Page 1

30” Q-Model Water/Remote Insulation

Installation Instructions

Material List Q-0280 - Q-1000 Water and Remote Ice Machines:

Quantity

1 Armaflex Insulation 6’ x 2” ID x 3/8” wall thickness

1 Armaflex Insulation 6’ x 3/4” ID x 3/8” wall

(used on evaporator inlet/outlet and dump valve drain line)

1 Bulkhead Insulation Back 9” x 30” x 3/4”

1 Bulkhead Insulation Back 3” x 30” x 3/8”

2 Side Wall Insulation 9” x 10” x 3/4”

1 Vacuum Formed Base with Insulation 12 3/4” x 30” x 3/4"

1 Foam Gasket For Top Edge of Bin 2’ x 3/4” x 1/4”

1 Tube Silicone Sealant Black Used to seal base/bulkhead insulation

1 Tube Silicone Sealant White Used to seal front edge of vacuum-formed base

1 Mylar Strip 5” x 25”

Additional materials required: caulk gun, 2” x 4” wood blocks, wire ties.

Preparation

1. Disconnect power from ice machine.

2. Remove front, top, and side panels.

3. Drain water from sump trough.

4. Ice machine must be thoroughly dried before the insulation can be installed. Use towels to dry bulkhead and base assembly.

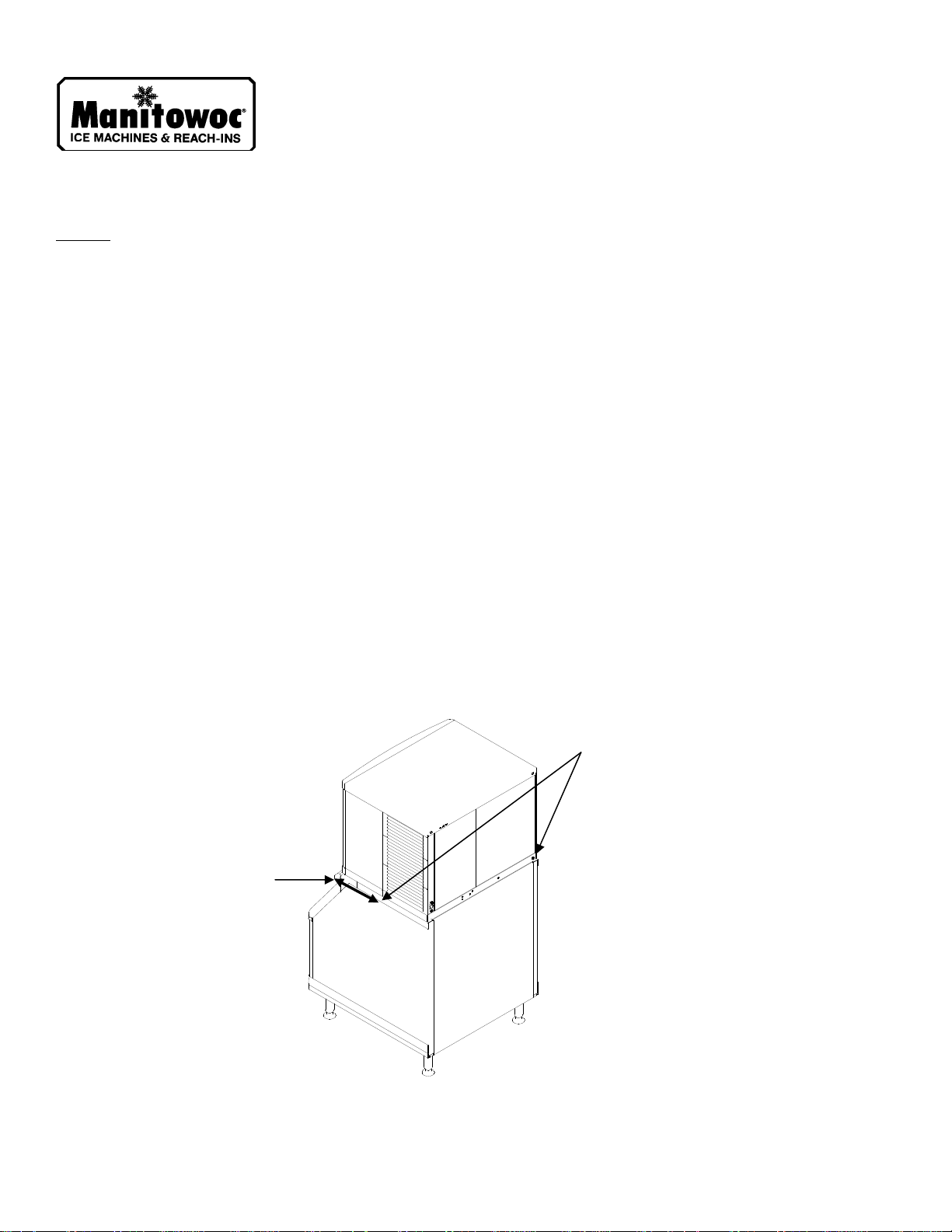

Base Insulation Installation

1. Raise the ice machine above the bin. A high lift can be used or (two people required) lift front edge of ice machine and place

2. Slide vacuum-formed base insulation assembly between the ice machine and bin. Align the in sulation with the b ack and sides of

3. Add one layer of foam tape insulation from the front of the bin to the front of the base insulation on the left and right side.

wood blocks (2” x 4”) between ice machine and bin. Lifting one side of ice machine at a time, move wood blocks to center

balance point of ice machine.

the bin and ice machine.

2. Install vacuum-formed base

insulation and align back and sides.

3. Add foam tape both sides.

Manitowoc Ice, Inc.

2110 South 26 Street, P.O. Box 1720, Manitowoc, WI 54221-1720 USA 8005493

Telephone 920-682-0161, Fax - Sales: 920-683-7589, Service/Parts: 920-683-7585, Other: 920-683-7879 Sheet 1 of 3

Web Site - www.manitowocice.com 06/02/00

4. Raise front of ice machine and position the wood blocks on edge (3 1/2” height). This will allow the top of the vacuum-formed

base to be accessed.

Page 2

5. Place two beads of black silicone sealant (1” in from the edge) on the front and both sides of the vacuum-formed base.

6. Remove wood blocks and lower the ice machine onto the vacuum-formed base (check side and back alignment). Push the center

of the vacuum-formed base tight to the ice machine base. Secure the vacuum-formed base to the ice machine water trough with

tape. Remove tape after silicone sealant has set.

7. Seal the front edge of the base insulation to the bin with white silicone sealant.

Install Mylar Strip between Evaporator and Bulkhead

Mylar will cover the joint where the bulkhead attaches to the base. It will extend from the left sidewall past the water inlet fitting.

1. Remove screws (right and left side) that secure the evaporator to the bulkhead.

2. Remove three screws located between the evaporator and water inlet line. Remove the screw ho lding the water inlet fitting.

3. Determine bin switch wire location and cut a slot in the top edge of the mylar strip (adhesive edge = top).

4. Apply silicone sealant at the bin switch wire entrance and the left side corner (4” each direction) where the base and bulkhead

meet.

5. Pull evaporator away from bulkhead. Place bottom of mylar strip in sump trough and slip up behind evaporator (align slot cut in

step 3 with bin switch wire). Mylar must extend above bottom evaporator mounting screw (approximately 2” above

gasket/bulkhead joint).

6. Remove paper backing from mylar. Apply tension to mylar and work toward the ends to eliminate wrinkles, as the tape is

pressed to the bulkhead.

7. Align evaporator extrusion and bulkhead screw holes; puncture mylar for the bottom screw holes and insert screws. Install all

remaining evaporator screws.

8. Puncture mylar and insert screws removed in step 2.

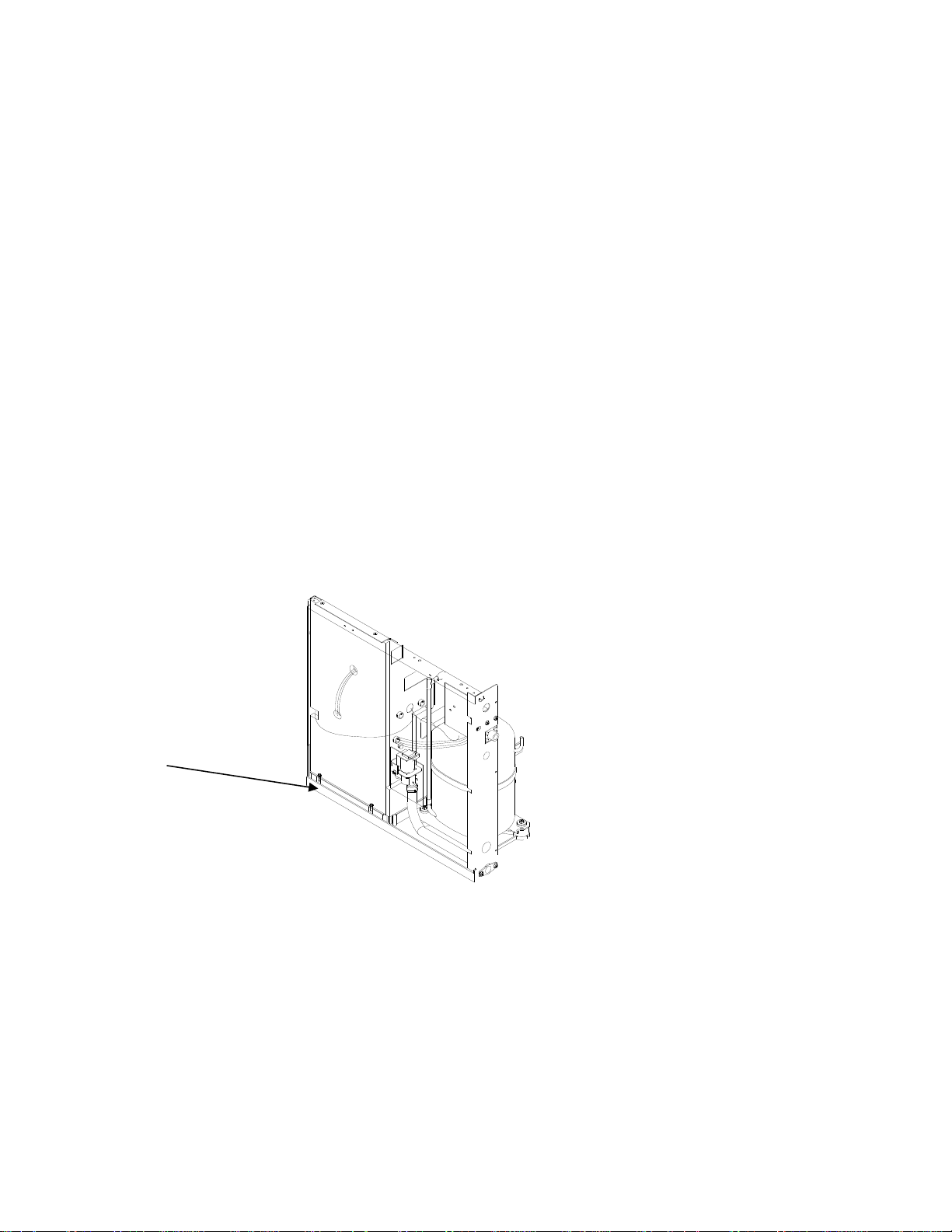

Bulkhead and Sidewall Insulation

1. Using the supplied insulation as a template, cut and remove the fiberglass insulatio n (approximately 9” from base to top of cut).

Using a putty knife, scrape insulation and glue from the bottom of the bulkhead on the rear and both sides.

2. Remove upper white backing to expose tape surface (do not remove backing below slit at bottom). Slide the insulation down into

the base and then press the insulation against the b ulkhead to secure. Insulation must bottom out on the base and be tight to the

fiberglass insulation.

Insulation must extend all the

way into the base.

3. Repeat step 2 on the left side bulkhead.

8005493

Sheet 2 of 3

06/02/00

4. The back panel insulation will rest in a bed of silicone. Apply a continuous bead of black silicone sealant to the base of the ice

machine next to the bulkhead wall.

Page 3

9. Install additional insulation on entire suction

line

4. Apply bead of silicone before applying insulation

5. Align insulation slits with base ribbing

7. Seal insulation to base with silicone sealant

10. Insulate drain line

5. When installing in limited access areas, the insulation can be cut to allow installation of the bulkhead insulation in two pieces.

Peel the white backing off of the insulation for the b ack bulk head (9” x 30”). Alig n the slo ts in the insu lation with the ridges in

the base. Press the insulation against the bulkhead to secu re. The insulation will overlap the left and right side insulation

installed earlier. Ensure that the foam and fiberglass insulation mates flush with no voids.

6. Peel the white backing off of the 3” x 30” strip of insulation and install over the bottom section of the 9” x 30” insulation

installed in step 6. Align cut slots with the back bulkhead insulation and press to seal.

7. Use black silicone sealant to seal: insulation to the base, foam insulation to foam insulation joints, any voids where insulation

meets or overlaps. Add bulkhead corner insulation covers where the rear bulkhead and side panel corners meet.

8. Verify no moisture is present in the suction line tubing. If moisture is present, drain and dry the insulation and reinstall

following step 10 instructions.

9. Install armaflex insulation over the existing insulation on suction line. Use 3/4” x 3/8” insulation on the evaporator outlet and

inlet tubing and 2” x 3/8” on the rest of the suction line. Use suitable glue to seal insulation airtight (do not use electrical tape).

Seal the ends of the insulation with wire ties.

10. Remove clear vinyl tube from dump valve and brass wing adapter. Install armaflex insulation over tube and then reinstall tube

to dump valve and adapter. Ensure white clamps are secure to prevent water from leaking.

8005493

Sheet 3 of 3

06/02/00

Loading...

Loading...