Makita MAC500 User guide

OWNERS MANUAL

FOR

Oil-less

Air

Compressor

MODEL

NO.

MAC500

SPECIFICATION CHART

Model

Horsepower 1

SCFM

SCFM

Cut-In

cut-out 125

Bore 1 3/4"

Stroke 1 1/4"

Voltage-Single Phase

*Fuse Type Quick Acting

Amperage at Max. Pressure

Tank Size

Weight

U.L.

No.

@

40

psig 4.1

@

90

psig 3.0

&

CSA Listed

MAC500

100

PSI

PSI

11

0-1

10.0

(Actual)

2.5

Gallon

25

Ibs.

20

Minimum Circuit Requirement

*A

circuit breaker is preferred. Use only a fuse or circuit breaker that is the same rating as the

branch circuit the air compressor is operated on. If the air compressor is connected to

I

protected

For identification of

in this Manual.

I

I

WMAC500

7/19/95

15

by

fuses, use quick acting fuses.

NOTE:

Parts,

see

Page

I

AMPS

11

IMPORTANT:

Read the Safety Guidelines and

structions Carefully

Before

I

a

circuit

All

In-

Operating.

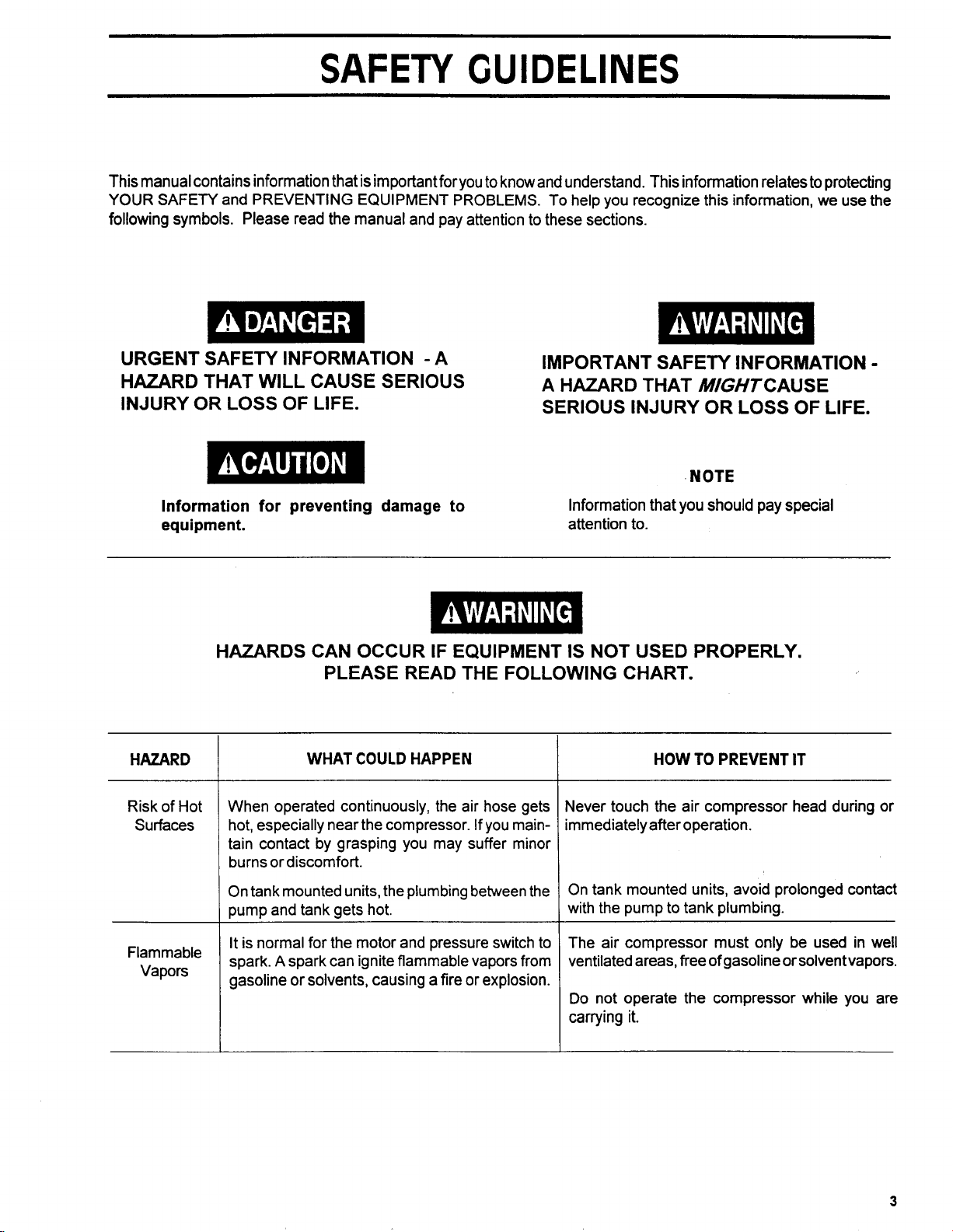

TABLE

OF

CONTENTS

SAFETY GUIDELINES

WARNING CHART

GLOSSARY

DUTY CYCLE

STORAGE

DESCRIPTION

INSTALLATION AND BREAK-IN

PROCEDURES

Location

...........................................

........................................

..............................................

OF

..................................

of

Air Compressor

..........................

.............................

OPERATION

............ 6

Page

3-4

...........

6.7

3

5

5

5

6

Voltage and Circuit Protection

Extension Cords

Grounding Instructions

Additional Regulators and

Controls

Break-In Procedures

OPERATING PROCEDURES

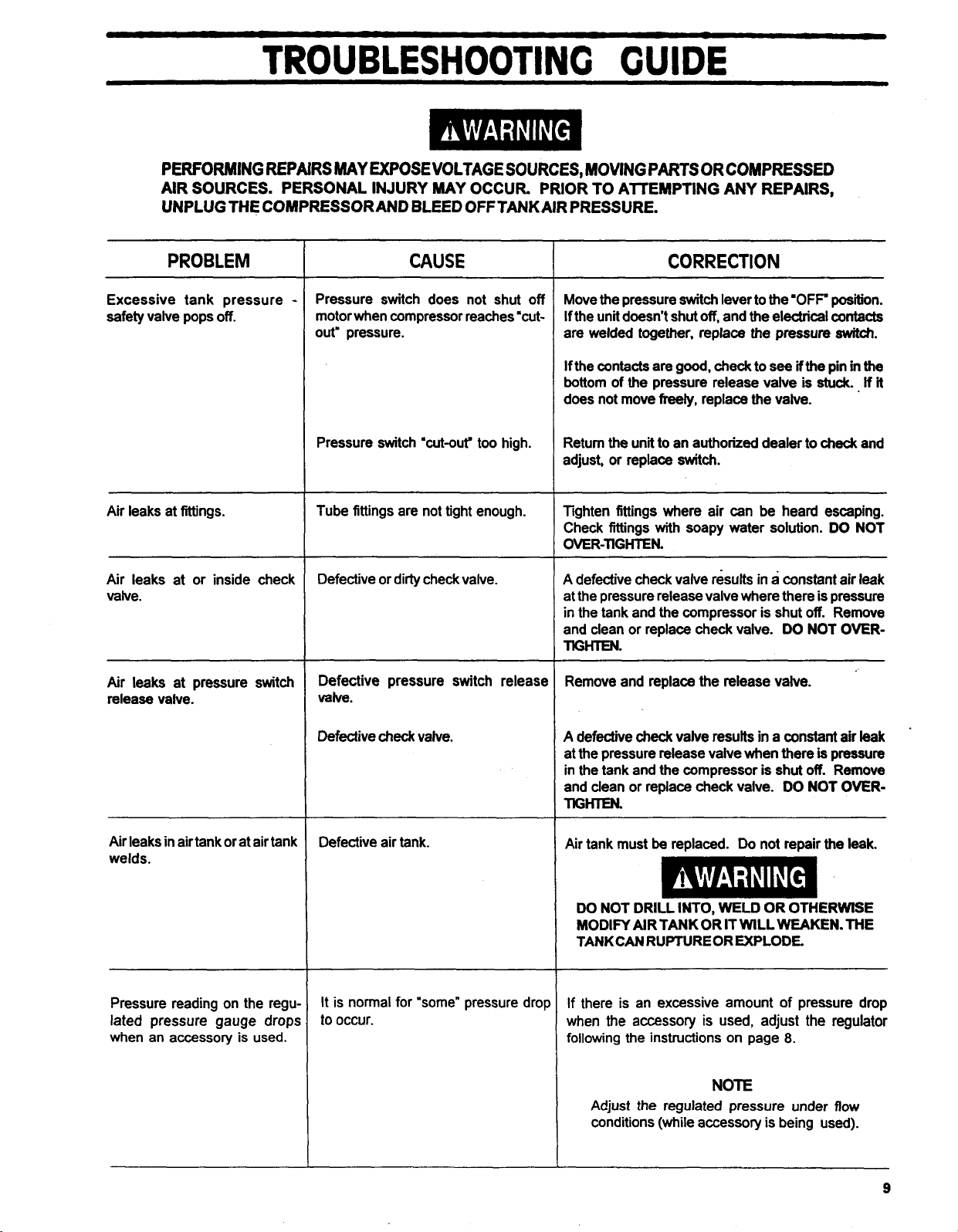

TROUBLESHOOTING GUIDE

COMPRESSOR PARTS LIST

WARRANTY/FACTORY SERVICE

CENTERS

.............................................

.............................

................................

........................

..........................

...........

...............

.......

.............

Back Cover

Page

6

6

7

7

7

8

9-10

11

2

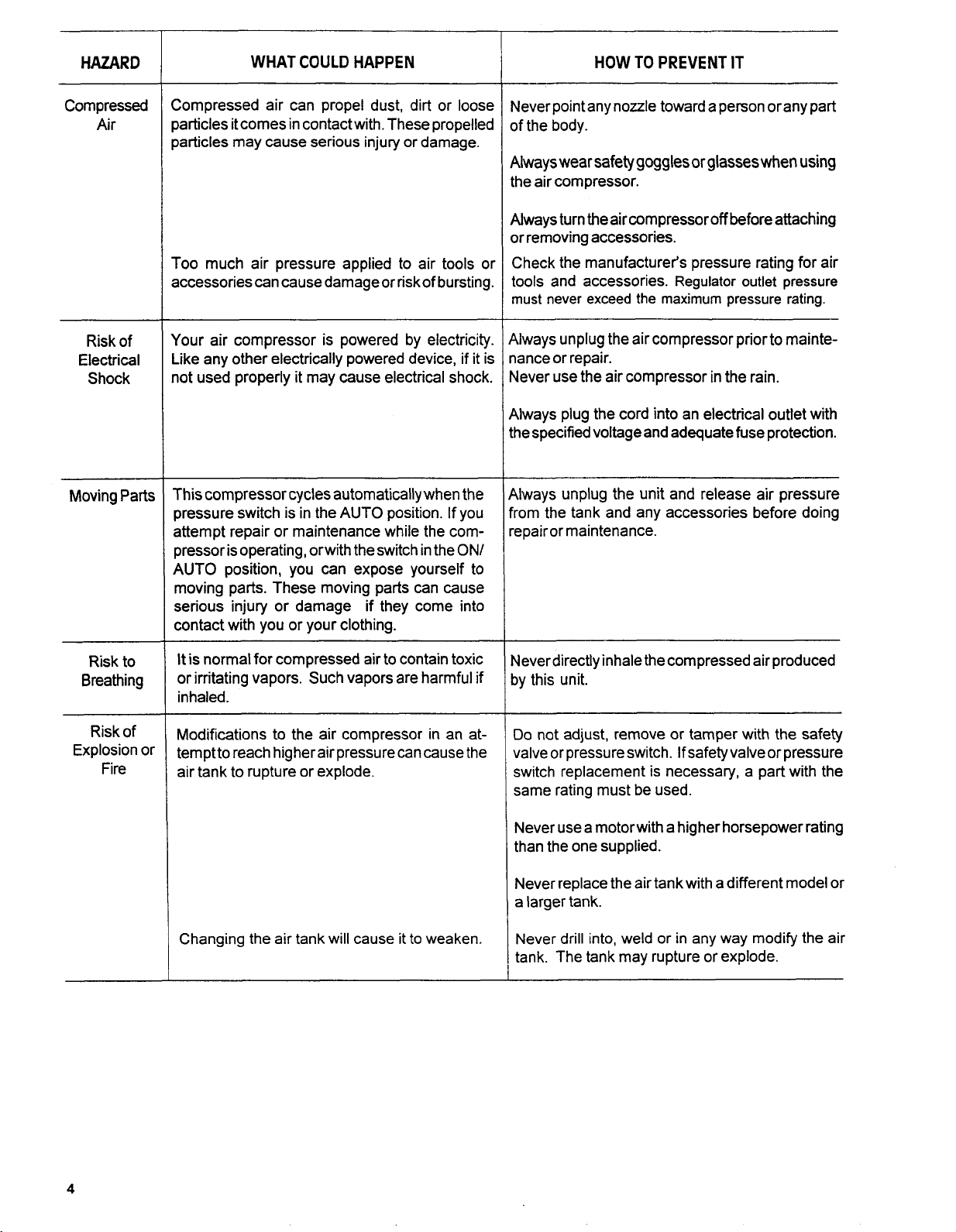

SAFETY

GUIDELINES

This manual contains information that

YOUR

following symbols. Please read the manual and pay attention to these sections.

SAFETY

and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

URGENT SAFETY INFORMATION -A

HAZARD THAT WILL CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

Information for preventing damage to

equipment.

is

important for you

to

know and understand. This information relates to protecting

IMPORTANT SAFETY INFORMATION

A

HAZARD THAT MGHTCAUSE

SERIOUS INJURY OR LOSS OF LIFE.

Information that

attention to.

NOTE

you

should pay special

-

HAZARD

Risk

of

Hot

Surfaces

Flammable

Vapors

HAZARDS CAN OCCUR IF EQUIPMENT

PLEASE READ THE FOLLOWING CHART.

WHAT COULD HAPPEN

When operated continuously, the air hose gets

hot, especially near the compressor. If you maintain contact by grasping you may suffer minor

burns or discomfort.

On tank mounted units, the plumbing between the

pump and tank gets hot.

It is normal for the motor and pressure switch to

A

spark.

gasoline or solvents, causing a fire or explosion.

spark can ignite flammable vapors from

IS

NOT USED PROPERLY.

HOW

TO PREVENT

Never touch the air compressor head during or

immediately after operation.

On tank mounted units, avoid prolonged contact

to

with the pump

The air compressor must only be used in well

ventilated areas, free

Do

not operate the compressor while you are

carrying it.

tank plumbing.

of

gasoline or solventvapors.

IT

3

HAZARD

WHAT COULD HAPPEN

HOW TO PREVENT IT

Compressed

Air

Risk of

Electrical

Shock

Moving Parts

;ompressed air can propel dust, dirt or loose

)articles it comes in contact with. These propelled

)articles may cause serious injury or damage.

roo

much air pressure applied to air tools or

accessories can cause damage or risk of bursting.

lour air compressor is powered by electricity.

ike any other electrically powered device, if it is

lot used properly it may cause electrical shock.

This compressor cycles automatically when the

Dressure switch is in the

AUTO

position. If you

attempt repair or maintenance while the comDressor is operating, orwith the switch in the

ON/

AUTO position, you can expose yourself to

moving parts. These moving parts can cause

serious injury or damage if they come into

contact with you or your clothing.

Jever point any nozzle toward a person orany part

)f

the body.

Uways

wear

safety goggles

or

glasses

when

using

he air compressor.

Uways turn the air compressor

off

before attaching

)r removing accessories.

:heck the manufacturer's pressure rating for air

001s

and accessories. Regulator outlet pressure

nust

never exceed the maximum pressure rating.

ilways unplug the air compressor prior to maintelance or repair.

Jever use the air compressor in the rain.

ilways plug the cord into an electrical outlet with

he specified voltage and adequate fuse protection.

~~

{lways unplug the unit and release air pressure

rom the tank and any accessories before doing

epairor maintenance.

Risk to

Breathing

Risk of

Explosion or

Fire

It

is normal for compressed air to contain toxic

or irritating vapors. Such vapors are harmful if

inhaled.

Modifications to the air compressor in an atternptto reach higherairpressurecancause the

air tank to rupture or explode.

Changing the air tank will cause it to weaken.

Jeverdirectly inhale the compressed air produced

)y this unit.

Do

not adjust, remove or tamper with the safety

ialve or pressure switch. If safety valve or pressure

switch replacement is necessary, a part with the

same rating must be used.

Never use a motorwith a higher horsepower rating

than the one supplied.

Never replace the air tank with a different model or

a larger tank.

Never drill into, weld or in any way modify the air

or

tank. The tank may rupture

explode.

4

GLOSSARY

SCFM

measurement of air delivery.

PSlG

CUT-IN

pressure drops as you continue to use your accessory.

When the tank pressure drops to approximately

the motor will restart automatically. The low pressure at

which the motor automatically re-starts is called "cut-in

pressure."

or

CFM:

or

PSI:

Pounds per square inch gauge.

PRESSURE:

Standard Cubic Feet per Minute; a unit of

While the motor is

off,

air tank

100

PSI

DUN

CUT-OUT PRESSURE:

pressor and it begins to run, air pressure in the air tank

begins to build. It builds to to approximately

the motor automatically shuts

which the motor shuts

When you turn on your air com-

125

PSI

before

off

.The high pressure at

off

is called "cut-out pressure."

CYCLE

This air compressor's optimum life may be achieved by operating the unit at a

A

50%

duty cycle is considered

Should the unit operate at a greater than a

required job demand and continued operation above a

to

be

30

minutes of 'run time' in any 1 hour time period.

50%

duty cycle, then the compressor may be undersized for the

50%

duty cycle may constitute misuse of the product.

STORAGE

When

you

have finished using the air compressor:

3. Protecttheelectrical cord and air hose from damage by

1.

Setthe"0NIOFF" switch to"0FF"and unplug the cord.

2.

Relieve all pressure from the aircompressor head and

air hose by opening the regulator.

winding them loosely around the air compressor.

4.

Store the air compressor in a clean and dry location.

50

% duty cycle, or less.

5

DESCRIPTION

OF

OPERATION

Air Compressor Pump:

moves up and down in the cylinder. On the downstroke, air

isdrawn in through theairintakevalves. Theexhaustvalves

remain closed. On the upstroke of the piston, air is

compressed. The intake valves close and compressed air

is forced out through the exhaustvalves, through theoutlet

tubes, through the check valve and into the air tank.

Working air is not available until the compressor has raised

the air tank pressure above that required at the air outlet.

Check Valve:

checkvalve is’lopen”, allowing compressed air toenter the

air tank. When the air compressor reaches “cut-out”

pressure, the check valve “closes”, allowing air pressure to

remain inside the air tank.

Pressure Switch:

starts the motorwhen the air tank pressure drops below the

factory set “cut-in’’ pressure. It stops the motor when the

airtank pressure reaches the factory set”cut-out” pressure,

Regulator:

controlled by the regulator. Turn the regulator knob clockwise to increase pressure and counter-clockwise to

decrease pressure. To avoid minor readjustment after

making a change in pressure setting, always approach the

desired pressure from a lower pressure. When reducing

from a higher to a lower setting, first reduce to some

pressure less than that desired, then bring up to the desired

When the air compressor

The air pressure coming from the air tank is

To compress air, the piston

is

operating, the

The pressure switch automatically

pressure. Depending on the air requirements of each

particular accessory, the outlet regulated air pressure may

have to be adjusted while operating the accessory.

Outlet Pressure Gauge:

indicates the air pressure available at the outlet side of the

regulator. This pressure is controlled by the regulator and

is always less or equal to the tank pressure. See “Operating Procedures”.

Tank Pressure Gauge:

the reserve air pressure in the tank.

Cooling System:

design cooling system. At the heart of this cooling system

is an engineered fan.

air through the vent holes in large amounts. You know that

the cooling system is working when air is being expelled.

Air Intake Filter:

unique design of the air intake system.

Drain Valve:

air tank and is used to drain condensation at the end of each

use.

OnlAuto-Off Switch:

automatic powerto the pressure switch and

power at the end of each use.

This compressor contains an advanced

It

The unit requires

The drain valve is located at the base of the

The outlet pressure gauge

Thetank pressuregauge indicates

is perfectly normal forthis fan to blow

no

air filter due

Turn this switch

ON

OFF

to

the

to provide

to remove

INSTALLATION AND BREAK4N PROCEDURES

Location

Your compressor comes to you completely assembled

and ready for use. Operate the air compressor in a dry,

clean, cool and well ventilated area. The air compressor

pump and case are designed to allow for proper cooling.

Clean or blow

compressor. A clean air compressor runs cooler and

provides longer service. The ventilation openings on your

air compressorare necessary to maintain proper operating

temperature.

near these openings.

of

the Air Compressor

off

dust or dirt that collects on the air

Do

not place rags or other containers on or

Voltage and Circuit Protection

See front cover.

6

Extension Cords

Use extra air hose instead of an extension cord to avoid

voltage drop and power

sized cord will cause a drop in the line voltage resulting

loss

of power and overheating.

in

If an extension cord must be used, be sure it is:

a 3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that will accept the

plug on the compressor

in good condition

no longer than

14 gauge (AWG) orlarger. (Wire size increases as

gaugenumberdecreases.) 12AWG, 10AWGand

8

AWG

may also be used.

AWG.

50

loss

feet

to the motor. An under-

DO

NOT

USE

16 OR

18

INSTALLATION AND BREAK-IN

PROCEDURES

GROUNDING INSTRUCTIONS

RISK

OF

ELECTRICAL SHOCK! IN THE EVENTOF A

SHORTCIRCUIT,GROUNDING REDUCESTHE RISK

OFSHOCKBY PROVlDlNG AN ESCAPEWIRE FOR

THE ELECTRICCURRENT. THISAIRCOMPRESSOR MUST BE PROPERLY GROUNDED.

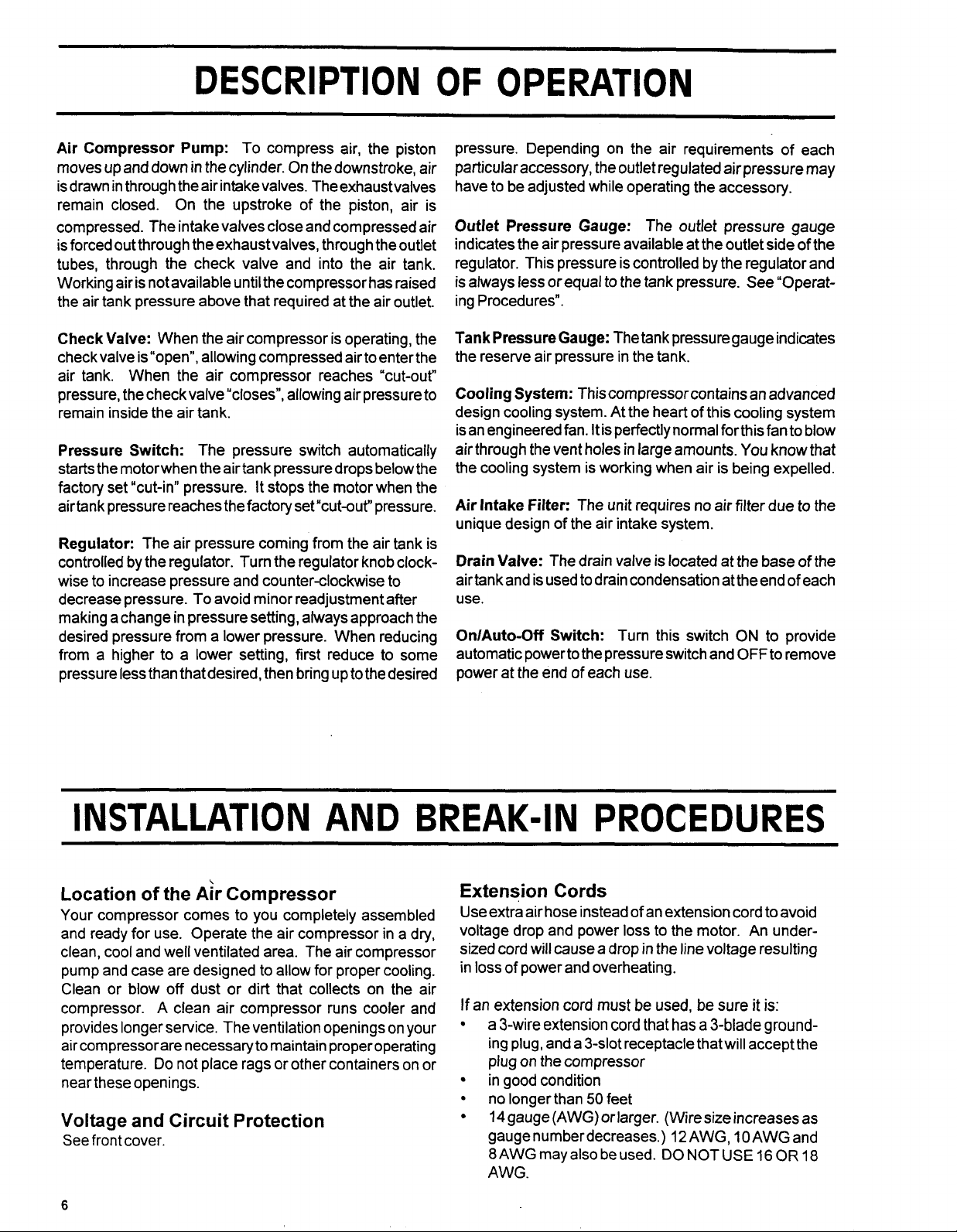

The air compressor is equipped with a cord having a

grounding wirewith an appropriate grounding plug. The

plug must be used with an outlet that has been installed

and grounded in accordance with all local codes and

ordinances. The outlet must have the same configuration

as the plug. See illustration.

ER

Inspect the plug and cord before each use.

there are signs of damage.

IMPROPERGROUNDING CAN RESULTIN ELEC-

TRICALSHOCK.

Do

not modify the plug that has been provided. If

not fit the available outlet, the correct outlet should be

installed by a qualified electrician.

If repairing or replacing cord or plug, the grounding wire

must be kept separate from the current-carrying wires.

Never connect the grounding wire to a flat blade plug

terminal. The grounding wire has insulation with an outer

surface that is green -with or without yellow stripes.

If these grounding instructions are not completely under-

stood, or if in doubt as to whether the compressor is

properly grounded, have the installation checked by a

qualified electrician.

DO

NOT

USE

AN

ADAPT-

Do

not use if

it

does

Additional Regulators and

Con

t

ro

Is

Since the air tank pressure is usually greater than that

is

which is needed, a separate regulator

to control the air pressure ahead of any individual air driven

device.

Separate air transformers which combine the function of air

regulation, moisture and dirt removal should be used where

applicable.

usually employed

Break-in Procedures

Serious damage may result if the following break-in instructions are not

closely followed.

This procedure is required:

1.

Before the air compressor is put into service.

2.

When the check valve is replaced.

Set the pressure switch lever to the

a.

position.

Plug the power cord into the correct branch

b.

circuit receptacle.

Turn the regulator clockwise, opening it fully, to

C.

prevent air pressure build-up in the tank.

d.

Move the pressure switch lever to

The compressor will start.

Run the compressor for

e.

the regulator is open and there is no tank

pressure build-u p.

After

15

f.

knob counter clockwise. The air receiver will

to cut-out pressure and the motor will stop. The

compressor is now ready for use.

minutes, close the regulator by turning

15

minutes. Make sure

"OFF"

"ONIAUTO.

fill

7

OPERATING PROCEDURES

1.

Before attaching air hose or accessories, make sure

the OFFlAUTO lever is set to "OFF" and the air

regulator or shut-off valve is closed.

2.

Attach hose and accessories. pressure to zero.

TOO MUCH AIR PRESSURE CAUSES A HAZARDOUS RISKOF BURSTING. CHECKTHE MANUFACTURERS MAXIMUM PRESSURERATING FORAIR

TOOLS AND ACCESSORIES. THE REGULATOR

OUTLET PRESSURE MUST NEVER EXCEEDTHE

MAXIMUM PRESSURE RATING. ON MODELS HAVING ONLYASHUT-OFFVALVE, YOU MUST INSTALL

A REGULATOR BEFORE USING ACCESSORIES

125

RATEDATLESSTHAN

3.

Turn the OFF/AUTO lever to "AUTO" and allow tank

PSIG.

pressure to build. Motor will stop when tank pressure

reaches"cut-out" pressure.

When youare finished:

6.

Setthe"OFF/AUTO"leverto"OFF".

7.

Tum

the

8.

Remove the air tool or accessory.

9. Open the regulator and allow the air to slowly bleed

from the tank. Close the regulatorwhen tank pressure

is approximately

10.

Drain water from air tank. By opening drain valve

underneath the tank.

WATERWILLCONDENSEIN THEAIRTANK. IF

NOTDRAINED, WATERWILLCORRODE AND

WEAKEN THE AIR TANK CAUSING A RISK OF

AIRTANK RUPTURE.

regulatorcounterclockwiseand set theoutlet

.

20

psi.

Open the regulator by turning it clockwise. Adjust the

4.

regulator to the correct pressure setting. Your compressor is ready for use.

Always operate the air compressor

5.

in

well-ventilated

areas; free of gasoline or other solvent vapors. Do not

operate the compressor near a paint spray area.

NOTE

If drain cock valve is plugged, release all air

pressure. The valve

cleaned,

11.

Afterthewater has been drained, closethedrain cock

then

can

reinstalled.

then be removed,

ordrainvalve. Theaircompressorcan now bestored.

8

TROUBLESHOOTING

GUIDE

PERFORMING REPAIRS

AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY REPAIRS,

UNPLUG THE COMPRESSOR

PROBLEM

Excessive tank pressure

safely valve pops

Air leaks at fittings.

Air leaks at or inside check

valve.

off.

MAY

EXPOSEVOLTAGE

AND

BLEED

OFFTANK

CAUSE

Pressure switch does not shut

-

motor when compressor reaches 'cut-

out,

pressure.

Pressure switch 'cut-out' too high.

Tube fittings are not tight enough.

~

Defective or dirty check valve.

SOURCES, MOVING PARTS OR COMPRESSED

AIR PRESSURE.

CORRECTION

off

Move the pressure switch lever to the

off,

f the unit doesn't shut

ore

welded

If the contacts are

mttom

joes not move

2etum the unit to an authorized dealer to

adjust, or replace

fighten fittings where air can be heard escaping.

:heck fittings

3VER-TIGHIEN.

~~ ~ ~ ~ ~~ ~

9

defective check valve results in a constant air leak

at the pressure release valve where there is pressure

n the tank and the compressor is shut

and clean or replace check valve.

ffim.

together, replace the pressure

good,

of the pressure release valve is

freely,

with

and the electrical

check to

replace the valve.

switch.

soapy water solution. DO NOT

'OFF

position.

contacts

see

if

the pin

stuck..

check and

off.

DO NOT OVER-

switch.

in

the

If

it

Remove

Air

leaks

at pressure switch

release valve.

Air leaks in air tank or at air tank

welds.

Pressure reading on the regu

lated pressure gauge drop!

when an accessory is used.

Defective pressure switch release

valve.

check

Defective

Defective air tank.

It

is

normal for "some" pressure drop

to

occur.

valve.

Remove and replace the release valve.

9

defective

nt the pressure release valve when there

n the tank and the compressor is shut

nnd clean or replace

nGm.

Air tank must

DO NOT DRILL INTO, WELD OR OTHERWE

MODIFY AIRTANKOR ITWlLLWEAKEN.THE

TANKCAN

If there

when the

following the instructions on page

check

valve results in a constant

check

valve.

DO

be

replaced. Do not repair the

RUPTUREOREXPLODE.

is

an excessive amount of pressure drop

accessory

is

used, adjust

8.

air

is

pressure

off.

Remove

NOT OVER-

the

regulator

leak.

NOTE

Adjust the regulated pressure under

conditions (while

accessory

is

being used).

flow

leak

TROUBLESHOOTING

GUIDE

(Continued)

PROBLEM

Air leak from safety valve.

Knocking Noise

Compressor is not supplying

enough air to operate accessories.

Motor will not run.

CAUSE

Possible defect in safety valve.

Defective check valve.

Prolonged excessive use of air.

Compressor is not large enough for

air requirement.

Hole in hose.

Check valve restricted.

Air leaks.

Tank pressure exceeds pressure

switch "cut-in" pressure.

Wrong gauge wire or length of exten

sion cord.

CORRECTION

Operate safety valve manually by pulling on ring.

valve still leaks, it should be replaced.

Remove and clean, or replace.

Decrease amount of air usage.

Check the accessory air requirement. If

than the SCFM or pressure supplied by your air

compressor, you need a larger compressor.

Check and replace if required.

Remove and clean, or replace.

Tighten fittings. (See Air Leaks Section of

Troubleshooting Guide.)

Motor will start automatically when tank pressure

drops below "cut-in" pressure of pressure switch.

Check for proper gauge wire and cord length.

it

If

is higher

Check valve stuck open.

Loose electrical connections.

Paint spray on internal motor parts.

Possible defective motor.

Fuse blown, circuit breaker tripped.

Pressure release valve on pressur

switch has not unloaded head prez

sure.

Remove and clean, or replace.

Check wiring connection inside pressure switch and

terminal box area.

-lave checked at an Authorized Warranty Senrice

Senter.

spray area.

iave checked at an Authorized Warranty Service

:enter.

1.

2.

3.

4.

Bleed the line by pushing the lever on the pressure

switch

replace it.

Do

not operate the compressor in the paint

See flammable vapor warning.

Check fuse box for blown fuse and replace, if

necessary. Reset circuit breaker. Do not use a

fuse or circuit breakerwith higher rating than that

specified for your particular branch circuit.

Check for proper fuse; on1y"Fusetron" typeT

equivalent) fuses are acceptable.

Check for low voltage conditions and/or proper

extension cord.

Disconnect the other electrical appliances from

circuit or operate the compressor in its own

branch circuit.

to

the

"off

position; if the valve does not open,

(or

Regulator knob continuous ai

leak. Regulator will not shut

at air outlet.

10

of

Dirty or damaged regulator internz

parts.

Clean or replace regulator, or internal parts.

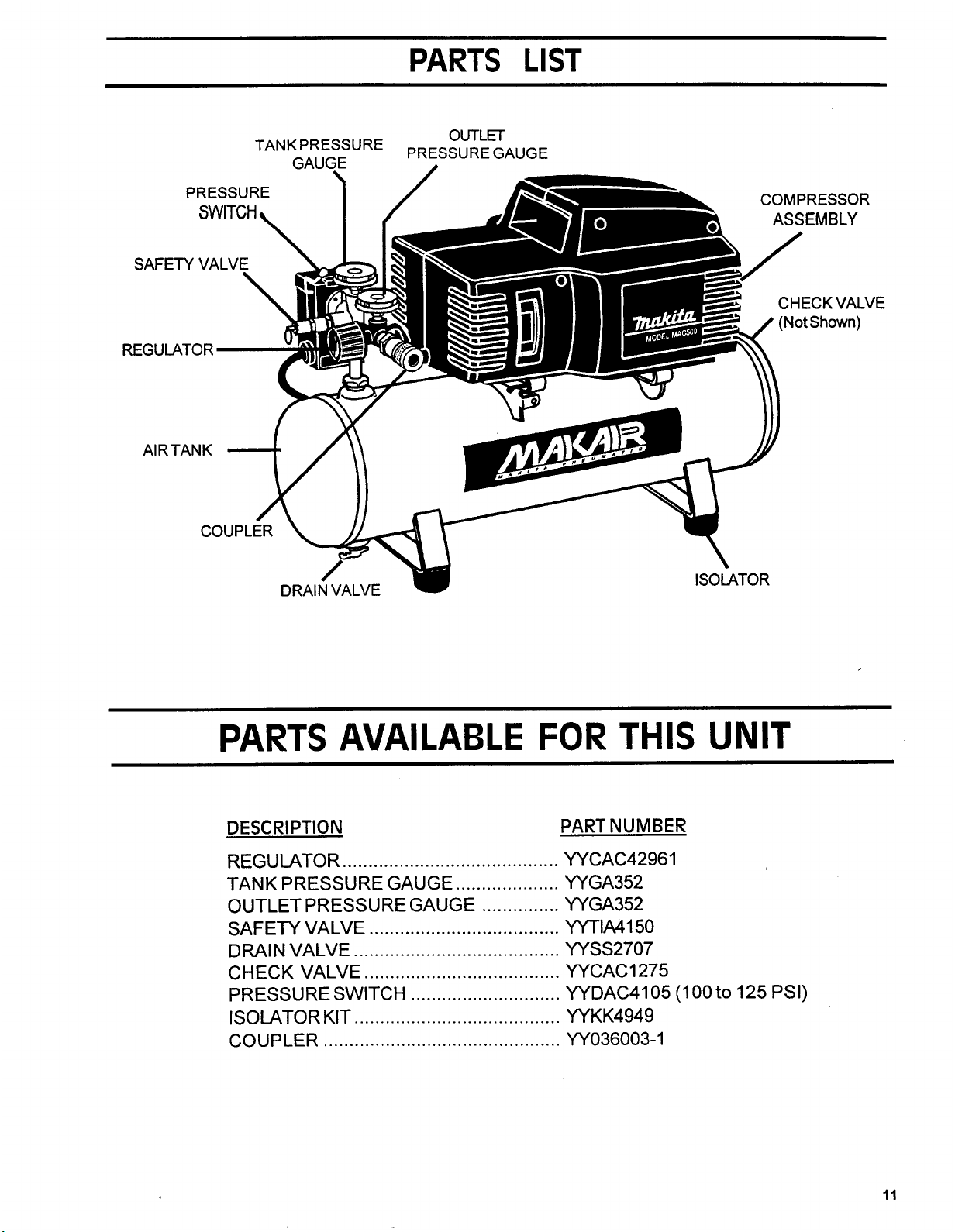

PRESSURE

SAFETY VALV

R

GAUGE

PARTS

OUTLET

PRESSURE

GAUGE

LIST

CHECKVALVE

PARTS AVAILABLE

DESCRl PTlON PART NUMBER

REGU IATOR

TANK PRESSURE GAUGE

OUTLETPRESSURE GAUGE

SAFETY VALVE

DRAIN VALVE

CHECK VALVE

PRESSURE SWITCH

ISOLATOR KIT

COUPLER

..........................................

....................

...............

.....................................

........................................

......................................

.............................

........................................

..............................................

FOR

YYCAC4296

YYGA352

YYGA352

yyTIA4150

YYSS2707

YYCAC1275

YYDAC4105 (1

YYKK4949

YYO36003-1

THIS

1

UNIT

00

to

125

PSI)

11

Loading...

Loading...