Mallory Ignition 74186 User Manual

1

INTRODUCTION

Congratulations on the purchase of your new Accel Digital Nitrous Master Mind Processor. With over 20 years in designing and

producing state of the art EFI & Ignition systems, we are confident that this NO2 Mastermind will be a great addition to your car.

It is designed with you, the end user, in mind to make it easy for you to program and use.

State of the Art Technology: This system uses the latest available technology to offer unparalleled accuracy, repeatability, and reliability.

Easy to Read LCD Display with Touch Button Programming: Included with the Digital Nitrous Processor is a user friendly interface

that provides quick and accurate programming of Nitrous system directly from the driver’s seat.

Data Memory: There is no need to re-program the controller after the battery is disconnected. All data is stored in flash memory and

will be retained with no power applied to the controller.

NO2/Fuel Solenoids Outputs: The Processor provides separate NO2/Fuel Solenoid outputs. This allows you to have total control over

the flow time of the fuel solenoid.

(PROGRAM THE NO2/FUEL OFFSET TO GIVE THE FUEL A CHANCE TO START FLOWING BEFORE THE NO2 HITS, THUS

AVOIDING A BACK FIRE.)

DIGITAL NITROUS PROCESSOR

PART NO. 74186

INSTALLATION INSTRUCTIONS

FORM INSTR74186 11/09

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com

T

ABLE OF CONTENTS PAGE

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

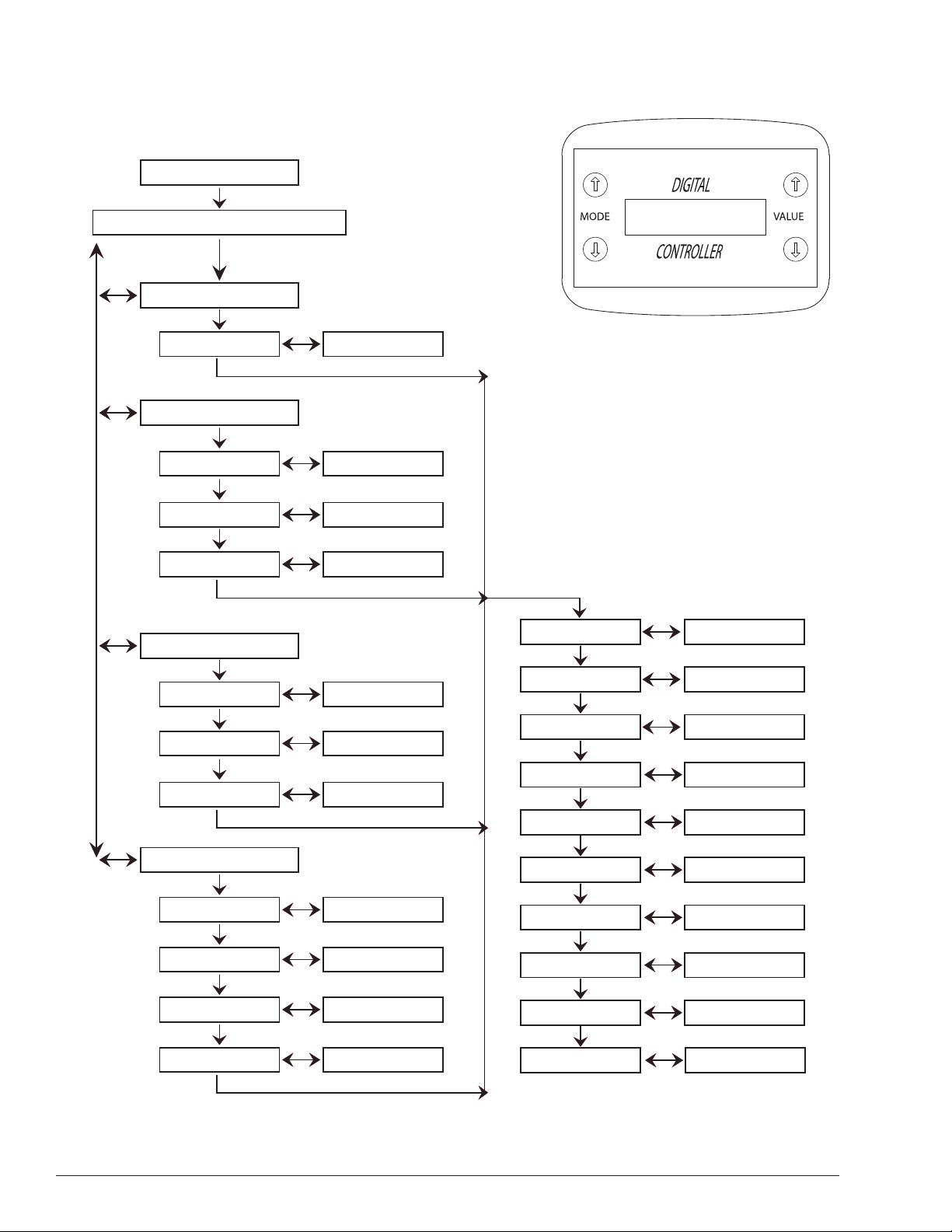

Handheld Programmer Quick Menu Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Programming The Processor Using The Handheld Programmer . . . . . . . . . . . . . . . . . . . .3-4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Input/Output Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Illustrations & Figures:

With HEI Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

With L98/LT1 Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

With FORD TFI Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

With Inductive Pickup Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

With Honda Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

With Universal Import Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

With Aftermarket EFI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

With Mallory/Hall Effect Distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

With Dodge Late Model Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Example NO2 RPM/Time Graph . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Using your Nitrous Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Harness Schematic Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18-19

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2

www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

HANDHELD PROGRAMMER QUICK MENU FLOW

Engine RPM

NO2 Delivery

100% ON

NO2 Start RPM

1000 - 12700

RPM Control

NO2 Start RPM 1000 - 12700

NO2 Start %

100% RPM

5 - 90%

1000 - 12700

Time Control

NO2 Start RPM

NO2 Start %

Launch Time

1000 - 12700

5 - 90%

1 - 20 Seconds

NO2 Delay 1 - 20 Seconds

H/S Retard 0 - 25 Deg

RPM Switch

Main RPM Limit

1000 - 12700

1000 - 12700

AUX RPM Limit 1000 - 12700

RPM & Time

NO2 Start RPM

NO2 Start %

Launch Time

100% RPM

1000 - 12700

5 - 90%

1 - 20 Seconds

1000 - 12700

Safety RPM Limit

PWM Frequency

Trigger Volts 0 - 20v

Number of CyL

Fuel NO2 Offset 1 - 64 Ms

1000 - 12700

5 - 30 Hz

4 - 5 - 6 - 8 - 10 -12

3ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com

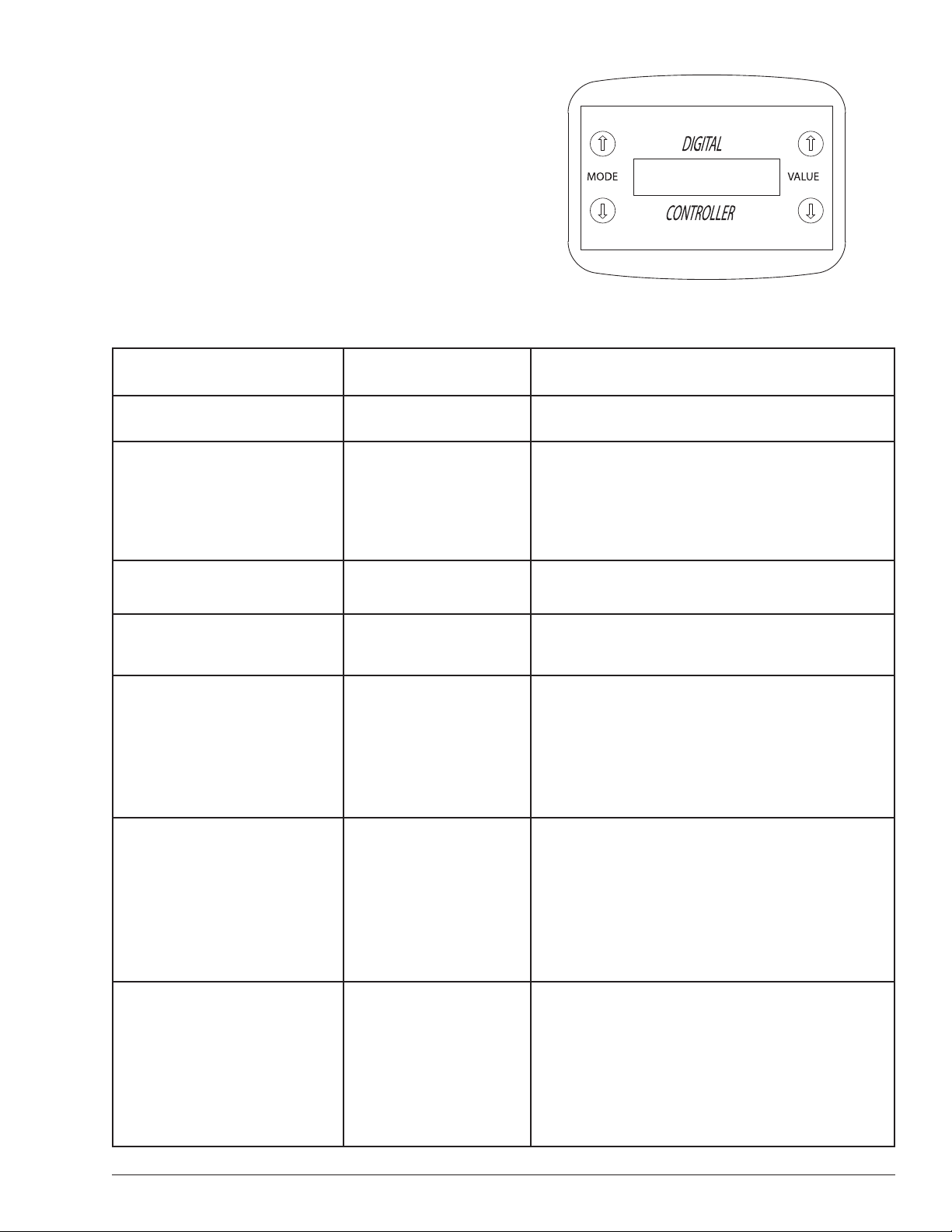

HANDHELD CONTROLLER INSTRUCTIONS

The controller has a 9-pin DSUB socket which plugs into the end

panel. It does not need to be plugged in for the ignition to run,

only to change the settings.

The control “modes’ are listed below. To set the modes, plug the

controller in and turn on the ignition. After a brief pause, the

controller display will light up. Use the “MODE” keys to select the

desired mode, and then use the up/down “VALUE” keys on the

right side to change the values.

Once you have finished with your settings, you can either turn the

power off and unplug the controller, or just leave it plugged in.

PROGRAMMING USING HANDHELD PROGRAMMER

Display Range/Resolution Explanation

Engine RPM NO2/Status 10 RPM Actual Engine RPM and NO2 Status

NO2 Delivery

Four choices of No2 Delivery.

1st 100% On (No time or RPM PWM)

2nd RPM Control

3rd Time Control

4th RPM & Time Control

100% ON

NO2 turns on full with any pulse width modulations on the

programmed thresholds are met.

NO2 Settings

Start RPM

1000-12700

RPM/100 RPM

RPM where the nitrous system starts working. Lowering the

value until the display says “OFF” disables this function.

RPM Control

1000-12700

RPM/100 RPM

The software linearly increases the duty cycle percentage as

a function of RPM between the two (N2O Start and N2O

100%) values. This RPM setting should be 1000 RPM above

the activation RPM.

NOTE:

Regardless of the nitrous settings, the nitrous

system is shut off 300 RPM before the main RPM limiter.

Time Control

.0 to 20.0 seconds/

.1 second increments

Launch time modulates the pulse width as a function of

time. This is useful when traction becomes a problem.

Once the arming and triggering conditions are met, the

launch timer modulates the solenoids to help with tire spin.

For example: If Launch time is set at 5 seconds and when

the NO2 activates, the pulsing of the solenoids will increase

as the time set decreases. (.1second 1% Flow 5 second

100% Flow)

RPM & Time

Control

1000-12700/

.1 – 20 Seconds

This mode is useful for a car with a loose converter or a

weak clutch. It prevents the user from driving through the

converter with the NO2 full on. It allows the user to have

complete control over ramping the power in, so that when

the NO2 is at 100%, the full power of the Nitrous hit is well

past the converter RPM threshold. (Example of this is on

page 18)

4 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

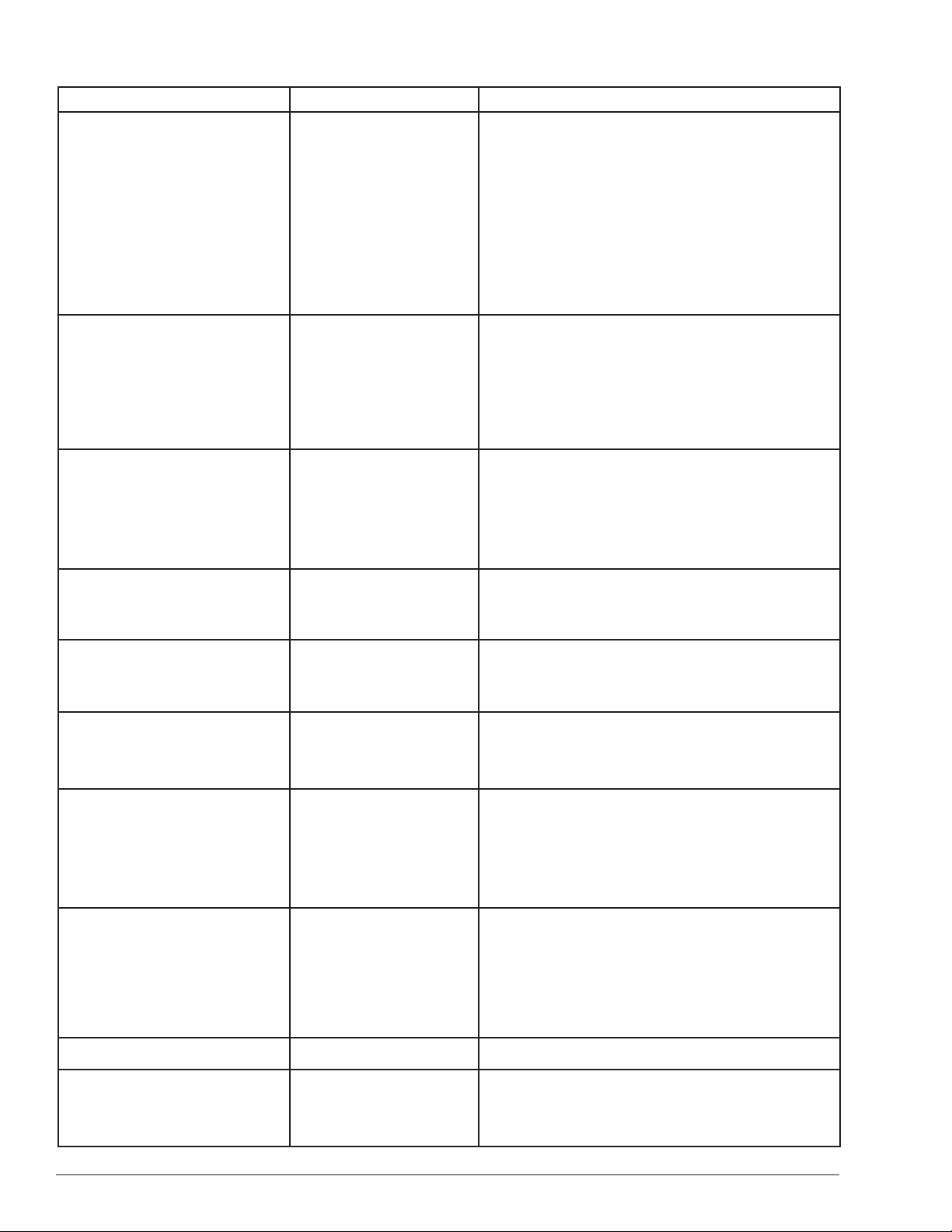

Display Range/Resolution Explanation

NO2 Delay 0 – 20 Seconds

The delay timer is used to delay the nitrous system from

engaging once the arming and triggering thresholds are

met. For example: if the system is armed (12v on the arming

input) and the Micro Switch/TPS and RPM input thresholds

are met, the system will wait for the amount shown in Delay

Time before activating the nitrous system. This delay only

occurs after the initial start of the process. If the Micro

Switch/TPS voltage falls below the set threshold, the nitrous

will shut off, but if it goes back above the set threshold, the

nitrous will start again immediately, with no delay. The

arming input is the reset for this function.

NO2/High Speed Timing Retard

0 – 25 Deg in 1

deg increments

This is the ignition retard setting that is used when the

NO2 is activated. Timing is pulled out to avoid detonation

that can cause engine failure. This feature offers a High

Speed Retard that can also be used to pull timing out when

NO2 is disabled. By applying 12V+ to Pin C Yellow Wire on

the 8 pin connector, the processor will retard the timing by

amount set.

RPM Switch

1000-12700

RPM/100 RPM

When the set RPM is reached, the output wire will be pulled

to ground (5 amps max) PIN G Orange Wire. When the RPM

drops 500 below the RPM switch setting, the switch will be

shut off. This prevents “chattering” when the RPM is not

stable. (Can be used to trigger a shift light, secondary

fuel pump, Data acquisition system, etc.)

Main RPM Limit

1000-12700

RPM/100 RPM

This is a fast-acting pulse-by-pulse RPM limiter. It does not

average the incoming period, so it will be rough when the

engine is unloaded, but will control RPM very accurately.

Auxiliary RPM Limit

(Two Step)

1000-12700

RPM/100 RPM

Activated by applying 12v on the Pin D Green/White wire of

the 4 wire connector marked “AUX” input. Same operation

as the Main RPM Limit. (Used mainly as a 2 Step).

Safety RPM 1000-12700

This is used as a NO2 shutoff RPM set point on deceleration.

(Example: If the NO2 Trigger relay or micro switch fails to

disengage the NO2 after you are off the throttle, the Safety

RPM will shutoff the NO2 once below the set RPM.

PWM frequency 5 – 30 Hz / 1 Hz steps

This function is how often per second the solenoids are

cycled. Lower numbers are easier on the solenoids, but can

result in “shuddering”, especially at lower speeds and low

duty cycles. Higher PWM frequency is better for smooth

delivery, but is much harder on the solenoids.

NOTE: Accel/DFI is not responsible for solenoid damage.

Trigger Volts 0 to 20V /.1 volts

After arming the system, this is used as a “start” input from

a Micro switch – Push Button or TPS.

NOTE: If the value is set to zero, the system will start

delivering nitrous when the arming input and RPM setting

is reached. ( We recommend that you use a Micro switch

with this system)

Number Of Cyl Selection 4, 5,6,8,10,12 Cyl. Pick the number of cylinders for your application.

Fuel/N2O offset 1 to 64 Ms / 1 Ms

This is the amount of time that the system delays the

activation of the N2O solenoid after the fuel solenoid, to

give the fuel a chance to start flowing before the nitrous

hits, thus avoiding a lean spike.

PROGRAMMING USING HANDHELD PROGRAMMER CONT’D

5ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com

INSTALLATION

WHAT YOU SHOULD KNOW

Please read these instructions carefully before installing your

Digital Nitrous Processor.

Important Tips

• Do not use solid core spark plug wires with this unit. It contains

digital electronics and will NOT function correctly with solid

core wires.

• Do not install harness or run Points Input / Output wires near

spark plug wire or ignition coil. Mount the Processor as far

away from secondary ignition components (coil, ignition wires,

etc.) as physically possible.

• This unit is not water resistant or water proof, we suggest that

it is mounted in the passenger compartment so as not to get

wet from rain, car washing or a liquid of any type!

• The Handheld programmer buttons are very delicate and can

be damaged by misuse and/or carelessness. Programmers that

have been determined to be damaged due to neglect will NOT

be covered under warranty.

Safety Tips, Please Read

• It is the responsibility of the purchaser to follow all guidelines

and safety procedures supplied with this product and any other

manufacturer’s product used with this product.

• Follow all recommended safety guidelines from this and other

manufacturer’s installation guides.

• It is also the responsibility of the purchaser to determine

compatibility of this device with the vehicle and other components.

• ACCEL DFI Corporation assumes no responsibility for damages

resulting from accident, improper installation, misuse, abuse,

improper operation, lack of reasonable care, or all previously

stated reasons due to incompatibility with other manufacturer’s

products.

• ACCEL DFI Corporation assumes no responsibility or liability

for damages incurred from the use of products manufactured

or sold by Accel DFI Corporation on vehicles used for

competition racing.

• ACCEL DFI Corporation neither recommends nor approves the

use of its products on vehicles which may be driven on public

highways or roads, and assumes no responsibility for damages

incurred from such use.

• It is the purchaser’s responsibility to check the state and local

laws pertaining to the use of Nitrous Oxide for racing applications.

ACCEL DFI Corporation does not recommend nor condone the

use of its products for illegal street racing.

INSTALLATION OF THIS PRODUCT SIGNIFIES THAT YOU HAVE

READ THIS DOCUMENT AND AGREE TO THE TERMS STATED WITHIN.

Due to the technical nature of ACCEL DFI products, we are unable

to answer technical questions via the Internet. If you have any

questions, Please call the ACCEL DFI Technical Support hotline.

Tech Line: 1-248-380-2780 from 8:30 am – 6 pm, MondayFriday, Eastern Standard Time.

Please fill out and mail your warranty card.

WARRANTY

FACTORY DIRECT LIMITED WARRANTY. ALL ACCEL/DFI

PRODUCTS* ARE WARRANTED AGAINST DEFECTS IN MATERIALS

OR WORKMANSHIP. ACCEL/DFI LIABILITY UNDER THIS WARRANTY

SHALL BE LIMITED TO THE PROMPT REPAIR CORRECTION OR

REPLACEMENT OF ANY DEFECTIVE PART OF THE PRODUCT

WHICH ACCEL/DFI DETERMINES TO BE NECESSARY. THIS LIMITED

WARRANTY IS TO THE ORIGINAL PURCHASER FOR AS LONG AS

HE OR SHE OWNS THE VEHICLE ON WHICH THE PRODUCT IS

ORIGINALLY INSTALLED, PROVIDING ALL THE INFORMATION

REQUESTED IS FURNISHED. YOU MUST RETAIN A COPY OF YOUR

ORIGINAL SALES INVOICE OR RECEIPT. WITHOUT PROPER

DOCUMENTATION, THIS WARRANTY IS VOID.

RESOLD UNITS ARE NOT COVERED UNDER THIS WARRANTY.

CAUTIONS AND WARNINGS

1. Always follow safety & installation guidelines and precautions

when installing this and any other related component.

2. Always remove both battery cables when installing new

electrical components and/or wiring.

3. Always use Circuit protection (Fuses) where required.

4. Wire in all your connections with the Processor disconnected.

5. Connect ground wires directly to battery negative terminal or

at battery negative cable end.

6. Test system for proper operation after completing installation.

PARTS INCLUDED

1 ACCEL/DFI Digital Nitrous Processor

1 Handheld Programmer

1 Handheld Programmer Cable

1 8-way Processor Control Harness

1 4-way Processor Power Harness

1 Magnetic Pickup Harness

1 NO2 Solenoid Harness

RECOMMENDED PARTS NOT SUPPLIED

Parts Part #

1 NO2 Single Stage System

1 Accel/DFI 6A or DFI 6A 75606 - DFI Pro 7 75609

PRO 7 CD Ignition Box

1 Accel DFI “E” Core DFI “E” Core 75607 - DFI Pro 7 75608

or Pro 7 Coil

1 Micro Switch

1 Lighted Toggle Switch

1 Firewall Rubber Grommet

(To keep wires from chafing

on metal edge)

www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.27806

INSTALLATION – HOW TO

Start by locating a spot in the passenger compartment (Recommended) to mount the NO2 Processor. Keep it away from any moisture

spots and from any area where it can be damaged by the passengers. DO NOT install it in an area where it can get very hot, the

internal components require good ventilation.

1. Mount Processor

2. Drill hole through fire wall (Check Grommet Center OD for correct drill size) directly behind engine. Install rubber grommet. (Keep

hole away from exhaust headers)

3. Pull harness through fire wall, (Do Not Plug Harness in processor at This Time).

4. Run the wires to their components in the engine compartment, (Example: NO2 Solenoid Wires, 6A CD Box, Battery + -, MAG Trigger.)

5. Using wire chart on page 8 and figure 1 through 9 on pages 09 -17, hook up processor to vehicle components.

6. After all wiring and installations are done; plug all connectors together at the Processor.

NO2 Acc. Harness

8 Pin Connector Wire Color

Pin A = RPM input (Points) White Trigger Signal Input

Pin B = NOT Used

Pin C = High Speed Retard Yellow Requires 12V+ Input

Pin D = Spark Trigger RPM Out DK Blue To CD Box (Accel/DFI 6A)

Pin E = NO2 Enable (0-20 Volt+) Gray To Micro Switch or TPS

Pin F = Sensor Return (TPS) Gray/Red To TPS Sensor Return

Pin G = RPM Switch Out (Ground) Orange Example: Shift Light ground

Pin H = Master Arm Input 12V+ Blue/Pink NO2 Arming Switch 12V+

NO2 Power Harness

4 Pin Connector

Pin A = Ignition 12 Volt Batt+ Red To + 12 Battery

Pin B = Ground Black To - Battery

Pin C = Tach Output LT Green To Tach Input

Pin D = AUX RPM Input 12V+ Green/White To trans brake +12 button

NO2 MAG Pickup Harness

2 Pin Connector

Pin 1 = MAG + Pickup Purple Distributor IPU +

Pin 2 = MAG – Pickup Green Distributor IPU -

NO2 Stage 1

2 Pin Black Connector (Note: 25 AMPS MAX Rating per Solenoid)

Pin A = Stage 1 Fuel Out (Ground) White/Red To Fuel Solenoid Ground

Pin B = Stage 1 NO2 Out (Ground) White/Blue To Nitrous Solenoid Ground

SINGLE STAGE INPUT/OUTPUT DIAGRAM FOR ACCEL/DFI DIGITAL NO2 PROCESSOR

SYSTEM VOLTAGE SPECS

Voltage Operating Range: 12 to 16 Volts

Nitrous Solenoid Grounds: 25 AMPS Maximum for 15 Seconds

Fuel Solenoid Grounds: 25 AMPS Maximum for 15 Seconds

Systems enable inputs: 12 Volts

Loading...

Loading...