Malber P13 Owner Manual

M

W

C

e

n

n

m

A

U

a

S

G

G

O

C

U

U

r

a

C

o

m

r

OWNER’S MANUAL

Model P13

Washing Machine

Contents

Technical Data............................................. 2

Installation Requirements............................. 3

Installation Instructions................................. 4

Important Safety Information.........................6

About Your Washing Machine ....................... 7

Understanding the Control Panel................... 8

Fabric Care Labels..................................... 10

Stain Removal Chart.................................. 10

Guide to Wash Programs .......................... 11

Guide to Wash Only Programs..................... 12

Operating Instructions................................. 13

Preparing Your Laundry...............................13

Choosing Load Size.....................................13

Using the Laundry Aid Dispenser..................14

Using Your Washing Machine ....................... 14

Troubleshooting.......................................... 14

Taking Care of Your Washing Machine.......... 15

Common Laundry Problems........................ 17

Important! To get the best performance

from your washing machine, read all operating

instructions before using for the first time.

TECHNICAL DATA

N

o

i

e

d

t

r

n

d

d

o

p

e

n

c

e

t

fi

n

c

w

n

c

u

p

u

r

e

t

n

c

/

DESCRIPTION OF THE APPLIANCE

- The MALBER P13 machine has been constructed

in steel panels which have been treated and painted

to guarantees that its aesthetic qualities remain

unaltered over time.

- The motor and all moving parts have been designed

and manufactured to guarantee the minimum

possible noise levels

- The large easily-accessible stainless steel drum will

ensure a better quality wash and help to prolong the

life of your washing

- The easy to use control panel will satisfy all washing

needs (see control panel and programme table).

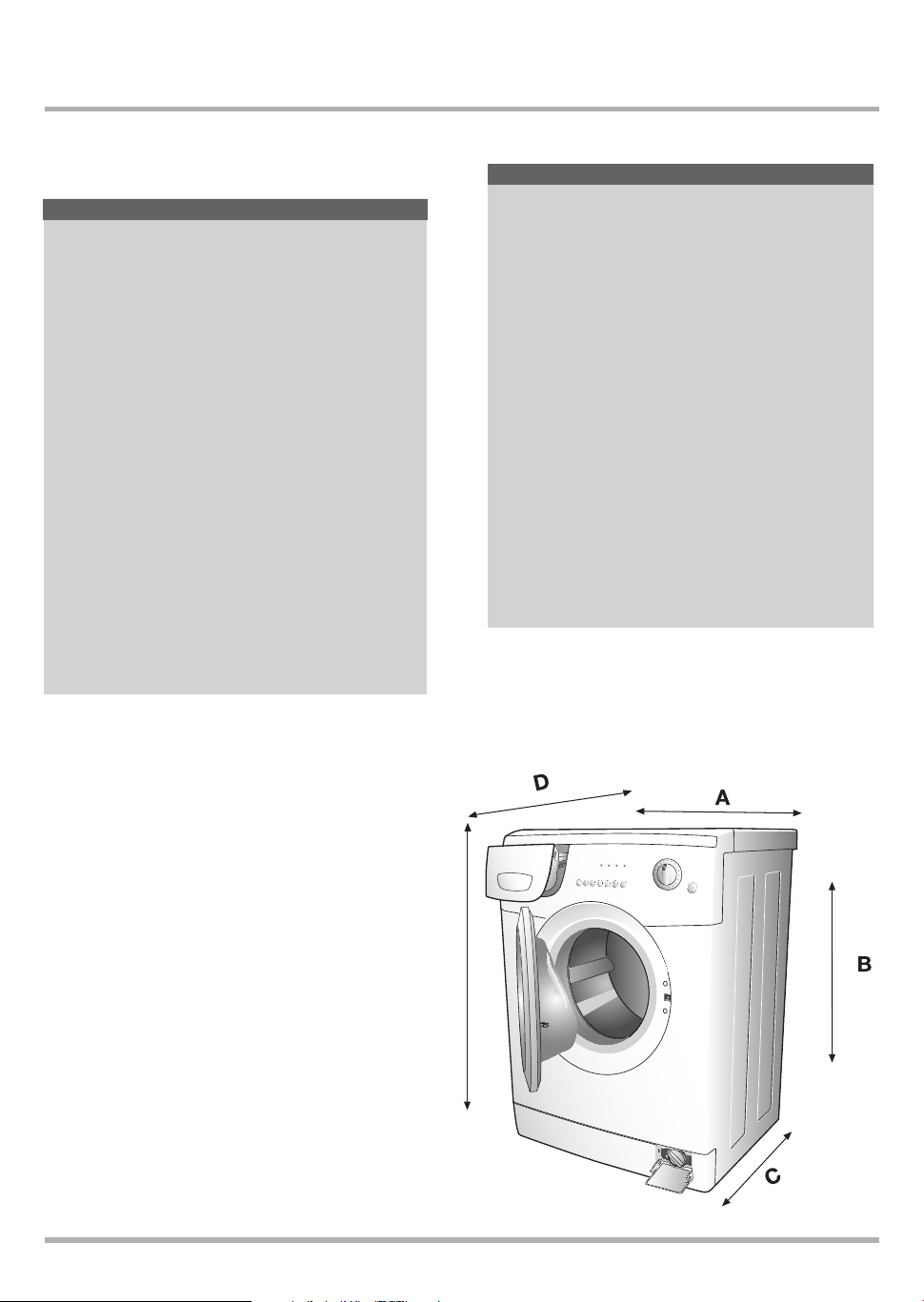

Dimensions

A. Width: 23 ½” (597 mm)

B. Height: 33 ¼”- 34“ (845 - 864 mm)

C. Depth: 23 5/8” (600 mm)

D. Depth w/door open: 39” (991 mm)

Capacity

Large

Electrical Conn.

Voltage: 120 Volts, 15 Amp, 60Hz

Water Conn.

Inlet supply hose: Two 6’ (1.5 m) fill hoses, hot & cold

Supply pressure: 15 – 142 PSI

Outlet hose” 6.5’ (1.7 m) polypropylene hose, ¾” ID

Note: The manufacturer reserves the right to improve appliance

specifications without prior notice. For more information, see

the type plate on inner door facing of machine.

2

INSTALLATION REQUIREMENTS

Location

Grounding Instructions

This appliance must be properly grounded. In the

event of breakdown or malfunction, grounding

reduces the risk of electric shock by providing a

path of least resistance for electric current. The

cord for this appliance has an equipment-grounding

conductor and a grounding plug. The plug must

be plugged into an outlet that is properly installed

and grounded in accordance with all local codes

and ordinances. Do not modify the electrical plug

provided with the appliance – if it does not fit the

electrical outlet, have a qualified electrician install

a proper outlet. Make sure the power supply and

electrical outlet support a 110/120V, 15 amp

single-phase circuit.

The washing machine can be installed as a freestanding unit

or in a recessed area, under a counter or in a closet with

appropriate clearance. See page 4.

FILL/DRAIN HOSES

Fill Hoses – Two hoses are supplied with the machine. The hot

water hose has a red stripe running the length of the hose.

Drain Hose – Drain outlet should be between 23” (60 cm) and

35” (90 cm) above the floor. To prevent siphoning, do not seal

t

he drain hose connection into the drain outlet. If machine

is not connected to a drain outlet, position drain hose and

bracket over the edge of sink or wash basin and secure in

place before draining. See page 5 for complete installation

instructions for the fill and drain hoses.

MALBER USA all liability if installation use and care instructions

are not followed completely.

Warning!

Improper connection of the equipment-grounding conductor may

result in electric shock. If you are in doubt as to whether the

appliance is properly grounded, check with a qualified electrician or

service representative.

Important!

To prevent accidents, injury and fire, read instructions carefully before

you install the machine.

A qualified installer familiar with all local codes and ordinances for

plumbing and electricity should do the installation and grounding.

Incorrect installation may cause damage or injury.

Install washing machine on a strong, level floor in a protected, dry and

well-ventilated area with room for electrical cords and hoses behind

the machine. Temperature should be not less than 38° F

Make sure power supply and outlet support a 110/120 V, 15 amp

single-phase circuit.

Do not use an extension cord.

If integrity of the machine is in doubt, do not use it. Call Customer

Care Center.

(3° C)

Electrical

Machine Voltage/Amperage – 120V, 60Hz, 15 Amp

Connection – 3-prong plug (must be grounded)

Circuit/Protector – single phase, 15 AMP, 120V, 60Hz

Tools

1. Adjustable Wrenches

(if you use adjustable

fittings)

2 Open-ended Wrench

[10mm]

3. Tape Measure

4. Spirit Level

5. Channel Lock

6. 20 Torx screwdriver

3

INSTALLATION INSTRUCTIONS

N

a

m

n

e

o

g

v

n

e

o

a

O

b

o

h

t

a

m

o

w

e

b

E

h

h

t

o

p

Installation/Removal

1. Unpack Washing Machine

Move the machine to its installation position. Remove the packing materials

carefully to avoid damage to the machine’s pre installed drain hose and

power cord. Make sure the machine is intact and report any damage to the

retail location you purchased your product from immediately.

WARNING: Destroy the carton and plastic bags after unpacking

Washing Machine. Plastic bags and other packing material are not

children’s toys and can be dangerous.

Built-In Installation

The MALBER P13 e can be installed beneath a cabinet or worktop

with a height of 34-1/2“ ( 876

mm). There must be a gap of

about 1/2“ (12 mm) all around

the machine, including between

the rear edge of the machine

top panel and the back wall.

The opening width must be

at least 24-1/2“ (622 mm).

Space must also be available

for the inlet and drain hoses.

See the diagram above for

measurements and positions.

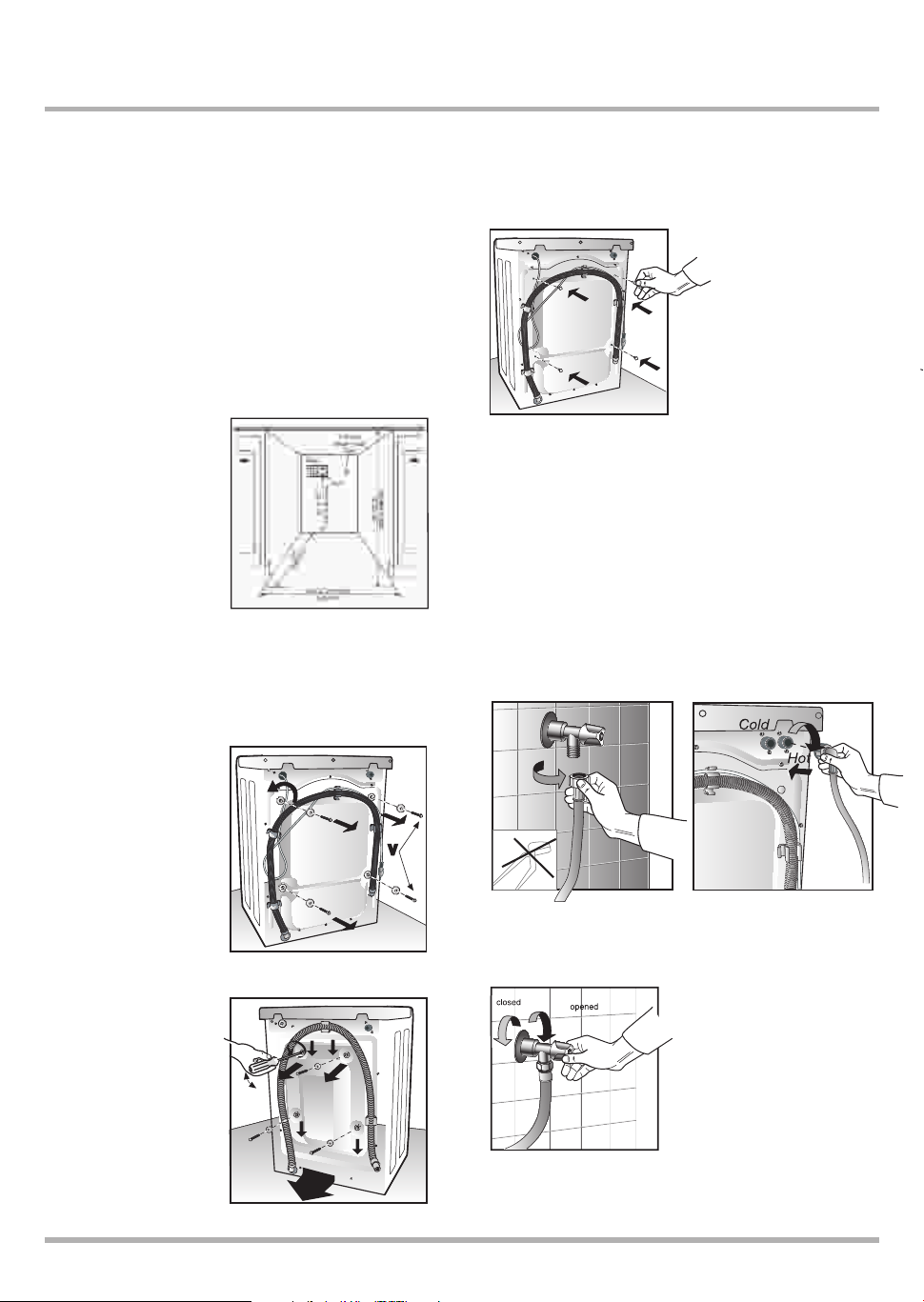

2. Remove Shipping Bolts/Spacers/Grommets

The machines shipping security consists of shipping bolts (4), spacers

and grommets on the back panel to secure the wash drum during

shipping and delivery.

IMPORTANT: Remove all

grommets before using

the Washing Machine to

allow proper operation

and prevent damage to

the appliance

Failure to remove bolts and

spacers prior to use will

void the warranty.

Once the machine is in its

installation location, remove

the four locking 10mm bolts

and plastic spacers (Fig.1A).

If plastic spacers cannot be

removed, open rear panel (20

torx) screwdriver as shown in Fig

1B, remove spacers and replace

the panel.

Keep bolts, shipping bolts,

and grommets for future

Plug holes with four plastic plugs

enclosed packed with manual

(Fig. 2)

Remove power cord restraints

before plugging in machine.

.

shipping bolts/spacers/

Fig. 1A

spacers

use.

IMPORTANT: Retain all shipping bolts, spacers and

grommets Reinstall to prevent damage if you transport

machine in the future.

Fig. 2

* Do not plug in power supply until

shipping bolts are removed.

3. Connect Water Inlet

If connecting to new or unused water pipes, run water until clear

before connecting to machine to remove any debris that could clog

the water valve screens. NOTE: Make sure water supply shut-off

valves are easily accessible.

IMPORTANT: Water pressure MUST be within the range of

values indicated in Specifications.

Two inlet hoses are provided with the machine. Hot water hose has

red stripe running the length of the hose. Insert washer/filter (Fig. 5A)

before connecting water inlet hose to valve. Check that other end of the

hose is tight

Connect to faucet (Fig. 5A). Connect to machine (Fig. 5B).

NOTE: connect fill hoses, plastic end to machine AND metal end

to the water faucet.

IMPORTANT: Do not over-tighten.

Excessive force can damage the

couplings. Tighten by hand; use a

tool only in case of a leak.

Turn on water supply (Fig 5C).

Flush out water lines before connecting the hoses to machine.

4

Fig. 1B

Loading...

Loading...