Makita XSL03, XSL04, XSL06 Instruction Manual

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

Cordless Slide Compound

Miter Saw

Sierra de Inglete Inalámbrica

XSL03

XSL04

XSL06

IMPORTANT: Read Before Using.

IMPORTANTE: Lea antes de usar.

2 ENGLISH

ENGLISH (Original instructions)

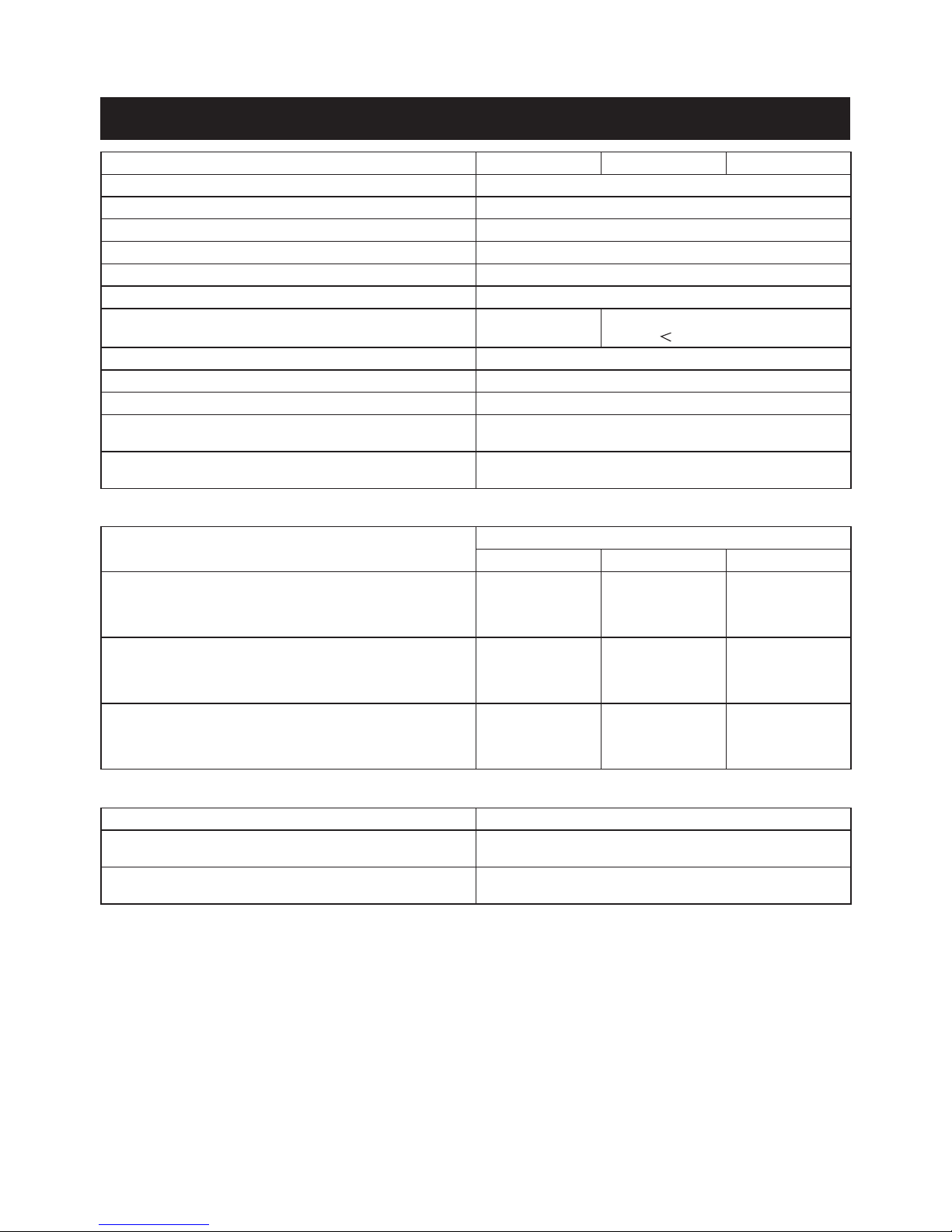

SPECIFICATIONS

Model: XSL03 XSL04 XSL06

Blade diameter 255 mm (10″)

Hole diameter 15.88 mm (5/8″)

Max. kerf thickness of the saw blade 3.2 mm (1/8″)

Max. miter angle Right 60°, Left 60°

Max. bevel angle Right 48°, Left 48°

No load speed (RPM) 4,400 /min

Laser type - Wavelength 655 nm, Maximum output

1mW (Laser Class II)

Rated voltage D.C. 36 V

Battery cartridge

BL1815N, BL1820B, BL1830, BL1830B, BL1840B, BL1850B, BL1860B

Charger DC18RC, DC18RD, DC18RE, DC18SD, DC18SE, DC18SF

Dimensions (L x W x H) 805 mm x 644 mm x 660 mm

(31-3/4" x 25-3/8" x 26")

Net weight 26.6 - 27.3 kg

(58.6 - 60.2 lbs)

Cutting capacities (H x W)

Miter angle Bevel angle

45° (left) 0° 45° (right)

0° 47 mm x 305 mm

(1-7/8″ x 12″)

61 mm x 279 mm

(2-3/8″ x 11″)

71 mm x 305 mm

(2-13/16″ x 12″)

91 mm x 279 mm

(3-5/8″ x 11″)

29 mm x 305 mm

(1-1/8″ x 12″)

43 mm x 279 mm

(1-11/16″ x 11″)

45° (right and left) 47 mm x 215 mm

(1-7/8″ x 8-1/2″)

61 mm x 197 mm

(2-3/8″ x 7-3/4″)

71 mm x 215 mm

(2-13/16″ x 8-1/2″)

91 mm x 197 mm

(3-5/8″ x 7-3/4″)

29 mm x 215 mm

(1-1/8″ x 8-1/2″)

43 mm x 197 mm

(1-11/16″ x 7-3/4″)

60° (right and left) - 71 mm x 152 mm

(2-13/16″ x 6″)

91 mm x 139 mm

(3-5/8″ x 5-1/2″)

-

Cutting capacities for special cuttings

Type of cutting Cutting capacity

Crown molding 45° type

(with crown molding stopper used)

168 mm

(6-5/8″)

Base board

(with horizontal vise used)

133 mm

(5-1/4″)

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications and battery cartridge may differ from country to country.

• The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heaviest combination, according to EPTA-Procedure 01/2014, are shown in the table.

3 ENGLISH

SAFETY WARNINGS

For your own safety, read instruction manual before operating tool.

Save it for future reference.

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listed below may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or BATTERYoperated (cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

1. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

2. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

3. Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase

the risk of electric shock.

4. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

6. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electric shock.

7. Power tools can produce electromagnetic

elds (EMF) that are not harmful to the user.

However, users of pacemakers and other similar

medical devices should contact the maker of their

device and/or doctor for advice before operating

this power tool.

Personal Safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

2. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

3. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or BATTERY pack, picking up or carrying the tool. Carrying power tools

with your nger on the switch or energising power

tools that have the switch on invites accidents.

4. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

5. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

7. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

8.

Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

9. Always wear protective goggles to protect

your eyes from injury when using power tools.

The goggles must comply with ANSI Z87.1 in

the USA.

It is an employer's responsibility to enforce

the use of appropriate safety protective equipments by the tool operators and by other persons in the immediate working area.

Power tool use and care

1. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

2. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

3.

Disconnect the plug from the power source and/

or remove the BATTERY pack, if detachable,

from the power tool before making any adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the

risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

4 ENGLISH

5. Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

6. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

8. Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unexpected

situations.

9. When using the tool, do not wear cloth work

gloves which may be entangled. The entangle-

ment of cloth work gloves in the moving parts may

result in personal injury.

BATTERY tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of BATTERY pack may create a risk of

re when used with another BATTERY pack.

2. Use power tools only with specically des-

ignated BATTERY packs. Use of any other

BATTERY packs may create a risk of injury and

re.

3. When BATTERY pack is not in use, keep it

away from other metal objects, like paper

clips, coins, keys, nails, screws or other small

metal objects, that can make a connection

from one terminal to another. Shorting the

BATTERY terminals together may cause burns or

a re.

4. Under abusive conditions, liquid may be

ejected from the BATTERY; avoid contact. If

contact accidentally occurs, ush with water.

If liquid contacts eyes, additionally seek medical help. Liquid ejected from the BATTERY may

cause irritation or burns.

5. Do not use a BATTERY pack or tool that is

damaged or modied. Damaged or modied

batteries may exhibit unpredictable behaviour

resulting in re, EXPLOSION or risk of injury.

6. Do not expose a BATTERY pack or tool to re

or excessive temperature. Exposure to re or

temperature above 130 °C may cause explosion.

7. Follow all charging instructions and do not

charge the BATTERY pack or tool outside the

temperature range specied in the instructions. Charging improperly or at temperatures

outside the specied range may damage the

BATTERY and increase the risk of re.

Service

1. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2. Never service damaged BATTERY packs.

Service of BATTERY packs should only be performed by the manufacturer or authorized service

providers.

3. Follow instruction for lubricating and chang-

ing accessories.

Safety instructions for mitre saws

1. Mitre saws are intended to cut wood or woodlike products, they cannot be used with abrasive cut-off wheels for cutting ferrous material

such as bars, rods, studs, etc. Abrasive dust

causes moving parts such as the lower guard to

jam. Sparks from abrasive cutting will burn the

lower guard, the kerf insert and other plastic parts.

2.

Use clamps to support the workpiece whenever

possible. If supporting the workpiece by hand,

you must always keep your hand at least 100

mm from either side of the saw blade. Do not

use this saw to cut pieces that are too small to

be securely clamped or held by hand. If your

hand is placed too close to the saw blade, there is

an increased risk of injury from blade contact.

3. The workpiece must be stationary and

clamped or held against both the fence and the

table. Do not feed the workpiece into the blade

or cut "freehand" in any way. Unrestrained

or moving workpieces could be thrown at high

speeds, causing injury.

4. Push the saw through the workpiece. Do not

pull the saw through the workpiece. To make

a cut, raise the saw head and pull it out over

the workpiece without cutting, start the motor,

press the saw head down and push the saw

through the workpiece. Cutting on the pull stroke

is likely to cause the saw blade to climb on top

of the workpiece and violently throw the blade

assembly towards the operator.

5.

Never cross your hand over the intended line of

cutting either in front or behind the saw blade.

Supporting the workpiece "cross handed" i.e. holding

the workpiece to the right of the saw blade with your

left hand or vice versa is very dangerous.

5 ENGLISH

6. Do not reach behind the fence with either hand

closer than 100 mm from either side of the saw

blade, to remove wood scraps, or for any other

reason while the blade is spinning. The proxim-

ity of the spinning saw blade to your hand may not

be obvious and you may be seriously injured.

7. Inspect your workpiece before cutting. If the

workpiece is bowed or warped, clamp it with

the outside bowed face toward the fence.

Always make certain that there is no gap

between the workpiece, fence and table along

the line of the cut. Bent or warped workpieces

can twist or shift and may cause binding on the

spinning saw blade while cutting. There should be

no nails or foreign objects in the workpiece.

8. Do not use the saw until the table is clear of all

tools, wood scraps, etc., except for the workpiece. Small debris or loose pieces of wood or

other objects that contact the revolving blade can

be thrown with high speed.

9. Cut only one workpiece at a time. Stacked multi-

ple workpieces cannot be adequately clamped or

braced and may bind on the blade or shift during

cutting.

10. Ensure the mitre saw is mounted or placed on

a level, rm work surface before use. A level

and rm work surface reduces the risk of the mitre

saw becoming unstable.

11. Plan your work. Every time you change the

bevel or mitre angle setting, make sure the

adjustable fence is set correctly to support the

workpiece and will not interfere with the blade

or the guarding system. Without turning the tool

"ON" and with no workpiece on the table, move

the saw blade through a complete simulated cut to

assure there will be no interference or danger of

cutting the fence.

12. Provide adequate support such as table exten-

sions, saw horses, etc. for a workpiece that is

wider or longer than the table top. Workpieces

longer or wider than the mitre saw table can tip

if not securely supported. If the cut-off piece or

workpiece tips, it can lift the lower guard or be

thrown by the spinning blade.

13. Do not use another person as a substitute for

a table extension or as additional support.

Unstable support for the workpiece can cause the

blade to bind or the workpiece to shift during the

cutting operation pulling you and the helper into

the spinning blade.

14. The cut-off piece must not be jammed or

pressed by any means against the spinning

saw blade. If conned, i.e. using length stops, the

cut-off piece could get wedged against the blade

and thrown violently.

15. Always use a clamp or a xture designed to

properly support round material such as rods

or tubing. Rods have a tendency to roll while

being cut, causing the blade to "bite" and pull the

work with your hand into the blade.

16. Let the blade reach full speed before contact-

ing the workpiece. This will reduce the risk of the

workpiece being thrown.

17. If the workpiece or blade becomes jammed,

turn the mitre saw off. Wait for all moving

parts to stop and disconnect the plug from

the power source and/or remove the battery

pack. Then work to free the jammed material.

Continued sawing with a jammed workpiece could

cause loss of control or damage to the mitre saw.

18. After nishing the cut, release the switch,

hold the saw head down and wait for the blade

to stop before removing the cut-off piece.

Reaching with your hand near the coasting blade

is dangerous.

19. Hold the handle rmly when making an incom-

plete cut or when releasing the switch before

the saw head is completely in the down position. The braking action of the saw may cause

the saw head to be suddenly pulled downward,

causing a risk of injury.

20. Only use the saw blade with the diameter that

is marked on the tool or specied in the manual. Use of an incorrectly sized blade may affect

the proper guarding of the blade or guard opera-

tion which could result in serious personal injury.

21. Only use the saw blades that are marked with

a speed equal or higher than the speed marked

on the tool.

22. Always select the correct saw blade for the

material to be cut. Do not use the saw blade to

cut materials other than those specied.

23. Do not use the saw to cut other than wood,

aluminum or similar materials.

Additional instructions

1. Make workshop kid proof with padlocks.

2. Never stand on the tool. Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

3. Never leave the tool running unattended. Turn

the power off. Do not leave tool until it comes

to a complete stop.

4. Do not operate saw without guards in place.

Check blade guard for proper closing before

each use. Do not operate saw if blade guard

does not move freely and close instantly.

Never clamp or tie the blade guard into the

open position.

5. Keep hands out of path of saw blade. Avoid

contact with any coasting blade. It can still

cause severe injury.

6. To reduce the risk of injury, return carriage

to the full rear position after each crosscut

operation.

7. Always secure all moving portions before

carrying the tool.

8. Stopper pin which locks the cutter head down

is for carrying and storage purposes only and

not for any cutting operations.

9. Check the blade carefully for cracks or damage before operation. Replace cracked or damaged blade immediately. Gum and wood pitch

hardened on blades slows saw and increases

potential for kickback. Keep blade clean by

rst removing it from tool, then cleaning it with

gum and pitch remover, hot water or kerosene.

Never use gasoline to clean blade.

6 ENGLISH

10. While making a slide cut, KICKBACK can

occur. KICKBACK occurs when the blade

binds in the workpiece during a cutting operation and the saw blade is driven rapidly

towards the operator. Loss of control and serious personal injury can result. If blade begins

to bind during a cutting operation, do not continue to cut and release switch immediately.

11. Use only anges specied for this tool.

12.

Be careful not to damage the arbor, anges

(especially the installing surface) or bolt. Damage

to these parts could result in blade breakage.

13. Make sure that the turn base is properly

secured so it will not move during operation.

Use the holes in the base to fasten the saw to a

stable work platform or bench. NEVER use tool

where operator positioning would be awkward.

14. Make sure the shaft lock is released before the

switch is turned on.

15. Be sure that the blade does not contact the

turn base in the lowest position.

16. Hold the handle rmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

17. Make sure the blade is not contacting the

workpiece before the switch is turned on.

18. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced blade.

19. Stop operation immediately if you notice anything abnormal.

20. Do not attempt to lock the trigger in the "ON"

position.

21. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive wheels may cause an injury.

22. Some material contains chemicals which may

be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier

safety data.

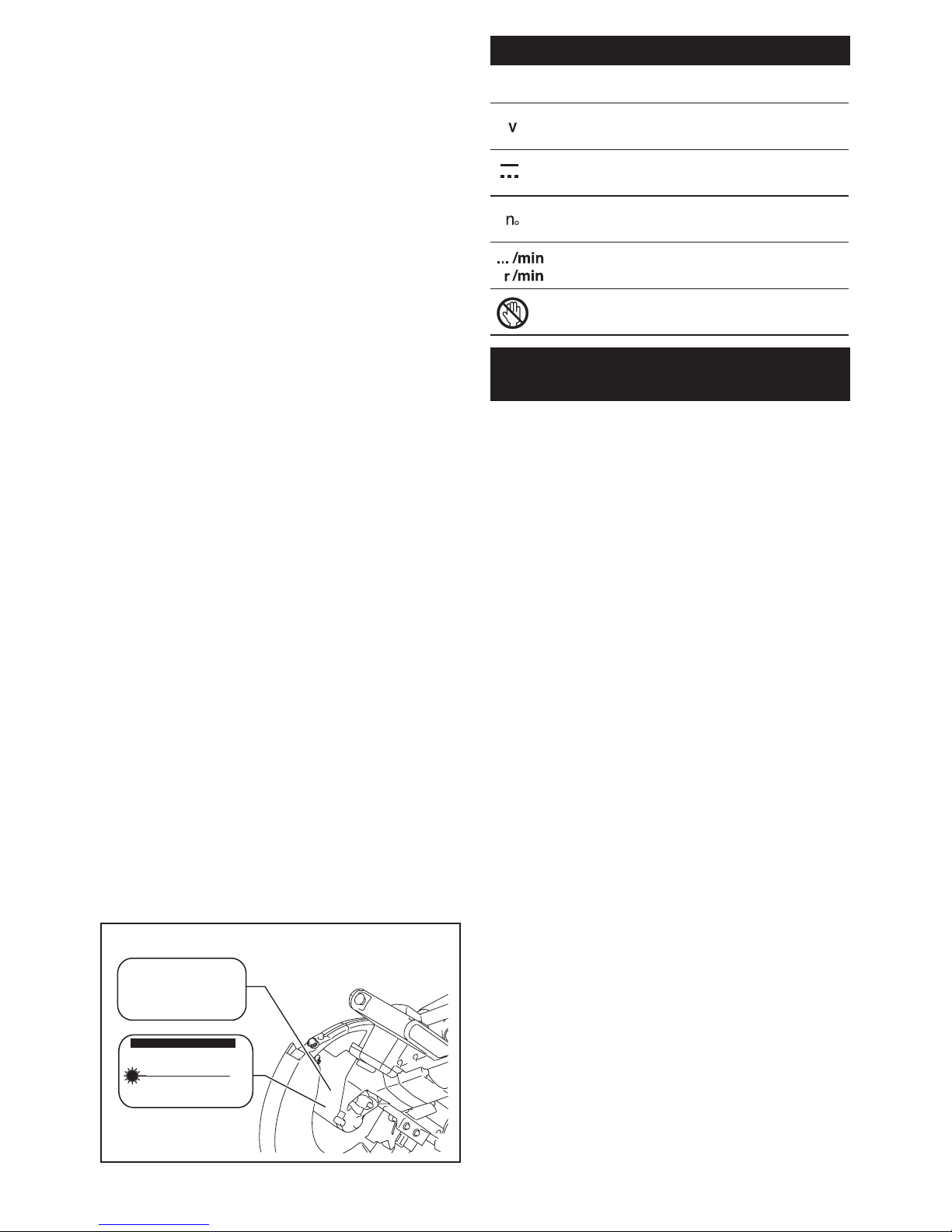

Additional safety rules for the laser

1.

LASER RADIATION DO NOT STARE INTO BEAM.

2. AVOID EXPOSURE - LASER RADIATION IS

EMITTED FROM APERTURE.

3.

USE OF CONTROLS OR ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES OTHER

THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

Complies with 21CFR

1040.10 and 1040.11

AVOID EXPOSURE-Laser

radiation is emitted from

LASER RADIATION

this aperture

DO NOT STARE INTO BEAM

Maximum Output

<1mW,Wavelength:655nm

CLASS II LASER PRODUCT

CAUTION

Symbols

The followings show the symbols used for tool.

volts

direct current

no load speed

revolutions or reciprocation per minute

Do not place hand or ngers close to the

blade.

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical attention right away. It may result in loss of your

eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consulting an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

7 ENGLISH

11. Follow your local regulations relating to disposal of battery.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery

service life.

3. Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let

a hot battery cartridge cool down before

charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

Important safety instructions for

wireless unit

1. Do not disassemble or tamper with the wireless unit.

2. Keep the wireless unit away from young children. If accidentally swallowed, seek medical

attention immediately.

3. Use the wireless unit only with Makita tools.

4. Do not expose the wireless unit to rain or wet

conditions.

5. Do not use the wireless unit in places where

the temperature exceeds 50°C (122°F).

6. Do not operate the wireless unit in places

where medical instruments, such as heart

pace makers are near by.

7. Do not operate the wireless unit in places

where automated devices are near by. If oper-

ated, automated devices may develop malfunction

or error.

8. The wireless unit can produce electromagnetic

elds (EMF) but they are not harmful to the

user.

9. The wireless unit is an accurate instrument. Be

careful not to drop or strike the wireless unit.

10. Avoid touching the terminal of the wireless

unit with bare hands or metallic materials.

11. Always remove the battery on the tool when

installing the wireless unit.

12. When opening the lid of the slot, avoid the

place where dust and water may come into the

slot. Always keep the inlet of the slot clean.

13. Always insert the wireless unit in the correct

direction.

14. Do not press the wireless activation button

on the wireless unit too hard and/or press the

button with an object with a sharp edge.

15. Always close the lid of the slot when

operating.

16. Do not remove the wireless unit from the slot

while the power is being supplied to the tool.

Doing so may cause a malfunction of the wireless

unit.

17. Do not remove the sticker on the wireless unit.

18. Do not put any sticker on the wireless unit.

19. Do not leave the wireless unit in a place where

static electricity or electrical noise could be

generated.

20. Do not leave the wireless unit in a place subject to high heat, such as a car sitting in the

sun.

21. Do not leave the wireless unit in a dusty or

powdery place or in a place corrosive gas

could be generated.

22. Sudden change of the temperature may bedew

the wireless unit. Do not use the wireless unit

until the dew is completely dried.

23. When cleaning the wireless unit, gently wipe

with a dry soft cloth. Do not use benzine, thinner, conductive grease or the like.

24. When storing the wireless unit, keep it in the

supplied case or a static-free container.

25. Do not insert any devices other than Makita

wireless unit into the slot on the tool.

26. Do not use the tool with the lid of the slot damaged. Water, dust, and dirt come into the slot may

cause malfunction.

27. Do not pull and/or twist the lid of the slot more

than necessary. Restore the lid if it comes off

from the tool.

28. Replace the lid of the slot if it is lost or

damaged.

SAVE THESE INSTRUCTIONS.

8 ENGLISH

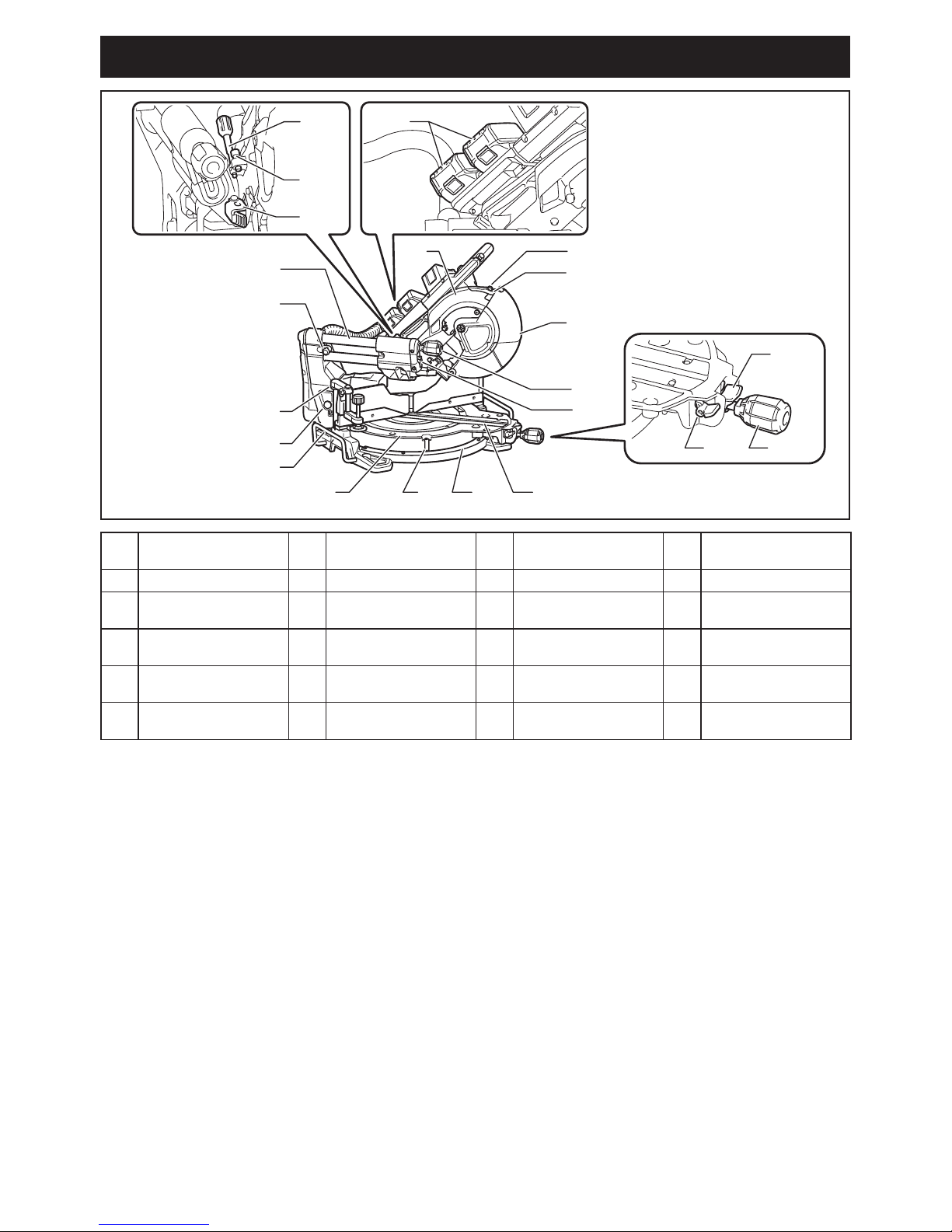

PARTS DESCRIPTION

10 11

12

14

15

3

2

4

5

879

13

6

1

16

17

18

20

21

22

19

1 Slide pole 2 Stopper pin

(for carriage sliding)

3 Vertical vise 4 Releasing button

(for right side bevel angle)

5 Holder 6 Turn base 7 Pointer (for miter angle) 8 Miter angle scale

9 Kerf board 10 Blade case 11 Adjusting screw

(for laser line)

12 Range adjustment screw

(for laser line)

13 Blade guard 14 Knob (for bevel angle) 15 Hex wrench 16 Adjusting screw

(for lower limit position)

17 Adjusting bolt (for maxi-

mum cutting capacity)

18 Stopper arm 19 Battery cartridge 20 Lock lever (for turn base)

21 Releasing lever

(for turn base)

22 Grip (for turn base) - - - -

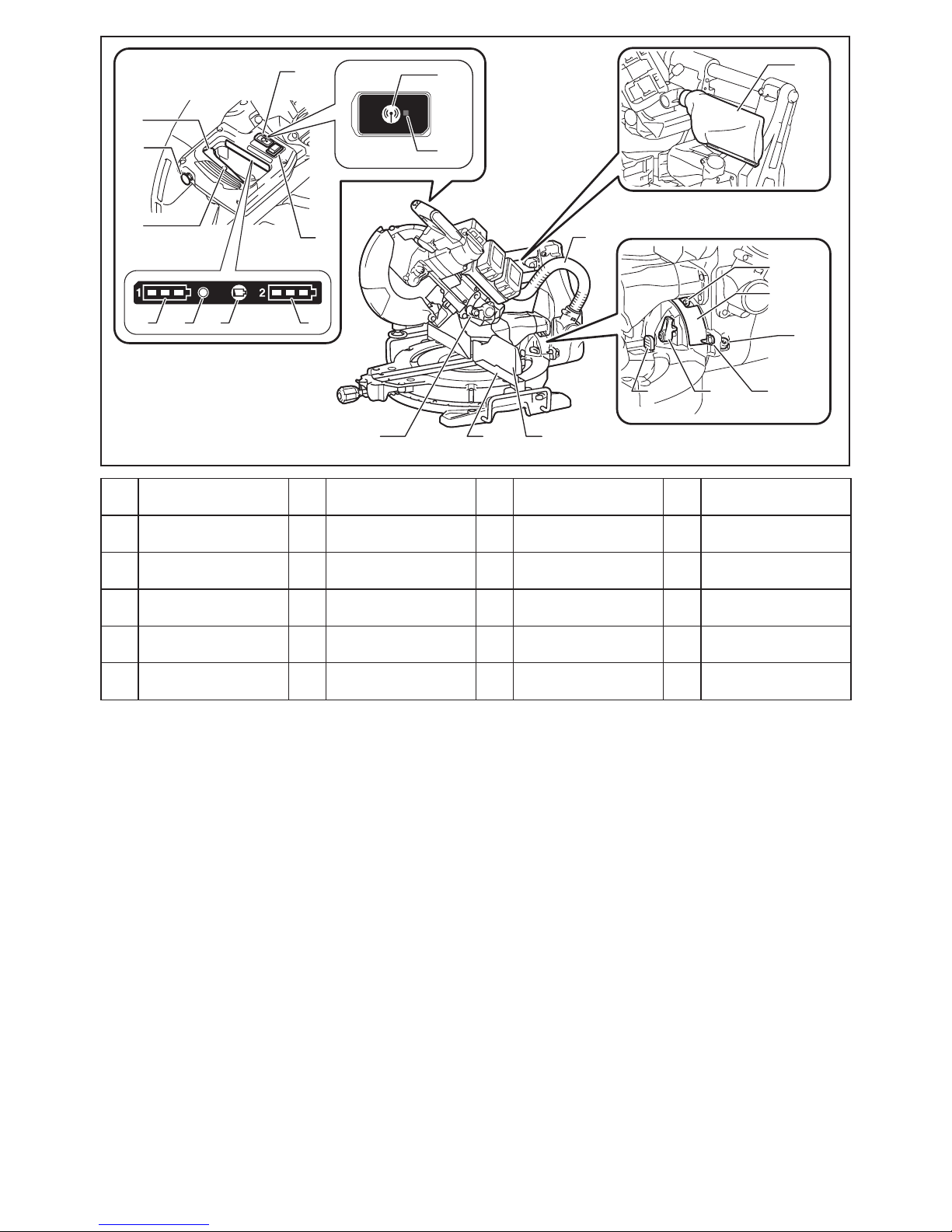

9 ENGLISH

16

17

201918

21

15

1

2

3

11

13 14

12

4

6

67 8

5

9

10

1 Switch trigger 2 Lock-off button 3 Hole for padlock 4 Lid (for wireless unit)

(For XSL04 only)

5 Switch (for laser line)

(For XSL04, XSL06 only)

6 Battery indicator 7 Mode indicator 8 Check button

9 Wireless activation

button

10 Wireless activation lamp 11 Hose

(for dust extraction)

12 Stopper pin

(for carriage elevation)

13 Guide fence

(lower fence)

14 Guide fence

(upper fence)

15 Dust bag 16 0° adjusting bolt

(for bevel angle)

17 Bevel angle scale 18 Releasing lever

(for 48° bevel angle)

19 Latch lever

(for bevel angle)

20 Pointer (for bevel angle)

21 45° adjusting bolt

(for bevel angle)

- - - - - -

10 ENGLISH

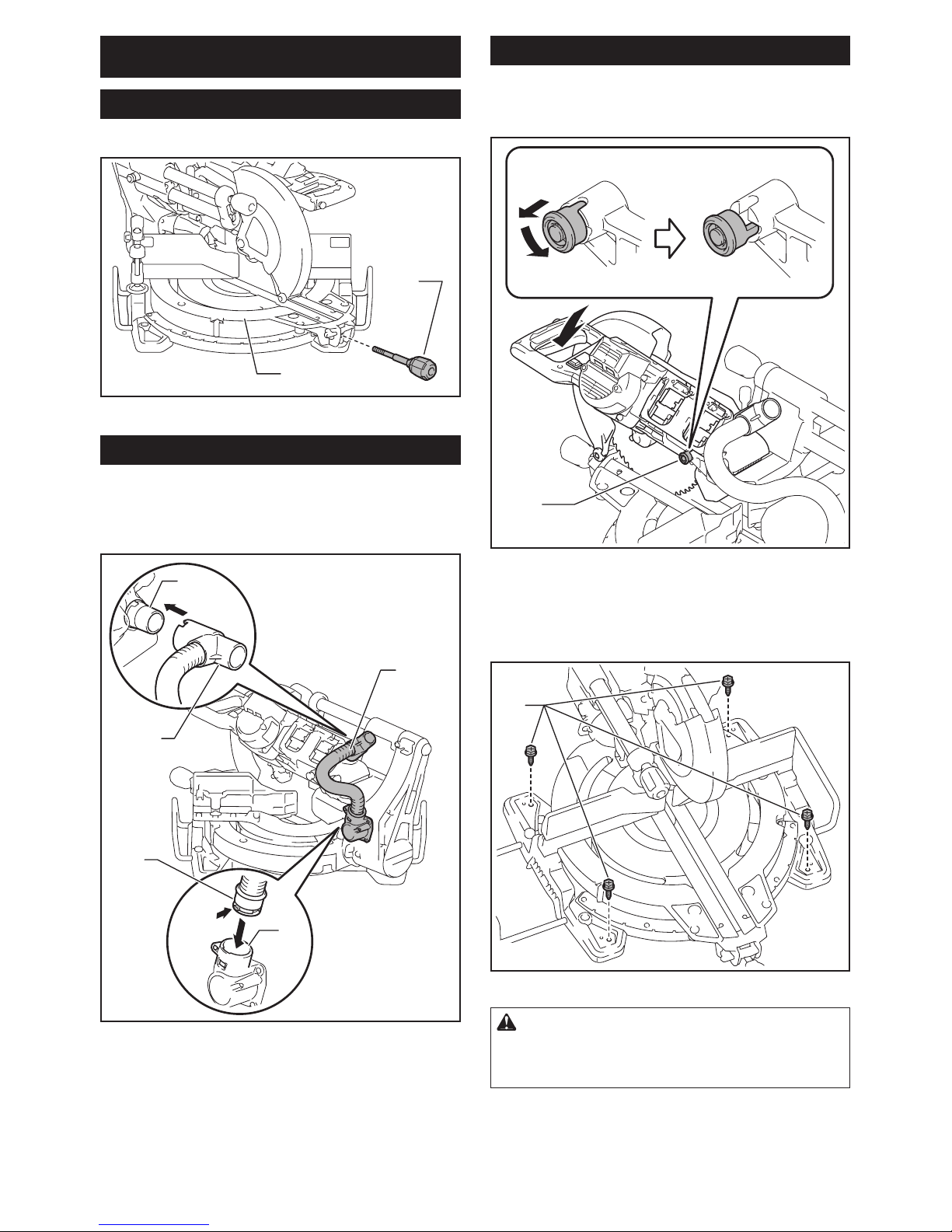

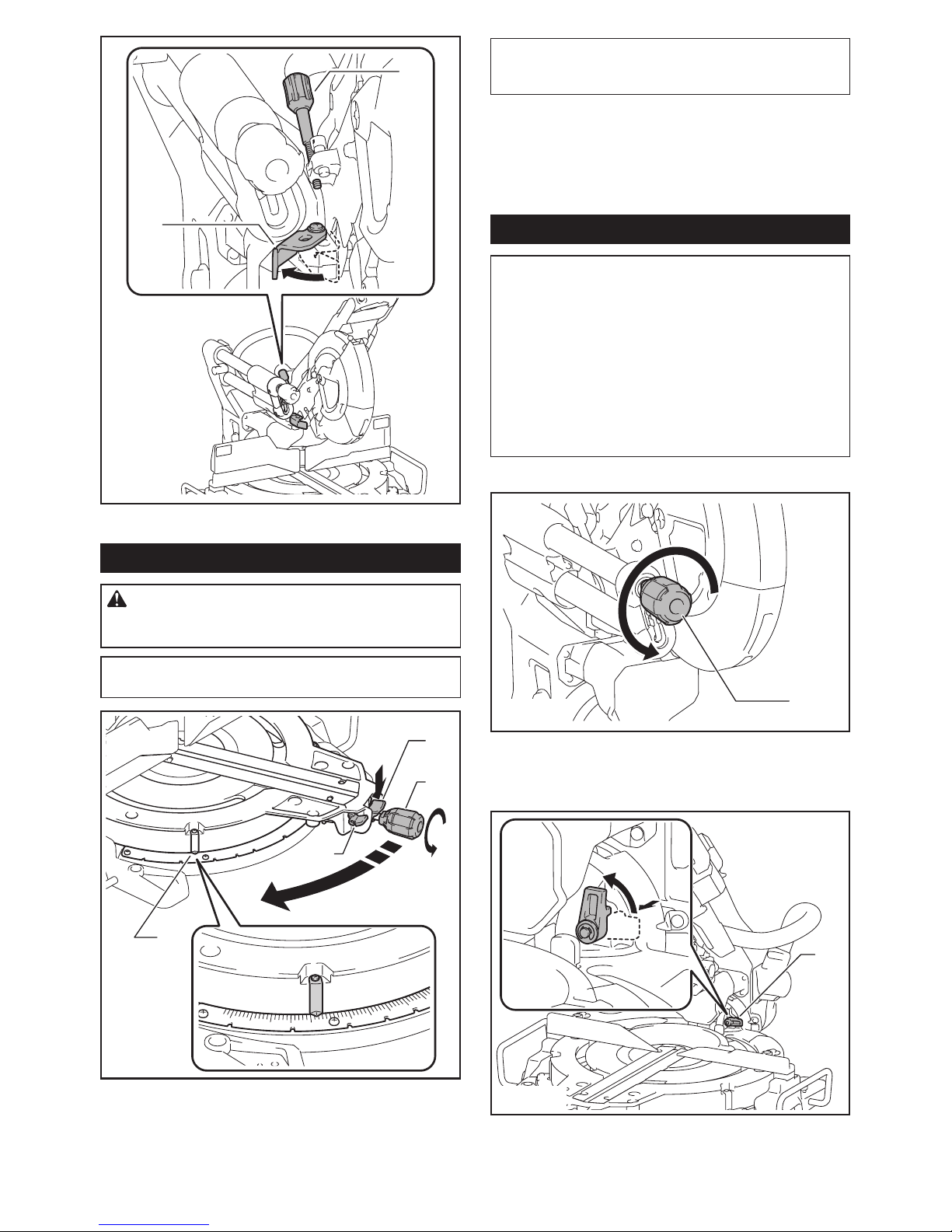

INSTALLATION

Installing the grip

Screw the threaded shaft of the grip into the turn base.

1

2

► 1. Grip 2. Turn base

Installing the dust extraction hose

Connect the dust extraction hose to the tool as

illustrated.

Make sure that the elbow and the sleeve t properly to

the ports of the tool.

1

2

4

4

3

► 1. Dust extraction hose 2. Elbow 3. Sleeve 4. Port

Bench mounting

When the tool is shipped, the handle is locked in the

lowered position by the stopper pin. While lowering the

handle slightly, pull the stopper pin and rotate it 90°.

21

3

► 1. Locked position 2. Unlocked position 3. Stopper

pin

This tool should be bolted with four bolts to a level and

stable surface using the bolt holes provided in the tool's

base. This will help prevent tipping and possible injury.

1

► 1. Bolt

WARNING: Ensure that the tool will not move

on the supporting surface. Movement of the miter

saw on the supporting surface while cutting may

result in loss of control and serious personal injury.

11 ENGLISH

FUNCTIONAL

DESCRIPTION

WARNING: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking the functions on

the tool. Failure to switch off and remove the battery

cartridge may result in serious personal injury from

accidental start-up.

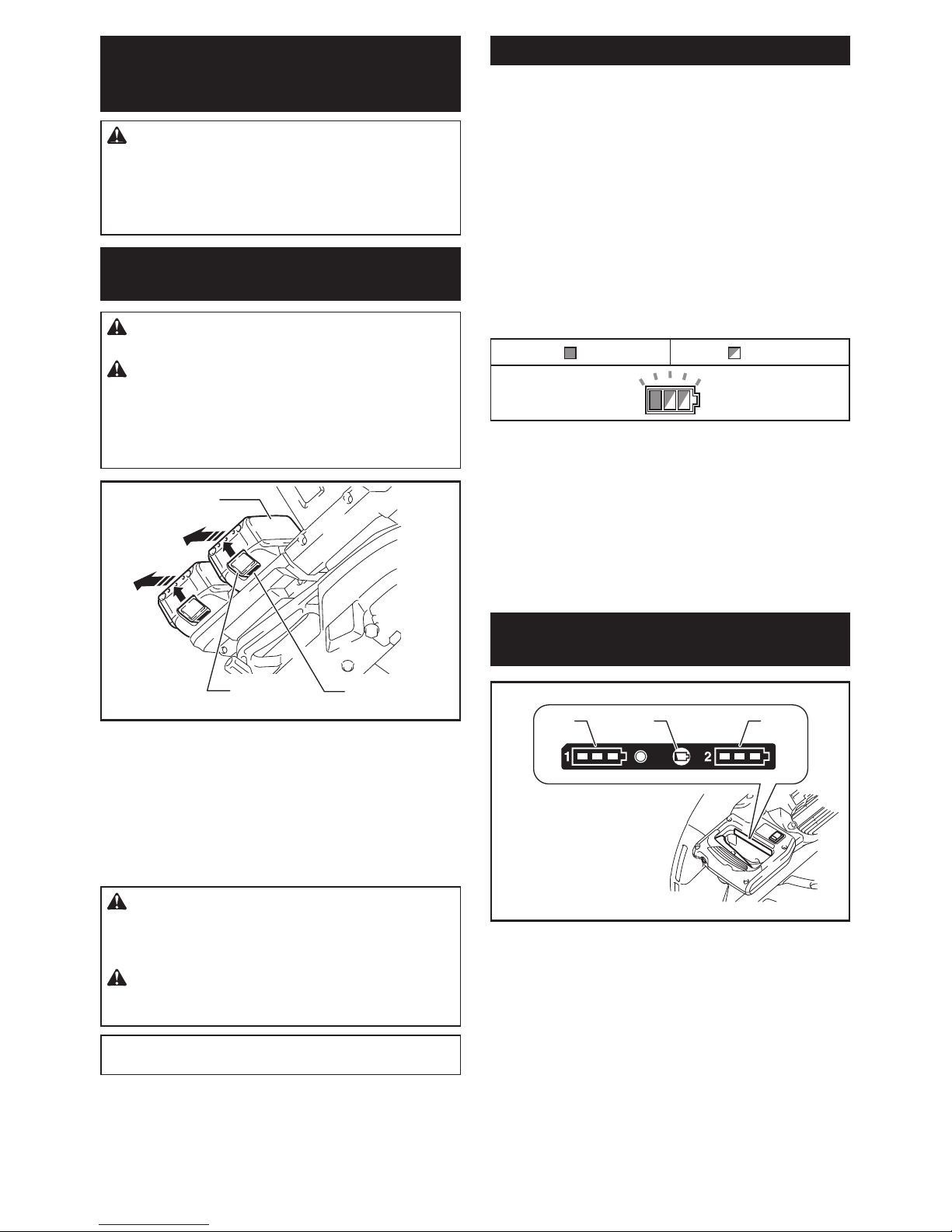

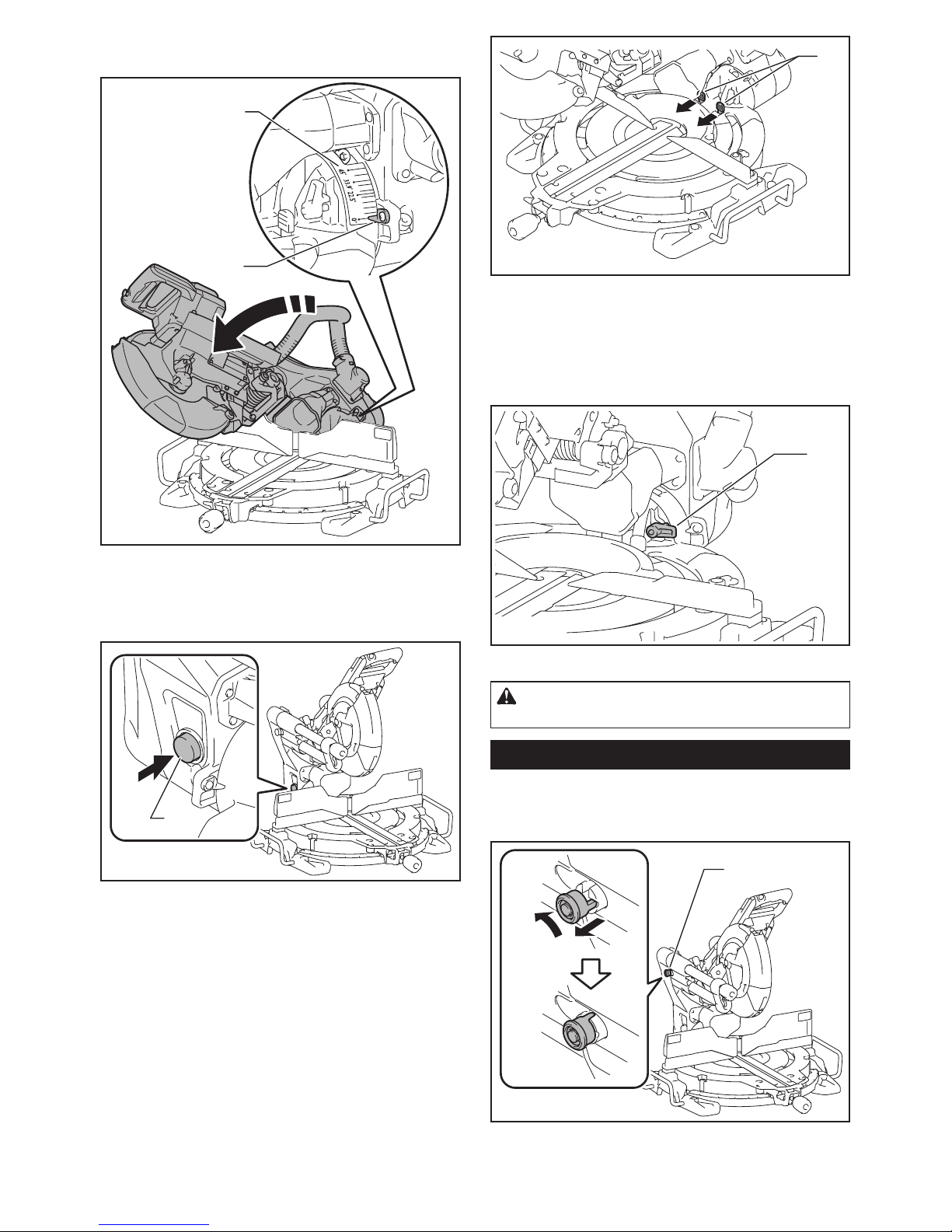

Installing or removing battery

cartridge

CAUTION: Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip off your hands

and result in damage to the tool and battery cartridge

and a personal injury.

1

2

3

► 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

NOTE: The tool does not work with only one battery

cartridge.

Tool / battery protection system

The tool is equipped with a tool/battery protection system. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will auto-

matically stop during operation if the tool or battery is

placed under one of the following conditions:

Overload protection

When the tool is operated in a manner that causes it to

draw an abnormally high current, the tool automatically

stops without any indication. In this situation, turn the

tool off and stop the application that caused the tool to

become overloaded. Then turn the tool on to restart.

Overheat protection

On Blinking

When the tool is overheated, the tool stops automatically, and the battery indicator blinks about 60 seconds.

In this situation, let the tool cool down before turning the

tool on again.

Overdischarge protection

When the battery capacity becomes low, the tool stops

automatically. If the product does not operate even

when the switches are operated, remove the batteries

from the tool and charge the batteries.

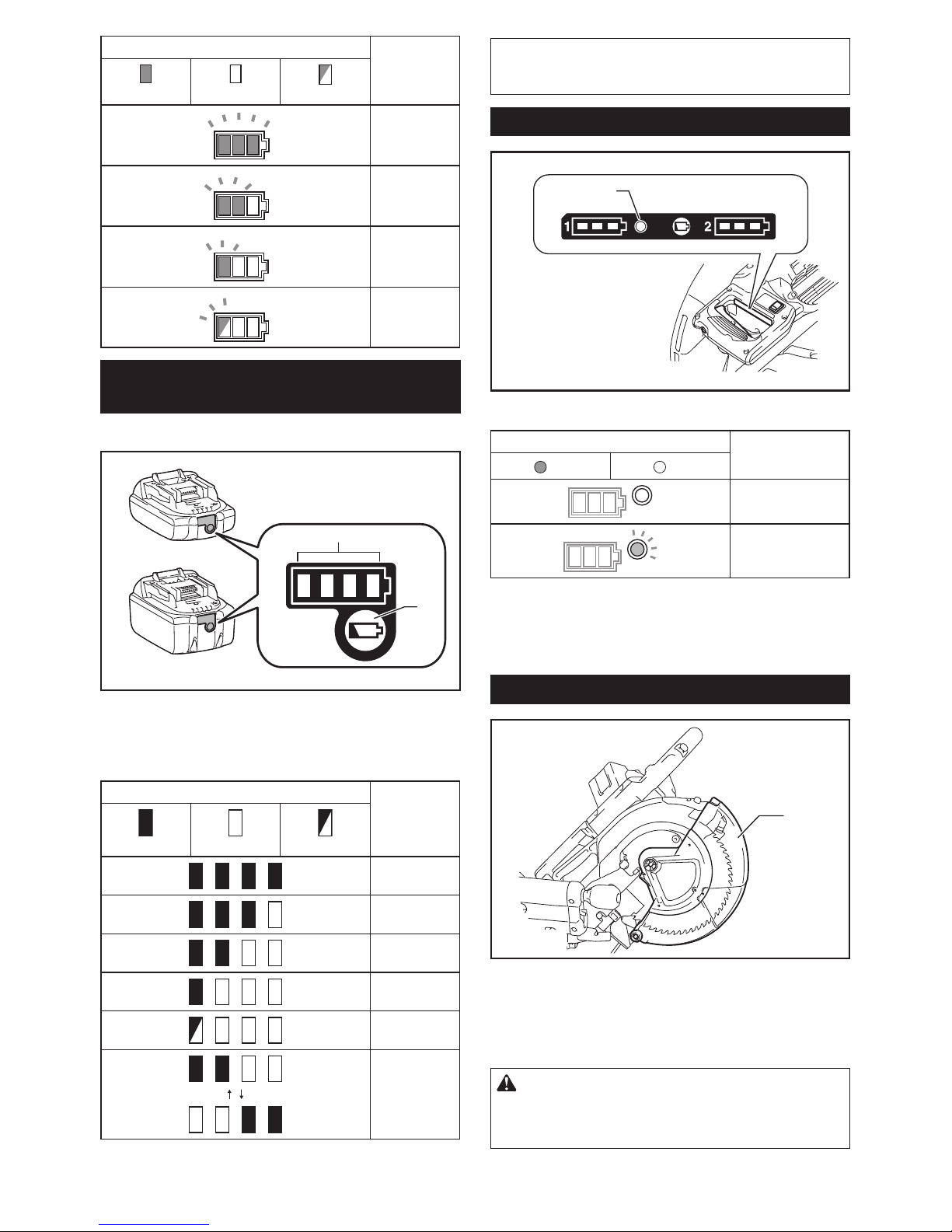

Indicating the remaining battery

capacity

21 1

► 1. Battery indicator 2. Check button

Press the check button to indicate the remaining battery

capacities. The battery indicators correspond to each

battery.

12 ENGLISH

Battery indicator status Remaining

battery

capacity

On

Off

Blinking

50% to 100%

20% to 50%

0% to 20%

Charge the

battery

Indicating the remaining battery

capacity

Only for battery cartridges with the indicator

1

2

► 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indi-

cate the remaining battery capacity. The indicator lamps

light up for a few seconds.

Indicator lamps Remaining

capacity

Lighted Off Blinking

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

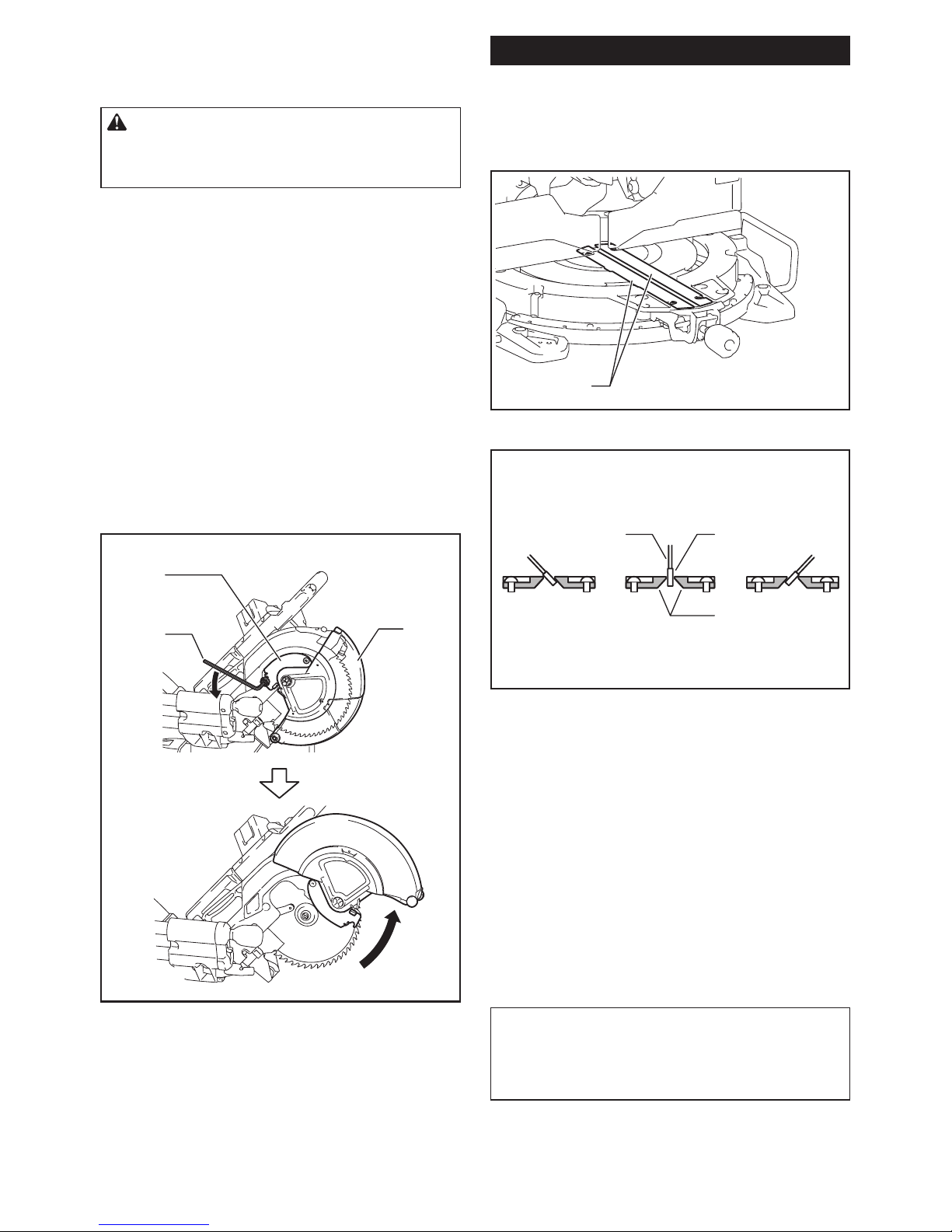

Automatic speed change function

1

► 1. Mode indicator

Mode indicator status Operation mode

On Off

High speed mode

High torque mode

This tool has "high speed mode" and "high torque

mode". It automatically changes operation mode

depending on the work load. When mode indicator

lights up during operation, the tool is in high torque

mode.

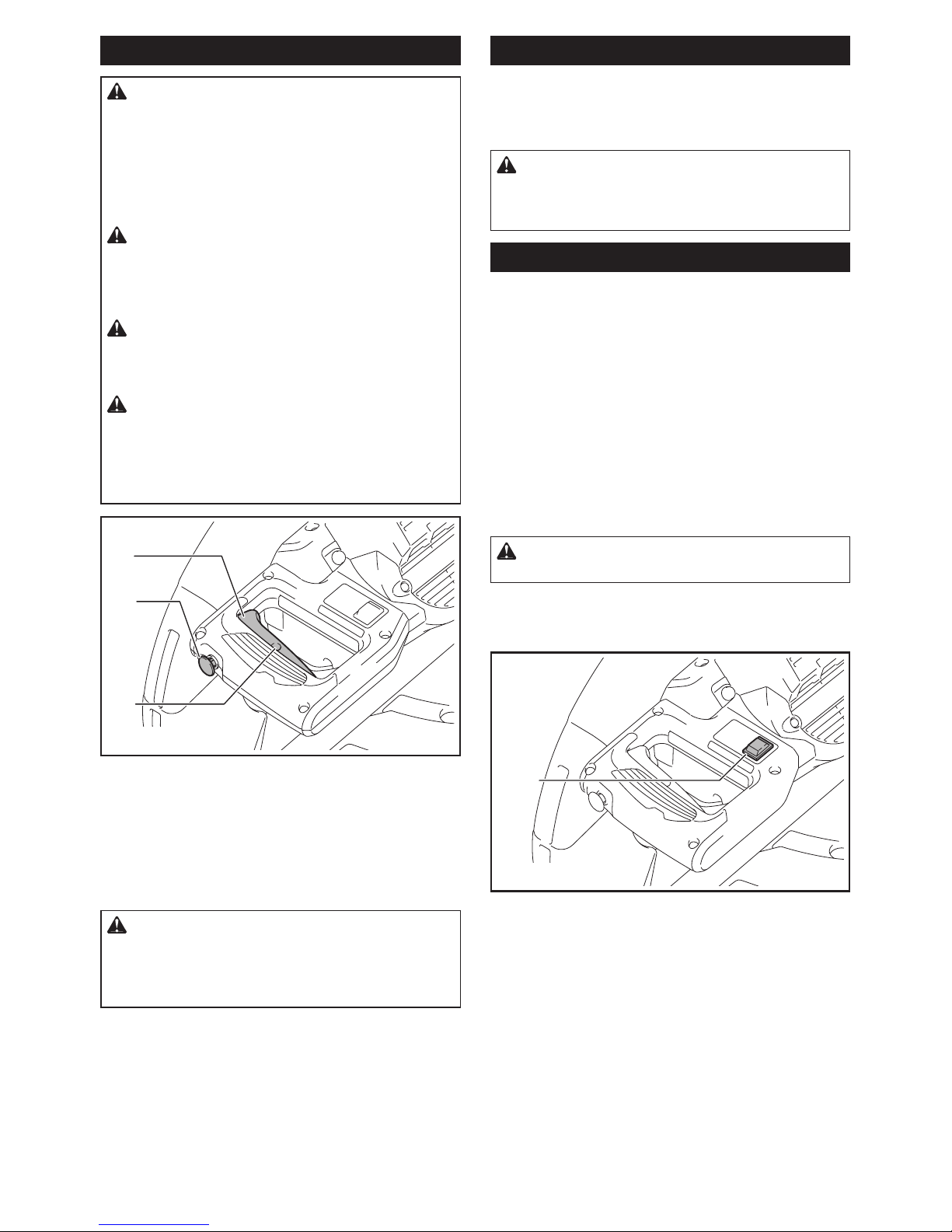

Blade guard

1

► 1. Blade guard

When lowering the handle, the blade guard rises auto-

matically. The guard is spring loaded so it returns to

its original position when the cut is completed and the

handle is raised.

WARNING: Never defeat or remove the blade

guard or the spring which attaches to the guard.

An exposed blade as a result of defeated guarding

may result in serious personal injury during operation.

13 ENGLISH

In the interest of your personal safety, always maintain

the blade guard in good condition. Any irregular operation of the blade guard should be corrected immediately.

Check to assure spring loaded return action of guard.

WARNING: Never use the tool if the blade

guard or spring are damaged, faulty or removed.

Operation of the tool with a damaged, faulty or

removed guard may result in serious personal injury.

If the see-through blade guard becomes dirty, or sawdust adheres to it in such a way that the blade and/or

workpiece is no longer easily visible, remove the batteries and clean the guard carefully with a damp cloth.

Do not use solvents or any petroleum-based cleaners

on the plastic guard because this may cause damage

to the guard.

If the blade guard is especially dirty and vision through

the guard is impaired, remove the batteries and use the

supplied wrench to loosen the hex bolt holding the center cover. Loosen the hex bolt by turning it counterclockwise and raise the blade guard and center cover. With

the blade guard so positioned, cleaning can be more

completely and efciently accomplished. When cleaning

is complete, reverse procedure above and secure bolt.

Do not remove spring holding blade guard. If guard

becomes discolored through age or UV light exposure,

contact a Makita service center for a new guard. DO

NOT DEFEAT OR REMOVE GUARD.

3

1

2

► 1. Center cover 2. Hex wrench 3. Blade guard

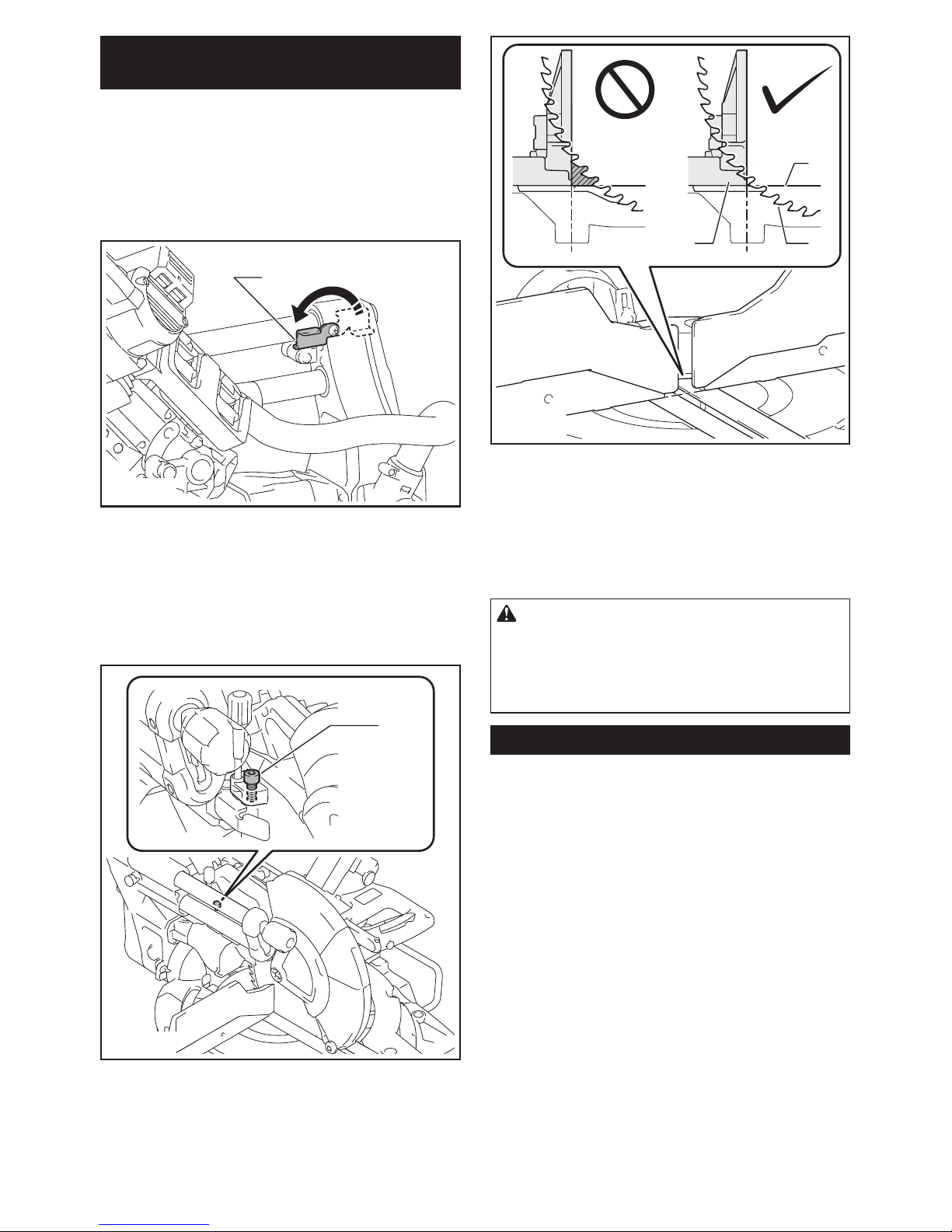

Kerf boards

This tool is provided with the kerf boards in the turn

base to minimize tearing on the exit side of a cut. The

kerf boards are factory adjusted so that the saw blade

does not contact the kerf boards. Before use, adjust the

kerf boards as follows:

1

► 1. Kerf board

1

23

4

6

5

► 1. Left bevel cut 2. Straight cut 3. Right bevel cut

4. Saw blade 5. Blade teeth 6. Kerf board

First, remove the batteries. Loosen all the screws (2

each on left and right) securing the kerf boards until the

kerf boards can still be easily moved by hand. Lower the

handle fully, then pull and turn the stopper pin to lock

the handle in the lowered position. Release the stopper

pin on the sliding pole and pull the carriage toward you

fully. Adjust the kerf boards so that the kerf boards just

contact the sides of the blade teeth. Tighten the front

screws (do not tighten rmly). Push the carriage toward

the guide fence fully and adjust the kerf boards so that

the kerf boards just contact the sides of blade teeth.

Tighten the rear screws (do not tighten rmly).

After adjusting the kerf boards, release the stopper

pin and raise the handle. Then tighten all the screws

securely.

NOTICE: After setting the bevel angle ensure

that the kerf boards are adjusted properly. Correct

adjustment of the kerf boards will help provide proper

support of the workpiece minimizing workpiece tear

out.

14 ENGLISH

Maintaining maximum cutting

capacity

This tool is factory adjusted to provide the maximum

cutting capacity for a 255 mm (10") saw blade.

When installing a new blade, always check the lower

limit position of the blade and if necessary, adjust it as

follows:

First, remove the batteries. Turn the stopper lever to

engaged position.

1

► 1. Stopper lever

Push the carriage toward the guide fence fully and

lower the handle completely.

Adjust the blade position by turning the adjusting bolt

with the hex wrench. The periphery of the blade should

extend slightly below the top surface of the turn base

and also comes to the point where the front face of the

guide fence meets the top surface of the turn base.

1

► 1. Adjusting bolt

1

23

► 1. Top surface of turn base 2. Periphery of blade

3. Guide fence

With the batteries removed, rotate the blade by hand

while holding the handle all the way down to be sure

that the blade does not contact any part of the lower

base. Re-adjust slightly, if necessary.

After adjustment, always return the stopper lever to the

original position.

WARNING: After installing a new blade and

with the batteries removed, always be sure that

the blade does not contact any part of the lower

base when the handle is lowered completely. If

a blade makes contact with the base it may cause

kickback and result in serious personal injury.

Stopper arm

The lower limit position of the blade can be easily

adjusted with the stopper arm. To adjust it, turn the

stopper arm in the direction of the arrow as shown in the

gure. Turn the adjusting screw so that the blade stops

at the desired position when lowering the handle fully.

15 ENGLISH

1

2

► 1. Stopper arm 2. Adjusting screw

Adjusting the miter angle

CAUTION: After changing the miter angle,

always secure the turn base by tightening the grip

rmly.

NOTICE: When turning the turn base, be sure to

raise the handle fully.

1

2

3

4

► 1. Lock lever 2. Grip 3. Releasing lever 4. Pointer

Rotate the grip counterclockwise to unlock the turn

base. Turn the grip while holding down the lock lever to

move the turn base. Align the pointer with your desired

angle on the scale then tighten the grip.

NOTE: If you depress the releasing lever, you can

move the turn base without holding down the lock

lever. Tighten the grip at your desired position.

This miter saw employs positive stop function. You can

set 0°, 15°, 22.5°, 31.6°, 45°, and 60° right/left miter

angle quickly. To use this function, move the turn base

close to your desired positive stop angle while holding

down the lock lever. Then release the lock lever and

move the turn base forward until the turn base is locked.

Adjusting the bevel angle

NOTICE: Always remove the upper guide fences

and vertical vise before adjusting the bevel angle.

NOTICE: When changing bevel angles, be sure

to position the kerf boards appropriately as

explained in the "Kerf boards" section.

NOTICE: When tilting the saw blade, be sure to

raise the handle fully.

NOTICE: Do not tighten the knob too hard. Doing

so may cause malfunction of the locking mechanism of the bevel angle.

1. Turn the knob on the slide pole counterclockwise.

1

► 1. Knob

2. Pull and turn the latch lever to the position as

illustrated.

1

► 1. Latch lever

16 ENGLISH

3. Match the pointer with your desired angle on the

scale by moving the carriage then tighten the knob.

1

2

► 1. Bevel angle scale 2. Pointer

To tilt the carriage to the right, tilt the carriage to the left

slightly and then tilt it to the right while pressing down

the releasing button.

1

► 1. Releasing button

If you perform a bevel cut greater than 45°, move the

carriage while sliding the releasing lever toward the

front of the tool. You can perform up to 48° bevel cut.

1

► 1. Releasing lever

This miter saw employs positive stop function. You can

set 22.5° and 33.9° angle to both right and left quickly.

Set the latch lever in the position as illustrated and tilt

the carriage. To change the angle, pull the latch lever

and tilt the carriage.

1

► 1. Latch lever

CAUTION: After changing the bevel angle,

always secure the knob.

Slide lock

To lock the sliding movement of the carriage, push the

carriage toward the guide fence until it stops. Pull the

stopper pin and rotate it 90°.

1

2

3

► 1. Unlocked position 2. Locked position 3. Stopper

pin

17 ENGLISH

Switch action

WARNING: Before installing the batteries

into the tool, always check to see that the switch

trigger actuates properly and returns to the "OFF"

position when released. Do not pull the switch

trigger hard without pressing in the lock-off button. This can cause switch breakage. Operating a

tool with a switch that does not actuate properly can

lead to loss of control and serious personal injury.

WARNING: NEVER use tool without a fully

operative switch trigger. Any tool with an inoper-

ative switch is HIGHLY DANGEROUS and must be

repaired before further usage or serious personal

injury may occur.

WARNING: NEVER defeat the lock-off button

by taping down or some other means. A switch with

a negated lock-off button may result in unintentional

operation and serious personal injury.

WARNING: NEVER use the tool if it runs when

you simply pull the switch trigger without pressing the lock-off button. A switch in need of repair

may result in unintentional operation and serious

personal injury. Return tool to a Makita service center

for proper repairs BEFORE further usage.

1

2

3

► 1. Switch trigger 2. Lock-off button 3. Hole for

padlock

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided. To start the tool,

press in the lock-off button and pull the switch trigger.

Release the switch trigger to stop.

A hole is provided in the switch trigger for insertion of a

padlock to lock the tool off.

WARNING: Do not use a lock with a shank or

cable any smaller than 6.35 mm (1/4") in diameter.

A smaller shank or cable may not properly lock the

tool in the off position and unintentional operation

may occur resulting in serious personal injury.

Electric brake

This tool is equipped with an electric blade brake. If the

tool consistently fails to quickly stop the blade after the

switch trigger is released, have the tool serviced at a

Makita service center.

CAUTION: The blade brake system is not a

substitute for the blade guard. Never use tool

without a functioning blade guard. An unguarded

blade may result in serious personal injury.

Electronic function

Constant speed control

The tool is provided with an electronic speed control

which helps maintain a constant blade rotation speed

even under load. A constant blade rotation speed will

result in a very smooth cut.

Soft start feature

This function allows the smooth start-up of the tool by

limiting the start-up torque.

Laser beam action

For XSL04, XSL06 only

CAUTION: Never look into the laser beam.

Direct laser beam may injure your eyes.

To turn on the laser beam, press the upper position (I)

of the switch. To turn off the laser beam, press the lower

position (0) of the switch.

1

► 1. Switch for laser

Laser line can be shifted to either the left or right side of

the saw blade by turning the adjusting screw as follows.

18 ENGLISH

1

► 1. Adjusting screw

1. Loosen the adjusting screw by turning it

counterclockwise.

2. With the adjusting screw loosened, slide the

adjusting screw to the right or left as far as it goes.

3. Tighten the adjusting screw rmly at the position

where it stops sliding.

NOTE: Laser line is factory adjusted so that it is

positioned within 1 mm (0.04") from the side surface

of the blade (cutting position).

NOTE: When laser line appears dim and hard to see

because of direct sunlight, relocate the work area to a

place where there is less direct sunlight.

Aligning the laser line

Align the cutting line on your workpiece with the laser

line.

A

B

A) When you want to obtain the correct size on the left

side of workpiece, shift the laser line to the left of the

blade.

B) When you want to obtain the correct size on the right

side of workpiece, shift the laser line to the right of the

blade.

NOTE: Use wood facing against the guide fence

when aligning the cutting line with the laser line at the

side of guide fence in compound cutting (bevel angle

45° and miter angle right 45°).

ASSEMBLY

WARNING: Always be sure that the tool is

switched off and the battery cartridge is removed

before working on the tool. Failure to switch off and

remove the battery cartridge may result in serious

personal injury.

Hex wrench storage

When not in use, store the hex wrench as shown in the

gure to keep it from being lost.

1

► 1. Hex wrench

Removing and installing saw blade

WARNING: Always be sure that the tool is

switched off and the battery cartridge is removed

before installing or removing the blade. Accidental

start up of the tool may result in serious personal

injury.

WARNING: Use only the Makita wrench pro-

vided to install or remove the blade. Failure to use

the wrench may result in overtightening or insufcient

tightening of the hex socket bolt and serious personal

injury.

Always lock the carriage with raised position when

removing and installing the blade. Pull the stopper pin

and rotate it 90° with the carriage raised.

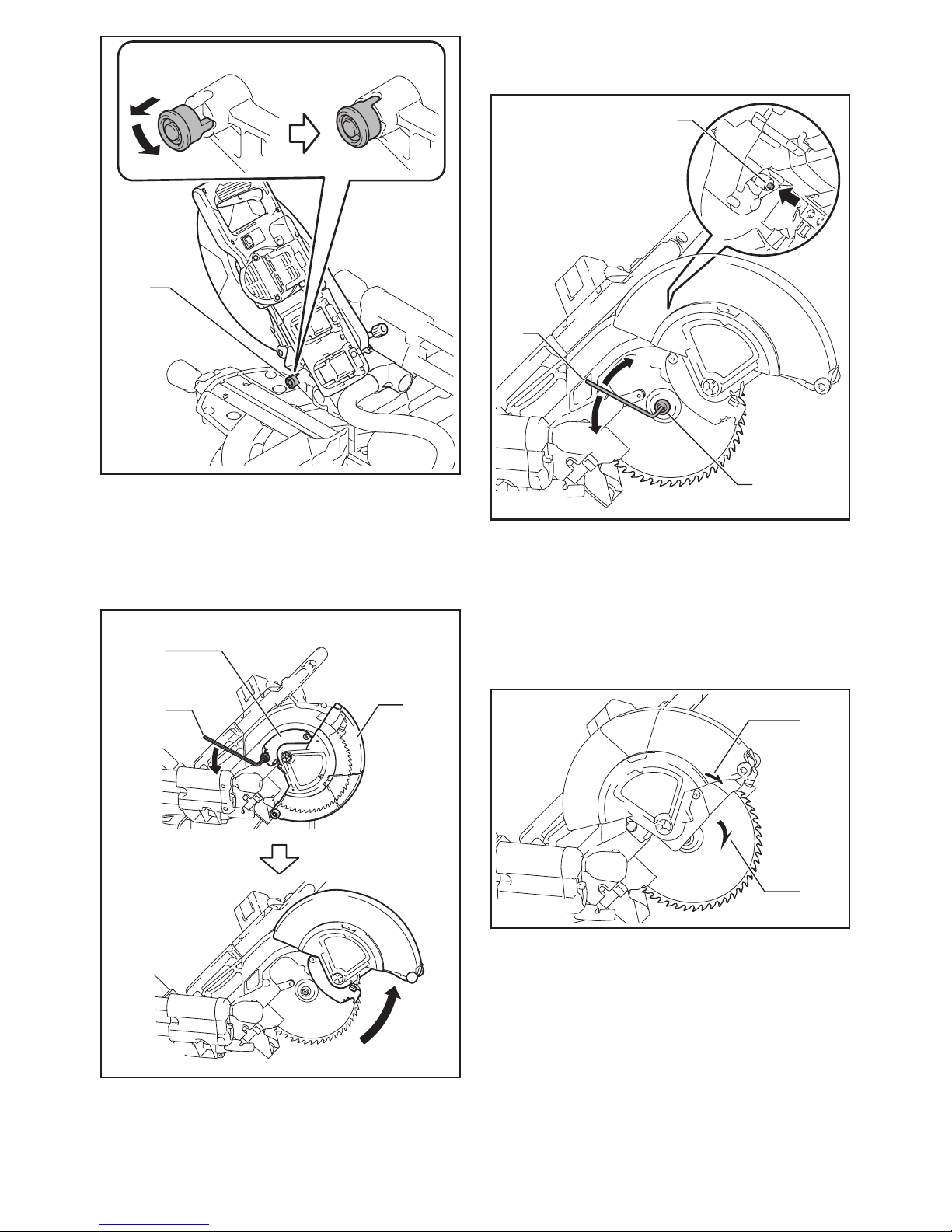

19 ENGLISH

21

3

► 1. Unlocked position 2. Locked position 3. Stopper

pin

Removing the blade

Loosen the hex bolt holding the center cover using the

hex wrench. Raise the blade guard and center cover.

3

1

2

► 1. Center cover 2. Hex wrench 3. Blade guard

Press the shaft lock to lock the spindle and use the hex

wrench to loosen the hex socket bolt. Then remove the

hex socket bolt, outer ange and blade.

1

2

5

3

4

► 1. Shaft lock 2. Hex wrench 3. Hex socket bolt (left-

handed) 4. Loosen 5. Tighten

Installing the blade

Mount the blade carefully onto the spindle, making

sure that the direction of the arrow on the surface of the

blade matches the direction of the arrow on the blade

case.

1

2

► 1. Arrow on the blade case 2. Arrow on the blade

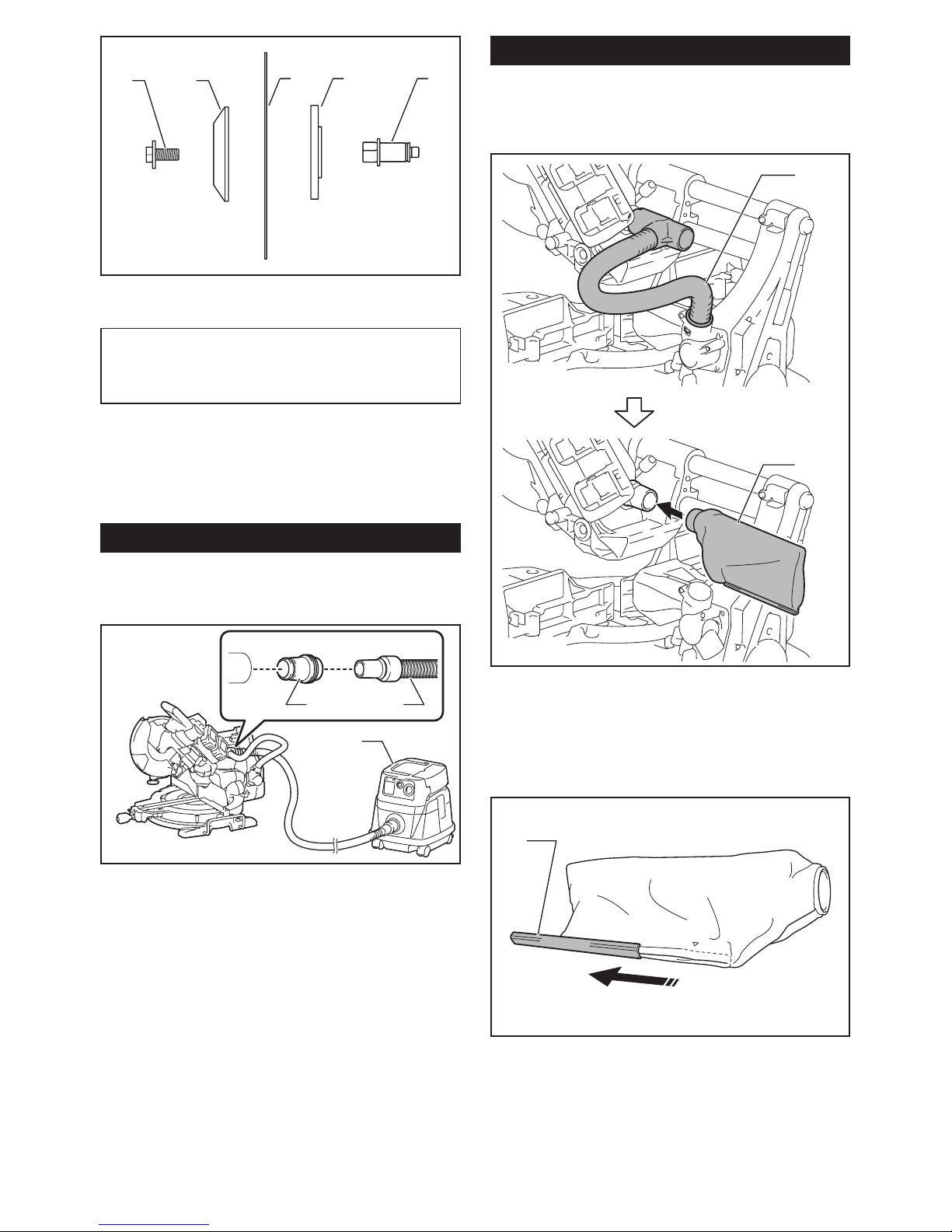

Install the outer ange and hex socket bolt. Tighten the

hex socket bolt counterclockwise using the hex wrench

while pressing the shaft lock.

20 ENGLISH

1 2

34 5

► 1. Hex socket bolt 2. Outer ange 3. Saw blade

4. Inner ange 5. Spindle

NOTICE: If the inner ange is removed, be sure to

install it on the spindle with its protrusion facing away

from the blade. If the ange is installed incorrectly, the

ange will rub against the machine.

Return the blade guard and center cover to its original

position. Then tighten the hex bolt clockwise to secure

the center cover. Unlock the stopper pin to release

carriage from the raised position. Lower the handle to

make sure that the blade guard moves properly. Make

sure shaft lock has released spindle before making cut.

Connecting a vacuum cleaner

When you wish to perform clean cutting operation, connect a Makita vacuum cleaner to the dust nozzle using

a front cuff 24 (optional accessory).

1 2

3

1 2

3

► 1. Front cuff 24 2. Hose 3. Vacuum cleaner

Dust bag

The use of the dust bag makes cutting operations clean

and dust collection easy. To attach the dust bag, remove

the dust extraction hose on the tool and connect the

dust bag.

1

2

► 1. Dust extraction hose 2. Dust bag

When the dust bag is about half full, remove the dust

bag from the tool and pull the fastener out. Empty

the dust bag of its contents, tapping it lightly so as to

remove particles adhering to the insides which might

hamper further collection.

1

► 1. Fastener

21 ENGLISH

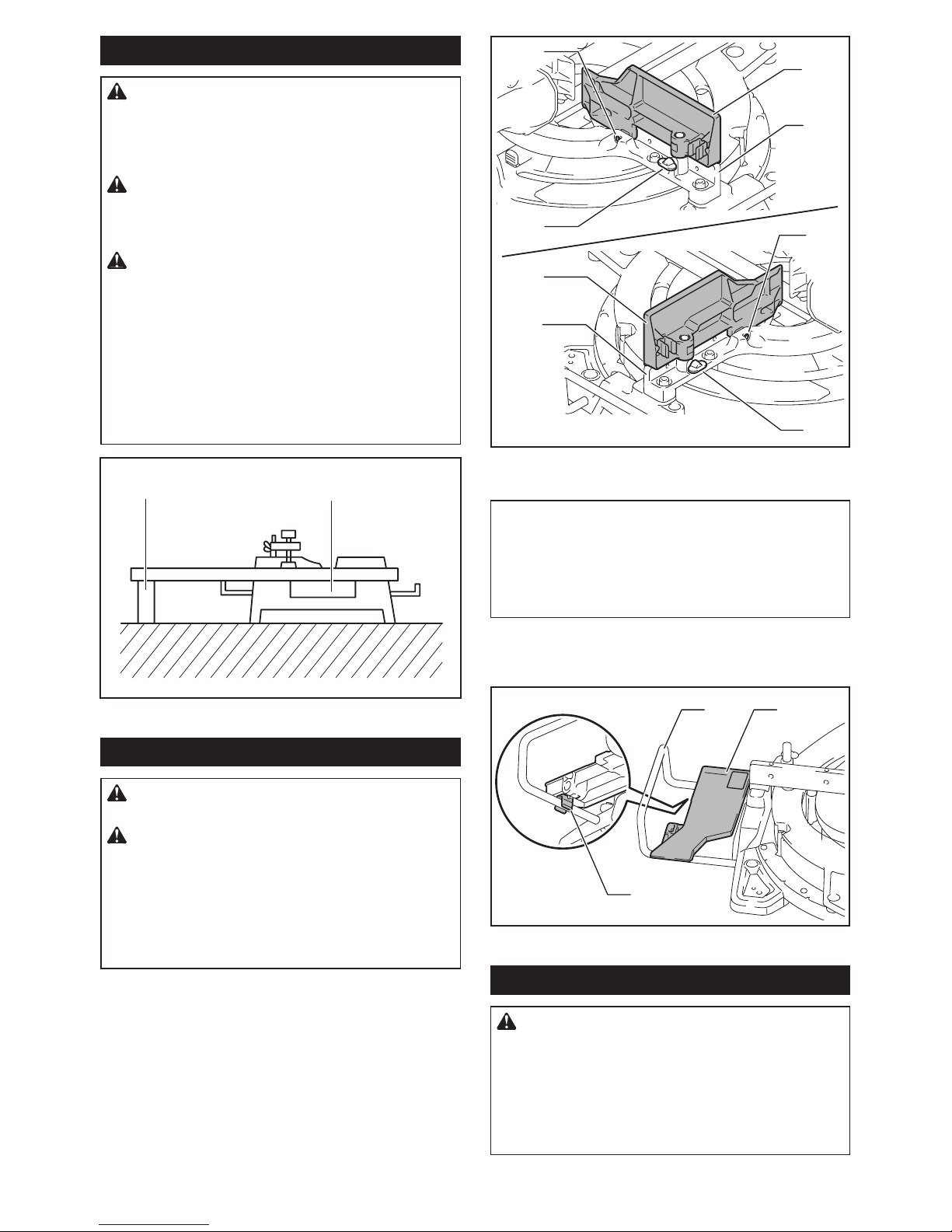

Securing workpiece

WARNING: It is extremely important to always

secure the workpiece correctly with the proper

type of vise or crown molding stoppers. Failure to

do so may result in serious personal injury and cause

damage to the tool and/or the workpiece.

WARNING: After a cutting operation do not

raise the blade until it has come to a complete

stop. The raising of a coasting blade may result in

serious personal injury and damage to the workpiece.

WARNING: When cutting a workpiece that

is longer than the support base of the saw, the

material should be supported the entire length

beyond the support base and at the same height

to keep the material level. Proper workpiece support

will help avoid blade pinch and possible kickback

which may result in serious personal injury. Do not

rely solely on the vertical vise and/or horizontal vise

to secure the workpiece. Thin material tends to sag.

Support workpiece over its entire length to avoid

blade pinch and possible KICKBACK.

1

2

► 1. Support 2. Turn base

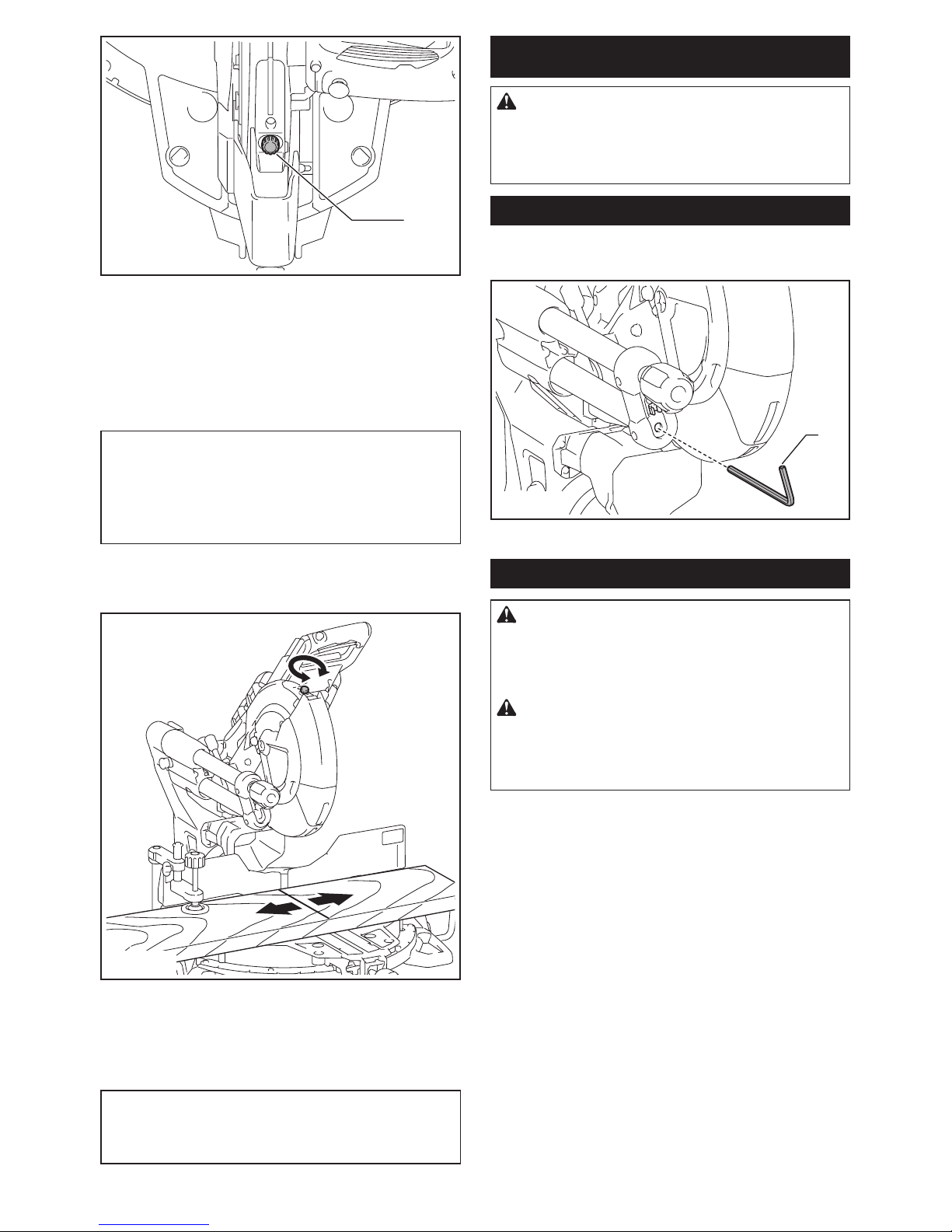

Guide fences

WARNING: Before operating the tool, make

sure that the upper fence is secured rmly.

WARNING: Before bevel-cutting, make sure

that no part of the tool, especially the blade, contacts the upper and lower fences when fully lowering and raising the handle in any position and

while moving the carriage through its full range

of travel. If the tool or blade makes contact with

the fence this may result in kickback or unexpected

movement of the material and serious personal injury.

Use upper fences to support the material higher than

the lower fences. Insert the upper fence into the hole on

the lower fence and tighten the clamping screw.

1

2

3

1

2

3

4

4

► 1. Upper fence 2. Lower fence 3. Clamping screw

4. Adjusting screw

NOTICE: The lower fences are xed to the base in

the factory. Do not remove the lower fences.

NOTICE: If the upper fence is still loose after tight-

ening the clamping screw, turn the adjusting screw to

close a gap. The adjusting screw is factory adjusted.

You don't need to use it unless needed.

You can store the upper fences onto the holder when

not in use. Use the clip on the upper fence to hold it on

the holder.

1 2

3

► 1. Holder 2. Upper fence 3. Clip

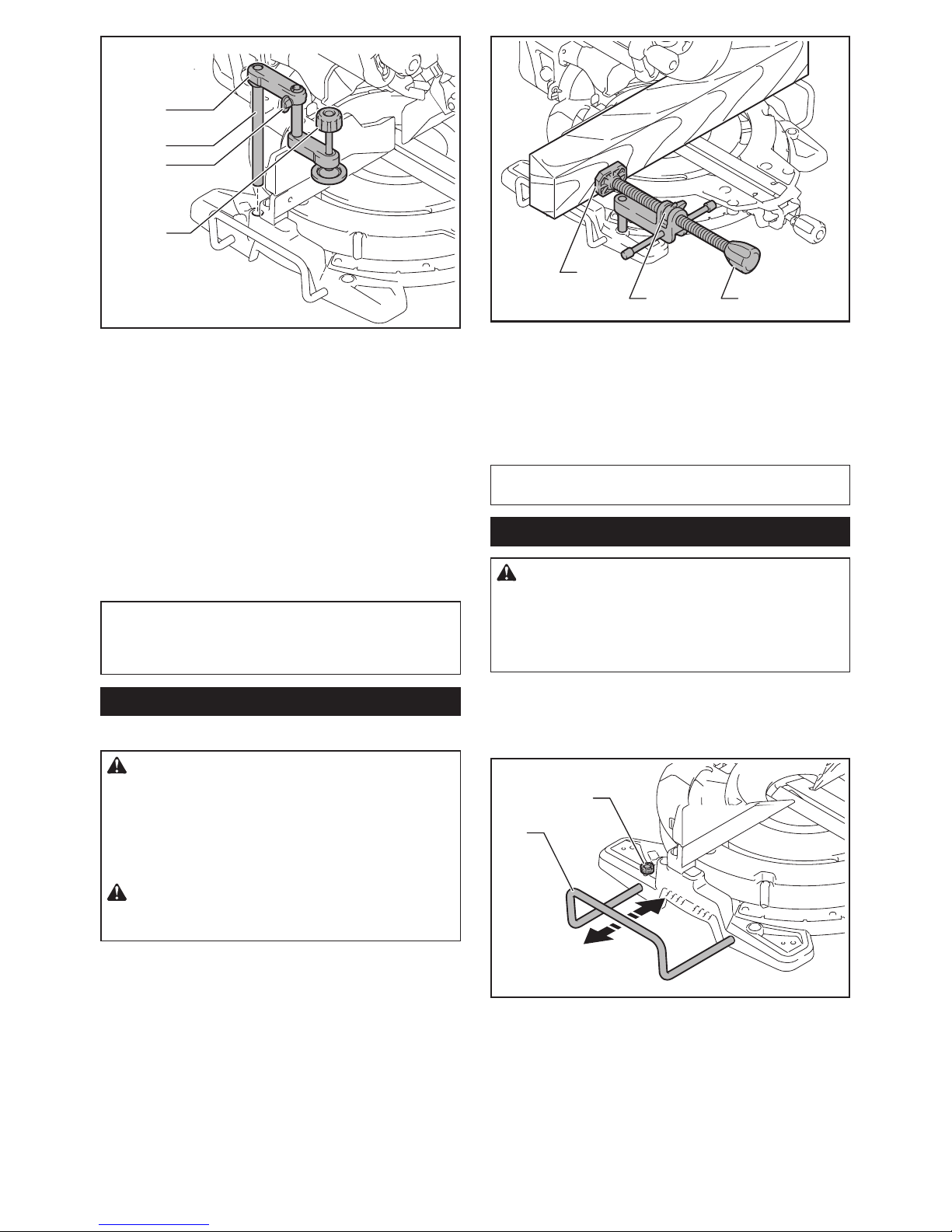

Vertical vise

WARNING: The workpiece must be secured

rmly against the turn base and guide fence with

the vise during all operations. If the workpiece is

not properly secured against the fence the material

may move during the cutting operation causing

possible damage to the blade, causing the material

to be thrown and loss of control resulting in serious

personal injury.

22 ENGLISH

1

2

3

4

► 1. Vise arm 2. Vise rod 3. Clamping screw 4. Vise

knob

The vertical vise can be installed in two positions on

either the left or right side of the base. Insert the vise

rod into the hole in the base.

Position the vise arm according to the thickness and

shape of the workpiece and secure the vise arm by

tightening the screw. If the clamping screw contacts

the carriage, install it on the opposite side of vise arm.

Make sure that no part of the tool contacts the vise

when lowering the handle all the way. If some part

contacts the vise, re-position the vise.

Press the workpiece at against the guide fence and the

turn base. Position the workpiece at the desired cutting

position and secure it rmly by tightening the vise knob.

NOTE: For a quick setting of workpiece, turning the

vise knob to 90° counterclockwise allows the vise

knob to be moved up and down. To secure the workpiece after setting, turn the vise knob clockwise.

Horizontal vise

Optional accessory

WARNING: Always rotate the vise nut clock-

wise until the workpiece is properly secured. If

the workpiece is not properly secured the material

may move during the cutting operation causing

possible damage to the blade, causing the material

to be thrown and loss of control resulting in serious

personal injury.

WARNING: When cutting a thin workpiece,

such as base boards, against the fence, always

use the horizontal vise.

The horizontal vise can be installed in two positions on

either the left or right side of the base. When performing

22.5° or greater miter cuts, install the horizontal vise on

the side opposite the direction in which the turn base is

to be turned.

1

2 3

► 1. Vise plate 2. Vise nut 3. Vise knob

By ipping the vise nut counterclockwise, the vise is

released, and rapidly moves in and out. To grip the

workpiece, push the vise knob forward until the vise

plate contacts the workpiece and ip the vise nut clockwise. Then turn the vise knob clockwise to secure the

workpiece.

NOTE: The maximum width of workpiece which can

be secured by the horizontal vise is 228 mm (9″).

Holders

WARNING: Always support a long workpiece

so it is level with the top surface of the turn base

for an accurate cut and to prevent dangerous loss

of tool control. Proper workpiece support will help

avoid blade pinch and possible kickback which may

result in serious personal injury.

To hold long workpieces horizontally, holders are pro-

vided on both sides of the tool. Loosen the screws and

extend the holders to the appropriate length for holding

the workpiece. Then tighten the screws.

1

2

► 1. Holder 2. Screw

23 ENGLISH

OPERATION

WARNING: Make sure the blade is not con-

tacting the workpiece, etc. before the switch

is turned on. Turning the tool on with the blade in

contact with the workpiece may result in kickback and

serious personal injury.

WARNING: After a cutting operation, do not

raise the blade until it has come to a complete

stop. The raising of a coasting blade may result in

serious personal injury and damage to the workpiece.

WARNING: Do not perform any adjustment

such as turning grip, knob, and levers on the tool

while the blade is rotating. Adjustment while the

blade is rotating may result in serious personal injury.

NOTICE: Before use, be sure to unlock the stop-

per pin and release the handle from the lowered

position.

NOTICE: Do not apply excessive pressure on the

handle when cutting. Too much force may result in

overload of the motor and/or decreased cutting efciency. Press down handle with only as much force as

necessary for smooth cutting and without signicant

decrease in blade speed.

NOTICE: Gently press down the handle to per-

form the cut. If the handle is pressed down with force

or if lateral force is applied, the blade may vibrate and

leave a mark (saw mark) in the workpiece and the

precision of the cut may be impaired.

NOTICE: During a slide cut, gently push the

carriage toward the guide fence without stopping.

If the carriage movement is stopped during the cut, a

mark will be left in the workpiece and the precision of

the cut will be impaired.

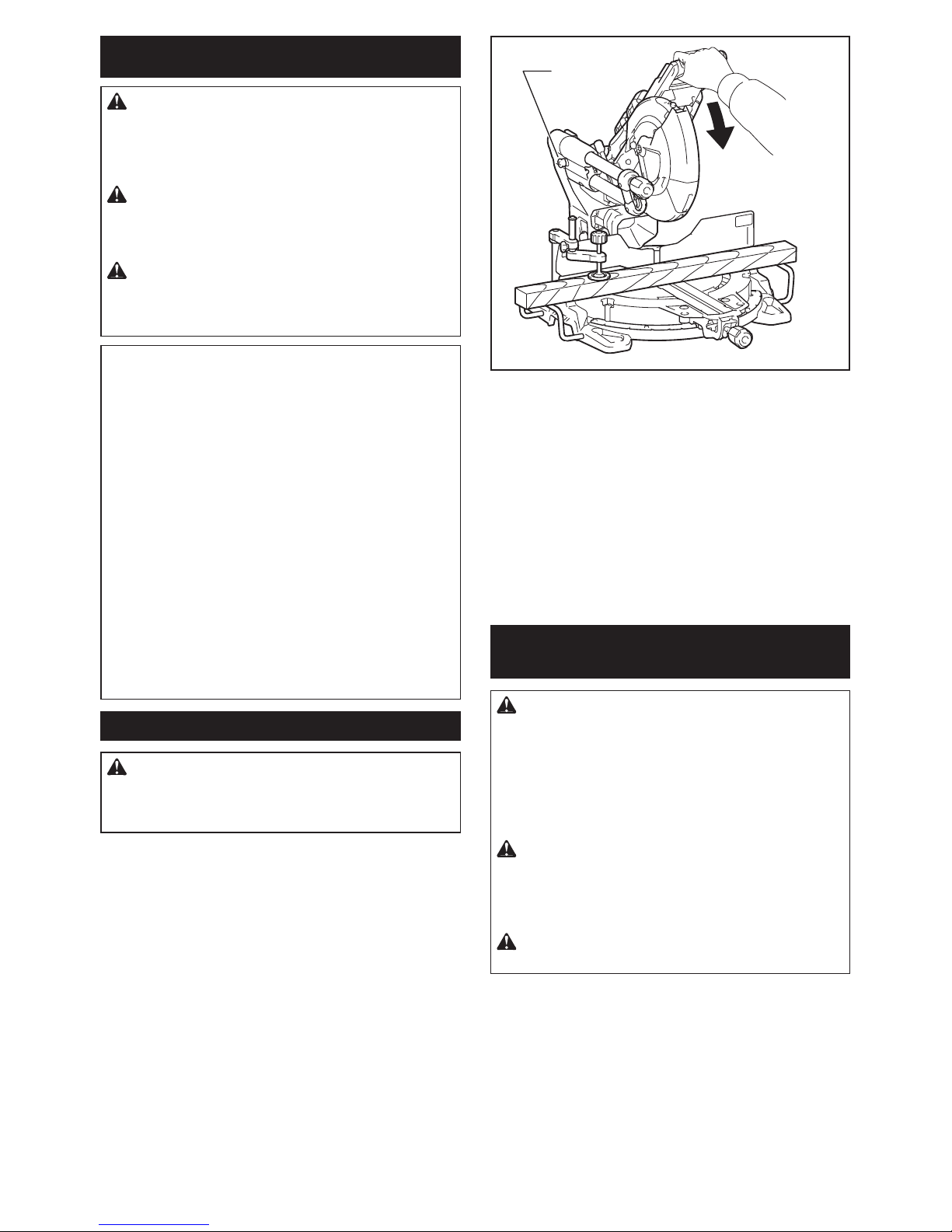

Press cutting

WARNING: Always lock the sliding movement

of the carriage when performing a press cutting.

Cutting without lock may cause possible kickback

which may result in serious personal injury.

Workpieces up to 71 mm (2-13/16") high and 155 mm

(6-1/8") wide can be cut in the following manner.

1

► 1. Stopper pin

1. Push the carriage toward the guide fence until it

stops and lock it with the stopper pin.

2. Secure the workpiece with the proper type of vise.

3. Switch on the tool without the blade making any

contact and wait until the blade attains full speed before

lowering.

4. Gently lower the handle to the fully lowered posi-

tion to cut the workpiece.

5. When the cut is completed, switch off the tool and

wait until the blade has come to a complete stop

before returning the blade to its fully elevated position.

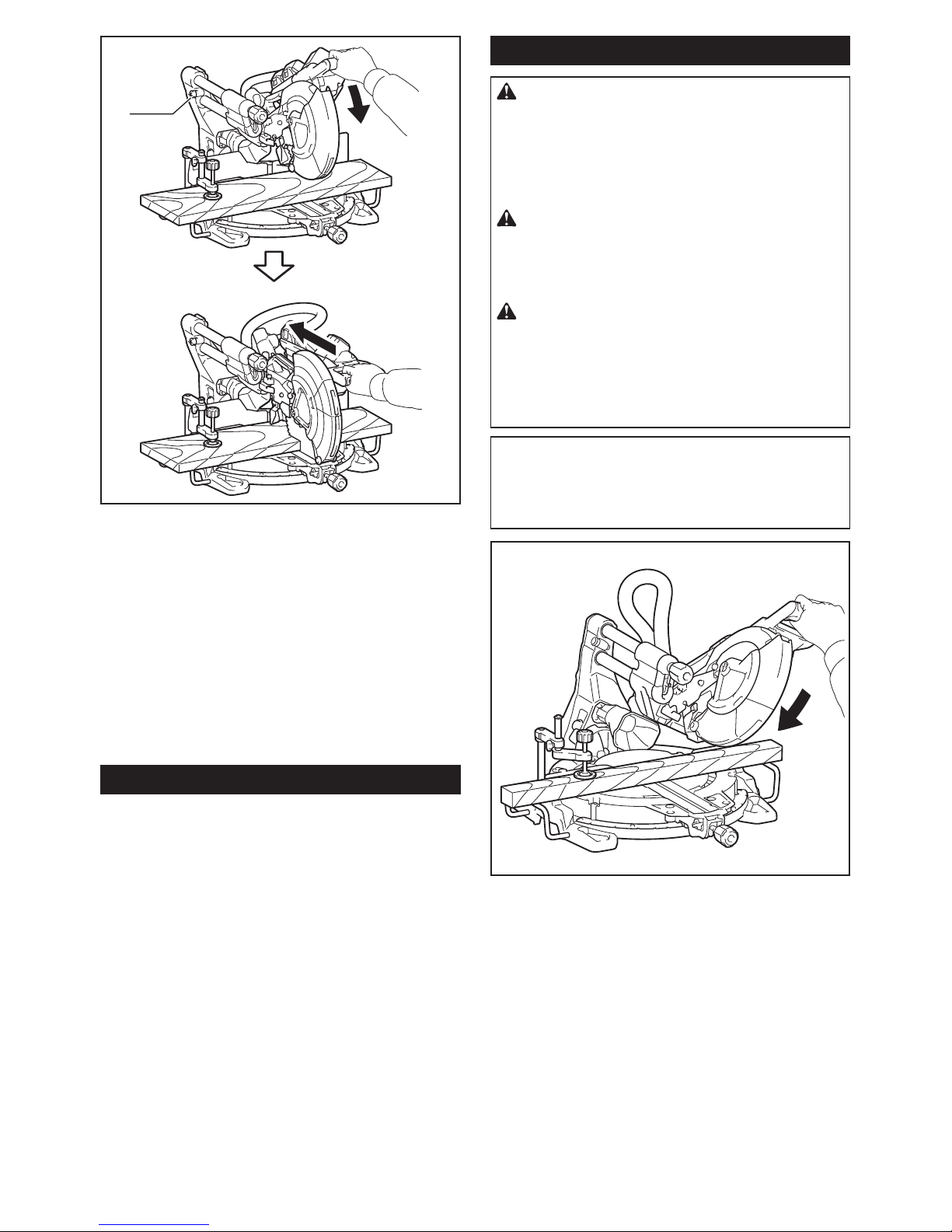

Slide (push) cutting (cutting wide

workpieces)

WARNING: Whenever performing a slide cut,

rst pull the carriage full towards you and press

the handle all the way down, then push the carriage toward the guide fence. Never start the cut

with the carriage not pulled fully toward you. If

you perform the slide cut without the carriage pulled

fully toward you unexpected kickback may occur and

serious personal injury may result.

WARNING: Never attempt to perform a slide

cut by pulling the carriage towards you. Pulling

the carriage towards you while cutting may cause

unexpected kickback resulting in possible serious

personal injury.

WARNING: Never perform the slide cut with

the handle locked in the lowered position.

24 ENGLISH

1

► 1. Stopper pin

1. Unlock the stopper pin so that the carriage can

slide freely.

2. Secure the workpiece with the proper type of vise.

3. Pull the carriage toward you fully.

4. Switch on the tool without the blade making any

contact and wait until the blade attains full speed.

5. Press the handle down and push the carriage

toward the guide fence and through the workpiece.

6. When the cut is completed, switch off the tool and

wait until the blade has come to a complete stop

before returning the blade to its fully elevated position.

Miter cutting

Refer to the previously covered "Adjusting the miter

angle".

Bevel cut

WARNING: After setting the blade for a bevel

cut, ensure that the carriage and blade will have

free travel throughout the entire range of the

intended cut before operating the tool. Interruption

of the carriage or blade travel during the cutting operation may result in kickback and serious personal

injury.

WARNING: While making a bevel cut keep

hands out of the path of the blade. The angle of the

blade may confuse the operator as to the actual blade

path while cutting and contact with the blade will

result in serious personal injury

WARNING: The blade should not be raised

until it has come to a complete stop. During a

bevel cut the piece cut off may come to rest against

the blade. If the blade is raised while it is rotating the

cut-off piece maybe ejected by the blade causing

the material to fragment which may result in serious

personal injury.

NOTICE: When pressing down the handle, apply

pressure in parallel with the blade. If a force is

applied perpendicularly to the turn base or if the pressure direction is changed during a cut, the precision

of the cut will be impaired.

1. Remove the upper fence on the side that you are

going to tilt the carriage.

2. Unlock the stopper pin.

3. Adjust the bevel angle according to the procedure

explained in the "Adjusting the bevel angle" section.

Then tighten the knob.

4. Secure the workpiece with a vise.

5. Pull the carriage toward you fully.

6. Switch on the tool without the blade making any

contact and wait until the blade attains full speed.

7. Gently lower the handle to the fully lowered posi-

tion while applying pressure in parallel with the blade

and push the carriage toward the guide fence to cut

the workpiece.

25 ENGLISH

8. When the cut is completed, switch off the tool and

wait until the blade has come to a complete stop

before returning the blade to its fully elevated position.

Compound cutting

Compound cutting is the process in which a bevel

angle is made at the same time in which a miter angle

is being cut on a workpiece. Compound cutting can be

performed at the angle shown in the table.

Miter angle Bevel angle

Left and Right 0° - 45° Left and Right 0° - 45°

When performing compound cutting, refer to "Press cut-

ting", "Slide (push) cutting", "Miter cutting" and "Bevel

cut" explanations

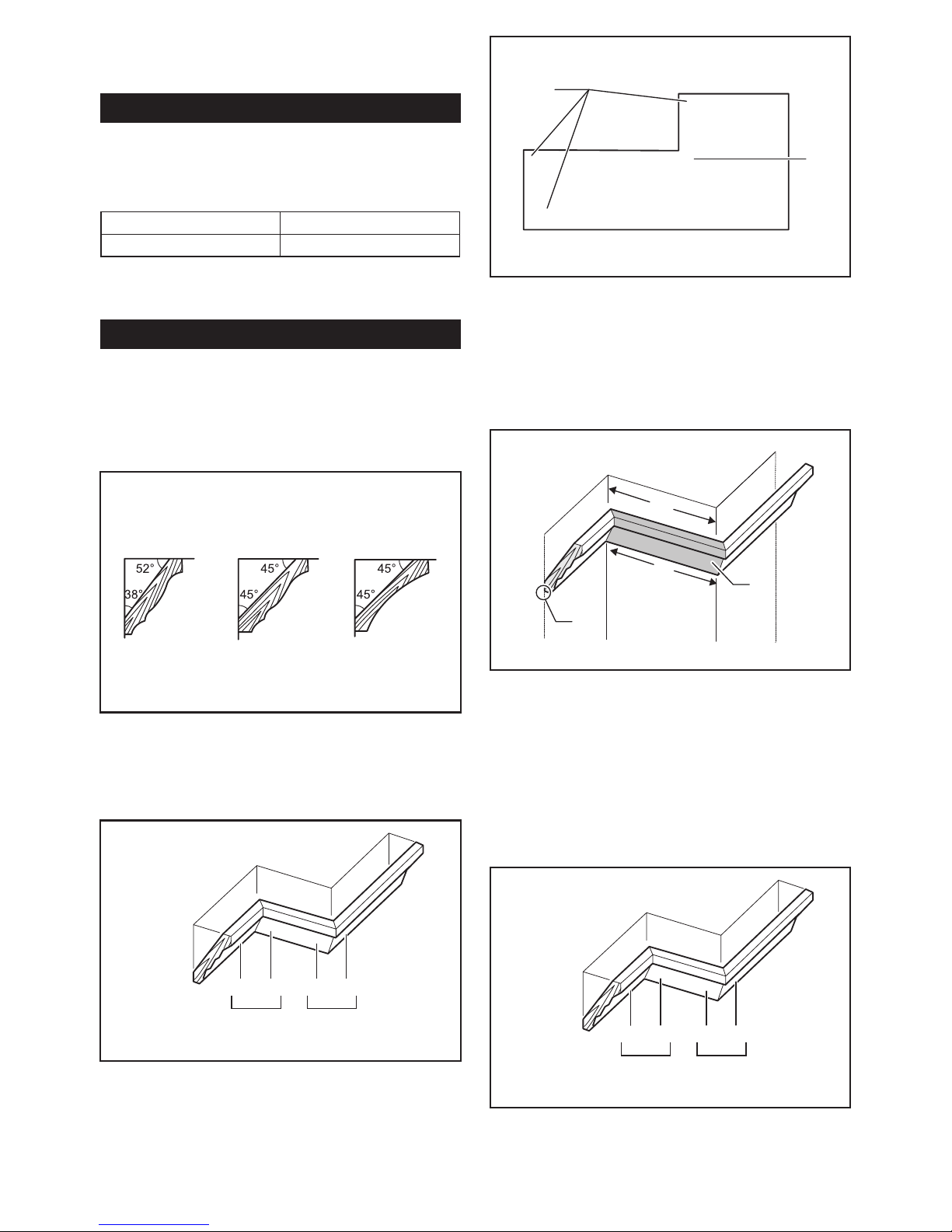

Cutting crown and cove moldings

Crown and cove moldings can be cut on a compound

miter saw with the moldings laid at on the turn base.

There are two common types of crown moldings and

one type of cove moldings; 52/38° wall angle crown

molding, 45° wall angle crown molding and 45° wall

angle cove molding.

123

► 1. 52/38° type crown molding 2. 45° type crown

molding 3. 45° type cove molding

There are crown and cove molding joints which are

made to t "Inside" 90° corners ((a) and (b) in the gure)

and "Outside" 90° corners ((c) and (d) in the gure.)

(a) (b) (c) (d)

12

1. Inside corner 2. Outside corner

2

(a)

(b)

(a)

(b)

(b)

(a)

(b)

(a)

(a)

(b)

(c)

(d)

1

1. Inside corner 2. Outside corner

Measuring

Measure the wall width, and adjust the width of the

workpiece according to it. Always make sure that width

of the workpiece's wall contact edge is the same as wall

length.

2

3

1

4

► 1. Workpiece 2. Wall width 3. Width of the work-

piece 4. Wall contact edge

Always use several pieces for test cuts to check the

saw angles.

When cutting crown and cove moldings, set the bevel

angle and miter angle as indicated in the table (A) and

position the moldings on the top surface of the saw

base as indicated in the table (B).

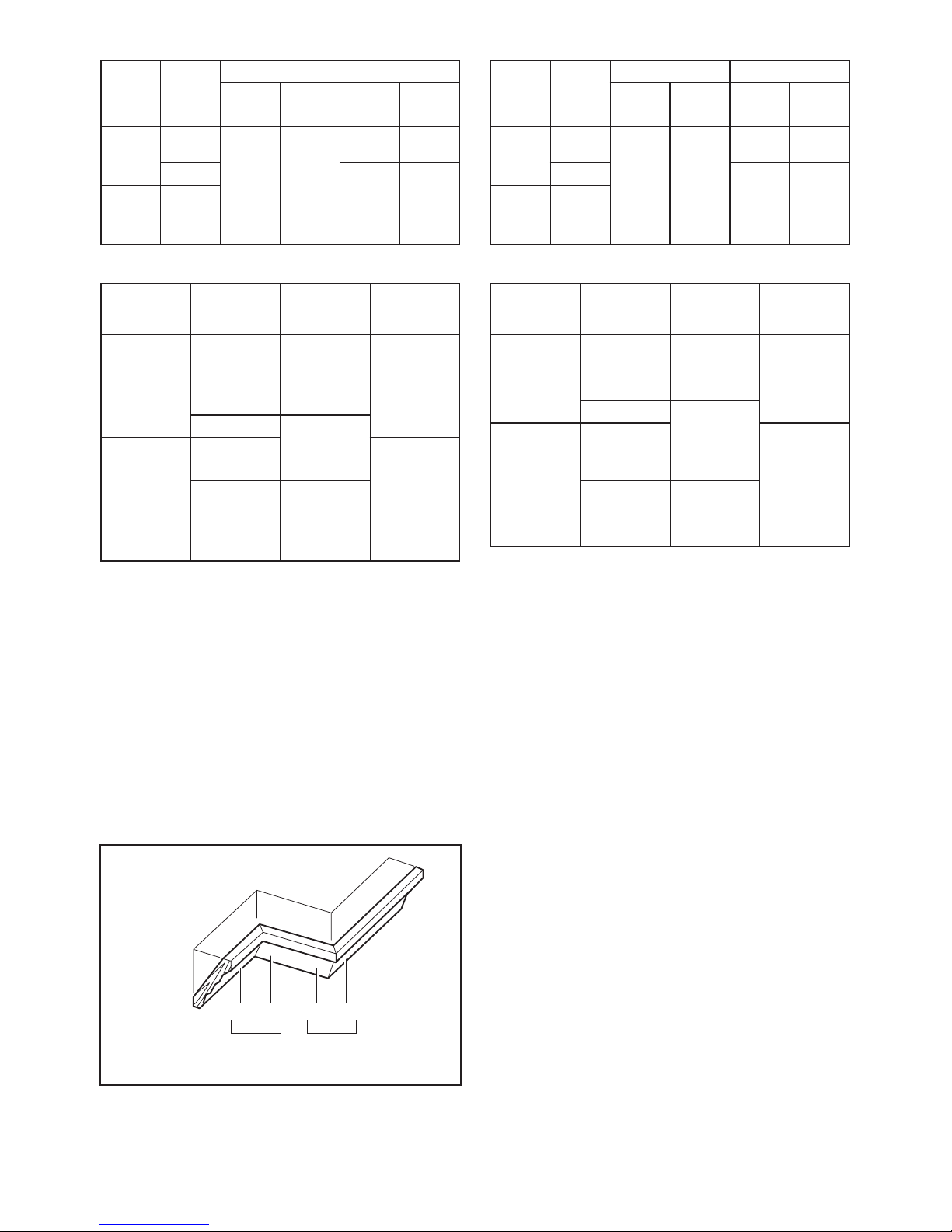

In the case of left bevel cut

(a) (b) (c) (d)

12

1. Inside corner 2. Outside corner

26 ENGLISH

Table (A)

– Molding

position

in the

gure

Bevel angle Miter angle

52/38°

type

45° type 52/38°

type

45° type

For

inside

corner

(a) Left

33.9°

Left 30° Right

31.6°

Right

35.3°

(b) Left

31.6°

Left

35.3°

For

outside

corner

(c)

(d) Right

31.6°

Right

35.3°

Table (B)

– Molding

position in

the gure

Molding

edge against

guide fence

Finished

piece

For inside

corner

(a) Ceiling

contact edge

should be

against guide

fence.

Finished

piece will be

on the Left

side of blade.

(b) Wall contact

edge should

be against

guide fence.

For outside

corner

(c) Finished

piece will be

on the Right

side of blade.(d) Ceiling

contact edge

should be

against guide

fence.

Example:

In the case of cutting 52/38° type crown molding for

position (a) in the above gure:

• Tilt and secure bevel angle setting to 33.9° LEFT.

• Adjust and secure miter angle setting to 31.6°

RIGHT.

• Lay crown molding with its broad back (hidden)

surface down on the turn base with its CEILING

CONTACT EDGE against the guide fence on the

saw.

• The nished piece to be used will always be on

the LEFT side of the blade after the cut has been

made.

In the case of right bevel cut

(a) (b) (c) (d)

12

1. Inside corner 2. Outside corner

Table (A)

– Molding

position

in the

gure

Bevel angle Miter angle

52/38°

type

45° type 52/38°

type

45° type

For

inside

corner

(a) Right

33.9°

Right

30°

Right

31.6°

Right

35.3°

(b) Left

31.6°

Left

35.3°

For

outside

corner

(c)

(d) Right

31.6°

Right

35.3°

Table (B)

– Molding

position in

the gure

Molding

edge against

guide fence

Finished

piece

For inside

corner

(a) Wall contact

edge should

be against

guide fence.

Finished

piece will be

on the Right

side of blade.

(b) Ceiling

contact edge

should be

against guide

fence.

For outside

corner

(c) Finished

piece will be

on the Left

side of blade.

(d) Wall contact

edge should

be against

guide fence.

Example:

In the case of cutting 52/38° type crown molding for

position (a) in the above gure:

• Tilt and secure bevel angle setting to 33.9° RIGHT.

• Adjust and secure miter angle setting to 31.6°

RIGHT.

• Lay crown molding with its broad back (hidden)

surface down on the turn base with its WALL

CONTACT EDGE against the guide fence on the

saw.

• The nished piece to be used will always be on

the RIGHT side of the blade after the cut has been

made.

Loading...

Loading...