Makita XRU16, XRU17 User guide

INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

Cordless Grass Trimmer

Cortador Inalámbrico de Pasto

XRU16

XRU17

IMPORTANT: Read Before Using.

IMPORTANTE: Lea antes de usar.

ENGLISH (Original instructions)

SPECIFICATIONS

Model: XRU16 XRU17

Handle type Bike handle Loop handle

No load speed

(at each rotation speed level)

Overall length

(without cutting tool)

Nylon cord diameter 2.0 - 2.3 mm (0.08″ - 0.09″)

Applicable cutting tool and

cutting diameter

Rated voltage D.C. 36 V

Net weight 5.9 - 6.5 kg (13.0 - 14.3 lbs) 5.7 - 6.3 kg (12.6 - 13.9 lbs)

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications may dier from country to country.

• The weight may dier depending on the attachment(s), including the battery cartridge. The lightest and heavi-

est combination, according to EPTA-Procedure 01/2014, are shown in the table.

2-tooth blade

(P/N 198345-9)

3-tooth blade

(P/N 195299-1)

4-tooth blade

(P/N 195150-5)

(P/N 196895-8)

Nylon cutting head

(P/N 198893-8)

Applicable battery cartridge, battery adapter and charger

Battery cartridge BL1820B / BL1830 / BL1830B / BL1840B / BL1850B / BL1860B

Battery adapter BAP182 / PDC01

Charger

• Some of the battery cartridges and chargers listed above may not be available depending on your region of

residence.

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

and chargers may cause injury and/or re.

DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF / DC18SH

3: 0-7,000 /min

2: 0-5,500 /min

1: 0-4,600 /min

1,846 mm (72-1/2″)

255 mm (10″)

255 mm (10″)

230 mm (9″)

255 mm (10″)

430 mm (17″)

SAFETY WARNINGS

Important safety instructions

WARNING: When using electric gardening

appliances, basic safety precautions should

always be followed to reduce the risk of re,

electric shock, and personal injury, including the

following.

Read All Instructions

Failure to follow the warnings and instructions may

result in electric shock, re and/or serious injury.

SAVE THESE INSTRUCTIONS.

General instructions

1. Never allow people unfamiliar with these

instructions or children to use the machine.

Local regulations can restrict the age of the

operator. It is dangerous in the hands of untrained

users or children.

2. Be sure that anyone who is to operate the tool

has rst read the instruction manual.

3. Use the tool with the utmost care and

attention.

4. Operate the tool only if you are in good physical condition. Perform all work calmly and

carefully. Use common sense and keep in mind

that the operator or user is responsible for

accidents or hazards occurring to other people

or their property.

2 ENGLISH

5. Never operate the tool when tired, feeling ill or

under the inuence of alcohol or drugs.

6. Avoid accidentally starting:

— Ensure the switch is in the o posi-

tion before installing the battery pack.

Inserting the battery pack into the tool with

the switch on invites accidents.

— Carrying the tool with your nger on the

switch invites accidents.

7. The tool should be switched o immediately if

it shows any signs of abnormal operation.

8. Don't force the tool. It will do the job better and

with less likelihood of a risk of injury at the rate for

which it was designed.

9. Don't overreach. Keep proper footing and

balance at all times.

10. Stay Alert - Watch what you are doing. Use

common sense. Do not operate appliance

when you are tired.

11. Store idle appliances indoors.

12. Keep ngers away from switch trigger when

not operating the tool and when moving from

one operating position to another.

Intended use of the tool

1. Use right tool. This tool is only intended for

cutting grass and light weeds. It should not be

used for any other purpose such as edging or

hedge cutting as this may cause injury.

2. Use only the manufacturer’s recommended

accessories and attachments. Use of any other

accessories and attachments may increase the

risk of injury.

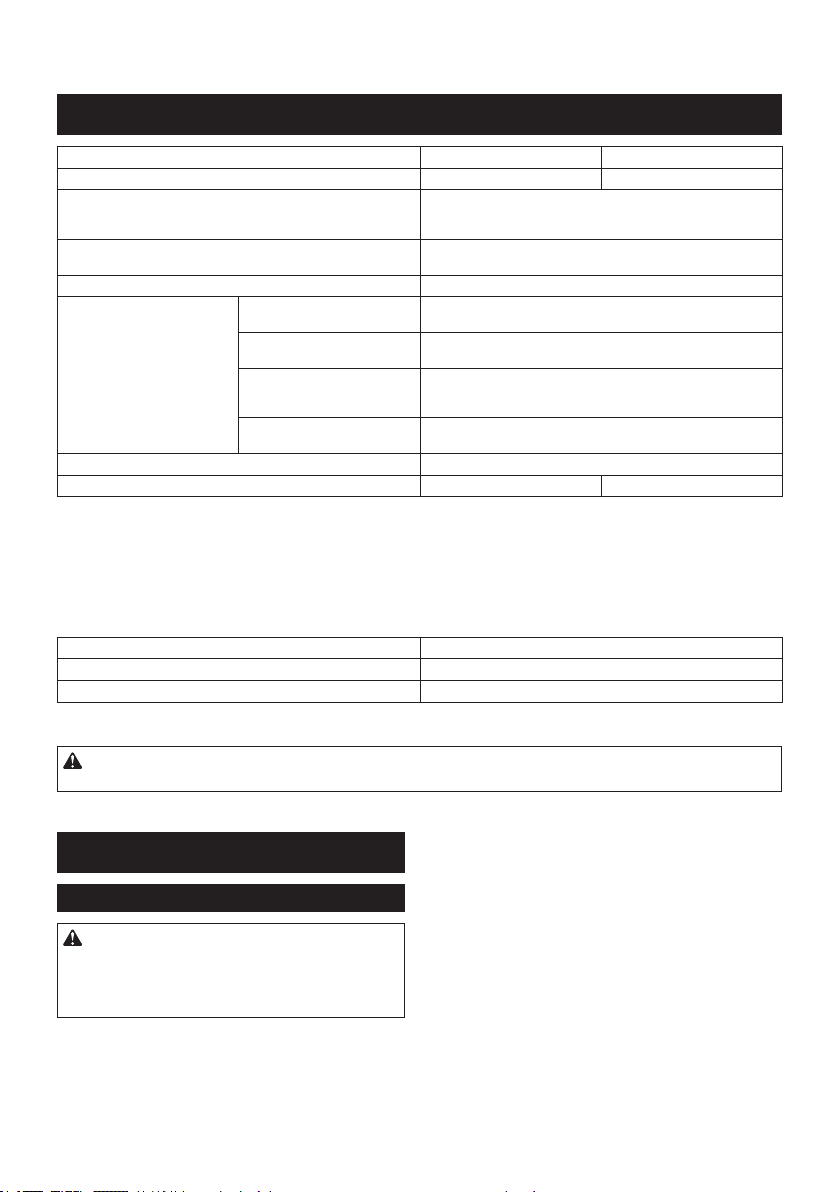

Personal protective equipment

1. Dress Properly. The clothing worn should be

functional and appropriate, i.e. it should be

tight-tting but not cause hindrance. Do not

wear loose clothing or jewelry. They can be

caught in moving parts. Use of thick leather

gloves and substantial footwear is recommended when working outdoors. Wear protective hair covering to contain long hair.

2. In order to avoid either head, eye, hand or foot

injuries as well as to protect your hearing the

following protective equipment and protective

clothing must be used during operation of the

equipment.

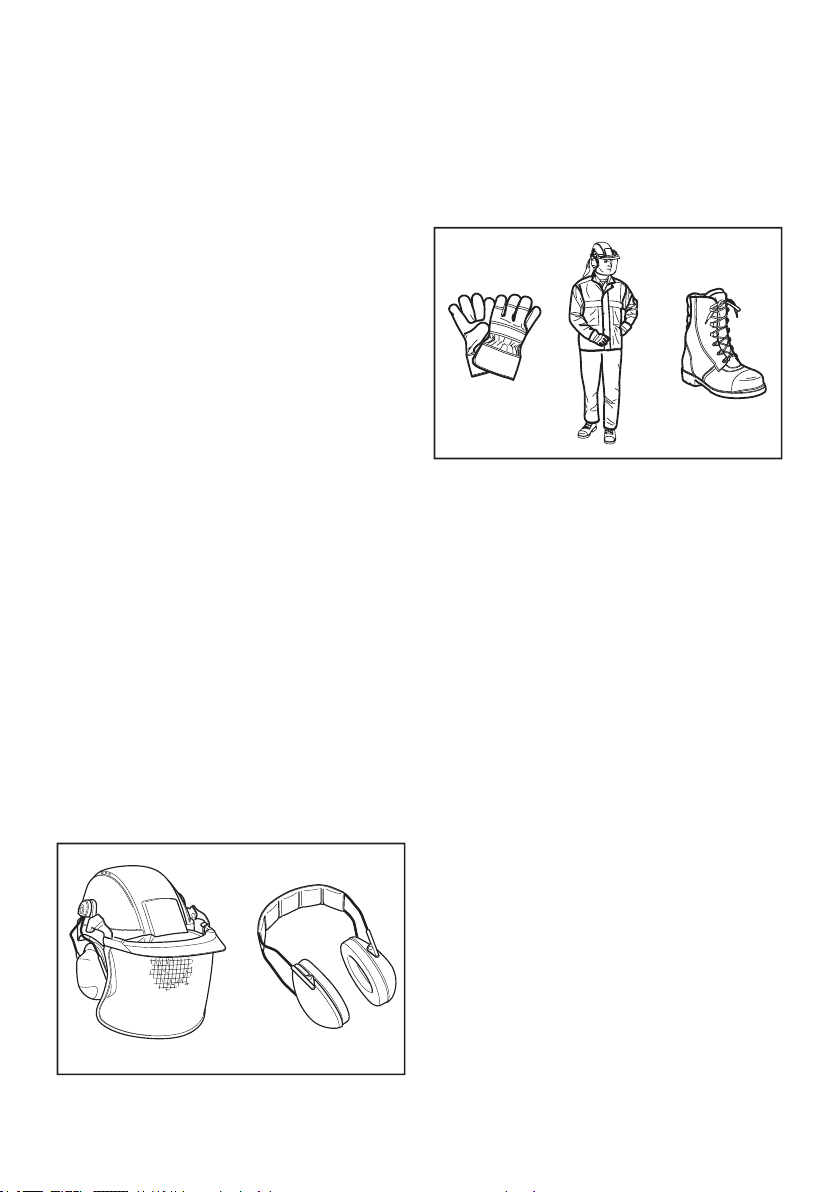

3. Always wear a helmet where there is a risk of

falling objects. The protective helmet is to be

checked at regular intervals for damage and

is to be replaced at least every ve years. Use

only approved protective helmets.

4.

Use safety glasses. The visor of the helmet (or alter-

natively goggles) protects the face from ying debris

and stones. During operation of the tool always wear

goggles, or a visor to prevent eye injuries.

5.

Wear adequate noise protection equipment to avoid

hearing impairment (ear mus , ear plugs etc.).

6. Work overalls protect against injury from

ying stones and debris. It is strongly recommended that the user wears work overalls.

7. Special gloves made of thick leather are part of

the prescribed equipment and must always be

worn during operation of the tool.

8. When using the tool, always wear sturdy shoes

with a nonslip sole. This protects against injuries

from ying debris and ensures a good footing.

9. Use a dust mask if operation is dusty.

Electrical and battery safety

1. Avoid dangerous environment. Don't use the

tool in damp or wet locations or expose it to

rain. Water entering the tool will increase the risk

of electric shock.

2. Prevent unintentional starting. Ensure the

switch is in the o-position before connecting

to battery pack, picking up or carrying the

machine. Carrying the machine with your nger

on the switch or energizing machine that have the

switch on invites accidents.

3. Disconnect the battery pack from the machine

before making any adjustments, changing

accessories, or storing machine. Such preven-

tive safety measures reduce the risk of starting the

machine accidentally.

4. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

5. Use machines only with specically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and re.

6. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a re.

3 ENGLISH

7. Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If con-

tact accidentally occurs, ush with water. If

liquid contacts eyes, seek medical help. Liquid

ejected from the battery may cause irritation or

burns.

8. Do not use a battery pack or machine that is

damaged or modied. Damaged or modied

batteries may exhibit unpredictable behaviour

resulting in re, explosion or risk of injury.

9. Do not expose a battery pack or machine to

re or excessive temperature. Exposure to re

or temperature above 130°C (265°F) may cause

explosion.

10. Follow all charging instructions and do not

charge the battery pack or machine outside of

the temperature range specied in the instructions. Charging improperly or at temperatures

outside of the specied range may damage the

battery and increase the risk of re.

11. Have servicing performed by a qualied repair

person using only identical replacement parts.

This will ensure that the safety of the product is

maintained.

12. Do not modify or attempt to repair the machine

or the battery pack except as indicated in the

instructions for use and care.

13. Do not dispose of the battery(ies) in a re.

The cell may explode. Check with local codes for

possible special disposal instructions.

14. Do not open or mutilate the battery(ies).

Released electrolyte is corrosive and may cause

damage to the eyes or skin. It may be toxic if

swallowed.

15. Do not charge battery in rain, or in wet

locations.

16. Make sure there are no electrical cables, water

pipes, gas pipes etc. that could cause a hazard

if damaged by use of the tool.

Starting up the tool

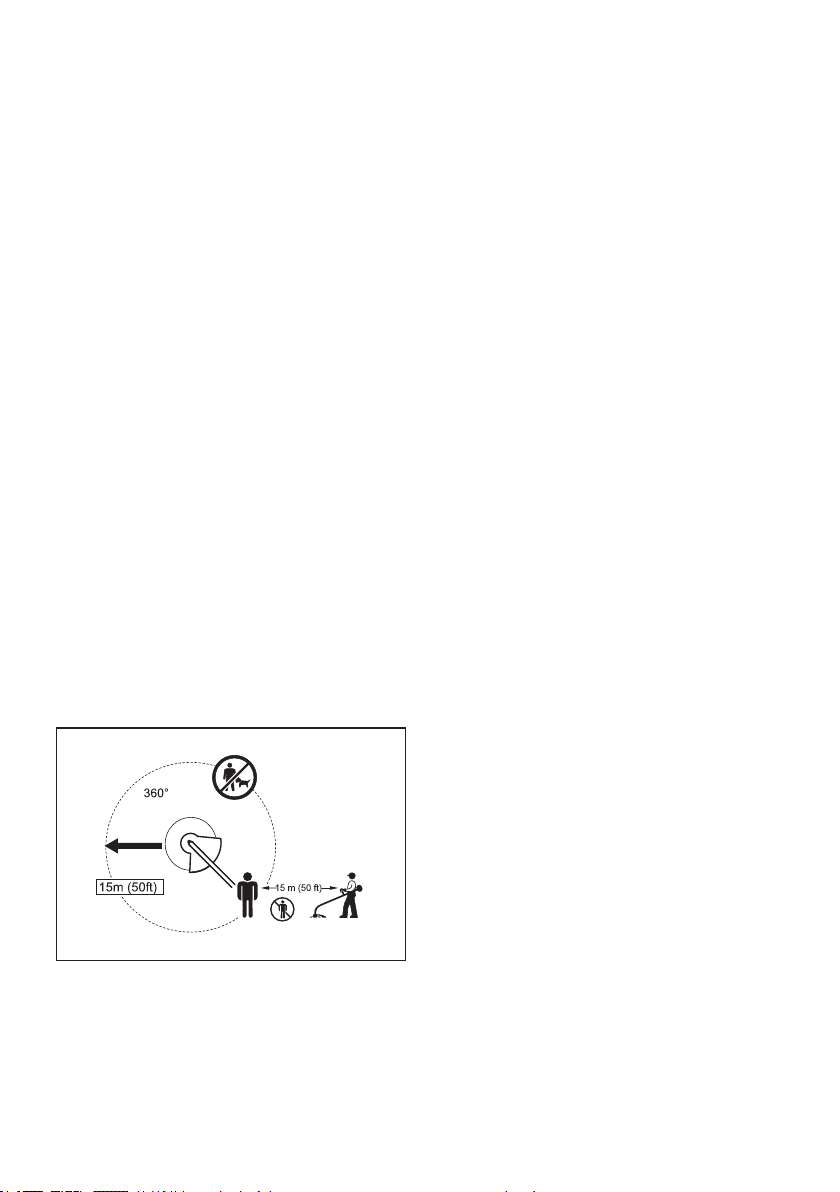

1. Make sure that there are no children or other

people within a working range of 15 meters

(50 ft), also pay attention to any animals in the

working vicinity. Otherwise stop using the tool.

2. Before use always check that the tool is safe

for operation. Check the security of the cutting

tool and the guard and the switch trigger/lever

for easy and proper action. Check for clean

and dry handles and test the on/o function of

the switch.

3. Check damaged parts before further use of

the tool. A guard or other part that is damaged

should be carefully checked to determine

that it will operate properly and perform its

intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting, and any other condi-

tion that may aect its operation. A guard or

other part that is damaged should be properly

repaired or replaced by our authorized service center unless indicated elsewhere in this

manual.

4. Switch on the motor only when hands and feet

are away from the cutting tool.

5. Before starting make sure that the cutting

tool has no contact with hard objects such as

branches, stones etc. as the cutting tool will

revolve when starting.

6. Remove any adjusting key, wrench or blade

cover before turning the power tool on. An

accessory left attached to a rotating part of the

power tool may result in personal injury.

7. Make sure there are no electrical cables, water

pipes, gas pipes etc. that could cause a hazard

if damaged by use of the tool.

8. Do not use a cutting tool which is not recommended by Makita.

9. Do not operate the tool in bad weather or if

there is a risk of lightning.

Method of operation

1. Only use the tool in good light and visibility.

During the winter season beware of slippery

or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

2. Take care against injury to feet and hands from

the cutting tool.

3. Never cut above waist height.

4. Never stand on a ladder and run the tool.

5. Never climb up into trees to perform cutting

operation with the tool.

6. Never work on unstable surfaces.

7. Remove sand, stones, nails etc. found within

the working range. Foreign particles may damage the cutting tool.

8. Should the cutting tool hit stones or other hard

objects, immediately switch o the motor and

inspect the cutting tool.

9. Before commencing cutting, the cutting tool

must reach full working speed.

10. During operation always hold the tool with

both hands. Never hold the tool with one hand

during use. Always ensure a safe footing.

11. The cutting tool has to be equipped with the

guard. Never run the tool with damaged guards

or without guards in place!

12. All protective equipment such as guards

supplied with the tool must be used during

operation.

13. Except in case of emergency, never drop

or cast the tool to the ground or this may

severely damage the tool.

4 ENGLISH

14. Never drag the tool on the ground when moving from place to place, the tool may become

damaged if moved in this manner.

15. Always remove the battery cartridge from the

tool:

— whenever leaving the tool unattended;

— before clearing a blockage;

— before checking, cleaning or working on

the tool;

— whenever the tool starts vibrating

abnormally;

— whenever transporting the tool.

16. Always ensure that the ventilation openings

are kept clear of debris.

17. Cutting elements continue to rotate after the

motor is switched o.

18. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

19. Take a rest to prevent loss of control caused

by fatigue. We recommend to take a 10 to

20-minute rest every hour.

20. Hold the power tool by insulated gripping

surfaces only, because the cutter blade may

contact hidden wiring. Cutter blades contacting

a “live” wire may make exposed metal parts of the

power tool “live” and could give the operator an

electric shock.

21. Do not use the tool on steep slopes.

22. The shoulder harness must be used during

operation, if supplied with the tool.

23. Do not touch the gear case during and immediately after the operation. The gear case

becomes hot during operation and can cause burn

injury.

24. Do not start the tool when the cutting tool is

tangled with cut grass.

25. Before starting the tool, be sure that the cutting tool is not touching the ground and other

obstacles such as a tree.

26. Always keep your hands, face, and clothes

away from the cutting tool when it is rotating.

Failure to do so may cause personal injury.

27. Only use the cutting tool that are marked with

a speed equal or higher than the speed marked

on the tool.

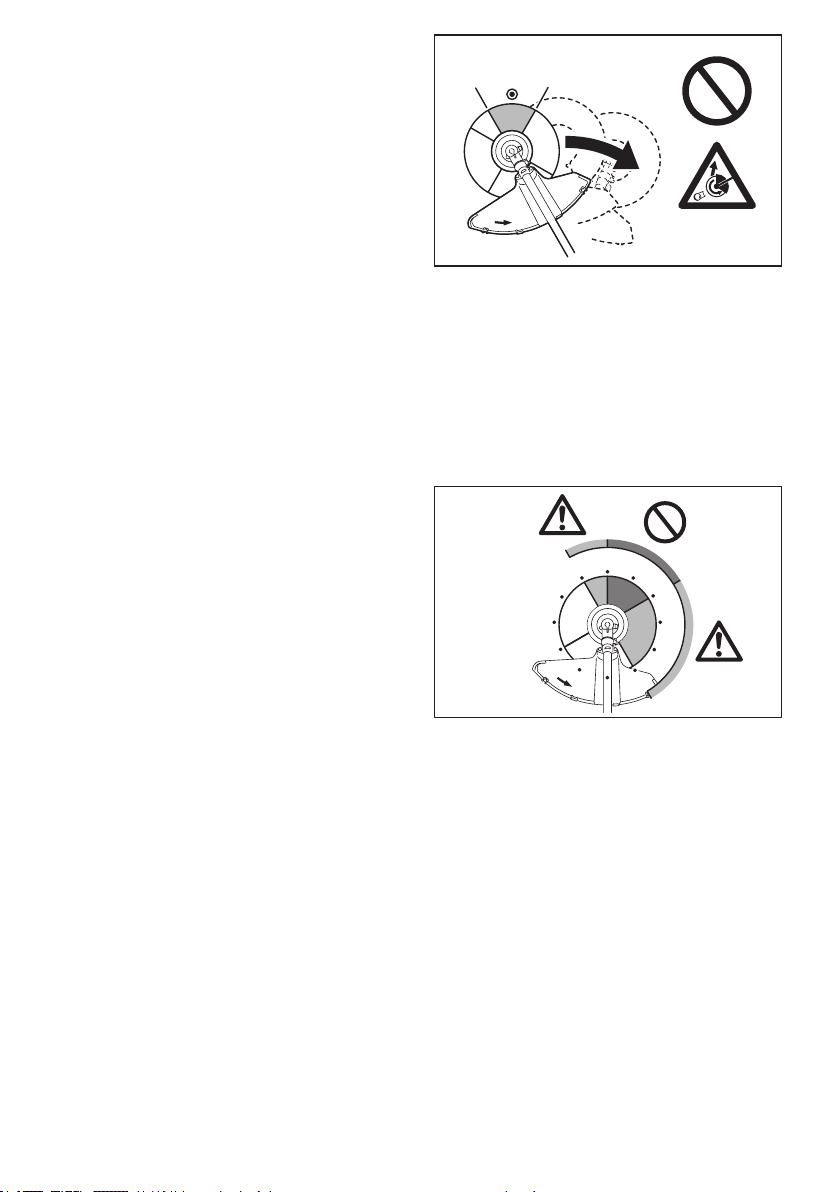

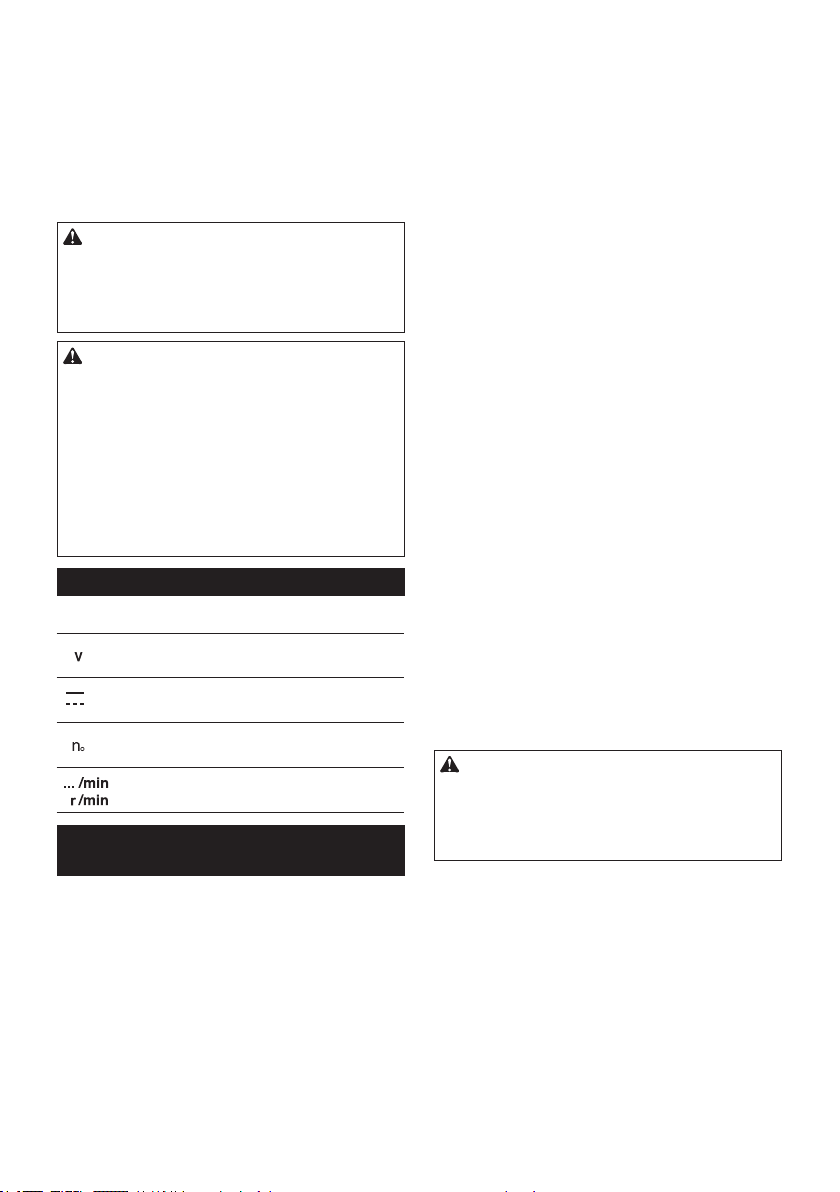

Kickback (blade thrust)

Kickback (blade thrust) may occur when the spin-

ning blade contacts an object that it can not immediately cut. It can be violent enough to cause the

unit and/or operator to be propelled in any direction, and possibly lose control of the unit, resulting

in a serious injury. Kickback can occur without

warning if the blade snags, stalls or binds and is

more likely to occur in areas where it is dicult to

see the material being cut.

Kickback occurs particularly when applying the

blade segment between 12 and 2 o’clock to hard

objects, bushes and trees with a diameter of 3 cm

or larger.

12

To avoid kickback:

1. Apply the segment between 8 and 11 o’clock.

2. Swing the tool evenly in a half-circle from

right to left, like using a scythe. This allows the

proper segment of the blade to contact plants to

be cut.

3. Never apply the segment between 12 and 2

o’clock.

4. Never apply the segment between 11 and 12

o’clock and between 2 and 5 o’clock, unless

the operator is well trained and experienced

and does it at his/her own risk.

5. Never use cutting blades close to hard objects,

such as fences, walls, tree trunks and stones.

6. Never use cutting blades vertically, for such

operations as edging and trimming hedges.

7. Avoid using the tool in areas where it is di-

cult to see the object being cut.

Maintenance instructions

1. The condition of the cutting tool, protective

devices must be checked before commencing

work.

2. Turn o the motor and remove the battery

cartridge before carrying out maintenance,

replacing the cutting tool and cleaning the

tool.

3. Check for loose fasteners and damaged parts

such as cracks in the cutting tool.

4. Follow instructions for lubricating and changing accessories if applicable.

5. When not in use store the equipment in an

indoor dry location that is locked up or out of

children's reach.

6. Use only the manufacturer's recommended

replacement parts and accessories.

5 ENGLISH

2

12

11

10

9

8

1

2

3

4

5

7. Inspect and maintain the tool regularly, especially before/after use. Have the tool repaired

only by our authorized service center.

8. Keep handles dry, clean and free from oil and

grease. Keep all cooling air inlets clear of

debris.

9. Always keep the tool in good working condition. Poor maintenance can result in inferior per-

formance and shorten the life of the tool.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

WARNING: Use of this product can create

dust containing chemicals which may cause

respiratory or other illnesses. Some examples of

these chemicals are compounds found in pesticides, insecticides, fertilizers and herbicides.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved

safety equipment, such as those dust masks that

are specially designed to lter out microscopic

particles.

Symbols

The followings show the symbols used for tool.

volts

direct current

no load speed

revolutions or reciprocation per minute

Important safety instructions for

battery cartridge

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using

battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical attention right away. It may result in loss of your

eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consulting an

expert for hazardous material is required. Please also

observe possibly more detailed national regulations.

Tape or mask o open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. When disposing the battery cartridge, remove

it from the tool and dispose of it in a safe

place. Follow your local regulations relating to

disposal of battery.

12. Use the batteries only with the products

specied by Makita. Installing the batteries to

non-compliant products may result in a re, excessive heat, explosion, or leak of electrolyte.

13. If the tool is not used for a long period of time,

the battery must be removed from the tool.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery

service life.

3.

Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let a hot

battery cartridge cool down before charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

6 ENGLISH

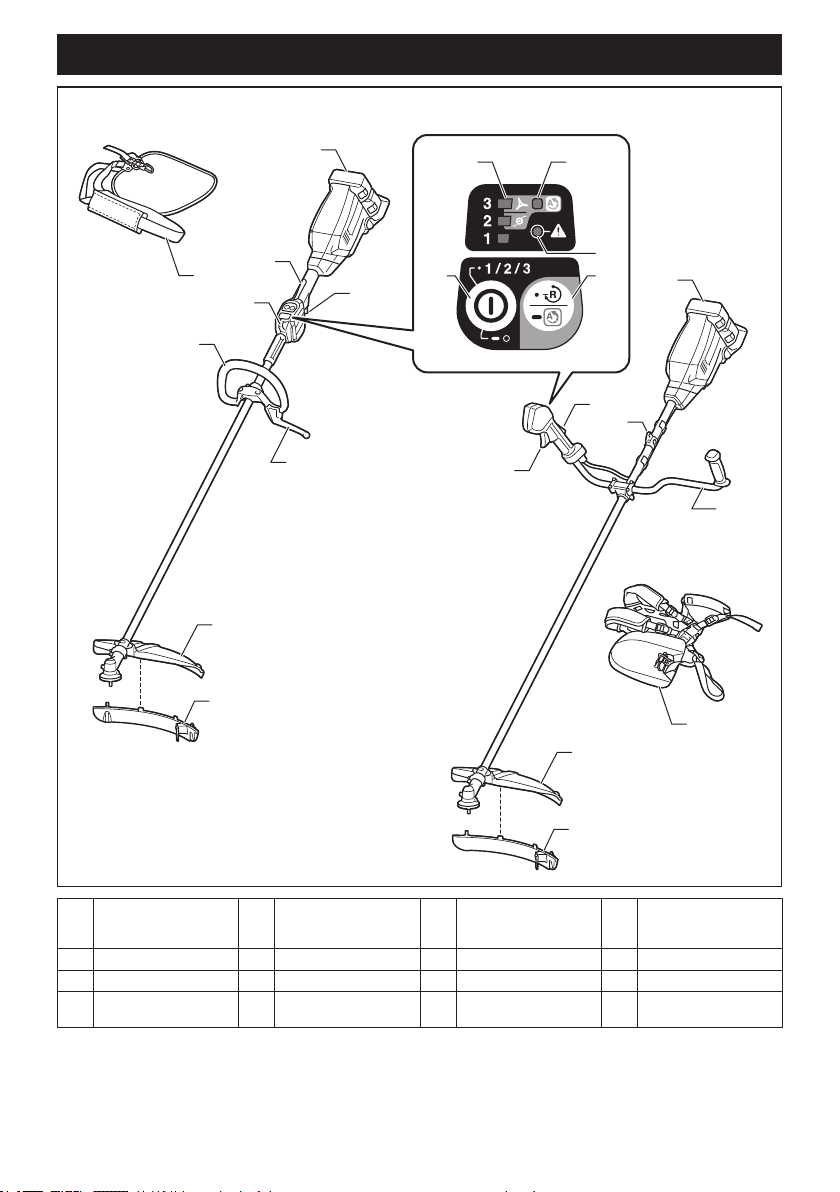

PARTS DESCRIPTION

XRU17

6

1 2

10

14

13

12

7

9

8

4 5

3

XRU16

6

7

9

11

8

10

14

12

13

1 Speed indicator 2 ADT indicator

5 Reverse button 6 Battery cartridge 7 Lock-o lever 8 Switch trigger

9 Hanger 10 Handle 11 Barrier (country specic) 12 Protector

13 Protector extension (for

nylon cutting head)

(ADT = Automatic Torque

Drive Technology)

14 Shoulder harness - - - -

3 Caution lamp 4 Main power button

7 ENGLISH

FUNCTIONAL

DESCRIPTION

WARNING: Always be sure that the tool is

switched o and the battery cartridge is removed

before adjusting or checking function on the tool.

Failure to switch o and remove the battery cartridge

may result in serious personal injury from accidental

start-up.

Installing or removing battery

cartridge

CAUTION: Always switch o the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip o your hands

and result in damage to the tool and battery cartridge

and a personal injury.

1

2

3

Caution lamp Status

Color

Green

Red

Red

On Blinking

(tool) / (battery)

Overload

Overheat

Over

discharge

Overload protection

If the tool gets into one of the following situation, the

tool automatically stops and the caution lamp starts

blinking in green:

— The tool is overloaded by entangled weeds or

other debris.

— The cutting tool is locked or kicked back.

— The main power button is turned on while the

switch trigger is being pulled.

In this situation, release the switch trigger and remove

entangled weeds or debris if necessary. After that, pull

the switch trigger again to resume.

CAUTION: If you need to remove the entan-

gled weeds on the tool or release the locked

cutting tool, be sure to turn the tool o before you

start.

Overheat protection for tool or

battery

If the tool or battery cartridge is overheated, the tool

stops automatically. When the tool is overheated, the

caution lamp lights up in red. When the battery cartridge

is overheated, the caution lamp blinks in red. Let the

tool and/or battery cool down before turning the tool on

again.

► 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

Tool / battery protection system

The tool is equipped with a tool/battery protection

system. This system automatically cuts o power to

the motor to extend tool and battery life. The tool will

automatically stop during operation if the tool is placed

under one of the following conditions:

Overdischarge protection

When the battery capacity becomes low, the tool stops

automatically and the caution lamp starts blinking in red.

If the tool does not operate even when the switches are

operated, remove the battery cartridge from the tool and

charge it.

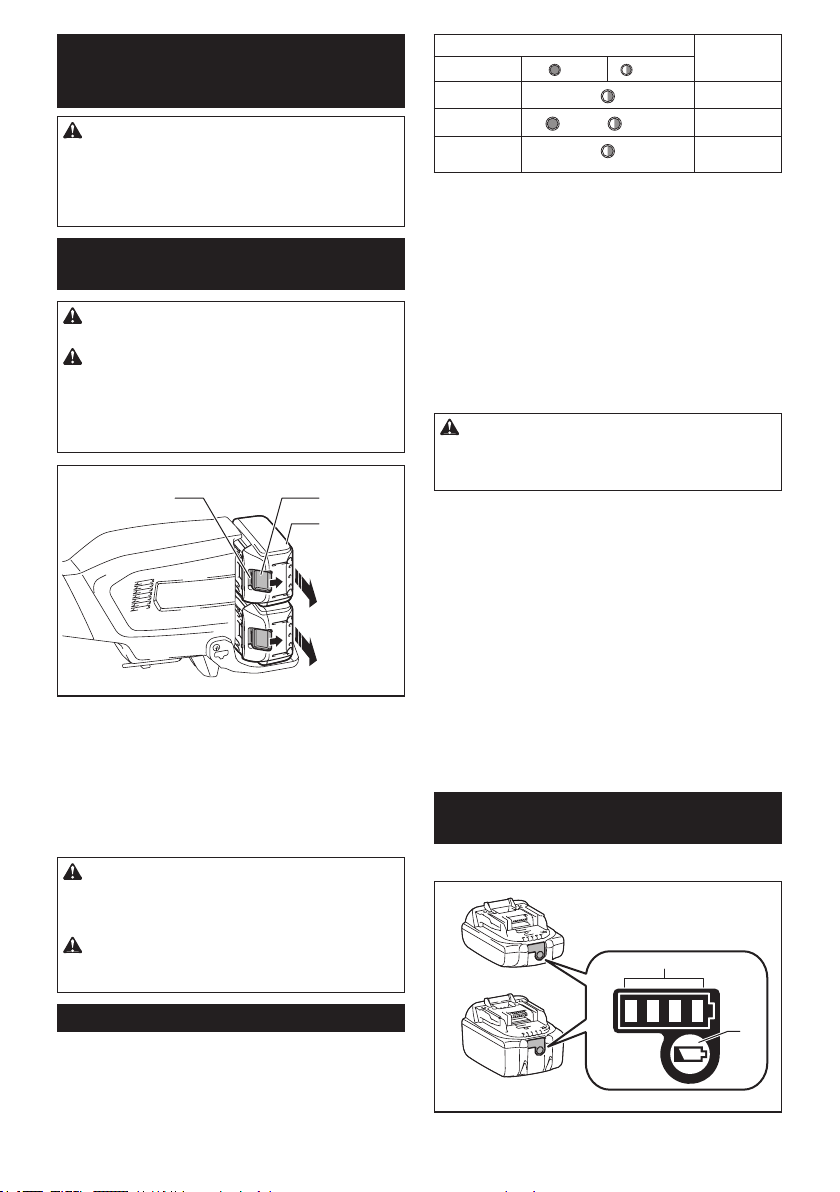

Indicating the remaining battery

capacity

Only for battery cartridges with the indicator

1

2

► 1. Indicator lamps 2. Check button

8 ENGLISH

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for a few seconds.

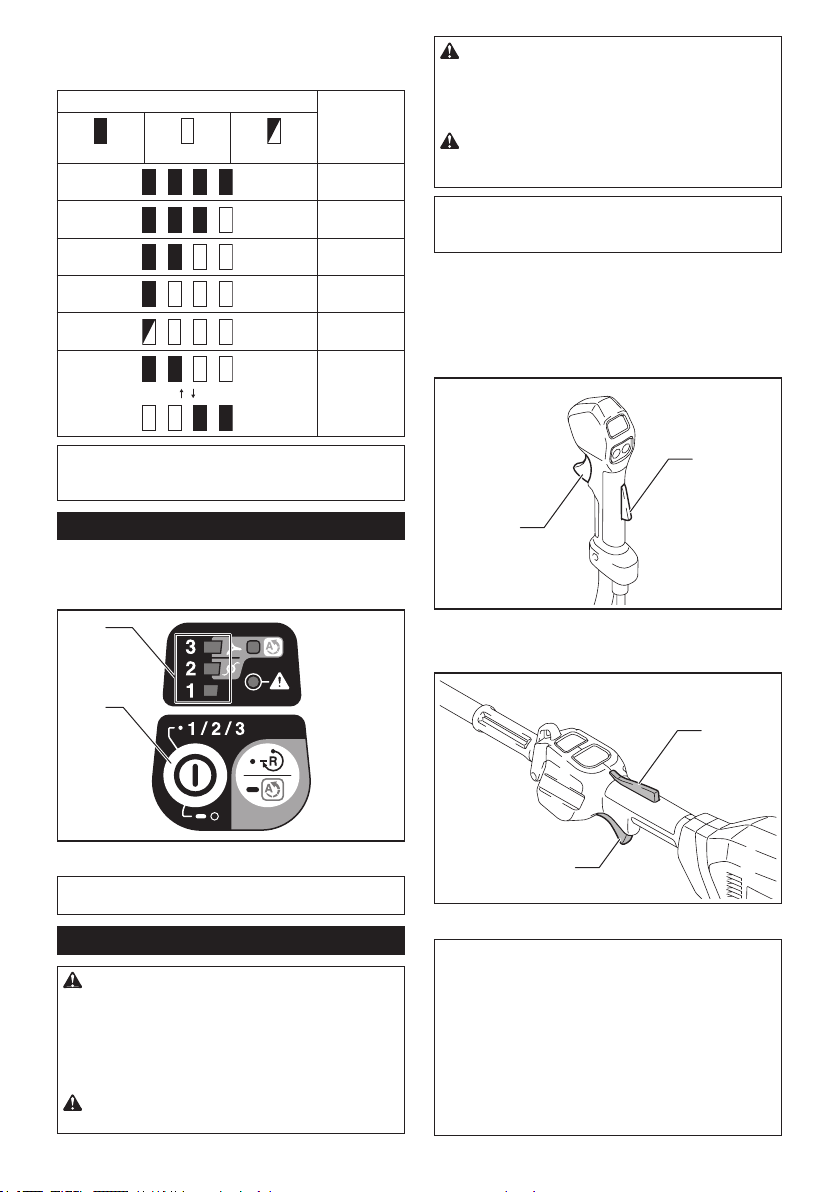

Indicator lamps Remaining

Lighted O Blinking

capacity

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

CAUTION:

into the tool, always check to see that the switch trigger

actuates properly and returns to the "OFF" position when

released. Operating a tool with a switch that does not actuate

properly can lead to loss of control and serious personal injury.

CAUTION:

power button and switch trigger when carrying the

tool. The tool may start unintentionally and cause injury.

Before installing the battery cartridge

Never put your nger on the main

NOTICE: Do not pull the switch trigger hard with-

out pressing the lock-o lever. This can cause

switch breakage.

To prevent the switch trigger from being accidentally

pulled, a lock-o lever is provided. To start the tool,

depress the lock-o lever and pull the switch trigger.

The tool speed increases by increasing pressure on the

switch trigger. Release the switch trigger to stop.

XRU16

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may dier slightly

from the actual capacity.

Main power switch

Tap the main power button to turn on the tool.

To turn o the tool, press and hold the main power

button until the speed indicator goes o.

1

2

► 1. Speed indicator 2. Main power button

NOTE: The tool will automatically turned o if it is left

without any operations for a certain period of time.

Switch action

WARNING: For your safety, this tool is

equipped with lock-o lever which prevents the

tool from unintended starting. NEVER use the tool

if it runs when you simply pull the switch trigger

without pressing the lock-o lever. Return the

tool to our authorized service center for proper

repairs BEFORE further usage.

WARNING: NEVER tape down or defeat pur-

pose and function of lock-o lever.

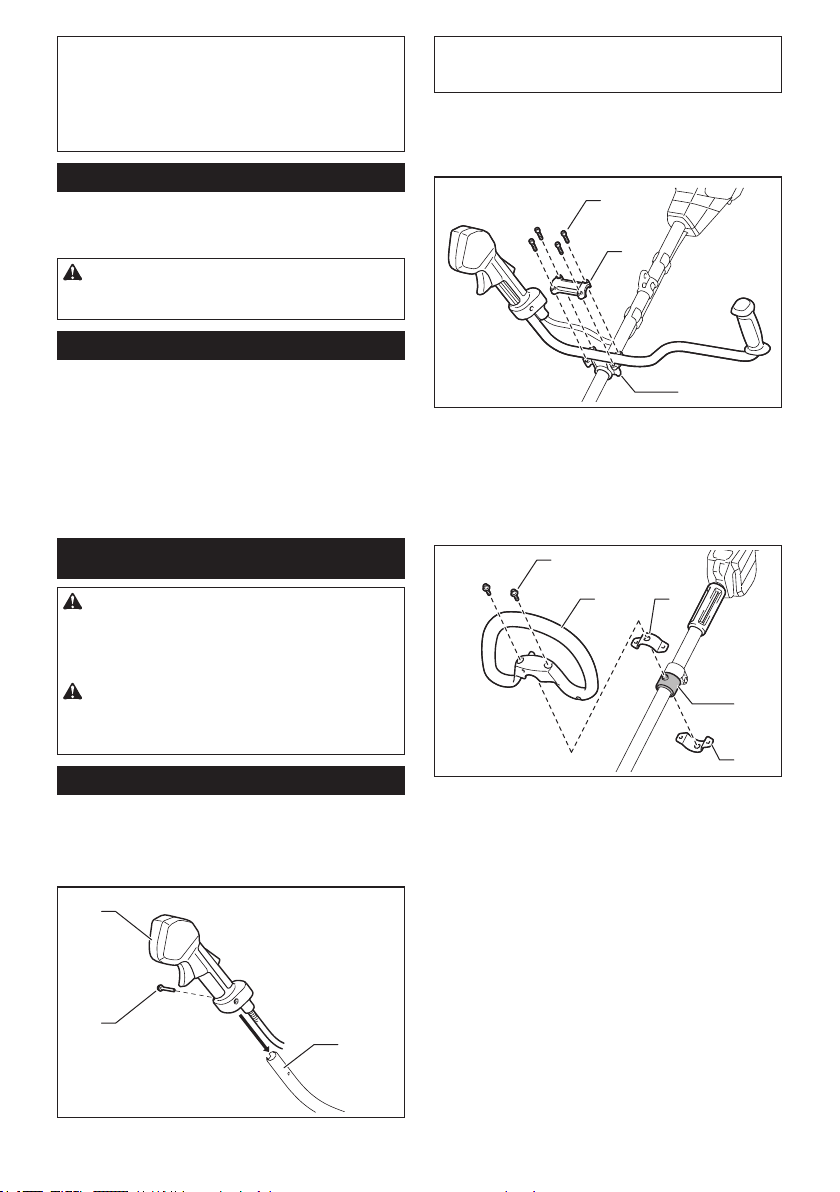

1

2

► 1. Lock-o lever 2. Switch trigger

XRU17

1

2

► 1. Lock-o lever 2. Switch trigger

NOTE: Always depress the lock-o lever and pull the

switch trigger to run the tool. In the following cases,

the main power switch turns o automatically:

— When both the lock-o lever and switch trigger

are released.

— When the lock-o lever is released for 1 second.

— When the lock-o lever is not depressed within

45 seconds after the main power switch is

turned on.

— When the switch trigger is not pulled for 60 sec-

onds while the lock-o lever is being depressed.

9 ENGLISH

Speed adjusting

You can select the tool speed by tapping the main

power button. Each time you tap the main power button,

the level of speed will change.

1

2

1

2

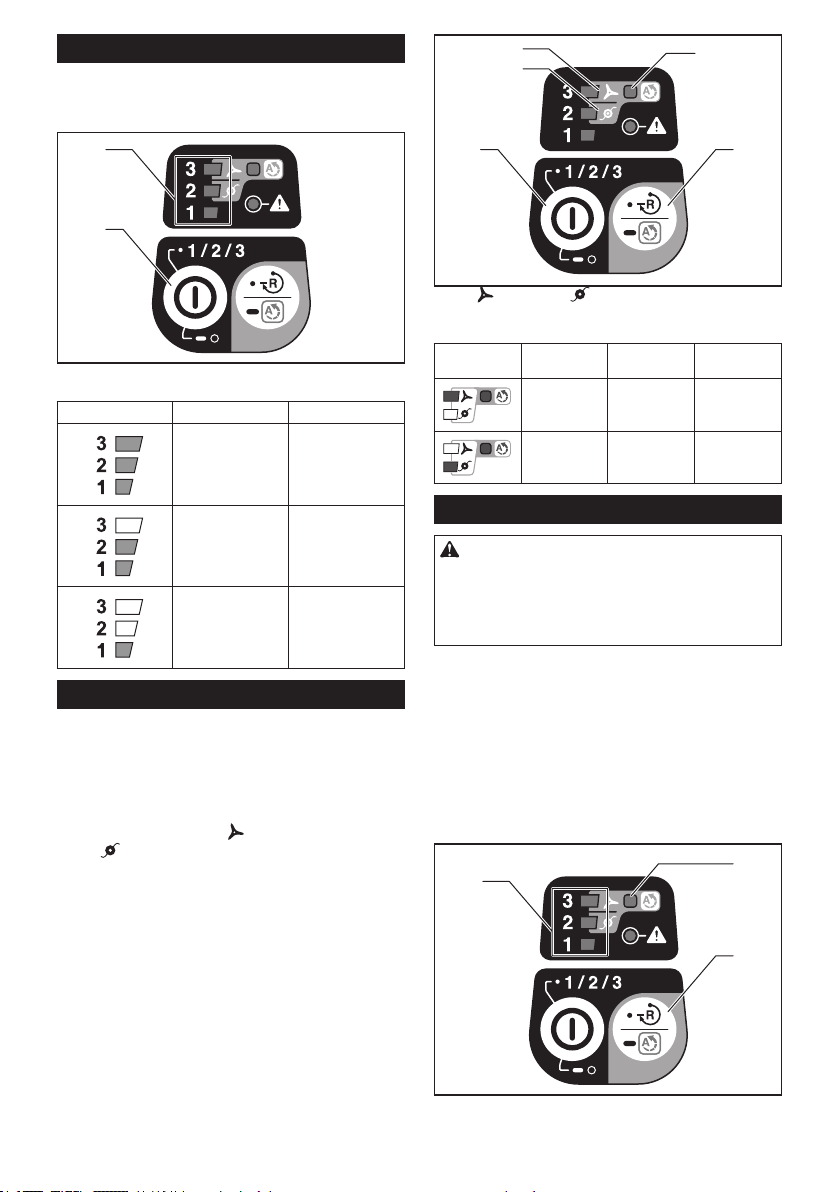

► 1. marking 2. marking 3. ADT indicator

4. Main power button 5. Reverse button

3

54

► 1. Speed indicator 2. Main power button

Speed indicator Mode Rotation speed

High 0-7,000 /min

Medium 0-5,500 /min

Low 0-4,600 /min

Automatic Torque Drive Technology

When you turn on the Automatic Torque Drive

Technology (ADT), the tool runs at optimum rotation

speed and torque for the condition of grass being cut.

To start ADT, press and hold the reverse button until

the ADT indicator turns on. After that, tap the main

power button to select the cutting tool attached to the

tool. Light the lamp beside

blade, marking to select nylon cutting head.

To stop ADT, press and hold the reverse button until the

ADT indicator turns o.

marking to select cutter

Indicator Mode Cutting tool Rotation

ADT

(Cutter blade)

ADT

(Nylon cutting

head)

Cutter blade 3,500-7,000

Nylon cutting

head

speed

/min

3,500-5,500

/min

Reverse button for debris removal

WARNING: Switch o the tool and remove

the battery cartridge before you remove entangled weeds or debris which the reverse rotation

function can not remove. Failure to switch o and

remove the battery cartridge may result in serious

personal injury from accidental start-up.

This tool has a reverse button to change the direction of

rotation. It is only for removing weeds and debris entangled in the tool.

To reverse the rotation, tap the reverse button and pull

the switch trigger while depressing the lock-o lever

when the cutting tool is stopped. The speed indicators

and ADT indicator start blinking, and the cutting tool

rotates in reverse direction when you pull the switch

trigger.

To return to regular rotation, release the trigger and wait

until the cutting tool stops.

1

2

► 1. Speed indicator 2. ADT indicator 3. Reverse

button

10 ENGLISH

3

During the reverse rotation, the tool operates only

NOTE:

for a short period of time and then automatically stops.

NOTE: Once the tool is stopped, the rotation returns

to regular direction when you start the tool again.

If you tap the reverse button while the cutting tool is still

NOTE:

rotating, the tool comes to stop and to be ready for reverse rotation.

Electric brake

This tool is equipped with an electric brake. If the tool

consistently fails to quickly stop after the switch trigger

is released, have the tool serviced at our service center.

CAUTION:

the protector. Never use the tool without the protector. An

unguarded cutting tool may result in serious personal injury.

This brake system is not a substitute for

Electronic function

NOTICE: Note the direction of the grip. The

screw holes will not be aligned if the grip is not

inserted in the correct direction.

2. Place handle between handle clamp and handle

holder. Adjust the handle to an angle that provides a

comfortable working position and then secure with hex

socket head bolts.

1

2

Constant speed control

The speed control function provides the constant rotation speed regardless of load conditions.

Soft start feature

Soft start because of suppressed starting shock.

ASSEMBLY

WARNING: Always be sure that the tool is

switched o and battery cartridge is removed

before carrying out any work on the tool. Failure to

switch o and remove the battery cartridge may result

in serious personal injury from accidental start-up.

WARNING: Never start the tool unless it is

completely assembled. Operation of the tool in a

partially assembled state may result in serious per-

sonal injury from accidental start-up.

Installing the handle

For XRU16

1. Insert the shaft of the handle into the grip. Align

the screw hole in the grip with the one in the shaft.

Tighten the screw securely.

1

3

► 1. Hex socket head bolt 2. Handle clamp 3. Handle

holder

For XRU17

1. Attach the upper and lower clamps on the damper.

2. Put the handle on the upper clamp and x it with

hex socket head bolts as illustrated.

1

2 3

4

5

► 1. Hex socket head bolt 2. Handle 3. Upper clamp

4. Damper 5. Lower clamp

2

► 1. Grip 2. Screw 3. Shaft

3

11 ENGLISH

Attaching the barrier

For the loop handle model only (country specic)

If the barrier is included in your model, attach it to the

handle using the screw on the barrier.

For the loop handle model, the hex wrench can also be

stored on the handle as illustrated.

1

2

► 1. Barrier 2. Screw

CAUTION: After assembling the barrier, do

not remove it. The barrier works as a safety part

to prevent you from contacting the cutting blade

accidentally.

Hex wrench storage

CAUTION: Be careful not to leave the hex

wrench inserted in the tool head. It may cause

injury and/or damage to the tool.

When not in use, store the hex wrench as illustrated to

keep it from being lost.

1

1

► 1. Hex wrench

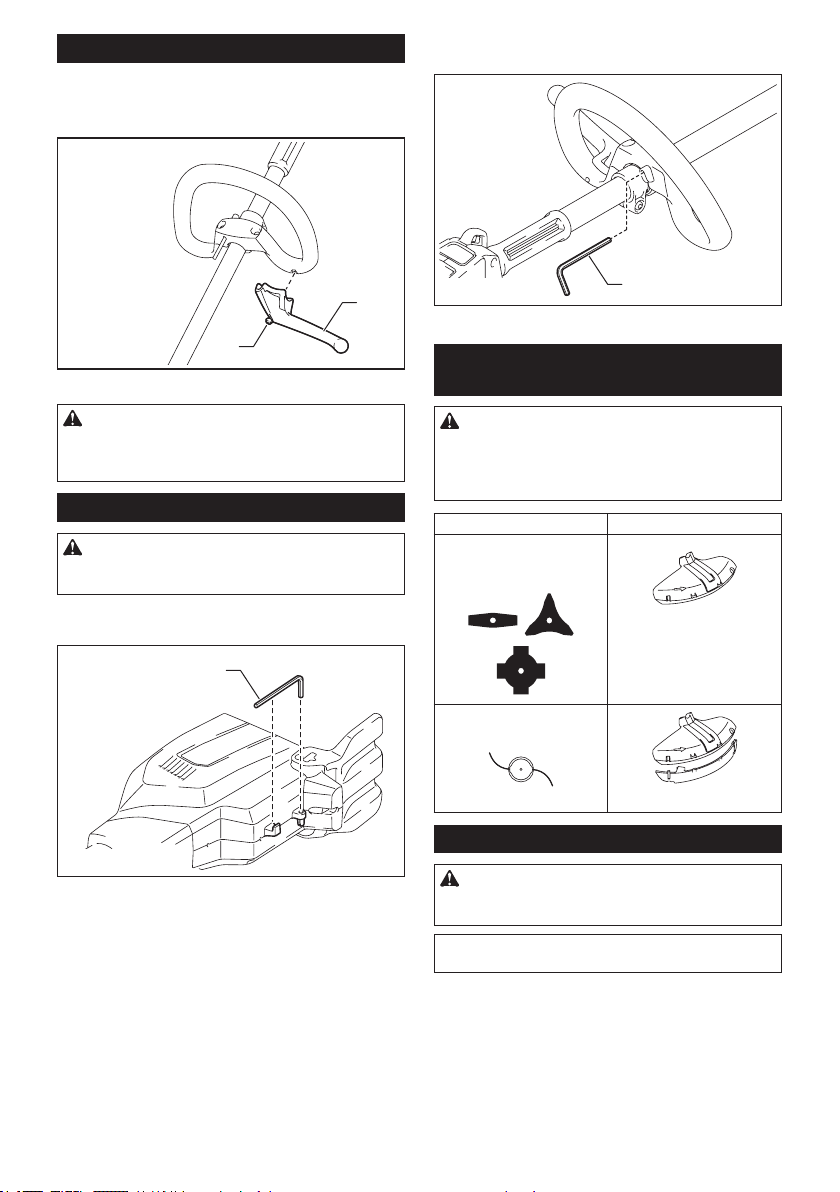

Correct combination of the cutting

tool and the protector

CAUTION: Always use the correct combi-

nation of cutting tool and the protector. A wrong

combination may not protect you from the cutting tool,

ying debris, and stones. It can also aect the balance of the tool and result in an injury.

Cutting tool Protector

Cutter blade

(2-tooth, 3-tooth, 4-tooth

blades)

Nylon cutting head

Installing the protector

► 1. Hex wrench

WARNING: Never use the tool without the

guard or with the guard improperly installed.

Failure to do so can cause serious personal injury.

NOTE: The type of the protector supplied as the standard accessory varies depending on the countries.

12 ENGLISH

For cutter blade

Attach the protector to the clamp using bolts.

2

Installing the cutting tool

1

CAUTION: Always use the supplied wrenches

to remove or to install the cutting tool.

CAUTION: Be sure to remove the hex wrench

inserted into the tool head after installing the

cutting tool.

NOTE: The type of the cutting tool(s) supplied as

the standard accessory varies depending on the

countries. The cutting tool is not included in some

countries.

NOTE: Turn the tool upside down so that you can

replace the cutting tool easily.

► 1. Clamp 2. Protector

For nylon cutting head

CAUTION: Take care not to injure yourself on

the cutter for cutting the nylon cord.

Attach the protector to the clamp using bolts. After

that, install the protector extension. Insert the protector

extension to the protector and then snap the clips on.

Make sure that the tabs on the protector extension t

into the slots on the protector.

1

2

3

4

► 1. Protector 2. Clip 3. Protector extension 4. Cutter

5. Slot 6. Tab

To remove the protector extension from the protector, unclasp the clips by inserting the hex wrench as

illustrated.

5

6

Cutter blade

CAUTION: When handling a cutter blade,

always wear gloves and put the blade cover on

the blade.

CAUTION: The cutter blade must be well pol-

ished, and free of cracks or breakage. If the cutter

blade hits a stone during operation, stop the tool and

check the cutter blade immediately.

CAUTION: Always use the cutter blade

with the diameter described in the section for

specications.

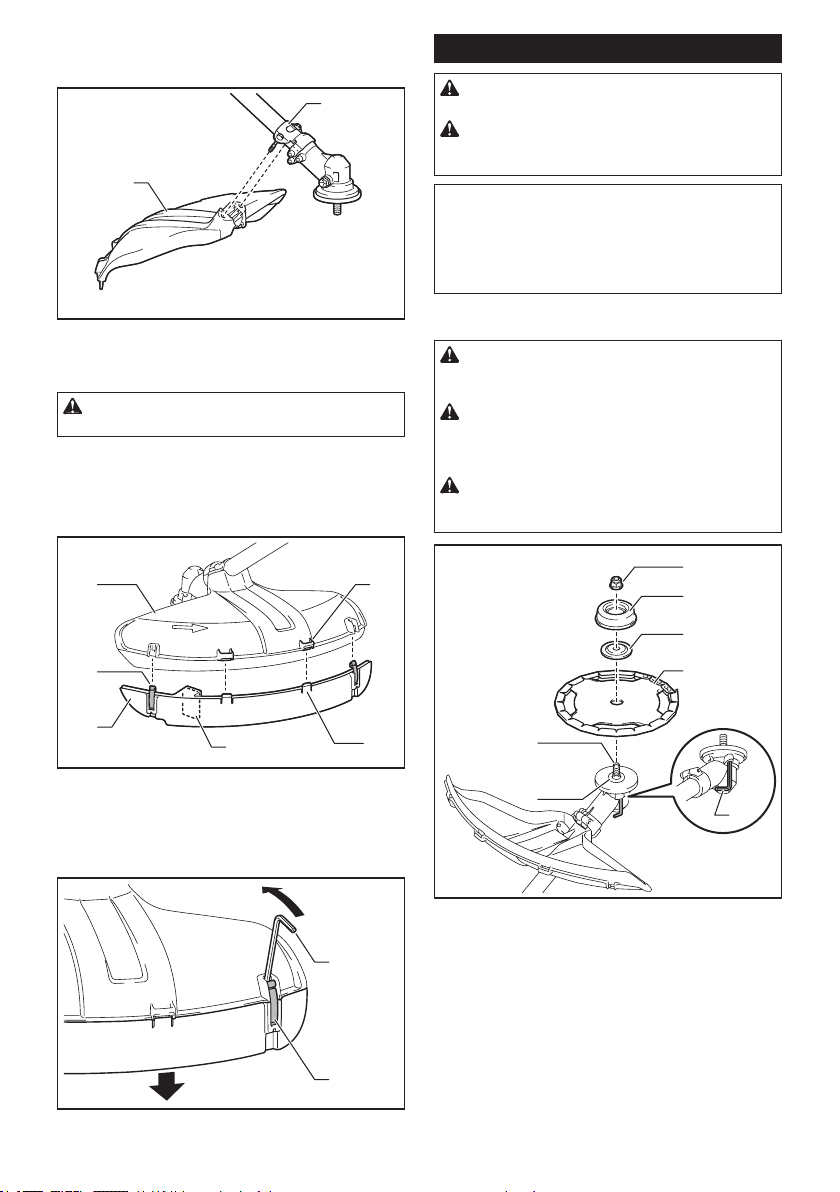

1

2

3

4

5

6

7

► 1. Hex wrench 2. Clip

1

2

► 1. Nut 2. Cup 3. Clamp washer 4. Cutter blade

5. Spindle 6. Receive washer 7. Hex wrench

1. Insert the hex wrench through the hole in the gear

case to lock the spindle. Rotate the spindle until the hex

wrench is fully inserted.

13 ENGLISH

2. Mount the cutter blade onto the receive washer

so that the arrows on the cutter blade and protector are

pointing in the same direction.

1

1

► 1. Arrow

Nylon cutting head

NOTICE: Be sure to use genuine Makita nylon

cutting head.

4

5

2

1

3

3. Put the clamp washer and cup onto the cutter

blade and then tighten the nut securely by the box

wrench.

1

4

3

2

► 1. Box wrench 2. Hex wrench 3. Loosen 4. Tighten

NOTE: Tightening torque : 20 - 30 N•m

4. Remove the hex wrench from the gear case.

To remove the cutter blade, follow the installation procedures in reverse.

► 1. Nylon cutting head 2. Spindle 3. Hex wrench

4. Loosen 5. Tighten

1. Insert the hex wrench through the hole in the gear

case to lock the spindle. Rotate the spindle until the hex

wrench is fully inserted.

2. Place the nylon cutting head onto the spindle and

tighten it securely by hand.

3. Remove the hex wrench from the gear case.

To remove the nylon cutting head, follow the installation

procedures in reverse.

OPERATION

Attaching the shoulder harness

CAUTION: Always use the shoulder harness

attached to the tool. Before operation, adjust the

shoulder harness according to the user size to

prevent fatigue.

CAUTION: Before operation, make sure that

the shoulder harness is properly attached to the

hanger on the tool.

For XRU16

1. Put on the shoulder harness and fasten the

buckle.

14 ENGLISH

Loading...

Loading...