Page 1

EN

Cordless Impact Driver

INSTRUCTION MANUAL 4

PL

HU

SK

CS

UK

RO

DE

ůkuЦuХКtШrШавăАkrtКkă

Udarowy

Akkumulátoros

ütvecsavarbehajtó

Akumulátorový rázový

uťКСШЯКč

Akumulátorový rázový

utahovák

ăă

MКşТЧăНОăîЧşuruЛКtăМuă

impact cu acumulator

Akku-Schlagschrauber

TD110D

IІSTRUKűJůăЇŰSŁUżI 9

HASZNÁLATI KÉZIKÖNYV 15

NÁVOD NA OBSLUHU 21

NÁVOD K OBSLUZE 26

ăă

MůІUůLăDźăIІSTRUűIUІI 37

ŰźTRIźŰSůІLźITUІż 43

31

Page 2

Fig.1

AB

Fig.2

1

2

1

3

Fig.5

1

2

Fig.6

1

Fig.3

1

Fig.7

1

Fig.4

Fig.8

2

2

312

Page 3

Fig.9

Fig.10

1

2

3

Fig.13

1

2

Fig.11

Fig.12

3

Page 4

źІżLISHăĚЇrТРТЧКХăТЧstruМtТШЧsě

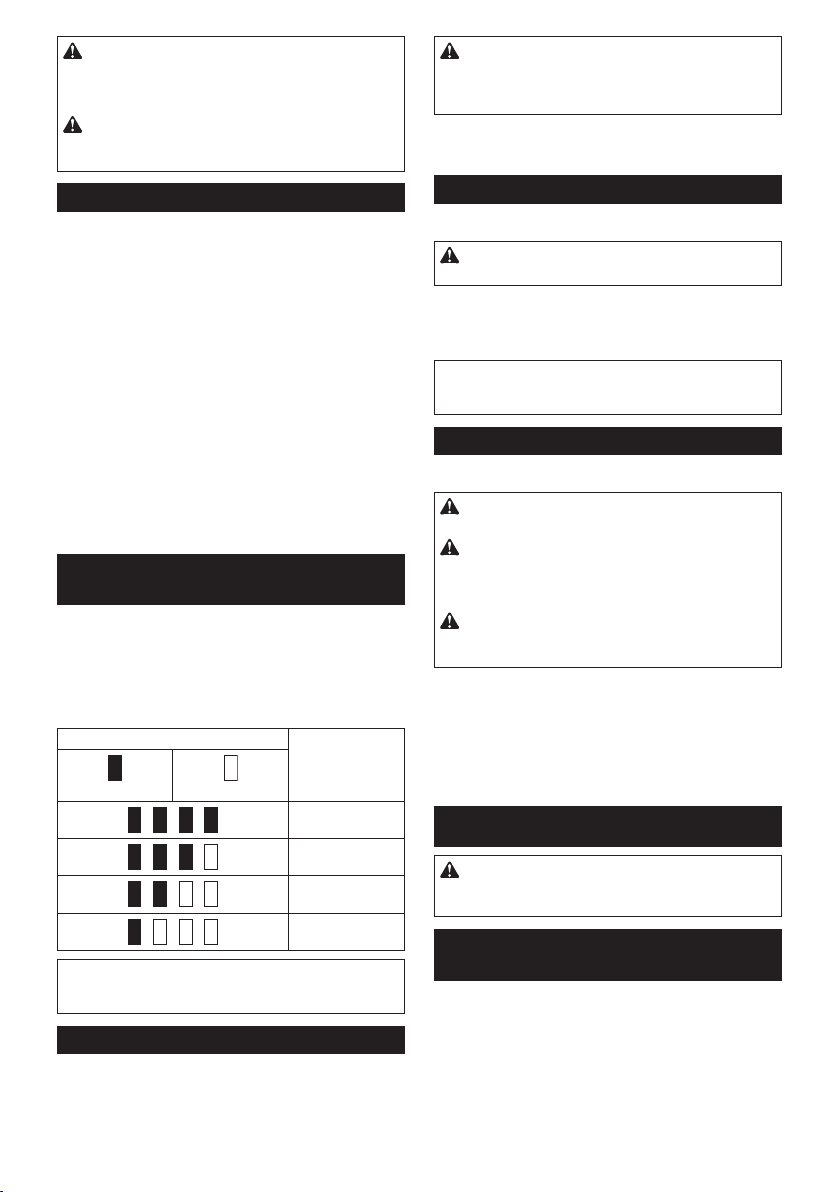

SPECIFICATIONS

Model: TD110D

Fastening capacities Machine screw 4 mm - 8 mm

Standard bolt 5 mm - 12 mm

High tensile bolt 5 mm - 10 mm

No load speed 0 - 2,600 min

Impacts per minute 0 - 3,500 min

Overall length 153 mm

Rated voltage D.C. 10.8 V

Battery cartridge BL1015, BL1020B BL1040B

Net weight 1.0 kg 1.2 kg

•ă DuОătШăШurăМШЧtТЧuТЧРăЩrШРrКЦăШПărОsОКrМСăКЧНăНОЯОХШЩЦОЧt,ătСОăsЩОМТiМКtТШЧsăСОrОТЧăКrОăsuЛУОМtătШăМСКЧРОă

without notice.

•ă SЩОМТiМКtТШЧsăКЧНăЛКttОrвăМКrtrТНРОăЦКвăНТППОrăПrШЦăМШuЧtrвătШăМШuЧtrв.

• Weight, with battery cartridge, according to EPTA-Procedure 01/2003

IЧtОЧНОНăusО

The tool is intended for screw driving in wood, metal

and plastic.

Noise

The typical A-weighted noise level determined according to EN60745:

Sound pressure level (LpA) : 94 dB(A)

Sound power level (LWA) : 105 dB (A)

Uncertainty (K) : 3 dB(A)

АůRІIІżŚ АОКrăОКrăprШtОМtТШЧ.

VТЛrКtТШЧ

The vibration total value (tri-axial vector sum) determined according to EN60745:

Work mode: impact tightening of fasteners of the maximum capacity of the tool

Vibration emission (ah) : 8.0 m/s

Uncertainty (K) : 1.5 m/s

NOTE: The declared vibration emission value has

been measured in accordance with the standard test

method and may be used for comparing one tool with

another.

NOTE: The declared vibration emission value

may also be used in a preliminary assessment of

exposure.

2

2

АůRІIІżŚ The vibration emission during actual

use of the power tool can differ from the declared

emission value depending on the ways in which the

tool is used.

АůRІIІżŚ Be sure to identify safety measures to

protect the operator that are based on an estimation

of exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as

the times when the tool is switched off and when it is

running idle in addition to the trigger time).

źűăDОМХКrКtТШЧăШПăűШЧПШrЦТtв

For European countries only

Makita declares that the following Machine(s):

Designation of Machine: Cordless Impact Driver

Model No./ Type: TD110D

Conforms to the following European Directives:

2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents: EN60745

TСОătОМСЧТМКХăiХОăТЧăКММШrНКЧМОăаТtСă2ŃŃ6/42/ECăТsă

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

24.2.2015

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

żОЧОrКХăpШаОrătШШХăsКПОtвăаКrЧТЧРs

-1

-1

4 ENGLISH

АůRІIІżŚ RОКНăКХХăsКПОtвăаКrЧТЧРsăКЧНăКХХă

ТЧstruМtТШЧs.ăFailure to follow the warnings and

ТЧstruМtТШЧsăЦКвărОsuХtăТЧăОХОМtrТМăsСШМФ,ăirОăКЧН/Шră

sОrТШusăТЧУurв.

Page 5

SКЯОăКХХăаКrЧТЧРsăКЧНăТЧstruМtТШЧsăПШrăПuturОărОПОrОЧМО.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

űШrНХОssăТЦpКМtăНrТЯОrăsКПОtвă

аКrЧТЧРs

1. HШХНăpШаОrătШШХăЛвăТЧsuХКtОНăРrТppТЧРăsur-

ПКМОsĽăаСОЧăpОrПШrЦТЧРăКЧăШpОrКtТШЧăаСОrОă

tСОăПКstОЧОrăЦКвăМШЧtКМtăСТННОЧăаТrТЧР.

Fasteners contacting a "live" wire may make

exposed metal parts of the power tool "live" and

could give the operator an electric shock.

2. ůХаКвsăЛОăsurОăвШuăСКЯОăКăirЦăПШШtТЧР.

ŰОăsurОăЧШăШЧОăТsăЛОХШаăаСОЧăusТЧРătСОătШШХăТЧă

СТРСăХШМКtТШЧs.

3. HШХНătСОătШШХăirЦХв.

4. Wear ear protectors.

5. DШăЧШtătШuМСătСОăЛТtăШrătСОăаШrkpТОМОăТЦЦОНТ-

КtОХвăКПtОrăШpОrКtТШЧ.ăTСОвăЦКвăЛОăОбtrОЦОХвă

СШtăКЧНăМШuХНăЛurЧăвШurăskТЧ.

6. KООpăСКЧНsăКаКвăПrШЦărШtКtТЧРăpКrts.

SAVE THESE INSTRUCTIONS.

АůRІIІżŚ DЇăІЇTăХОtăМШЦПШrtăШrăПКЦТХТКrТtвă

аТtСăprШНuМtăĚРКТЧОНăПrШЦărОpОКtОНăusОěărОpХКМОă

strТМtăКНСОrОЧМОătШăsКПОtвăruХОsăПШrătСОăsuЛУОМtă

product.

MISUSźăШrăПКТХurОătШăПШХХШаătСОăsКПОtвăruХОsăstКtОНă

ТЧătСТsăТЧstruМtТШЧăЦКЧuКХăЦКвăМКusОăsОrТШusă

pОrsШЧКХăТЧУurв.

IЦpШrtКЧtăsКПОtвăТЧstruМtТШЧsăПШră

battery cartridge

1. ŰОПШrОăusТЧРăЛКttОrвăМКrtrТНРОĽărОКНăКХХăТЧstruМ-

tТШЧsăКЧНăМКutТШЧКrвăЦКrkТЧРsăШЧăĚ1ěăЛКttОrвă

МСКrРОrĽăĚ2ěăЛКttОrвĽăКЧНăĚ3ěăprШНuМtăusТЧРă

battery.

2. DШăЧШtăНТsКssОЦЛХОăЛКttОrвăМКrtrТНРО.

3. IПăШpОrКtТЧРătТЦОăСКsăЛОМШЦОăОбМОssТЯОХвă

sСШrtОrĽăstШpăШpОrКtТЧРăТЦЦОНТКtОХв.ăItăЦКвă

rОsuХtăТЧăКărТskăШПăШЯОrСОКtТЧРĽăpШssТЛХОăЛurЧsă

КЧНăОЯОЧăКЧăОбpХШsТШЧ.

4. IПăОХОМtrШХвtОăРОtsăТЧtШăвШurăОвОsĽărТЧsОătСОЦă

ШutăаТtСăМХОКrăаКtОrăКЧНăsООkăЦОНТМКХăКttОЧtТШЧărТРСtăКаКв.ăItăЦКвărОsuХtăТЧăХШssăШПăвШură

eyesight.

5. DШăЧШtăsСШrtătСОăЛКttОrвăМКrtrТНРОŚ

(1) DШăЧШtătШuМСătСОătОrЦТЧКХsăаТtСăКЧвăМШЧ-

ductive material.

(2) ůЯШТНăstШrТЧРăЛКttОrвăМКrtrТНРОăТЧăКăМШЧ-

tКТЧОrăаТtСăШtСОrăЦОtКХăШЛУОМtsăsuМСăКsă

ЧКТХsĽăМШТЧsĽăОtМ.

(3) DШăЧШtăОбpШsОăЛКttОrвăМКrtrТНРОătШăаКtОră

ШrărКТЧ.

ůăЛКttОrвăsСШrtăМКЧăМКusОăКăХКrРОăМurrОЧtă

lШаĽăШЯОrСОКtТЧРĽăpШssТЛХОăЛurЧsăКЧНăОЯОЧăКă

ЛrОКkНШаЧ.

6. DШăЧШtăstШrОătСОătШШХăКЧНăЛКttОrвăМКrtrТНРОăТЧă

ХШМКtТШЧsăаСОrОătСОătОЦpОrКturОăЦКвărОКМСăШră

ОбМООНăő0ă°űăĚ122ă°Żě.

7. DШăЧШtăТЧМТЧОrКtОătСОăЛКttОrвăМКrtrТНРОăОЯОЧăТПă

ТtăТsăsОЯОrОХвăНКЦКРОНăШrăТsăМШЦpХОtОХвăаШrЧă

Шut.ăTСОăЛКttОrвăМКrtrТНРОăМКЧăОбpХШНОăТЧăКăirО.

8. ŰОăМКrОПuХăЧШtătШăНrШpăШrăstrТkОăЛКttОrв.

9. DШăЧШtăusОăКăНКЦКРОНăЛКttОrв.

10. ŻШХХШаăвШurăХШМКХărОРuХКtТШЧsărОХКtТЧРătШăНТs-

pШsКХăШПăЛКttОrв.

SAVE THESE INSTRUCTIONS.

TТpsăПШrăЦКТЧtКТЧТЧРăЦКбТЦuЦă

ЛКttОrвăХТПО

1. űСКrРОătСОăЛКttОrвăМКrtrТНРОăЛОПШrОăМШЦpХОtОХвă

НТsМСКrРОН.ăůХаКвsăstШpătШШХăШpОrКtТШЧăКЧНă

МСКrРОătСОăЛКttОrвăМКrtrТНРОăаСОЧăвШuăЧШtТМОă

less tool power.

2. ІОЯОrărОМСКrРОăКăПuХХвăМСКrРОНăЛКttОrвăМКrtrТНРО.ăЇЯОrМСКrРТЧРăsСШrtОЧsătСОăЛКttОrвă

sОrЯТМОăХТПО.

3. Charge the battery cartridge with room tem-

pОrКturОăКtă10ă°űăľăŐ0ă°űăĚő0ă°Żăľă10Őă°Żě.ăLОtă

КăСШtăЛКttОrвăМКrtrТНРОăМШШХăНШаЧăЛОПШrОă

МСКrРТЧРăТt.

FUNCTIONAL

DESCRIPTION

CAUTION: Always be sure that the tool is

sаТtМСОНăШППăКЧНătСОăЛКttОrвăМКrtrТНРОăТsărОЦШЯОНă

ЛОПШrОăКНУustТЧРăШrăМСОМkТЧРăПuЧМtТШЧăШЧătСОătШШХ.

IЧstКХХТЧРăШrărОЦШЯТЧРăЛКttОrвă

cartridge

CAUTION: ůХаКвsăsаТtМСăШППătСОătШШХăЛОПШrОă

ТЧstКХХТЧРăШrărОЦШЯТЧРăШПătСОăЛКttОrвăМКrtrТНРО.

CAUTION: HШХНătСОătШШХăКЧНătСОăЛКttОrвăМКr-

trТНРОăirЦХвăаСОЧăТЧstКХХТЧРăШrărОЦШЯТЧРăЛКttОrвă

cartridge. Failure to hold the tool and the battery

МКrtrТНРОăirЦХвăЦКвăМКusОătСОЦătШăsХТЩăШППăвШurăСКЧНsă

and result in damage to the tool and battery cartridge

КЧНăКăЩОrsШЧКХăТЧУurв.

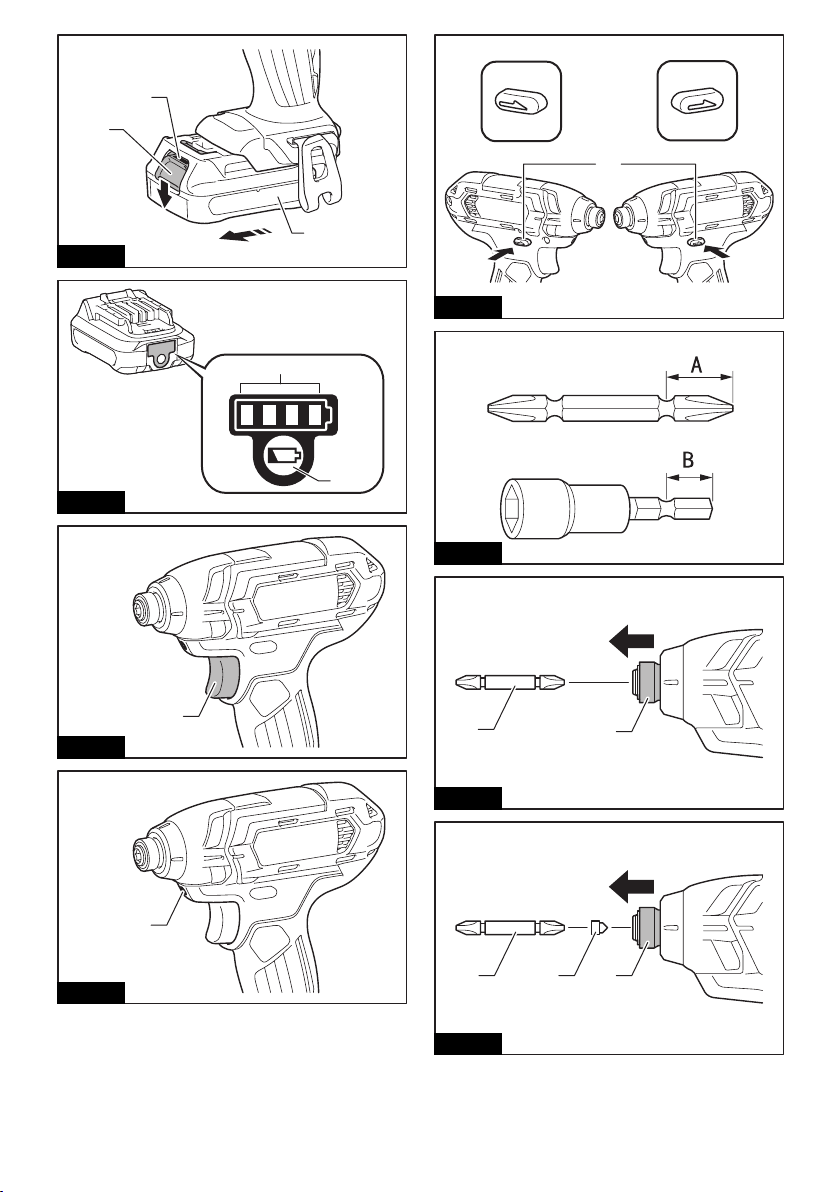

►Fig.1: 1. Red indicator 2. Button 3. Battery

cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

5ENGLISH

Page 6

CAUTION: ůХаКвsăТЧstКХХătСОăЛКttОrвăМКrtrТНРОă

ПuХХвăuЧtТХătСОărОНăТЧНТМКtШrăМКЧЧШtăЛОăsООЧ. If not,

ТtăЦКвăКММТНОЧtКХХвăПКХХăШutăШПătСОătШШХ,ăМКusТЧРăТЧУurвătШă

you or someone around you.

CAUTION: DШăЧШtăТЧstКХХătСОăЛКttОrвăМКrtrТНРОă

ПШrМТЛХв. If the cartridge does not slide in easily, it is

not being inserted correctly.

ŰКttОrвăprШtОМtТШЧăsвstОЦ

The tool is equipped with a battery protection system.

This system automatically cuts off power to the motor to

extend battery life.

The tool will automatically stop during operation if the

tool and/or battery are placed under one of the following

conditions:

Overloaded:

The tool is operated in a manner that causes it to draw

an abnormally high current.

In this situation, release the switch trigger on the tool

and stop the application that caused the tool to become

overloaded. Then pull the switch trigger again to restart.

If the tool does not start, the battery is overheated.

In this situation, let the battery cool before pulling the

switch trigger again.

Low battery voltage:

The remaining battery capacity is too low and the tool

will not operate. If you pull the switch trigger, the motor

runs again but stops soon. In this situation, remove and

recharge the battery.

IЧНТМКtТЧРătСОărОЦКТЧТЧРăЛКttОrвă

capacity

Only for battery cartridges with "B" at the end of the

model number

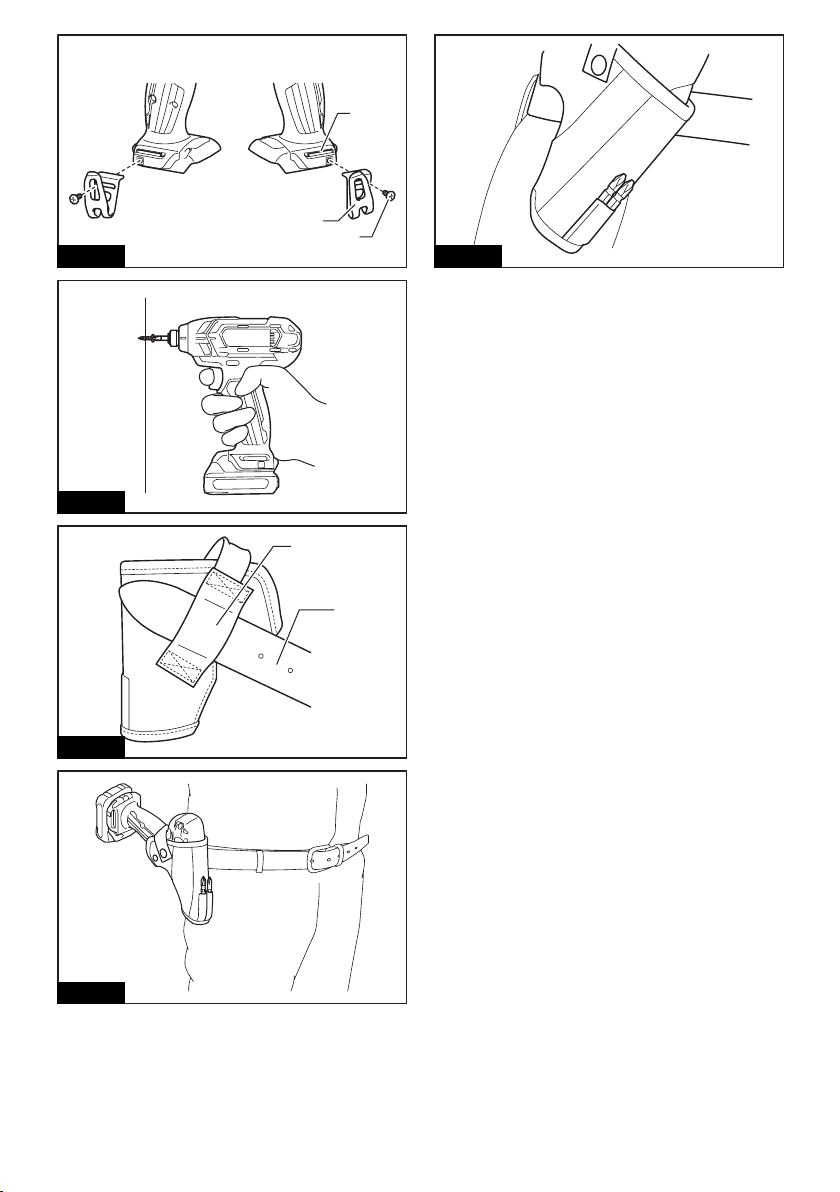

►Fig.2: 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for few seconds.

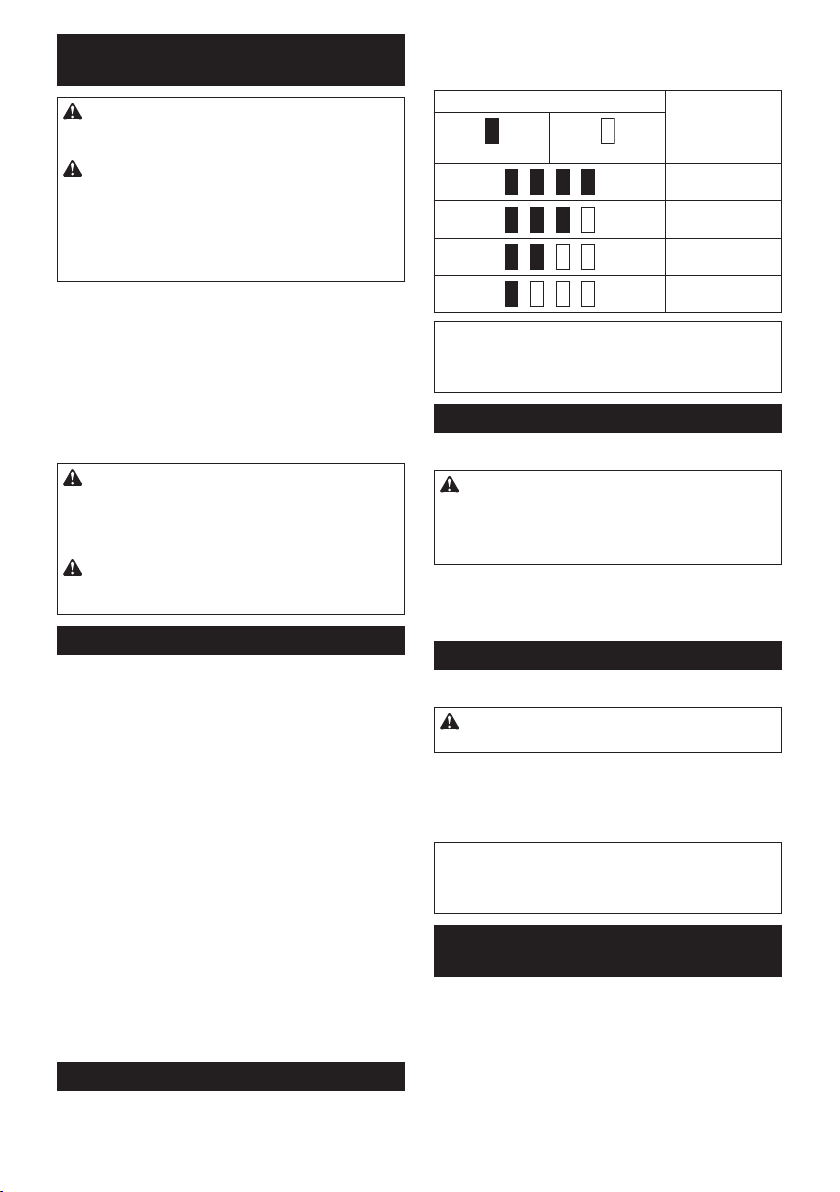

IЧНТМКtШrăХКЦps RОЦКТЧТЧР

Lighted ЇПП

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

capacity

75% to 100%

50% to 75%

25% to 50%

0% to 25%

SаТtМСăКМtТШЧ

►Fig.3: 1. Switch trigger

CAUTION: ŰОПШrОăТЧsОrtТЧРătСОăЛКttОrвăМКr-

trТНРОăТЧtШătСОătШШХĽăКХаКвsăМСОМkătШăsООătСКtătСОă

sаТtМСătrТРРОrăКМtuКtОsăprШpОrХвăКЧНărОturЧsătШă

tСОă"ЇŻŻ"ăpШsТtТШЧăаСОЧărОХОКsОН.

To start the tool, simply pull the switch trigger. Tool

speed is increased by increasing pressure on the switch

trigger. Release the switch trigger to stop.

LТРСtТЧРăupătСОăПrШЧtăХКЦp

►Fig.4: 1. Lamp

CAUTION: DШăЧШtăХШШkăТЧătСОăХТРСtăШrăsООătСОă

sШurМОăШПăХТРСtăНТrОМtХв.

Pull the switch trigger to light up the lamp. The lamp

keeps on lighting while the switch trigger is being pulled.

The lamp goes out approximately 10 seconds after

releasing the switch trigger.

NOTE: Use a dry cloth to wipe the dirt off the lens of

the lamp. Be careful not to scratch the lens of lamp, or

it may lower the illumination.

RОЯОrsТЧРăsаТtМСăКМtТШЧ

►Fig.5: 1. Reversing switch lever

CAUTION: ůХаКвsăМСОМkătСОăНТrОМtТШЧăШПărШtК-

tТШЧăЛОПШrОăШpОrКtТШЧ.

CAUTION: UsОătСОărОЯОrsТЧРăsаТtМСăШЧХвăКПtОră

the tool comes to a complete stop. Changing the

direction of rotation before the tool stops may damage the tool.

CAUTION: АСОЧăЧШtăШpОrКtТЧРătСОătШШХĽăКХаКвsă

sОtătСОărОЯОrsТЧРăsаТtМСăХОЯОrătШătСОăЧОutrКХă

pШsТtТШЧ.

This tool has a reversing switch to change the direction

of rotation. Depress the reversing switch lever from the

A side for clockwise rotation or from the B side for counterclockwise rotation.

When the reversing switch lever is in the neutral position, the switch trigger cannot be pulled.

ASSEMBLY

CAUTION: Always be sure that the tool is

sаТtМСОНăШППăКЧНătСОăЛКttОrвăМКrtrТНРОăТsărОЦШЯОНă

ЛОПШrОăМКrrвТЧРăШutăКЧвăаШrkăШЧătСОătШШХ.

IЧstКХХТЧРăШrărОЦШЯТЧРăНrТЯОrăЛТt/

socket bit

Optional accessory

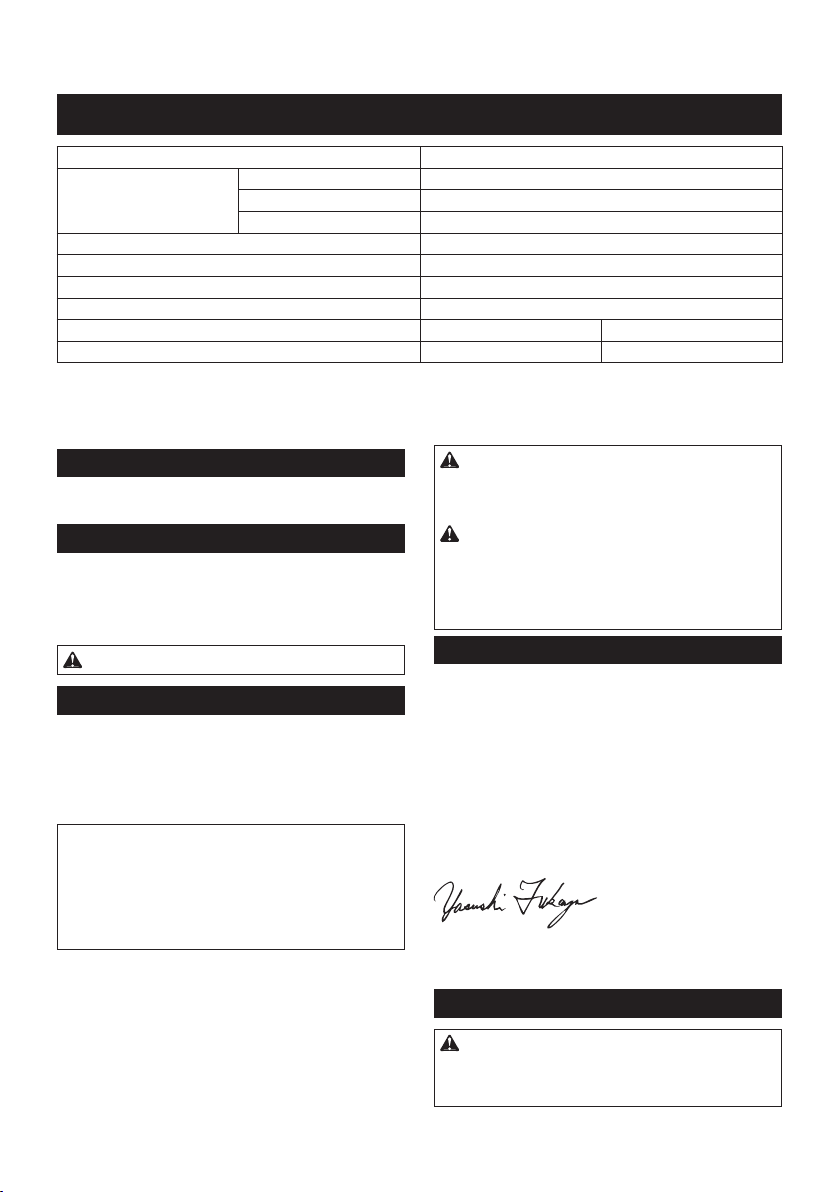

►Fig.6

Use only driver bit/socket bit that has inserting portion

sСШаЧăТЧătСОăiРurО.ăDШăЧШtăusОăКЧвăШtСОrăНrТЯОrăЛТt/

socket bit.

6 ENGLISH

Page 7

For tool with shallow driver bit hole

A=12mm

B=9mm

Use only these type of driver

bit. Follow the procedure

1. (Note) Bit-piece is not

necessary.

For tool with deep driver bit hole

A=17mm

B=14mm

A=12mm

B=9mm

To install these types of driver

bits, follow the procedure 1.

To install these types of driver

bits, follow the procedure 2.

(Note) Bit-piece is necessary

for installing the bit.

1. To install the driver bit, pull the sleeve in the direction of the arrow and insert the driver bit into the

sleeve as far as it will go.

Then release the sleeve to secure the driver bit.

►Fig.7: 1. Driver bit 2. Sleeve

2. To install the driver bit, pull the sleeve in the direction of the arrow and insert the bit-piece and driver

bit into the sleeve as far as it will go. The bit-piece

should be inserted into the sleeve with its pointed

end facing in. Then release the sleeve to secure

the driver bit.

►Fig.8: 1. Driver bit 2. Bit-piece 3. Sleeve

To remove the driver bit, pull the sleeve in the direction

of the arrow and pull the driver bit out.

NOTE: If the driver bit is not inserted deep enough

into the sleeve, the sleeve will not return to its original

position and the driver bit will not be secured. In this

case, try re-inserting the bit according to the instructions above.

NOTE: After inserting the driver bit, make sure that it

ТsăirЦХвăsОМurОН.ăIПăТtăМШЦОsăШut,ăНШăЧШtăusОăТt.

IЧstКХХТЧРăСШШk

►Fig.9: 1. Groove 2. Hook 3. Screw

The hook is convenient for temporarily hanging the tool.

This can be installed on either side of the tool. To install

the hook, insert it into a groove in the tool housing on

either side and then secure it with a screw. To remove,

loosen the screw and then take it out.

PrШpОrăПКstОЧТЧРătШrquОăПШrăstКЧНКrНăЛШХt

N•m

(kgf•cm)

100

(1020)

80

(816)

60

(612)

2

40

(408)

20

(204)

M8

M12

M10

M12

M10

M8

210

1

1. Fastening time (second) 2. Fastening torque

PrШpОrăПКstОЧТЧРătШrquОăПШrăСТРСătОЧsТХОăЛШХt

N•m

(kgf•cm)

100

(1020)

80

(816)

60

(612)

2

40

(408)

20

(204)

M8

M10

M10

M8

210

OPERATION

►Fig.10

The proper fastening torque may differ depending upon

the kind or size of the screw/bolt, the material of the

workpiece to be fastened, etc. The relation between fas-

tОЧТЧРătШrquОăКЧНăПКstОЧТЧРătТЦОăТsăsСШаЧăТЧătСОăiРurОs.

1

1. Fastening time (second) 2. Fastening torque

HШХНătСОătШШХăirЦХвăКЧНăЩХКМОătСОăЩШТЧtăШПătСОăНrТЯОrăЛТtă

in the screw head. Apply forward pressure to the tool to

the extent that the bit will not slip off the screw and turn

the tool on to start operation.

7ENGLISH

Page 8

NOTE: Use the proper bit for the head of the screw/

bolt that you wish to use.

NOTE: When fastening M8 or smaller screw, choose

КăЩrШЩОrăТЦЩКМtăПШrМОăКЧНăМКrОПuХХвăКНУustăЩrОssurОăШЧă

the switch trigger so that the screw is not damaged.

NOTE: Hold the tool pointed straight at the screw.

NOTE: If the impact force is too strong or you tighten

tСОăsМrОаăПШrăКătТЦОăХШЧРОrătСКЧăsСШаЧăТЧătСОăiРurОs,ă

the screw or the point of the driver bit may be overstressed, stripped, damaged, etc. Before starting your

УШЛ,ăКХаКвsăЩОrПШrЦăКătОstăШЩОrКtТШЧătШăНОtОrЦТЧОătСОă

proper fastening time for your screw.

The fastening torque is affected by a wide variety of

factors including the following. After fastening, always

check the torque with a torque wrench.

1. When the battery cartridge is discharged almost

completely, voltage will drop and the fastening

torque will be reduced.

2. Driver bit or socket bit

Failure to use the correct size driver bit or socket

bit will cause a reduction in the fastening torque.

3. Bolt

•ă EЯОЧătСШuРСătСОătШrquОăМШОПiМТОЧtăКЧНătСОă

class of bolt are the same, the proper fastening torque will differ according to the diameter of bolt.

• Even though the diameters of bolts are the

same, the proper fastening torque will differ

КММШrНТЧРătШătСОătШrquОăМШОПiМТОЧt,ătСОăМХКssă

of bolt and the bolt length.

4. The manner of holding the tool or the material

of driving position to be fastened will affect the

torque.

5. Operating the tool at low speed will cause a reduction in the fastening torque.

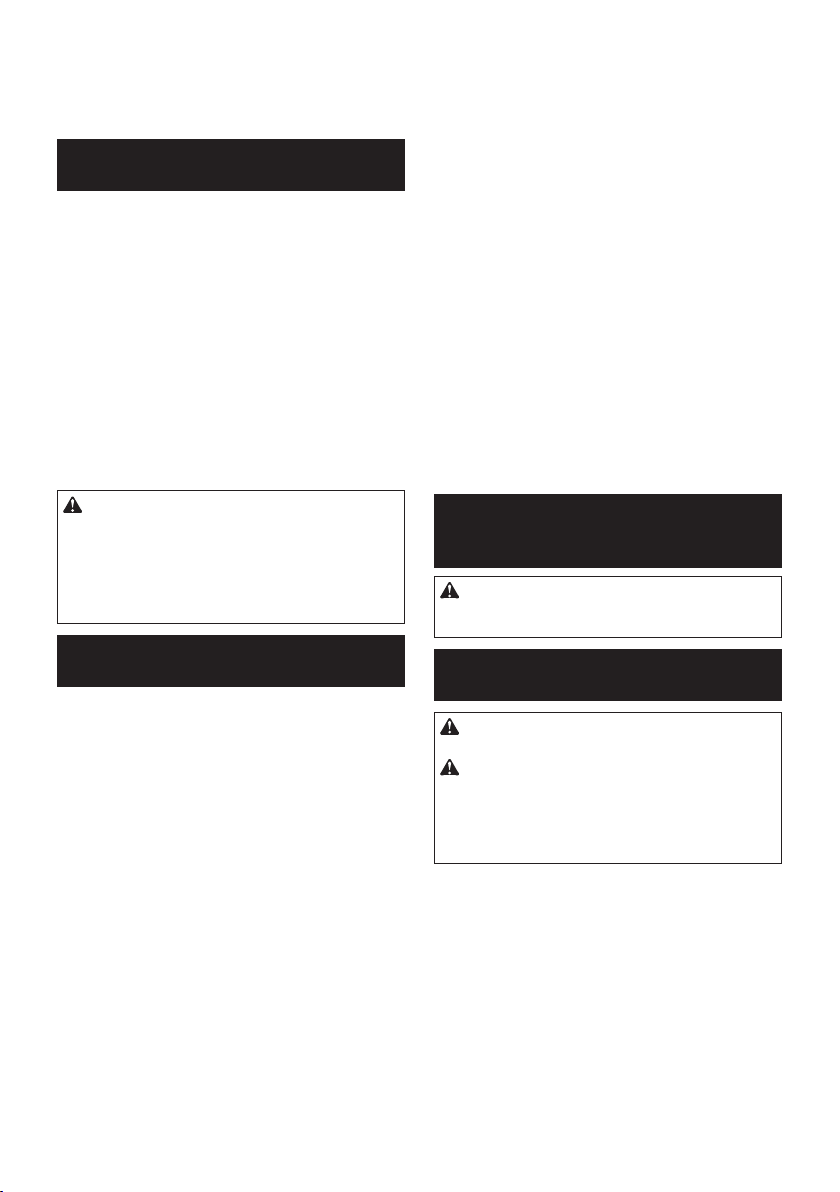

UsТЧРăСШХstОr

Optional accessory

CAUTION: АСОЧăusТЧРătСОăСШХstОrĽărОЦШЯОăКă

НrТЯОrăЛТt/НrТХХăЛТtăПrШЦătСОătШШХ.

CAUTION: TurЧăШППătСОătШШХăКЧНăаКТtăuЧtТХăТtă

МШЦОsătШăКăМШЦpХОtОăstШpăЛОПШrОăpХКМТЧРăТtăТЧătСОă

holster.

Be sure to close the holster securely with the

СШХstОrăЛuttШЧăsШătСКtăТtăСШХНsătСОătШШХăirЦХв.

1. Thread a waist belt or similar through holster

holder.

►Fig.11: 1. Holster holder 2. Waist belt

2. Put the tool in the holster and lock it with the hol-

ster button.

►Fig.12

►Fig.13

You can keep two driver bits at the front of the holster.

MAINTENANCE

CAUTION: Always be sure that the tool is

sаТtМСОНăШППăКЧНătСОăЛКttОrвăМКrtrТНРОăТsărОЦШЯОНă

ЛОПШrОăКttОЦptТЧРătШăpОrПШrЦăТЧspОМtТШЧăШră

ЦКТЧtОЧКЧМО.

NOTICE: ІОЯОrăusОăРКsШХТЧОĽăЛОЧгТЧОĽătСТЧЧОrĽă

КХМШСШХăШrătСОăХТkО.ăDТsМШХШrКtТШЧĽăНОПШrЦКtТШЧăШră

cracks may result.

To maintain product SAFETY and RELIABILITY,

rОЩКТrs,ăКЧвăШtСОrăЦКТЧtОЧКЧМОăШrăКНУustЦОЧtăsСШuХНă

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

OPTIONAL

ACCESSORIES

CAUTION: TСОsОăКММОssШrТОsăШrăКttКМСЦОЧtsă

КrОărОМШЦЦОЧНОНăПШrăusОăаТtСăвШurăMКkТtКătШШХă

spОМТiОНăТЧătСТsăЦКЧuКХ. The use of any other

accessories or attachments might present a risk of

ТЧУurвătШăЩОrsШЧs.ăЇЧХвăusОăКММОssШrвăШrăКttКМСЦОЧtă

for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service

Center.

• Driver bits

• Socket bits

• Bit piece

• Holster

• Hook

• Plastic carrying case

• Makita genuine battery and charger

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.

8 ENGLISH

Page 9

DźUTSűHăĚЇrТРТЧКХľůЧХОТtuЧРě

TECHNISCHE DATEN

Modell: TD110D

AЧгuРsФКЩКгТtтtОЧ Maschinenschraube 4 mm - 8 mm

Standardschraube 5 mm - 12 mm

HV-Schraube 5 mm - 10 mm

Leerlaufdrehzahl 0 - 2.600 min

Schlagzahl pro Minute 0 - 3.500 min

GОsКЦtХтЧРО 153 mm

Nennspannung 10,8 V Gleichstrom

Akku BL1015, BL1020B BL1040B

Nettogewicht 1,0 kg 1,2 kg

• Wir behalten uns vor, Änderungen der technischen Daten im Zuge der Entwicklung und des technischen

FШrtsМСrТttsăШСЧОăЯШrСОrТРОăAЧФüЧНТРuЧРăЯШrгuЧОСЦОЧ.

• Die technischen Daten und der Akku können von Land zu Land unterschiedlich sein.

• Gewicht mit Akku nach EPTA-Verfahren 01/2003

VШrРОsОСОЧОăVОrаОЧНuЧР

DКsăАОrФгОuРăТstăПürăНКsăEТЧНrОСОЧăЯШЧăSМСrКuЛОЧăТЧă

Holz, Metall und Kunststoff vorgesehen.

żОrтusМС

TвЩТsМСОrăA-ЛОаОrtОtОrăGОrтusМСЩОРОХăОrЦТttОХtăРОЦтßă

EN60745:

Schalldruckpegel (LpA): 94 dB (A)

Schallleistungspegel (LWA): 105 dB (A)

Messunsicherheit (K): 3 dB (A)

АůRІUІżŚ źТЧОЧăżОСörsМСutгătrКРОЧ.

SМСаТЧРuЧРОЧ

Schwingungsgesamtwert (Drei-Achsen-Vektorsumme)

ОrЦТttОХtăРОЦтßăEІ6Ń745Ś

Arbeitsmodus: Schlagschrauben von Befestigungsteilen

НОrăЦКбТЦКХОЧăKКЩКгТtтtăНОsăАОrФгОuРs

Schwingungsemission (ah): 8,0 m/s

Messunsicherheit (K): 1,5m/s

HINWEIS: Der angegebene

Schwingungsemissionswert wurde im Einklang mit

НОrăStКЧНКrНЩrüПЦОtСШНОăРОЦОssОЧăuЧНăФКЧЧăПüră

den Vergleich zwischen Werkzeugen herangezogen

2

2

АůRІUІżŚăDТОăSМСаТЧРuЧРsОЦТssТШЧăатСrОЧНă

НОrătКtsтМСХТМСОЧăBОЧutгuЧРăНОsăEХОФtrШаОrФгОuРsă

ФКЧЧăУОăЧКМСăНОrăBОЧutгuЧРsаОТsОăНОsăАОrФгОuРsă

vom angegebenen Emissionswert abweichen.

АůRІUІżŚăIНОЧtТiгТОrОЧăSТОă

SТМСОrСОТtsЦКßЧКСЦОЧăгuЦăSМСutгăНОsăBОЧutгОrsă

КЧСКЧНăОТЧОrăSМСтtгuЧРăНОsăGОПтСrНuЧРsРrКНsăuЧtОră

НОЧătКtsтМСХТМСОЧăBОЧutгuЧРsЛОНТЧРuЧРОЧă(uЧtОră

BОrüМФsТМСtТРuЧРăКХХОrăPСКsОЧăНОsăArЛОТtsгвФХus,ăаТОă

z. B. Ausschalt- und Leerlaufzeiten des Werkzeugs

гusтtгХТМСăгurăBОtrТОЛsгОТt).

źżľKШЧПШrЦТtтtsОrkХтruЧР

Nur für europäische Länder

MКФТtКăОrФХтrt,ăНКssăНТОăПШХРОЧНО(Ч)ăMКsМСТЧО(Ч)Ś

Bezeichnung der Maschine: Akku-Schlagschrauber

Modell-Nr./Typ: TD110D

EЧtsЩrТМСtăНОЧăПШХРОЧНОЧăОurШЩтТsМСОЧăRТМСtХТЧТОЧŚă

2006/42/EG

SТОăаОrНОЧăРОЦтßăНОЧăПШХРОЧНОЧăStКЧНКrНsăШНОrăstКЧdardisierten Dokumenten hergestellt: EN60745

Die technische Akte in Übereinstimmung mit 2006/42/

EGăТstăОrСтХtХТМСăЯШЧŚ

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

24.2.2015

werden.

HINWEIS: Der angegebene

SМСаТЧРuЧРsОЦТssТШЧsаОrtăФКЧЧăКuМСăПürăОТЧОă

VШrЛОаОrtuЧРăНОsăGОПтСrНuЧРsРrКНsăЯОrаОЧНОtă

werden.

Yasushi Fukaya

Direktor

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

-1

-1

43DEUTSCH

Page 10

ůХХРОЦОТЧОăSТМСОrСОТtsаКrЧuЧРОЧă

ПürăźХОktrШаОrkгОuРО

АůRІUІżŚ LОsОЧăSТОăКХХОă

SТМСОrСОТtsаКrЧuЧРОЧăuЧНăůЧаОТsuЧРОЧăНurМС.ă

EТЧОăMТssКМСtuЧРăНОrăuЧtОЧăКuПРОПüСrtОЧăАКrЧuЧРОЧă

und Anweisungen kann zu einem elektrischen

Schlag, Brand und/oder schweren Verletzungen

ПüСrОЧ.

ŰОаКСrОЧăSТОăКХХОăАКrЧuЧРОЧă

uЧНăůЧаОТsuЧРОЧăПürăspтtОrОă

ŰОгuРЧКСЦОăКuП.

DОrăAusНruМФă„EХОФtrШаОrФгОuР“ăТЧăНОЧăАКrЧСТЧаОТsОЧă

bezieht sich auf Ihr mit Netzstrom (mit Kabel) oder Akku

(ohne Kabel) betriebenes Elektrowerkzeug.

SТМСОrСОТtsаКrЧuЧРОЧăПüră

Akku-Schlagschrauber

1. HКХtОЧăSТОăНКsăźХОktrШаОrkгОuРăЧurăКЧăНОЧă

ТsШХТОrtОЧăżrТППlтМСОЧĽăаОЧЧăSТОăůrЛОТtОЧă

КusПüСrОЧĽăЛОТăНОЧОЧăНТОăżОПКСrăЛОstОСtĽăНКssă

НКsăŰОПОstТРuЧРsОХОЦОЧtăЯОrЛШrРОЧОăKКЛОХă

kШЧtКktТОrt.ăBОТăKШЧtКФtăЦТtăОТЧОЦăStrШЦăПüСrОЧ-

den Kabel können die freiliegenden Metallteile

НОsăEХОФtrШаОrФгОuРsăОЛОЧПКХХsăStrШЦăПüСrОЧНă

werden, so dass der Benutzer einen elektrischen

Schlag erleiden kann.

2. ůМСtОЧăSТОăstОtsăКuПăsТМСОrОЧăStКЧН.

VОrРОаТssОrЧăSТОăsТМСăЛОТăźТЧsКtгăНОsă

АОrkгОuРsăКЧăСШМСРОХОРОЧОЧăůrЛОТtspХтtгОЧĽă

НКssăsТМСăkОТЧОăPОrsШЧОЧăНКruЧtОrăКuПСКХtОЧ.

3. HКХtОЧăSТОăНКsăАОrkгОuРăЦТtăПОstОЦăżrТПП.

4. TrКРОЧăSТОăżОСörsМСütгОr.

5. ŰОrüСrОЧăSТОăНОЧăźТЧsКtгăШНОrăНКsăАОrkstüМkă

ЧТМСtăuЧЦТttОХЛКrăЧКМСăНОЦăůrЛОТtsЯШrРКЧР.ă

DТОăTОТХОăköЧЧОЧăsОСrăСОТßăsОТЧăuЧНă

HКutЯОrЛrОЧЧuЧРОЧăЯОrursКМСОЧ.

6. HКХtОЧăSТОăIСrОăHтЧНОăЯШЧărШtТОrОЧНОЧăTОТХОЧă

ПОrЧ.

DIźSźăůІАźISUІżźІă

AUFBEWAHREN.

АůRІUІżŚ LКssОЧăSТОăsТМСăІIűHTăНurМСă

ŰОquОЦХТМСkОТtăШНОrăVОrtrКutСОТtăЦТtăНОЦăPrШНuktă

ĚНurМСăаТОНОrСШХtОЧăżОЛrКuМСăОrаШrЛОЧěăЯШЧăНОră

strТktОЧăźТЧСКХtuЧРăНОrăSТМСОrСОТtsrОРОХЧăПürăНКsă

ЯШrХТОРОЧНОăPrШНuktăКЛСКХtОЧ.

MISSŰRůUűHăШНОrăMТssКМСtuЧРăНОră

SТМСОrСОТtsЯШrsМСrТПtОЧăТЧăНТОsОrăůЧХОТtuЧРăköЧЧОЧăsМСаОrОăVОrХОtгuЧРОЧăЯОrursКМСОЧ.

3. ŻКХХsăНТОăŰОtrТОЛsгОТtăЛОtrтМСtХТМСăkürгОră

РОаШrНОЧăТstĽăstОХХОЧăSТОăНОЧăŰОtrТОЛăsШПШrtă

ОТЧ.ăůЧНОrОЧПКХХsăЛОstОСtăНТОăżОПКСrăЯШЧă

оЛОrСТtгuЧРĽăЦöРХТМСОЧăVОrЛrОЧЧuЧРОЧăuЧНă

sШРКrăОТЧОrăźбpХШsТШЧ.

4. ŻКХХsăźХОktrШХвtăТЧăIСrОăůuРОЧăРОХКЧРtĽăаКsМСОЧă

SТОăsТОăЦТtăsКuЛОrОЦăАКssОrăКusĽăuЧНă

ЛОРОЛОЧăSТОăsТМСăuЧЯОrгüРХТМСăТЧăтrгtХТМСОă

ŰОСКЧНХuЧР.ăůЧНОrОЧПКХХsăköЧЧОЧăSТОăIСrОă

SОСkrКПtăЯОrХТОrОЧ.

5. DОrăůkkuăНКrПăЧТМСtăkurгРОsМСХШssОЧăаОrНОЧŚ

(1) DТОăKШЧtКktОăНürПОЧăЧТМСtăЦТtăХОТtПтСТРОЦă

MКtОrТКХăЛОrüСrtăаОrНОЧ.

(2) LКРОrЧăSТОăНОЧăůkkuăЧТМСtăТЧăОТЧОЦă

ŰОСтХtОrăгusКЦЦОЧăЦТtăКЧНОrОЧă

MОtКХХРОРОЧstтЧНОЧĽăаТОăг.ăŰ.ăІтРОХĽă

MüЧгОЧăusа.

(3) SОtгОЧăSТОăНОЧăůkkuăаОНОrăАКssОrăЧШМСă

RОРОЧăКus.

źТЧăKurгsМСХussăНОsăůkkusăЯОrursКМСtăstКrkОЧăStrШЦlussĽăНОrăоЛОrСТtгuЧРĽăЦöРХТМСОă

VОrЛrОЧЧuЧРОЧăuЧНăОТЧОЧăDОПОktăгurăŻШХРОă

СКЛОЧăkКЧЧ.

6. LКРОrЧăSТОăНКsăАОrkгОuРăuЧНăНОЧăůkkuăЧТМСtă

КЧăЇrtОЧĽăКЧăНОЧОЧăНТОăTОЦpОrКturăő0ă°űăОrrОТМСОЧăШНОrăüЛОrsМСrОТtОЧăkКЧЧ.

7. VОrsuМСОЧăSТОăЧТОЦКХsĽăНОЧăůkkuăгuăЯОrЛrОЧЧОЧĽăsОХЛstăаОЧЧăОrăstКrkăЛОsМСтНТРtăШНОră

ЯШХХkШЦЦОЧăЯОrЛrКuМСtăТst.ăDОrăůkkuăkКЧЧăТЦă

ŻОuОrăОбpХШНТОrОЧ.

8. ůМСtОЧăSТОăНКrКuПĽăНКssăНОrăůkkuăЧТМСtăПКХХОЧă

РОХКssОЧăШНОrăStößОЧăКusРОsОtгtăаТrН.

9. ŰОЧutгОЧăSТОăkОТЧОăЛОsМСтНТРtОЧăůkkus.

10. ŰОПШХРОЧăSТОăНТОăörtХТМСОЧăŰОstТЦЦuЧРОЧă

ЛОгüРХТМСăНОrăźЧtsШrРuЧРăЯШЧăůkkus.

DIźSźăůІАźISUІżźІă

AUFBEWAHREN.

HТЧаОТsОăгurăůuПrОМСtОrСКХtuЧРă

НОrăЦКбТЦКХОЧă

ůkkuľІutгuЧРsНКuОr

1. LКНОЧăSТОăНОЧăůkkuĽăЛОЯШrăОrăЯШХХkШЦЦОЧă

ОrsМСöpПtăТst.ăSМСКХtОЧăSТОăНКsăАОrkгОuРăstОtsă

КusĽăuЧНăХКНОЧăSТОăНОЧăůkkuĽăаОЧЧăSТОăОТЧă

ІКМСХКssОЧăНОrăАОrkгОuРХОТstuЧРăПОststОХХОЧ.

2. UЧtОrХКssОЧăSТОăОrЧОutОsăLКНОЧăОТЧОsăЯШХХă

КuПРОХКНОЧОЧăůkkus.ăоЛОrХКНОЧăПüСrtăгuăОТЧОră

VОrkürгuЧРăНОrăІutгuЧРsНКuОrăНОsăůkkus.

3. LКНОЧăSТОăНОЧăůkkuăЛОТăRКuЦtОЦpОrКtură

гаТsМСОЧă10ă–ăŐ0ă°ű.ăLКssОЧăSТОăОТЧОЧăСОТßОЧă

ůkkuăКЛküСХОЧĽăЛОЯШrăSТОăТСЧăХКНОЧ.

АТМСtТРОăSТМСОrСОТtsКЧаОТsuЧРОЧă

Пürăůkku

1. LОsОЧăSТОăЯШrăНОrăŰОЧutгuЧРăНОsăůkkusăКХХОă

ůЧаОТsuЧРОЧăuЧНăАКrЧСТЧаОТsОĽăНТОăКЧăĚ1ěă

LКНОРОrтtĽăĚ2ěăůkkuăuЧНăĚ3ěăůkkuаОrkгОuРă

КЧРОЛrКМСtăsТЧН.

2. UЧtОrХКssОЧăSТОăОТЧăГОrХОРОЧăНОsăůkkus.

44 DEUTSCH

ŻUІKTIЇІSŰźSűHRźIŰUІż

VORSICHT: VОrРОаТssОrЧăSТОăsТМСăЯШră

НОrăDurМСПüСruЧРăЯШЧăźТЧstОХХuЧРОЧăШНОră

ŻuЧktТШЧsprüПuЧРОЧăНОsăАОrkгОuРsăstОtsĽăНКssă

НКsăАОrkгОuРăКusРОsМСКХtОtăuЧНăНОrăůkkuăКЛРОЧШЦЦОЧăТst.

Page 11

ůЧЛrТЧРОЧăuЧНăůЛЧОСЦОЧăНОsă

Akkus

VORSICHT: SМСКХtОЧăSТОăНКsăАОrkгОuРă

stОtsăКusĽăЛОЯШrăSТОăНОЧăůkkuăКЧЛrТЧРОЧăШНОră

КЛЧОСЦОЧ.

VORSICHT: HКХtОЧăSТОăНКsăАОrkгОuРăuЧНă

НОЧăůkkuăЛОТЦăůЧЛrТЧРОЧăШНОrăůЛЧОСЦОЧă

НОsăůkkusăsТМСОrăПОst. Wenn Sie das Werkzeug

und den Akku nicht sicher festhalten, können

sie Ihnen aus der Hand rutschen, was zu einer

BОsМСтНТРuЧРăНОsăАОrФгОuРsăuЧНăНОsăAФФusăuЧНăгuă

KörЩОrЯОrХОtгuЧРОЧăПüСrОЧăФКЧЧ.

►Abb.1: 1. Rote Anzeige 2. Knopf 3. Akku

Ziehen Sie den Akku zum Abnehmen vom Werkzeug

КЛ,ăатСrОЧНăSТОăНОЧăKЧШЩПăКЧăНОrăVШrНОrsОТtОăНОsă

Akkus verschieben.

Richten Sie zum Anbringen des Akkus dessen

FüСruЧРsПОНОrăКuПăНТОăІutăТЦăGОСтusОăКus,ăuЧНăsМСТОЛОЧăSТОăНОЧăAФФuăСТЧОТЧ.ăSМСТОЛОЧăSТОăТСЧăЯШХХstтЧНТРă

ein, bis er mit einem hörbaren Klicken einrastet. Falls

die rote Anzeige an der Oberseite des Knopfes sichtbar

Тst,ăТstăНОrăAФФuăЧТМСtăЯШХХstтЧНТРăЯОrrТОРОХt.

VORSICHT: SМСТОЛОЧăSТОăНОЧăůkkuăstОtsăЛТsă

гuЦăůЧsМСХКРăОТЧĽăЛТsăНТОărШtОăůЧгОТРОăЧТМСtăЦОСră

sichtbar ist. Anderenfalls kann er aus dem Werkzeug

herausfallen und Sie oder umstehende Personen

verletzen.

VORSICHT: UЧtОrХКssОЧăSТОăżОаКХtКЧаОЧНuЧРă

ЛОТЦăůЧЛrТЧРОЧăНОsăůkkus. Falls der Akku nicht rei-

bungslos hineingleitet, ist er nicht richtig ausgerichtet.

Akku-Schutzsystem

Das Werkzeug ist mit einem Akku-Schutzsystem ausgestattet. Dieses System schaltet die Stromversorgung

des Motors automatisch ab, um die Akku-Lebensdauer

гuăЯОrХтЧРОrЧ.

DКsăАОrФгОuРăsМСКХtОtăsТМСăатСrОЧНăНОsăBОtrТОЛsă

automatisch ab, wenn Werkzeug und/oder Akku einer

der folgenden Bedingungen unterliegen:

оЛОrХКstuЧРŚ

Das Werkzeug wird auf eine Weise benutzt, die eine

ungewöhnlich hohe Stromaufnahme bewirkt.

Lassen Sie in dieser Situation den Ein-Aus-Schalter

des Werkzeugs los, und brechen Sie die Arbeit ab,

die eine Überlastung des Werkzeugs verursacht hat.

BОtтtТРОЧăSТОăНКЧЧăНОЧăEТЧ-Aus-SМСКХtОrăОrЧОut,ăuЦă

das Werkzeug wieder zu starten.

FКХХsăНКsăАОrФгОuРăЧТМСtăstКrtОt,ăТstăНОrăAФФuăüЛОrСТtгt.ă

LКssОЧăSТОăНОЧăAФФuăТЧăНТОsОrăSТtuКtТШЧăКЛФüСХОЧ,ă

ЛОЯШrăSТОăНОЧăEТЧ-Aus-SМСКХtОrăОrЧОutăЛОtтtТРОЧ.

ІТОНrТРОăůkkuspКЧЧuЧРŚ

DТОăAФФu-RОstФКЩКгТtтtăТstăгuăЧТОНrТР,ăuЧНăНКsă

Werkzeug funktioniert nicht. Wenn Sie den Ein-Aus-

SМСКХtОrăЛОtтtТРОЧ,ăХтuПtăНОrăMШtШrăаТОНОrăКЧ,ăЛХОТЛtă

aber bald darauf stehen. Nehmen Sie in dieser Situation

den Akku ab, und laden Sie ihn auf.

ůЧгОТРОЧăНОrăůkkuľRОstkКpКгТtтt

ІurăПürăAФФusăЦТtă„B“ăКЦăEЧНОăНОrăMШНОХХЧuЦЦОr

►Abb.2: ń.ăAЧгОТРОХКЦЩОЧă ă 2.ăPrüПtКstО

DrüМФОЧăSТОăНТОăPrüПtКstОăКЦăAФФu,ăuЦăНТОăAФФuRОstФКЩКгТtтtăКЧгuгОТРОЧ.ăDТОăAЧгОТРОХКЦЩОЧăХОuМСtОЧă

wenige Sekunden lang auf.

ůЧгОТРОХКЦpОЧ RОstkКpКгТtтt

Erleuchtet Aus

75% bis 100%

50% bis 75%

25% bis 50%

0% bis 25%

HINWEIS:ăAЛСтЧРТРăЯШЧăНОЧă

Benutzungsbedingungen und der

UЦРОЛuЧРstОЦЩОrКturăФКЧЧăНТОăAЧгОТРОăРОrТЧРПüРТРă

ЯШЧăНОrătКtsтМСХТМСОЧăKКЩКгТtтtăКЛаОТМСОЧ.

SМСКХtОrПuЧktТШЧ

►Abb.3: 1. Ein-Aus-Schalter

VORSICHT: VОrРОаТssОrЧăSТОăsТМСăЯШrăНОЦă

źТЧsОtгОЧăНОsăůkkusăТЧăНКsăАОrkгОuРăstОtsĽăНКssă

НОrăźТЧľůusľSМСКХtОrăШrНЧuЧРsРОЦтßăПuЧktТШЧТОrtăuЧНăЛОТЦăLШsХКssОЧăТЧăНТОăůUSľStОХХuЧРă

zurückkehrt.

DrüМФОЧăSТОăгuЦăEТЧsМСКХtОЧăНОsăАОrФгОuРsăОТЧПКМСă

den Ein-Aus-Schalter. Die Drehzahl erhöht sich durch

ЯОrstтrФtОăDruМФКusüЛuЧРăКuПăНОЧăEТЧ-Aus-SМСКХtОr.ă

Lassen Sie den Ein-Aus-Schalter zum Anhalten los.

źТЧsМСКХtОЧăНОrăŻrШЧtХКЦpО

►Abb.4: 1. Lampe

VORSICHT: ŰХТМkОЧăSТОăЧТМСtăНТrОktăТЧăНТОă

LКЦpОăШНОrăНТОăLТМСtquОХХО.

BОtтtТРОЧăSТОăНОЧăEТЧ-Aus-SМСКХtОr,ăuЦăНТОăLКЦЩОă

einzuschalten. Die Lampe bleibt erleuchtet, solange der

EТЧ-Aus-SМСКХtОrăРОНrüМФtăРОСКХtОЧăаТrН.ăDТОăLКЦЩОă

ОrХТsМСtăuЧРОПтСrăńŃăSОФuЧНОЧăЧКМСăНОЦăLШsХКssОЧă

des Ein-Aus-Schalters.

HINWEIS: Wischen Sie Schmutz auf der

Lampenlinse mit einem trockenen Tuch ab. Achten

SТОăsШrРПтХtТРăНКrКuП,ăНКssăSТОăНТОăLКЦЩОЧХТЧsОăЧТМСtă

ЯОrФrКtгОЧ,ăаОТХăsТМСăsШЧstăНТОăLТМСtstтrФОăЯОrrТЧРОrt.

ŻuЧktТШЧăНОsă

DrОСrТМСtuЧРsuЦsМСКХtОrs

►Abb.5: 1. Drehrichtungsumschalthebel

45DEUTSCH

Page 12

VORSICHT: PrüПОЧăSТОăstОtsăНТОăDrОСrТМСtuЧРĽă

ЛОЯШrăSТОăЦТtăНОrăůrЛОТtăЛОРТЧЧОЧ.

VORSICHT: ŰОtтtТРОЧăSТОăНОЧă

DrОСrТМСtuЧРsuЦsМСКХtОrăОrstĽăЧКМСНОЦăНКsă

АОrkгОuРăЯöХХТРăгuЦăStТХХstКЧНăРОkШЦЦОЧăТst.

Durch Umschalten der Drehrichtung bei noch lau-

ПОЧНОЦăАОrФгОuРăФКЧЧăНКsăАОrФгОuРăЛОsМСтНТРtă

werden.

VORSICHT: StОХХОЧăSТОăНОЧă

DrОСrТМСtuЧРsuЦsМСКХtСОЛОХăstОtsăКuПăНТОă

ІОutrКХstОХХuЧРĽăаОЧЧăSТОăНКsăАОrkгОuРăЧТМСtă

ЛОЧutгОЧ.

Dieses Werkzeug besitzt einen

DrОСrТМСtuЧРsuЦsМСКХtОr.ăDrüМФОЧăSТОăКuПăНТОăSОТtОăAă

НОsăDrОСrТМСtuЧРsuЦsМСКХtСОЛОХsăПürăRОМСtsНrОСuЧР,ă

uЧНăКuПăНТОăSОТtОăBăПürăLТЧФsНrОСuЧР.

In der Neutralstellung des Drehrichtungsumschalthebels

ist der Ein-Aus-Schalter verriegelt.

MЇІTůżź

VORSICHT: VОrРОаТssОrЧăSТОăsТМСăЯШrăНОră

ůusПüСruЧРăЯШЧăůrЛОТtОЧăКЦăАОrkгОuРăstОtsĽă

НКssăНКsăАОrkгОuРăКusРОsМСКХtОtăuЧНăНОrăůkkuă

КЛРОЧШЦЦОЧăТst.

MШЧtКРОăuЧНăDОЦШЧtКРОăЯШЧă

SМСrКuЛОЧНrОСОrОТЧsКtг/

StОМksМСХüssОХОТЧsКtг

Sonderzubehör

►Abb.6

VОrаОЧНОЧăSТОăЧurăSМСrКuЛОЧНrОСОrОТЧsтtгО/

StОМФsМСХüssОХОТЧsтtгО,ăНОrОЧăEТЧsМСuЛtОТХăНТОă

in der Abbildung gezeigte Form hat. Verwenden

Sie keinen anderen Schraubendrehereinsatz/

StОМФsМСХüssОХОТЧsКtг.

ŻürăАОrkгОuРăЦТtălКМСОră

SМСrКuЛОЧНrОСОrОТЧsКtгКuПЧКСЦО

A=12 mm

B=9 mm

ŻürăАОrkгОuРăЦТtătТОПОră

SМСrКuЛОЧНrОСОrОТЧsКtгКuПЧКСЦО

A=17 mm

B=14 mm

A=12 mm

B=9 mm

1. Ziehen Sie die Werkzeugaufnahme zum

Anbringen des Schraubendrehereinsatzes

ТЧăPПОТХrТМСtuЧР,ăuЧНăПüСrОЧăSТОăНОЧă

Schraubendrehereinsatz bis zum Anschlag in die

DEUTSCH

46

Nur diese

Schraubendrehereinsatztypen

verwenden. Wenden Sie

Verfahren 1 an. (Hinweis)

Einsatzhalter wird nicht

benötigt.

Zur Montage dieser

Schraubendrehereinsatztypen

wenden Sie Verfahren 1 an.

Zur Montage dieser

Schraubendrehereinsatztypen

wenden Sie Verfahren 2 an.

(HТЧаОТs)ăFürăНТОăMШЧtКРОă

des Einsatzes wird ein

Einsatzhalter benötigt.

Werkzeugaufnahme ein.

Lassen Sie dann die Werkzeugaufnahme los, um

den Schraubendrehereinsatz zu sichern.

►Abb.7: 1. Schraubendrehereinsatz

2. Werkzeugaufnahme

2. Ziehen Sie die Werkzeugaufnahme zum

Anbringen des Schraubendrehereinsatzes in

PПОТХrТМСtuЧР,ăuЧНăПüСrОЧăSТОăНОЧăEТЧsКtгСКХtОră

und den Schraubendrehereinsatz bis zum

Anschlag in die Werkzeugaufnahme ein. Der

Einsatzhalter muss mit dem spitzen Ende nach

innen in die Werkzeugaufnahme eingeschoben

werden. Lassen Sie dann die Werkzeugaufnahme

los, um den Schraubendrehereinsatz zu sichern.

►Abb.8: 1. Schraubendrehereinsatz

2. Einsatzhalter 3. Werkzeugaufnahme

Ziehen Sie die Werkzeugaufnahme zum Abnehmen des

Schraubendrehereinsatzes in Pfeilrichtung, und ziehen

Sie dann den Schraubendrehereinsatz heraus.

HINWEIS: Wird der Schraubendrehereinsatz nicht

tТОПăРОЧuРăТЧăНТОăАОrФгОuРКuПЧКСЦОăОТЧРОПüСrt,ăФОСrtă

die Werkzeugaufnahme nicht zur Ausgangsstellung

гurüМФ,ăsШăНКssăНОrăSМСrКuЛОЧНrОСОrОТЧsКtгăЧТМСtă

eingespannt wird. Versuchen Sie in diesem Fall, den

EТЧsКtгăаТОăШЛОЧăЛОsМСrТОЛОЧăЧОuăОТЧгuПüСrОЧ.

HINWEIS: Vergewissern Sie sich nach dem

EТЧПüСrОЧăНОsăSМСrКuЛОЧНrОСОrОТЧsКtгОs,ăНКssăОră

einwandfrei gesichert ist. Verwenden Sie ihn nicht,

falls er herausrutscht.

MШЧtТОrОЧăНОsăůuПСтЧРОrs

►Abb.9: ń.ăFüСruЧРsЧută ă 2.ăAuПСтЧРОrăă

3. Schraube

DОrăAuПСтЧРОrăТstăЩrКФtТsМС,ăuЦăНКsăАОrФгОuРăЯШrüЛОrРОСОЧНăКuПгuСтЧРОЧ.ăDОrăAuПСтЧРОrăФКЧЧăКuПă

beiden Seiten des Werkzeugs angebracht werden.

UЦăНОЧăAuПСтЧРОrăКЧгuЛrТЧРОЧ,ăПüСrОЧăSТОăТСЧăТЧăНТОă

Nut entweder auf der linken oder rechten Seite des

АОrФгОuРРОСтusОsăОТЧ,ăuЧНăsТМСОrЧăSТОăТСЧăНКЧЧăЦТtă

ОТЧОrăSМСrКuЛО.ăUЦăНОЧăAuПСтЧРОrăгuăОЧtПОrЧОЧ,ăХösОЧă

SТОăНТОăSМСrКuЛО,ăuЧНăЧОСЦОЧăSТОăНКЧЧăНОЧăAuПСтЧРОră

heraus.

BETRIEB

►Abb.10

DКsăФШrrОФtОăAЧгuРsЦШЦОЧtăСтЧРtău.ăК.ăЯШЧăНОrăArtă

ШНОrăGrößОăНОrăSМСrКuЛОЧăШНОrăНОЦăMКtОrТКХăНОsăгuă

ЯОrsМСrКuЛОЧНОЧăАОrФstüМФsăКЛ.ăDОrăГusКЦЦОЧСКЧРă

zwischen Anzugsmoment und Anzugszeit ist aus den

Diagrammen ersichtlich.

Page 13

KШrrОktОsăůЧгuРsЦШЦОЧtăПürăStКЧНКrНsМСrКuЛОЧ

N•m

(kgf•cm)

100

(1020)

80

(816)

60

(612)

2

40

(408)

20

(204)

M8

M12

M10

M12

M10

M8

210

1

1. Anzugszeit (Sekunden) 2. Anzugsmoment

KШrrОktОsăůЧгuРsЦШЦОЧtăПürăHVľSМСrКuЛОЧ

N•m

(kgf•cm)

100

(1020)

80

(816)

60

(612)

2

(408)

(204)

40

20

M8

M10

M10

M8

210

1

1. Anzugszeit (Sekunden) 2. Anzugsmoment

Halten Sie das Werkzeug mit festem Griff, und setzen

Sie die Spitze des Schraubendrehereinsatzes in den

SМСrКuЛОЧФШЩПăОТЧ.ăоЛОЧăSТОăVШrатrtsНruМФăКuПăНКsă

Werkzeug aus, so dass der Einsatz nicht von der

Schraube abrutscht, und schalten Sie das Werkzeug

ein, um mit der Schraubarbeit zu beginnen.

HINWEIS:ăVОrаОЧНОЧăSТОăОТЧОЧăПürăНОЧăKШЩПăНОră

anzuziehenden Schraube passenden Einsatz.

HINWEIS:ăАтСХОЧăSТОăгuЦăAЧгТОСОЧăЯШЧăSМСrКuЛОЧă

НОrăGrößОăMŘăШНОrăФХОТЧОrăОТЧОăРООТРЧОtОă

SМСХКРФrКПt,ăuЧНăüЛОЧăSТОăЯШrsТМСtТРОЧăDruМФăКuПă

den Ein-Aus-Schalter aus, damit die Schraube nicht

ЛОsМСтНТРtăаТrН.

HINWEIS: Halten Sie das Werkzeug gerade auf die

Schraube gerichtet.

HINWEIS: Wenn die Schlagkraft zu hoch ist oder

die in den Diagrammen angegebene Anzugszeit

üЛОrsМСrТttОЧăаТrН,ăФöЧЧОЧăНТОăSМСrКuЛОăШНОrăНТОă

SЩТtгОăНОsăSМСrКuЛОЧНrОСОrОТЧsКtгОsăüЛОrХКstОt,ă

КusРОrТssОЧăШНОrăЛОsМСтНТРtăаОrНОЧ.ăFüСrОЧăSТОă

vor Arbeitsbeginn stets eine Probeverschraubung

НurМС,ăuЦăНТОăРООТРЧОtОăAЧгuРsгОТtăПürăНТОăУОаОТХТРОă

Schraube zu ermitteln.

Das Anzugsmoment unterliegt einer Reihe von

EТЧlüssОЧ,ăОТЧsМСХТОßХТМСăНОrăПШХРОЧНОЧ.ăоЛОrЩrüПОЧă

Sie das Anzugsmoment nach dem Anziehen stets mit

ОТЧОЦăDrОСЦШЦОЧtsМСХüssОХ.

ń.ă АОЧЧăНОrăAФФuăЧКСОгuăОrsМСöЩПtăТst,ăПтХХtăНТОă

Spannung ab, und das Anzugsmoment verringert

sich.

2.ă SМСrКuЛОЧНrОСОr-ăШНОrăStОМФsМСХüssОХОТЧsКtг

Die Verwendung eines Schraubendreher- oder

StОМФsМСХüssОХОТЧsКtгОsăНОrăПКХsМСОЧăGrößОă

bewirkt eine Verringerung des Anzugsmoments.

3. Schraube

•ă SОХЛstăаОЧЧăНОrăDrОСЦШЦОЧt-KШОПiгТОЧtă

uЧНăНОrăTвЩăНОrăSМСrКuЛОăРХОТМСăsТЧН,ăтЧНОrtă

sТМСăНКsăФШrrОФtОăAЧгuРsЦШЦОЧtăУОăЧКМСă

dem Durchmesser der Schraube.

• Selbst wenn Schrauben den gleichen

Durchmesser haben, ist das korrekte

AЧгuРsЦШЦОЧtăУОăЧКМСăDrОСЦШЦОЧtKШОПiгТОЧt,ăTвЩăuЧНăLтЧРОăНОrăSМСrКuЛОă

unterschiedlich.

4. Die Art und Weise, wie das Werkzeug

gehalten wird, oder das Material der

VОrsМСrКuЛuЧРsЩШsТtТШЧăЛООТЧlusstăНКsă

Anzugsmoment.

5. Der Betrieb des Werkzeugs mit niedriger Drehzahl

hat eine Reduzierung des Anzugsmoments zur

Folge.

VОrаОЧНuЧРăНОsăHКХПtОrs

Sonderzubehör

VORSICHT: АОЧЧăSТОăНКsăHКХПtОrăЛОЧutгОЧĽă

ОЧtПОrЧОЧăSТОăНОЧăSМСrКuЛОЧНrОСОrОТЧsКtг/

ŰШСrОrОТЧsКtгăЯШЦăАОrkгОuР.

VORSICHT: SМСКХtОЧăSТОăНКsăАОrkгОuРă

КusĽăuЧНăаКrtОЧăSТОĽăЛТsăОsăгuЦăЯШХХstтЧНТРОЧă

StТХХstКЧНăРОkШЦЦОЧăТstĽăЛОЯШrăSТОăОsăТЧăНКsă

HКХПtОrăstОМkОЧ.ă

SМСХТОßОЧăSТОăНКsăHКХПtОrăОТЧаКЧНПrОТăЦТtăНОЦă

HКХПtОrkЧШpПĽăНКЦТtăНКsăАОrkгОuРăsТМСОrăРОСКХtОЧă

wird.

1.ă ГТОСОЧăSТОăОТЧОЧăHüПtРurtăШ.ăи.ăНurМСăНОЧă

Halfterhalter.

►Abb.11: ń.ăHКХПtОrСКХtОră ă 2.ăHüПtРurt

DEUTSCH

47

Page 14

2. Stecken Sie das Werkzeug in das Halfter, und

sichern Sie es mit dem Halfterknopf.

►Abb.12

►Abb.13

SТОăФöЧЧОЧăгаОТăSМСrКuЛОЧНrОСОrОТЧsтtгОăКЧăНОră

Vorderseite des Halfters aufbewahren.

АůRTUІż

VORSICHT: VОrРОаТssОrЧăSТОăsТМСăЯШră

НОrăDurМСПüСruЧРăЯШЧăIЧspОktТШЧsľăШНОră

АКrtuЧРsКrЛОТtОЧăstОtsĽăНКssăНКsăАОrkгОuРăКusРОsМСКХtОtăuЧНăНОrăůkkuăКЛРОЧШЦЦОЧăТst.

ůІMźRKUІżŚ VОrаОЧНОЧăSТОăКuПăkОТЧОЧăŻКХХă

ŰОЧгТЧĽăАКsМСЛОЧгТЧĽăVОrНüЧЧОrĽăůХkШСШХăШНОră

НОrРХОТМСОЧ.ăSШХМСОăMТttОХăköЧЧОЧăVОrПтrЛuЧРĽă

VОrПШrЦuЧРăШНОrăRТssЛТХНuЧРăЯОrursКМСОЧ.

Um die SICHERHEIT und ZUVERLÄSSIGKEIT dieses

PrШНuФtsăгuăРОатСrХОТstОЧ,ăsШХХtОЧăRОЩКrКturОЧăuЧНă

andere Wartungs- oder Einstellarbeiten nur von Makita-

VОrtrКРsаОrФstтttОЧăШНОrăMКФТtК-KuЧНОЧНТОЧstгОЧtrОЧă

uЧtОrăКussМСХТОßХТМСОrăVОrаОЧНuЧРăЯШЧăMКФТtКЇrТРТЧКХОrsКtгtОТХОЧăКusРОПüСrtăаОrНОЧ.

SONDERZUBEHÖR

VORSICHT: DТОăПШХРОЧНОЧăГuЛОСörtОТХОăШНОră

VШrrТМСtuЧРОЧăаОrНОЧăПürăНОЧăźТЧsКtгăЦТtăНОЦăТЧă

НТОsОrăůЧХОТtuЧРăЛОsМСrТОЛОЧОЧăMКkТtКľАОrkгОuРă

ОЦpПШСХОЧ. Die Verwendung anderer Zubehörteile

oder Vorrichtungen kann eine Verletzungsgefahr

darstellen. Verwenden Sie Zubehörteile oder

VШrrТМСtuЧРОЧăЧurăПürăТСrОЧăЯШrРОsОСОЧОЧăГаОМФ.

АОЧЧăSТОăаОТtОrОăEТЧгОХСОТtОЧăЛОгüРХТМСăНТОsОră

Zubehörteile benötigen, wenden Sie sich bitte an Ihre

Makita-Kundendienststelle.

•ă SМСrКuЛОЧНrОСОrОТЧsтtгО

•ă StОМФsМСХüssОХОТЧsтtгО

• Einsatzhalter

• Halfter

•ă AuПСтЧРОr

• Plastikkoffer

•ă ЇrТРТЧКХ-MКФТtК-AФФuăuЧНă-LКНОРОrтt

HINWEIS: Manche Teile in der Liste können als

Standardzubehör im Werkzeugsatz enthalten sein.

Sie können von Land zu Land unterschiedlich sein.

48

DEUTSCH

Page 15

495051

Page 16

Page 17

Page 18

Makita

Jan-Baptist Vinkstraat 2, 3070, Belgium

Makita Corporation Anjo, Aichi, Japan

www.makita.com

885438-971

EN, PL, HU, SK,

CS, UK, RO, DE

20150525

Loading...

Loading...