Page 1

T

ECHNICAL INFORMATION

Model No.

Description

UH200D (HU01*)

Cordless Hedge Trimmer 200mm (7-7/8)

*1: Model number for North and Central American countries

CONCEPT AND MAIN APPLICATIONS

Model UH200D is 200mm Cordless hedge trimmer

powered by 10.8V/ 1.3Ah Li-ion battery BL1013.

Its main features are:

Lightweight and compact design for easy handling

Optional Grass shear blade kit can convert this model

into Model UM164D Cordless grass shear.

This product is available in the following variations.

Model No.

UH200DZ No No

UH200DW

UH200DWE 2

(Li-ion 1.3Ah)

Battery

type quantity

BL1013

1

Charger

DC10WA

L

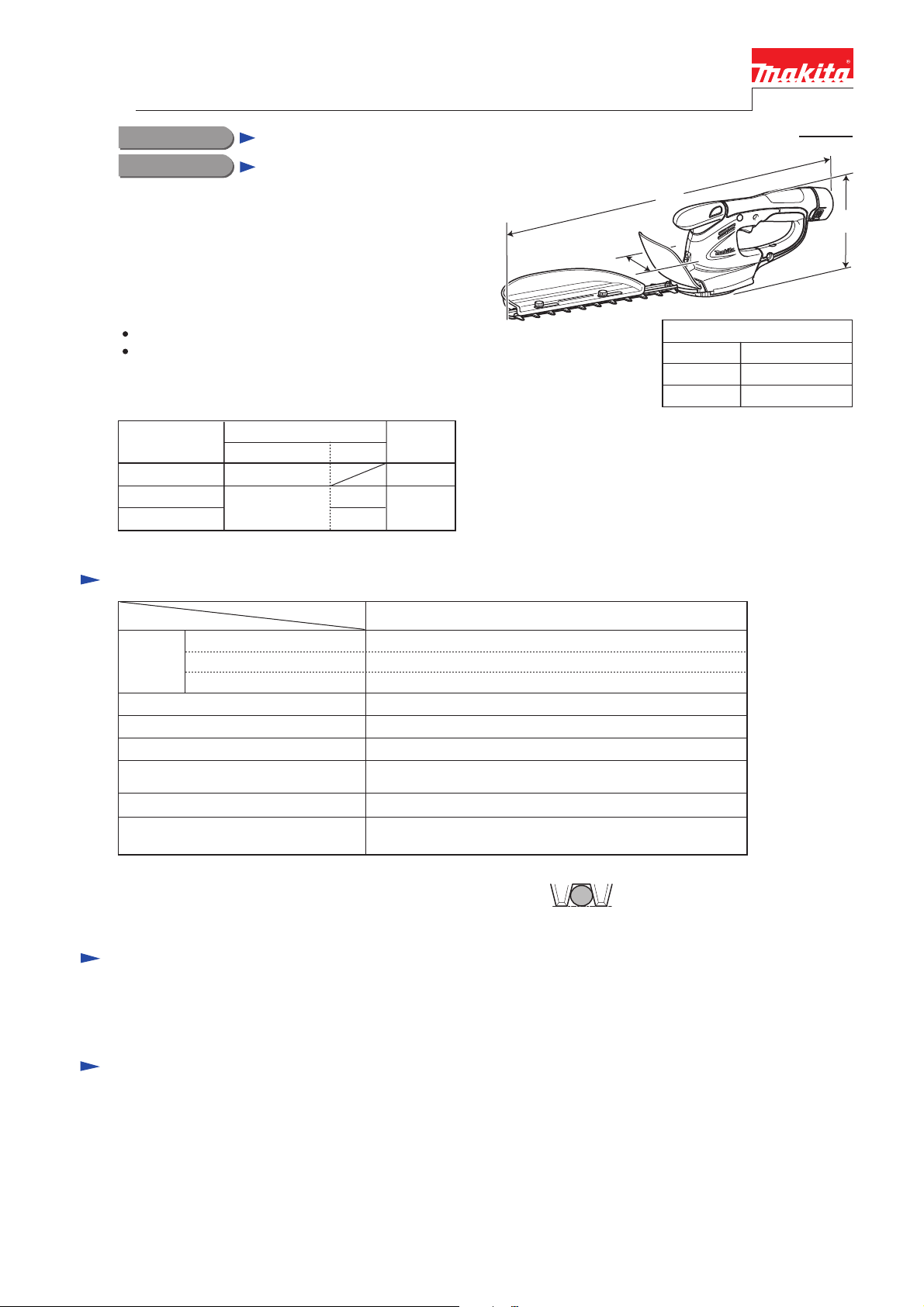

W

Dimensions*1: mm (")

Length (L) 460 (18-1/8)

Width (W)

Height (H)

*1 without chip receiver

PRODUCT

P 1/ 8

H

120 (4-3/4)

130 (5-1/8)

All models also include the accessories listed in "Standard equipment".

Specification

Specification

Voltage: V

Battery

No load speed: min-1=spm*2

Blade length: mm (") 200 (7-7/8)

Tooth spacing: mm (") 26 (1)

Maximum branch

diameter*3: mm (")

Overload protection

Weight according to

EPTA-Procedure 01/2003 *4: kg (lbs)

*2 spm= stroke per minute

*3: Indicates maximum diameter of the branch that can be received

between adjacent two blade teeth. (See the figure on right.)

*4 with hedge trimmer blade, chip receiver

Capacity: Ah

Cell

Model

UH200D

10.8

1.3

Li-ion

1,250

8 (5/16)

Yes

1.2 (2.7)

Standard equipment

Chip receiver ..................................................... 1

Blade cover ........................................................ 1

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

Battery BL1013

Charger DC10WA

Grass shear blade kit*5 (with a bottle of lubricant grease)

Hedge trimmer blade kit*6 (with a bottle of lubricant grease)

Extension handle kit*5

Chip receiver set*6

Accessory kit for use as a hedge trimmer*6 (including Blade cover, etc.)

Accessory kit for use as a grass shear*5 (including Base frame, etc.)

*5 for use as a grass shear

*6 for use as a hedge trimmer

Page 2

P 2/ 8

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

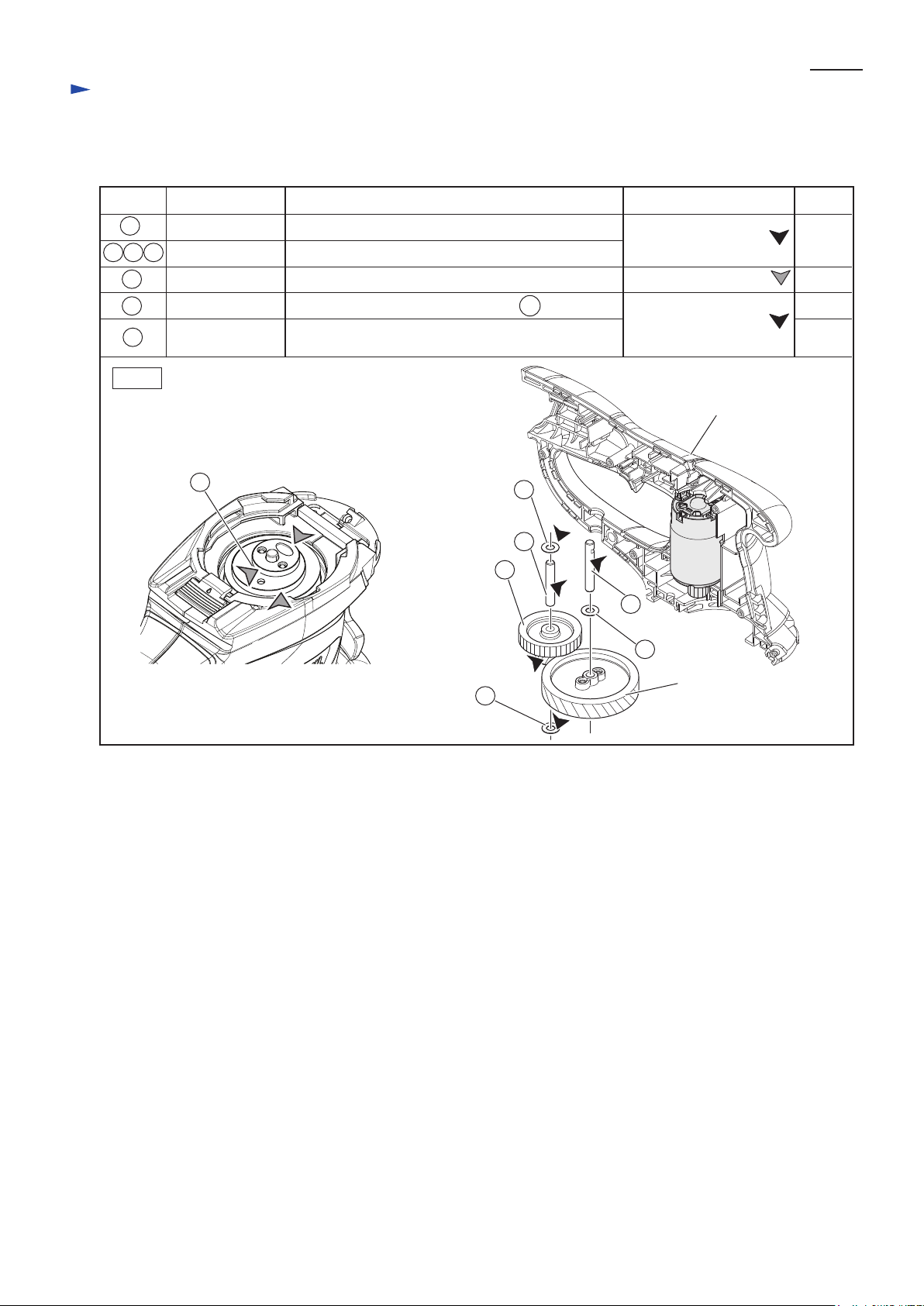

[1] LUBRICATIONS

Fig. 1

Item No.

Apply the following lubricant to protect parts and product from unusual abrasion.

Description

Crank

Helical gear 47

Housing complete (L)

Gear 12-31

Gear teeth with which Helical gear 47 and DC motor

gear engage

Drum portions where Blade contact

17 Pin 6 (with notch) Drum portion for smooth rotation of Helical gear 47

18 24 26 Washer 6 Whole portion

a little

2g

Lubricant

Amount

Portion to lubricate

18

24

17

26

21

21

2323Pin 6

1.5g

a little

Makita grease N No.2

Molybdenum disulfide

Drum portion for smooth rotation of 25 Gear 12-31

25

25

Makita grease N No.2

Page 3

Shear blade assembly

P 3/ 8

Fig. 2

Repair

[2] DISASSEMBLY/ASSEMBLY

[2]-1. Gear 12-31, Helical gear 47

DISASSEMBLING

(1) Remove Blade, Crank and Housing set (R) as illustrated in Fig. 2.

3. Loosen two M4 Countersunk

head screws, and then remove

Shear blade assembly.

Under cover

complete

4. Remove Crank complete and Dust guard.

Dust guard

2. Remove Under cover complete.

Shear blade

assembly

M4 Countersunk head screw

Crank complete

Lock lever

Under cover

complete

1. With pressing Lock lever, turn Under cover complete

to the unlocked position as drawn below.

Unlocked position

Set plate

5. Remove Set plate with slotted screwdriver. 6. Separate Housing set (R) by unscrewing five 3x16 Tapping screws.

Fig. 3

Helical gear 47

1. Remove Helical gear 47 and Gear 12-31 from Housing set (L). 2. After removing Washer 6 and Pin 6 which

functions as a shaft for the Helical gear 47,

remove 2 pcs. of Pin 4 by pressing with

Arbor press. Helical gear 47 can be replaced.

Gear 12-31

Pin 6 (with a notch)

Washer 6

Arbor press

(2) After removing Housing set (R), Helical gear 47 and Gear 12-31 can be removed. (Fig. 3)

Helical gear 47

Housing set (L)

Pin 4

(2pcs.)

Housing set (R)

Housing set (L)

3x16 Tapping screw

(5pcs.)

Page 4

P 4/ 8

Repair

[2] DISASSEMBLY/ASSEMBLY

[2]-1. Gear 12-31, Helical gear 47

Fig. 4

Fig. 5

Fig. 6

ASSEMBLING

(1) Assemble Helical gear 47, Gear 12-31. (Figs. 4, 5)

And mount them to Housing set (L). (Fig. 6)

Crank side of Helical gear 47

1. Face the crank side of

Helical gear 47 to the bottom.

2. Assemble two Pins 4 to

Helical gear 47 by pressing

with Arbor press.

3. Facing the notch side of Pin 6

to top, pass it through Washer 6

into Helical gear 47.

5. Assemble Helical gear 47 with

fitting the notch of Pin 6 on the Rib

of Housing set (L).

Notch on Pin 6

Helical gear 47

DC Motor

Rib

Washer 6

Housing set (L)

Notch

Pin 6

Pin 4

(2pcs.)

Fig. 7

(2) Assemble Protector to housing set. (Center right in Fig. 2)

(3) Mount Crank complete. (Fig. 7)

(4) Mount Shear blade assembly and Under cover. See Figs. 10, 11 in “[3]-3. Shear Blade Assembly”.

Dust guard

6. Mount Crank complete and Dust guard.

for UH200D

for UM164D

Crank complete

<Note>

Crank complete has an interchangeability between UM164D

cordless grass shear and UH200D cordless hedge trimmer by

reversing as illustrated below.

In case of UH200D, engage this side with Shear blade assembly.

4. Pass Pin 6 through Gear 12-31

and two Washers 6 as drawn below,

then set them in place in Housing L.

Pin 6

Washer 6

Washer 6

Gear 12-31

Page 5

P 5/ 8

Repair

[2] DISASSEMBLY/ASSEMBLY

[2]-2. DC motor

Fig. 8

Fig. 9

DISASSEMBLING

(1) Disassemble DC motor. (Fig. 8)

Set plate

1. Remove Set plate and separate Housing set (R)

by unscrewing five 3x16 Tapping screws.

2. DC Motor can be removed

from Housing set (L).

3x16 Tapping screw

(5pcs.)

Housing set (R)

DC motor

Housing set (L)

ASSEMBLING

Set DC motor to Housing set (L). (Fig. 9)

Assemble DC motor with fitting its notch

on the convex of Housing set (L).

DC motor

Page 6

P 6/ 8

Repair

[2] DISASSEMBLY/ASSEMBLY

[2]-3. Shear blade assembly

1. Adjust Crank complete to

the position as drawn below.

Joint of Housing set (L)

and Housing set (R)

2. Align the Holes of Shear blade A and B

to the Hole of Guide plate in order to set

M4 Pan head screw as a positioning pin.

M4 Pan head

screw

Shear blade B

Guide plate

Shear blade A

Crank complete

M4 Countersunk

head screw

Shear blade

assembly

4. Tighten M4 Countersunk head screws.

DISASSEMBLING

(1) Pull the rear portion of Base frame toward rear side designated with arrow. (Top left in Fig. 2)

(2) With pressing Lock lever, turn under cover complete to the unlocked position. (Top right in Fig. 2)

(3) Disassemble Under cover, and then remove Shear blade assembly. (Center left in Fig. 2)

Fig. 10

ASSEMBLING

(1) Mount Shear blade assembly. (Fig. 10)

3. Mount Shear blade assembly

with fitting the loops of Shear

blades A and B into Crank

complete

Fig. 11

(2) Mount Under cover complete. (Fig. 11)

5. Put Under cover complete on the bottom of

Housing set as drawn below.

6. With pressing Lock lever, turn Under cover complete

toward the locking position as drawn below.

Lock lever

Under cover

complete

Unlocked position

Locking position

Page 7

Circuit diagram

P 7/ 8

Fig. D-1

White

Color index of lead wires' sheath

Black

Red

Blue

LED

(Warning lamp for battery)

DC Motor

Controller

Line filter

Switch

Terminal

Line filter is not used

for some countries.

Wiring diagram

Fig. D-2

1. Find Terminal marked with Red dot marking.

2. Now connect the Lead wire (white) receptacle to

the Terminal with Red dot marking and the Lead

wire (blue) receptacle to the another Terminal.

Lead wire

(blue)

Red dot marking

Wire connecting portion of

Receptacles

Lead wire

(white)

Housing set (L)

3. DC motor can be mounted with facing

the wire connecting portions of Receptacles

to Housing set (L) side.

Page 8

P 8/ 8

Fig. D-6

Fig. D-5

Switch

Fix Controller´s Lead wires

(red, black) in this Lead

wire holder.

Connect Receptacles to the Switch with facing the wire

connecting portion to the Housing set (L) side in order

to put the Lead wires on the Housing set (L).

Connect Receptacles to the Terminal with facing

the wire connecting portion to Housing set (L) side.

Adhesive

Pass the Lead wires of

LED circuit between

the Ribs.

LED circuit

In case Line filter has to

be used, put Line filter

into the space designated

with gray color.

Controller

Controller

Housing set

(L) side

Housing set

(L) side

DC motor

Switch

Terminal

Fix all of the Lead wires

of Controller in this

Lead wire holder.

from Plus pole

of Terminal

from Controller

Terminal

Wiring diagram (cont.)

Fig. D-3 Fig. D-4

Controller

Controller has to be put into Housing set (L).

Note: Bring the Lead wire (blue) connecting portion to the bottom

side (Helical gear 47 side) and the wires connecting portions

to the front side (protector side).

Line filter

Wind Controller´s Lead wires (blue, white)

one time around Line filter.

To Plus pole of DC Motor

To Minus pole

of DC Motor

Lead wire (blue)

Front side

(Protector side)

Bottom side (Helical gear 47 side)

Housing set (L)

DC Motor

Loading...

Loading...