Page 1

RED

LEAD

LEAD

JUMPER

K00364 Electronic Bin Thermostat

Installation Instructions

This kit reduces overfill and cond ensation issues and can be used on any Manit owoc ice machine installed on an ice

dispenser. Order kit number K00336 for the following models IB0620, IB0820, IB1020, QF0400 and QF2300.

Control Settings

Flake/Nugget/Chiplet:

The control must be reset from the factory setting.

Refer to the jumper and control settings.

Ice Cube Machines:

The machines use the factory control settings.

The controller has a one-minute time delay anytime

power is interrupted and restored.

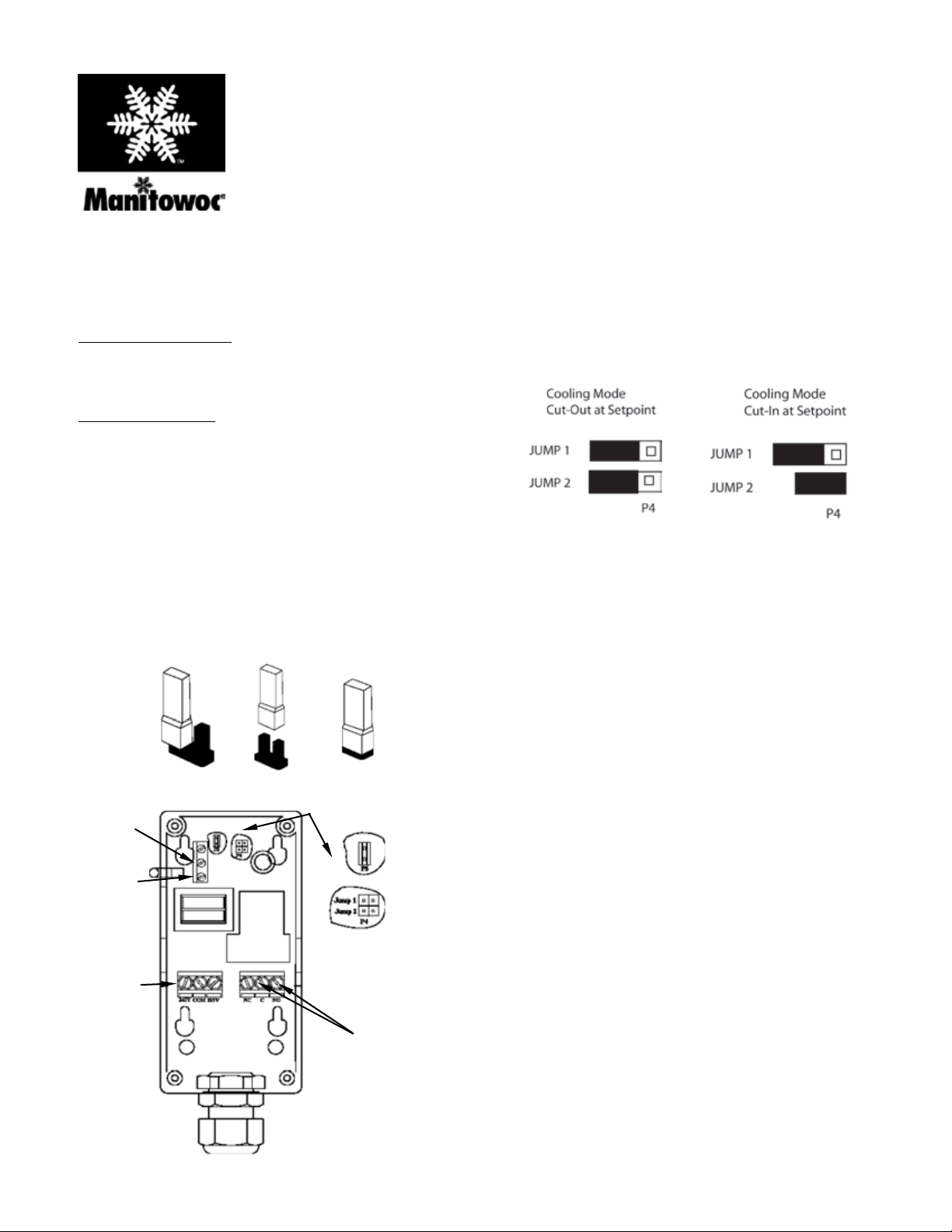

Positioning the Touchpad Jumpers

P5 Jumper

The P5 jumper position determines if the touchpad is

locked or unlocked. The control is factory locked; to

unlock, move the jumper from one pin to two pins.

SENSOR

BLACK

SENSOR

MATCH

WIRING

TO ICE

MACHINE

VOLTAGE

LOCATIONS

BIN SWITCH OR

TOGGLE SWITCH

P4 Jumper

The P4 jumper labeled Jump 1 is used to set the control

for heating or cooling mode. Jump 2 is used to

establish set point at either cut-in or cut-out.

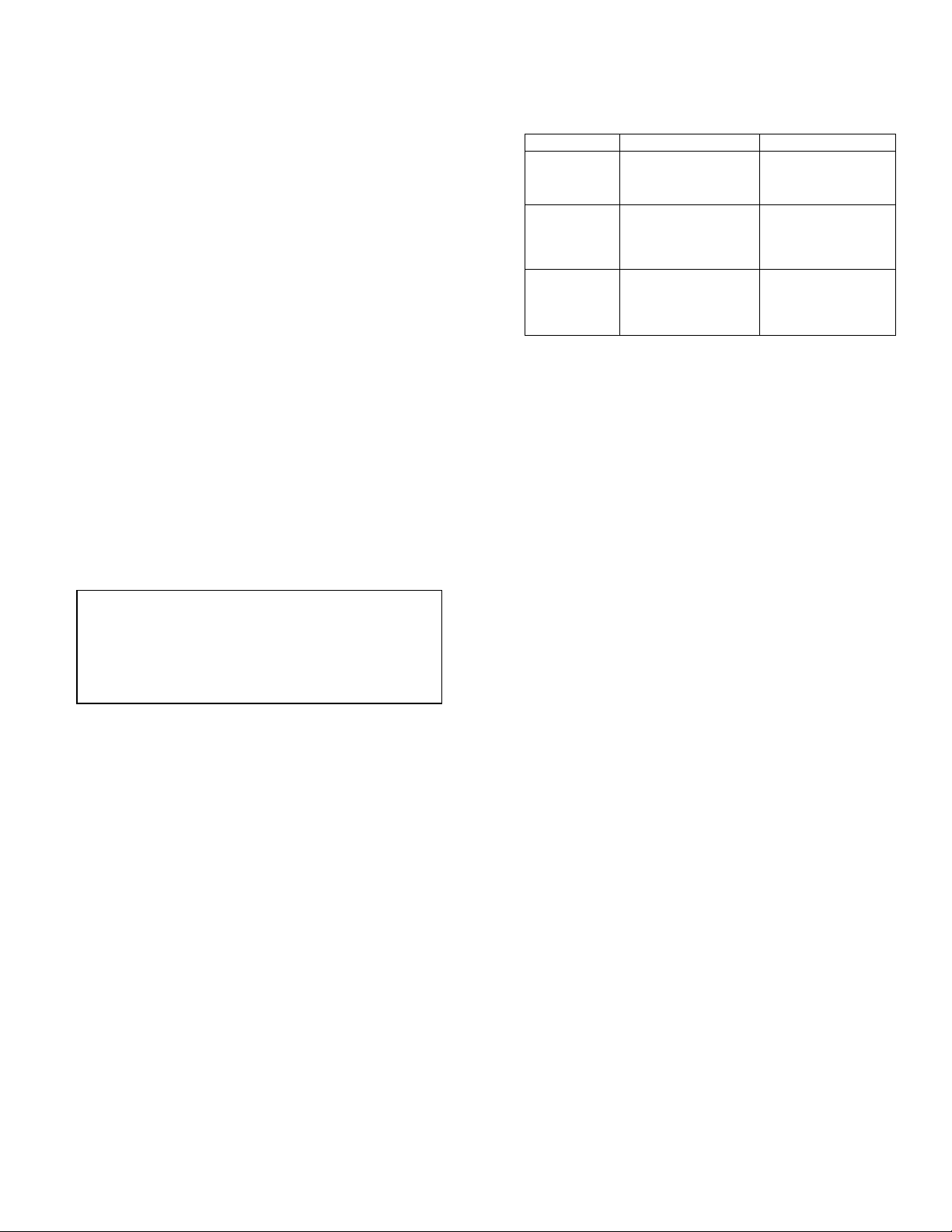

Cubers Flake/Nugget/Chiplet

Setting Control Set point Value

To view and adjust set point, foll ow these steps:

A. Press MENU until the display flashes SP.

B. Press MENU ag ain to display the existing set

point value.

C. Press up or down (arrows) to change the set

point value.

D. Press MENU again to save the new value. The

display returns to the sensed temperature.

E. If no setup entry is made for 30 seconds, the

control reverts to the normal temperature

display.

IMPORTANT:

If MENU is not pressed after changing the set point

value, the control reverts to the previously

programmed set point value.

Page 2

Manitowoc Ice, Inc.

2110 South 26th Street, P.O. Box 1720, Manitowoc, WI 54221-1720 USA 8016563

Telephone 920-682-0161, Fax - Sales: 920-683-7589, Service/Parts: 920-683-7585, Other: 920-683-7879 Sheet 1 of 4

Web Site - www.manitowocice.com Rev. 03/14/06

Page 3

Fault Code

Definition

Solution

Differential, Anti-Short Cycle Delay, Temperature Offset, or Sensor Failure Operation

To set or verify the Differential, Anti-Short Cycle

Delay, Temperature Offset or Sensor Failure Op eration

use the following method:

Factory preset temperature control code settings, as

follows:

A. Press and hold MENU until the display

changes to flashing SP.

B. Press up and down (arrows) repeatedly until

the desired function is displayed.

C. Press MENU to display the function’s current

value.

D. Press up and down (arrows) until the desired

value is displayed.

E. Press MENU to save the new value. The

display returns to the sensor temperatur e.

F. If no setup entry is made for 30 seconds, the

control reverts to the temperature display.

Any saved control settings are non-v olatile and remain

in the control’s memory during power interruptions.

Check Procedure

WARNING

Line voltage is present inside control. Contact

with line voltage can cause serious injury or

death.

If the control system does not function properly, verify

that the control is wired and set up properly. If the

problem persists, use the following procedures to

determine the cause of the problem

IMPORTANT:

Follow these troubleshooting procedures in the order

presented. Do not skip any of the steps in the

procedures.

1. Check for proper voltage to the control.

A. Remove the cover by loosening the four cover

screws.

B. Use an AC voltmeter to check the voltage

between the common and 120V or 240V

terminals.

C. The voltage must be between 102 and 132

volts for 120V applications; 177 and 264 volts

for 208/230V applications.

D. If the voltage reading is not within the required

range, check the power source and input power

wires for problems.

2. Fault Codes

If the LCD displays an alarm or fault code (SF or EE):

SF flashing

alternately with

OP

SF flashing

alternately with

SH

EE

Open temperature

sensor or sensor wiring

Shorted temperature

sensor or sensor wiring

Program failure

See Step 3. Cycle

power to reset control.

See Step 3. Cycle

power to reset control

Reset the control by

pressing MENU. If

problem persists,

replace the control.

3. Check for proper operation.

IMPORTANT:

Perform Steps 1 and 2 before performing these steps:

A. Disconnect the load from the output relay

terminals.

B. Reconnect the sensor leads and supply power

to the control.

C. Replace t he cover.

D. Check the control settings for proper values.

E. Press and hold MENU until SP appears.

F. Press u p and down (arrows) to change the set

point temperature above and below the sensor

temperature until the relay energizes and deenergizes.

G. If the output relay does not perform as

indicated, replace the control.

H. If proper operation of the control is verified,

reconnect the load.

Page 4

8016563

Sheet 2 of 4

Rev. 03/14/06

Page 5

View A

Position the controller in a suitable

Route sensor wire between

Install romex connector in a vacant

Universal Thermostat Kit

Installation Instructions

FOR USE WITH DISPENSERS ONLY

THIS CONTROL KIT IS INTENDED TO REDUCE OVERFILL AND CONDENSATION ISSUES

1. Remove all ice from dispenser.

2. Disconnect all power to the ice machine and

dispenser at the service disconnect or fuse/ breaker

panel.

3. Move the ice machine and dispenser away from

the wall for easier access.

4. Remove all panels and control box cover.

5. If an ice machine is already installed on the

dispenser, raise and support the right side of the

ice machine. Install the mounting bracket on the

right-hand side of the dispenser 6” from the right

rear corner. Compress the bracket to the thickn ess

of the dispenser wall and tighten the two screws.

6. Route thermistor wire out back of the ice

machine/dispenser (lower the ice machine, if

supported). Remove unused knockout on the ice

machine back panel, install romex connector and

route wire into the ice machine compressor

compartment.

7. Normally the controller can be mounted on the

bulkhead flange. If not, a suitable area must be

found for your model. Use controller bracket to

locate mounting holes on the flange of the

bulkhead. Drill two 9/32" diameter holes (used to

mount the controller bracket - see View A). Do

not mount the controller, at this time.

8. Route the four wires from the temperature control

to the control box (insuring that the wires will not

come in contact with any refrigeration tubing).

IMPORTANT:

The thermostat must be wired to match the voltage

of the ice machine. The thermostat is pre-wired for

115 volts. Rewire thermostat, if your ice machine is

240 volts.

9. The control box line voltage wiring offers two options:

• Connect thermostat L1 (brown) and L2 (blue) wires

to contactor (incoming line voltage side) L1 and L2.

OR

• Disconnect incoming power line wire nuts.

Remove quick-connect fittings from brown and

blue wires and strip 1/2” of insulation from the

wires. Connect incoming power L1, ice machine

L1, and thermostat L1 (brown) wires together with

wire nut. Connect incoming power L2, ice machine

L2, and thermostat L2 (blue) wires together with

wire nut.

10. Disconnect the red male/female connector bin switch

wire and connect the red male wire from the controller

to the red female bin switch wire.

11. Connect the white male bin switch wire to the white

female wire of the controller.

12. Restore all p ower to the ice machine and the dispenser

at the service-disconnect or fuse/breaker panel.

13. The fact ory setting on the thermostat will b e correct for

most applications. Adjust only when necessary.

14. With two screws, secure the controller bracket

assembly to the flange of the bulkhead.

15. Reinstall the control box cover and all panels.

location. It can be installed here on most

ice machines. Use bracket to locate

mounting holes - drill two 9/32" holes

through bulkhead flange to secure

dispenser and ice machine

knockout and route sensor wire into

compressor compartment

Page 6

8016563

Sheet 3 of 4

Rev. 03/14/06

Page 7

View C

FACTORY PRESET

Keypad Locked Out

Jumper Position

Red Lead

Sensor Probe

Black Lead

Sensor Probe

Brown Lead

Power

Blue Lead

Power

White 22AWG Lead

Route Sensor

Wiring Here

Red 22AWG Lead

Bin Switch or

Toggle Switch

Bin Switch or

Toggle Switch

TEMPERATURE

CONTROL CODE SETTINGS AS

FOLLOWS:

Set Point - SP: 40

Differential - DIF: 1

Anti Short Cycle Delay - ASD: 1

Temperature Offset - OFS: 0

Sensor Failure Operation - SF:

1 - Cube

0 - Flake/Nugget/Chiplet

Page 8

8016563

Sheet 4 of 4

Rev. 03/14/06

Loading...

Loading...