Makita UH520D, UH522D, UH422D, BUH481, BUH521 Technical Information

...

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 13

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

Model No.

Description

UH520D

UH422D/ UH482D/ UH522D

BUH481/ BUH521

BUH483/ BUH523

Cordless Hedge Trimmer 520mm (20-1/2")

Cordless Hedge Trimmers 420mm/ 480mm/ 520mm

(16-1/2"/ 18-7/8"/ 20-1/2")

Cordless Hedge Trimmers 480mm/ 520mm (18-7/8"/ 20-1/2")

Cordless Hedge Trimmers 480mm/ 520mm (18-7/8"/ 20-1/2")

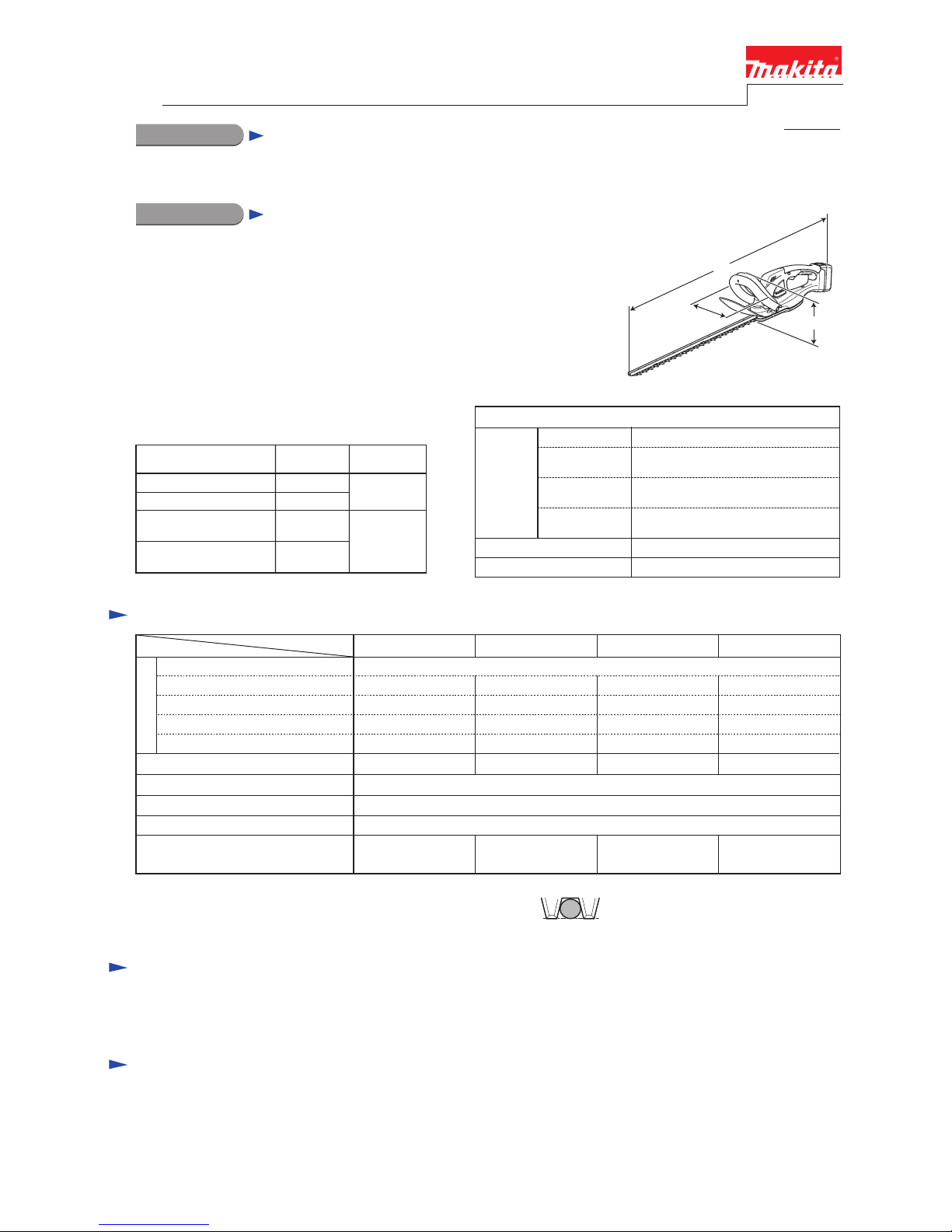

Dimensions: mm (")

Width (W)

Height (H)

*2 with 3.0Ah Li-ion battery *3 with 1.3Ah Li-ion battery

Length (L)

888 (35)/ 938 (37)*1

873 (34-3/8)/ 923 (36-1/4)*3

923 (36-1/4)

829 (32-5/8)/ 879 (34-1/2)/ 929 (36-1/2)

BUH483/ 523

881 (34-3/4)/ 931 (36-3/4)*2

869 (34-1/4)/ 919 (36-1/4)*3

BUH481/ 521

UH520D

UH422D/ 482D/

522D

195 (7-5/8)

193 (7-5/8)

Battery

Charging time (approx.): min.

Weight according to

EPTA-Procedure 01/2003*

5: kg (lbs)

Capacity: Ah

Cell

Voltage: V

14.414.4 18

No load speed: min

ˉ¹=spm*3

420 (16-1/2)/ 480 (18-7/8)/ 520 (20-1/2)

--- / --- / UH520D --- / BUH481/ 521 --- / BUH483/ 523

Blade length: mm (")

--- / --- / 3.0

(--- / --- / 6.7)

--- / 3.0/ 3.0 (--- / 6.5/ 6.7),

--- / 3.1/ 3.2 (--- / 6.9/ 7.1)

3.0/ 3.0/ 3.1

(6.6/ 6.7/ 6.8)

--- / 3.0/ 3.1 (--- / 6.7/ 6.8),

--- / 3.2/ 3.3 (--- / 7.1/ 7.3)

1.3, 3.01.1 1.3, 3.0

Energy capacity: Wh 19, 4416 24, 54

Li-ion

190190 210210

15, 22 with DC18RC60 with DC18WA

18

UH422D/ 482D/ 522D

1.1

20

60 with DC18WA 15, 22 with DC18RC

1,350

Max output (W)

Blade cover ............................................. 1

Battery cover ........................................... 1 (same quantity as that of spare battery)

Battery BL1815 (for BUH483/ 523)

Battery BL1830 (for BUH483/ 523)

Charger DC18WA (for UH422D/ 482D/ 520D/ 522D)

Fast charger DC18RC (for BUH481/ 483/ 521/ 523)

Charger DC18SD (for BUH481/ 483/ 521/ 523)

Charger DC24SC (for BUH481/ 483/ 521/ 523)

Automotive charger DC18SE (for BUH481/ 483/ 521/ 523)

The subject models are 14.4V/18V cordless hedge trimmers.

Their main features are:

• Anti-vibration structure

• User-replaceable blade

These products are compatible with the batteries

and the chargers in the list below.

BUH483/ 523

UH422D/ 482D/ 522D BL1811G

UH520D BL1411G

DC18WA

BUH481/ 521

BL1415

BL1430

DC18RC,

DC18SD,

DC24SC,

DC18SE

Model No.

Compatible

charger

BL1815

BL1830

Compatible

battery

Model

Specification

*3: spm= strokes per minute

*4: Indicates maximum diameter of the branch that can be received

between adjacent two blade teeth. (See the figure on right.)

*5: with battery, shear blade assembly

Shear blade complete set

Blade cover

Chip receiver assembly set

Battery BL1411G (for UH520D)

Battery BL1811G (for UH422D/ 482D/ 522D)

Battery BL1415 (for BUH481/ 521)

Battery BL1430 (for BUH481/ 521)

Max. cutting diameter*

4: mm (") ø15 (9/16)

T

ECHNICAL INFORMATION

L

H

W

Apply the following grease to the portions designated with the black triangle to protect parts and product from unusual

abrasion.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R035 Bearing Setting Plate Supporting Spur gear 93, when removing Spindle with Arbor press

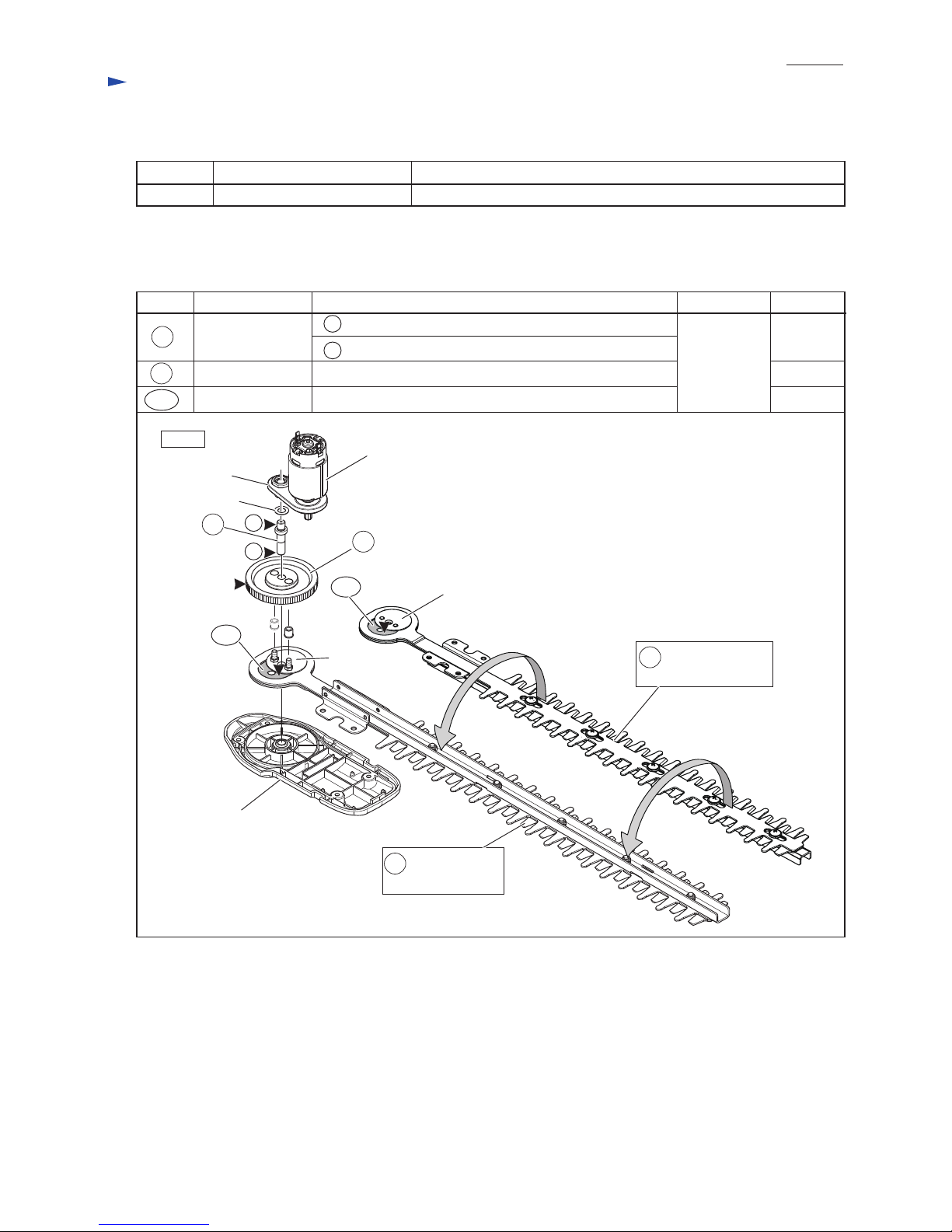

[2] LUBRICATION

Fig. 1

Item No. Description

Grease

Makita

grease N

No.2

Amount

Portion to lubricate

27A

24

23

Flat washer 8

Bearing box

Crank plate B

Under cover

DC motor

a

b

27A

27 viewed from

Under cover side

Crank plate A

23 Spindle

The drum portion which is accepted by Bearing box

The drum portion which is accepted by Under cover

24 Spur gear 93 Teeth portion for smooth engaging with DC motor’s gear

27 viewed from

Front grip side

Both side where Crank plate A and Crank plate B contact 27A Spacer of Blade

a

a little

a little

b

3 g

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Repair

P 2/ 13

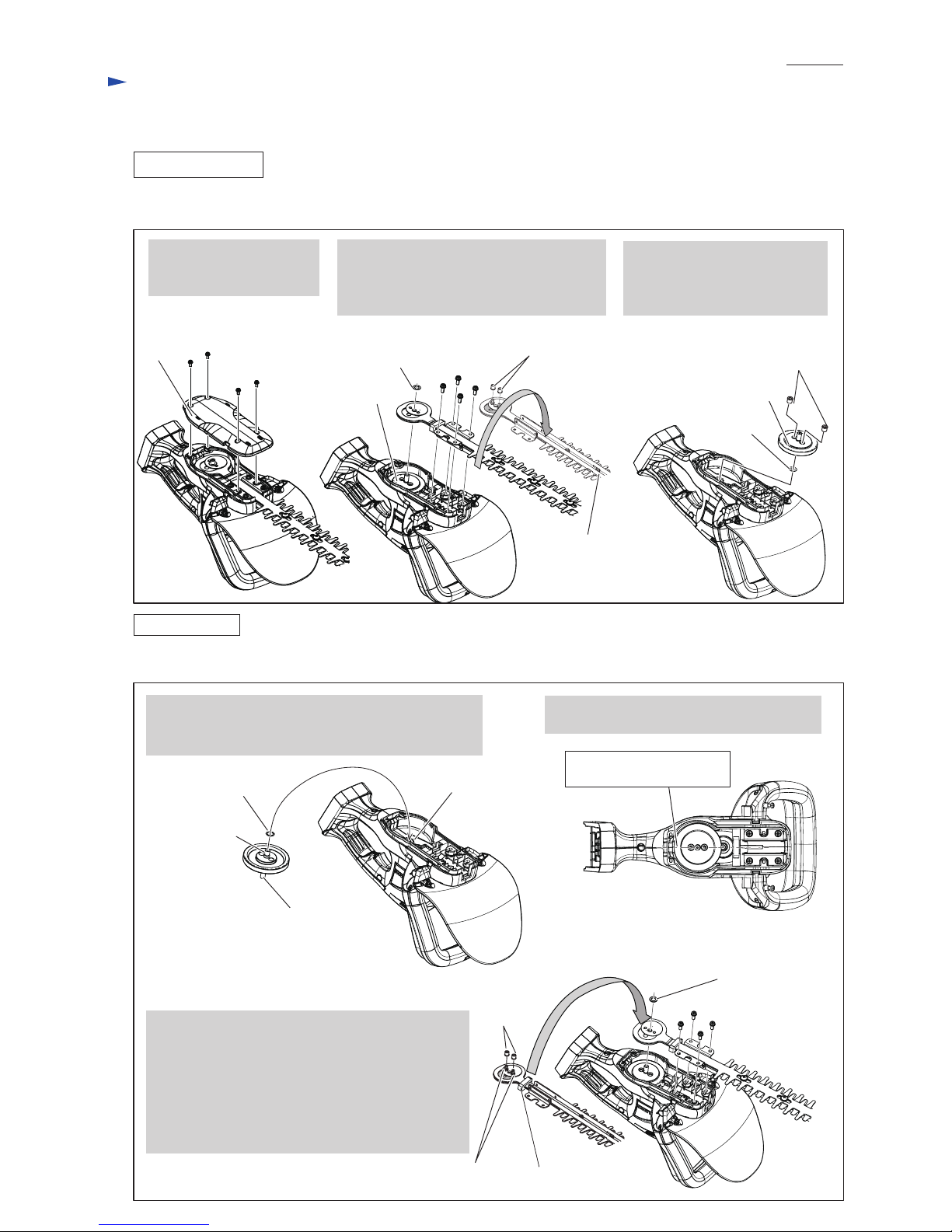

Fig. 2

Fig. 3

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Shear blade complete

DISASSEMBLING

1. Remove Under cover by

unscrewing four M4x10

Pan head screws.

2. Remove Shear blade complete by

unscrewing four M5x14 Pan head screws.

And remove two Nylon sleeves from

Shear blade complete.

Shear blade viewed

from Front grip side

Nylon sleeve

(2 pcs.)

Nylon sleeve (2 pcs.)

Spur gear section

Spur gear section

ASSEMBLING

1. Pass Spindle through Flat washer 8 and then set them

in Bearing box complete so that the depressed side of

Spur gear 93 faces to Bearing box complete.

M5x14 Pan

head screw

(4 pcs.)

M5x14 Pan

head screw (4 pcs.)

M4x10 Pan head

screw (4 pcs.)

Under

cover

Disassemble Shear blade complete as drawn in Fig. 2.

Assemble Shear blade complete to the machine as drawn in Fig. 3.

Flat washer 8

3. If Nylon sleeves are left in

the holes of Spur gear section,

remove them after disassembly

of Super gear section.

Flat washer 8

Mating line of Housing L

and Housing R

2. Turn Spur gear 93 until its holes come on

the mating line of Housing set.

Flat washer 8

Spindle on the projected side

of Super gear 93 to Under cover

(Also refer to Fig. 12)

Spindle on

the depressed

side of Supper

gear 93 (Also

refer to Fig. 12)

Bearing box complete

Dust guard

Nylon sleeve

(2 pcs.)

Pins of Shear blade

complete (2 pcs.)

3. Set two Nylon sleeves to two pins of Shear blade

complete.

4. Set Dust guard to Shear blade complete.

Note: Dust gurad is not directional when assembled

with Shear blade complete.

5. Inserting the Nylon sleeves into the holes of

Spur gear 93, set Shear blade complete in place.

Do not forget to set Flat washer 8 to Spindle.

Repair

P 3/ 13

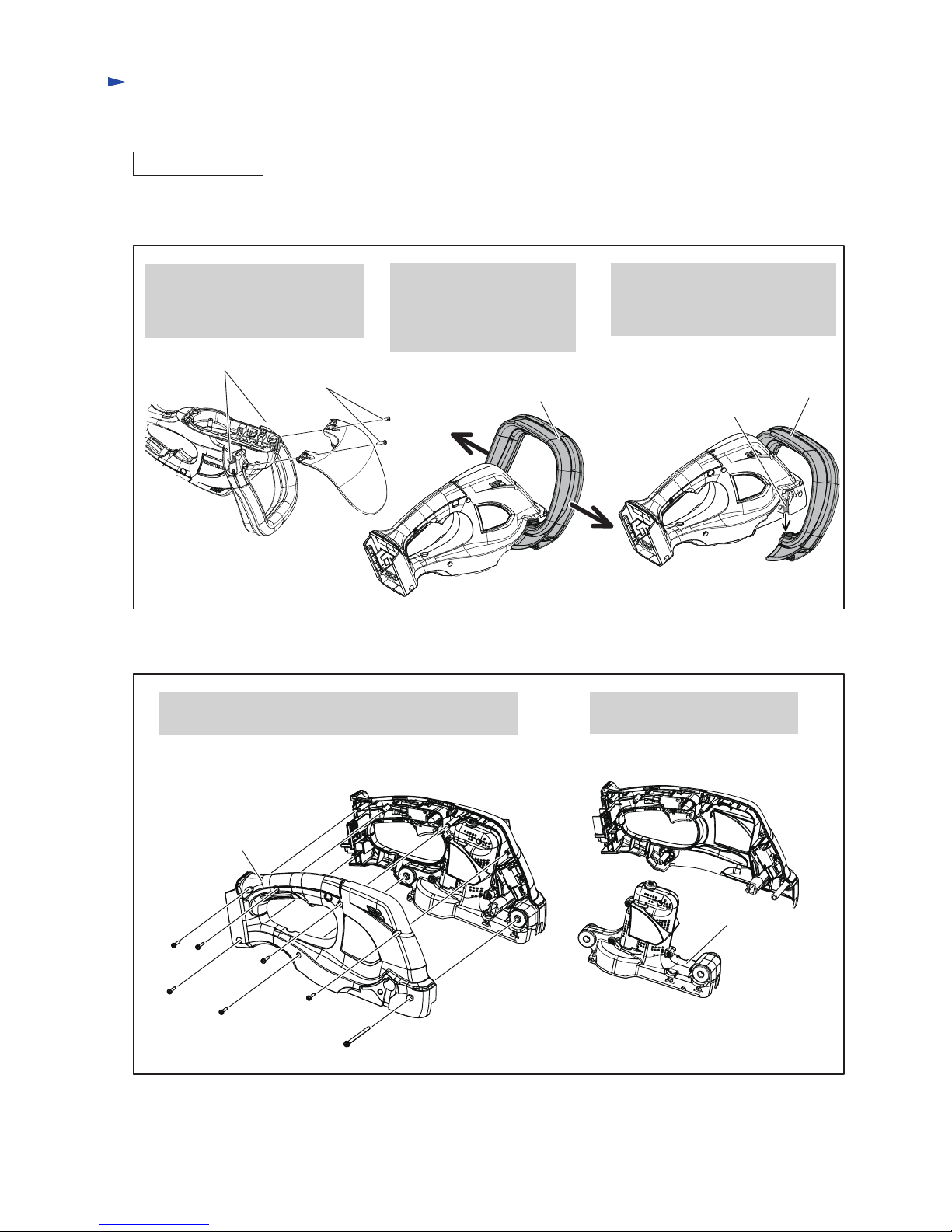

Fig. 4

Fig. 5

[3] DISASSEMBLY/ASSEMBLY

[3] -2. DC motor

DISASSEMBLING

(1) Disassemble Shear blade complete and Spur gear 93 as drawn in Fig. 2.

(2) Remove Protector and Front grip section as drawn in Fig. 4.

(3) Separate Housing R from Housing L. Then, remove Motor housing section from Housing L. See Fig. 5.

3x16 Tapping screw

(6 pcs.)

M4x65 Pan head screw

(1 pc.)

1. Remove Protector by unscrewing

two 4x18 Tapping screws.

And loosen two M5x25 Pan head

screws on the joints of Front grip.

1. Unscrewing six 3x16 Tapping screws and one M4x65

Pan head screw, separate Housing R from Housing L.

2.Separate Motor housing section

from Housing L.

2. Pulling Front grip toward

the direction designated

with arrow, remove it from

the holes on the both side

of Housing set.

3. Push Front grip along the grooves

on the both side of Housing set.

Front grip section is disassembled

from Housing set.

M5x25 Pan head

screw (2 pcs.)

Housing R

4x18 Tapping

screw (2 pcs.)

Motor housing section

groove

Front grip section Front grip section

Repair

P 4/ 13

Loading...

Loading...