Page 1

FORM 1078 (Rev B) 01/12

INSTALLATION INSTRUCTIONS

3-PORT COMPETITION

FUEL PRESSURE REGULATOR

(RETURN STYLE)

PART NO. 4309

NOTE: DO NOT RUN THIS PUMP WITHOUT FUEL (EXCEPT FOR BRIEF PERIODS WHILE PRIMING).

IMPORTANT: This regulator must use a fuel return line. The fuel return line runs between the fuel return port of the regulator and the fuel

tank. Fuel pressures cannot be adjusted if the fuel return line is absent.

PART INCLUDED IN THIS KIT

1 3-Port Fuel Pressure Regulator

1 Bracket

2 Bracket Mounting Screws

1 Bypass Spacer (to modify COMP PUMP® 110 and 140 Series

Electric Fuel Pumps)

SPECIFICATIONS:

Port thread sizes (ALL): 3/8” NPT

Adjustment range: 3-12 PSI (approximate)

Fuel Application: Gasoline, Automotive/Street and Racing

applications

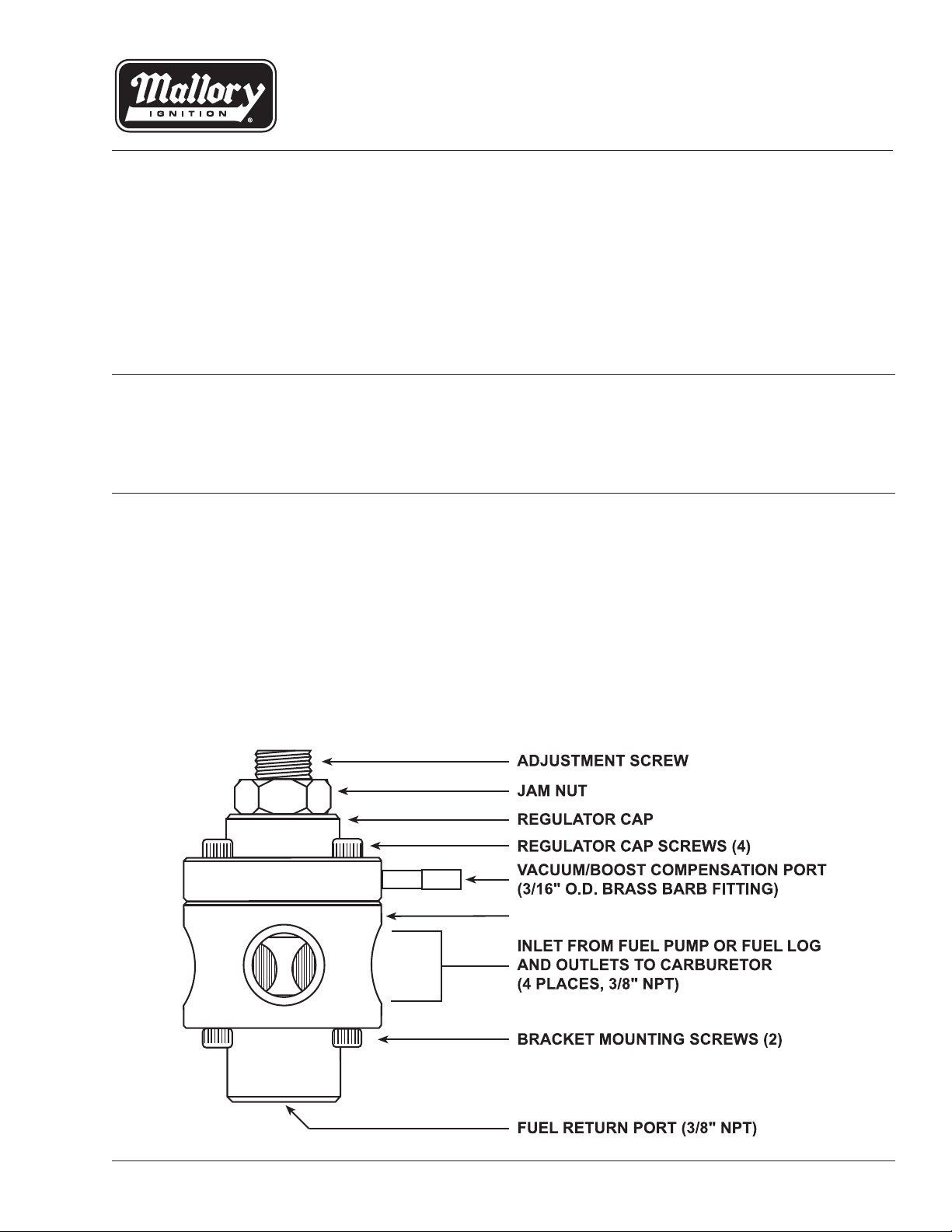

GENERAL INFORMATION

Mallory’s 3-Port, return style regulator regulates fuel pressure between high pressure fuel pumps and carburetors. The

regulator is recommended for Mallory COMP PUMP® 110, and 140 Series Electric Fuel Pumps.

NOTE: This regulator is not recommended for pumps over 200 gallons per hour.

By returning excess fuel and fuel pressure to the fuel tank, this regulator benefits fuel pumps in several ways. The fuel pump will run

cooler, draw less current and will always have full volume output available at the pressure setting. The fuel return line runs between

the fuel return port of the regulator and the top of the fuel tank. The fuel tank must have

provisions for a fuel return line.

This regulator is equipped with a vacuum/boost compensation port (brass barb fitting) that can be used tomomentarily decrease

fuel pressure (vacuum compensation) at idle and part throttle, or increase fuel pressure under blower boost (boost compensation).

While it is not necessary to connect a hose to the vacuum/boost compensation port, it may be

beneficial in some cases. However, the small plug on the barb must be removed before use.

MALLORY IGNITION www.mallory-ignition.com

1

Page 2

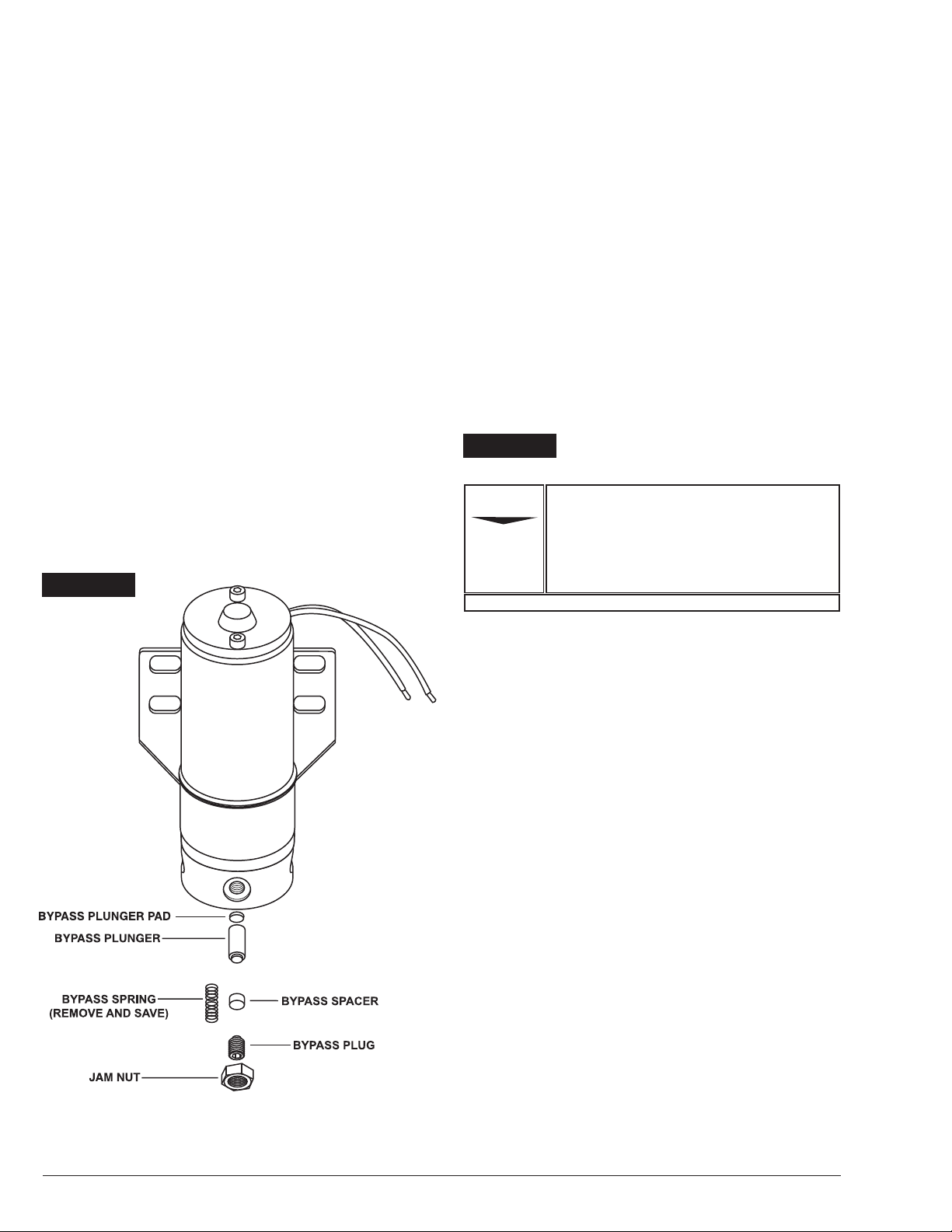

MALLORY COMP PUMP® 110 AND 140

SERIES ELECTRIC FUEL PUMP SUGGESTED

MODIFICATION ONLY WHEN USING RETURN STYLE

REGULATORS(See Figure 1)

Step 1

Release the jam nut on the bypass plug. Remove the

bypass plug. Remove the bypass spring and plunger. Save

the bypass spring for possible future use.

Step 2

Inspect the bypass plunger. The bypass plunger surface

should be clean and slide freely in the chamber. Check

the bypass plunger pad and remove any debris embedded in its surface.

Step 3

Install the bypass plunger pad in the bypass plunger.

Install the bypass plunger and bypass spacer. Clean the

bypass plug.

Step 4

Apply thread sealant compound on the bypass plug.

You can find thread sealant compound at a hardware

store. Do not use thread sealing tape.

Step 5

Install the bypass plug. Gently tighten bypass plug until

you feel it lock (torque to 5 in/lbs). Install and tighten the

jam nut.

FIGURE 1

MOUNTING PROCEDURE

The regulator may be mounted at any angle. For maximum efficiency, mount the regulator as close as possible

to the carburetors.

DO NOT mount the regulator on or near exhaust manifolds. A bracket is provided for convenient mounting

under an intake bolt.

FITTINGS, FUEL LINES AND FUEL RETURN LINE

The fuel return line should be as large, or larger, as the

fuel line between the fuel pump and the regulator. See

Figure 3.

Purchase fittings (and plugs). Use a thread sealant

compound on the fitting threads. You can find thread

sealant compound at a hardware store. Do not use

thread sealing tape. Install the fittings. Do not overtighten the fittings. This could damage the regulator.

Connect the fuel lines and fuel return line. See Figure

3A-3C.

FIGURE 2

FUEL RETURN LINE SIZE

RECOMMENDATIONS

Fuel Return Line

Length/ Distance

16 – 20’

11 – 15’

6 – 10’

1 – 5’

3/8” = #6AN 1/2” = #8AN 5/8” = #10AN

FUEL PUMP GALLONS PER HOUR (FREE FLOW)

1 TO 99 100 TO 129 130 TO 199

1/2” 1/2” 5/8”

3/8” 1/2” 5/8”

3/8” 1/2” 1/2”

2

www.mallory-ignition.com MALLORY IGNITION

Page 3

FIGURE 3A

FIGURE 3B

FIGURE 3C

3

www.mallory-ignition.com MALLORY IGNITION

Page 4

FUEL PRESSURE ADJUSTMENT

NOTE: It is not necessary to have the engine running

while setting fuel pressures with this type of regulator.

DO NOT exceed the fuel pump manufacturer’s maximum

recommended operating pressures. This could damage

the fuel pump. (See Figure 4 for Mallory COMP PUMP

® Series Electric Fuel Pumps maximum recommended

operating pressures.)

Step 1

Remove and discard the plastic cap on the vacuum/

boost compensation port. Release the jam nut on the

adjustment screw. Remove the adjustment screw.

Step 2

With the engine off, turn on the fuel pump. Check the

fuel system for fuel leaks. Check the fuel pressure with

the adjustment screw removed. The pressure must be

less than 3 psi. If not, a less restrictive return line must be

used. Turn off the fuel pump and correct any fuel leaks

before proceeding. Install adjustment screw.

Step 3

Adjust fuel pressure. Check the fuel system for fuel

leaks. Turn off the fuel pump and correct any fuel

leaks before proceeding. Install and tighten jam nut.

VACUUM/BOOST COMPENSATION POR

While it is not necessary to connect a hose to the vacuum/boost compensation port, it may be beneficial in

some cases. The vacuum/boost compensation port can

be used to momentarily decrease fuel pressure (vacuum

compensation) at idle and part throttle, or increase fuel

pressure under blower boost (boost compensation).

Connect a hose between the vacuum/boost compensation port and a carburetor or intake manifold vacuum

port to vacuum index the regulator. The set pressure of

the regulator decreases about 1 PSI for every 2 inches

Hg (2 inches on the vacuum gauge). Connect a hose

between the vacuum/boost compensation port and an

intake manifold boost port to boost index the regulator.

The set pressure of the regulator increases 1 PSI for every

1 PSI of boost.

NOTE: DONOT exceed the fuel pump manufacturer’s

maximum recommended operating pressures. This could

damage the fuel pump.

REGULATOR SERVICE PARTS:

D IAPHRAGM KIT, G ASOLINE, FO R

REGULATOR PART NO. 4309.

KI T

PART NO.

3156

FIGURE 4

MAXIMUM OPERA TING

PRESSURE

COMP PUM P ® SERIES

110 14 0

7 PSI 14 PSI

MALLORY IS A TRADEMARK OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

MALLORY IGNITION www.mallory-ignition.com

FORM 1078

(Rev B) 01/12

4

Loading...

Loading...