

CONTACTS

(42)

L1

TB33

(64)

(66)

(51)

(55)

BIN SWITCH

(52)

(62)

(63)

(65)

*OVERLOAD

(48)

R

(85) (86)

FAN CYCLE CONTROL

2

4

1

3

5

TRANS.

1C

1F

1G

C

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

(68)

(62)

(53)

RUN CAPACITOR**

Self-Contained Models

6. Harvest (Until Bin Switch Activation)

Toggle Switch

Bin Switch

Control Board Relays

#1 Water Pump Open / OFF

#2

#3 Hot Gas Solenoid Closed / ON

#4 Water Dump Valve Open / OFF

#5 Contactor Coil Closed / ON

Compressor ON

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

ICE

Closed

Electrical System

(61)

(60)

(57)

(58)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

TOGGLE SWITCH

ICE

(69)

INTERNAL WORKING

OFF

VIEW

CLEAN

(49)

RUN CAPACITOR

(47)

(46) (50)

PTCR

TB34

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

TB31

TB37

(59)

(73)

(56)

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

(98)

TERMINATES AT

PIN CONNECTION

CONTACTOR

COIL

VIEW FOR WIRING

R

(80)

66

62

(22)

(81)

WATER

PUMP

L2 (N)

(75)

(99)

(74)

68

67

69

SV1646-6

TB30

TB30

TB30

TB30

B30

TB30

7

Page 12

Electrical System

T

7. Automatic Shut-Off

If the storage bin is full at the end of a

harvest cycle, the sheet of cubes fails

to clear the water curtain and holds it

open. After the water curtain is held

open for 7 seconds, the ice machine

shuts off.

The ice machine remains off until

enough ice is removed from the

storage bin to allow the sheet of cubes

to drop clear of the water curtain. As

the water curtain swings back to the

operating position, the bin switch

closes and the ice machine restarts

(steps 1-2).

NOTE: The ice machine must remain

L1

TB35

TB32

HIGH PRES

CUTOUT

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

(64)

(66)

(55)

BIN SWITCH

(62)

(63)

(65)

2

4

1

3

5

TRANS.

1C

1F

1G

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

off for 3 minutes before it can

automatically restart.

TB35

(42)

CONTACTOR

CONTACTS

L1

TB33

(51)

(52)

*OVERLOAD

(48)

(85)

FAN CYCLE CONTROL

R

C

(86)

COMPRESSOR

S

RUN CAPACITOR**

Self-Contained Models

7. Automatic Shut-Off (Until Bin Switch Closes)

Toggle Switch

Bin Switch

ICE

Open

Control Board Relays

#1 Water Pump Open / OFF

#2

#3 Hot Gas Solenoid Open / OFF

#4 Water Dump Valve Open / OFF

#5 Contactor Coil Open / OFF

Compressor OFF

Safety Controls (Which could stop ice machine operation)

High Pressure Cut-Out Closed

Main Fuse (On Control Board) Closed

(53)

(61)

(60)

(58)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(68)

(69)

(62)

TOGGLE SWITCH

ICE

INTERNAL WORKING

OFF

VIEW

CLEAN

(49)

RUN CAPACITOR

(47)

(46) (50)

PTCR

TB34

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

(57)

(98)

TB31

TB37

(59)

TERMINATES AT

PIN CONNECTION

(73)

(56)

R

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

CONTACTOR

COIL

VIEW FOR WIRING

66

62

(22)

(80)

(81)

WATER

PUMP

L2 (N)

(75)

(99)

(74)

68

67

69

SV1646-7

TB30

TB30

TB30

TB30

B30

TB30

8

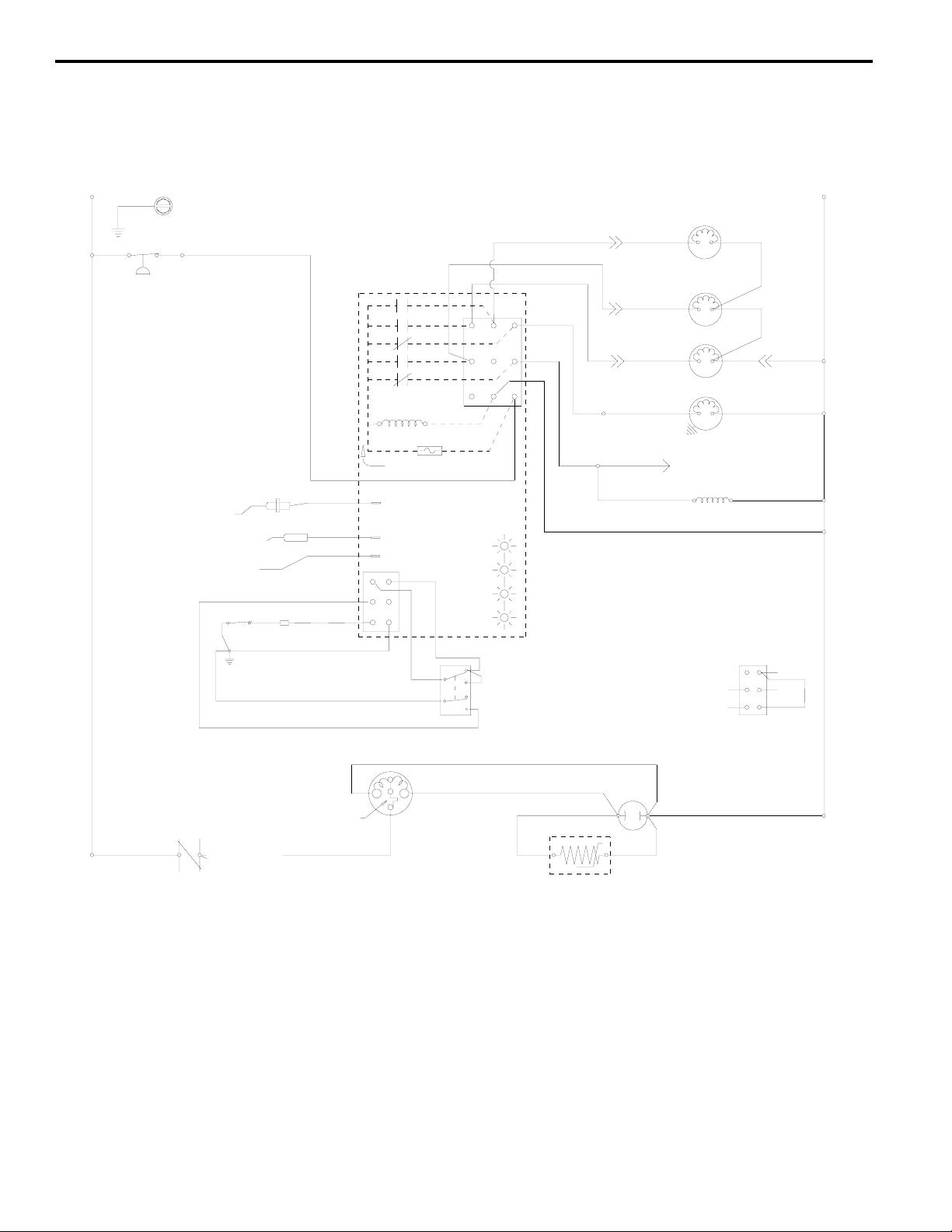

Page 13

Electrical System

Wiring Diagrams

The following pages contain electrical wiring diagrams. Be sure you are referring to the correct diagram for

the ice machine which you are servicing.

WARNING

Always disconnect power before working on

electrical circuitry.

WIRING DIAGRAM LEGEND

The following symbols are used on all of the wiring diagrams:

* Internal Compressor Overload

(Some models have external compressor overloads)

TB Terminal Board Connection

(Terminal board numbers are printed on the actual terminal board)

( ) Wire Number Designation

(The number is marked at each end of the wire)

⎯>>⎯ Multi-Pin Connection

(Electrical Box Side) ⎯>>⎯ (Compressor Compartment Side)

9

Page 14

Electrical System

(62) (63) (64) (65) (66) (66)

(67)

(68)

(69)

(62)

(74)

(55) (61)

(60)

(77)

(76)

(80) (75)

(98)

(57)

(99)

(81)

(58)

(59)

(73)

(56)

A

(7A)

(21)

(22)

V

(49)

(48)

(47)

(42)

(50)

(45)

(46)

Q800 - 1 PHASE

L1

CAUTION: DISCONNECT POWER BEFORE

WORKING ON ELECTRICAL CIRCUITRY.

NOTE: DIAGRAM SHOWN DURING FREEZE CYCLE.

SEE SERIAL PLATE FOR VOLTAGE

L2 (N)

TB

35

HIGH

PRESSURE

CUT-OUT

ICE THICKNESS PROBE

TB32

WATER LEVEL PROBE

NOT USED

BIN SWITCH

WATER

ALVE

2

4

1

3

5

TR

1C

1F

1G

NS.

FUSE

LOW D.C.

VOLTAGE

PLUG

TOGGLE SWITCH

CLEAN LIGHT

WATER LEVEL LIGHT

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

ICE

OFF

CLEAN

TB31

TB37

← INTERNAL

WORKING VIEW

HOT GAS

SOLENOID

DUMP

SOLENOID

PIN CONNECTION

TERMINATES AT

CONTACTOR

COIL

WATER

PUMP

VIEW FOR WIRING

68

66

62

67

69

TB30

TB30

TB30

TB30

TB35

10

CONTACTOR

CONTACTS

L1

*OVERLOAD

COMPRESSOR

SR

C

RUN CAPACITOR

RR

TB30

PTCR

SV1646

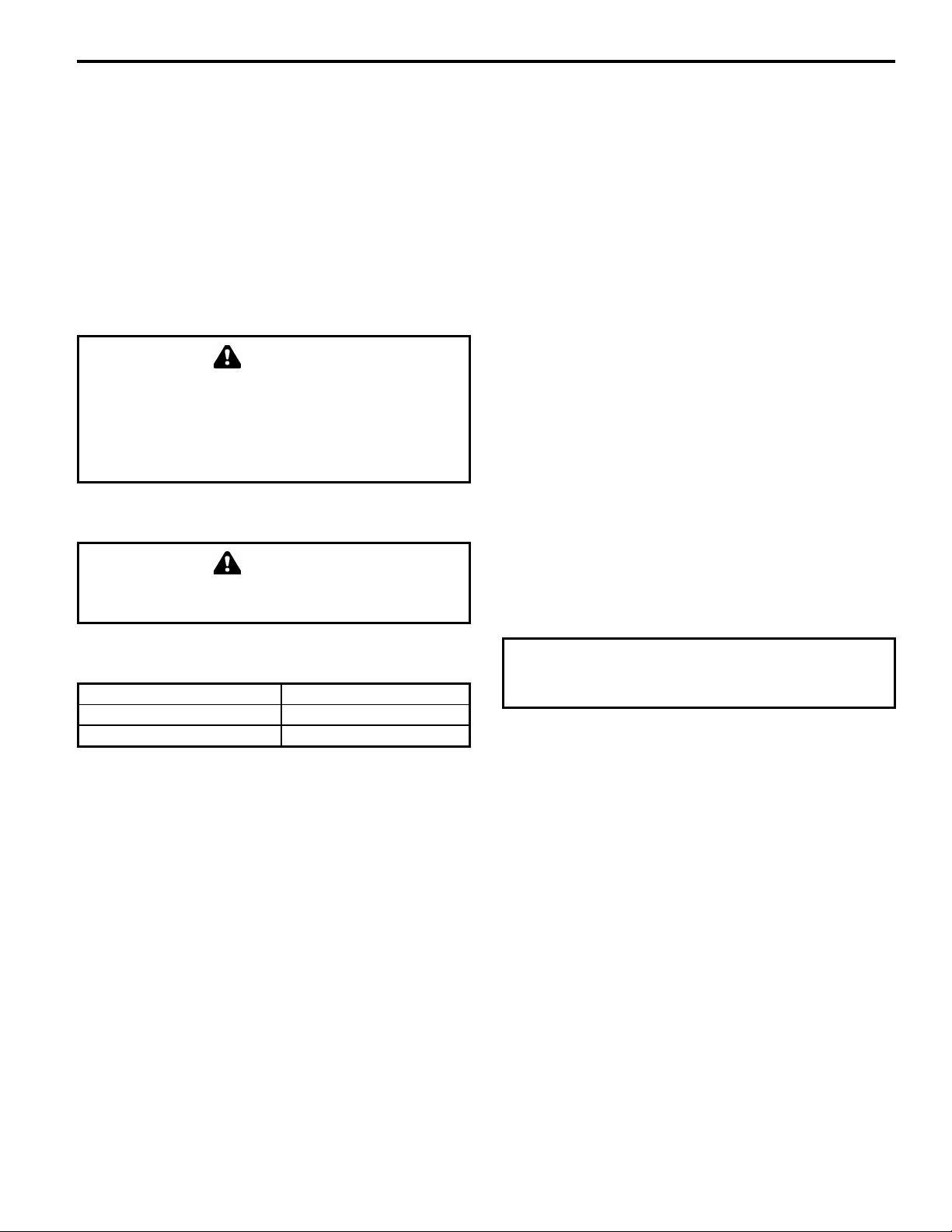

Page 15

Component Specifications and Diagnostics

MAIN FUSE

Function

The control board fuse stops ice machine operation

if electrical components fail causing high amp

draw.

Specifications

The main fuse is 250 Volt, 7 amp.

Check Procedure

WARNING

High (line) voltage is applied to the control board

BIN SWITCH

Function

Bin switch operation is controlled by movement of

the water curtain. The bin switch has two main

functions:

1. Terminating the harvest cycle and returning the

2. Automatic ice machine shut-off.

(terminals #55 and #56) at all times. Removing

the control board fuse or moving the toggle

switch to OFF will not remove the power

supplied to the control board.

1. If the bin switch light is on with the water

curtain closed, the fuse is good.

WARNING

Disconnect electrical power to the entire ice

machine before proceeding.

2. Remove the fuse. Check the resistance across

the fuse with an ohm meter.

Reading Result

Open (OL) Replace fuse

Closed (O) Fuse is good

The water curtain must be ON (bin switch closed)

to start ice making.

Specifications

The bin switch is a magnetically operated reed

switch. The magnet is attached to the lower right

corner of the water curtain. The switch is attached

to the evaporator mounting bracket.

The bin switch is connected to a varying D.C.

voltage circuit. (Voltage does not remain constant.)

NOTE: Because of a wide variation in D.C. voltage,

it is not recommended that a voltmeter be used to

check bin switch operation.

Electrical System

ice machine to the freeze cycle.

This occurs when the bin switch is opened and

closed again within 7 seconds during the harvest

cycle.

If the storage bin is full at the end of a harvest

cycle, the sheet of cubes fails to clear the water

curtain and holds it open. After the water curtain

is held open for 7 seconds, the ice machine

shuts off.

The ice machine remains off until enough ice is

removed from the storage bin to allow the sheet

of cubes to drop clear of the water curtain. As

the water curtain swings back to the operating

position, the bin switch closes and the ice

machine restarts.

Important

11

Page 16

Electrical System

Check Procedure

1. Set the toggle switch to OFF.

2. Watch the bin switch light on the control board.

3. Move the water curtain toward the evaporator.

The bin switch must close. The bin switch light

“on” indicates the bin switch has closed

properly.

4. Move the water curtain away from the

evaporator. The bin switch must open. The bin

switch light “off” indicates the bin switch has

opened properly.

Ohm Test

1. Disconnect the bin switch wires to isolate the

bin switch from the control board.

2. Connect an ohmmeter to the disconnected bin

switch wires. Set the ohmmeter to the 10,000

ohm scale.

3. Cycle the bin switch by opening and closing the

water curtain.

4. With the bin switch open: Resistance readings

of more than 30,000 ohms indicate a correctly

operating bin switch.

5. With the bin switch closed: Resistance readings

of less than 70 ohms indicates a correctly

operating bin switch.

Important

Any reading between 70 and 30,000 ohms,

regardless of curtain position, indicates a

defective bin switch

Water Curtain Removal Notes

The water curtain must be on (bin switch closed) to

start ice making. While a freeze cycle is in progress,

the water curtain can be removed and installed at

any time without interfering with the electrical

control sequence.

If the ice machine goes into harvest sequence while

the water curtain is removed, one of the following

will happen:

• Water curtain remains off

When the harvest cycle time reaches 3.5

minutes and the bin switch is not closed, the ice

machine stops as though the bin were full.

• Water curtain is put back on

If the bin switch closes prior to reaching the 3.5

minute point, the ice machine immediately

returns to another freeze sequence prechill.

12

30,000 OHMS

SWITCH OPEN

70 OHMS

SWITCH CLOSED

0 OHMS

GOOD

BAD

Bin Switch Resistance Readings

GOOD

INFINITE

OHMS

METER

READS

(OL)

Page 17

COMPRESSOR ELECTRICAL DIAGNOSTICS

The compressor will not start or will trip repeatedly

on overload.

Check Resistance (Ohm) Values

NOTE: Compressor windings can have very low

ohm values. Use a properly calibrated meter.

Perform the resistance test after the compressor

cools. The compressor dome should be cool enough

to touch (below 120°F/49°C) to assure that the

overload is closed and the resistance readings will

be accurate.

SINGLE PHASE COMPRESSORS

1. Disconnect power from the cuber and remove

the wires from the compressor terminals.

2. The resistance values must be within published

guidelines for the compressor. The resistance

values between C and S and between C and R,

when added together, should equal the

resistance value between S and R.

3. If the overload is open, there will be a resistance

reading between S and R, and open readings

between C and S and between C and R. Allow

the compressor to cool, then check the readings

again.

Check Motor Windings to Ground

Check continuity between all three terminals and

the compressor shell or copper refrigeration line.

Scrape metal surface to get good contact. If

continuity is present, the compressor windings are

grounded and the compressor should be replaced.

Electrical System

Determine if the Compressor is Seized

Check the amp draw while the compressor is trying

to start.

COMPRESSOR DRAWING LOCKED ROTOR

The two likely causes of this are:

• Defective starting component

• Mechanically seized compressor

To determine which you have:

1. Install high and low side gauges.

2. Try to start the compressor.

3. Watch the pressures closely.

A. If the pressures do not move, the compressor

is seized. Replace the compressor.

B. If the pressures move, the compressor is

turning slowly and is not seized. Check the

capacitors and start relay.

COMPRESSOR DRAWING HIGH AMPS

The continuous amperage draw on start-up should

not be near the maximum fuse size indicated on the

serial tag.

The voltage when the compressor is trying to start

must be within ±10% of the nameplate voltage.

Diagnosing Capacitors

• If the compressor attempts to start, or hums and

trips the overload protector, check the starting

components before replacing the compressor.

• Visual evidence of capacitor failure can include

a bulged terminal end or a ruptured membrane.

Do not assume a capacitor is good if no visual

evidence is present.

• A good test is to install a known good substitute

capacitor.

• Use a capacitor tester when checking a suspect

capacitor. Clip the bleed resistor off the

capacitor terminals before testing.

Diagnosing PTCR’s

See “PTCR Diagnostics” on the next page.

13

Page 18

Electrical System

PTCR DIAGNOSTICS

What is a PTCR?

A PTCR (or Positive Temperature Coefficient

Resistor) is made from high-purity, semiconducting ceramics.

A PTCR is useful because of its resistance versus

temperature characteristic. The PTCR has a low

resistance over a wide (low) temperature range, but

upon reaching a certain higher temperature, its

resistance greatly increases, virtually stopping

current flow. When the source of heat is removed,

the PTCR returns to its initial base resistance.

In severe duty cycles, it can be used to repeatedly

switch (virtually stop) large currents at line

voltages.

PTCR’s have been used for many years in millions

of HVAC applications. In place of using the

conventional start relay/start capacitor, a simple

PTCR provides the starting torque assistance to

PSC (Permanent Split Capacitor) single-phase

compressors, which can equalize pressures before

starting.

Compressor Start Sequence

PTCR’s provide additional starting torque by

increasing the current in the auxiliary (start)

winding during starting. The PTCR is wired across

the run capacitor (in series with the start winding).

1. It is important for the refrigerant discharge and

suction pressures to be somewhat equalized

prior to the compressor starting. To assure

equalization of pressures the hot gas valve (and

HPR valve on remotes) will energize for 45

seconds prior to compressor starting. The hot

gas valve (and HPR valve on remotes) remains

on for an additional 5 seconds while the

compressor is starting.

2. When starting the compressor, the contactor

closes and the PTCR, which is at a low

resistance value, allows high starting current to

flow in the start winding.

3. The current passing through the PTCR causes it

to rapidly heat up, and after approximately .25-1

second it abruptly “switches” to a very high

resistance, virtually stopping current flow

through it.

4. At this point the motor is up to speed and all

current going through the start winding will now

pass through the run capacitor.

5. The PTCR remains hot and at a high resistance

as long as voltage remains on the circuit.

6. It is important to provide time between

compressor restarts to allow the PTCR to cool

down to near its initial temperature (low

resistance). When the contactor opens to stop

the compressor, the PTCR cools down to its

initial low resistance and is again ready to

provide starting torque assistance. To assure the

PTCR has cooled down, during an automatic

shut-off, the Q model ice machines have a builtin 3-minute off time before it can restart.

14

Page 19

Q-Model Automatic Shut-Off and Restart

When the storage bin is full at the end of a harvest

cycle, the sheet of cubes fails to clear the water

curtain and will hold it open. After the water curtain

is held open for 7 seconds, the ice machine shuts

off. To assure the PTCR has cooled, the ice

machine remains off for 3 minutes before it can

automatically restart.

The ice machine remains off until enough ice has

been removed from the storage bin to allow the ice

to fall clear of the water curtain. As the water

curtain swings back to operating position, the bin

switch closes and the ice machine restarts, provided

the three-minute delay period is complete.

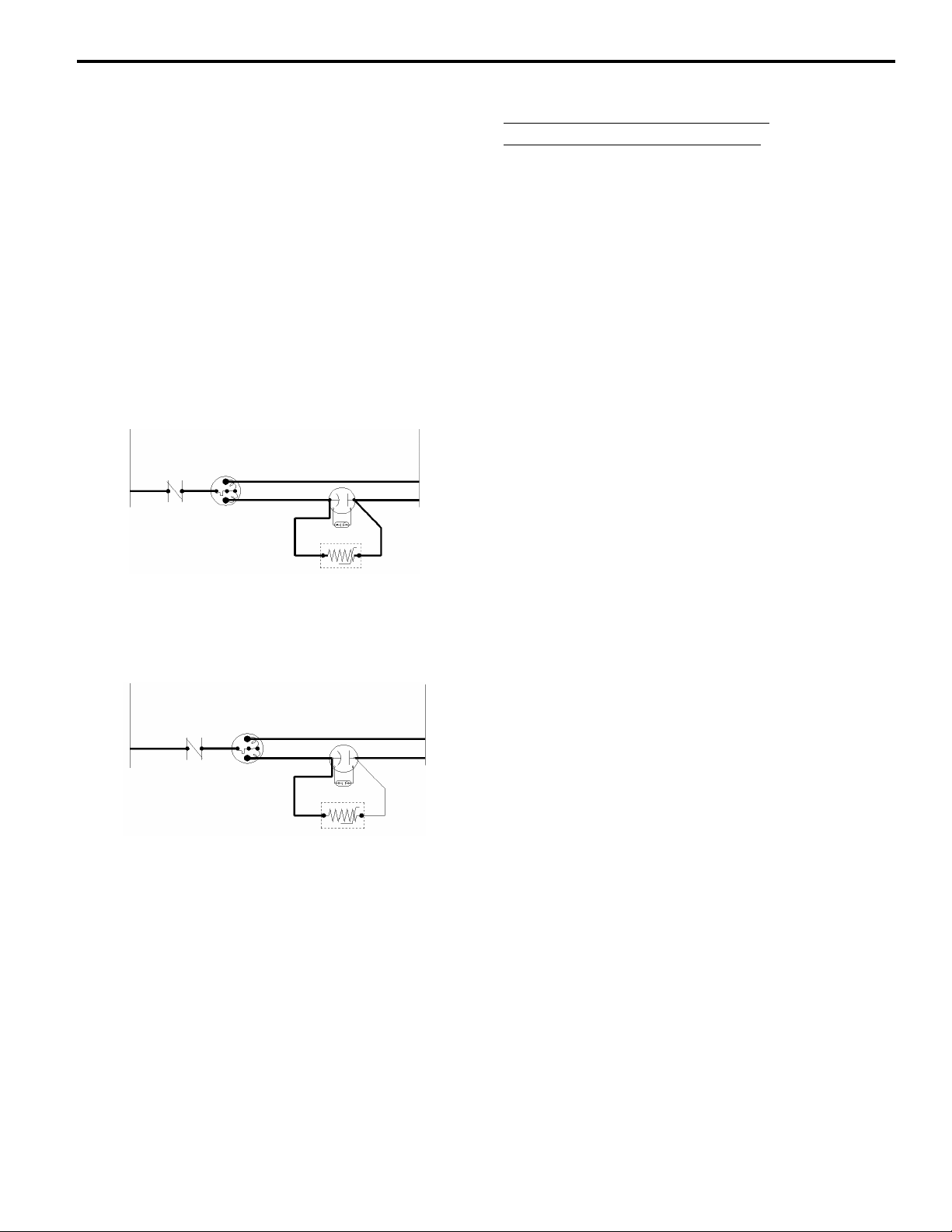

L1 L2

CONTACTOR

CONTACTS

C

COMPRESSOR

R

S

RUN CAPACITOR

R R

PTCR

SV1506

During Start-Up (First .25 - 1.0 Seconds)

L1 L2

CONTACTOR

CONTACTS

C

COMPRESSOR

R

RUN CAPACITOR

R R

S

PTCR

SV1507

After Start-Up

(Current Flows Through Run Capacitor)

Electrical System

Troubleshooting PTCR’s

WHY A GOOD PTCR MAY FAIL

TO START THE COMPRESSOR

The PTCR must be cooled before attempting to start

the compressor, otherwise the high starting torque

may not last long enough.

For example, if the PTCR is properly cooled, say

60°F (15.6°C) when the compressor starts, it will

take .25 to 1.0 seconds before its temperature

reaches 260°F (126.6°C), and current flow is

stopped.

If the PTCR is still warm, say 160°F (71.1°C) when

the compressor starts, it will take only .125 to .50

seconds before its temperature reaches 260°F

(126.6°C), and current flow is stopped. This

decreased time may be insufficient to start the

compressor.

A good PTCR may be too hot to operate properly at

start-up because:

• The ice machine’s 3-minute delay has been

overridden. Opening and closing the service

disconnect or cycling the toggle switch from

OFF to ICE will override the delay period.

• The control box temperature is too high.

Though rare, very high air temperatures (intense

sunlight, etc.) can greatly increase the

temperature of the control box and its contents.

This may require a longer off time to allow the

PTCR to cool.

• The compressor has short-cycled, or the

compressor overload has opened. Move the

toggle switch to OFF and allow the compressor

and PTCR to cool.

Continued on next page…

15

Page 20

Electrical System

There are other problems that may cause

compressor start-up failure with a good PTCR in a

new, properly wired ice machine.

• The voltage at the compressor during start-up is

too low.

Manitowoc ice machines are rated at ±10% of

nameplate voltage at compressor start-up. (Ex:

An ice machine rated at 208-230 should have a

compressor start-up voltage between 187 and

253 volts.)

• The compressor discharge and suction pressures

are not matched closely enough or equalized.

These two pressures must be somewhat

equalized before attempting to start the

compressor. The hot gas valve (and HPR valve

on remotes) energizes for 45 seconds before the

compressor starts, and remains on 5 seconds

after the compressor starts. Make sure this is

occurring before assuming that the PTCR is

bad.

CHECKING THE PTCR

WARNING

Disconnect electrical power to the entire ice

machine at the building electrical disconnect box

before proceeding.

1. Visually inspect the PTCR. Check for signs of

physical damage.

NOTE: The PTCR case temperature may reach

210°F (100°C) while the compressor is running.

This is normal. Do not change a PTCR just because

it is hot.

2. Wait at least 10 minutes for the PTCR to cool to

room temperature.

3. Remove the PTCR from the ice machine.

4. Measure the resistance of the PTCR as shown

below. If the resistance falls outside of the

acceptable range, replace it.

Model

Q800 8504993 305C19 18-40 Ohms

Manitowoc

Part Number

Cera-Mite

Part Number

Room

Temperature

Resistance

MEASURE OHMS BETWEEN

CENTER TAB AND END TAB

LEAVE JUMPER

WIRE IN PLACE

SV1541

Manitowoc PTCR 8504913

16

Page 21

ICE/OFF/CLEAN TOGGLE SWITCH

Function

The switch is used to place the ice machine in ICE,

OFF or CLEAN mode of operation.

Electrical System

CONTROL BOARD RELAYS

Function

The control board relays energize and de-energize

system components.

Specifications

Double-pole, double-throw switch. The switch is

connected into a varying low D.C. voltage circuit.

Check Procedure

NOTE: Because of a wide variation in D.C. voltage,

it is not recommended that a volt meter be used to

check toggle switch operation.

1. Inspect the toggle switch for correct wiring.

2. Isolate the toggle switch by disconnecting all

wires from the switch, or by disconnecting the

Molex connector and removing wire #69 from

the toggle switch.

3. Check across the toggle switch terminals using a

calibrated ohm meter. Note where the wire

numbers are connected to the switch terminals,

or refer to the wiring diagram to take proper

readings.

Switch Setting Terminals Ohm Reading

66-62 Open

ICE 67-68 Closed

67-69 Open

66-62 Closed

CLEAN 67-68 Open

67-69 Closed

66-62 Open

OFF 67-68 Open

67-69 Open

4. Replace the toggle switch if ohm readings do

not match all three switch settings.

Specifications

Relays are not field replaceable. There are five

relays on the control board:

Relay

#1 Water Pump

#2

#3 Hot Gas V alve

#4 Water Dump Valve

#5 Contactor (Self-Contained)

Contactor / Liquid Line Solenoid (Remotes)

Controls

17

Page 22

Electrical System

ELECTRONIC CONTROL BOARD

AC LINE VOLTAGE

ELECTRICAL PLUG

(NUMBERS MARKED ON

WIRES)

MAIN FUSE (7A)

AUTOMATIC CLEANING

SYSTEM (AuCS)

ACCESSORY PLUG

60

61

20

56

57

58

55

L1 PRIMARY

POWER SUPPLY

N 115V

L2 208-230V

CLEAN LIGHT

YELLOW

NOT USED

BIN SWITCH LIGHT

GREEN

HARVEST LIGHT/

SAFETY LIMIT

CODE LIGHT

RED

(3/16” CONNECTION)

ICE THICKNESS

PROBE

NOT USED

NOT USED

DC LOW VOLTAGE

ELECTRICAL PLUG

(NUMBERS MARKED

ON WIRES)

67

62

63

1C

1F

1G

68

65

Control Board

SV1588

18

Page 23

General

Q-Model control boards use a dual voltage

transformer. This means only one control board is

needed for both 115V and 208-230V use.

Safety Limits

In addition to standard safety controls, such as the

high pressure cut-out, the control board has built-in

safety limits.

These safety limits protect the ice machine from

major component failures. For more information,

see “Safety Limits”.

Electrical System

Inputs

The control board, along with inputs, controls all

electrical components, including the ice machine

sequence of operation. Prior to diagnosing, you

must understand how the inputs affect the control

board operation.

Refer to specific component specifications (inputs),

wiring diagrams and ice machine sequence of

operation sections for details.

As an example, refer to “Ice Thickness Probe” in

the component specifications section of this manual

for information relating to how the probe and

control board function together.

This section will include items such as:

• How a harvest cycle is initiated

• How the harvest light functions with the probe

• Freeze time lock-in feature

• Maximum freeze time

• Diagnosing ice thickness control circuitry

19

Page 24

Electrical System

Ice Thickness Probe (Harvest Initiation)

HOW THE PROBE WORKS

Manitowoc’s electronic sensing circuit does not rely

on refrigerant pressure, evaporator temperature,

water levels or timers to produce consistent ice

formation.

As ice forms on the evaporator, water (not ice)

contacts the ice thickness probe. After the water

completes this circuit across the probe continuously

for 6-10 seconds, a harvest cycle is initiated.

SV1729A

Ice Thickness Probe

To allow the service technician to initiate a harvest

cycle without delay, this feature is not used on the

first cycle after moving the toggle switch OFF and

back to ICE.

MAXIMUM FREEZE TIME

The control system includes a built-in safety which

will automatically cycle the ice machine into

harvest after 60 minutes in the freeze cycle.

ICE THICKNESS CHECK

The ice thickness probe is factory-set to maintain

the ice bridge thickness at 1/8” (3.2 mm).

NOTE: Make sure the water curtain is in place

when performing this check. It prevents water from

splashing out of the water trough.

1. Inspect the bridge connecting the cubes. It

should be about 1/8” (3.2 mm) thick.

2. If adjustment is necessary, turn the ice thickness

probe adjustment screw clockwise to increase

bridge thickness, or counterclockwise to

decrease bridge thickness.

HARVEST/SAFETY LIMIT LIGHT

This light’s primary function is to be on as water

contacts the ice thickness probe during the freeze

cycle, and remain on throughout the entire harvest

cycle. The light will flicker as water splashes on the

probes.

The light’s secondary function is to continuously

flash when the ice machine is shut off on a safety

limit, and to indicate which safety limit shut off the

ice machine.

FREEZE TIME LOCK-IN FEATURE

The ice machine control system incorporates a

freeze time lock-in feature. This prevents the ice

machine from short cycling in and out of harvest.

The control board locks the ice machine in the

freeze cycle for six minutes. If water contacts the

ice thickness probe during these six minutes, the

harvest light will come on (to indicate that water is

in contact with the probe), but the ice machine will

stay in the freeze cycle. After the six minutes are

up, a harvest cycle is initiated. This is important to

remember when performing diagnostic procedures

on the ice thickness control circuitry.

NOTE: Turning the adjustment 1/3 of a turn will

change the ice thickness about 1/16” (1.5 mm).

ADJUSTING

SCREW

1/8” (3.2MM)

ICE

THICKNESS

SV1208

Ice Thickness Check

Make sure the ice thickness probe wire and the

bracket do not restrict movement of the probe.

20

Page 25

A

Electrical System

DIAGNOSING ICE THICKNESS CONTROL CIRCUITRY

Ice Machine Does Not Cycle Into Harvest when Water Contacts the Ice Thickness Control Probe

Step 1 Bypass the freeze time lock-in feature by moving the ICE/OFF/CLEAN switch to OFF and back to

ICE. Wait until the water starts to flow over the evaporator.

Step 2 Clip the jumper wire leads to the ice thickness probe and any cabinet ground.

ICE THICKNESS PROBE

CLEAN LIGHT

WATER LEVEL LIGHT

EVAPORATOR

1C

HARVEST/SAFETY LIMIT LIGHT

SV1592G

SV1588

Step 2

Step 2 Jumper wire connected from probe to ground

Monitoring of Harvest Light Correction

The harvest light comes on, and 6-10 seconds later,

ice machine cycles from freeze to harvest.

The harvest light comes on but the ice machine

stays in the freeze sequence.

The ice thickness control circuitry is functioning

properly. Do not change any parts.

The ice thickness control circuitry is functioning

properly. The ice machine is in a six-minute freeze

time lock-in. Verify step 1 of this procedure was

followed correctly.

The harvest light does not come on. Proceed to Step 3, below.

Step 3 Disconnect the ice thickness probe from the control board at terminal 1C. Clip the jumper wire leads

to terminal 1C on the control board and any cabinet ground. Monitor the harvest light.

ICE THICKNESS PROBE

GROUND

JUMPER WIRE

CLEAN LIGHT

WATER LEVEL LIGHT

EVAPORATOR

1C

HARVEST/SAFETY LIMIT LIGHT

SV1591G

SV1588G

Step 3

Step 3 Jumper wire connected from control board terminal 1C to ground

Monitoring of Harvest Light Correction

The harvest light comes on, and 6-10 seconds later,

ice machine cycles from freeze to harvest.

The harvest light comes on but the ice machine

stays in the freeze sequence.

The harvest light does not come on. The control board is causing the malfunction.

The ice thickness probe is causing the malfunction.

The control circuitry is functioning properly. The ice

machine is in a six-minute freeze time lock-in (verify

step 1 of this procedure was followed correctly).

21

Page 26

Electrical System

Ice Machine Cycles Into Harvest Before Water Contact With The Ice Thickness Probe

Step 1 Disconnect the ice thickness probe from the control board at terminal 1C.

Step 2 Bypass the freeze time lock-in feature by moving the ICE/OFF/CLEAN switch to OFF and back to

ICE. Wait until the water starts to flow over the evaporator, then monitor the harvest light.

ICE THICKNESS PROBE

CLEAN LIGHT

WATER LEVEL LIGHT

EVAPORATOR

1C

HARVEST/SAFETY LIMIT LIGHT

SV1591G

SV1588G

Step 2

Step 2 Disconnect probe from control board terminal 1C

Monitoring of Harvest Light Correction

The harvest light stays off and the ice machine

remains in the freeze sequence.

The ice thickness probe is causing the malfunction.

Verify that the Ice Thickness probe is adjusted

correctly.

The harvest light comes on, and 6-10 seconds later,

The control board is causing the malfunction.

the ice machine cycles from freeze to harvest.

22

Page 27

Electrical System

Diagnosing Ice Machine That Will Not Run

WARNING

High (line) voltage is applied to the control board

(terminals #55 and #56) at all times. Removing

control board fuse or moving the toggle switch to

OFF will not remove the power supplied to the

control board.

Step Check Notes

1 Verify primary voltage supply to ice

machine.

2 Verify the high-pressure cutout is

closed.

3 Verify control board fuse is OK. If the bin switch light functions, the fuse is OK.

4 Verify the bin switch functions properly. A defective bin switch can falsely indicate a full bin of ice.

5 Verify ICE/OFF/CLEAN toggle switch

functions properly.

6 Verify low DC voltage is properly

grounded.

7 Replace the control board. Be sure Steps 1-6 were followed thoroughly. Intermittent

L1

Q0420/Q0450/Q0600/Q0800/Q1000 ICE MACHINES

SELF-CONTAINED 1 PHASE

CAUTION: DISCONNECT POWER BEFORE WORKING

ON ELECTRICAL CIRCUITRY.

DIAGRAM SHOWN DURING FREEZE CYCLE

(55)

TB35

HIGH PRES

CUTOUT

TB32

2

3

ICE THICKNESS PROBE

WATER LEVEL PROBE

NOT USED

4

(64)

6

(66)

BIN SWITCH

5

(42)

CONTACTOR

CONTACTS

L1

TB33

TB35

(51)

*OVERLOAD

(48)

(52)

FAN CYCLE CONTROL

Verify that the fuse or circuit breaker is closed.

The H.P.C.O. is closed if primary power voltage is present

at terminals #55 and #56 on the control board.

A defective toggle switch may keep the ice machine in

the OFF mode.

Loose DC wire connections may intermittently stop the ice

machine.

problems are not usually related to the control board.

2

4

1

3

5

TRANS.

1C

1F

1G

(62)

(63)

(65)

R

C

(85) (86)

1

FUSE (7A)

LOW D.C.

VOLTAGE

PLUG

(67)

(66)

COMPRESSOR

S

(53)

RUN CAPACITOR**

(61)

(60)

(58)

CLEAN LIGHT

WATER LEVEL

BIN SWITCH LIGHT

HARVEST LIGHT/

SAFETY LIMIT CODE LIGHT

(68)

(69)

(62)

TB34

TOGGLE SWITCH

ICE

INTERNAL WORKING

OFF

VIEW

CLEAN

(49)

RUN CAPACITOR

(47)

(46) (50)

PTCR

SEE SERIAL PLATE FOR VOLTAGE

(21)

WATER

VALVE

(77)

HOT GAS

SOLENOID

(76)

DUMP

SOLENOID

(57)

(98)

TB31

TB37

(59)

TERMINATES AT

PIN CONNECTION

(73)

(56)

R

R

(45)

FAN MOTOR

(AIR COOLED ONLY)

CONTACTOR

COIL

VIEW FOR WIRING

(22)

(80)

(81)

66

62

WATER

PUMP

(99)

(74)

68

67

(75)

69

L2 (N)

TB30

TB30

TB30

TB30

TB30

TB30

23

Page 28

Electrical System

24

Page 29

Q

Sequence of Operation

WATER-COOLED MODELS

HEAT

EXCHANGER

Refrigeration System

EXPANSION

VALVE

HOT GAS

SOLENOID VALVE

Electrical System

EVAPORATOR

COMPRESSOR

DRIER

RECEIVER

HIGH PRESSURE VAPOR

HIGH PRESSURE LI

UID LOW PRESSURE LIQUID LOW PRESSURE VAPOR

Self-Contained Prechill and Freeze Cycle

Prechill Refrigeration Sequence

No water flows over the evaporator during the

prechill. The refrigerant absorbs heat (picked up

during the harvest cycle) from the evaporator. The

suction pressure decreases during the prechill.

AIR OR WATER

STRAINER

CONDENSER

SV1569

Freeze Cycle Refrigeration Sequence

The refrigerant absorbs heat from water running

over the evaporator surface. The suction pressure

gradually drops as ice forms.

25

Page 30

Refrigeration System

HEAT

EXCHANGER

EXPANSION

VALVE

HOT GAS

SOLENOID VALVE

EVAPORATOR

COMPRESSOR

DRIER

RECEIVER

HIGH PRESSURE VAPOR HIGH PRESSURE LIQUID LOW PRESSURE LIQUID LOW PRESSURE VAPOR

Self-Contained Harvest Cycle

Harvest Cycle Refrigeration Sequence

Hot gas flows through the energized hot gas valve,

heating the evaporator. The hot gas valve is sized to

allow the proper amount of refrigerant into the

evaporator. This specific sizing (along with the

WATER

STRAINER

CONDENSER

SV1570

proper system refrigerant charge) assures proper

heat transfer, without the refrigerant condensing and

slugging the compressor.

26

Page 31

Operational Analysis (Diagnostics)

GENERAL

When analyzing the refrigeration system, it is

important to understand that different refrigeration

component malfunctions may cause very similar

symptoms.

Also, many external factors can make good

refrigeration components appear bad. These factors

can include improper installation, or water system

malfunctions such as hot incoming water supply or

water loss.

The following two examples illustrate how similar

symptoms can result in a misdiagnosis.

1. An expansion valve bulb that is not securely

fastened to the suction line and/or not insulated

will cause a good expansion valve to flood. If a

service technician fails to check for proper

expansion valve bulb mounting, he may replace

the expansion valve in error.

The ice machine now functions normally. The

technician erroneously thinks that the problem

was properly diagnosed and corrected by

replacing the expansion valve. Actually, the

problem (loose bulb) was corrected when the

technician properly mounted the bulb of the

replacement expansion valve.

Refrigeration System

3. An ice machine that is low on charge may cause

a good expansion valve to starve. If a service

technician fails to verify the system charge, he

may replace the expansion valve in error.

During the replacement procedure, recovery,

evacuation and recharging are performed

correctly. The ice machine now functions

normally. The technician erroneously thinks that

the problem was properly diagnosed and

corrected by replacing the expansion valve.

The service technician’s failure to check the ice

machine for a low charge condition resulted in a

misdiagnosis and the needless replacement of a

good expansion valve.

When analyzing the refrigeration system, use the

Refrigeration System Operational Analysis Table.

This table, along with detailed checklists and

references, will help prevent replacing good

refrigeration components due to external problems.

The service technician’s failure to check the

expansion valve bulb for proper mounting (an

external check) resulted in a misdiagnosis and

the needless replacement of a good expansion

valve.

27

Page 32

Refrigeration System

BEFORE BEGINNING SERVICE

Ice machines may experience operational problems

only during certain times of the day or night. A

machine may function properly while it is being

serviced, but malfunctions later. Information

provided by the user can help the technician start in

the right direction, and may be a determining factor

in the final diagnosis.

Ask these questions before beginning service:

• When does the ice machine malfunction? (night,

day, all the time, only during the freeze cycle,

etc.)

• When do you notice low ice production? (one

day a week, every day, on weekends, etc.)

• Can you describe exactly what the ice machine

seems to be doing?

• Has anyone been working on the ice machine?

• Is anything (such as boxes) usually stored near

or on the ice machine which could obstruct

airflow around the machine?

• During “store shutdown,” is the circuit breaker,

water supply or air temperature altered?

• Is there any reason why incoming water

pressure might rise or drop substantially?

ICE PRODUCTION CHECK

The amount of ice a machine produces directly

relates to the operating water and air temperatures.

This means an ice machine in a 70°F (21.2°C) room

with 50°F (10.0°C) water produces more ice than

the same model ice machine in a 90°F (32.2°C)

room with 70°F (21.2°C) water.

1. Determine the ice machine operating conditions:

Air temp. entering condenser: ____°

Air temp. around ice machine: ____°

Water temp. entering sump trough: ____°

2. Refer to the appropriate 24 Hour Ice Production

Chart. Use the operating conditions determined

in Step 1 to find published 24 hour ice

production: ______

3. Perform an actual ice production check. Use the

formula below.

1. __________ + __________ =

Freeze Time Harvest Time Total Cycle Time

2.

3. __________ x __________ =

1440 ÷ __________ =

Minutes in 24 Hours Total Cycle Time Cycles Per Day

Weight of One Harvest Cycles Per Day Actual 24 Hour Ice Production

__________

__________

__________

Important

• Times are in minutes.

Example: 1 min., 15 sec. converts to 1.25 min.

(15 seconds ÷ 60 seconds = .25 minutes)

• Weights are in pounds.

Example: 2 lb., 6 oz. converts to 2.375 lb.

(6 oz. ÷16 oz. = .375 lb.)

• Weighing the ice is the only 100% accurate

check. However, if the ice pattern is normal

and the 1/8” thickness is maintained, the ice

slab weights listed with the 24 Hour Ice

Production Charts may be used.

4. Compare the results of Step 3 with Step 2. Ice

production is normal when these numbers match

closely. If they match closely, determine if:

• another ice machine is required.

• more storage capacity is required.

• relocating the existing equipment to lower

the load conditions is required.

Contact the local Manitowoc distributor for

information on available options and

accessories.

28

Page 33

INSTALLATION/VISUAL INSPECTION CHECKLIST

Possible Problem Corrective Action

Ice machine is not level Level the ice machine

Improper clearance

around top, sides and/or

back of ice machine

Ice machine is not on an

independent electrical

circuit

Water filtration is

plugged (if used)

Water drains are not run

separately and/or are

not vented

Reinstall according to

the Installation M anual

Reinstall according to

the Installation M anual

Install a new water filter

Run and vent drains

according to the

Installation Manual

Refrigeration System

WATER SYSTEM CHECKLIST

A water-related problem often causes the same

symptoms as a refrigeration system component

malfunction.

Example: A water dump valve leaking during the

freeze cycle, a system low on charge, and a starving

TXV have similar symptoms.

Water system problems must be identified and

eliminated prior to replacing refrigeration

components.

Possible Problem Corrective Action

Water area (evaporator)

is dirty

Water inlet pressure not

between 20 and 80 psi

Incoming water

temperature is not

between 35°F (1.7°C) and

90°F (32.2°C).

Water filtration is plugged

(if used)

Water dump valve

leaking during the freeze

cycle

Vent tube is not installed

on water outlet drain

Hoses, fittings, etc., are

leaking water

Water fill valve is stuck

open

Water is spraying out of

the sump trough area

Uneven water flow across

the evaporator

Water is freezing behind

the evaporator

Plastic extrusions and

gaskets are not secured

to the evaporator

Water does not flow over

the evaporator (not

trickle) immediately after

the prechill

Clean as needed

Install a water

regulator valve or

increase the water

pressure

If too hot, check the

hot water line check

valves in other store

equipment

Install a new water

filter

Clean/replace dump

valve as needed

See Installation

Instructions

Repair/replace as

needed

Clean/replace as

needed

Stop the water spray

Clean the ice

machine

Correct the water

flow

Remount/replace as

needed

Clean/replace water

level probe as

needed

29

Page 34

Refrigeration System

ICE FORMATION PATTERN 2. Extremely Thin at Evaporator Outlet

Evaporator ice formation pattern analysis is helpful

in ice machine diagnostics.

Analyzing the ice formation pattern alone cannot

diagnose an ice machine malfunction. However,

when this analysis is used along with Manitowoc’s

Refrigeration System Operational Analysis Table, it

can help diagnose an ice machine malfunction.

Improper ice formation can be caused by any

There is no ice, or a considerable lack of ice

formation on the top of the evaporator (tubing

outlet).

Examples: No ice at all on the top of the evaporator,

but ice forms on the bottom half of the evaporator.

Or, the ice at the top of the evaporator reaches 1/8”

to initiate a harvest, but the bottom of the

evaporator already has 1/2” to 1” of ice formation.

number of problems.

Example: An ice formation that is “extremely thin

ICE

on top” could be caused by a hot water supply, a

dump valve leaking water, a faulty water fill valve,

OUTLET

a low refrigerant charge, etc.

Important

Keep the water curtain in place while checking

ICE

the ice formation pattern to ensure no water is

lost.

1. Normal Ice Formation

Ice forms across the entire evaporator surface.

At the beginning of the freeze cycle, it may appear

INLET

that more ice is forming on the bottom of the

evaporator than on the top. At the end of the freeze

cycle, ice formation on the top will be close to, or

Extremely Thin Ice Formation

at Evaporator Outlet

just a bit thinner than, ice formation on the bottom.

The dimples in the cubes at the top of the

evaporator may be more pronounced than those on

the bottom. This is normal.

SV1576

The ice thickness probe must be set to maintain the

ice bridge thickness at approximately 1/8”. If ice

forms uniformly across the evaporator surface, but

does not reach 1/8” in the proper amount of time,

this is still considered normal.

30

Page 35

Refrigeration System

3. Extremely Thin at Evaporator Inlet 5. No Ice Formation

There is no ice, or a considerable lack of ice

formation on the bottom of the evaporator (tubing

inlet). Examples: The ice at the top of the

evaporator reaches 1/8” to initiate a harvest, but

The ice machine operates for an extended period,

but there is no ice formation at all on the

evaporator.

there is no ice formation at all on the bottom of the

evaporator.

OUTLET

ICE

INLET

SV1575

Extremely Thin Ice Formation at Evaporator

Inlet

4. Spotty Ice Formation

There are small sections on the evaporator where

there is no ice formation. This could be a single

corner, or a single spot in the middle of the

evaporator. This is generally caused by loss of heat

transfer from the tubing on the back side of the

evaporator.

OUTLET

ICE

INLET

Spotty Ice Formation

SV1577

31

Page 36

Refrigeration System

SAFETY LIMITS

General

In addition to standard safety controls, such as high

pressure cut-out, the control board has two built in

safety limit controls which protect the ice machine

from major component failures.

Safety Limit #1: If the freeze time reaches 60

minutes, the control board automatically initiates a

harvest cycle. If three consecutive 60-minute freeze

cycles occur, the ice machine stops.

Safety Limit #2: If the harvest time reaches 3.5

minutes, the control board automatically returns the

ice machine to the freeze cycle. If three consecutive

3.5 minute harvest cycles occur, the ice machine

stops.

Determining Which Safety Limit Stopped The Ice Machine

When a safety limit condition causes the ice

machine to stop, the harvest light on the control

board continually flashes on and off. Use the

following procedures to determine which safety

limit has stopped the ice machine.

1. Move the toggle switch to OFF.

2. Move the toggle switch back to ICE.

3. Watch the harvest light. It will flash one or two

times, corresponding to safety limits 1 and 2, to

indicate which safety limit stopped the ice

machine.

After safety limit indication, the ice machine will

restart and run until a safety limit is exceeded again.

Analyzing Why Safety Limits

May Stop the Ice Machine

According to the refrigeration industry, a high

percentage of compressors fail as a result of

external causes. These can include: flooding or

starving expansion valves, dirty condensers, water

loss to the ice machine, etc. The safety limits

protect the ice machine (primarily the compressor)

from external failures by stopping ice machine

operation before major component damage occurs.

The safety limit system is similar to a high pressure

cut-out control. It stops the ice machine, but does

not tell what is wrong. The service technician must

analyze the system to determine what caused the

high pressure cut-out, or a particular safety limit, to

stop the ice machine.

The safety limits are designed to stop the ice

machine prior to major component failures, most

often a minor problem or something external to the

ice machine. This may be difficult to diagnose, as

many external problems occur intermittently.

Example: An ice machine stops intermittently on

safety limit #1 (long freeze times). The problem

could be a low ambient temperature at night, a

water pressure drop, the water is turned off one

night a week, etc.

When a high pressure cut-out or a safety limit stops

the ice machine, they are doing what they are

supposed to do. That is, stopping the ice machine

before a major component failure occurs.

Refrigeration and electrical component failures may

also trip a safety limit. Eliminate all electrical

components and external causes first. If it appears

that the refrigeration system is causing the problem,

use Manitowoc’s Refrigeration System Operational

Analysis Table, along with detailed charts,

checklists, and other references to determine the

cause.

32

The following checklists are designed to assist the

service technician in analysis. However, because