Mallory Ignition 4307M User Manual

INSTALLATION INSTRUCTIONS

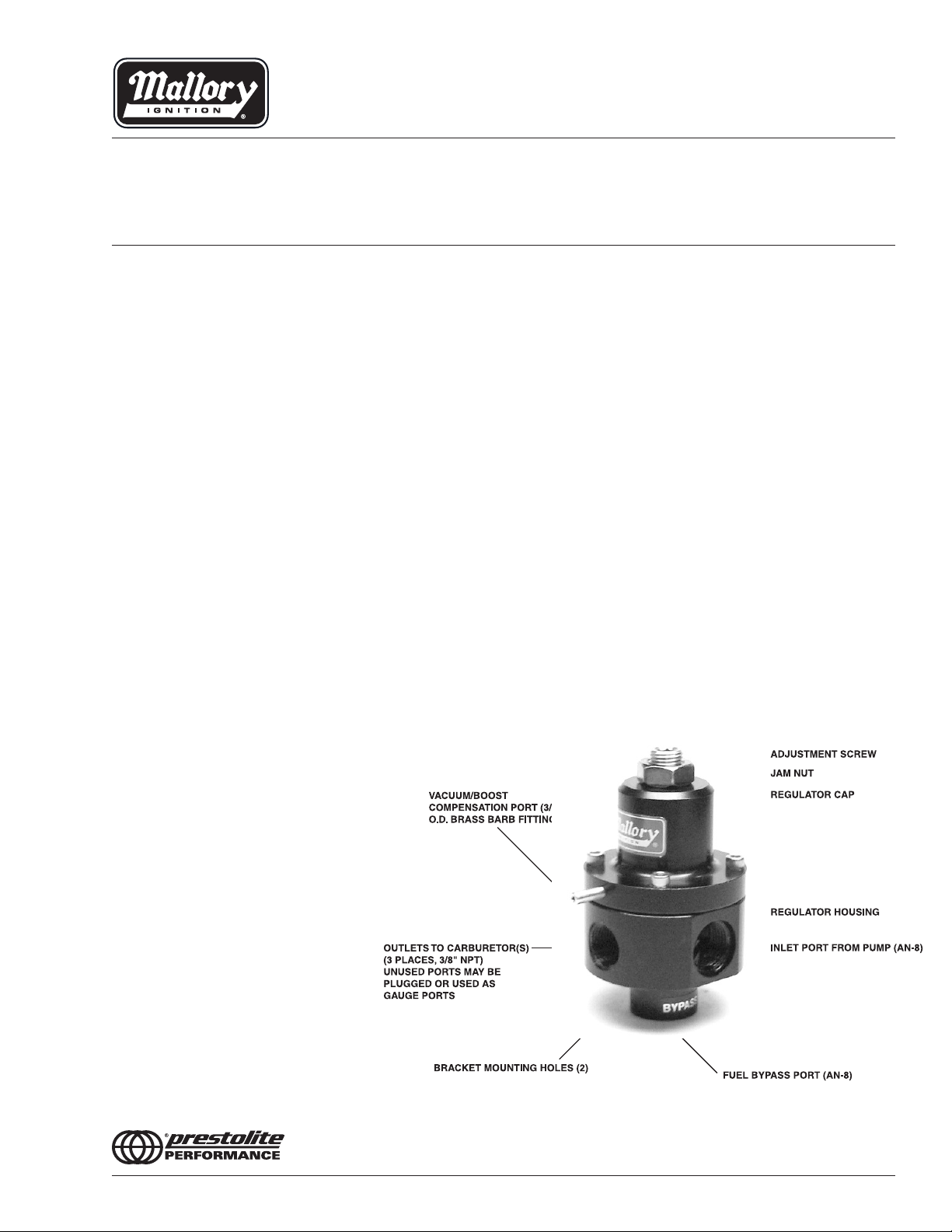

COMPETITION RETURN STYLE

FUEL PRESSURE REGULATOR

PART NO. 4307M

FORM 1529M (REV. C) 01/12

IMPORTANT: This regulator must use a fuel return line. The fuel

return line runs between the fuel bypass port of the regulator

and the fuel tank. Fuel pressures cannot be adjusted if the fuel

return line is absent.

PARTS INCLUDED IN THIS KIT

1 Fuel Pressure Regulator 2 3/8” NPT Pipe Plugs

1 Bracket 2 AN-8 Fittings

2 Bracket Mounting Screws 2 O-rings for Fittings

SPECIFICATIONS:

Port thread sizes: 3/8” NPT and AN-8

Adjustment range: 4-25 PSI NOTE: Exact adjustment range

depends on pump capacity and

return line size.

Fuel Application: Gasoline and Alcohol/Methanol

Service Kit: Part No. 3178

GENERAL INFORMATION

Mallory’s 4305M regulator regulates fuel pressure between high

pressure fuel pumps and carburetors or throttle body fuel injection

systems. The regulator is recommended for fuel pumps up to 200

gallons per hour.

The 4307M regulator is a return style fuel pressure regulator. The

excess fuel and fuel pressure is sent back to the fuel tank through the

fuel return line. The fuel return line runs between the fuel bypass port

of the regulator and the top of the fuel tank. The fuel tank must have

provisions for a fuel return line.

This regulator is equipped with a vacuum/boost

compensation port (brass barb fitting) that can

be used to momentarily decrease fuel pressure

(vacuum compensation) at idle and part throttle, or

increase fuel pressure under blower boost (boost

compensation). While it is not necessary to

nect a hose to the vacuum/boost compensation

it may be beneficial in some cases. However,

small plug on the barb must be removed before use.

You can mount the 4307M regulator at any angle.

For maximum efficiency, mount it as close as

possible to the carb or throttle body. DO NOT

mount the regulator on or near exhaust

manifolds. A bracket is provided for

convenient mounting.

con-

port,

the

2. Turn the fuel pump on and check for leaks. If leaks are found on the

NPT (tapered) fittings, make sure the threads are covered properly

with thread sealer.

NOTE: If the fuel system will not prime properly, back the

adjustment screw all the way out of the regulator until the

system is primed. Then reinstall the adjustment screw.

3. Set the fuel pressure. Loosen the jam nut on the top of the

regulator and turn the brass adjustment screw to adjust the

pressure. Clockwise increases pressure.

FUEL LINE SIZE (FROM PUMP TO REGULATOR)

Minimum fuel line size is determined by the horsepower of the

engine.

Up to 350 HP: 3/8” or –6AN

Up to 500 HP: 1/2” or –8AN

Up to 700 HP: 5/8” or –10AN

RETURN LINE SIZE

The minimum return line size is determined by the output of the

fuel pump.

Up to 29 gal/hr (110 liter/hr): 5/16” or –4AN

Up to 45 gal/hr (170 liter/hr): 3/8” or –6AN

Up to 90 gal/hr (340 liter/hr): 1/2” or –8AN

Up to 200 gal/hr (680 liter/hr): 5/8” or –10AN

INSTALLING THE 4307M REGULATOR

1. Connect the fuel line and the return line. The

return line must be attached to the bottom port

on the regulator. The fuel line must be

to the upper -8AN port on the regulator.

must be purchased to adapt the fuel line and

the return line to the regulator. The unused

port(s) in the regulator can be plugged or used

as gauge port(s).

attached

Fittings

MALLORY IS A TRADEMARK OF PRESTOLITE PERFORMANCE

10601 MEMPHIS AVE. #12, CLEVELAND, OH 44144

216.688.8300 FAX 216.688.8306

FORM 1529M

(REV. C) 01/12

Made in U.S.A.

Printed in U.S.A.

www.mallory-ignition.com

Loading...

Loading...