Page 1

FORM 1459-01 (REV. B) 7/99

®

FUEL PRESSURE REGULATOR

Part No. 4213

INSTALLATION INSTRUCTIONS

INSTALLATION

Mallory's 4213 Adjustable Fuel Pressure Regulator is designed to be a bolton replacement for the OEM Ford 1994-1998 5.0 and 4.6 fuel injection

regulator (except 1998 SOHC). The Mallory Regulator is installed in the

same manner as the factory Ford regulator (see repair manual). Be sure to

lubricate the O-rings with a drop or two of motor oil before installation.

VACUUM PORT

A vacuum line is connected to the stock regulator. This vacuum line should

be connected to the vacuum port on the Mallory regulator to reduce fuel

pressure at idle and part throttle.

SETTING THE PRESSURE

Factory Ford regulators produce about 35-40 psi at full throttle. The Mallory

regulator is factory set at about 45 psi. Adjust the pressure by loosening the

jam nut and turning the adjustment screw (clockwise increases pressure).

The full throttle pressure can be adjusted between about 30 and 75 psi. The

ideal pressure depends on many variables. On a mostly stock engine, a

slightly higher pressure (about 45 psi) will usually result in a slight power

increase. Modified engines may require higher pressures to optimize power

output. If a pressure over 60 psi is required to optimize power output, larger

injectors should be considered.

FUEL PRESSURE GAUGE PORT

A 1/8 NPT port is tapped into the side of the Mallory regulator housing. The

port is supplied from Mallory with a plug. If a fuel pressure gauge is used, the

plug can be removed and the gauge connected to the port.

FIGURE 1

GAUGEGAUGE

PORTPORT

GASKETGASKET

ADJUSTMENT SCREWADJUSTMENT SCREW

JAM NUTJAM NUT

VACUUM PORTVACUUM PORT

O-RINGSO-RINGS

REBUILDING

See Figure 2

If the regulator develops a leak or the pressure begins to fluctuate, rebuilding

may be necessary. A rebuild kit is available (Part No. 3162). This kit includes

a new diaphragm assembly, sealing washer, gasket and O-rings. The

diaphragm and sealing washer can be replaced without removing the

regulator housing.

REPLACING THE DIAPHRAGM

AND SEALING WASHER

Remove the nut and adjustment screw. Remove the three upper screws.

Remove the cap, thrust washer, springs, diaphragm assembly and the

sealing washer. Install the new sealing washer and diaphragm assembly.

Re-install the springs, washer, and cap. Re-install the three screws. Great

care must be taken to tighten the screws gradually and evenly so that the

cap stays flat with the housing.

REPLACING THE GASKET AND O-RING

If replacing the diaphragm and sealing washer does not help, it may be

necessary to replace the gasket and O-rings. Remove the regulator from the

fuel rail and replace the gasket and O-rings. Be sure to lubricate the O-rings

with a drop or two of motor oil before re-installing.

Page 2

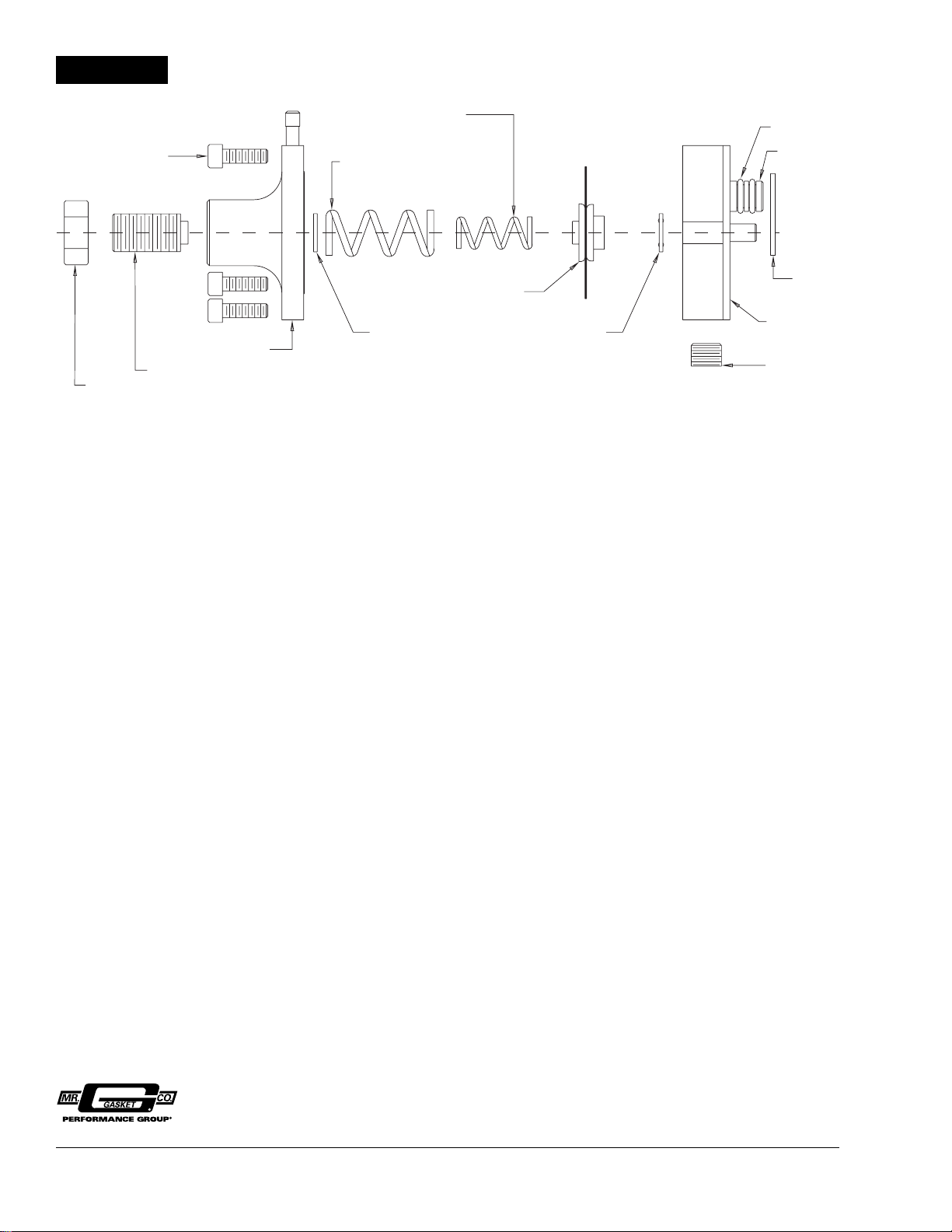

FIGURE 2

NUT

SCREW

3 PLACES

ADJUSTMENT SCREW

CAP

SPRING, INNER

SPRING, OUTER

DIAPHRAGM ASSEMBLY

O-RINGS

COUPLER

GASKET

SEALING WASHERTHRUST WASHER

HOUSING

PLUG

MALLORY IS A DIVISION OF THE MR. GASKET PERFORMANCE GROUP

550 MALLORY WAY, CARSON CITY, NEVADA 89701

(775) 882-6600 FAX (775) 887-4326

www.mrgasket.com

FORM 1459-01

(REV. B) 7/99

Made in U.S.A.

Printed in U.S.A.

Loading...

Loading...