Page 1

Multi-Circuit Condensers

®

with CVD Technology

Now approved

for use with Manitowoc

QuietQube® Ice Machines

Page 2

CONTENTS

Multi-Pak Advantages � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Multi-Pak Refrigeration Systems � � � � � � � � � � � � � � � � � � 4

Dimensional Data � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Job Information Request Form � � � � � � � � � � � � � � � � � � � 6

Warranty � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

2

Page 3

MULTI-PAK • Multi-circuit Condensing Unit

The all new Multi-Pak is a multi-circuited vertical discharge condensing unit that can be configured to handle multiple

compressors� The MC1 single fan model is capable of handling up to three compressors with a maximum of 5 HP� The

MC2 two fan model is capable of handling up to five compressors with a maximum of 8 HP� The MC3 three fan model is

capable of handling up to seven compressors with a maximum of 14 HP� The MC4 four fan model is capable of handling

nine compressors with a maximum of 20 HP�

Multi-Pak Advantages:

• Available with Hermetic, Semi-hermetic or S

croll compressors

• Installer has only one unit to mount (reduces the

amount of space required)

• Single point electrical connection

• Condenser circuits may be allocated for use with

ice machines or other condenser requirements

• Easily removable panels for service

• Timer for electric defrost application is mounted

and pre-wired

• Compressors are individually protected

(circuit breakers)

• Crank case heaters only come on when unit

is in off-cycle (reduces excess heat that the

compressors have to overcome during warm

conditions and reduces energy consumption

• Head master valves (allows refrigerant to bypass he

condenser coil during cold weather conditions by

maintaining a minimum head pressure)

• Color-coded wiring

• All units have liquid line sight glass and dryer

• Single energy efficient 1/2 HP (1100 RPM)

PSC fan motor

• Large 24" diameter fan blade

• Exterior finish 18 Ga. G90 galvanized

• Unique placement of air intake louvers

provides maximum air flow over compressors

for cooler operation

• Provided with weather-proof housing

• Adjustable low pressure control

• Refrigerant lines piped for roof curb or ground

pad connections

overall)

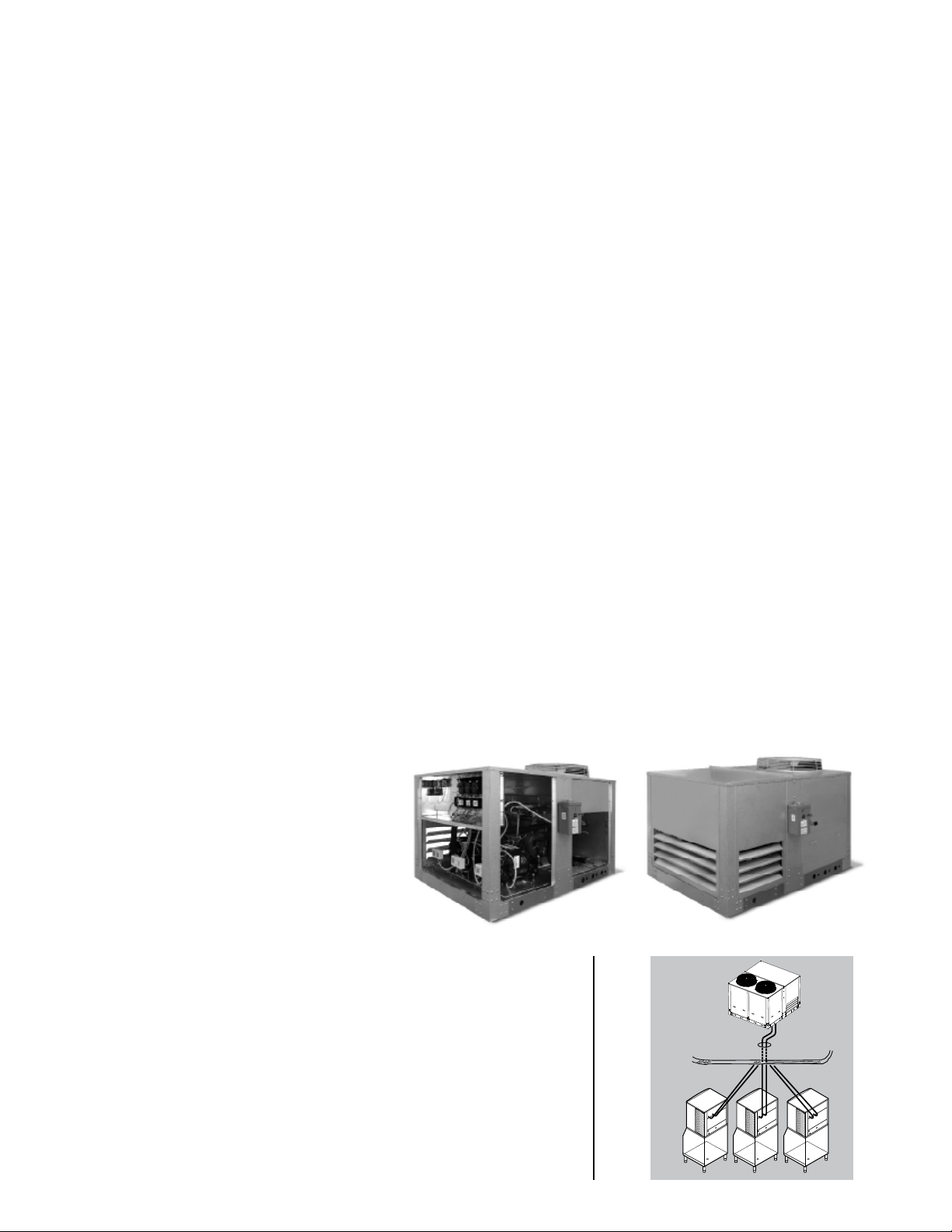

The flexibility of this

unit makes it ideal for

walk-in cooler/freezer

applications, as well

as ice machines

and other remote

condenser needs.

3

Page 4

Multi-pak • Multi-circuit Condensing

Multi-Pak Refrigeration System

The Multi-Pak refrigeration system will be ETL Listed to

UL Standard 1995, and may be located either on the roof

of the building, or, on a pad outside of the building. The

condensing unit consists of compressors, multi-circuit

condenser, receivers, and electrical panel, all located

within a weatherproof outdoor housing� The evaporator

coils supplied as part of the system, are complete with

all of the accessories required� All of the component

parts, and required options and accessories will be

mounted, wired, and piped as required. The system will

be manufactured to operate at either 208-230/1/60,

or, 208-230/3/60. This unit can also be congured to

support remote condenser loads�

Weatherproof Outdoor Housing

The Outdoor Weatherproof Housing is fabricated

of either 18 ga. G90 galvanized or 20 ga. stainless

steel� Each panel of the housing is removable for

complete access to the interior of the unit for servicing�

The perimeter rails are punched with openings to

accommodate spreader bars for lifting purposes�

Compressors and

Multi-Circuit Condenser

All compressors shall be Hermetic, Semi-Hermetic or

Scroll� Compressors are available to operate R-404A as

standard refrigerant but may be supplied with others

when required� Each compressor will be charged

with the appropriate refrigerant oil as required� Each

compressor will be provided with discharge and suction

vibration isolation (vibrasorbers will be provided on

semi-hermetic compressors)� Each compressor system

will include a dual pressure control, liquid line lter/drier,

sight glass w/moisture indicator, crankcase heater, and

receiver tank� Each receiver tank will be provided with

an isolation valve and access port at its outlet and are

sized to accommodate the required refrigerant charge,

without exceeding its capacity� The capacity can be

exceeded if the lines are too long�

The multi-circuit condenser system includes up to four

1/2 HP, PSC energy ecient fan motors with a 24” fan

blade mounted in a formed venture fan orifice� The

fan motor/blade assembly is protected by a coated

fan guard� Each compressor and condenser circuit is

equipped with “headmaster” ooded condenser head

pressure control. The compressor/condenser circuit is

sized to operate at an average temperature dierential

(TD) between the ambient and condensing temperature

of 20°F�

Electrical Control Panel

The weatherproof electrical control panel is mounted

on the interior of the housing, and is fabricated of

18ga. Galvanized steel. The control panel is equipped

with circuit breakers for each compressor system,

contactors, auxiliary contacts, fuses, defrost time clocks,

and compressor starting components (for single phase

operation). A color-coded wiring diagram is provided,

and mounted to the interior of the removable access

panel. The wiring is color coded per the diagram, and is

held in place with the appropriate fasteners� The entire

electrical system is protected by an exterior mounted

NEMA 3R rated fused disconnect switch�

Refrigeration System Piping

The refrigeration system piping is routed within the

housing so the installation contractor can pipe the

lines through the roof for roof curb applications or

through protective bushings in the lower perimeter rail

for ground pad mounting. Each set of liquid/suction

lines will be identified as to the system they serve� All

refrigeration piping will be A�C�R� grade refrigeration

copper, and will be held in place with tubing straps. All

suction lines shall be covered with 1/2” thick insulation

tube� The entire condensing unit assembly shall be

tested at a minimum of 250 psig for leaks� The system

will be shipped with a 50psig holding charge of

dry nitrogen�

Evaporator Coils

The evaporator coils will be mounted inside each walkin compartment� Each evaporator coil will include a

thermostatic expansion valve (matched to the system

capacity requirements), liquid line solenoid valve (for

pump down), and a temperature control. If two or more

evaporators are required for a system, the solenoid

valve will be mounted on each evaporator and the

temperature control is shipped loose for field installation

in a central location�

4

Page 5

Air-Cooled Refrigeration Systems

46"

Dimensional Data

Multi-Pak Model MC-1 Multi-Pak Model MC-2

41"

94"

94"

63"

43"

43"

36"

63"

36"

70"

63"

64"

51"

64"

Multi-Pak Model MC-3 Multi-Pak Model MC-4

94"

124"

70"

46"

70"

46"

94"

51"

51"

70"

46"

46"

64"

46"

70"

70"

124"

70"

70"

Maximum

Total HP

5

8

14

20

Maximum Number

of Compressor Spaces

May contain up to 6 fractional

3

hermetic condensers

May contain up to 10 fractional

5

hermetic condensers.

May contain up to 14 fractional

7

hermetic condensers.

May contain up to 16 fractional

9

hermetic condensers.

Physical Data

Number of

Condenser Fans

.

1 43" 63" 41" 750

Length Width Height

Dimensions (In.)

Approximate

Weight (lbs.)

2 64" 70" 51" 1100

3 94" 70" 51" 1450

4 124" 70" 51" 2000

5

Page 6

Job Information Request Form

Outdoor, Vertical Discharge Multi-Circuited Condensing Unit

General Data

Customer

Location

Sales Branch

Contact Name

Contact Phone Number

Date

Required Voltage Volts Phase Cycle or HZ

Fused Disconnect Switch

Refrigeration Data

*

System

*

Circuit

*

Cabinet

Temperature

In º F

*

Evaporator

Temperature

In º F

*

Refrigerant

*

Defrost Type

Required Capacity

in BTU

*

Requested

Compressor

Existing

RDI

STD Model #

* Required Information

Note: Cooler Temperature Systems Will Be Sized for 16 HR Run Time or Less at 90° Ambient

Note: Freezer Temperature Systems Will Be Sized for 18 HR Run Time or Less at 90° Ambient

Accessory Data

System

Defrost

Type

Suction

Accumulator

Suction

Filter

Vibration

Eliminator

Oil

Separator

Standard Equipment:

• Drier

• Sight Glass

• Receiver with Shut-Off Valve

• Head Pressure Control (Headmaster)

• Vibration Eliminators on

Semi-Hermetic Compressors

• Suction and Discharge

Shut-off Valve on Semi-Hermetic

Compressors

• Fixed Low Pressure Control

• Fixed High Pressure Control

• Defrost Clock (With

Contactor and Circuit Protection

When Needed)

• Single Point Electrical Connection

• Circuit Breaker per Compressor Circuit

6

Page 7

Warranty

RDI Parts and Labor Warranty (11-5-04)

All invoices submitted for consideration under RDI’s

parts and labor warranty must include the product serial

number and must be received by RDI within 60 days of

the date of service�

Parts Coverage

One (1) year from original start up date but no more

than fteen (18) months from ship date RDI will at it’s

option repair, replace, or reimburse for local purchase

of parts or assemblies found to be defective in material

or workmanship� Reimbursement for local purchase will

require a copy of the wholesale invoice and a maximum

20% markup� During the first year defective compressors

shall be exchanged over the counter by the compressor

manufacturer’s wholesaler� RDI will match the standard

3-year parts-and-labor warranty provided by Manitowoc

Ice on all components attached to the Manitowoc ice

machine�

Labor Coverage

RDI systems are covered by a 30 day labor warranty for

the replacement of component parts which are defective

in material or workmanship� The warranty period begins

on the original start up date but no more than 18

months from ship date� RDI reserves the right to pay

maximum hourly rates equal to the average commercial

hourly rates within that territory or region of the country�

General Conditions

This warranty is issued only to the original purchaser-user

at the original installation location and is in lieu of all

other warranties expressed or implied�

Following the expiration of the basic parts warranty,

replacement parts purchased from RDI shall be

warranted for parts replacement and shipping only for a

period of ninety days from ship date�

Exclusions From Warranty Coverage

1. Normal maintenance and adjustments such as

temperature controls, thermal expansion valves,

defrost timers and cleaning�

2. Repairs due to unauthorized modications of

warranted equipment�

3. Damage or failure caused by improper installation,

improper electrical supply, re, ood, or other natural

disasters, acts of terrorism or war.

4� Damage or delays occurring in transit�

5. Parts or assemblies subject to misuse, abuse, neglect

or accidents�

6. Damage or loss of any products, property, loss of

income or profit due to malfunctioning of sold unit�

Extended Compressor Coverage

If the optional four (4) year compressor warranty is

purchased and the original compressor fails after the

expiration of the one (1) year parts warranty. RDI will

provide a replacement compressor for the condensing

unit assembly� RDI will at it’s option provide directly or

authorize local purchase of the replacement compressor.

If local purchase is authorized the wholesale invoice

along with the serial tag from the original defective

compressor shall be sent to RDI for reimbursement� In

some instances the entire failed compressor may be

required. Labor, freight/transportation, and additional

parts/supplies are not covered.

7

Page 8

Semi-Hermetic

Medium Temp - Semi-Hermetic

Model Electrical RLA Amps LRA Amps Compressor

MC-54M-2 208-230/1/60 3.7 22.0 HAJB-005E-CAV 7374 5922.00 1.25 2

MC-54M-3 208-230/3/60 2.2 13.0 HAJB-005E-TAC 7374 5922.00 1.25 2

MC-74M-2 208-230/1/60 6.1 36.0 KANB-007E-CAV 9057 5922.00 1.53 2

MC-74M-3 208-230/3/60 3.5 19.9 KANA-007E-TAC 9057 5922.00 1.53 2

MC-104M-2 208-230/1/60 7.4 40.0 KARB-010E-CAV 11732 5922.00 1.98 2

MC-104M-3 208-230/3/60 4.3 27.0 KARA-010E-TAC 13797 5922.00 2.33 3

MC-124M-2 208-230/1/60 7.5 40.0 KAGB-010E-CAV 12803 5922.00 2.16 3

MC-124M-3 208-230/3/60 4.3 27.0 KAGA-010E-TAC 12803 5922.00 2.16 3

MC-154M-2 208-230/1/60 10.6 55.0 KAKB-021E-CAV 21948 5922.00 3.71 4

MC-154M-3 208-230/3/60 6.8 50.0 KAKA-020E-TAC 22155 5922.00 3.74 4

MC-204M-3 208-230/3/60 6.6 46.0 ERCA-021E-TAC 28096 5922.00 4.74 5

MC-304M-2 208-230/1/60 17.0 86.0 ERFB-031E-CAB 40307 5922.00 6.81 7

MC-304M-3 208-230/3/60 12.4 82.0 ERFA-031E-TAC 40307 5922.00 6.81 7

MC-305M-3 208-230/3/60 14.2 82.0 3RAA-031E-TAC 40110 5922.00 6.77 7

MC-404M-3 208-230/3/60 21.8 141.0 NRB2-040E-TFC 55420 5922.00 9.36 10

MC-504M-3 208-230/3/60 22.3 120.0 2DC3-050E-TFC 59485 5922.00 10.04 10

MC-505M-3 208-230/3/60 22.3 120.0 2DD3-050E-TFC 70750 5922.00 11.95 12

@20° TD

THR

20° TD

THR

Per Circuit

# Of Circuits

Required

Circuiting

Bundels

Low Temp - Semi-Hermetic

Model Electrical RLA Amps LRA Amps Compressor

MC-54L-2 208-230/1/60 3.6 24.0 KANB-005E-CAV 5200 5922.00 0.88 1

MC-54L-3 208-230/3/60 2.2 13.2 KANA-005E-TAC 5200 5922.00 0.88 1

MC-74L-2 208-230/1/60 5.6 36.0 KAMB-007E-CAV 8375 5922.00 1.41 2

MC-74L-3 208-230/3/60 3.2 19.9 KAMA-007E-TAC 8375 5922.00 1.41 2

MC-104L-2 208-230/1/60 6.9 40.0 KA JB-010E-CAV 9168 5922.00 1.55 2

MC-104L-3 208-230/3/60 4.6 27.0 KAJA-011E-TAC 9168 5922.00 1.55 2

MC-154L-2 208-230/1/60 9.9 55.0 KALB-015E-CAV 16262 5922.00 2.75 3

MC-154L-3 208-230/3/60 6.6 50.0 KALA-016E-TAC 16536 5922.00 2.79 3

MC-204L-2 208-230/1/60 14.7 102.0 EAVB-021E-CAV 22364 5922.00 3.78 4

MC-204L-3 208-230/3/60 7.4 50.0 EAVA-021E-TAC 22364 5922.00 3.78 4

MC-304L-2 208-230/1/60 16.7 105.0 LAHB-032E-CAB 35467 5922.00 5.99 6

MC-304L-3 208-230/3/60 12.8 112.0 LAHA-032E-TAC 29924 5922.00 5.05 6

MC-305L-3 208-230/3/60 16.8 102.0 2DF3F16KE-TFC-200 31743 5922.00 5.36 6

MC-404L-3 208-230/3/60 26.3 161.0 2DL3-040E-TFC 31348 5922.00 5.29 6

MC-601L-3 208-230/3/60 30.3 150.0 3DA3F28KE-TFC 45462 5922.00 7.68 8

@20° TD

THR

20° TD

THR

Per Circuit

# Of Circuits

Required

Circuiting

Bundels

8

Page 9

Scroll

Medium Temp - Semi-Hermetic

Model Electrical RLA Amps LRA Amps Compressor

MC-139MZ-2 208-230/1/60 10.0 41.0 ZB10KCE-PFV 16944 5922.00 2.86 3

MC-149MZ-2 208-230/1/60 10.0 45.0 ZB11KCE-PFV 21116 5922.00 3.57 4

MC-179MZ-2 208-230/3/60 12.9 54.0 ZB13KCE-PFV 22682 5922.00 3.83 4

MC-199MZ-2 208-230/1/60 15.7 61.0 ZS15K4E-PFV 30384 5922.00 5.13

MC-199MZ-3 208-230/3/60 8.9 55.0 ZB15KCE-TF5 25130 5922.00 4.24 5

MC-249MZ-2 208-230/1/60 16.4 73.0 ZS19K4E-PFV 32210 5922.00 5.44 6

MC-249MZ-3 208-230/3/60 9.7 63.0 ZS19K4E-TF5 32210 5922.00 5.44 6

MC-299MZ-2 208-230/1/60 16.4 20.2 ZB21K4E-PFV 34364 5922.00 5.80 6

MC-299MZ-3 208-230/3/60 11.1 77.0 ZS21K4E-TF5 34685 5922.00 5.86 6

MC-349MZ-3 208-230/3/60 13.6 88.0 ZS26K4E-TF5 43809 5922.00 7.40 8

MC-399MZ-3 208-230/3/60 15.0 99.0 ZS30K4E-TF5 50060 5922.00 8.45 9

MC-499MZ-3 208-230/3/60 21.4 123.0 ZS38K4E-TF5 68255 5922.00 11.53 12

MC-599MZ-3 208-230/3/60 22.1 172.0 ZS45K4E-TF5 68355 5922.00 11.54 12

MC-749MZ-3 208-230/3/60 30.0 189.0 ZS56K4E-TF5 90500 5922.00 15.28 16

MC-999MZ-3 208-230/3/60 43.6 278.0 ZS75K4E-TF5 5922.00 0.00

MC-1299MZ-3 208-230/3/60 52.9 55.4 ZS92K4E-TF5 5922.00 0.00

@20° TD

THR

20° TD

THR

Per Circuit

# Of Circuits

Required

Circuiting

Bundels

Low Temp - Semi-Hermetic

Model Electrical RLA Amps LRA Amps Compressor

MC-199LZ-2 208-230/1/60 13.6 61.0 ZF06K4E-PFV 17397 5922.00 2.94 3

MC-199LZ-3 208-230/3/60 9.3 55.0 ZF06K4E-TF5 17397 5922.00 2.94 3

MC-249LZ-2 208-230/1/60 16.4 73.0 ZF08K4E-PFV 18313 5922.00 3.09 3

MC-249LZ-3 208-230/3/60 9.7 63.0 ZF08K4E-TF5 18313 5922.00 3.09 3

MC-299LZ-2 208-230/1/60 16.4 88.0 ZF09K4E-PFV 19345 5922.00 3.27 4

MC-299LZ-3 208-230/3/60 11.1 77.0 ZF09K4E-TF5 19345 5922.00 3.27 4

MC-349LZ-2 208-230/1/60 20.7 109.0 ZF11K4E-PFV 24088 5922.00 4.07 4

MC-349LZ-3 208-230/3/60 13.6 88.0 ZF11K4E-TF5 24088 5922.00 4.07 4

MC-399LZ-2 208-230/1/60 26.8 129.0 ZF13K4E-PFV 27553 5922.00 4.65 5

MC-399LZ-3 208-230/3/60 15.0 99.0 ZF13K4E-TF5 27553 5922.00 4.65 5

MC-499LZ-2 208-230/1/60 31.8 169.0 ZF15K4E-PFV 30384 5922.00 5.13 5

MC-499LZ-3 208-230/3/60 21.4 123.0 ZF15K4E-TF5 30384 5922.00 5.13 5

MC-599LZ-3 208-230/3/60 23.9 156.0 ZF18K4E-TF5 40770 5922.00 6.88 7

MC-749LZ-3 208-230/3/60 30.0 189.0 ZF24K4E-TWC 57207 5922.00 9.66 10

MC-999LZ-3 208-230/3/60 43.6 278.0 ZF33K4E-TWC 63645 5922.00 10.75 11

MC-1299LZ-3 208-230/3/60 52.9 350.0 ZF40K4E-TWC 79656 5922.00 13.45 14

@20° TD

THR

20° TD

THR

Per Circuit

# Of Circuits

Required

Circuiting

Bundels

9

Page 10

Hermetic

Medium Temp - Semi-Hermetic

Model Electrical RLA Amps LRA Amps Compressor

MC-49M-1 115/1/60 10.1 51.0 RS43C1E-IAA 10171 5922.00 1.72 2

MC-49M-2 208-230/1/60 5.4 24.1 RS43C1E-CAV 8665 5922.00 1.46 2

MC-69M-2 208-230/1/60 6.1 40.0 RS55C2E-CAV 12954 5922.00 2.19 3

MC-99M-2 208-230/1/60 7.0 34.2 RS70C1E-PFV 16010 5922.00 2.70 3

MC-99M-3 208-230/3/60 4.7 31.0 RS70C1E-TFC 13449 5922.00 2.27 3

MC-149M-2 208-230/1/60 9.6 59.2 CF04K6E-PFV 22070 5922.00 3.73 4

MC-149M-3 208-230/3/60 6.8 52.0 CS10K6E-TF5 19035 5922.00 3.21 4

MC-199M-2 208-230/1/60 10.9 56.0 CS12K6E-PFV 22990 5922.00 3.88 4

MC-199M-3 208-230/3/60 7.5 51.0 CS12K6E-TF5 22450 5922.00 3.79 4

MC-299M-2 208-230/1/60 16.0 82.0 CS18K6E-PFV 33860 5922.00 5.72 6

MC-299M-3 208-230/3/60 8.8 65.0 CS18K6E-TF5 33150 5922.00 5.60 6

MC-399M-2 208-230/2/60 23.9 121.0 CS27K6E-PFV 52053 5922.00 8.79 9

MC-399M-3 208-230/3/60 15.6 105.0 CS27K6E-TF5 50885 5922.00 8.59 9

MC-499M-3 208-230/3/60 20.7 90.0 CS33K3E-TF5 59589 5922.00 10.06 10

@20° TD

THR

20° TD

THR

Per Circuit

# Of Circuits

Required

Circuiting

Bundels

Low Temp - Semi-Hermetic

Model Electrical RLA Amps LRA Amps Compressor

MC-49L-1 115/1/60 4.1 30.0 AFT18C1E-IAV 5103 5922.00 0.86 1

MC-69L-2 208-230/1/60 9.8 43.3 RS86C1E-PFV 10192 5922.00 1.72 2

MC-99L-2 208-230/1/60 9.6 59.2 CF04K6E-PFV 6680 5922.00 1.13 2

MC-99L-3 208-230/3/60 6.8 52.0 CF04K6E-TF5 6271 5922.00 1.06 2

MC-149L-2 208-230/1/60 11.4 59.2 CF06K6E-PFV 10905 5922.00 1.84 2

MC-149L-3 208-230/3/60 7.0 52.0 CF06K6E-TF5 10328 5922.00 1.74 2

MC-199L-2 208-230/1/60 16.7 87.0 CF09K6E-PFV 15751 5922.00 2.66 3

MC-199L-3 208-230/3/60 10.2 72.2 CF09K6E-TF5 15534 5922.00 2.62 3

MC-249L-2 208-230/1/60 16.7 87.0 CF09K6E-PFV 18901 5922.00 3.19 4

MC-249L-3 208-230/3/60 10.2 72.2 CF09K6E-TF5 18640 5922.00 3.15 4

MC-299L-2 208-230/1/60 20.5 105.0 CF12K6E-PFV 25448 5922.00 4.30 5

MC-299L-3 208-230/3/60 12.3 85.0 CF12K6E-TF5 25448 5922.00 4.30 5

MC-404L-3 208-230/3/60 26.3 161.0 2DL3-040E-TFC 34766 5922.00 5.87 6

@20° TD

THR

20° TD

THR

Per Circuit

# Of Circuits

Required

Circuiting

Bundels

10

Page 11

11

Page 12

RDI

2915 T en nessee A ve n or Th , PA rs on s, T n 3836 3 • 1-877-759- 9019 • FAx 1- 731-847-901 2

SolutionS

RDI provides many of the operational solutions from Manitowoc Foodservice, a global company dedicated to bringing

value to foodservice operators by equipping them with highly individualized real-world answers that enhance menus,

service, profits and efficiency.

To learn how Manitowoc Foodservice and its leading brands can equip you, visit our global web site at

www�manitowocfoodservice�com then find the regional or local resources available to you�

©2009 Manitowoc Foodservice except where explicitly stated otherwise. All rights reserved. 3617D 1/10

Loading...

Loading...