Page 1

Installation Manual

For The Ford ACCEL

Digital Fuel Injection

Engine Management

System

Part #74030

The Mr. Gasket Performance Group

Cleveland, Ohio

216.398.8300

www.mrgasket.com

Page 2

ACCEL/DFI

Prior to starting the installation of your ACCEL DFI system,

read this manual carefully!!

Contents Pages

Introduction 1

I) Obtaining Your Manifold 2

II) Setting Up Your Manifold 2

III) Mounting Your ACCEL ECM 4

IV) Injector Harness Installation 5

V) Main Wire Harness Routing And Connections 5

VI) Choosing Your Distributor 9

VII) Fuel Pump Mounting and Fuel Line Installation 13

VIII) Mounting The Oxygen Sensor 19

IX) Air Cleaner Assembly 20

X) Starting The Vehicle 20

XI) Optional Items 21

XII) Trouble Shooting Guide 23

Some parts are not legal for sale or use in California or on

any pollution-controlled motor vehicle.

ii

Page 3

ACCEL/DFI

INTRODUCTION

CONGRATULATIONS! You have just purchased the finest

engine management system available. EFI control is an

exact science that ACCEL has made simple. This manual is

written to assist you with the installation of your new

system to your FORD application. Please read this manual

carefully.

Prior to starting your installation, please verify the contents

of your ACCEL DFI package. You should find the following

components:

Quantity Component

(1) Electronic Control Module (ECM)

(1) Main Wiring Harness (MWH)

(1) Injector Wire Harness (IWH)

(1) Manifold Absolute Pressure (MAP) sensor

(1) Heated Oxygen Sensor with mounting nut

(1) Coolant Temperature Sensor (CTS)

(1) 6 way to 4 way TFI adapter harness

(1) Throttle Position Sensor (TPS)

conversion connector

(1) Idle Air Control (IAC) Motor

(1) Idle Air Control (IAC) Motor Housing

(1) IAC Motor Housing Adapter Plate

(1) IAC Adapter Plate with gasket and screws

If your are missing any item , please contact your dealer

immediately.

1

Page 4

ACCEL/DFI

Although this package is designed to allow you to convert

a carbureted engine to fuel injection or allow you better

control over your present fuel injected engine, it does not

include the hydraulic portion of the installation. If you need

a fuel pump, filter, fittings, etc. contact your local ACCEL

EMIC center for the proper ACCEL DFI part numbers for

your application.

I. OBTAINING YOUR MANIFOLD

Currently ACCEL DFI only has manifolds for Chevrolet

applications, for your Ford application you may use an

OEM or aftermarket fuel injection manifold. Talk to some of

our ACCEL DFI’s EMIC centers for fabricating or modifying

a carbureted style manifold for your application. ACCEL

DFI EMIC Centers can also sell, install, and tune all ACCEL

DFI products. For the nearest dealer to you please call:

1.800.992.2235.

II. SETTING UP YOUR MANIFOLD

Prior to installing your manifold make sure that all gasket

surfaces are clean. ACCEL recommends using a 180 degree

thermostat in most applications. Place your thermostat and

gasket onto your manifold, put your thermostat housing

onto the manifold and bolt in place. When installing your

fuel injectors, be careful not to cut the O-Rings. A small

amount of oil on each O-Ring will aid in the assembly.

Please reference a service manual for proper torque

sequence and vacuum line routing. If this is a custom manifold,

please contact your fabricator for this information.

NOTE: It is recommended at this point to use a hole saw

(i.e. Green Lee punch) to put two (2) 1-5/8” diameter holes

in the firewall to accommodate the main wiring harness.

Please refer the figure below.

2

Page 5

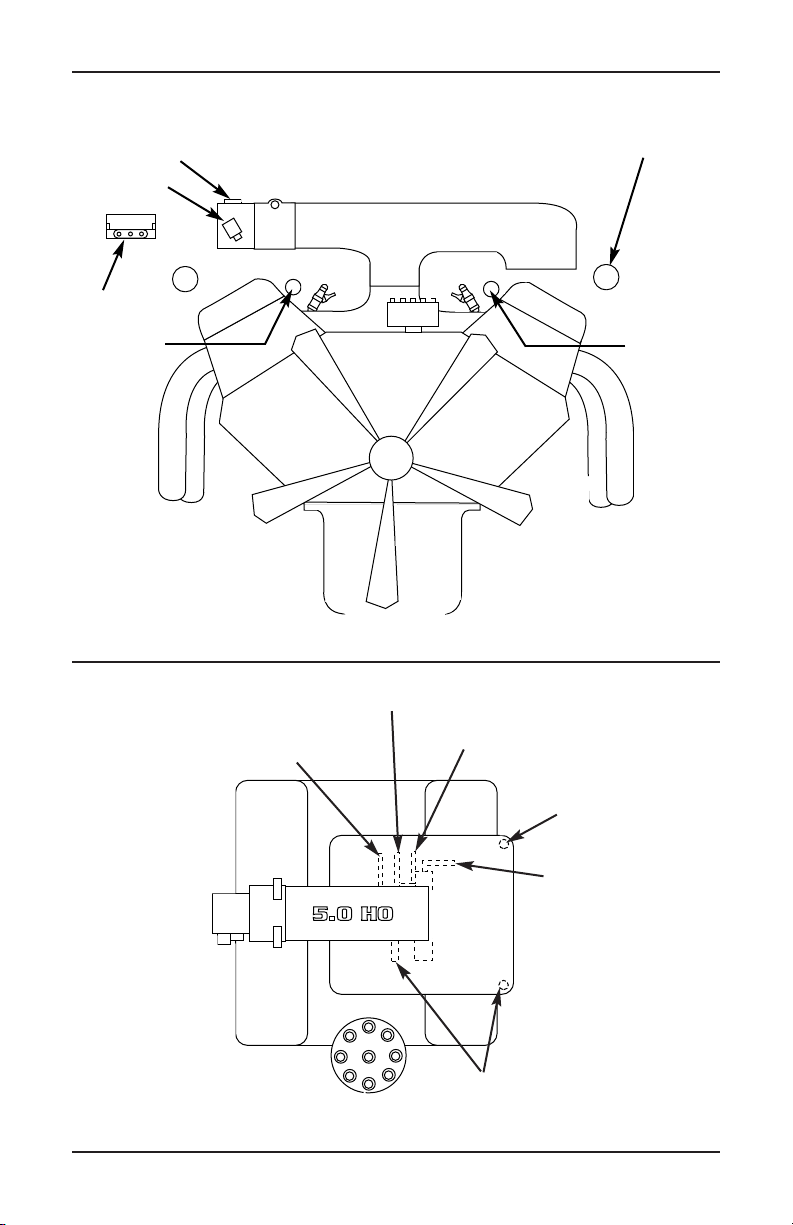

TPS Sensor

IAC Motor

MAP Sensor

Main Wire

Harness

ACCEL/DFI

1-5/8 Hole thru firewall

for grommet in main

harness - 2 places

Main Wire

Harness

Manifold Vacuum

to MAP Sensor

Manifold Vacuum to

Pressure Regulator

Manifold Vacuum to Automatic

Transmission Modulator

Additional Manifold Vacuum

Sources. (Plug all vacuum

sources not used)

PCV Valve

Vacuum Line

Manifold Vacuum

to Power Barke

Booster

3

Page 6

ACCEL/DFI

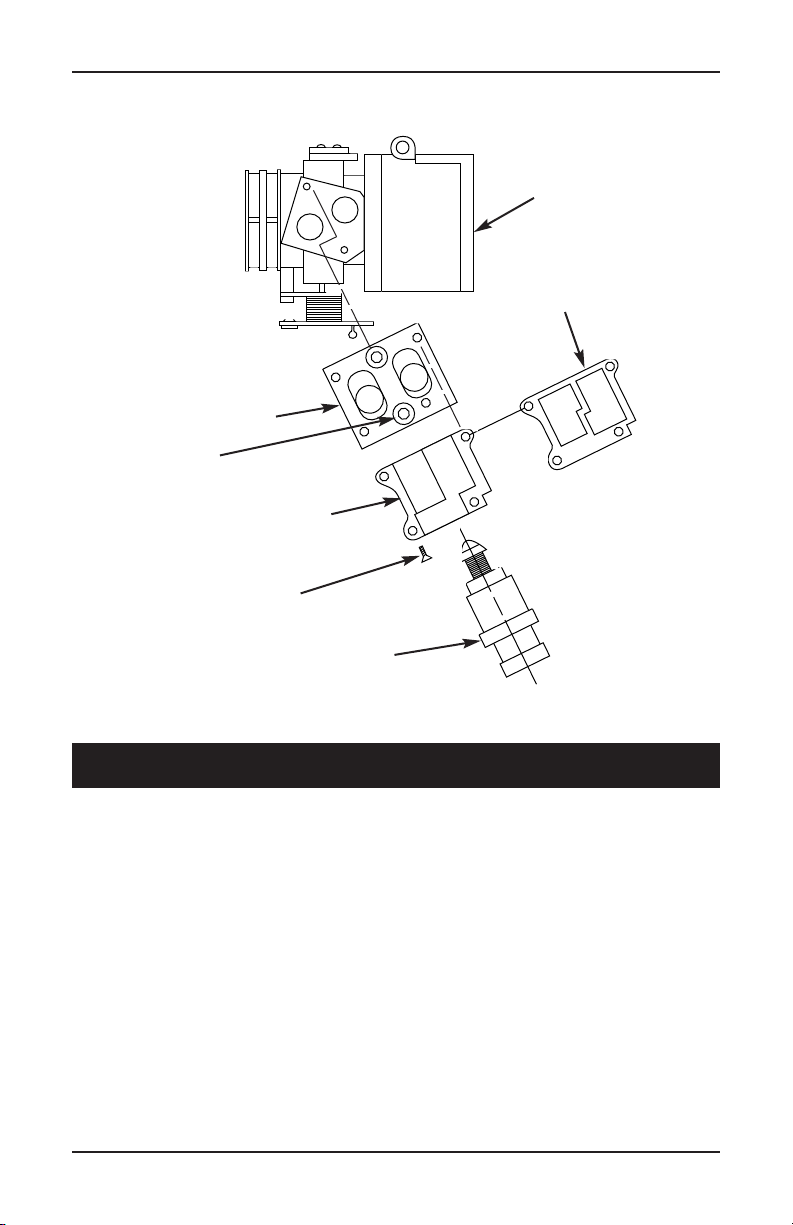

IAC Adapter Plate

Bolt Size

IAC Housing

Bolt Size

Throttle Body

IAC Gasket

IAC Valve

III. MOUNTING YOUR ECM

The ECM comes with three (3) mounting tabs designed for

a #8 sheet metal screw. It is recommended that you mount

the ECM in the passenger side kick panel. If the kick panel

has an air vent incorporated into it, DO NOT mount the

ECM here. This unit is not waterproof and therefore needs

to be mounted in a location free of moisture. The alternate

locations are in the dash board and behind the glove box.

NEVER MOUNT THE ECM IN THE ENGINE

COMPARTMENT!

4

Page 7

ACCEL/DFI

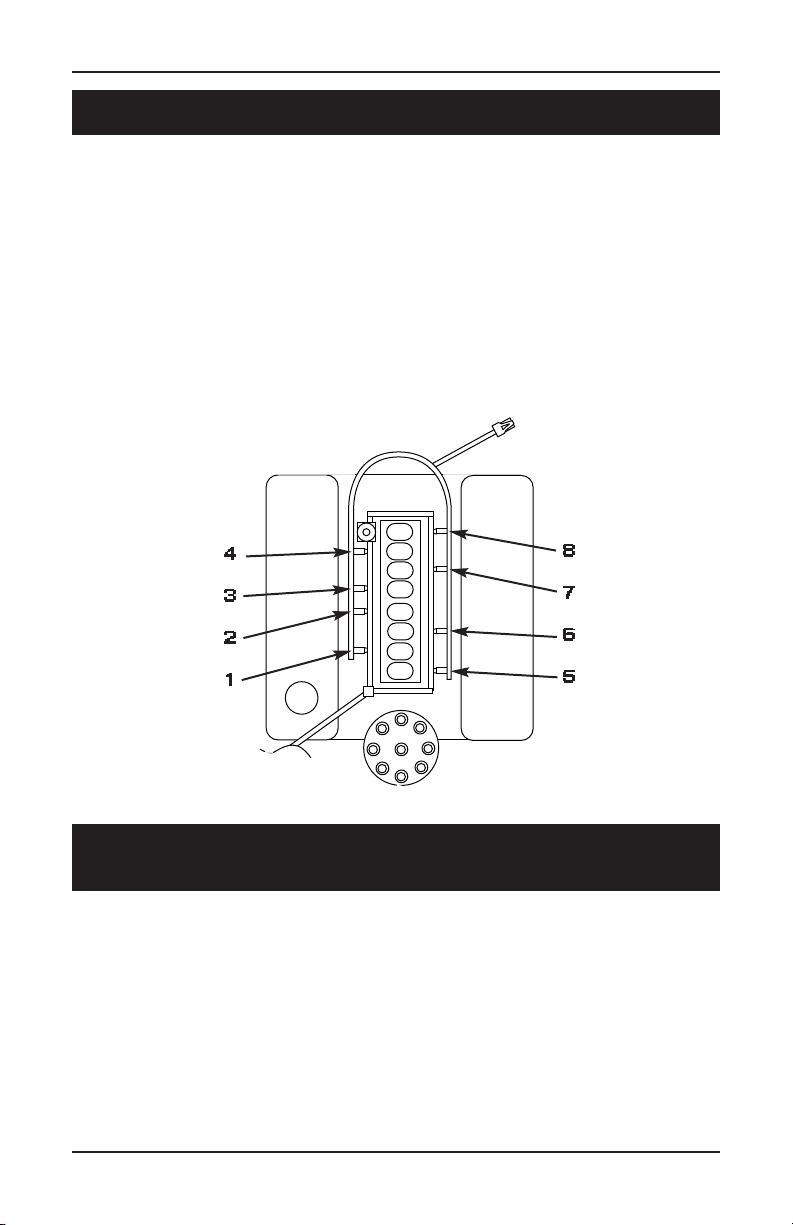

IV. INJECTOR HARNESS INSTALLATION

This ACCEL DFI system is simultaneous double fire,

therefore it does not matter what injector connector goes

to what injector. For your convenience the connectors are

paired in sets of two, similar to the way the injectors are

mounted in the manifold. Lay the injector harness so that it

lays naturally on the manifold. Clip the connectors onto the

fuel injectors making sure that the metal clips snap into

place.

4

3

2

1

8

7

6

5

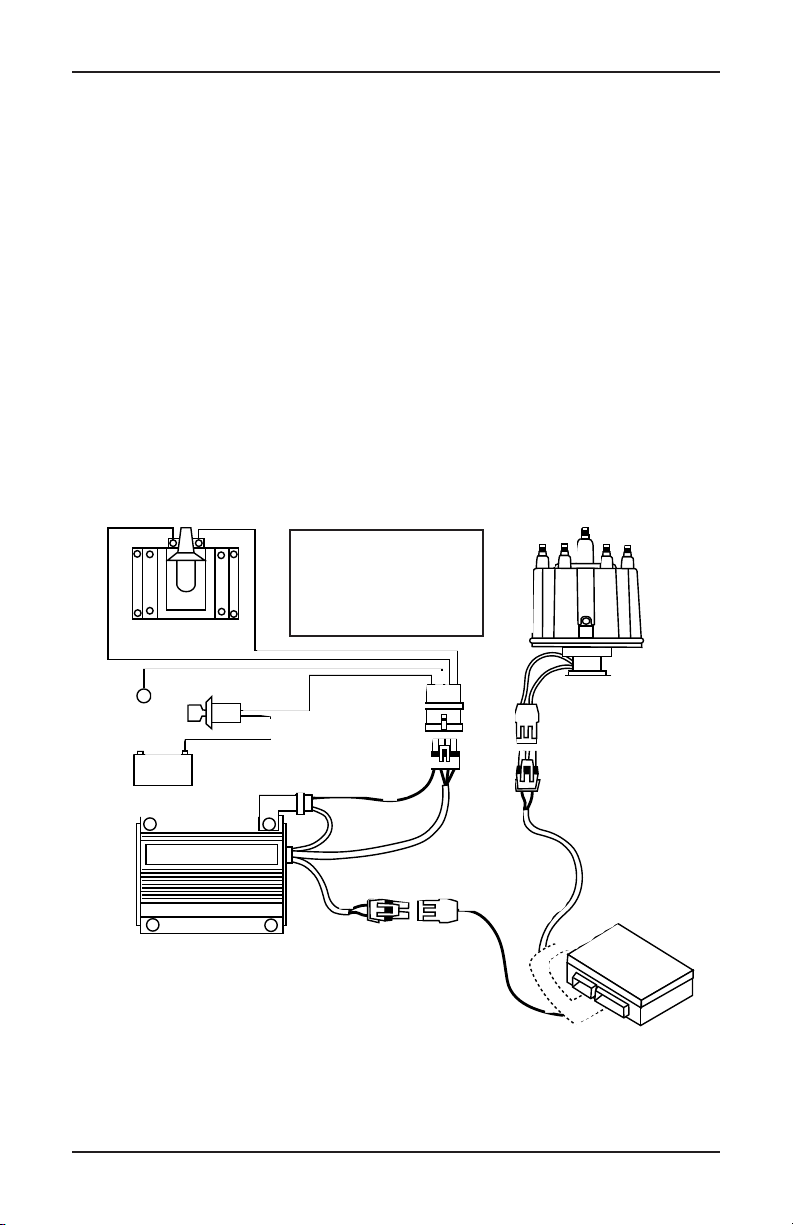

V. MAIN WIRE HARNESS ROUTING

AND CONNECTIONS

An overview diagram of the main wiring harness is shown

at the end of this section. Please reference this when making

the connections between the ECM and the corresponding

sensors/components. The harness can be routed and connected as follows: Begin by connecting the 32 pin and 24

pin ECM connectors to the ACCEL DFI ECM, making sure

that the tabs snap into place. Then route the longer of the

5

Page 8

ACCEL/DFI

two legs through the drivers side firewall hole that you cut

in step two followed by the shorter leg though the

passenger side firewall hole. Continue pulling the harness

legs through the firewall until the rubber grommets seat

themselves in the firewall. Once the grommets have been

properly seated into the firewall, each leg can be routed

between the manifold and the valve covers.

The drivers side leg will contain connectors for the following:

• MAP (3-pin green male connector)

• Computer Controlled Ignition (4-pin male black

connector, for a TFI you will use the TFI adapter)

• ESC (purple wire, bare lead)

• Air (2-pin gray connector)

• Coolant (2-pin black connector)

• TPS (3-pin black male connector)

Make sure to connect the switched +12 volt wire (long pink

wire with a female spade connector) to a switched ignition

accessory in the fuse box. The switched ignition accessory

MUST maintain 12 volts during cranking. If it does not, the

vehicle will not start.

NOTE: If you are not controlling timing with the ACCEL

DFI ECM (using a non-computer-controlled ignition system

such as a points distributor) you will not be using the

computer-controlled ignition connector (4-pin male black

connector) or the ESC connector (purple wire with bare lead).

The passenger side harness leg will contain the following

sensor connections:

6

Page 9

ACCEL/DFI

• Oxygen (3-pin female black connector)

• Injector (5-pin round white connector)

• Tach pick-up (1-pin brown connector)

• Fuel pump (bare lead, red wire with white stripe)

• IAC (4-pin square male black connector)

Connect each to the appropriate sensor using the diagram

at the end of this section. If you need to lengthen the fuel

pump wire to reach your fuel pump, make sure to use at

least 14 gauge wire, soldering and heat shrinking the

connection between the two wires. Finally be sure to

connect both the positive and ground terminals on the main

wiring harness DIRECTLY to the battery. If you fail to do

this, intermittent and unusual problems may occur.

NOTE: If you are controlling timing with the ACCEL DFI

ECM (using a computer-controlled ignition system, TFI,

etc.) the Tach pick-up will not be used. If you connect the

Tach pick-up and the computer-controlled ignition connector

at the same time, your ACCEL DFI ECM will cancel them

both out resulting in a no spark (no RPM signal) situation.

In many cases this will also damage your ECM.

At this time you can connect your User Interface Module

(UIM, or Power Tuner) to the MWH by connecting the

6-way connector (located near the ECM connectors) to the

6-way connector on the UIM. If you did not order a UIM

there is nothing for you to do with the 6-way connector on

the MWH. If using a UIM mount the unit with two (2) #8

sheet metal screws or 20 pan head screws with nuts, in a

location convenient to the driver.

7

Page 10

ACCEL/DFI

Connector to Main

Firewall

Grommet

3 PIN Green

Connector to

MAP Sensor

3 PIN Black

Connector to

TPS Sensor

4 PIN Black

Connector to

IAC Motor

5 PIN Grey

Harness

5 PIN Black

Connector to Injector

Harness (Male)

Pink Wire to 12V

Switched on Fuse Box

3 PIN Black

Connector to O

Sensor

Red/White to Fuel

pump Positive (+)

2 PIN Black

Connector to Water

Temp Sensor

Only connect white wire to

negative (–) side of ignition coil

when using a non-computer

controlled distributor. See

installation instructions if using

Mallory or ACCEL 300+

2

2 PIN Grey

Connector to

Optional Air

Temp Sensor

4 PIN Black

Connector to be used

only with a computer

controlled distributor

To 6 PIN Jumper Harness to interface

between 4 PIN Main Wiring Harness

Connector and 6 PIN Thick Film Module

(TFM) Connector on Computer

Controlled Distrubutor

Only connect black wire to

negative (–) side of ignition coil when

using a computer controlled distributor.

See installation instructions if using

Mallory or ACCEL 300+

8

Red wire

DIRECTLY to Battery

Black, Purple/Black,

Black/White wire

MUST GO DIRECTLY

to Battery Ground (-)

MUST GO

Positive (+)

+

-

Page 11

ACCEL/DFI

VI. CHOOSING YOUR DISTRIBUTOR

NON-COMPUTER-CONTROLLED IGNITION

If you are using a stand-alone magnetic pick-up distributor,

points distributor, etc., the Tach pick-up (1-pin brown

connector) must be used. Connect this lead to the negative

side of the coil. If the brown connector must be removed,

make sure not to remove the 39K ohm resistor which is

located 3” away from the existing connector.

NOTE: If you are using an aftermarket ignition enhancer

box (i.e. ACCEL 300+, Mallory Hyfire) the MWH’s Tach

pick-up connector MUST be connected to the enhancer

box’s Tach output signal. It is also necessary to remove the

39K ohm resistor from the Tach pick-up wire. It is located 3”

from the end of the Tach pick-up lead. DO NOT connect

this lead to the negative side of the coil if using an enhancer

box. This can result in ECM damage.

ACCEL strongly urges the use of a good quality suppression

wire such as ACCEL 300+ or ACCEL RFI Suppression

Wires. We have encountered problems (including not

suppressing electrical noise) with various ignition wires

available on the market such as helically-wound or solid

core. The use of these wires may interfere with the

operation of the ECM. Further, some high energy aftermarket

ignition units also produce electrical fields which will

interfere with the ECM’s operation. Use of these units is

strictly at the risk of the owner. Call ACCEL for

recommendations of ignition system compatibility.

9

Page 12

ACCEL/DFI

The total advance to which you set the engine will depend

upon the engine you have. Vacuum advance should be

controlled with the EGR port, which is located before the

throttle blades. ACCEL DFI recommends a distributor with

an adjustable vacuum advance. Once the total advance is

set, connect the vacuum line to the canister. Adjust the canister to maintain 20-26 degrees with a hot idle at 800 RPM.

Again, this is ACCEL’s recommendation, depending upon

compression ratio and cam profile, you may have to

decrease this to avoid detonation.

COMPUTER-CONTROLLED IGNITION

If you are using a TFI distributor you will need to connect

the TFI adapter harness to the 4-pin black ignition control

connector on the MWH. After doing so you can plug the

6-way end into your TFI distributor; the 1-pin black

connector will go to the negative side of your ignition coil

or points/lead of your enhancer box. You can also control

timing by using a magnetic pick-up distributor or crank

trigger. In order to do so you must get a modification done

to your ACCEL DFI ECM (ACCEL DFI part number

74043-I). This modification will come with the necessary

wiring (this wiring with replace the TFI adapter) but will

not come with an enhancer box that is required. If you will

need this modification, contact ACCEL DFI for further

instructions and a shipping address.

In order to set the initial timing, the ignition bypass

connectors (two 1-pin connectors) incorporated into the

ignition control leg must be disconnected. With the engine

running hot at 800 RPM, manually adjust the distributor to

6 degrees BTDC. Once adjusted, reconnect the ignition

bypass line. As soon as you connect the bypass line the

ACCEL DFI ECM regains control of the timing. The spark

10

Page 13

Distributor

PIP

SPOUT

BLANK

SWITCHED GN

COIL (–)

GND

Thick Film Module Jumper

Harness to be connected

between Distributor and

Main Wiring Harness

One Way Female

Connector

One Way Male Connector

provided with kit

ACCEL/DFI

4 Way Connector on

Main Wiring Harness

DFI 4 PIN

A – EST (B–1)

B – REF (A–2)

C – Switched GN (D–7)

D – GND (A–12)

–

COIL

+

Push to

insert

Seal

12-16 GA Wire

Male Terminal

Instructions for assembling

1,2,3,4 or 6 Way electrical

connectors

Connector

Female Terminal

Push to

insert

Seal

12-16 GA Wire

11

Page 14

ACCEL/DFI

curve is pre-programmed into the ECM from ACCEL DFI. It

has initial timing of 20 degrees BTDC and a total timing of

34 degrees BTDC in by 3000 RPM. The timing curves, as

well as all other tables in the ECM, can be adjusted to better

suit your engines requirements using ACCEL DFI’s

calibration software “CALMAP”.

NOTE: If an aftermarket ignition enhancer box is used (i.e.

ACCEL 300+, MALLORY HyFire), the TFI distributor can be

wired as described by the manufacturer of the enhancer

box. However, if you are controlling timing with a magnetic

pick-up distributor or a crank trigger, refer to the

illustration below.

-+

MSD Purple = (-)

ACCEL Red = (-)

Coil

Orange = (+)

Green = (+)

Black = (-)

White = (+)

12

Ground

ACCEL 300+

Key

Battery

Purple

Black

(-)

Distributor

Orange

(+)

Change

P1-B1 to

P1-B7

ACCEL

DFI

Page 15

ACCEL/DFI

VII. FUEL PUMP MOUNTING

AND HIGH PRESSURE LINE INSTALLATION

ACCEL DFI currently has two high pressure fuel pumps

available: part number 74701, an external mount fuel pump

which can support up to 450 horsepower @ 45 PSI, and part

number 74702 which can support up to 840 horsepower @

45 PSI. This fuel pump can be mounted in the fuel tank or

on the frame rail. You can use part number 74710 to mount

this pump onto your frame rail. Regardless of the fuel

pump used, be sure to mount your fuel pump near the tank

at a point of fuel level and in a protected area. System

components must also be protected and shielded from

exhaust and engine compartment heat as well as from

potential road damage.

FUEL PUMP WIRING

The fuel pump requires a +12 volt source. If your vehicle

was originally an EFI vehicle and already has a fuel pump

installed, you still MUST use the ACCEL DFI wiring.

Connect the +12 VDC side of the fuel pump to the ACCEL

DFI main wiring harness, using the red wire with white

tracer. The fuel pump relay is already an integral part of the

main wiring harness and is controlled by the ECM, therefore

no wiring is necessary for the relay. A pump will draw

between 4 and 8 amps of current depending on size and

fuel system pressure, so 14 gauge wire should be used from

the pump to the red wire with white tracer. Also, be sure to

solder the connection between these two wires. The ground

for the fuel pump can be at any clean, paint-free point on

the chassis to the negative (-) terminal of the fuel pump.

Make sure that wiring between the fuel pump and the

engine compartment does not hang below the vehicle, interfere

with rotating parts, or become exposed to excess heat.

13

Page 16

ACCEL/DFI

MECHANICAL PUMP REMOVAL

If your engine was carbureted, be sure to either cap off the

fittings on your mechanical pump or remove the pump and

cover the opening with a block off plate.

HIGH PRESSURE FUEL FILTER MOUNTING

Locate the high pressure fuel filter at the outlet of the high

pressure fuel pump on the frame rail. It is recommended to

place a filter between the fuel tank outlet and the pump

inlet if the pickup tube in the tank does not have a filter.

Failure to do so can result in fuel pump damage. ACCEL

DFI high pressure filter, part number 74720 requires 3/8”

Saginaw fittings. If your filter does not have these fittings

you can use part number 74721, these adapter fittings will

fit the 74720 filter and allow you to use a 6AN fitting.

ROUTING HIGH PRESSURE FUEL HOSE

At this point the high pressure circuit of the fuel system can

be plumbed (refer to diagram at the end of this section). If

the existing fuel supply line cannot sustain 150 PSI fuel

pressure (ACCEL recommends a fuel line rated to at least

330 PSI), then it must be replaced with high pressure fuel

line/tubing. Remember, with a carburetor, your fuel system

operated at about 6 PSI. However, with fuel injection, the

system operates around 50 PSI of fuel pressure. Never take

any chances. If in doubt, replace the hose. You will need a

minimum of 3/8” ID supply line and 5/16” ID return.

14

Page 17

Page 18

ACCEL/DFI

DUAL FUEL TANKS

It is important to note that for vehicles with two fuel tanks

and/or a class “A” RV, it is highly recommended that a

boost pump be installed in each tank and feed though a

multi-port switching valve, especially when operating in

hot climates. Boost pumps used on such vehicles as a 1985

Ford F-250 5.0L EFI will work well for this type of application. The switching valve from a 1984 Ford Diesel or a 1986

Chevrolet C-10 (305 CID) will work well in dual tank applications. Dual tank equipped vehicles must be plumbed to

return excess fuel to the tank which is supplying fuel to the

EFI system to avoid tank overflow problems. The remotelyactivated dual tank three-way valves described above will

work well in these applications.

A NOTE TO THE INSTALLER

There seems to be a misunderstanding with some people

that a fuel pump “produces pressure”. This is not accurate.

What actually happens is the pump produces fuel flow at a

given system pressure which is dictated by the pressure

regulator. The pressure regulator has a spring which is

preset to provide a certain system pressure, i.e. 45 PSI. The

regulator opens as the pressure in the fuel line increases

due to the flow of fuel provided by the pump.

As the pressure drops, due to bypassing of fuel to the tank,

the regulator closes at a pressure of 45 PSI (this pressure is

variable on adjustable regulators). This process will begin

again as pressure raises. Therefore, the pressure regulator is

a dynamic modulating device which always tries to seek its

preset pressure.

16

Page 19

ACCEL/DFI

SENDING UNIT MODIFICATIONS

To install a return line in your tank, remove the sender

assembly from the fuel tank and drill a 5/16” hole through

the top of the flange. Be sure to give yourself enough room

to weld the tube into place, welding procedures are

discussed later in this section. ACCEL DFI jumper line kit,

part number 74731, will supply you with this line as well as

other lines that you may need. Pre-bend a piece of 5/16”

fuel line so that the in-tank portion end is 2” from the

bottom of the tank and away from existing outlet tubes (See

figure at the end of this section). Ensure that the installation

of this tube does not interfere with any other components

on the tank unit. Clean the unit with soap and water prior

to the next step. Seal and secure the return line to the flange

by welding or brazing with low heat so that flange warpage

does not occur. Also make sure that applied heat does not

damage the sending unit wires or wire seals. Clean the

welded area and check for cracks or holes in the flange,

tubes or welded area.

Check the condition of the filter sock on the pick-up tube.

If the sock is torn or contaminated, replace it. Again, if you

are not using a filter sock in your application then install a

filter between the fuel tank supply line and the inlet side of

your fuel pump.

17

Page 20

ACCEL/DFI

5/16 Fuel Return Line Must Be

Added to Non-Fuel Injected

Vehicles. See Installation

Manual for Proper Installation

Braze Tube to Flange

making Sure Not to

Melt any Rubber or

Plastic Components

Top of Tank

Return Line

2"

Bottom of Tank

Existing Wire Harness

High Pressure Feed

Vapor Vent

Emissions/Canister

RETURN FUEL LINE INSTALLATION

If your vehicle was originally equipped with a carburetor,

you MUST run a 5/16” ID (inner diameter) or larger return

line from the engine (fuel pressure regulator) to the fuel

tank. Some vehicles with carburetors came with 1/4”

diameter return lines. This is too small in ID (inner

diameter) and will create an unacceptable amount of back

pressure in the fuel line, thus causing a rich condition.

Using good judgment install a fuel line from the pressure

regulator outlet to the fuel tank with restriction free bends

in protected areas (refer to the diagram at the end of the

“Routing High Pressure Fuel Hose” section). The fitting at

18

Page 21

Page 22

ACCEL/DFI

IX. AIR CLEANER ASSEMBLY

If you are using a stock throttle body on your application,

the ACCEL POWERFILTER division of ACCEL may very

well have a high performance reusable air cleaner for you.

They may also have one for your custom application, contact

ACCEL’s Technical support team for more information.

At this point all the electrical connections should be made

between the sensors, computer, and optional equipment.

Keep in mind that you will have at least one extra connector

that will not be used on the main wiring harness. Now

connect the positive terminal to the positive side of the

battery, and the ground wires to the negative battery

terminal (refer to the diagram in section V).

X. STARTING THE VEHICLE

Turn the ignition key to the run position. Do not crank yet.

The fuel pump should run for two seconds, then shut off.

Now turn the ignition key off. Repeat this procedure of

turning the key on and off four times, listening carefully for

the fuel pump. This is needed to prime the fuel delivery

system. The best way to check if the system is priming is to

connect a fuel pressure gauge to the shroeder valve on the

fuel rail. ACCEL DFI offers gauges for some Ford

applications, check your application with one of ACCEL’s

dealers. Now check for leaks along the entire length of the

vehicle. Crank the engine. After the engine starts, the engine

should fast idle and the speed will decrease as the coolant

temperature heats up. If the engine does not start after ten

seconds of cranking, check the following:

20

Page 23

ACCEL/DFI

A) All electrical and mechanical connections are made

securely.

B) There are no fuel leaks.

C) The fuel feed line is pressurized with fuel. The most

common problem is the fuel pump is wired backward.

On the ACCEL pumps, the positive (+) and negative (-)

designations are casted in the pump adjacent to the

terminals. If the ACCEL 74702 pump is wired

backwards, it will run backwards.

D) Ensure that the engine timing is properly set.

XI. OPTIONAL ITEMS

(1) User Interface Module (UIM, part number 74500)

This option allows the driver to change the three

dimensional fuel table while the engine is running. The

UIM contains two potentiometers for increasing or

decreasing the amount of fuel supplied to the engine during

idle and WOT. The idle potentiometer provides the user

with the ability to increase or decrease the amount of fuel at

idle and part throttle by 10%. The WOT potentiometer

comes into play only when the throttle is fully opened. The

percent increase and decrease is 25%. The UIM does not

change the amount of fuel delivered during cranking.

The UIM must remain connected to the main wiring

harness after adjustments are made to the ECM. If it is

disconnected, the ECM will automatically default back to

its preset values.

If your engine requires a somewhat different calibration

than is noted on the ECM or you are calibrating a unique

engine combination, use the ACCEL DFI Serial

21

Page 24

ACCEL/DFI

Communications Interface option, CALMAP (part number

74990-S with a 5ft cable, 74990-L with a 25ft cable). This

software will allow you to customize the Fuel and Timing

curves as well as all other parameters in the ECM.

FAN CONTROL KIT (PART NUMBER 74171)

This kit includes a harness with a integral relay that

interfaces between the ECM and the fan. This allows you

to turn on an electric fan at a given engine temperature via

CALMAP. This kit does not include a fan.

NITROUS OXIDE CONTROL (part numbers listed below)

Single Stage Harness Only

Part Number 74253

Multi-Stage Harness Only

Part Number 74697

Although ACCEL DFI currently does not have complete

nitrous oxide kits available for Ford applications, we do

offer the necessary wiring to allow you to control your

nitrous through the ACCEL DFI ECM. The part numbers

listed above are ready to plug into your ACCEL DFI ECM

and nitrous solenoid to give you exact delay control,

ignition timing and fuel control over your nitrous system.

ACCEL can also offer you the nitrous solenoid, contact your

local ACCEL EMIC dealer for more information.

22

Page 25

ACCEL/DFI

XII. TROUBLE SHOOTING GUIDE

The following are some common problems we have

encountered with various installations.

Injectors not firing (clicking) - the vehicle will not start:

• Usually due to a low battery. Voltage must be above nine

(9) volts during cranking to activate the ECM.

• Injector harness not connected to the main wiring harness.

• Short in either pin P1-C7 or P1-C8. Check continuity to

battery positive (+) and negative (-) wires with an OHM

meter.

• Tach wires to positive (+) side of coil instead of negative (-).

• P1-D7 (long pink wire with female spade connector) not

receiving +12 volts during cranking. Usually due to

connecting this wire to a voltage source that is disabled

during cranking.

Runs rich at idle:

• Vacuum line to fuel pressure regulator not connected.

• MAP sensor vacuum line pinched.

• UIM idle knob turned all one way.

• Wrong injectors for the application.

• Return fuel line is too small/restricted.

• Calibration in the ECM is wrong for the application.

Runs rich all the time:

• Wrong injectors for the application

• Return line is too small/restricted.

• Calibration in the ECM is wrong for the application.

Engine cranks a while before starting:

• +12V and ground terminals not connected directly to battery.

• Fuel pump is not priming the fuel system.

If you are experiencing problems please contact your ACCEL

dealer, of feel free to call ACCEL’s technical service line and talk

to an ACCEL DFI technical representative at 1.216.398.8300 ext. 5.

23

Page 26

The Mr. Gasket Performance Group

Cleveland, Ohio

216.398.8300

www.mrgasket.com

Printed in U.S.A. INST0097A 3-99

Loading...

Loading...