Page 1

Ice Storage and

Manitowoc

Transport System

Installation, Use & Care Manual

This manual is updated as new information and models are released.

Visit our website for the latest manual. www.manitowocice.com

America’s #1 Selling Ice Machine

Part Number 000006529 10/09

This manual contains English and French text

Page 2

Section 1

General Information

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Warnings and Operating Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Section 2

Installation Instructions

Uncrating Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Uncrating and Installing Base Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing Tie-down Straps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Sealing Bin Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Drain Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Plumbing Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Affixing Operating Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Door Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ice Guide Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table of Contents

Removing Lower Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Reinstalling Lower Door Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Repositioning Ice Guides After Legs Have Been Adjusted . . . . . . . . . . . . . . . . 6

Section 3

Operation

Section 4

Maintenance

Section 5

Customer Support

Cart Drain Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cart Lids . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ice Transport System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

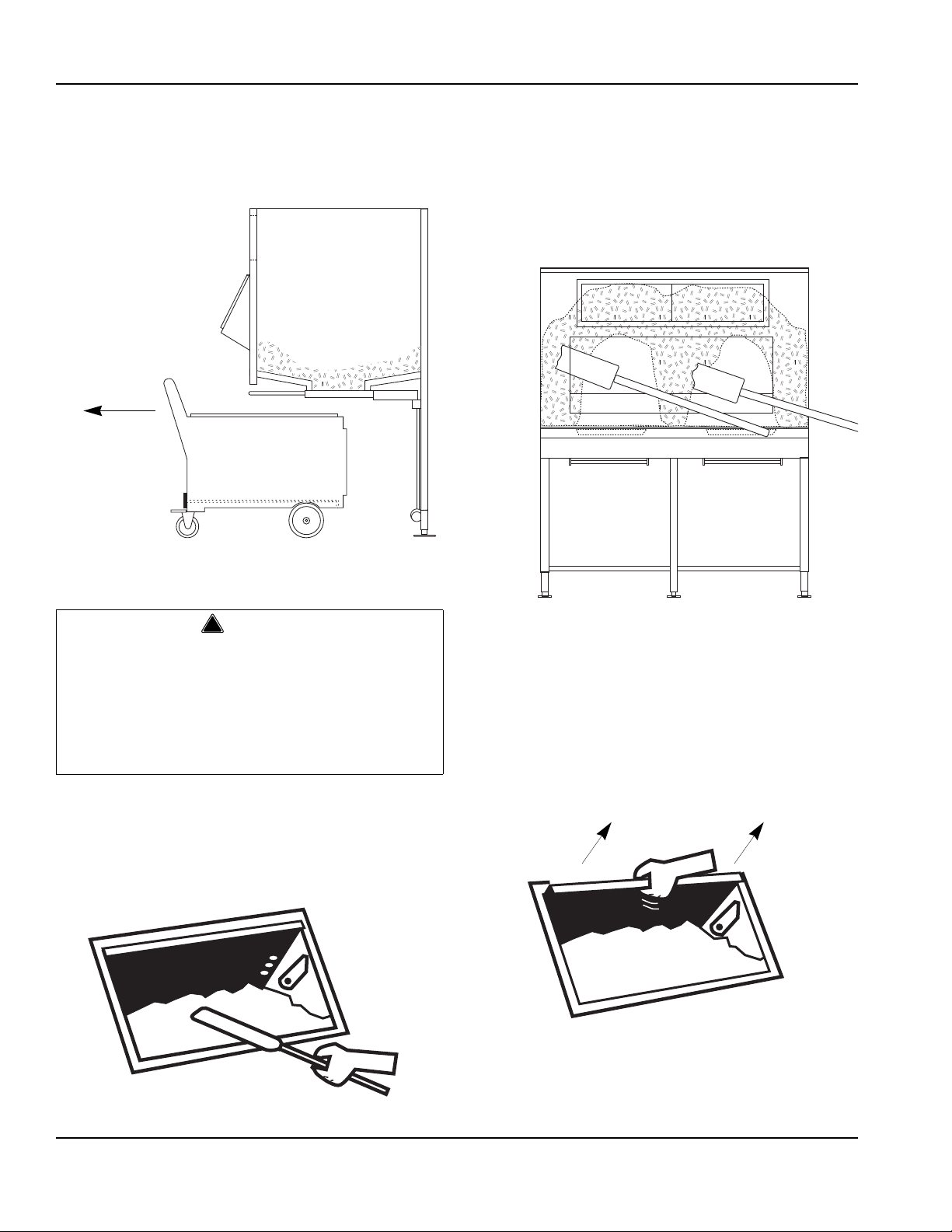

Pushing Cart Into Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loading Ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pulling Cart Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Transporting Ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Breaking Ice Bridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Baffle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning and Sanitizing Interior Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Parts Removal for Cleaning/Sanitizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Shutter Doors and Rails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drain Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Bin Drain System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Cleaning Exterior Bin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Before Calling For Service Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Limited Warranty For Ice Storage Bin & Dispensers . . . . . . . . . . . . . . . . . . . . . . 12

Web site: www.manitowocice.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Part Number 000006529 10/09

Page 3

Model Numbers

Important

!

Warning

!

Warning

!

Warning

Section 1

General Information

This manual covers the following model:

Ice Storage and Transport System

FC1350

Following installation, please forward this manual to

the appropriate operations person.

Before You Begin

After uncrating and removing all packing material,

inspect the equipment for concealed shipping damage.

If damage is found, notify the shipper immediately.

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified

from that of original manufactured specifications.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision concerning use of the appliance by a

person responsible for their safety.

Important Warnings and Operating Rules

Read this manual completely before assembling or

operating Ice Transport System and follow warnings and

instructions listed below.

To avoid injury during operation of unit:

• Keep entire body clear of bin when breaking up

ice

• Keep head and face away from paddle handle

when breaking up ice

• Lock caster before scooping or shoveling ice

from cart and when parked in bay

• Keep floor around Ice Transport System free of

ice and water

• Always operate cart at a slow, reasonable speed

For best operation and to ensure delivery of clean,

sanitary ice:

• Be sure bin system is level in both directions to

provide proper drainage

• Position cart in bay before opening hopper door

• Install charcoal water filter on inlet water for ice

machine

• Hang paddle implement in supplied bracket after

each use

• Keep paddle clean and in good repair to avoid ice

contamination

• Cover ice with cart lid when transporting

• Follow instructions in this manual for bin and cart

cleaning and maintenance

• Drain melt water from cart when positioned in bay by

opening drain valve

• Keep glass, dirt and other foreign objects out of bin

and cart at all times

To avoid damage to Ice Transport System and injury

during operation:

• Do not move Ice Transport System once ice

machine has been installed

• Anchor flanged feet to floor as instructed on page 4

• Only use paddle provided to assist ice flow

• Only use cart to transport ice and reinstall

carefully in bin bay when not in use

Part Number 000006529 10/09 3

Page 4

Section 2

! Warning

! Warning

LOCATING PIN

BEAD OF

SILASTIC

GASKET

BIN

SECTION

BASE

SECTION

BEAD OF

SILASTIC

GASKET

Installation Instructions

Uncrating Cart

1. Remove paddle from skid by cutting plastic straps.

2. Cut strap holding front axle to skid.

3. Remove wheel chocks from skid at handle end of

cart.

4. Roll cart(s) out of base section.

5. Remove tape holding lid to cart.

6. Remove lid storage bracket(s) from inside cart.

(Brackets may be installed on left or right side of bin.

See Installing Bin section.)

Uncrating and Installing Base Section

1. Remove screws holding flanged feet and tie-down

straps to skid and remove skid.

2. Remove packing material from inside of legs and

around shutter door.

3. Position base in intended position and adjust feet to

level unit in both directions.

4. Mark position of each flanged foot anchoring hole.

5. Move base out of way and install anchors for 1/4"

bolts in floor (supplied by others).

6. Reposition unit in intended position and anchor base

unit to floor through flanged feet.

5. Use fasteners provided to install paddle support

bracket on right or left side of bin in holes provided.

6. Remove paper from back of cart lid storage

bracket(s) and position brackets on side of bin.

7. Remove all tape and temporary fastenings from

door assemblies and outside of bin.

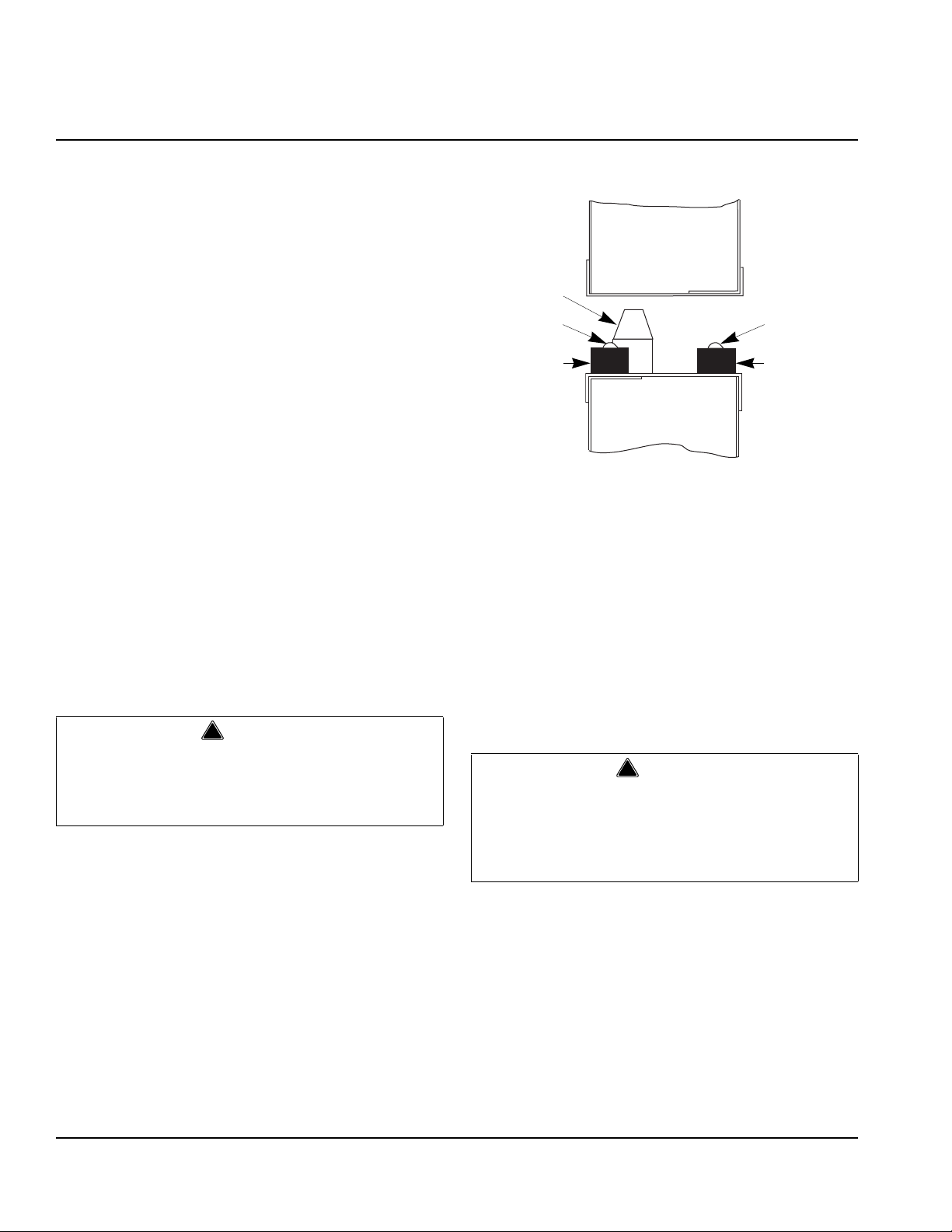

8. Mount ice machine(s) on top of bin in accordance

with ice machine instructions.

9. Install tie-down straps.

Installing Tie-down Straps

When leveling, do not extend any leg more than 1"

(26 mm) for total leg height no greater than 2.125"

(54 mm). Legs must be secured to floor through feet

to avoid possible movement and resulting injury.

Installing Bin

1. Remove 4 bolts fastening skid to underside of bin.

2. Remove all protective wrap from exterior.

3. Run 1/8" bead of supplied silastic in center of each

gasket band on base.

4. Install bin section on base section, taking care that

locating pins in base engage holes in bin.

4 Part Number 000006529 10/09

Tie-down straps to secure bin to base are provided

on each side of unit. Straps must be installed to

avoid possible injury should unit move. Bolt unit to

wall for increased stability, and bolt to floor to

prevent side-to-side movement.

1. Remove screws from rivnuts on each side of bin

section.

2. Reposition tie-down strap up until slot matches

rivnut opening.

3. Reinstall screws in rivnuts and tighten.

Page 5

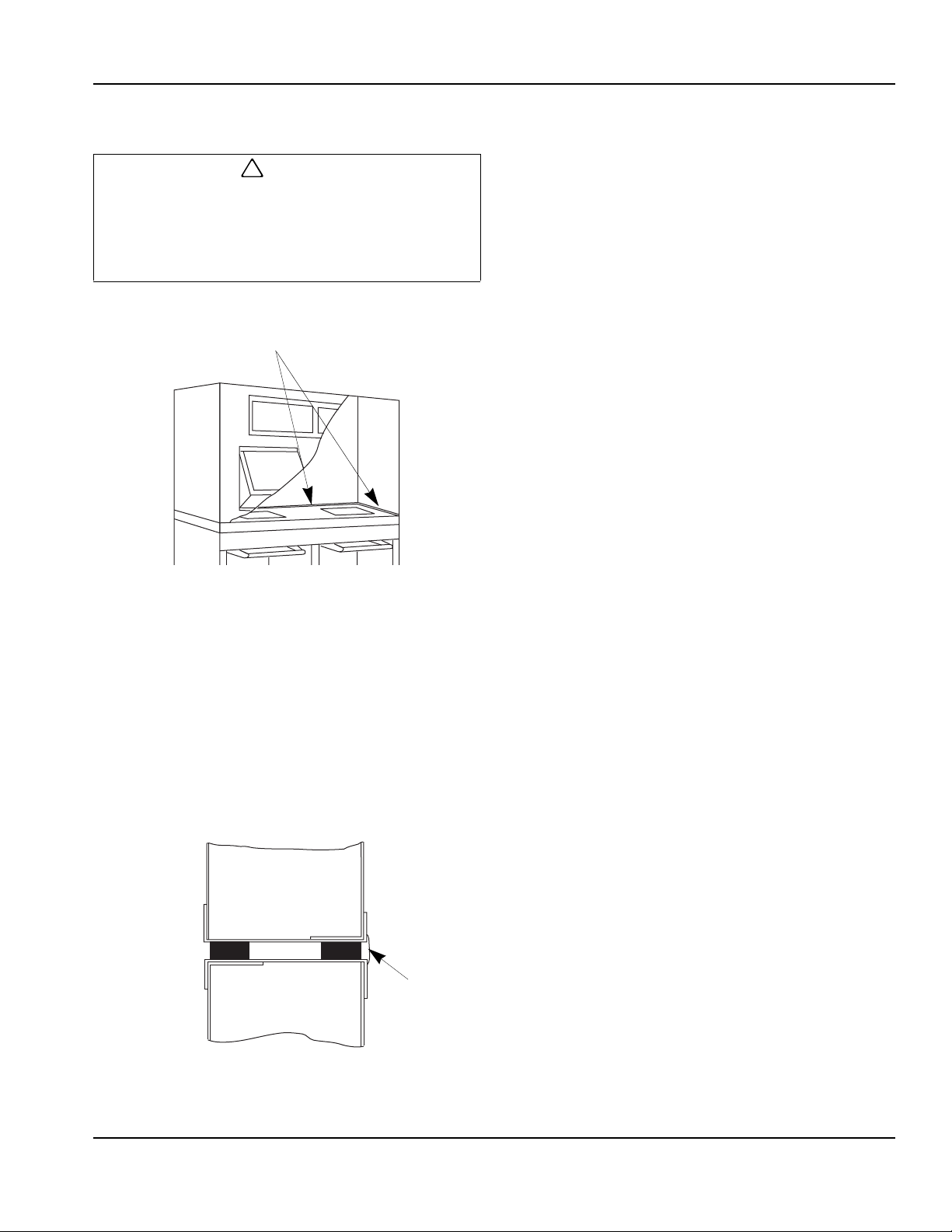

Section 2 Installation Instructions

!

Caution

USE SEALANT PROVIDED TO SEAL

ENTIRE PERIMETER OF SEAM WHERE

BASE AND BIN SECTION JOIN.

INTERIOR

COMPLETELY

SEAL GASKET

BIN

SECTION

BASE

SECTION

EXTERIOR

Sealing Bin Interior

The joint between base and bin sections must be

sealed with silastic to prevent leakage and/or ice

contamination and potential voiding of warranty. One

or more shutter doors may need to be removed to

seal bin.

1. Support shutter door(s) with one hand and remove

thumbscrews from side of shutter door(s) at

underside of base.

2. Pivot door(s) downward to remove.

3. Gain access through this opening and seal entire

perimeter of seam between bin and base with

provided sealant or equivalent.

4. After sealant has set but before shutter door(s) have

been reinstalled, clean inside of bin following

instructions in this manual.

5. Reinstall shutter door(s).

Drain Requirements

• Bin drain termination must have an air gap.

• Drain lines must have a 1.5 inch drop per 5 feet of

run (2.5 cm per meter), and must not create traps.

• The floor drain must be large enough to

accommodate drainage from all drains.

• Run separate bin and ice machine drain lines and

insulate to prevent condensation.

Plumbing Connections

NOTE: It is recommended that a full width grated floor

drain be installed in front of bin.

1. Units are shipped for a right side exiting drain. To

drain to left, switch positions of screws in trough

brackets from lower hole to upper hole on left

bracket and upper hole to lower hole on right

bracket.

2. Remove plug from left side of drain trough and insert

in right side.

3. Connect drain line to 1-1/4" PVC slip fit drain fitting.

4. Make final connections to ice machine.

Affixing Operating Labels

Operating labels taped to base front educate staff to

shutter door operation. If desired, these labels can be

affixed permanently by peeling off back paper and

affixing in locations desired.

NOTE: Adhesive backing is extremely strong and labels

cannot be easily removed once installed.

Part Number 000006529 10/09 5

Cross Section of Ice Transfer System

Sections Joined

Page 6

Installation Instructions Section 2

ACCESS

DOOR

LOWER DOOR

ASSEMBLY

BAFFLE

BRACKETS ON UNDERSIDE OF HOPPER

TO WHICH ICE GUIDES ARE SECURED

Door Removal

REMOVING LOWER DOOR ASSEMBLY

(Only if required for access through narrow doors)

1. With lower access door closed, remove Phillips

head screw and washer from hinge area on each

side of lower access door.

2. Insert screwdriver between door and hinge bracket

on one side of door and gently push against bracket

to provide room for door stud to clear bracket.

3. Remove access door.

4. Pull up on baffle to remove.

5. Remove three or four (3 or 4) screws along top of

door assembly.

6. Pull forward on assembly and remove.

Ice Guide Adjustment

Ice may flow over sides of cart when exiting hopper. Ice

guides hang down below hopper and help contain

flowing ice inside cart.

Guides are installed in highest position at factory,

providing 3/4" (19 mm) clearance to top of cart when

legs are in full down position. If legs are adjusted up

during leveling of Ice Transport System, ice guides

should be lowered to maintain 3/4" (19 mm) clearance.

Access to sides of Ice Transport System is required to

perform operation.

REPOSITIONING ICE GUIDES AFTER LEGS HAVE

BEEN ADJUSTED

1. Position cart (with totes, if so equipped) in bay below

shutter door opening.

2. Determine amount guides must be lowered to

maintain 3/4" (19 mm) clearance.

3. Remove thumbscrews holding guides.

4. Select hole to reposition guide at proper level and

resecure with thumbscrew.

5. Repeat process for each bay in system.

REINSTALLING LOWER DOOR ASSEMBLY

1. Reinstall lower door assembly in bin opening.

2. Reinstall three or four (3 or 4) screws in hood at top

of door assembly.

3. Reinstall the baffle in side panel tracks and push

down to seat.

4. With door closed insert one door stud through hinge

bracket.

NOTE: For proper operation the access door must be

reinstalled in the closed position.

5. On other side, insert screwdriver between door and

hinge bracket and gently push against bracket to

provide room for door stud to clear bracket.

6. Reinstall washers and screws in lift door and tighten.

7. Check door to ensure proper operation.

6

Part Number 000006529 10/09

Page 7

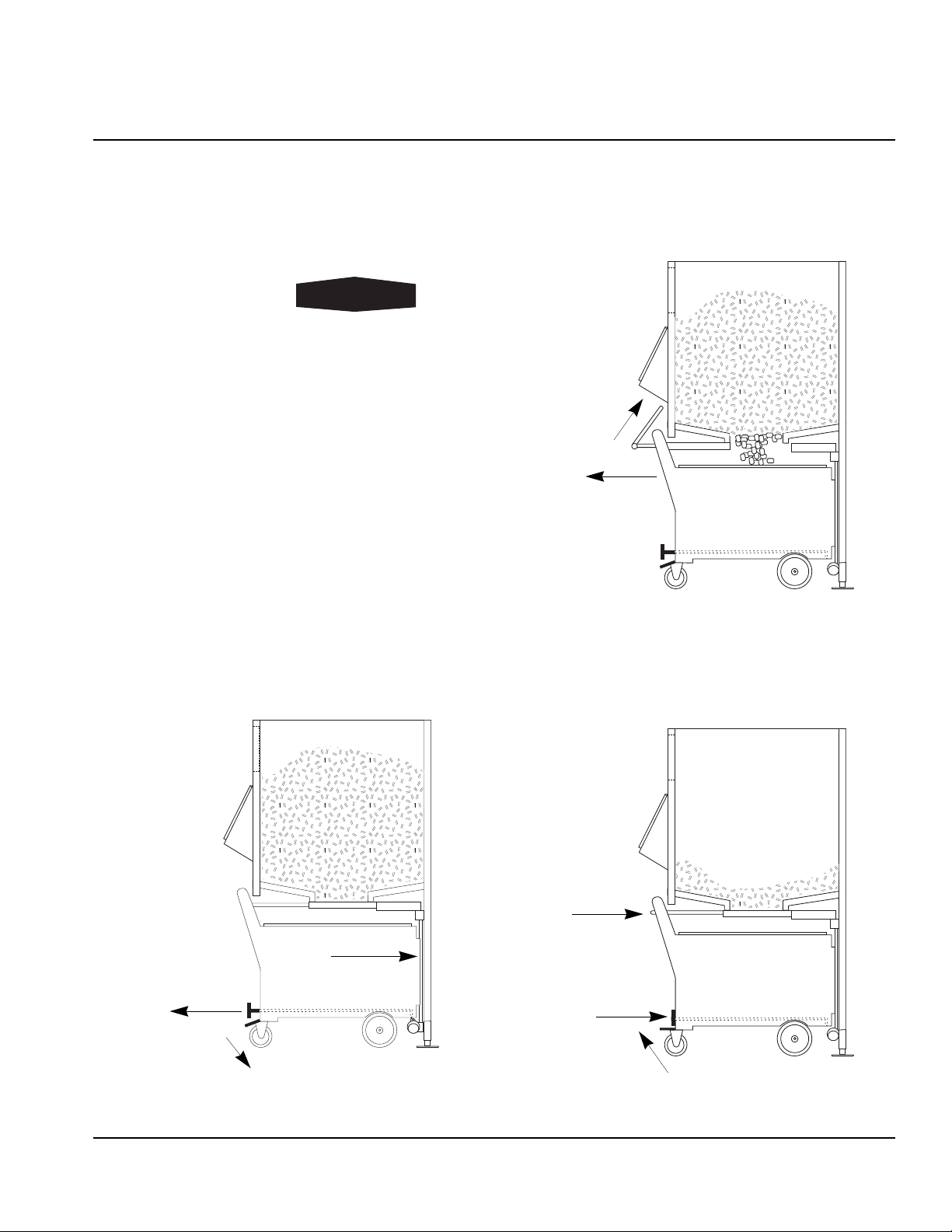

Section 3

PUSH TO CLOSE

3

2

1

1

2

1

3

2

Operation

Cart Drain Operation

1. Position cart all the way in bay.

2. Lock caster to prevent cart movement.

3. To open drain, pull knob out.

4. To close, push knob in.

Cart Lids

1. Hang cart lids on brackets on bin side when carts

are positioned in bay.

2. Remove from bracket and place lid on cart when

transporting ice.

3. To avoid placing lid on floor, position lid horizontally

on cart lip, resting lid against cart handle when

unloading ice from cart.

4. Reinstall lid in bracket on side of bin before placing

cart in bay.

Ice Transport System Operation

PUSHING CART INTO BAY

1. PUSH cart all the way to back.

2. PULL cart drain open.

3. Lock brake on caster DOWN.

LOADING ICE

1. PULL shutter handle open.

2. Store handle up against bin.

PULLING CART OUT

1. PUSH shutter handle closed.

2. PUSH cart drain closed.

3. Release brake on caster.

Part Number 000006529 10/09 7

Page 8

Operation Section 3

! Warning

1

TRANSPORTING ICE

1. PULL cart from base.

2. Place lid on cart.

1. Completely knock down all ice from sides and back

of bin.

2. Knock down any bridge that has occurred in middle.

3. Agitate paddle back and forth to break up congealed

ice mass.

Breaking Ice Bridges

Do not dig up at ice. Instead, break away “legs” that

are holding bridges. Ice above will then fall.

To avoid injury, do not attempt to break up bridged

ice through upper windows or hopper shutter door. A

falling ice bridge can cause paddle to lift. Keep head

and face away from paddle handle to avoid injury.

It may be necessary to use the paddle to break up ice

bridges that occur along the sides and in the middle of

the bin. This often happens if ice has been held in

storage for a period of time without use. Use supplied

paddle accessory to break up bridges.

Baffle Operation

The baffle can be adjusted and locked at one of several

levels to accommodate flow characteristics of different

types of ice.

Bin is shipped with the baffle in full down position. The

baffle can be raised and locked in higher position for

better flow or when more access is needed.

8

Part Number 000006529 10/09

Page 9

Section 4

!

Caution

! Warning

REAR WINDOW

FRONT WINDOW

Important

Maintenance

Clean and sanitize bin and cart(s) interiors prior to

use and on regular schedule as needed. Use only

Manitowoc approved Ice Machine Cleaner (940546-3 or 000000084) and Sanitizer (94-0565-3) for

this application. Do NOT use chlorine-based

cleaners, which can cause staining and pitting of

stainless steel components. Do not run Totes

through a dishwasher. Turn off ice machine(s) and

remove ice from bin before beginning.

Wear rubber gloves and safety goggles (and/or face

shield) when handling Ice Machine Cleaner or

Sanitizer.

Cleaning and Sanitizing Interior Bin

Interior of bin must be cleaned and sanitized prior to use

and should be cleaned on a routine basis during use.

The ice storage bin is equipped with polyethylene liner

walls which must be cleaned and sanitized every six

months with Manitowoc Ice Machine Cleaner and

Sanitizer.

1. Remove upper inspection windows by sliding

windows to one side. Grasp the end of the front

window and pull toward you as the window is slid to

the opposite side. Repeat for rear window.

3. Wash bin walls, hopper, access door plate and

partition (if any), and rinse all areas thoroughly with

clean water.

Do not rinse after sanitizing.

4. Mix a solution of sanitizer and warm water.

Solution Type Water Mixed With

Sanitizer 3 gal. (11 L) 2 oz. (60 ml)

sanitizer

5. Sanitize bin walls, hopper and access door plate.

Use a spray bottle to liberally apply the solution. Do

not rinse the sanitized areas.

6. Clean and sanitize the ice delivery carts.

A. Wash cart liner with an approved cleaner.

B. Rinse all areas thoroughly with clean water.

C. Sanitize the cart - Use a spray bottle to liberally

apply the solution. Do not rinse the sanitized

areas.

7. Remove the following bin components for cleaning

and sanitizing.

• Shutter Door

•Drain Tray

• Bin Drain Lines

8. Use cleaning solution to clean the removed

components, rinse with clean water and sanitize (do

not rinse after sanitizing).

9. Clean, rinse and sanitize the shutter door rails.

10. Reassemble all removed components.

2. Mix a solution of cleaner and warm water.

Depending upon the amount of mineral buildup, a

larger quantity of solution may be required. Use the

ratio in the table below to mix enough solution to

thoroughly clean all parts.

Solution Type Water Mixed With

Cleaner 1 gal. (4 L) 16 oz. (500 ml)

cleaner

Part Number 000006529 10/09 9

Page 10

Maintenance Section 4

REMOVE THUMBSCREWS AND BOTH SHUTTERS

REMOVE THUMBSCREWS AND

BOTH UPPER DRAIN TRAYS

REMOVE AND CLEAN/SANITIZE DRAIN LINES

CLEAN AND SANITIZE SHUTTER RAILS

BEFORE REINSTALLING SHUTTER

Parts Removal for Cleaning/Sanitizing

SHUTTER DOORS AND RAILS

• Support hopper shutter door with one hand and

remove thumbscrews from side of hopper shutter

door at under side of base section.

• Pivot door down to remove.

• Remove thumbscrews holding front and rear of

shutter tracks.

DRAIN TRAY

• Remove two thumbscrews on side of drain tray and

pull drain tray forward to remove.

BIN DRAIN SYSTEM

• Remove upper trays.

• Saturate a cloth with cleaning solution and insert

through a loop in end of a piece of wire.

• Feed wire through drain tube, and pull wire and cloth

through tube.

Cleaning Exterior Bin

Exterior stainless steel surfaces can be cleaned with a

stainless steel cleaner and polish.

10

Part Number 000006529 10/09

Page 11

Section 5

Customer Support

Before Calling For Service Checklist

If a problem arises during operation of your ice storage bin, follow the checklist below before calling service. Routine

adjustments and maintenance procedures are not covered by the warranty.

Problem Possible Cause To Correct

Water overflowing from drain assembly Drain incorrectly installed Drain must be open site with an air gap

and correct pitch

Ice machine and bin do not have

separate drains

Water-cooled condenser and bin do not

have separate drains

Drain obstructed Clear drain

Ice in bin does not drop Baffle is incorrectly positioned Refer to Section 3, Operation

Ice forming ice bridge Refer to Section 3, Operation

Ice in bin is congealed and will not

break up

Ice spills when filling cart Ice guides incorrectly adjusted Refer to Section 2 and adjust ice guides

Water in bottom of cart Drain closed Refer to Section 3, Operation

Bin is not emptied on a regular basis Refer to Section 3, Operation - If the

Drain obstructed Clear drain

Correct drain installation

Correct drain installation

issue is not resolved, install a thermostat

to lower level of ice in bin to meet current

usage

Part Number 000006529 10/09 11

Page 12

Customer Support Section 5

Limited Warranty For Ice Storage Bin & Dispensers

LIMITED WARRANTY

Manitowoc Ice a division of Manitowoc FSG Services, LLC,

(“Company”) warrants that new Ice Storage Bins or Dispensers sold by

Company shall be free of defects in material or workmanship under

normal and proper use and maintenance as specified by the Company and

upon proper installation and start-up in accordance with the instruction

manual supplied.

WHAT IS COVERED

• Parts and Labor for a period of three (3) years.

• Accessory Ice Transport Carts for two (2) years parts and labor.

The Ice Storage Bin / Dispenser warranty begins on the date of the

original installation. This warranty shall not apply to any Ice Storage Bin

or Dispenser initially installed more than five (5) years from the serial

number production date.

The obligation of the Company under this warranty is limited to the

repair or replacement of parts, components, or assemblies that in the sole

opinion of the Company are defective. This warranty is further limited to

the cost of parts, components or assemblies and standard straight time

labor charges at the servicing location.

Time and hourly rate schedules, as published from time to time by the

Company, apply to all service procedures. Additional expenses including

without limitation, travel time, overtime premium, material cost,

accessing or removal of the Ice Storage Bin / Dispenser, or shipping are

the responsibility of the purchaser, along with all maintenance,

adjustments, cleaning, and ice purchases. Labor covered under this

warranty must be performed by an approved Company contracted

Service Representative or a refrigeration service agency as qualified and

authorized by the Company’s local Distributor. The Company’s liability

under this warranty shall in no event be greater than the actual purchase

price paid by purchaser for the Ice Storage Bin or Dispenser.

EXCLUSIONS FROM COVERAGE

• Repair or replacement of parts required because of misuse, improper

care or storage, negligence, alteration, use of incompatible supplies or

lack of specified maintenance shall be excluded.

• Normal maintenance items.

Failures caused by adverse environmental, water conditions, or improper

drainage.

• Improper or unauthorized repair.

• Any Ice Storage Bin / Dispenser that has been installed and/or

maintained inconsistent with the instructions provided by the Company.

• Parts subject to damage beyond the control of Company, or to Ice

Storage Bin’s / Dispenser’s which have been subject to accidents,

damage in shipment, fire, floods, other hazards or acts of God that are

beyond the control of the Company.

• This Limited Warranty shall not apply if the Ice Storage Bin / Dispenser

is modified with parts and assemblies other than those manufactured by

the Company, unless the Company approves these modifications for

specific locations in writing prior to the commencement of such

modification.

LIMITATIONS OF LIABILITY

The preceding paragraphs set forth the exclusive remedy for all claims

based on failure of, or defect in, Ice Storage Bins or Dispensers sold

hereunder, whether the failure or defect arises before or during the

warranty period, and whether a claim, however instituted, is based on

contract, indemnity, warranty, tort (including negligence), strict liability,

implied by statute, common-law or otherwise, and Company and agents

shall not be liable for any claims for personal injuries or consequential

damages or loss, howsoever caused. Upon the expiration of the warranty

period, all such liability shall terminate. THE FOREGOING

WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, WHETHER WRITTEN, ORAL, IMPLIED OR

STATUTORY NO IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR PARTICULAR PURPOSE SHALL APPLY,

COMPANY DOES NOT WARRANT ANY PRODUCTS OR

SERVICES OF OTHERS.

REMEDIES

The liability of Company for breach of any warranty obligation

hereunder is limited to: (i) the repair or replacement of the Ice Storage

Bin or Dispenser on which the liability is based, or with respect to

services, re-performance of the services; or (ii) at Company’s option, the

refund of the amount paid for said equipment or services. Any breach by

Company with respect to any item or unit of equipment or services shall

be deemed a breach with respect to that item or unit or service only.

WARRANTY CLAIM PROCEDURE

Customer shall be responsible to:

• Complete and return warranty registration card or register on line within

five (5) days from the installation date.

Complete the following and retain for your records:

Distributor/Dealer

Model Number and Serial Number

Installation Date

• All warranty service must be preformed by an approved Manitowoc

contracted or authorized Service Representative. To schedule a service

appointment contact your local Manitowoc Service Representative or

visit us at www.manitowocice.com to find a Service Representative near

you.

GOVERNING LAW

This Limited Warranty shall be governed by the laws of the state of

Wisconsin, USA, excluding their conflicts of law principles. The United

Nations Convention on Contracts for the International Sale of Goods is

hereby excluded in its entirety from application to this Limited Warranty.

COMPLETE AND RETAIN FOR YOUR RECORD:

Distributor/Dealer ______________________________________

Model Number _______________________________________

Serial Number _______________________________________

Installation Date _______________________________________

Manitowoc Ice

2110 South 26th Street

P.O. Box 1720

Manitowoc, WI 54221-1720

Web site: www.manitowocice.com

12

Part Number 000006529 10/09

Page 13

Section 1

Généralités

Références des modèles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Avant de commencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Avertissements importants et règles d’exploitation . . . . . . . . . . . . . . . . . . . . . . 14

Section 2

Instructions d’installation

Déballage du chariot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Déballage et installation de la section de base . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation du bac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Installation des sangles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Étanchéité de l’intérieur du bac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Conditions requises d’évacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Raccordements de plomberie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Apposition des étiquettes d’exploitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Retrait des portes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Réglage de guides de glaçons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table des matières

Retrait de l’ensemble de porte inférieure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Remontage de l’ensemble de porte inférieure . . . . . . . . . . . . . . . . . . . . . . . . . 17

Repositionnement des guides de glaçons après réglage des pieds . . . . . . . . . 17

Section 3

Fonctionnement

Section 4

Entretien

Section 5

Service clientèle

Fonctionnement de l’évacuation du chariot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Couvercles de chariot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fonctionnement du système de transport de glaçons . . . . . . . . . . . . . . . . . . . . 18

Mise du chariot dans le compartiment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chargement des glaçons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Sortie du chariot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transport des glaçons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Séparation des ponts de glace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fonctionnement du déflecteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Nettoyage et désinfection de l’intérieur du bac . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Retrait des pièces pour le nettoyage/la désinfection . . . . . . . . . . . . . . . . . . . . . . 21

Volets et glissières . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Plateau d’évacuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Système d’évacuation du bac de stockage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Nettoyage de l’extérieur du bac . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Liste de vérification avant d’appeler le service technique . . . . . . . . . . . . . . . . . 22

Garantie limitée pour bac de stockage et distributeurs de glaçons . . . . . . . . . . 23

Site Web : www.manitowocice.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Part Number 000006529 10/09 13

Page 14

Section 1

Important

!

Avertissement

! Avertissement

! Avertissement

Généralités

Références des modèles

Le présent manuel s’applique au modèle suivant :

Système de stockage et de transport des glaçons

FC1350

Après l’installation, prière de remettre le présent

manuel au responsable des opérations.

Avant de commencer

Après avoir déballé et retiré tout le matériau

d’emballage, inspecter l’équipement pour tout dommage

d’expédition dissimulé. En cas de dommage, notifier

immédiatement le transporteur.

RISQUE DE BLESSURES CORPORELLES

Ne pas utiliser un équipement qui aura été mal utilisé,

abusé, négligé, endommagé ou dont les spécifications

originales de fabrication auront été altérées/modifiées.

Le présent appareil ne doit pas être utilisé par des

personnes (enfants y compris) ayant des capacités

physiques, sensorielles ou mentales diminuées, ou

ayant un manque d’expérience et de connaissance, à

moins que celles-ci n’aient reçu une formation sur

l’utilisation de l’appareil par une personne responsable

de leur sécurité.

Avertissements importants et règles

d’exploitation

Lire le présent manuel dans son intégralité avant de

monter ou de faire fonctionner le système de transport

de glaçons. Suivre également les avertissements et

instructions indiqués ci-dessous.

Pour éviter d’endommager le système de transport

de glaçons ainsi que toute blessure corporelle

pendant le fonctionnement :

• Ne pas déplacer le système de transport de

glaçons une fois que la machine à glaçons a été

installée

• Ancrer les pieds à brides au sol comme il l’est

indiqué en page 4

• Utiliser uniquement la palette fournie pour

faciliter le débit de glaçons

• Utiliser le chariot uniquement pour transporter

les glaçons et le remettre soigneusement en

place dans le compartiment du bac lorsqu’il n’est

pas utilisé

Pour éviter toute blessure pendant le

fonctionnement de l’unité :

• Tenir le corps entier éloigné du bac lors de la

séparation des glaçons

• Tenir la tête et le visage éloignés du manche de

la palette lors de la séparation des glaçons

• Verrouiller les roulettes avant de retirer les

glaçons à la pelle du chariot et quand il est

entreposé dans le compartiment

• Garder le sol autour du système de transport de

glaçons exempt de glace et d’eau

• Toujours utiliser le chariot à une vitesse lente et

raisonnable

Pour avoir le meilleur fonctionnement possible et pour

garantir la livraison de glaçons propres et sanitaires :

• S’assurer que le système de bac est de niveau dans

les deux sens et ce, afin d’avoir une évacuation

appropriée

• Positionner le chariot dans le compartiment avant

d’ouvrir la porte de la trémie

• Installer un filtre à eau au charbon sur l’eau d’arrivée

pour la machine à glaçons

• Suspendre la palette dans le support prévu à cet

effet après chaque utilisation

• Conserver la palette propre et en bon état pour éviter

toute contamination des glaçons

• Lors du transport, couvrir les glaçons à l’aide du

couvercle de chariot

• Suivre les instructions figurant dans le présent

manuel pour nettoyer et entretenir le bac et le chariot

• Vider l’eau de fonte du chariot une fois positionné

dans le compartiment en ouvrant le robinet de

vidange

• Ne jamais mettre de verre, de saleté ou tout autre

corps étranger dans le bac et le chariot

14 Part Number 000006529 10/09

Page 15

Section 2

! Avertissement

! Avertissement

GOUPILLE DE

MONTAGE

CORDON DE

SILASTIC

JOINT

SECTION DE

BAC

SECTION DE

BASE

CORDON DE

SILASTIC

JOINT

Instructions d’installation

Déballage du chariot

1. Retirer la palette du patin de glissement en coupant

les sangles.

2. Couper la sangle maintenant l’essieu avant au patin

de glissement.

3. Retirer les cales de roue du patin de glissement à

l’extrémité poignée du chariot.

4. Sortir le ou les chariots de la section de base en les

faisant rouler.

5. Retirer le ruban adhésif maintenant le couvercle sur

le chariot.

6. Retirer le ou les taquets de rangement du couvercle

de l’intérieur du chariot. (Les taquets peuvent se

trouver sur la gauche ou sur la droite du bac. Voir

Installation du bac.)

Déballage et installation de la section de

base

1. Retirer les vis maintenant les patins à brides et les

sangles au patin de glissement, et retirer ce dernier.

2. Retirer le matériau d’emballage de l’intérieur des

pieds et autour du volet.

3. Positionner la base à l’emplacement prévu et ajuster

les patins pour mettre l’unité de niveau dans les

deux sens.

4. Marquer la position du trou d’ancrage de chaque

patin à bride.

5. Mettre la base de côté et installer les boulons

d’ancrage de 1/4" dans le sol (fournis par autrui).

6. Repositionner l’unité dans l’emplacement prévu et

ancrer l’unité de base au sol par le biais des patins à

brides.

4. Installer la section de bac sur la section de base en

veillant bien en enclencher les goupilles de montage

de la base dans les trous du bac.

5. Utiliser les fixations fournies pour installer la console

de support de palette sur la droite ou la gauche du

bac dans les trous prévus à cet effet.

6. Retirer le papier du dos du ou des taquets de

rangement du couvercle de chariot et les positionner

sur le côté du bac.

7. Retirer tout le ruban adhésif et toutes les fixations

temporaires des ensembles de porte et de

l’extérieur du bac.

8. Monter la ou les machines à glaçons sur le bac

conformément aux instructions de la machine à

glaçons.

9. Installer les sangles.

Installation des sangles

Lors de la mise à niveau, ne pas étendre les pieds

de plus de 26 mm (1") pour une hauteur totale des

pieds inférieure à 54 mm (2,125"). Les pieds doivent

être fixés au sol par le biais des patins pour éviter

tout mouvement éventuel et toute blessure en

résultant.

Installation du bac

1. Retirer les 4 boulons fixant le patin de glissement

sur le dessous du bac.

2. Retirer tout l’emballage de protection de l’extérieur.

Des sangles prévues pour sécuriser le bac à la base

sont fournies de chaque côté de l’unité. Installer les

sangles pour prévenir toute blessure éventuelle en

cas de déplacement de l’unité. Boulonner l’unité au

mur pour une stabilité accrue et au sol pour prévenir

tout déplacement latéral.

1. Retirer les vis des écrous à river de part et d’autre

de la section de bac.

2. Repositionner la sangle vers le haut jusqu’à ce que

la fente corresponde à l’ouverture de l’écrou à river.

3. Remonter les vis dans les écrous à river et serrer.

3. Appliquer un cordon de 1/8" de Silastic fourni au

centre de chaque bande de joint sur la base.

Part Number 000006529 10/09 15

Page 16

Instructions d’installation Section 2

!

Attention

UTILISER LE PRODUIT D’ÉTANCHÉITÉ FOURNI POUR

SCELLER TOUT LE POURTOUR DU JOINT À L’ENDROIT

OÙ LES SECTIONS DE BASE ET DE BAC SE JOIGNENT.

IINTÉRIEUR

SCELLER

COMPLÈTEMENT

LE JOINT

SECTION DE

BAC

SECTION DE

BASE

EXTÉRIEUR

Étanchéité de l’intérieur du bac

Le joint entre les sections de base et de bac doit être

scellé au Silastic pour prévenir toute fuite et/ou

contamination des glaçons, ainsi qu’une annulation

éventuelle de la garantie. Il faudra peut-être retirer

un ou plusieurs volets pour sceller le bac.

1. Supporter le ou les volets d’une main et retirer les

vis à oreilles du côté du ou des volets sur le dessous

de la base.

2. Faire pivoter le ou les volets vers le bas pour les

enlever.

3. Obtenir un accès par cette ouverture et sceller tout

le pourtour du joint entre le bac et la base à l’aide

d’un produit d’étanchéité fourni ou équivalent.

4. Une fois que le produit d’étanchéité est sec mais

avant de remonter le ou les volets, nettoyer

l’intérieur du bac en suivant les instructions figurant

dans le présent manuel.

5. Remonter le ou les volets.

Conditions requises d’évacuation

• Le raccordement de la ligne d’évacuation du bac doit

comporter un espace d'air.

• Les lignes d’évacuation doivent avoir une inclinaison

de 2,5 cm par mètre (1,5 pouce par 5 pieds) et ne

doivent pas créer de siphons.

• Le siphon de sol doit être suffisamment grand pour

recevoir l’eau provenant de toutes les évacuations.

• Faire fonctionner séparément les lignes d’évacuation

du bac et de la machine à glaçons pour éviter la

condensation.

Raccordements de plomberie

NOTE: Il est recommandé d’installer un drain de sol à

grilles pleine largeur devant le bac.

1. Les unités sont expédiées pour une évacuation à

sortie sur la droite. Pour évacuer vers la gauche,

inverser les positions de vis dans les supports du

bac du trou inférieur au trou supérieur sur le support

gauche et du trou supérieur au trou inférieur sur le

support droit.

2. Retirer le bouchon sur la gauche du bac

d’évacuation et l’insérer sur la droite.

3. Connecter la conduite d’évacuation à un raccord

d’évacuation à ajustement glissant en PVC de

1-1/4".

4. Effectuer les dernières connexions à la machine à

glaçons.

Apposition des étiquettes d’exploitation

Les étiquettes d’exploitation affichées sur le devant de la

base ont pour but d’informer le personnel sur le

fonctionnement du volet. Si besoin est, ces étiquettes

peuvent être apposées de manière permanente en

décollant le papier d’appui et en les apposant aux

emplacements souhaités.

NOTE: Le support adhésif est extrêmement solide et les

étiquettes ne pourront pas facilement être enlevées une

fois apposées.

Coupe transversale des sections jointes du système

de transfert de glaçons

16

Part Number 000006529 10/09

Page 17

Section 2 Instructions d’installation

PORTE

D’ACCÈS

ENSEMBLE DE

PORTE

INFÉRIEURE

DÉFLECTEUR

SUPPORTS SUR DESSOUS DE TRÉMIE

AUXQUELS SONT FIXÉS LES GUIDES DE

GLAÇONS

Retrait des portes

RETRAIT DE L’ENSEMBLE DE PORTE INFÉRIEURE

(Uniquement si nécessaire pour accès par les portes

étroites)

1. Une fois la porte d’accès inférieur en position

fermée, retirer la vis cruciforme et la rondelle de la

surface de charnières sur chaque côté de la porte

d’accès inférieure.

2. Insérer le tournevis entre la porte et la ferrure de

charnière d’un côté de la porte et pousser

délicatement contre la ferrure pour fournir de

l’espace pour le montant de porte pour dégager la

ferrure.

3. Retirer la porte d’accès.

4. Pousser sur le déflecteur pour le retirer.

5. Retirer trois ou quatre (3 ou 4) vis le long du haut de

l’ensemble de porte.

6. Pousser l’ensemble vers l’avant et le retirer.

Réglage de guides de glaçons

Les glaçons peuvent déborder des côtés du chariot lors

de leur sortie de la trémie. Les guides de glaçons sont

suspendus en dessous de la trémie et permettent de

contenir le flot des glaçons à l’intérieur du chariot.

Les guides sont installés dans la position la plus haute

en usine, en offrant un dégagement de 19 mm (3/4") en

haut du chariot lorsque les pieds sont en position

complètement basse. Si les pieds sont ajustés pendant

la mise à niveau du système de transport de glaçons, les

guides de glaçons doivent être abaissés de manière à

conserver un dégagement de 19 mm (3/4"). Il faut

pouvoir accéder aux côtés du système de transport de

glaçons pour effectuer cette opération.

REPOSITIONNEMENT DES GUIDES DE GLAÇONS

APRÈS RÉGLAGE DES PIEDS

1. Positionner le chariot (avec boîtes, le cas échéant)

dans le compartiment sous l’ouverture du volet.

2. Déterminer de combien les guides doivent être

abaissés pour conserver un dégagement de 19 mm

(3/4").

3. Retirer les vis à oreilles maintenant les guides.

4. Sélectionner le trou pour repositionner le guide au

niveau approprié et fixer à nouveau avec la vis à

oreilles.

5. Répéter ce processus pour chaque compartiment du

système.

REMONTAGE DE L’ENSEMBLE DE PORTE

INFÉRIEURE

1. Remonter l’ensemble de porte inférieure dans

l’ouverture du bac.

2. Remonter les trois ou quatre (3 ou 4) vis dans le

capot en haut de l’ensemble de porte.

3. Remonter le déflecteur dans les glissières de

panneaux latéraux et appuyer pour installer.

4. Une fois la porte fermée, insérer un montant de

porte dans la ferrure de charnière.

NOTE: Pour un fonctionnement adéquat, la porte

d’accès doit être remontée en position fermée.

5. Sur l’autre côté, insérer le tournevis entre la porte et

la ferrure de charnière et pousser délicatement

contre la ferrure pour fournir de l’espace pour le

montant de porte pour dégager la ferrure.

6. Remonter les rondelles et les vis dans la porte

relevable et serrer.

7. Vérifier la porte pour assurer un bon

fonctionnement.

Part Number 000006529 10/09 17

Page 18

Section 3

PUSH TO CLOSE

3

2

1

1

2

1

3

2

Fonctionnement

Fonctionnement de l’évacuation du chariot

1. Positionner le chariot complètement dans le

compartiment.

2. Bloquer la roulette pour éviter tout mouvement du

chariot.

3. Pour ouvrir l’évacuation, tirer le bouton.

4. Pour fermer, enfoncer le

bouton.

Couvercles de chariot

1. Suspendre les couvercles de chariot sur les

supports sur le côté du bac lorsque les chariots sont

entreposés dans le compartiment.

2. Retirer du support et placer le couvercle sur le

chariot lors du transport des glaçons.

3. Pour éviter de placer le couvercle à même le sol,

positionner le couvercle horizontalement sur le

rebord du chariot, en reposant le couvercle contre la

poignée du chariot lors du déchargement des

glaçons du chariot.

4. Remettre le couvercle sur le côté du bac avant de

mettre le chariot dans le compartiment.

Fonctionnement du système de transport

de glaçons

MISE DU CHARIOT DANS LE COMPARTIMENT

1. ENFONCER le chariot complètement au fond.

2. OUVRIR l’évacuation du chariot.

3. Verrouiller le frein sur la roulette vers le BAS.

CHARGEMENT DES GLAÇONS

1. TIRER sur la poignée du volet pour ouvrir.

2. Ranger la poignée contre le bac.

SORTIE DU CHARIOT

1. APPUYER sur la poignée du volet pour fermer.

2. FERMER l’évacuation du chariot.

3. Relâcher le frein sur la roulette.

18 Part Number 000006529 10/09

Page 19

Section 3 Fonctionnement

! Avertissement

1

TRANSPORT DES GLAÇONS

1. TIRER le chariot de la base.

2. Mettre le couvercle sur le chariot.

1. Faire complètement tomber toute la glace des côtés

et de l’arrière du bac.

2. Faire tomber tout pont qui s’est formé au milieu.

3. Agiter la palette d’un mouvement de va-et-vient pour

casser la masse de glaçons congelés.

Séparation des ponts de glace

Ne pas creuser dans la glace. Séparer plutôt les

« montants » qui maintiennent les ponts. La glace

au-dessus tombera.

Pour éviter toute blessure, ne pas tenter de séparer

le pont de glace par les regards supérieurs ou le

volet de la trémie. Un pont de glace qui tombe peut

faire relever la palette. Tenir la tête et le visage

éloignés du manche de la palette pour éviter toute

blessure.

Il faudra peut-être utiliser la palette pour séparer les

ponts de glace qui se produisent le long des côtés et au

milieu du bac. Ceci est courant si les glaçons ont été

stockés pendant une période prolongée sans être

utilisés. Utiliser l’accessoire palette fournie pour séparer

les ponts.

Fonctionnement du déflecteur

Le déflecteur peut être ajusté et bloqué à l’un des

plusieurs niveaux afin d’accommoder les

caractéristiques de débit de différents types de glaçons.

Le bac est expédié avec le déflecteur en position basse.

Le déflecteur peut être relevé et bloqué dans une

position supérieure pour un meilleur débit ou lorsqu’un

accès additionnel est requis.

Part Number 000006529 10/09 19

Page 20

Section 4

!

Attention

! Avertissement

REGARD

ARRIÈRE

REGARD AVANT

Important

Entretien

Nettoyer et désinfecter les intérieurs du bac et du ou

des chariots avant toute utilisation et

périodiquement selon les besoins. Utiliser

uniquement Nettoyant Manitowoc (94-0546-3 ou

000000084) et Désinfectant Manitowoc (94-0565-3)

pour machines à glaçons approuvés par Manitowoc

pour cette application. NE PAS utiliser de nettoyants

à base de chlore qui peuvent provoquer une

coloration et une corrosion profonde des

composants en acier inoxydable. Ne pas mettre les

boîtes au lave-vaisselle. Mettre la ou les machines à

glaçons hors tension et retirer les glaçons du bac

avant de commencer.

Porter des gants en caoutchouc et des lunettes de

sécurité (et/ou un masque) lors de la manipulation

du nettoyant ou du désinfectant pour machine à

glaçons.

Nettoyage et désinfection de l’intérieur du

bac

L’intérieur du bac doit être nettoyé et désinfecté avant

toute utilisation, et doit être nettoyé périodiquement

durant l’emploi. Le bac de stockage de glaçons est muni

de parois à revêtement en polyéthylène qui doivent être

nettoyées et désinfectées tous les six mois avec

Nettoyant Manitowoc et Désinfectant Manitowoc.

1. Retirer les regards supérieurs en les faisant glisser

sur un côté. Saisir l’extrémité du regard avant et tirer

vers soi lorsque le regard est glissé sur le côté

opposé. Répéter pour le regard arrière.

2. Mélanger une solution nettoyante avec de l’eau

chaude. Selon la quantité de dépôt minéral, une

quantité plus importante de solution peut être

requise. Utiliser le rapport dans le tableau cidessous pour mélanger suffisamment de solution

pour nettoyer toutes les pièces.

Type de solution Eau Mélangée avec

Nettoyant 4 L (1 gallon) 500 ml (16 oz) de

nettoyant

3. Laver les parois du bac, la trémie, la plaque de porte

d’accès et la partition (le cas échéant) et bien rincer

toutes les zones à l’eau claire.

Ne pas rincer après la désinfection.

4. Mélanger une solution désinfectante avec de l’eau

chaude.

Type de solution Eau Mélangée avec

Désinfectant 11 L (3 gallons) 60 ml (2 oz) de

désinfectant

5. Désinfecter les parois du bac, la trémie et la plaque

de porte d’accès. Utiliser un flacon pulvérisateur

pour appliquer abondamment la solution. Ne pas

rincer les zones désinfectées.

6. Nettoyer et désinfecter les chariots de livraison de

glaçons.

A. Laver le revêtement du chariot à l’aide d’un

nettoyant approuvé.

B. Rincer complètement toutes les zones à l’eau

claire.

C. Désinfection du chariot - Utiliser un flacon

pulvérisateur pour appliquer abondamment la

solution. Ne pas rincer les zones désinfectées.

7. Retirer les composants de bac suivants pour le

nettoyage et la désinfection.

•Volet

• Plateau d’évacuation

• Conduites d’évacuation du bac de stockage

8. Utiliser une solution nettoyante pour nettoyer les

composants déposés, rincer à l’eau propre et

désinfecter (ne pas rincer après la désinfection).

9. Nettoyer, rincer et désinfecter les glissières du volet.

10. Remonter tous les composants retirés.

20 Part Number 000006529 10/09

Page 21

Section 4 Entretien

RETIRER LES VIS À OREILLES ET LES DEUX VOLETS

RETIRER LES VIS À OREILLES ET LES

DEUX PLATEAUX SUPÉRIEURS

D’ÉVACUATION

RETIRER ET NETTOYER/DÉSINFECTER LES

CONDUITES D’ÉVACUATION

NETTOYER ET DÉSINFECTER LES

GLISSIÈRES DU VOLET AVANT DE

REMONTER LE VOLET

Retrait des pièces pour le nettoyage/la désinfection

VOLETS ET GLISSIÈRES

• Supporter le volet de trémie d’une main et retirer les

vis à oreilles du côté du volet de trémie sur le

dessous de la section de base.

• Pivoter le volet vers le bas pour le retirer.

• Retirer les vis à oreilles maintenant le devant et

l’arrière des coulisses de volet.

PLATEAU D’ÉVACUATION

• Retirer deux vis à oreilles sur le côté du plateau

d’évacuation et tirer le plateau d’évacuation vers

l’avant pour le retirer.

SYSTÈME D’ÉVACUATION DU BAC DE STOCKAGE

• Retirer les plateaux supérieurs.

• Saturer un chiffon avec une solution nettoyante et

l’insérer dans une boucle à l’extrémité d’un morceau

de fil.

• Faire passer le fil dans le tube d’évacuation, et tirer le

fil et le chiffon par le tube.

Nettoyage de l’extérieur du bac

Les surfaces extérieures en acier inoxydable peuvent

être nettoyées avec un produit à nettoyer et polir pour

acier inoxydable.

Part Number 000006529 10/09 21

Page 22

Section 5

Service clientèle

Liste de vérification avant d’appeler le service technique

En cas de problème pendant le fonctionnement du bac de stockage de glaçons, suivre la liste de vérification

ci-dessous avant de contacter le service technique. Les réglages périodiques et procédures d’entretien ne sont

pas couverts par la garantie.

Problème Cause possible Mesure corrective

Eau débordant de l’ensemble

d’évacuation

Les glaçons dans le bac ne

tombent pas

Les glaçons dans le bac sont

congelés et ne se séparent pas

Déversement de glaçons lors du

remplissage du chariot

Présence d’eau dans le fond du

chariot

Évacuation mal installée L’évacuation doit être un site ouvert avec un

écart anti-retour et une inclinaison correcte

La machine à glaçons et le bac n’ont pas

d’évacuations séparées

Le condenseur refroidi par eau et le bac

n’ont pas d’évacuations séparées

Évacuation obstruée Dégager l’évacuation

Le déflecteur est mal positionné Se reporter à la section 3, Fonctionnement

Glace formant le pont de glace Se reporter à la section 3, Fonctionnement

Le bac n’est pas vidé périodiquement Se reporter à la section 3, Fonctionnement –

Guides de glaçons mal ajustés Consulter la section 2 et ajuster les guides de

Évacuation fermée Se reporter à la section 3, Fonctionnement

Évacuation obstruée Dégager l’évacuation

Rectifier l’installation de l’évacuation

Rectifier l’installation de l’évacuation

Si le problème n’est pas rectifié, installer un

thermostat au niveau inférieur des glaçons

dans le bac pour répondre à l’usage courant

glaçons

22 Part Number 000006529 10/09

Page 23

Section 5 Service clientèle

Garantie limitée pour bac de stockage et distributeurs de glaçons

GARANTIE LIMITÉE

Manitowoc Ice, une division de Manitowoc FSG Services, LLC,

(« Société ») garantit que les bacs de stockage ou distributeurs de glaçons

neufs vendus par la Société sont exempts de tout défaut de matériau ou de

fabrication à condition d’une utilisation et d’un entretien normaux et

appropriés tels que spécifiés par la Société, et avec une installation et une

mise en service appropriées conformes au manuel d’instructions fourni.

LA GARANTIE COUVRE CE QUI SUIT :

• Pièces et main d’œuvre pendant une période de trois (3) ans.

• Pièces et main d’œuvre pour les chariots accessoires de transport de

glaçons pendant une période de deux (2) ans.

La garantie du bac de stockage/distributeur de glaçons entre en vigueur à

compte de la date de l’installation originale. La présente garantie ne

s’applique pas aux bacs de stockage ou distributeurs de glaçons

initialement installés pendant plus de cinq (5) ans à compter de la date de

production du numéro de série.

L’obligation de la Société en vertu de la présente garantie est limitée à la

réparation ou au remplacement des pièces, des composants ou des

ensembles qui, selon la Société uniquement, sont défectueux. La présente

garantie est également limitée au coût des pièces, composants ou

ensembles, et aux frais de main d’œuvre au salaire de base sur le lieu du

service technique.

Les tarifs de taux de base et horaires, tels que publiés de temps à autre par

la Société, s’appliquent à toutes les procédures de service. Les frais

supplémentaires, y compris mais sans s’y limiter, le temps de

déplacement, la majoration pour travail supplémentaire, le coût des

matériaux, l’accès au bac de stockage/distributeur de glaçons ou son

retrait, ou encore l’expédition, sont à la charge de l’acheteur, tout comme

le sont l’entretien, les réglages, le nettoyage et les achats de glaçons. Le

travail couvert par la présente garantie doit être effectué par un

représentant du service technique sous contrat homologué de la Société

ou par un organisme de service de réfrigération tel que qualifié et

homologué par le distributeur local de la Société. La responsabilité de la

Société en vertu de la présente garantie ne sera en aucun cas supérieure

au prix d’achat réel payé par l’acheteur pour le bac de stockage ou

distributeur de glaçons.

EXCLUSIONS DE GARANTIE

• La réparation ou le remplacement des pièces requis en raison d’une

mauvaise utilisation, d’un entretien ou d’un entreposage inadéquat, de

négligence, d’altération, d’utilisation de fournitures incompatibles ou du

manque d’entretien spécifié sont exclus.

• Points d’entretien normal.

Défaillances dues à des conditions environnementales ou d’eau

malsaines, ou évacuation inadéquate.

• Réparation incorrecte ou non autorisée.

• Tout bac de stockage/distributeur de glaçons qui n’aura pas été installé

conformément aux instructions fournies par la Société.

• Pièces ayant fait l’objet de dommages indépendants de la volonté de la

Société, ou bacs de stockage/distributeurs de glaçons qui ont fait l’objet

d’accidents, de dommages pendant l’expédition, un incendie, des

inondations, autres dangers et calamités naturelles indépendants de la

volonté de la Société.

• La présente garantie limitée n’entrera pas en vigueur en cas de

modification du bac de stockage/distributeur de glaçons avec des pièces

et ensembles autres que ceux fabriqués par la Société, sauf si la Société

approuve ces modifications pour des emplacements spécifiques par écrit

et avant le début de ladite modification.

LIMITATION DE LA RESPONSABILITÉ

Les paragraphes précédents indiquent le recours exclusif pour toutes les

réclamations basées sur la défaillance de, ou défaut dans, des bacs de

stockage ou distributeurs de glaçons vendus ci-dessous, que la

défaillance ou le défaut ait lieu avant ou pendant la période de garantie, et

qu’une réclamation, instituée de quelque manière que ce soit, soit basée

sur contrat, indemnité, garantie, délit civil (y compris négligence),

responsabilité objective, tacite par statut, common law ou autre, et la

Société et ses agents ne seront en aucun cas responsables de toute

réclamations concernant des blessures corporelles ou dommages

consécutifs ou pertes, quelle qu’en soit leur cause. Lors de l’échéance de

la période de garantie, toutes lesdites responsabilités viendront à

échéance. LES GARANTIES PRÉCÉDENTES SONT EXCLUSIVES

ET REMPLACENT TOUTES LES AUTRES GARANTIES,

QU’ELLES SOIENT ÉCRITES, ORALES, TACITES OU LÉGALES.

AUCUNE GARANTIE TACITE DE QUALITÉ MARCHANGE OU

D’ADAPTATION À UN USAGE PARTICULIER NE

S’APPLIQUERA. LA SOCIÉTÉ NE GARANTIT AUCUN PRODUIT

OU SERVICE FOURNI PAR AUTRUI.

RECOURS

La responsabilité de la Société dans le cas d’une violation de toute

obligation de garantie ci-dessous se limite à ce qui suit : (i) la réparation

ou le remplacement du bac de stockage ou distributeur de glaçons sur

lequel la responsabilité est basée, ou pour ce qui est des services, de la

nouvelle application de la caractéristique de contrôle des services ; ou

(ii), sur la décision de la Société, le remboursement du montant payé pour

lesdits équipements ou services. Toute violation de la Société pour ce qui

est tout article ou toute unité d’équipement ou tous services sera

considéré comme une violation par rapport à cet article, cette unité ou ce

service uniquement.

PROCÉDURE DE RÉCLAMATION AU TITRE DE LA GARANTIE

Le client sera responsable de ce qui suit :

• Remplir et renvoyer la carte de garantie ou s’enregistrer en ligne dans

les cinq (5) jours à compter de la date d’installation.

Remplir ce qui suit et conserver cette information :

Distributeur/Revendeur

Référence de modèle et Numéro de série

Date d’installation

• Tout service au titre de la garantie doit être effectué par un représentant

du service technique sous contrat ou autorisé homologué de Manitowoc.

Pour prendre rendez-vous pour tout service, contacter le représentant du

service technique local de Manitowoc ou consulter notre site à

www.manitowocice.com pour trouver un représentant du service

technique dans la région.

LOI APPLICABLE

La présente garantie limitée sera régie par les lois de l’État du Wisconsin

(États-Unis), à l’exclusion de leurs conflits des principes de droit. La

Convention des Nations Unies sur les contrats de vente internationale de

marchandises est exclue, par les présentes, dans son intégralité de

l’application à la présente garantie limitée.

REMPLIR CE QUI SUIT ET CONSERVER CETTE INFORMATION :

Distributeur/Revendeur _____________________________________

Référence ________________________________________________

Numéro de série ___________________________________________

Date d’installation _________________________________________

Manitowoc Ice

2110 South 26th Street

P.O. Box 1720

Manitowoc, WI 54221-1720 USA

Site Web : www.manitowocice.com

Part Number 000006529 10/09 23

Page 24

Manitowoc

© 2009 Manitowoc

Continuing product improvements

may necessitate change of

specifications without notice.

Part Number 000006529 10/09

2110 South 26th Street, P.O. Box 1720

Manitowoc Foodservice

Manitowoc, WI 54221-1720, USA

Ph: 920-682-0161 Fax: 920-683-7589

Visit us online at: www.manitowocice.com

Loading...

Loading...