INSTRUCTION MANUAL

MANUAL DE INSTRUCCIONES

Cordless Power Cutter

Cortadora de Concreto Inalámbrica

XEC01

IMPORTANT: Read Before Using.

IMPORTANTE: Lea antes de usar.

ENGLISH (Original instructions)

SPECIFICATIONS

Model: XEC01

Diamond wheel diameter 230 mm (9″)

Max. wheel thickness 3.0 mm (1/8″)

Max.cutting depth 88 mm (3-1/2″)

Rated speed 6,600 /min

Rated voltage D.C. 36 V

Max. permitted pressure of feed-water 5.0 bars

Overall length 554 mm (21-3/4″)

Net weight 5.6 - 6.3 kg (12.3 - 13.9 lbs)

•

Due to our continuing program of research and development, the specications herein are subject to change without notice.

• Specications may dier from country to country.

• The weight may dier depending on the attachment(s), including the battery cartridge. The lightest and heavi-

est combination, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge and charger

Battery cartridge

Charger

•

Some of the battery cartridges and chargers listed above may not be available depending on your region of residence.

BL1815N / BL1820B / BL1830 / BL1830B / BL1840B / BL1850B / BL1860B

DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF / DC18SH

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

and chargers may cause injury and/or re.

SAFETY WARNINGS

General power tool safety warnings

WARNING: Read all safety warnings, instruc-

tions, illustrations and specications provided

with this power tool. Failure to follow all instructions

listed below may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

1.

Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and

matching outlets will reduce risk of electric shock.

2. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

3. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

4. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5.

When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

suitable for outdoor use reduces the risk of electric shock.

6. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of a GFCI

reduces the risk of electric shock.

7. Power tools can produce electromagnetic

elds (EMF) that are not harmful to the user.

However, users of pacemakers and other similar

medical devices should contact the maker of their

device and/or doctor for advice before operating

this power tool.

2 ENGLISH

Personal Safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

2. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

3. Prevent unintentional starting. Ensure the

switch is in the o-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your nger on the switch or energising power tools

that have the switch on invites accidents.

4. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

5. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewel-

lery or long hair can be caught in moving parts.

7. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

8.

Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

9. Always wear protective goggles to protect

your eyes from injury when using power tools.

The goggles must comply with ANSI Z87.1 in

the USA.

It is an employer's responsibility to enforce the

use of appropriate safety protective equipment

by the tool operators and by other persons in

the immediate working area.

Power tool use and care

1. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

2. Do not use the power tool if the switch does

not turn it on and o. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

3. Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

5.

Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage of parts and any other condition that may

aect the power tool’s operation. If damaged, have

the power tool repaired before use. Many accidents

are caused by poorly maintained power tools.

6. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7.

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations dierent

from those intended could result in a hazardous situation.

8.

Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

9.

When using the tool, do not wear cloth work gloves

which may be entangled. The entanglement of cloth work

gloves in the moving parts may result in personal injury.

Battery tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

2. Use power tools only with specically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and re.

3. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a re.

4.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact acci-

dentally occurs, ush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected

from the battery may cause irritation or burns.

5. Do not use a battery pack or tool that is dam-

aged or modied. Damaged or modied batteries

may exhibit unpredictable behaviour resulting in

re, explosion or risk of injury.

6. Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or temperature above 130 °C may cause explosion.

7.

Follow all charging instructions and do not charge

the battery pack or tool outside the temperature

range specied in the instructions. Charging improp-

erly or at temperatures outside the specied range may

damage the battery and increase the risk of re.

Service

1.

Have your power tool serviced by a qualied repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

2. Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

3. Follow instruction for lubricating and chang-

ing accessories.

4. Do not modify or attempt to repair the appliance or the battery pack except as indicated in

the instructions for use and care.

3 ENGLISH

Cordless cutter safety warnings

1. The guard provided with the tool must be

securely attached to the power tool and

positioned for maximum safety, so the least

amount of wheel is exposed towards the operator. Position yourself and bystanders away

from the plane of the rotating wheel. The guard

helps to protect operator from broken wheel fragments and accidental contact with wheel.

2. Use only bonded reinforced or diamond cut-o

wheels for your power tool. Just because an

accessory can be attached to your power tool, it

does not assure safe operation.

3. The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and y apart.

4.

Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-o wheel. Abrasive cut-o wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

5. Always use undamaged wheel anges that are

of correct diameter for your selected wheel.

Proper wheel anges support the wheel thus

reducing the possibility of wheel breakage.

6. Do not use worn down reinforced wheels from

larger power tools. Wheels intended for a larger

power tool are not suitable for the higher speed of

a smaller tool and may burst.

7. The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

8.

The arbour size of wheels and anges must properly t the spindle of the power tool. Wheels and

anges with arbour holes that do not match the mounting hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

9.

Do not use damaged wheels. Before each use,

inspect the wheels for chips and cracks. If power

tool or wheel is dropped, inspect for damage or

install an undamaged wheel. After inspecting

and installing the wheel, position yourself and

bystanders away from the plane of the rotating

wheel and run the power tool at maximum no

load speed for one minute. Damaged wheels will

normally break apart during this test time.

10.

Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and shop apron capable

of stopping small abrasive or workpiece fragments.

The eye protection must be capable of stopping ying

debris generated by various operations. The dust mask

or respirator must be capable of ltrating particles

generated by your operation. Prolonged exposure to

high intensity noise may cause hearing loss.

11. Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken wheel may

y away and cause injury beyond immediate area

of operation.

Hold the power tool by insulated gripping sur-

12.

faces only, when performing an operation where

the cutting accessory may contact hidden wiring. Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

13. Never lay the power tool down until the acces-

sory has come to a complete stop. The spinning

wheel may grab the surface and pull the power

tool out of your control.

14. Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

15. Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

16. Do not operate the power tool near ammable

materials. Sparks could ignite these materials.

Kickback and related warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel. Pinching or snagging causes rapid stalling

of the rotating wheel which in turn causes the uncontrolled power tool to be forced in the direction opposite of

the wheel’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel that is entering

into the pinch point can dig into the surface of the material

causing the wheel to climb out or kick out. The wheel may

either jump toward or away from the operator, depending on

direction of the wheel’s movement at the point of pinching.

Abrasive wheels may also break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

1. Maintain a rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating acces-

sory. Accessory may kickback over your hand.

3. Do not position your body in line with the

rotating wheel. Kickback will propel the tool in

direction opposite to the wheel’s movement at the

point of snagging.

4. Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

5. Do not attach a saw chain, woodcarving blade,

segmented diamond wheel with a peripheral

gap greater than 10 mm or toothed saw blade.

Such blades create frequent kickback and loss of

control.

6. Do not “jam” the wheel or apply excessive

pressure. Do not attempt to make an excessive

depth of cut. Overstressing the wheel increases

the loading and susceptibility to twisting or binding

of the wheel in the cut and the possibility of kick-

back or wheel breakage.

4 ENGLISH

7. When wheel is binding or when interrupting

a cut for any reason, switch o the power

tool and hold the power tool motionless until

the wheel comes to a complete stop. Never

attempt to remove the wheel from the cut while

the wheel is in motion otherwise kickback may

occur. Investigate and take corrective action to

eliminate the cause of wheel binding.

8.

Do not restart the cutting operation in the workpiece. Let the wheel reach full speed and carefully

re-enter the cut. The wheel may bind, walk up or

kickback if the power tool is restarted in the workpiece.

9. Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge

of the workpiece on both sides of the wheel.

10. Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

Additional Safety Warnings:

1. Before using a segmented diamond wheel,

make sure that the diamond wheel has the

peripheral gap between segments of 10 mm or

less, only with a negative rake angle.

2. Never attempt to cut with the tool held upside

down in a vise. This can lead to serious accidents, because it is extremely dangerous.

3.

Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation and

skin contact. Follow material supplier safety data.

4.

Store wheels as per manufacturer recommendations. Improper storage may damage the wheels.

5. Always use the wheel suitable for your work

and the material to be cut.

6. Examine the material to be cut before cutting.

If the material contains explosive or ammable

substances, it may cause an explosion or re.

7. Do not use a corded power supply such as

battery adapter or portable power pack with

this tool. Using corded power supply hinders the

battery cover from closing and allow dust or water

coming into to the battery cartridge compartment,

which may result in electric shock.

8. Do not switch on the tool if a foreign object

is jammed between the guard and the wheel.

In this case, uninstall the battery cartridge and

remove the foreign object.

9. Use clamps or similar to support the workpiece whenever possible.

10. Always wear hearing protection during

operation.

11. Do not cut wood materials with this tool.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Symbols

The followings show the symbols used for tool.

diameter

volts

direct current

rated speed

revolutions or reciprocation per minute

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4.

If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current ow, overheating, possible burns and even a breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consulting an

expert for hazardous material is required. Please also

observe possibly more detailed national regulations.

Tape or mask o open contacts and pack up the battery in

such a manner that it cannot move around in the packaging.

11. When disposing the battery cartridge, remove

it from the tool and dispose of it in a safe

place. Follow your local regulations relating to

disposal of battery.

5 ENGLISH

12. Use the batteries only with the products

specied by Makita. Installing the batteries to

non-compliant products may result in a re, excessive heat, explosion, or leak of electrolyte.

13. If the tool is not used for a long period of time,

the battery must be removed from the tool.

SAVE THESE INSTRUCTIONS.

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

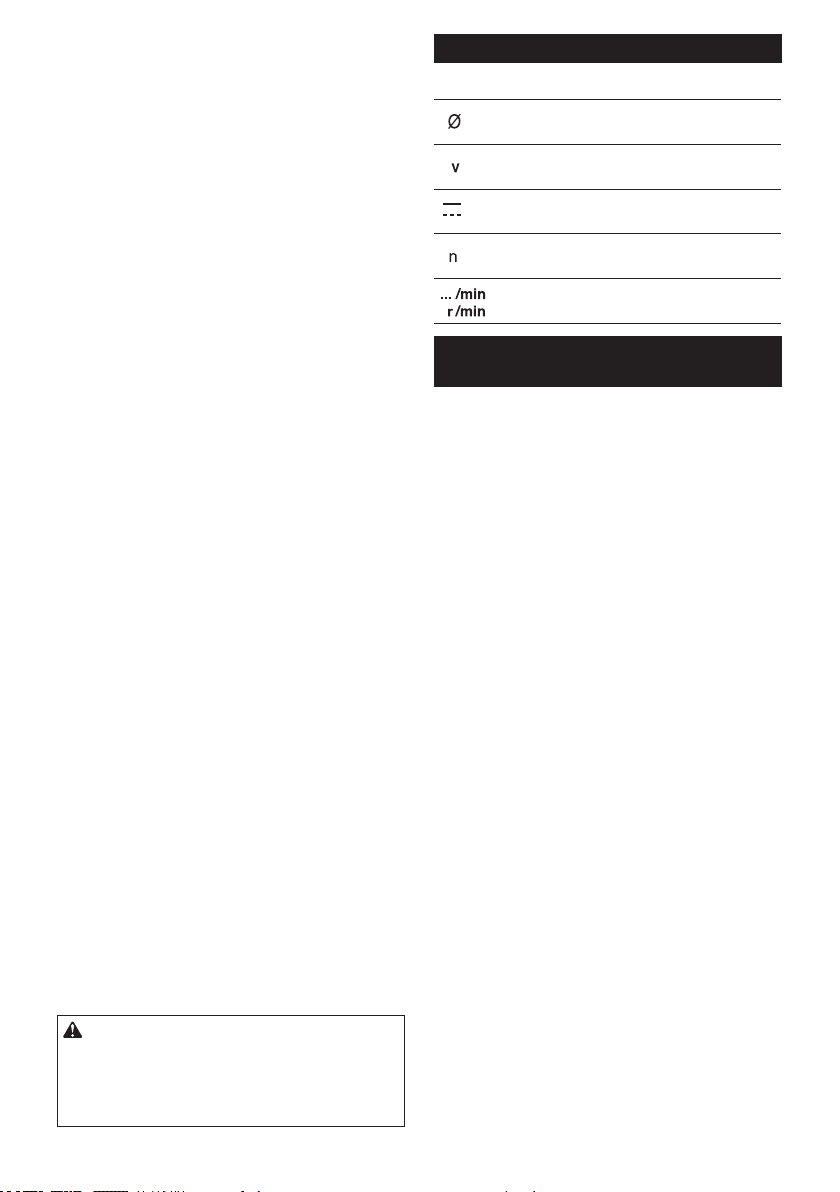

PARTS DESCRIPTION

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2.

Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3.

Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let a hot

battery cartridge cool down before charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

2

3 4

5

1

98

7

6

10

11

12

13

17

16

14

15

18

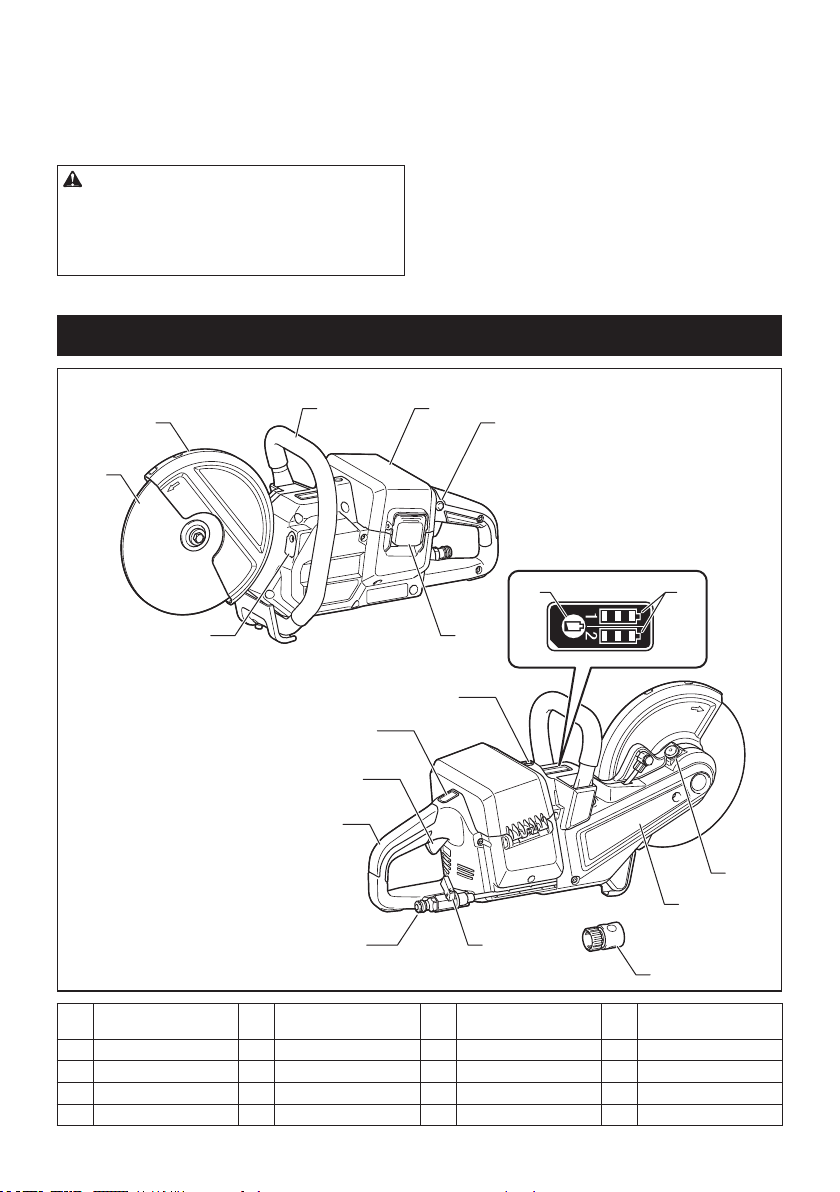

1 Abrasive cut-o wheel /

diamond wheel

5 Lock-o button 6 Hook 7 Lamp 8 Check button

9 Battery indicator 10 Overload indicator 11 Lamp button 12 Switch trigger

13 Handle 14 Water inlet 15 Cock 16 Cover (for V-belt)

17 Shaft lock button 18 Coupling sleeve - - - -

2 Wheel guard 3 Grip 4 Cover (for battery

6 ENGLISH

compartment)

FUNCTIONAL

DESCRIPTION

CAUTION: Always be sure that the tool is

switched o and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery

cartridge

CAUTION: Always switch o the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip o your hands

and result in damage to the tool and battery cartridge

and a personal injury.

To install the battery cartridge, open the cover while

releasing the hook. Align the tongue on the battery

cartridge with the groove in the housing and slip it into

place. Insert it all the way until it locks in place with a

little click. If you can see the red indicator on the upper

side of the button, it is not locked completely.

After installing or removing the battery cartridges, make

sure that the cover is closed and locked by the hook.

1

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

NOTE: The tool does not work with only one battery

cartridge.

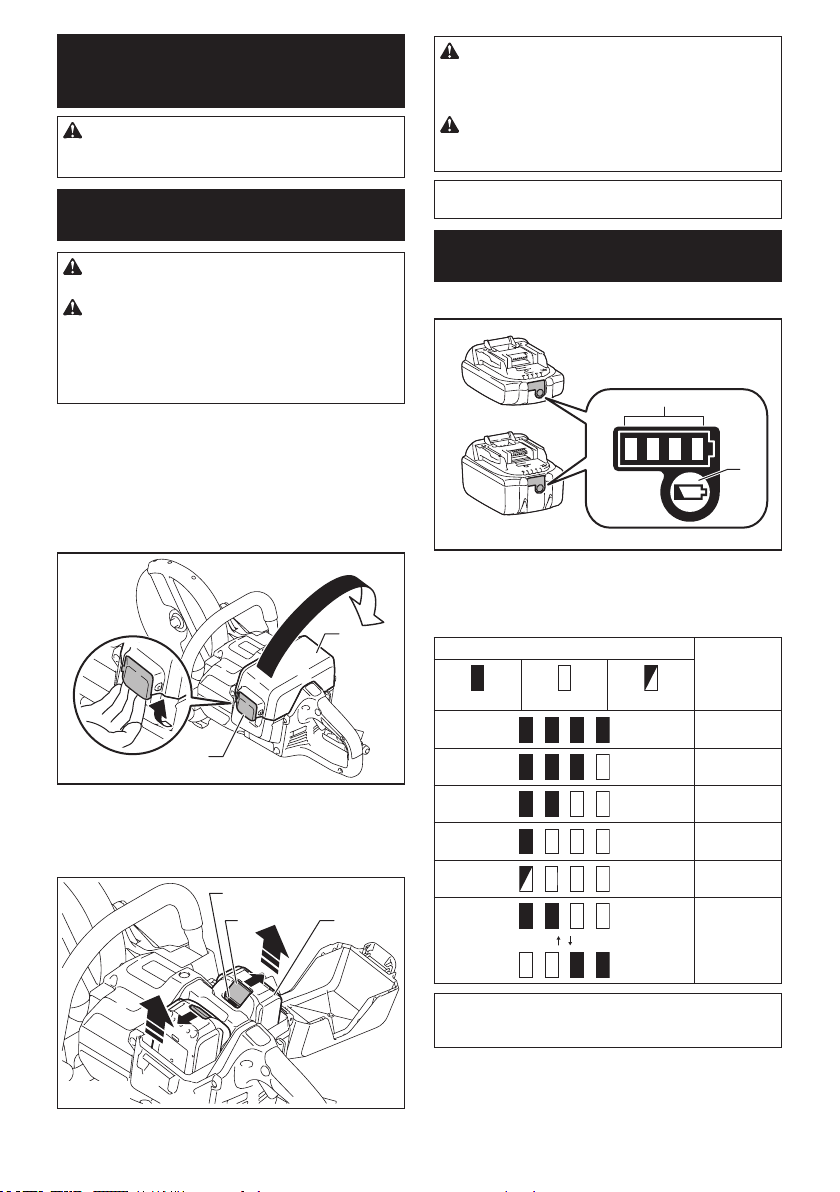

Indicating the remaining battery

capacity

Only for battery cartridges with the indicator

1

2

► 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for a few seconds.

Indicator lamps Remaining

capacity

2

► 1. Cover 2. Hook

To remove the battery cartridges, lift the battery car-

tridge while pushing the button on the front of the

cartridge.

1

2

► 1. Red indicator 2. Button 3. Battery cartridge

3

Lighted O Blinking

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may dier slightly

from the actual capacity.

7 ENGLISH

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

Indicating the remaining battery

capacity

battery

capacity

50% to 100%

20% to 50%

2

1

► 1. Battery indicator 2. Check button

Press the check button to indicate the remaining battery

capacities. The battery indicators correspond to each

battery.

Battery indicator status Remaining

On

O

Blinking

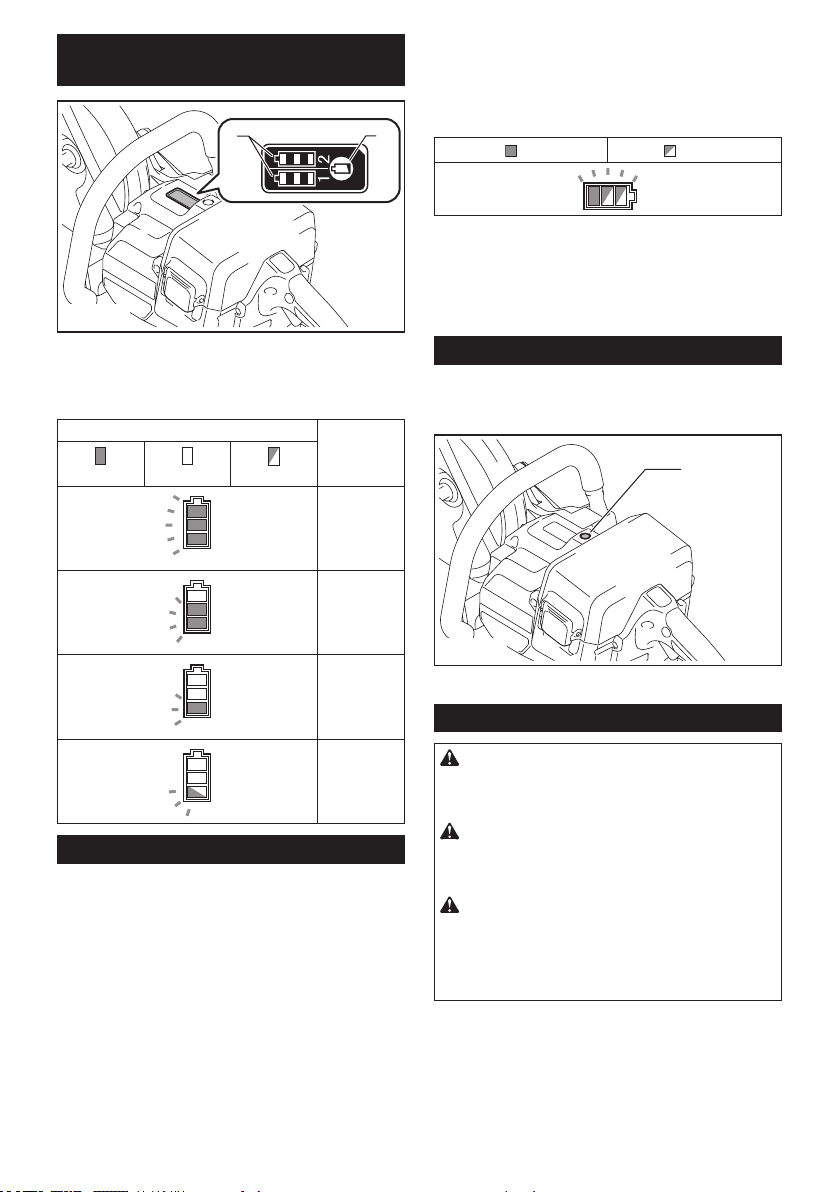

Overheat protection

When the tool is overheated, the tool stops automati-

cally, and the battery indicator blink about 60 seconds.

In this situation, let the tool cool down before turning the

tool on again.

On Blinking

Overdischarge protection

When the battery capacity becomes low, the tool stops

automatically. If the product does not operate even

when the switches are operated, remove the batteries

from the tool and charge the batteries.

Overload alert

If the tool is operated with excessive load, the overload

indicator will blink in red. In this situation, reduce the

load on the tool. Then, the indicator stops blinking.

1

0% to 20%

Charge the

battery

Tool / battery protection system

The tool is equipped with a tool/battery protection system. This system automatically cuts o power to the

motor to extend tool and battery life. The tool will automatically stop during operation if the tool or battery is

placed under one of the following conditions.

Overload protection

When the tool/battery is operated in a manner that

causes it to draw an abnormally high current, the tool

automatically stops. In this situation, turn the tool o

and stop the application that caused the tool to become

overloaded. Then turn the tool on to restart.

► 1. Overload indicator

Switch action

WARNING: Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

WARNING: NEVER defeat the lock-o button

by taping down or some other means. A switch with

a negated lock-o button may result in unintentional

operation and serious personal injury.

WARNING: NEVER use the tool if it runs when

you simply pull the switch trigger without press-

ing the lock-o button. A switch in need of repair

may result in unintentional operation and serious

personal injury. Return tool to a Makita service center

for proper repairs BEFORE further usage.

8 ENGLISH

To prevent the switch trigger from being accidentally

pulled, a lock-o button is provided. To start the tool,

depress the lock-o button and pull the switch trigger.

Release the switch trigger to stop.

2

1

► 1. Switch trigger 2. Lock-o button

NOTICE: Do not pull the switch trigger hard

without pressing in the lock-o button. This can

cause switch breakage.

Lighting the lamp

CAUTION: Do not look in the light or see the

source of light directly.

To turn on the lamp, press the lamp button. To turn o,

press the lamp button again.

Electric brake

Electric brake is activated after the tool is switched o.

The brake does not work when the power supply is shut

down, such as the battery is removed accidentally, with

the switch still on.

ASSEMBLY

CAUTION: Always be sure that the tool is

switched o and the battery cartridge is removed

before carrying out any work on the tool.

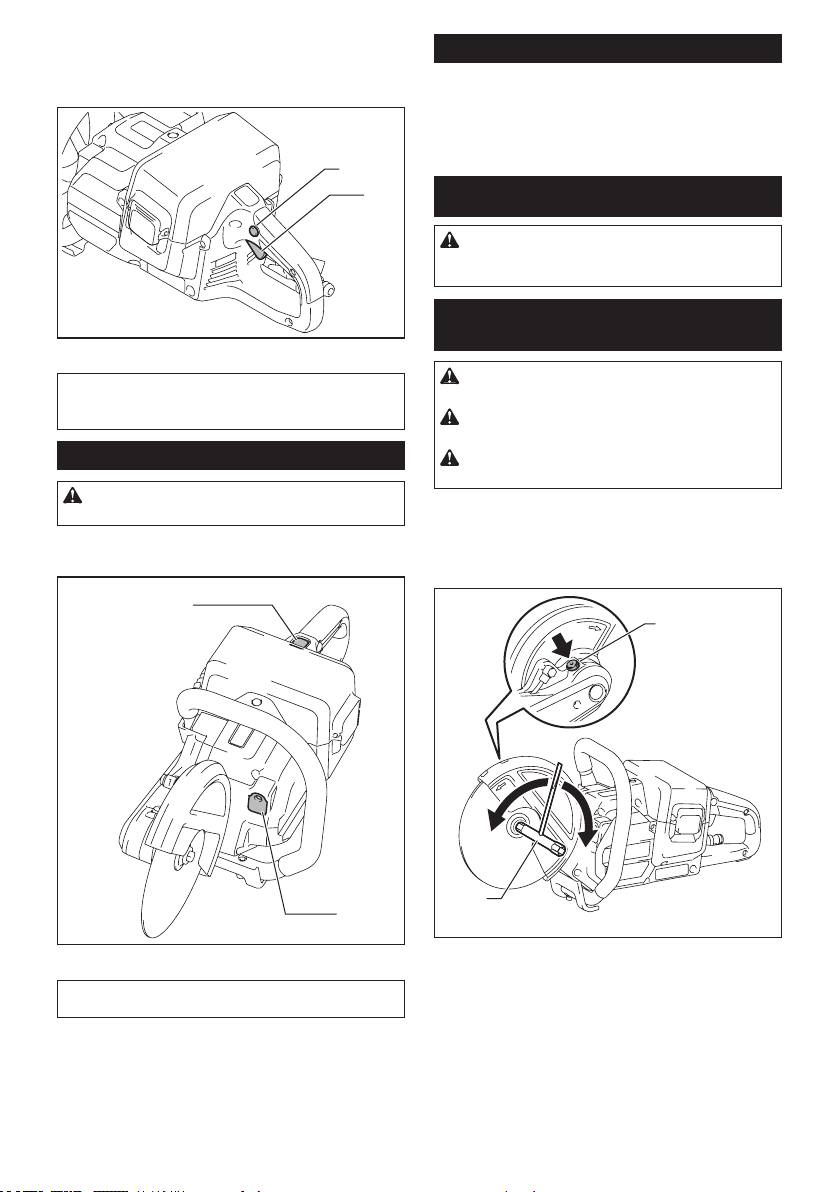

Installing or removing abrasive cut-

o wheel / diamond wheel

CAUTION: Use only the Makita wrench to

install or remove the wheel.

CAUTION: When installing the wheel, be sure

to tighten the bolt securely.

CAUTION: Do not press the shaft lock button

when the wheel is rotating.

To remove the wheel, press the shaft lock button and

rotate the wheel until the wheel cannot revolve. While

the shaft lock is fully locked, turn the hex bolt counterclockwise using the box wrench. Then remove the hex

bolt, outer ange and wheel.

1

2

► 1. Lamp button 2. Lamp

NOTE: The lamp will automatically be turned o if

there is no operation with the tool for one minute.

1

4

3

2

► 1. Shaft lock button 2. Box wrench 3. Tighten

4. Loosen

9 ENGLISH

5

5

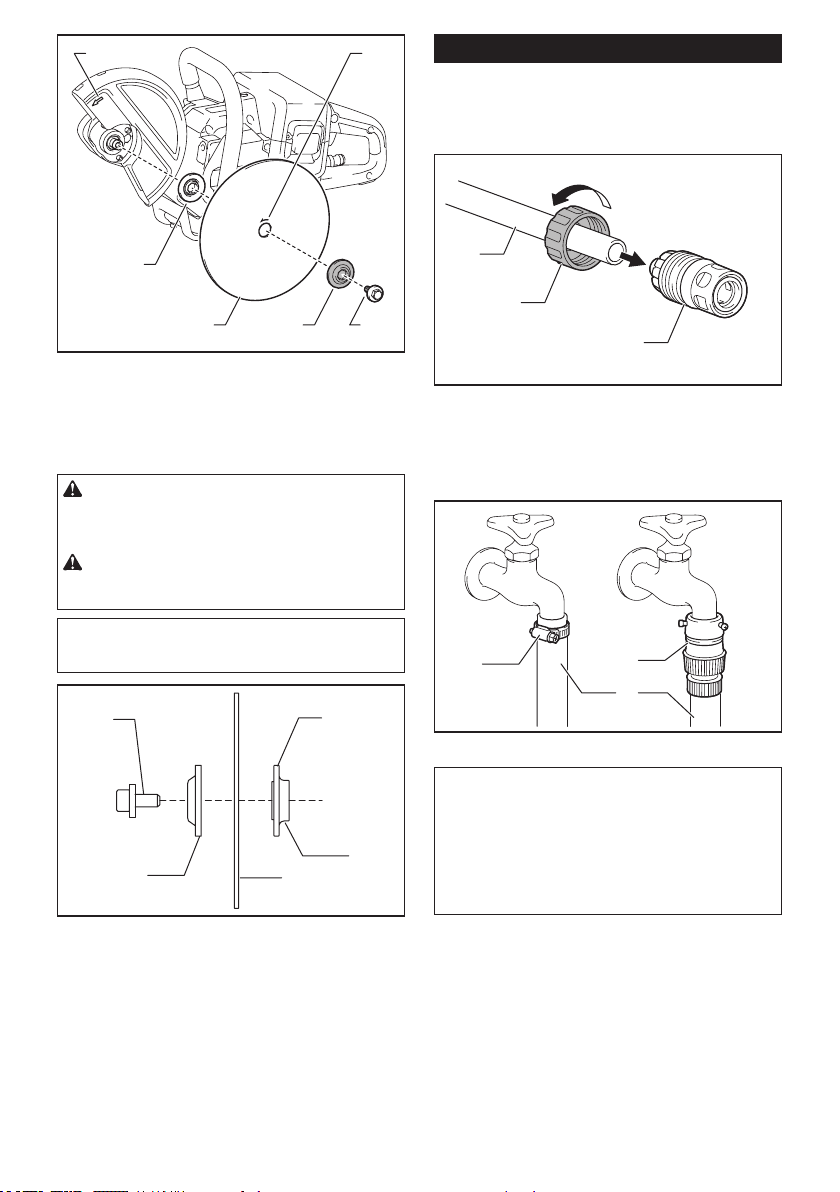

Connecting to water supply

1. Prepare a water hose.

2. Remove the nut on the coupling sleeve and pass

the water hose through the nut. Insert the end of the

hose into the coupling sleeve and then tighten the nut.

4

123

► 1. Hex bolt 2. Outer ange (black) 3. Abrasive cut-

o wheel / diamond wheel 4. Inner ange (silver)

5. Arrow (rotation direction of the wheel)

To install the wheel, follow the removal procedure in

reverse.

BE SURE TO TIGHTEN THE HEX BOLT SECURELY.

CAUTION: Always install the wheel so that

the arrow on it points in the same direction as

the arrow on the wheel guard. Otherwise the wheel

rotates in reverse, it may cause personal injury.

CAUTION: Only use the wheel that are

marked with a speed equal or higher than the

speed marked on the tool.

NOTE: If an inner ange is removed by chance,

install the inner ange so that taller protrusion faces

the tool side as shown in the gure.

1

4

5

2

► 1. Hex bolt 2. Outer ange (black) 3. Abrasive cut-

o wheel / diamond wheel 4. Inner ange (silver)

5. Protrusion (taller)

3

1

2

3

► 1. Water hose 2. Nut of the coupling sleeve

3. Coupling sleeve

3. Connect the water hose to the water supply.

When connecting to a water faucet, use a suitable tting

such as hose band or water tap joint.

1

2

3

► 1. Hose band 2. Water tap joint 3. Water hose

NOTE: The tting depends on the shape of the faucet

to which you connect. Prepare a suitable commercially-bought tting.

NOTE: If you use a water tap joint, prepare another

coupling sleeve and attach it to the other end of the

hose.

NOTE: When using a water pump, follow the instruc-

tions of your water pump to connect the water hose.

10 ENGLISH

4. Push the coupling sleeve into the water inlet until it

locks with a click.

3

2

1

► 1. Coupling sleeve 2. Water inlet 3. Cock

Hold the tool rmly. Grasp the handle with your right

hand and the grip with your left hand. To prevent electric

shock by accidental cutting of an electric cable, always

hold the grip by the designated portion as shown in the

gure.

1

NOTICE: Keep the cock closed until you start the

cutting operation with water feeding. For how to

feed water, refer to the section for the operation.

OPERATION

CAUTION: Be sure to lock the cover for bat-

tery compartment before operating.

CAUTION: Be sure to hold the workpiece

rmly down on a stable bench or table during

operation.

CAUTION: Do not twist or force the tool in the

cut, or the motor may be overloaded or the workpiece may break.

Cutting

CAUTION: During operation, do not bring the

tool higher than your shoulder height.

► 1. Part to hold

Move the tool over the workpiece surface, keeping it

at and advancing smoothly until the cutting is completed. Keep your cutting line straight and your speed of

advance uniform.

NOTE: When the battery cartridge temperature is

low, the tool may not work to its full capacity. At this

time, for example, use the tool for a light-duty cut for

a while until the battery cartridge warms up as high

as room temperature. Then, the tool can work to its

full capacity.

NOTE: If the cutting action of the diamond wheel

begins to diminish, dress the cutting edge of the

wheel using an old discarded coarse grit bench

grinder wheel or concrete block. Dress by pressing

lightly on the outer edge of the diamond wheel.

When feeding water during cutting

CAUTION: When using a wet-type diamond

wheel, always feed water during cutting.

Connect the tool to the water supply and turn the cock

in the direction of the arrow as illustrated. Adjust the

position of the cock to obtain a gentle ow of water.

1

► 1. Cock

11 ENGLISH

CAUTION: When feeding water, always keep

the tool head lower than the tool body to prevent

water entering into the tool mechanism. Failure to

do so may cause electric shock.

Cleaning the tool

After each use, remove the battery cartridge and the

wheel and then clean dust, dirt or metal chips accu-

mulated inside the wheel guard. Clean the tool body

by wiping o dust, dirt with a dry cloth or one dipped in

soapy water and wrung out. Use a dry cloth to wipe the

dirt o the lens of the lamp. Be careful not to scratch the

lens of lamp, or it may lower the illumination.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched o and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

1

► 1. Wheel guard 2. Lens of the lamp

Cleaning the air vent

Regularly clean the tool's air vents or whenever the

vents start to become obstructed.

1

2

2

► 1. Inhalation vent 2. Exhaust vent

12 ENGLISH

Changing the V-belt

1. Remove the battery cartridge and the wheel.

2. Loosen the hex socket bolts using the hex wrench

and then remove the cover .

1

4. Hook the new V-belt to the pulley (small). Put the

other end of the V-belt onto the half periphery of the

pulley (large) and then turn the bolt on the pulley (large)

clockwise using the box wrench.

The V-belt will get on the track as you turn the bolt.

12

2

► 1. Hex socket bolt 2. Cover

3. While twisting the V-belt inside, turn the bolt on the

pulley (large) clockwise using the box wrench.

The V-belt will deviate from the track and come o as

you turn the bolt.

2

3

3

► 1. Pulley (small) 2. Pulley (large) 3. Box wrench

Make sure that all the guides on the internal circle of the

V-belt t into the rails on the pulleys. All the rails on the

pulley must support the guides on the V-belt. If there is

a rail which does not support the guide, the V-belt is not

properly installed.

1

2

1

► 1. V-belt 2. Pulley (large) 3. Box wrench

NOTICE: Never turn the box wrench counter-

clockwise. Doing so loosen the bolt on the pulley

(large) and result in poor performance.

► 1. Rail on the pulley 2. Guide on the V-belt

13 ENGLISH

5. Place the cover onto the tool and tighten the hex

socket bolts using the hex wrench.

NOTICE: Make sure that the tube for water feed

is in the positions as shown in the gure before

attaching the cover.

1

2

3

► 1. Tube 2. Cover 3. Hex socket bolt

TROUBLESHOOTING

Before asking for repairs, conduct your own inspection rst. If you nd a problem that is not explained in the manual,

do not attempt to dismantle the tool. Instead, ask Makita Authorized Service Centers, always using Makita replace-

ment parts for repairs.

State of abnormality Probable cause (malfunction) Remedy

Motor does not run. Battery cartridges are not installed. Install two battery cartridges. This tool does not

Battery problem (under voltage) Recharge the battery. If recharging is not eective,

The drive system does not work

correctly.

Motor stops running after a little use. Battery's charge level is low. Recharge the battery. If recharging is not eective,

Overheating. Stop using of tool to allow it to cool down.

The wheel rotation does not acceler-

ate properly even after running the

tool without load for 20 seconds.

Wheel does not rotate:

stop the machine immediately!

Battery is installed improperly. Install the battery cartridge as described in this

Battery power is dropping. Recharge the battery cartridge. If recharging is not

The V-belt is slipping. Replace the V-belt with new one.

The drive system does not work

correctly.

The V-belt is slipping. Replace the V-belt with new one.

Foreign object is jammed between the

guard and the wheel.

The drive system does not work

correctly.

work with one battery cartridge.

replace the battery cartridge.

Ask your local authorized service center for repair.

replace the battery cartridge.

manual.

eective, replace the battery cartridge.

Ask your local authorized service center for repair.

Uninstall the battery cartridge and then remove the

foreign object.

Ask your local authorized service center for repair.

14 ENGLISH

State of abnormality Probable cause (malfunction) Remedy

Abnormal vibration:

stop the machine immediately!

Cutting tool and motor cannot stop:

Remove the battery cartridge

immediately!

Poor cutting performance It is time to replace the wheel. Replace the wheel with new one.

Water leaks from the inlet. Water is leaking from the O-ring part. Ask your local authorized service center for repair.

Improper attachment of the wheel. Install the wheel as instructed in this manual.

The drive system does not work

correctly.

Electric or electronic malfunction. Remove the battery cartridge and ask your local

Tighten the bolt to secure the wheel rmly.

Ask your local authorized service center for repair.

authorized service center for repair.

OPTIONAL

ACCESSORIES

CAUTION: These accessories or attachments

are recommended for use with your Makita tool

specied in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service

Center.

• Abrasive cut-o wheel

• Diamond wheel

• V-belt

• Coupling sleeve

• Box wrench

• Hex wrench

• Makita genuine battery and charger

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

dier from country to country.

MAKITA LIMITED WARRANTY

Please refer to the annexed warranty sheet for the

most current warranty terms applicable to this product.

If annexed warranty sheet is not available, refer to the

warranty details set forth at below website for your

respective country.

United States of America: www.makitatools.com

Canada: www.makita.ca

Other countries: www.makita.com

15 ENGLISH

ESPAÑOL (Instrucciones originales)

ESPECIFICACIONES

Modelo: XEC01

Diámetro de la rueda de diamante 230 mm (9″)

Grosor máx. de la rueda 3,0 mm (1/8″)

Profundidad de corte máxima 88 mm (3-1/2″)

Velocidad especicada 6 600 r/min

Tensión nominal 36 V c.c.

Presión máxima permitida del agua para alimentación 5,0 bars

Longitud total 554 mm (21-3/4″)

Peso neto 5,6 - 6,3 kg (12,3 - 13,9 lbs)

• Debido a nuestro continuo programa de investigación y desarrollo, las especicaciones aquí incluidas están

sujetas a cambio sin previo aviso.

• Las especicaciones pueden variar de país a país.

• El peso puede variar en función de los accesorios, incluido el cartucho de batería. En la tabla se muestra la

combinación de peso más ligero y más pesado conforme al procedimiento 01/2014 de EPTA.

Cartucho de batería y cargador aplicables

Cartucho de batería

Cargador

• Algunos de los cartuchos de batería y cargadores enumerados arriba podrían no estar disponibles dependiendo de su área de residencia.

BL1815N / BL1820B / BL1830 / BL1830B / BL1840B / BL1850B / BL1860B

DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF / DC18SH

ADVERTENCIA: Use únicamente los cartuchos de batería y los cargadores indicados arriba. El uso de

cualquier otro cartucho de batería y cargador podría ocasionar una lesión y/o un incendio.

2. No utilice las herramientas eléctricas en

ADVERTENCIAS DE

SEGURIDAD

Advertencias generales de seguridad

para herramientas eléctricas

ADVERTENCIA:

seguridad, instrucciones, ilustraciones y especicaciones

suministradas con esta herramienta eléctrica. El no seguir

todas las instrucciones indicadas a continuación podría ocasionar una descarga eléctrica, incendio y/o lesiones graves.

Conserve todas las advertencias

e instrucciones como referencia

en el futuro.

En las advertencias, el término “herramienta eléctrica” se

reere a su herramienta eléctrica de funcionamiento con

conexión a la red eléctrica (con cableado eléctrico) o herramienta eléctrica de funcionamiento a batería (inalámbrica).

Seguridad en el área de trabajo

1. Mantenga el área de trabajo limpia y bien iluminada. Las áreas oscuras o desordenadas son

propensas a accidentes.

Lea todas las advertencias de

16 ESPAÑOL

atmósferas explosivas, tal como en la presen-

cia de líquidos, gases o polvo inamables. Las

herramientas eléctricas crean chispas que pueden

prender fuego al polvo o los humos.

3. Mantenga a los niños y curiosos alejados

mientras utiliza una herramienta eléctrica. Las

distracciones le pueden hacer perder el control.

Seguridad eléctrica

1. Las clavijas de conexión de las herramientas

eléctricas deberán encajar perfectamente en la

toma de corriente. No modique nunca la clavija de conexión de ninguna forma. No utilice

ninguna clavija adaptadora con herramientas

eléctricas que tengan conexión a tierra (puesta

a tierra). La utilización de clavijas no modica-

das y que encajen perfectamente en la toma de

corriente reducirá el riesgo de que se produzca

una descarga eléctrica.

2.

Evite tocar con el cuerpo supercies conectadas

a tierra o puestas a tierra tales como tubos, radiadores, cocinas y refrigeradores. Si su cuerpo es

puesto a tierra o conectado a tierra existirá un mayor

riesgo de que sufra una descarga eléctrica.

3. No exponga las herramientas eléctricas a la

lluvia ni a condiciones húmedas. La entrada de

agua en una herramienta eléctrica aumentará el

riesgo de que se produzca una descarga eléctrica.

4. No maltrate el cable. Nunca utilice el cable

para transportar, jalar o desconectar la herramienta eléctrica. Mantenga el cable alejado del

calor, aceite, objetos cortantes o piezas móviles. Los cables dañados o enredados aumentan

el riesgo de sufrir una descarga eléctrica.

5.

Cuando utilice una herramienta eléctrica en

exteriores, utilice un cable de extensión apropiado para uso en exteriores. La utilización de un

cable apropiado para uso en exteriores reducirá el

riesgo de que se produzca una descarga eléctrica.

6. Si no es posible evitar usar una herramienta

eléctrica en condiciones húmedas, utilice un

alimentador protegido con interruptor de circuito de falla a tierra (ICFT). El uso de un ICFT

reduce el riesgo de descarga eléctrica.

7. Las herramientas eléctricas pueden producir

campos electromagnéticos (CEM) que no son

dañinos para el usuario. Sin embargo, si los

usuarios tienen marcapasos y otros dispositivos

médicos similares, deberán consultar al fabricante

de su dispositivo y/o a su médico antes de operar

esta herramienta eléctrica.

Seguridad personal

1.

Manténgase alerta, preste atención a lo que está

haciendo y utilice su sentido común cuando opere

una herramienta eléctrica. No utilice una herramienta eléctrica cuando esté cansado o bajo la

inuencia de drogas, alcohol o medicamentos. Un

momento de distracción mientras opera las herramientas eléctricas puede terminar en una lesión grave.

2. Use equipo de protección personal. Póngase

siempre protección para los ojos. El equipo

protector tal como máscara contra el polvo, zapa-

tos de seguridad antiderrapantes, casco rígido y

protección para oídos utilizado en las condiciones

apropiadas reducirá el riesgo de lesiones.

3.

Impida el encendido accidental. Asegúrese de que el

interruptor esté en la posición de apagado antes de

conectar a la alimentación eléctrica y/o de colocar

el cartucho de batería, así como al levantar o cargar

la herramienta. Cargar las herramientas eléctricas con

su dedo en el interruptor o enchufarlas con el interruptor

encendido hace que los accidentes sean comunes.

4. Retire cualquier llave de ajuste o llave de

apriete antes de encender la herramienta. Una

llave de ajuste o llave de apriete que haya sido

dejada puesta en una parte giratoria de la herra-

mienta eléctrica puede ocasionar alguna lesión.

5.

No utilice la herramienta donde no alcance.

Mantenga los pies sobre suelo rme y el equilibrio

en todo momento. Esto permite un mejor control de

la herramienta eléctrica en situaciones inesperadas.

6. Use una vestimenta apropiada. No use ropa

suelta ni alhajas. Mantenga el cabello, la ropa

y los guantes alejados de las piezas móviles.

Las prendas de vestir holgadas, las alhajas y

el cabello largo suelto podrían engancharse en

estas piezas móviles.

7. Si dispone de dispositivos para la conexión

de equipos de extracción y recolección de

polvo, asegúrese de conectarlos y utilizarlos

debidamente. Hacer uso de la recolección de

polvo puede reducir los riesgos relacionados con

el polvo.

8.

No permita que la familiaridad adquirida debido

al uso frecuente de las herramientas haga que se

sienta conado e ignore los principios de seguridad de las herramientas. Un descuido podría oca-

sionar una lesión grave en una fracción de segundo.

9. Utilice siempre gafas protectoras para prote-

ger sus ojos de lesiones al usar herramientas

eléctricas. Las gafas deben cumplir con la

Norma ANSI Z87.1 en EUA.

Es responsabilidad del empleador imponer

el uso de equipos protectores de seguridad

apropiados a los operadores de la herramienta

y demás personas cerca del área de trabajo.

Mantenimiento y uso de la herramienta eléctrica

1. No fuerce la herramienta eléctrica. Utilice la

herramienta eléctrica correcta para su aplicación. La herramienta eléctrica adecuada hará un

mejor trabajo y de forma más segura a la velocidad para la que ha sido fabricada.

2.

No utilice la herramienta eléctrica si el interruptor no la enciende y apaga. Cualquier herra-

mienta eléctrica que no pueda ser controlada con

el interruptor es peligrosa y debe ser reemplazada.

3.

Desconecte la clavija de la fuente de alimentación

y/o retire la batería de la herramienta eléctrica, en

caso de ser removible, antes de realizar ajustes,

cambiar accesorios o almacenar las herramientas

eléctricas. Tales medidas de seguridad preventivas

reducirán el riesgo de poner en marcha la herramienta eléctrica de forma accidental.

4. Guarde la herramienta eléctrica que no use

fuera del alcance de los niños y no permita

que las personas que no están familiarizadas

con ella o con las instrucciones la operen. Las

herramientas eléctricas son peligrosas en manos

de personas que no saben operarlas.

5.

Dé mantenimiento a las herramientas eléctricas

y los accesorios. Compruebe que no haya piezas

móviles desalineadas o estancadas, piezas rotas

y cualquier otra condición que pueda afectar al

funcionamiento de la herramienta eléctrica. Si la

herramienta eléctrica está dañada, haga que la

reparen antes de utilizarla. Muchos de los acciden-

tes son ocasionados por no dar un mantenimiento

adecuado a las herramientas eléctricas.

6.

Mantenga las herramientas de corte limpias y

losas. Si recibe un mantenimiento adecuado y tiene

los bordes alados, es probable que la herramienta

se atasque menos y sea más fácil controlarla.

7.

Utilice la herramienta eléctrica, los accesorios y

las brocas de acuerdo con estas instrucciones,

considerando las condiciones laborales y el

trabajo a realizar. Si utiliza la herramienta eléctrica

para realizar operaciones distintas de las indicadas,

podrá presentarse una situación peligrosa.

8.

Mantenga los mangos y supercies de asimiento secos, limpios y libres de aceite o grasa.

Los mangos y supercies de asimiento resbalosos

no permiten una manipulación segura ni el control

de la herramienta en situaciones inesperadas.

9. Cuando vaya a utilizar esta herramienta, evite

usar guantes de trabajo de tela ya que éstos

podrían atorarse. Si los guantes de trabajo de

tela llegaran a atorarse en las piezas móviles,

esto podría ocasionar lesiones personales.

17 ESPAÑOL

Uso y cuidado de la herramienta a batería

1. Recargue sólo con el cargador especicado

por el fabricante. Un cargador que es adecuado

para un solo tipo de batería puede generar riesgo

de incendio al ser utilizado con otra batería.

2. Utilice las herramientas eléctricas solamente

con las baterías designadas especícamente

para ellas. La utilización de cualquier otra batería

puede crear un riesgo de lesiones o incendio.

3.

Cuando no se esté usando la batería, manténgala

alejada de otros objetos metálicos, como sujetapapeles (clips), monedas, llaves, clavos, tornillos

u otros objetos pequeños de metal los cuales

pueden actuar creando una conexión entre las

terminales de la batería. Originar un cortocircuito en

las terminales puede causar quemaduras o incendios.

4. En condiciones abusivas, podrá escapar

líquido de la batería; evite tocarlo. Si lo toca

accidentalmente, enjuague con agua. Si hay

contacto del líquido con los ojos, busque asistencia médica. Puede que el líquido expulsado

de la batería cause irritación o quemaduras.

5. No utilice una herramienta ni una batería que

estén dañadas o hayan sido modicadas. Las

baterías dañadas o modicadas podrían ocasionar una situación inesperada provocando un

incendio, explosión o riesgo de lesiones.

6. No exponga la herramienta ni la batería al

fuego ni a una temperatura excesiva. La exposición al fuego o a una temperatura superior a los

130 °C podría causar una explosión.

7.

Siga todas las instrucciones para la carga y evite

cargar la herramienta o la batería fuera del rango

de temperatura especicado en las instrucciones. Una carga inadecuada o a una temperatura

fuera del rango especicado podría dañar la batería

e incrementar el riesgo de incendio.

Servicio

1. Haga que una persona calicada repare la

herramienta eléctrica utilizando sólo piezas de

repuesto idénticas. Esto asegura que se man-

tenga la seguridad de la herramienta eléctrica.

2. Nunca dé servicio a baterías que estén daña-

das. El servicio a las baterías solamente deberá

ser efectuado por el fabricante o un agente de

servicio autorizado.

3. Siga las instrucciones para la lubricación y

cambio de accesorios.

4. No modique ni intente reparar el aparato ni el

paquete de baterías salvo como se indique en

las instrucciones para el uso y cuidado.

Advertencias de seguridad para el

cortador inalámbrico

1. El protector que se incluye con la herramienta

debe quedar bien instalado y colocado en

la herramienta eléctrica para garantizar la

máxima seguridad, de tal manera que el operador esté lo menos expuesto posible a la rueda.

Usted y las personas alrededor deberán mantenerse alejados del plano de la rueda giratoria. El protector ayuda a proteger al operador de

los fragmentos rotos de la rueda y del contacto

accidental con la misma.

2. Use solamente ruedas de corte de diamante

o reforzadas adheridas para su herramienta

eléctrica. El que un accesorio pueda ensam-

blarse en su herramienta eléctrica no garantiza

una operación segura.

3. La velocidad especicada para el accesorio

debe ser por lo menos la misma que la velocidad máxima marcada en la herramienta eléctrica. Los accesorios que vayan a una velocidad

mayor que su velocidad especicada pueden

romperse y desintegrase.

4.

Las ruedas deben usarse únicamente para las

aplicaciones recomendadas. Por ejemplo, no

haga operaciones de esmerilado con la parte

plana de la rueda cortadora. Las ruedas abrasivas

de corte están diseñadas para el esmerilado periférico; las fuerzas aplicadas lateralmente a estas ruedas pueden ocasionar que se rompan en pedazos.

5. Siempre utilice bridas de rueda sin daños

que sean del diámetro correcto para la rueda

seleccionada. Las bridas de rueda adecuadas

soportan la rueda reduciendo así la posibilidad de

rotura de la rueda.

6. No utilice ruedas reforzadas que estén desgas-

tadas de herramientas eléctricas más grandes.

Las ruedas diseñadas para una herramienta eléctrica más grande no son adecuadas para la velo-

cidad mayor de una herramienta más pequeña y

pueden reventarse.

7. El diámetro externo y el grosor de su acceso-

rio debe estar dentro de la capacidad indicada

de su herramienta eléctrica. Los accesorios de

tamaño incorrecto no podrán ser protegidos ni

controlados adecuadamente.

8.

El tamaño del eje de las ruedas y bridas se debe

ajustar adecuadamente al eje de la herramienta

eléctrica. Las ruedas y bridas con oricios para ejes

que no se ajusten al equipo de montaje de la herramienta eléctrica se desequilibrarán, vibrarán excesi-

vamente y podrán causar la pérdida de control.

9. No use ruedas dañadas. Antes de cada uso,

inspeccione las ruedas para vericar que no

haya grietas ni astillas. Si la herramienta eléctrica o la rueda llegan a caerse, inspeccione

que no haya daños o instale una rueda que no

esté dañada. Después de inspeccionar e instalar la rueda, colóquense usted y las personas

alrededor lejos del plano de la rueda giratoria

y haga funcionar la herramienta eléctrica a

la velocidad máxima sin carga durante un

minuto. Las ruedas dañadas por lo general se

romperán durante este tiempo de prueba.

10. Use equipo de protección personal.

Dependiendo de la aplicación, use careta

y gafas protectoras o de seguridad. Según

resulte apropiado, use máscara contra polvo,

protectores para oídos, guantes y mandil de

trabajo que puedan detener pequeños fragmentos abrasivos o de la pieza de trabajo.

La protección para los ojos deberá ser capaz de

detener los residuos que salgan volando a causa

de las distintas operaciones. La máscara contra

polvo o respirador deberá ser capaz de ltrar las

partículas generadas durante su operación. La

exposición prolongada al ruido de alta intensidad

podrá provocar pérdida auditiva.

18 ESPAÑOL

11. Mantenga a las personas alrededor a una

distancia segura del área de trabajo. Cualquier

persona que ingrese al área de trabajo deberá

usar equipo de protección personal. Los frag-

mentos de la pieza de trabajo o de una rueda rota

podrán salir proyectados más allá del área inmediata de operación y causar lesiones.

12. Cuando realice una operación en la que el

accesorio de corte pueda entrar en contacto

con cableado oculto, sujete la herramienta

eléctrica únicamente por las supercies de

sujeción aisladas. Si el accesorio de corte entra

en contacto con un cable con corriente, las piezas

metálicas expuestas de la herramienta eléctrica

se cargarán también de corriente y el operador

podrá recibir una descarga eléctrica.

13. Nunca deje la herramienta eléctrica hasta que

el accesorio se haya detenido completamente.

La rueda giratoria puede agarrar la supercie y

jalar la herramienta eléctrica haciendo que usted

pierda el control sobre ella.

14. No tenga encendida la herramienta eléctrica

mientras la lleva cargando a un costado. El

contacto accidental con el accesorio giratorio

podría enganchar su ropa y jalar el accesorio

hacia su cuerpo.

15. Limpie regularmente los oricios de ventila-

ción de la herramienta eléctrica. El ventilador

del motor atraerá el polvo hacia el interior de la

carcasa y la acumulación excesiva de polvo metálico podrá ocasionar riesgos eléctricos.

16. No utilice la herramienta eléctrica cerca de

materiales inamables. Las chispas pueden

prender fuego a estos materiales.

Retrocesos bruscos y advertencias relacionadas

El retroceso brusco es una reacción repentina a un atoramiento o enganchamiento de la rueda giratoria. El atoramiento o enganchamiento ocasiona un rápido atascamiento

de la rueda giratoria que a su vez causa que la herramienta

eléctrica descontrolada sea forzada en la dirección opuesta

al giro de la rueda en el punto de atascamiento.

Por ejemplo, si una rueda abrasiva queda enganchada

o atorada por la pieza de trabajo, el borde de la rueda

que está entrando en el punto de atoramiento puede

hundirse en la supercie del material haciendo que la

rueda se salga o salte. La rueda podrá saltar hacia el

operador o en dirección contraria a él, dependiendo

de la dirección del movimiento de la rueda en el punto

de atoramiento. Las ruedas abrasivas también pueden

romperse en estas condiciones.

El retroceso brusco es el resultado de un mal uso de

la herramienta eléctrica y/o de procedimientos o condiciones de operación incorrectos y pueden evitarse

tomando las precauciones adecuadas tal como se

indica a continuación.

1. Mantenga sujetada rmemente la herramienta

eléctrica y posicione su cuerpo y brazo de

manera que pueda resistir las fuerzas del

retroceso brusco. De estar disponible, utilice

siempre el mango auxiliar para un control

máximo durante un retroceso brusco o reacción de torsión durante la puesta en marcha

de la herramienta. El operador puede controlar

las reacciones de torsión o fuerzas del retroceso

brusco siempre y cuando se tomen las precauciones adecuadas.

2. Nunca coloque su mano cerca del accesorio

giratorio. El accesorio puede tener un retroceso

brusco sobre su mano.

3. No coloque su cuerpo en línea con la rueda

giratoria. El retroceso brusco proyectará la herra-

mienta en dirección opuesta al movimiento de la

rueda en el punto de enganchamiento.

4. Tenga especial cuidado al trabajar en esqui-

nas, bordes losos, etc. Evite que el accesorio

rebote o se enganche. Las esquinas, bordes

losos o rebotes tienden a enganchar el accesorio

giratorio y ocasionar la pérdida de control o un

retroceso brusco.

5. No coloque una cadena de sierra, disco para

labrar madera, rueda de diamante segmentada

con un espacio periférico de separación mayor

a 10 mm, ni disco de sierra dentado. Dichos

discos generan un retroceso brusco y pérdida del

control con frecuencia.

6. Evite trabar la rueda o aplicar presión exce-

siva. No intente hacer un corte de profundidad

excesiva. Aplicar presión excesiva a la rueda

incrementa la carga y susceptibilidad a que

se tuerza o atore durante el corte, y de que se

genere un retroceso brusco o rotura de la rueda.

7. Cuando la rueda se atore o se interrumpa el

corte por cualquier razón, apague la herramienta eléctrica y sosténgala sin moverla

hasta que la rueda se detenga por completo.

No intente nunca retirar la rueda del corte

mientras la rueda esté moviéndose porque podría ocasionar un retroceso brusco.

Investigue y tome medidas correctivas para eliminar la causa del atoramiento de la rueda.

8. Evite reiniciar la operación de corte en la pieza

de trabajo. Permita que la rueda alcance su

velocidad completa y se reintroduzca con

cuidado en el corte. La rueda puede atorarse,

salirse del camino o generar un retroceso brusco

si la herramienta eléctrica es reiniciada estando

en la pieza de trabajo.

9. Proporcione apoyo a los paneles o cualquier

pieza de trabajo de gran tamaño para minimizar el riesgo de que la rueda se atore y dé un

retroceso brusco. Las piezas de trabajo grandes

tienden a hundirse bajo su propio peso. Deben

colocarse soportes bajo la pieza de trabajo a

ambos lados de la rueda, cerca de la línea de

corte y del borde de la pieza de trabajo.

10. Tenga especial cuidado cuando realice un

“corte de penetración” en las paredes existentes u otras áreas ciegas. La parte saliente de la

rueda puede cortar tuberías de gas o agua, así

como cableado eléctrico u objetos que produzcan

un retroceso brusco.

Advertencias de seguridad adicionales:

1. Antes de usar una rueda de diamante segmentada, asegúrese de que la rueda de diamante

cuente con espacio periférico de separación

entre los segmentos de 10 mm o menos, solo

con un ángulo de corte negativo.

2. Nunca intente cortar con la herramienta sostenida de cabeza en un tornillo de banco. Esto

puede provocar accidentes graves, ya que es

extremadamente peligroso.

19 ESPAÑOL

3. Algunos materiales contienen sustancias químicas que pueden ser tóxicas. Tome precauciones para evitar la inhalación de polvo o que

éste tenga contacto con la piel. Consulte la

hoja de seguridad de materiales del proveedor.

4. Almacene las ruedas de acuerdo con las

recomendaciones del fabricante. Un almacenamiento inadecuado podría dañar las ruedas.

5. Utilice siempre la rueda adecuada para su

trabajo y para el material que va a cortar.

6. Examine el material que va a cortar antes de

iniciar el corte. Si el material contiene sustan-

cias explosivas o inamables, podría causar una

explosión o un incendio.

7. No use ningún alimentador con cableado

eléctrico, como un adaptador para batería o

una unidad portátil de alimentación eléctrica,

con esta herramienta. El uso de una fuente de

alimentación con cable impide que se cierre la

cubierta de la batería y permite que entre polvo o

agua en el compartimento del cartucho de la bate-

ría, lo que podría provocar una descarga eléctrica.

8. No encienda la herramienta si se atasca un

objeto extraño entre el protector y la rueda. En

este caso, desinstale el cartucho de la batería y

retire el objeto extraño.

9. Siempre que sea posible, utilice abrazaderas

o elementos similares para sujetar la pieza de

trabajo.

10. Póngase siempre protección para los oídos

durante la operación.

11. No corte materiales de madera con esta

herramienta.

GUARDE ESTAS

INSTRUCCIONES.

ADVERTENCIA: NO DEJE que la comodidad

o familiaridad con el producto (a base de utilizarlo

repetidamente) sustituya la estricta observancia

de las normas de seguridad para dicho producto.

El MAL USO o el no seguir las normas de seguridad establecidas en este manual de instrucciones

puede ocasionar lesiones personales graves.

Símbolos

A continuación se muestran los símbolos utilizados

para la herramienta.

diámetro

volts o voltios

corriente directa o continua

velocidad especicada

revoluciones o alternaciones por minuto,

frecuencia de rotación

Instrucciones importantes de

seguridad para el cartucho de batería

1.

Antes de utilizar el cartucho de batería, lea todas

las instrucciones e indicaciones de precaución

en el (1) el cargador de batería, (2) la batería, y (3)

el producto con el que se utiliza la batería.

2. No desarme el cartucho de batería.

3. Si el tiempo de operación se ha acortado en

exceso, deje de operar de inmediato. Podría

correrse el riesgo de sobrecalentamiento,

posibles quemaduras e incluso explosión.

4. En caso de que ingresen electrolitos en sus

ojos, enjuáguelos bien con agua limpia y consulte de inmediato a un médico. Esto podría

ocasionar pérdida de visión.

5. Evite cortocircuitar el cartucho de batería:

(1) No toque las terminales con ningún mate-

rial conductor.

(2) Evite guardar el cartucho de batería en un

cajón junto con otros objetos metálicos,

tales como clavos, monedas, etc.

(3) No exponga el cartucho de batería al

agua o la lluvia.

Un cortocircuito en la batería puede causar

un ujo grande de corriente, sobrecalentamiento, posibles quemaduras e incluso una

descompostura.

6. No guarde la herramienta ni el cartucho de

batería en lugares donde la temperatura pueda

alcanzar o exceder los 50°C (122°F).

7. Nunca incinere el cartucho de batería incluso

en el caso de que esté dañado seriamente o

ya no sirva en absoluto. El cartucho de batería

puede explotar si se tira al fuego.

8.

Tenga cuidado de no dejar caer ni golpear la batería.

9. No use una batería dañada.

10.

Las baterías de ión de litio están sujetas a los requisitos reglamentarios en materia de bienes peligrosos.

Para el trasporte comercial, por ej., mediante

terceros o agentes de transporte, se deben tomar

en cuenta los requisitos especiales relativos al

empaque y el etiquetado.

Para efectuar los preparativos del artículo que se

va a enviar, se requiere consultar a un experto en

materiales peligrosos. Si es posible, consulte además otras regulaciones nacionales más detalladas.

Pegue o cubra con cinta adhesiva los contactos

abiertos y empaque la batería de manera que ésta

no pueda moverse dentro del paquete.

11. Para deshacerse del cartucho de batería,

sáquelo de la herramienta y deséchelo en un

lugar seguro. Siga las regulaciones locales

relacionadas al desecho de las baterías.

12.

Utilice las baterías únicamente con los produc-

tos especicados por Makita. Instalar las baterías

en productos que no cumplan con los requisitos

podría ocasionar un incendio, un calentamiento

excesivo, una explosión o una fuga de electrolito.

13. Si no se utiliza la herramienta por un

período largo, debe extraerse la batería de la

herramienta.

GUARDE ESTAS INSTRUCCIONES.

20 ESPAÑOL

PRECAUCIÓN: Utilice únicamente baterías

originales de Makita. El uso de baterías no origina-

les de Makita, o de baterías alteradas, puede ocasionar que las baterías exploten causando un incendio,

lesiones personales y daños. Asimismo, esto invalidará la garantía de Makita para la herramienta y el

cargador Makita.

Consejos para alargar al máximo

la vida útil de la batería

1.

2. No cargue nunca un cartucho de batería que

3.

4.

DESCRIPCIÓN DE LAS PIEZAS

Cargue el cartucho de batería antes de que se

descargue completamente. Pare siempre la operación y cargue el cartucho de batería cuando

note menos potencia en la herramienta.

esté completamente cargado. La sobrecarga

acortará la vida de servicio de la batería.

Cargue el cartucho de batería a una temperatura

ambiente de 10 °C - 40 °C (50 °F - 104 °F). Si un cartucho

de batería está caliente, déjelo enfriar antes de cargarlo.

Cargue el cartucho de batería si no va a utilizarlo

durante un período prolongado (más de seis meses).

2

3 4

5

1

98

7

6

10

11

12

13

17

16

14

15

18

1 Rueda cortadora abra-

siva / rueda de diamante

5 Botón de desbloqueo 6 Gancho 7 Lámpara 8 Botón de vericación

9 Indicador de batería 10 Indicador de sobrecarga 11 Botón de la lámpara 12 Gatillo interruptor

13 Mango 14 Entrada para agua 15 Llave 16

17 Botón de bloqueo del eje 18

2 Protector de la rueda 3 Empuñadura 4 Cubierta (para el com-

Manguito del acoplamiento

- - - -

21 ESPAÑOL

partimento de batería)

Cubierta (para la correa en V)

DESCRIPCIÓN DEL

FUNCIONAMIENTO

PRECAUCIÓN: Asegúrese siempre de que la

herramienta esté apagada y el cartucho de batería

haya sido extraído antes de realizar cualquier

ajuste o comprobación en la herramienta.

Instalación o extracción del

cartucho de batería

PRECAUCIÓN:

antes de colocar o quitar el cartucho de batería.

PRECAUCIÓN:

tucho de la batería con rmeza al colocar o quitar el

cartucho de batería. Si no se sujeta con rmeza la herramienta y el cartucho de batería, puede ocasionar que se

resbalen de sus manos causando daños a la herramienta

y al cartucho de batería, así como lesiones a la persona.

Para instalar el cartucho de batería, abra la cubierta mientras

libera el gancho. Alinee la lengüeta en el cartucho de batería

con la ranura en la carcasa y deslícelo en su lugar. Insértelo

por completo hasta que quede asegurado en su lugar haciendo

un pequeño clic. Si puede ver el indicador rojo del lado superior

del botón, esto indica que no ha quedado jo por completo.

Después de instalar o extraer los cartuchos de batería, asegúrese

de que la cubierta esté cerrada y asegurada mediante el gancho.

► 1. Cubierta 2. Gancho

Para extraer los cartuchos de batería, levante el cartucho de batería mientras oprime el botón en la parte delantera del cartucho.

Apague siempre la herramienta

Sujete la herramienta y el car-

1

2

1

2

3

PRECAUCIÓN: Introduzca siempre com-

pletamente el cartucho de batería hasta que

el indicador rojo no pueda verse. Si no, podría

accidentalmente salirse de la herramienta y caer al

suelo causando una lesión a usted o alguien a su

alrededor.

PRECAUCIÓN: No instale el cartucho de

batería a la fuerza. Si el cartucho no se desliza al

interior fácilmente, se debe a que no está siendo

insertado correctamente.

NOTA: La herramienta no funciona con un solo cartu-

cho de batería.

Indicación de la capacidad restante

de la batería

Únicamente para cartuchos de batería con el

indicador

1

2

► 1. Luces indicadoras 2. Botón de vericación

Oprima el botón de vericación en el cartucho de la

batería para que indique la capacidad restante de la

batería. Las luces indicadoras se iluminarán por algu-

nos segundos.

Luces indicadoras Capacidad

Iluminadas Apagadas Parpadeando

restante

75% a 100%

50% a 75%

25% a 50%

0% a 25%

Cargar la

batería.

La batería

pudo haber

funcionado

mal.

► 1. Indicador rojo 2. Botón 3. Cartucho de batería

NOTA: Dependiendo de las condiciones de uso y

la temperatura ambiente, la indicación podrá diferir

ligeramente de la capacidad real.

22 ESPAÑOL

Indicación de capacidad restante de la batería

1

► 1. Indicador de batería 2. Botón de vericación

Oprima el botón de vericación para indicar las capacidades restantes de la batería. Los indicadores de

batería corresponden a cada batería.

Estado del indicador de batería Capacidad

Encendido

Apagado

Parpadeando

restante de la

batería

50% a 100%

20% a 50%

Protección contra sobrecalentamiento

Cuando la herramienta se sobrecaliente, ésta se detendrá

automáticamente y el indicador de batería parpadeará

alrededor de 60 segundos. En este caso, permita que la

2

herramienta se enfríe antes de volver a encenderla.

Encendido Parpadeando

Protección contra sobredescarga

Cuando la capacidad de la batería se reduce, la herramienta se detiene automáticamente. Si el producto

no funciona incluso cuando los interruptores están

siendo operados, retire las baterías de la herramienta

y cárguelas.

Alerta de sobrecarga

Si la herramienta es operada con una carga excesiva,

el indicador de sobrecarga parpadeará en color rojo.

En esta situación, reduzca la carga en la herramienta.

Entonces, el indicador deja de parpadear.

1

0% a 20%

Cargar la

batería

Sistema de protección para la

herramienta/batería

La herramienta está equipada con un sistema de protección

para la herramienta/batería. Este sistema corta en forma auto

mática el suministro de energía al motor para prolongar la vida

útil de la herramienta y la batería. La herramienta se detendrá

automáticamente durante la operación si la herramienta o la

batería se someten a una de las siguientes condiciones. En

algunas condiciones, los indicadores pueden encenderse.

Protección contra sobrecarga

Cuando la herramienta/batería sean utilizadas de una

manera que cause que consuman una cantidad inusualmente alta de corriente, la herramienta se detendrá automá-

ticamente. En este caso, apague la herramienta y detenga

la aplicación que causó que la herramienta se sobrecargara. Luego encienda la herramienta para reiniciarla.

► 1. Indicador de sobrecarga

Accionamiento del interruptor

ADVERTENCIA: Antes de insertar el car-

tucho de batería en la herramienta, compruebe

siempre y cerciórese de que el gatillo interruptor

se acciona debidamente y que vuelve a la posición “OFF” (apagado) cuando lo suelta.

ADVERTENCIA: NUNCA inhabilite el botón

de desbloqueo manteniéndolo presionado con

-