Page 1

Portable Electric

Compressor

Instructions

NOTICE

Operating

www.makita.ca

Carefully read this instruction manual before attempting to

operate this compressor.

MODEL # MAC3001 SERIAL #

Page 2

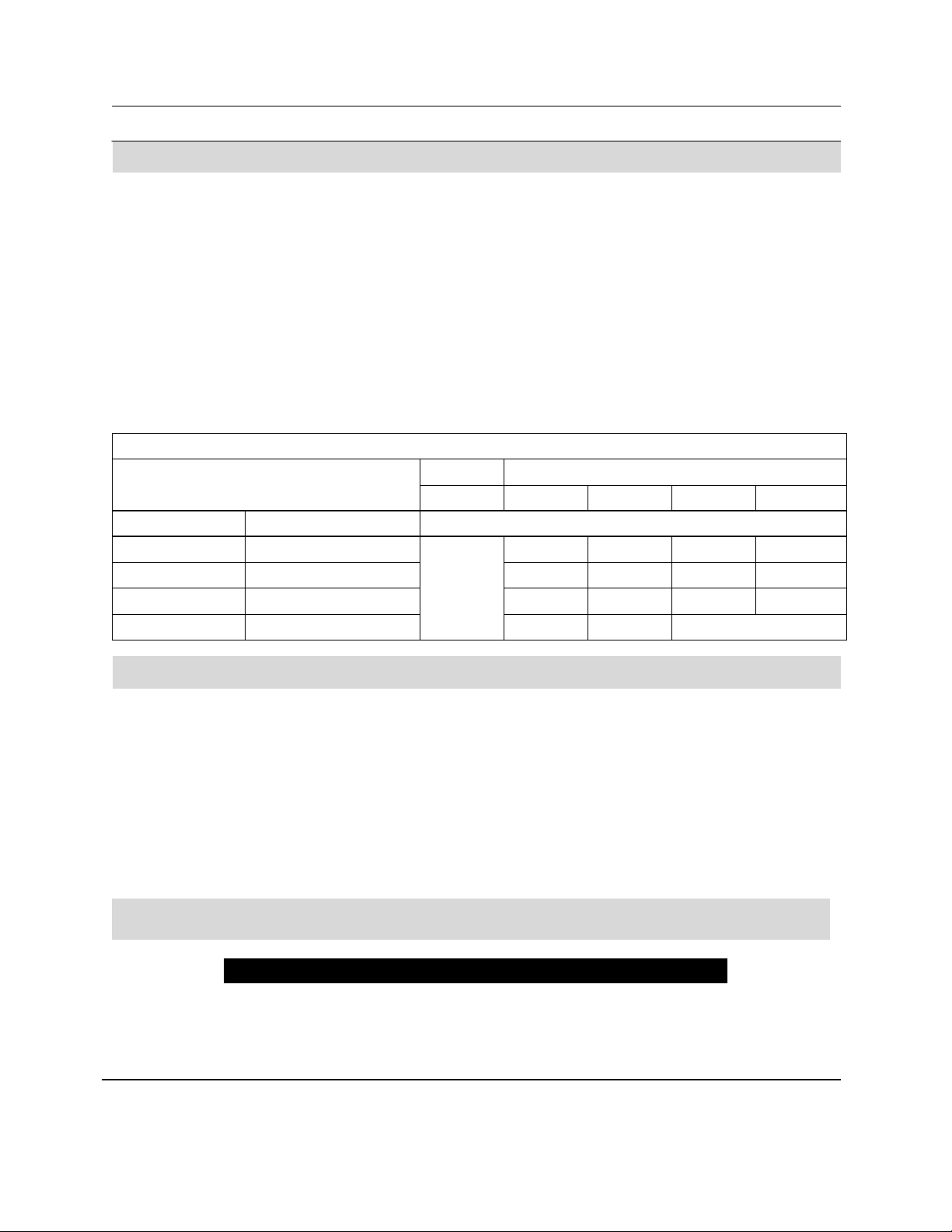

Horsepower

3

SCFM @ 40 PSIG

6.54

SCFM @ 100 PSIG

6

Cut in Pressure

100 PSI

Cut out Pressure

125 PSI

Bore

55 mm

Stroke

45 mm

Voltage – Single Phase

120V – 220V

Motor RPM

3450

Amperage @ max pressure

15

Tank Size

8 Gallon Twin Tank

CSA/US Listed

Yes

Read the Safety Guidelines and ALL

instructions carefully before operating.

OWNERS MANUAL FOR

Oil Lubricated Air Compressor

MODEL NO.

MAC3001

SPECIFICATION CHART

Minimum Circuit Requirement: 15 AMPS

* A circuit breaker is preferred. Use only a fuse or circuit breaker that

is the same rating as the branch circuit the air compressor is

operated on. If the air compressor is connected to a circuit protected

by fuses, use time delay fuses.

www.makita.ca

IMPORTANT:

Page 3

MAC3001

Wear hearing protection.

Wear eye protection.

Wear

protection.

www.makita.ca

Read the manual.

respiratory

Page 4

CAREFULLY READ THIS INSTRUCTION

OPERATE THIS COMPRESSOR.

TABLE OF CONTENTS

SPECIFICATION CHART……………………………………………...

2

SAFETY PRECAUTIONS ……………………………………………..

5

Cautions ……………………………………………………………...

5

Air receiver …………………………………………………………..

5

Safety valve ………………………………………………………….

5

INSTALLATION & OPERATION INSTRUCTIONS ………………..

6

Extension cords …………………………………………………….

6

Installation ……………………………………………………………

6

Before operating the air compressor …………………………….

6

Compressor lubrication …………………………………………….

7

Oil changes ………………………………………………………….

7

Maintenance …………………………………………………………

8

Checking belt for tension ………………………………………….

8

OPERATING YOUR AIR COMPRESSOR ………………………….

9

MAINTENANCE SCHEDULE ………………………..……………….

10

TROUBLESHOOTING GUIDE ……………..………………………...

11

MAINTENANCE LOG ………………………………………………….

15

MAKITA WARRANTY …………………………………………………

17

FACTORY SERVICE CENTERS ……………………………………..

16

PARTS BREAKDOWNS ………………………………………………

38

En Français ……………………………………………………………..

18

MANUAL BEFORE ATTEMPTING TO

4

Page 5

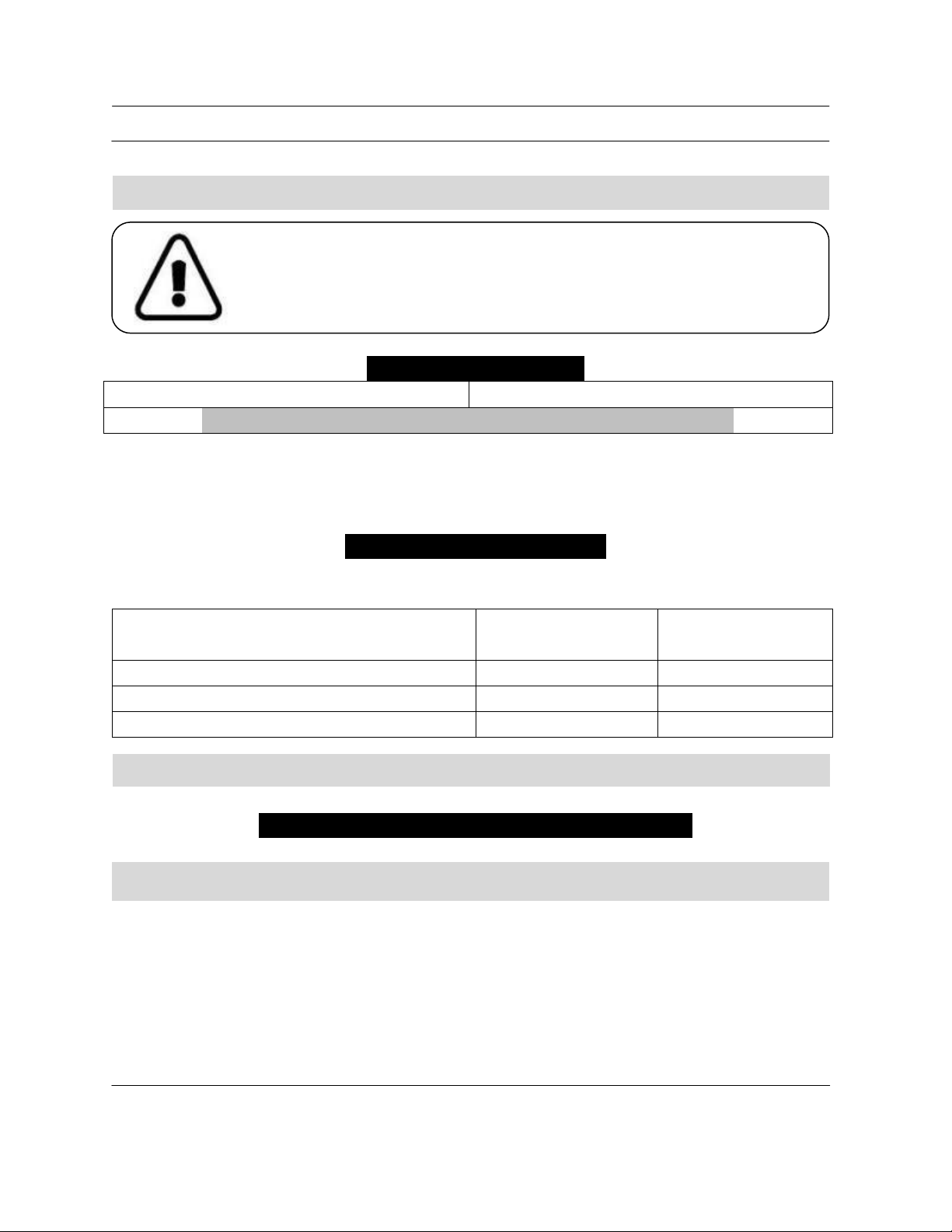

CAUTION

WARNING

SAFETY PRECAUTIONS

NEVER WELD, DRILL OR CHANGE THE AIR

RECEIVER IN ANY WAY

DO NOT REMOVE, MAKE ADJUSTMENTS TO

OR SUBSTITUTE THIS VALVE!

Please familiarize yourself with the following information to prevent

damage to your compressor unit and injury to the operator.

CAUTIONS

The air compressor motor will get hot while in

operation. Never touch the discharge tubing, motor or

compressor pump while in operation. The compressor

operates automatically while the power is connected and turned on.

Compressed air from the unit may contain hazardous

fumes. Air produced by this compressor is not suitable

for breathing purposes. Always use a respirator when

spraying paint or chemicals, or when sandblasting. Always wear safety

glasses or goggles when using compressed air.

It is not practical or possible to warn you about all the hazards associated

with operating or maintaining this equipment. You must use your own good

judgment.

AIR RECEIVER

Over pressurizing the air compressor could cause personal injury or

material damage. To protect from over pressurizing, a factory pre-set

safety valve is installed.

Any replacement parts should be purchased with the same specifications

as the original equipment. Please contact the authorized dealer for

replacement parts or specifications.

SAFETY VALVE

This valve is factory installed to prevent over pressurizing of the air receiver.

It is factory set at a specific limit for your particular model, and should never

be tampered with.

Adjustment by user will automatically VOID the warranty.

5

Page 6

INSTALLATION & OPERATION

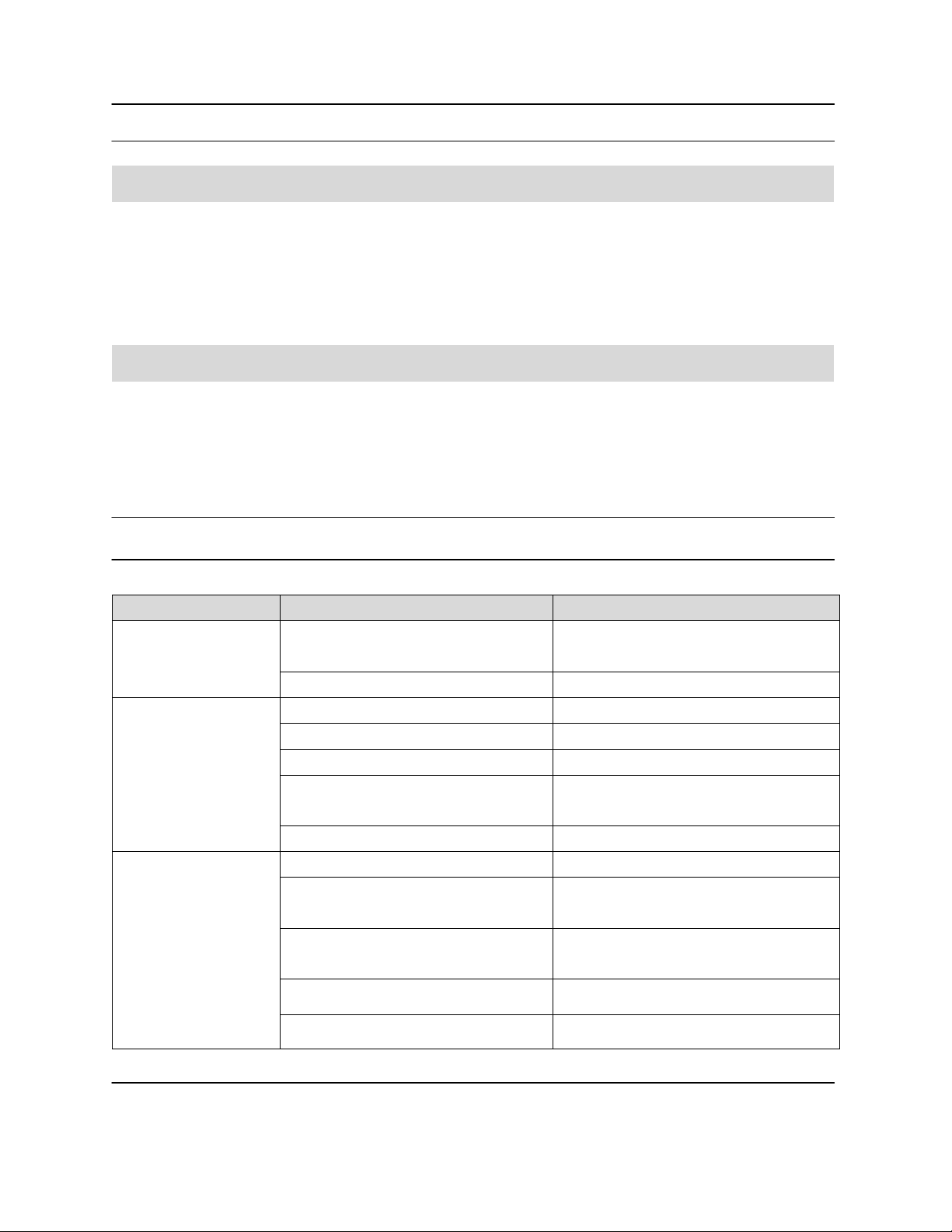

Table 1 – Minimum Gauge for Cord

Volts

Total length of cord in feet

120V

25ft

50ft

100ft

150ft

More Than

Not More Than

AWG

0

6

18

16

16

14

6

10

18

16

14

12

10

12

16

16

14

12

12

16

14

14

Not Recommended

EXTENSION CORDS

The use of extension cords is not recommended. Plug directly into a

dedicated circuit. If the use of an extension cord is unavoidable then make

sure your extension cord is in good condition. When using an extension

cord, be sure to use one heavy enough to carry the current your product

will draw. An undersized cord will cause a drop in line voltage resulting in

loss of power and overheating. Table 1 shows the correct size to use

depending on cord length and nameplate amperage rating. If in doubt, use

the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Ampere Rating

INSTALLATION

Proper care, maintenance and lubrication ensure longevity. The

compressor should always be level for proper lubrication. Do not ever

tighten foot bolts as excessive vibration may occur. Use only in a clean,

dry, and well-ventilated area. The compressor has heat dissipation fins for

proper cooling. Keep the fins and other parts that collect dust clean. Do

not place rags or other materials on top of the compressor, as this

obstructs cooling and can be a fire hazard.

BEFORE OPERATING THE AIR COMPRESSOR

PLEASE CHECK THE FOLLOWING CAREFULLY:

1) Check to see that nuts and bolts are all snug.

2) Check if the quantity and quality of oil is correct.

3) If the intake filters are dirty, they should be replaced or cleaned.

6

Page 7

INSTALLATION & OPERATION

Compressor oil

# EAOIL10 (1 Litre)

*Compressor originally filled with SAE 20W oil (ISO 68)

AMBIENT TEMPERATURE AT

POINT OF OPERATION

SAE

VISCOSITY

ISO

VISCOSITY

-16°C to 0°C (3.2°F to 32°F)

SAE 10W

ISO 32

1°C to 26°C (33.8°F to 78.8°F)

SAE 20W

ISO 68

Above 27°C (80.6°F)

SAE 30W

ISO 100

ALWAYS CHECK THE OIL LEVEL AND QUALITY BEFORE

START UP. DO NOT ADD OR CHANGE OIL WHILE THE UNIT

NON-DETERGENT OIL.

CHANGE OIL EVERY 300 HRS OR 3 MONTHS, WHICHEVER COMES FIRST.

COMPRESSOR LUBRICATION

Compressor oil is a non-detergent mineral oil formulated with additives to

help minimize carbon build up, increase ring life and reduce oil

consumption, for use at ambient temperatures of 0° to 30° C (32° - 86°F).

Regular mineral oils can also be used in this compressor. Always use nondetergent oil with the following specifications:

IS RUNNING. USE ONLY RECOMMENDED

RECOMMENDED OIL

OTHER APPROVED OILS

OIL CHANGES

INITIAL OIL CHANGE DUE AT 100 HOURS

1) Remove the oil drain plug. Allow oil to drain completely.

2) Replace the oil drain plug.

3) Refill with the recommended oil to the proper level.

7

Page 8

INSTALLATION & OPERATION

1)

Disconnect power supply.

2)

Remove belt guard.

3)

Loosen motor bolts and slide motor toward compressor head just

enough to allow old belt to be removed.

4)

Install proper replacement belt.

5)

Slide motor away from compressor head to provide recommended

tension as shown in diagram on page 5.

6)

Align belt using a straight edge ruler against pulley’s edge.

7)

Fasten motor bolts.

8)

Ensure motor and compressor pulleys are secure. Re-check alignment.

9)

Re-install belt guard and reconnect power supply.

10)

Belt tension should be checked after 20 hours of operation. Check

tension monthly thereafter.

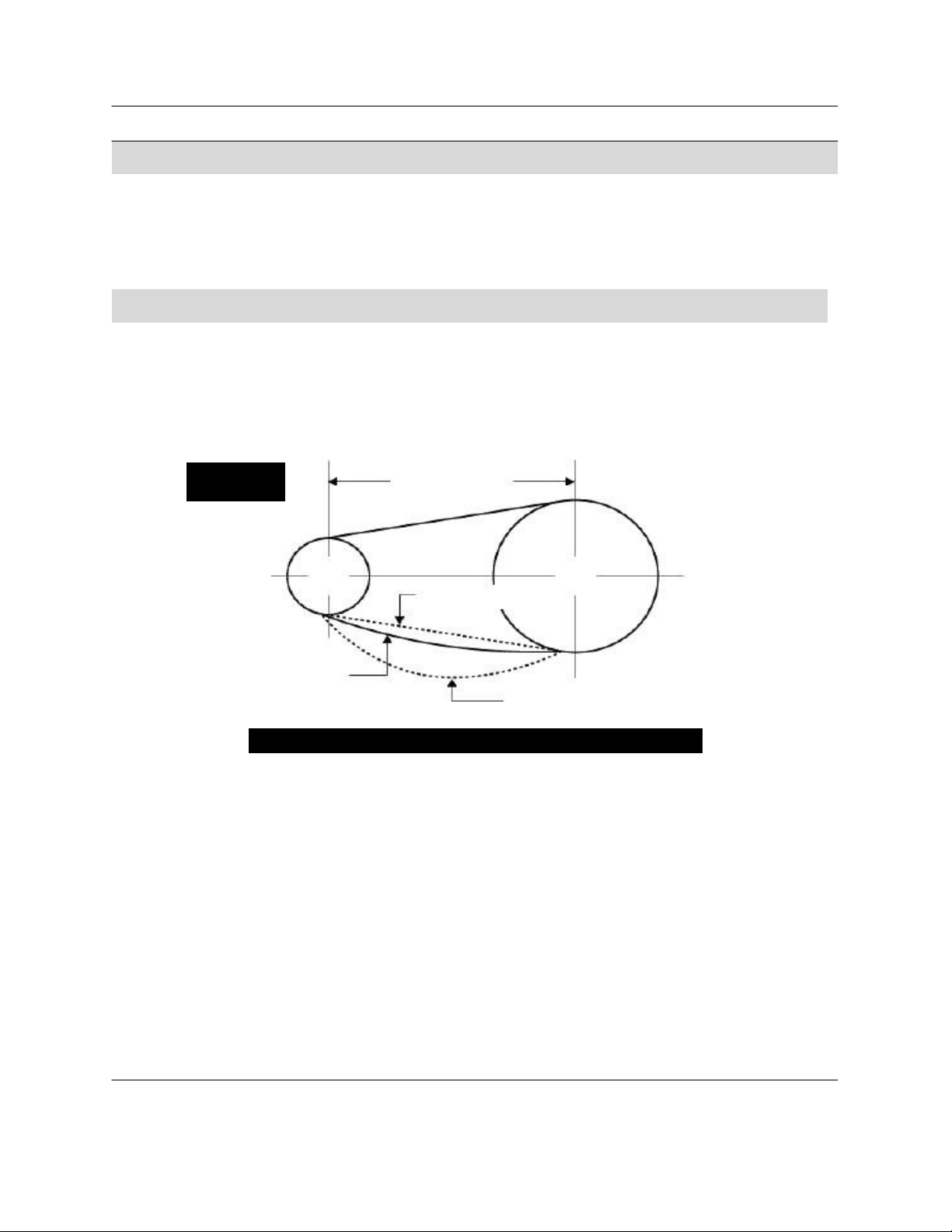

Figure A

Centre

Too Tight

Too Loose

Slight Bow

Correct

Tension

MAINTENANCE

Before doing any maintenance or adjustments to your air compressor, the

following safety precautions should be taken:

- TURN OFF AND UNPLUG POWER CORD.

- DRAIN AIR RECEIVER AND AIR LINES OF AIR PRESSURE.

CHECKING BELT TENSION

Adjust belt(s) so when pressure is applied at the center, there is approx.

1/2" slack (see diagram below). If the belt is installed too tight, the motor

might be overloaded. This will cause the motor to overheat. If the belt is

installed too loosely, it will slip and excessive wear and vibration will occur.

HOW TO INSTALL NEW BELT IF REQUIRED

8

Page 9

OPERATING YOUR AIR COMPRESSOR

ELECTRIC DRIVE WITH DUAL CONTROL

1) Check unit for any damage.

2) Check compressor oil level, fill or add if necessary.

3) Pressure switch “Off/Auto” knob should be in “Off” position.

4) Plug in power cord to proper electrical outlet.

5) Stop/Start (pressure switch) control

a) Shut-off valve on pilot unloader should be closed (“knurled” knob

on top of the pilot unloader should be turned all the way down).

b) Turn pressure switch “Off/Auto” switch to “Auto”. Electric motor

should now start and fill air receiver(s) with compressed air until

cut-out pressure is reached. Compressor should stop and remain

stopped until air receiver pressure reaches the cut-in pressure.

The unit will continue to cycle in this automatic operation until it is

turned off.

6) Continuous run (pilot unloader) control

a) Open the shut-off valve on pilot unloader (“knurled” knob on top of

the pilot unloader should be turned all the way up).

b) Turn pressure switch “Off/Auto” switch to “Auto”. Electric motor

should now start and fill air receiver(s) with compressed air until

full pressure is reached. To engage continuous run, turn “knurled”

knob down. Your compressor will idle down and continue to idle

once maximum pressure is achieved. When cut-in pressure is

reached, the unloader valve will de-activate and unit will compress

air. The unit will continue in this automatic operation until the unit

is stopped (“Off/Auto” switch turn to the “Off” position and/or

electric power supply is disconnected).

7) You can switch at anytime from Stop/Start to Continuous Run and vice

versa by opening or closing the valve on the pilot unloader.

ELECTRIC DRIVE

1) Check unit for any damage.

2) Check compressor oil level, fill or add oil if necessary.

3) Pressure switch “Off/Auto” switch should be in “Off” position.

4) Plug in power cord to proper electrical outlet. If compressor is not

equipped with a male plug, hire an electrician to install one.

9

Page 10

OPERATING YOUR AIR COMPRESSOR

EXTRA CARE SHOULD BE TAKEN TO AVOID

PERSONAL INJURIES WITH AUTOMATICALLY

CONTROLLED COMPRESSORS

DAILY OR BEFORE EACH USE

WEEKLY

ELECTRIC DRIVE

5) Stop/Start pressure switch control

a) Turn pressure switch “Off/Auto” switch to “Auto”. Electric motor

should now start and fill air receiver(s) with compressed air until

cut-out pressure is reached. Compressor should stop and remain

stopped until air receiver pressure reaches the cut-in pressure.

The unit will continue to cycle in this automatic operation until the

pressure switch is turned to the “Off” position and/or electric power

supply is disconnected).

MAINTENANCE SCHEDULE

¾ Check oil level

¾ Drain condensation from air receiver(s)

¾ Check for any unusual noise or vibration

¾ Be sure all nuts and bolts are tight

¾ Turn off power. Clean dust and foreign matter from cylinder heads,

motor, fan blades, intercooler and air receiver(s)

¾ Clean air filter by opening air filter, removing filter element and cleaning

it thoroughly with soapy water. Rinse thoroughly and allow to dry

completely before assembly.

¾ Worn filters should be replaced

¾ Check V-belts for wear

10

Page 11

MAINTENANCE SCHEDULE

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Will not start

Check power supply

Make sure power is turned

on

Check motor reset button

Depress motor reset button

Low pressure

Safety valve leaks

Replace safety valve

Drain cock open

Close drain cock

Loose tubes or fittings

Tighten fittings

Dirty or plugged air filter

Clean or replace as

necessary

Defective unloader valve

Replace unloader valve

Oil in discharge

Improper oil viscosity

Drain and replace oil

Too much oil in the

crankcase

Drain oil and fill to proper

level

Compressor overheated

Air pressure regulated too

high

Restricted air filter

Clean or replace air filter

Worn piston rings

Replace piston rings

MONTHLY

QUARTERLY

¾ Inspect unit for leaks

¾ Tighten joints if leaks are observed

¾ Check V-belt for proper tension

¾ Check compressor pulley and motor sheave are aligned and securely

fastened (see item 8)

¾ Inspect the air receiver for corrosion or other damage

¾ Change compressor oil

¾ Replace air filters (more often if compressor is used near paint spraying

operations or in dusty environments).

TROUBLESHOOTING GUIDE

11

Page 12

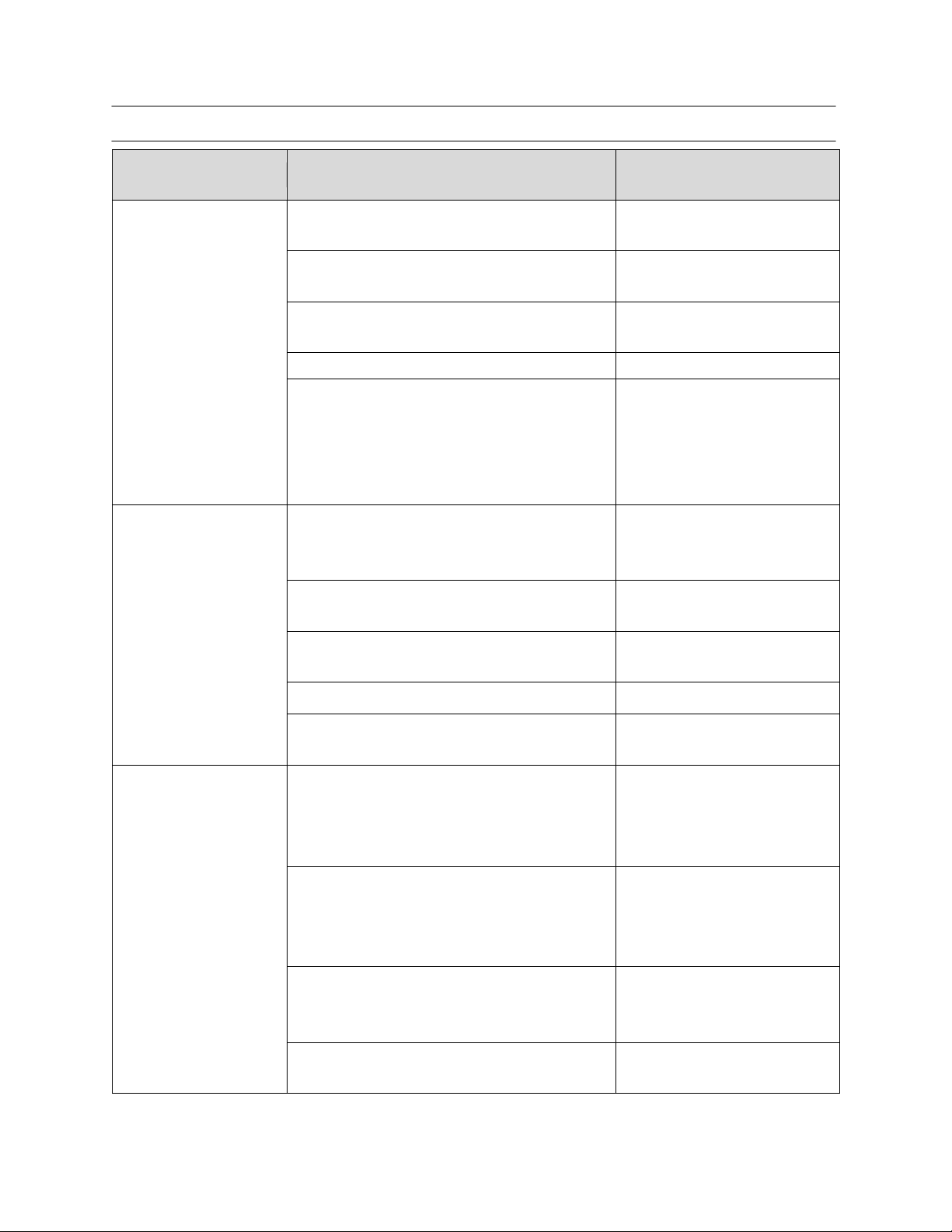

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

CORRECTIVE

ACTION

Compressor

Overheats

Clogged inlet filter

Clean or replace as

necessary

Dirty compressor, head,

cylinder, intercooler

Clean with

compressed air

Operating pressure too high

Reduce operating

pressure

Low oil or wrong oil being used

Drain and replace oil

Compressor cycle too long,

proper cycle is 50 to 60% on

Stop/Start operation and 75 to

80% on continuous run

operation

Allow for longer rest

bet

Compressor

loads and

unloads or

stops and starts

excessively

Leaks in air system

Replace worn

components as

necessary

Worn or loose drive belts

Tighten V-belts or

replace

Pilot valve or pressure switch

differential adjustment too close

Make necessary

adjustments

Defective compressor valves

Replace valves

Compressor too small for

intended use

Water in

crankcase, oil

breaking up, oil

gets dirty, rusty

valves or

cylinder(s)

Cycle too short; compressor

does not operate long enough

to

vaporize condensed moisture

during compression

Allow for a longer

operating cycle

Compressor operating outside

in cold conditions or inlet filter

not protected against weather

Provide adequate

protection against

extreme weather

conditions

System pressure leaking back

through check valve when

compressor is stopped

Check and replace

check valve if

necessary

Wrong oil being used

Drain and replace

with proper oil

ween cycles

12

Page 13

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

CORRECTIVE ACTION

Insufficient

output, low

discharge

pressure

Clogged inlet filter

Clean or replace as

necessary

Leaks in air lines, air

valves, fittings, etc…

Replace worn

components as

necessary

Drive belts slipping

Tension V-belts

Drain valve left open

Close drain valve

Defective pressure gauge

Replace pressure gauge

Compressor incorrectly

sized

Leaking head gasket

Replace head gasket

Dirty or plugged inter

cooler tubes

Remove and clean inter

cooler tubes

Unloader pilot or pressure

switch adjustment too low,

or defective

Make necessary

adjustments

Worn or defective

compressor valves

Replace worn parts

Worn piston, worn out

rings

Replace worn parts

Restrictive check valve

Clean check valve and

replace if necessary

Motor stalls

Faulty unloader/check

valve

Replace unloader or

check valve

Valves incorrectly installed

Install valves correctly

Drive belts too tight

Tension V-belts

Compressor

knocks

Compressor valves loose

or broken

Check and replace worn

or broken valves

Inspect check valve, it may

knock at low pressures

Remove and clean check

valve

Piston rings not

seated

Compressor not run long

enough to seat rings

Allow 100 hours of

normal operation for new

rings to seat

Wrong oil being used,

wrong viscosity

Drain and replace with

proper oil

13

Page 14

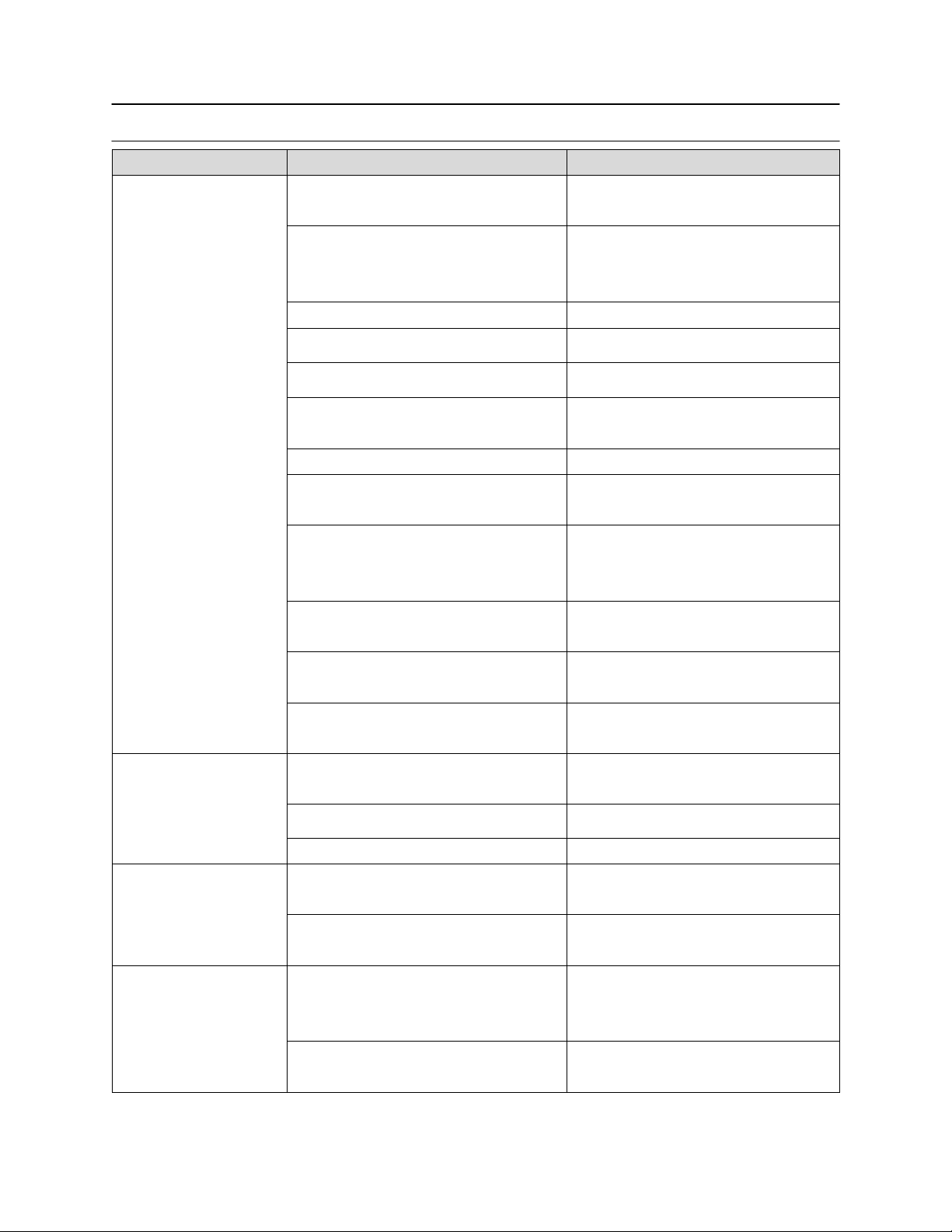

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE

CORRECTIVE

ACTION

Excessive

vibration

Loose compressor, motor, or

guard

Tighten components

Excessive discharge pressure

Reduce operating

pressure

Compressor not level

Level compressor

Leg bolts tightened too tightly to

floor

Loosen leg bolts

Wrong oil being used

Drain and replace

with proper oil

Loose flywheel, drive pulley or

drive belts

Tighten loose

components and

check belts

Worn rods, wrist pin or main

bearings

Check and replace

worn parts

Compressor

uses to

much

oil

Clogged inlet filter

Clean inlet filter or

replace if necessary

Wrong oil being used, wrong

viscosity

Drain and replace

with proper oil

Oil level too high

Fill compressor with

oil to proper level

Crankcase breather valve

malfunction

Replace crankcase

breather

Compressor operating outside

in cold conditions or inlet filter

not protected against weather

Provide adequate

protection against

extreme weather

conditions

Worn piston rings

Replace piston rings

Piston rings not seated

Allow for 100hrs of

normal operation for

rings to seat

Compressor runs unloaded too

long

Increase load or

stop compressor

when not needed

(check for air leaks)

o

14

Page 15

COMPRESSOR MAINTENANCE LOG

DATE

TYPE OF MAINTENANCE OR REPAIR

15

Page 16

FACTORY SERVICE CENTERS

HEAD OFFICE

REGIONAL OFFICE

REGIONAL OFFICE

1950 Forbes Street

11771 Hammersmith Way

6389 boul. Couture

Whitby, ON L1N 7B7

Richmond, BC V7A 5H6

St. Leonard, PQ H1P 3J5

(905) 571-2200

(604) 272-3104

(514) 323-1223

1-800-263-3734

1-800-663-0909

1-800-361-7049

Alberta

Nova Scotia

Quebec

#8 – 6115 4th St. S.E.

202 Brownlow Avenue

1140 rue Begin

Calgary, AB T2H 2H9

Dartmouth, NS B3B 1T5

St. Laurent, PQ H4R 1X1

(403) 243-3995

(902) 468-7064

(514) 745-5025

1-800-267-0445

1-800-625-4821

1-888-745-5025

Ontario

1200 St. Jean Baptiste,

11614 – 149th Street

1950 Forbes Street

Unit # 106

Edmonton, AB T5M 3R5

Whitby, ON L1N 7B7

Les Saules, PQ G2E 5E8

(780) 455-6644

(905) 571-2200

(418) 871-5720

1-888-455-6644

1-800-263-3734

1-800-663-5757

British Columbia

6389 boul. Couture

11771 Hammersmith way

6350 Tomken Rd, Unit B

St. Leonard, PQ H1P 3J5

Richmond, BC V7A 5H6

Mississauga, ON L5T 1Y3

(514) 323-1223

(604) 272-3104

(905) 670-7255

1-800-361-7049

1-800-663-0909

1-800-221-9811

Saskatchewan

2284 Holdom Ave

210 Colonnade Rd., Unit 11

206A-2750 Faithful Ave

Burnaby, BC V5B 4Y5

Nepean (Ottawa), ON K2E 7K5

Saskatoon, SK S7K 6M6

(604) 291-1511

(613) 224-5022

(306) 931-0111

1-877-295-1511

1-888-560-2214

1-888-931-0111

Manitoba

1670 St. James Street

317 Adelaide St. S. Unit 117

Winnipeg, MB R3H 0L3

London, ON N5Z 3L3

(204) 694-0402

(519) 686-3115

1-800-550-5073

1-800-571-0899

When you need service:

Send complete tool (prepaid)

to one of the Makita Factory

Service Centers listed, or to

an Authorized Makita Service

Center. Be sure to attach a

letter to the outside

of the

carton detailing the problem

with your tool.

Date Purchased:

Dealer’s Name and Address:

Model No:

Serial No:

16

Page 17

MAKITA WARRANTY

MAKITA LIMITED ONE YEAR WARRANTY

WARRANTY POLICY

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is

warranted to be free of defects from workmanship and materials for the period of ONE

YEAR from the date of original purchase. Should any trouble develop during this one

year period, return the COMPLETE tool, freight prepaid, to one of Makita’s Factory or

Authorized Service Centers. If inspection shows the trouble is caused by defective

workmanship or material, Makita will repair, (or at our option, replace) without charge.

This warranty does not apply where:

- Repairs have been made or attempted by others;

- Repairs are required because of normal wear and tear;

- The tool has been abused, misused or improperly maintained;

-

Alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES FROM THE SALE OR USE O

F THE PRODUCT. THIS

DISCLAIMER APPLIES BOTH DURING AND AFTER THE TERM OF THIS

WARRANTY.

-The Makita warranty is the only and entire written warranty given by Makita for

Makita tools. No dealer or his agent or employee is authorized to extend or enlarge

upon this warranty by any verbal or written statement or advertisement.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES, INCLUDING

WARRANTIES OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC

PURPOSE,” A

FTER THE ONE YEAR TERM OF THIS WARRANTY.

This warranty gives you specific legal rights. The provisions contained in this warranty

are not intended to limit, modify, take away from, disclaim or exclude any warranties set

forth in any provincial legislation. To the extent required by law, the provisions in any

provincial or federal legislation with respect to warranties take precedence over the

provisions in this warranty.

Makita Canada Inc.

1950 Forbes Street

Whitby, ON L1N 7B7

17

Page 18

Compresseur

AVIS

Portatif

Électrique

Manuel d’utilisation

www.makita.ca

Veuillez lire le présent manuel d’utilisation avant d’essayer

d’utiliser ce compresseur.

MODÈLE # MAC3001 SERIAL #

Page 19

Force

3

PCM @ 40 LPC

6.54

PCM @ 100 LPC

6

Pression de démarrage

100 PSI

Pression d’arrêt

125 PSI

Diamètre du piston

55 mm

Course

45 mm

Voltage – 1 Phase

120V – 220V

RPM du moteur

3450

Ampère @ pression maximum

15

Dimensions du réservoir

8 Gallon Réservoir Double

CSA/US Approuvé

Oui

Lire les directives de sûreté et

les

instructions soigneusement avant l’opération.

MANUEL D’UTILISATION POUR

Compresseur d’air lubrifié à l’huile

MODEL NO.

MAC3001

SPÉCIFICATIONS

Circuit Requis: 15 AMPS

* Un disjoncteur est préféré. Utiliser seulement un fusible ou un

disjoncteur qui est le même calibre que le circuit qu’est branché le

compresseur d’air est opéré. Si le compresseur est branché a un

circuit protégé d’une fusible, utiliser un fusible retard.

www.makita.ca

IMPORTANT:

TOUTES

Page 20

MAC3001

www.makita.ca

Protection d’audition d’usage.

Protection visuelle d’usage.

Protection respiratoire d’usage.

Lire le manuel d’instruction

Page 21

Veuillez lire le présent manuel

d’utiliser ce compresseur.

TABLE DES MATIÈRES

SPÉCIFICATIONS ………………………………………………………..

19

CONSIGNES DE SÉCURITÉ ……………………………………………

22

Précautions ……………………………………………………………

22

Réservoir d’air ………………………………………………………...

22

Soupape de sécurité ………………………………………………….

23

DIRECTIVES D’INSTALLATION ET D’OPÉRATION ………………..

23

Rallonges électriques ………………………………………………..

23

Installation ……………………………………………………………..

24

Avant d’utiliser le compresseur d’air ……………………………….

24

Lubrification du compresseur ……………………………………….

24

Vidanges d’huile ………………………………………………………

25

Entretien ……………………………………………………………….

26

Vérification de la tension de la courroie ………………………….

26

MODE D’EMPLOI DE VOTRE COMPRESSEUR D’AIR …………….

27

PROGRAMME D’ENTRETIEN ………………………………………….

29

DÉPANNAGE ……………………………………………………………..

30

NOTATION D’ENTRETIEN DU COMPRESSEUR ……………………

35

GARANTIE MAKITA ……..………………………………………………

36

CENTRES DE SERVICES EN USINE ………………………………….

37

LISTE DE PIÈCES ………………………………………………………..

38

In English …………………………………………………………………..

1

d’utilisation avant d’essayer

21

Page 22

NE JAMAIS SOUDER, PERCER OU MODIFIER LE RÉSERVOIR

D’AIR DE QUELQUE MANIÈRE QUE CE SOIT.

ATTENTION

AVERTISSEMENT

CONSIGNES DE SÉCURITÉ

Veuillez vous familiariser avec les renseignements qui suivent, afin d’éviter

d’endommager votre compresseur et de blesser l’operateur.

PRÉCAUTIONS

Le moteur et le compresseur d’air se réchauffent en

cours de fonctionnement. Ne touchez jamais la

tuyauterie d’échappement, le moteur ou la pompe du compresseur en

cours de fonctionnement.

L’air comprimé provenant de l’appareil peut contenir

des émanations nocives. L’air comprimé produit par

ce compresseur n’est pas respirable. Portez toujours un respirateur

lorsque vous pulvérisez de la peinture ou des produits chimiques, ou que

vous faites de sablage par jet. Portez toujours des lunettes de sécurité ou

des lunettes étanches de sécurité lorsque vous travaillez avec de l’air

comprimé.

Il n’est ni pratique ni possible de vous avertir de tous les dangers ilés à

l’utilisation ou l’entretien de cet équipement. Vous devez donc faire preuve

de jugement.

RÉSERVOIR D’AIR

La surpression du réservoir d’air peut provoquer des blessures ou des

dommages matériels. Pour prévenir toute surpression, une soupape de

sureté réglée en usine a été posée.

Achetez seulement des pièces de rechange conformes aux mêmes

spécifications que les pièces originales. Pour obtenir des pièces de

rechange ou des spécifications, veuillez communiquer avec le

concessionnaire agréé.

22

Page 23

NE PAS ENLEVER, ALTÉRER OU

REMPLACER CETTE SOUPAPE!

CONSIGNES DE SÉCURITÉ

Table 1 – Jauge minimum du cordon

Tension

Longueur totale du cordon

120V

25pi

50pi

100pi

150pi

Supérieur a

Inferieur ou égal a

AWG

0

6

18

16

16

14 6 10

18

16

14

12

10

12

16

16

14

12

12

16

14

14

Pas Recommandé

SOUPAPE DE SÉCURITÉ

Cette soupape a été posée en usine afin de prévenir toute surpression du

réservoir d’air. La soupape est réglée en usine à une limite donnée qui

dépend du modèle spécifique de votre appareil; elle ne doit jamais être

altérée.

Tout réglage effectue par l’utilisateur annule automatiquement la garantie.

INSTALLATION ET OPÉRATION

RALLONGES ÉLECTRIQUES

Assurez-vous que la rallonge électrique est en bon état. Lorsque vous

utilisez une rallonge électrique, assurez-vous que le fil est assez gros pour

supporter l’intensité de courant dont votre appareil a besoin. Une rallonge

électrique de capacité insuffisante provoquera une chute de tension de

secteur, ce qui entrainera une perte de puissance et une surchauffe. Le

Table 1 donne les grosseurs de fil correctes en fonction de la longueur du

cordon et du courant nominal qui apparaît sur la plaque signalétique. En

cas de doute, utilisez le fil de grosseur immédiatement supérieur. Plus le

numéro de jauge est petit, plus il est supérieur.

Courant nominal (A)

23

Page 24

VÉRIFIEZ TOUJOURS LE NIVEAU ET LA QUALITÉ DE

L’HUILE AVANT DE METTRE LE COMPRESSEUR EN

ET NE

L’APPAREIL EST EN MARCHE. UTILISEZ SEULEMENT

INSTALLATION ET OPÉRATION

INSTALLATION

La prudence ainsi qu’un entretien et une lubrification convenables assurent

la longévité de cet appareil. Le compresseur doit toujours être à niveau

pour assurer une lubrification suffisante. Ne serrez pas trop les boulons

d’ancrage car cela pourrait provoquer des vibrations excessives. Utilisez

cet appareil seulement dans un lieu propre, sec et bien aéré. Le

compresseur est muni d’ailettes afin d’assurer un refroidissement suffisant.

Gardez les ailettes, ainsi que les autres pièces auxquelles adhère la

poussière, propres. Ne déposez rien (chiffons ou autre matériel) sur le

compresseur, car ces objets nuisent au refroidissement et peuvent

présenter un risque d’incendie.

AVANT D’UTILISER LE COMPRESSEUR D’AIR

VEUILLEZ PROCÉDER AUX VÉRIFICATIONS SUIVANTES AVE SOIN:

1) Vérifiez que les écrous et les boulons sont tous bien serrés.

2) Vérifiez que l’appareil contient une quantité suffisante d’huile, de

qualité convenable.

3) Si les filtres d’aspiration sont sales, remplacez ou nettoyez-les.

LUBRIFICATION DU COMPRESSEUR

24

MARCHE. NE RAJOUTEZ JAMAIS DE L’HUILE

CHANGEZ JAMAIS L’HUILE PENDANT QUE

UNE HUILE NON-DÉTERGENTE RECOMMANDÉE.

Page 25

INSTALLATION ET OPÉRATION

VIDANGES D’HUILE

L’huile à compresseur est une huile minérale non-détergente qui contient

des additifs qui contribuent

à prévenir l’accumulation de carbone, à

prolonger la durée de vie des segments et

à réduire la consommation

d’huile, et qui est conçue pour fonctionner

à une température ambiante de

0

C à 30 C (32 F à 86 F).

HUILE RECOMMANDÉE:

Huile à compresseur:

# EAOIL10 (1 Litre)

*Le compresseur est initialement rempli d’huile SAE 20W (ISO 68)

AUTRES HUILES APPROUVÉES:

On peut utiliser des huiles minérales ordinaires dan

s les compresseurs

Makita. Utilisez toujours une huile non détergente conforme aux

spécifications suivantes

:

TEMPÉRATURES AMBIANTES AU

POINT DE FONCTIONNEMENT

SAE

VISCOSITÉ

ISO

VISCOSITÉ

-16°C à 0°C (3.2°F à 32°F)

SAE 10W

ISO 32

1°C à 26°C (33.8°F à 78.8°F)

SAE 20W

ISO 68

Supérieures à 27°C (80.6°F)

SAE 30W

ISO 100

PREMIÈRE VIDANGE D’HUILE A FAIRE APRÈS 100 HRS

CHANGEZ L’HUILE TOUTES LES 300 HEURES OU TOUS LES 3

MOIS, SELON LA PREMIÈRE ÉVENTUALITÉ.

1) Enlevez le bouchon de vidange d’huile. Laissez toute l’huile s’écouler.

2)

Remettez le bouchon de vidange d’huile.

3) Remplissez avec l’huile recommandée, jusqu’au niveau approprié.

REMPLISSAGE D’HUILE DU COMPRESSEUR

1) Enlevez le bouchon de remplissage d’huile.

2) Versez lentement l’huile appropriée dans le carter de pompe.

3) Assurez-vous de toujours garder le niveau d’huile au milieu de regard.

22

25

Page 26

INSTALLATION ET OPÉRATION

1)

Débranchez le bloc d’alimentation.

2)

Enlevez le capot de courroie.

3)

Désserrez les boulons du moteur et glissez le moteur vers la tête du

compresseur juste assez pour pouvoir enlever la courroie usée.

4)

Installez une courroie de rechange appropriée.

5)

Éloignez le moteur de la tête du compresseur juste assez pour établir la tension

recommandée, tel qu’illustré au schéma Figure A.

6)

Alignez la courroie en appuyant un reflet d’ajusteur contre le bord de la poulie.

7)

Resserrez les boulons de moteur.

8)

Assurez-vous que les poulies du moteur et du compresseur sont solidement

attachées. Vérifiez à nouveau l’alignement.

9)

Remettez le capot de courroie et rebranchez le bloc d’alimentation.

10)

La tension de courroie doit être vérifiée âpres 20 heures de fonctionnement.

Vérifiez ensuite la tension tous les mois.

Avant de procéder à tout entretien ou réglage de votre compresseur

d’air, veuillez prendre les précautions suivantes:

Figure A

Distance du milieu

Trop tendu

Trop détendu

Bonne tension

en arc

ENTRETIEN

¾ ARRÊTEZ LE COMPRESSEUR ET CONSIGNEZ-LE.

¾ RELÂCHEZ L’AIR COMPRIMÉ QUI SE TROUVE DANS LE

RÉSERVOIR D’AIR ET DANS LES CONDUITES D’AIR.

VÉRIFICATION DE LA TENSION DE LA COURROIE

Réglez la courroie de manière à ce que lorsqu’une charge est appliquée au

centre, la courroie fléchit d’environ 1/2 po (voir le schéma Figure A ci-

dessous). Si la courroie est trop tendue, cela peut surcharger le moteur.

Si la courroie est trop lâche, elle patinera, ce qui entrainera une usure et

des vibrations excessives.

un peu

COMMENT POSER UNE NOUVELLE COURROIE EN CAS DE BESOIN

26

Page 27

MODE D’EMPLOI

ENTRAINEMENT ÉLECTRIQUE A DOUBLE COMMANDE

1) Inspectez l’appareil au complet afin de déceler tout signe de dommage.

2) Vérifiez le niveau d’huile du compresseur; remplissez-le ou ajoutez de

l’huile au besoin.

3) Le bouton de sélection arrêt-automatique (« Off/Auto ») du pressostat

doit être en position d’arrêt (« Off »)

4) Branchez le cordon électrique dans une prise de courant convenable.

5) Commande marche-arrêt (pressostat)

a) Le robinet d’arrêt du dispositif de délestage pilote doit être fermé (le

bouton « moleté » au-dessus de dispositif de délestage pilote doit

être vissé à fond vers le bas).

b) Tournez le bouton de sélection arrêt-automatique (« Off/Auto ») de

pressostat en position de mode automatique (« Auto »). Le moteur

électrique devrait se mettre en marche à ce stade et remplir le

réservoir d’air comprimé jusqu'à ce que la pression de coupure soit

attente. Le compresseur devrait s’arrêter et rester arrêté jusqu'à ce

que la pression dans le réservoir d’air atteigne la pression

d’enclenchement. L’appareil continuera à suivre automatiquement ce

cycle jusqu'à ce qu’on l’arrête.

6) Commande en fonctionnement continu (dispositif de délestage pilote)

a. Ouvrez le robinet d’arrêt du dispositif de délestage pilote (le bouton

« moleté » au-dessus de dispositif de délestage pilote doit être

dévissé à fond vers le haut).

b. Tournez le bouton de sélection arrêt-marche (« Off/Auto ») vers la

position de mode automatique (« Auto »); le moteur électrique

devrait alors se mettre en marche et remplir le ou les réservoirs d’air

comprimé jusqu'à ce la pression maximale soit atteinte. Pour

enclencher le fonctionnement continu, vissez le bouton « moleté » à

fond vers le bas. Votre compresseur se mettra au ralenti et

continuera de tourner au ralenti une fois la pression maximale

atteinte. Lorsque la pression d’enclenchement est atteinte, les

robinets de délestage seront désactives et l’appareil se remettra à

fournir de l’air comprime. L’appareil continuera de fonctionner en

mode automatique jusqu'à ce qu’on l’arrête (en tournant le bouton

de sélection arrêt-automatique – en position d’arrêt – « Off » - et/ou

en coupant le courant).

27

Page 28

FAIRE PREUVE D’UNE EXTRÊME PRUDENCE POUR ÉVITER TOUTE

`A

MODE D’EMPLOI

ENTRAINEMENT ÉLECTRIQUE A DOUBLE COMMANDE

c. Lorsque le moteur tourne rond, le compresseur remplit le réservoir

d’air comprimé. Une fois la pression maximale atteinte (selon le

réglage du module de commande a robinet pilote), le moteur et le

compresseur se mettent au ralenti; il se remet à tourner à plein

régime lorsque la pression d’enclenchent est atteinte. L’appareil

continuera à suivre automatiquement ce cycle jusqu'à ce qu’on

arrête l’appareil.

d. Arrêt du moteur. Tournez le commutateur du moteur en position

d’arrêt (« Off »).

7) Vous pouvez passer à tout moment du mode arrêt-marche au mode de

fonctionnement continu et vice-versa en ouvrant ou en fermant le robinet

du dispositif de délestage pilote.

ENTRAINEMENT ÉLECTRIQUE

1) Inspectez l’appareil afin de déceler tout signe de dommage.

2) Vérifiez le niveau d’huile du compresseur; remplissez-le ou ajoutez de

l’huile au besoin.

3) Le bouton de sélection arrêt-automatique (« Off/Auto ») du pressostat

doit être en position d’arrêt (« Off »).

4) Branchez le cordon électrique dans une prise de courant convenable.

Si le compresseur n’est pas muni d’une fiche male, demandez à un

électricien d’en poser une.

5) Commande marche-arrêt (pressostat)

a. Tournez le bouton de sélection arrêt-automatique (« Off/Auto ») du

pressostat en position de mode automatique (« Auto »). Le

moteur électrique devrait se mettre en marche à ce stade et

remplir le réservoir d’air comprimé jusqu'à ce que la pression de

coupure soit atteinte. Le compresseur devrait s’arrêter et rester à

l’arrêt jusqu'à ce que la pression dans le réservoir d’air atteigne la

pression d’enclenchement. L’appareil continuera à suivre

automatiquement ce cycle jusqu'à ce qu’on tourne le bouton du

pressostat en position d’arrêt (« Off »).

BLESSURE LORSQU’ON TRAVAILLE AVEC TOUT COMPRESSEUR

COMMANDE AUTOMATIQUE.

28

Page 29

PROGRAMME D’ENTRETIEN

ENTRETIEN QUOTIDIEN OU PRÉCÉDANT CHAQUE UTILISATION

ENTRETIEN HEBDOMADAIRE

ENTRETIEN MENSUEL

ENTRETIEN TRIMESTRIEL OU A TOUTES LES 300 HEURES

¾ Vérifiez le niveau d’huile

¾ Drainez l’eau condensée du réservoir d’air

¾ Vérifiez l’absence de toute vibration et de tout bruit inhabituels

¾ Vérifiez que tous les boulons et tous les écrous sont convenablement

serres

¾ Coupez le courant. Nettoyez la culasse, le moteur, les pales de

ventilateur, le refroidisseur intermédiaire et le réservoir d’air pour

éliminer la poussière et les corps étrangers

¾ Nettoyez le filtre à air : ouvrez le filtre à air, enlevez l’élément filtrant et

nettoyez-le à fond avec de l’eau savonneuse. Rincez-le à fond et faites-

le sécher complètement avant de tout remonter

¾ Les filtres usés doivent être remplacés

¾ Vérifiez l’état d’usure des courroies trapézoïdales

¾ Vérifiez l’étanchéité de l’appareil

¾ Resserrez les raccordements si des fuites sont décelées

¾ Vérifiez que les courroies trapézoïdales sont convenablement tendues

¾ Vérifiez que les poulies du compresseur et du moteur sont

convenablement alignées et solidement attachées

¾ Inspectez le réservoir d’air afin de déceler toute trace de corrosion ou

d’autres dommages

¾ Changez l’huile du compresseur

¾ Remplacez le filtre à air (ceci doit être fait plus souvent si le

compresseur fonctionne près d’un lieu ou l’on pulvérise de la peinture ou

dans un lieu poussiéreux)

29

Page 30

DÉPANNAGE

PROBLÈME

CAUSE POSSIBLE

MESURE

CORRECTIVE

Ne démarre

pas

Vérifiez le bloc d’alimentation

Vérifiez que l’appareil est

effectivement alimenté

Basse

pression

Soupape de sureté qui fuit

Remplacez la soupape de

sureté

Robinet de purge ouvert

Fermez le robinet de purge

Desserrement de tuyaux ou de

raccords

Resserrez les raccords

Filtre à air encrassé ou obstrué

Nettoyez ou remplacez s’il y a

lieu

Robinet de délestage

défectueux

Remplacez le robinet de

délestage

Refoulement

d’huile

Huile de viscosité inappropriée

Évacuez et remplacez l’huile

Excès d’huile dans le carter

Évacuez l‘huile et remplissez

d’huile jusqu’au niveau

approprié

Surchauffe du compresseur

Le réglage de pression d’air

est trop élevé

Filtre à air obstrué

Nettoyez ou remplacez le

filtre à air

Segments de piston usés

Remplacez les segments de

piston

Le

compresseur

surchauffe

Filtre d’entrée obstrué

Nettoyez ou remplacez s’il y a

lieu

Compresseur, tête, cylindre et

refroidisseur intermédiaire

sales

Nettoyez à l’air comprimé

Pression de fonctionnement

trop élevé

Diminuez la pression de

fonctionnement

Manque d’huile ou mauvais

type d’huile

Évacuez et remplacez l’huile

Le cycle de fonctionnement du

compresseur est trop long

: un

cycle de fonctionnement

convenable est de 50 à 60 %

en mode marche

-arrêt et de 75

à 80 % en mode continu

Augmentez la période de

repos entre les cycles

30

Page 31

DÉPANNAGE

PROBLÈME

CAUSE POSSIBLE

MESURE

CORRECTIVE

Fréquence

trop élevée

de marche et

d’arrêt du

compresseur

ou de la

marche à vide

Fuites du système d’air

comprim

Remplacez les com-

posants usés s’il y a lieu

Courroies d’entrainement

usées ou molles

Tendez les courroies

trapézoïdales ou

remplacez-les

Réglage trop serré de la

différence de pression du

robinet pilote ou du pressostat

Faites les réglages qui

s’imposent

Défaillance d’éléments de

robinetterie du compresseur

Remplacez les robinets

La capacité du compresseur

est trop faible pour l’utilisation

prévue

Le moteur

cale

Robinet de délestage ou clapet

de non

Remplacez le robinet de

délestage ou le clapet de

non-retour

Erreur de montage d’éléments

de robinetterie

Montez les éléments de

robinetterie correctement

Courroies d’entrainement trop

tendues

Tendez les courroies

trapézoïdales

Cognement

du

compresseur

Les soupapes du compresseur

sont desserrées ou brisées

Faites une inspection et

remplacez les soupapes

usées ou brisées

Inspectez le clapet de nonretour, qui pourrait émettre un

cognement à basse pression

Démontez et nettoyez le

clapet de non

Segments de

piston mal

assis

Le compresseur n’a pas

fonctionné assez

longtemps

pour que les segments de

piston soient assis

convenablement

Prévoyez 100 heures de

fonctionnement normal

pour bien asseoir de

nouveaux segments

Mauvais type d’huile utilisé,

viscosité incorrecte

Évacuez l’huile et

remplacez

la par une

huile de type approprié

é

-retour défectueux

-retour

-

31

Page 32

PROBLÈME

CAUSE POSSIBLE

MESURE CORRECTIVE

Basse

pression de

refoulement

ou débit

refoule

insuffisant

Filtres d’entrée obstrué

Nettoyez ou remplacez s’il

y a lieu

Fuites dans les conduites ou

la robinetterie d’air

comprimé

Remplacez les composants

usé

Robinet de purge laisse

ouvert

Fermez le robinet de purge

Manomètre défectueux

Remplacez le manomètre

Mauvais choix de

dimensions du compresseur

Joint de culasse qui fuit

Remplacez le joint de

culasse

Canalisations du

refroidisseur intermédiaire

encrassées ou bouchées

Démontez et nettoyez les

canalisations du

refroidisseur intermédiaire

Robinet de marche à vide ou

pressostat réglé à une

pression trop basse ou

défectueuse

Remplacez les pièces

usées

Usure ou défaillance

d’éléments de robinetterie du

compresseur

Remplacez les pièces

usées

Piston ou segments de

piston uses

Remplacez les pièces

usées

Étranglement au niveau du

clapet

Inspectez le clapet de nonretour et remplacez-le au

besoin

DÉPANNAGE

s s’il y a lieu

, etc.

32

de non-retour

Page 33

DÉPANNAGE

PROBLÈME

CAUSE POSSIBLE

MESURE CORRECTIVE

Eau dans le

carter

Décomposition

de l’huile

Huile sale,

robinetterie ou

cylindres

rouille

Cycle trop court, le

compresseur ne fonctionne

pas assez longtemps pour

vaporiser la condensation lors

de la compression

Permettez un cycle de

fonctionnement plu

long

Le compresseur fonctionne à

l’extérieur par tem

s froid ou

le filtre d’entrée n’est pas

protégé contre les intempéries

Protégez le système

convenablement contre

les conditions

météorologiques

exceptionnelles

La pression du système à

causer de fuites en sens

inverse par le clapet de nonretour

Inspectez le clapet de

non

retour et remplacez-

le au besoin

Mauvais type d’huile

Évacuez l’huile et

remplacez

la par une

huile de type approprie

Vibration

excessive

Desserrement du

compresseur, du moteur ou du

capot

Resserrez les

composants

Pression de refoulement

excessive

Diminuez la pression de

fonctionnement

Compresseur incline

Mettez le compresseur à

niveau

Boulons d’ancrage des pieds

trop serrés

Desserrez les boulons

des pieds

Mauvais type d’huile

Évacuez l’huile et

remplacez

la par une

huile de type approprie

Desserrement du volant, de la

poulie ou de la courroie

d’entrainement

Resserrez les

composants desserres

et inspectez les

courroies

p

-

-

s

33

-

Page 34

DÉPANNAGE

PROBLÈME

CAUSE POSSIBLE

MESURE CORRECTIVE

Consommation

d’huile

excessive

Filtre d’entrée obstrué

Nettoyez le filtre d’entrée

ou remplacez

le s’il y a lieu

Mauvais type d’huile

utilisé, viscosité incorrecte

Évacuez l’huile et

remplacez

la par une huile

de type

Niveau d’huile trop élevé

Remplissez le compresseur

d’huile jusqu’au niveau

appropri

Soupape de respiration du

carter défectueuse

Remplacez la soupape de

respiration du carter

Le compresseur marche à

vide trop longtemps

Augmentez la charge du

compresseur ou arrêtez-le

lorsqu’il n’est pas utilise

(vérifiez l’étanchéité/la

pression d’air)

Le compresseur

fonctionne

l’extérieur par

tem

d’entrée n’est pas protégé

contre les intempéries

Protégez le système

convenablement contre les

conditions météorologiques

exceptionnelles

Segments de piston usés

Remplacez les segments

de piston

approprié

é

à

ps froid ou le filtre

-

-

34

Page 35

NOTATION D’ENTRETIEN DU COMPRESSEUR

DATE

TYPE D’ENTRETIEN OU DE REPARATION

35

Page 36

GARANTIE MAKITA

GARANTIE LIMITÉE DE MAKITA D’UN AN

POLICE DE GARANTIE

Chaque outil Makita est inspecté

et soigneusement éprouvé avant de quitter l’usine. Il

est garanti pendant UN AN, à compter de la date d’achat originale, contre tout vice de

matière de fabrication. En cas de panne durant cette période d’un an, veuillez retourner

l’outil au COMPLET, en port payé à l’un des centres de service après-vente agréé

Makita. S’il est évident que la panne a été causé par un défaut matériel ou de

fabrication, Makita réparera (ou a notre choix, remplacera) l’outil gratuitement.

Cette garantie ne s’aurait être invoquée dans le cas ou:

-

Les réparations on été exécutées ou attentées par d’autres;

- L’entretien normal est requis;

- L’outil a été utilisé

d’une manière abusive, inadéquate ou a été mal entretenu;

- L’outil a subi des modifications quelconques.

EN AUCUN CAS MAKITA NE SAURAIT ENDOSSER UNE RESPONSABILITÉ

QUELCONQUE POUR DES DOMMAGES INDIRECTS OU FORTUITS

CONSÉCUTIVEMENT `A LA VENTE ET `A L’UTILISATION DE SES PRODUITS.

CETTE DÉNÉGATION RESTERA VALIDE DURANT LA GARANTIE ET APRÈS SON

EXPIRATION

La garantie Makita est l’unique et entière garantie écrit applicable aux outils de cette

marque. Aucun distributeur, ni aucun revendeur ou employé d’un distributeur n’est

autorisé

à prolonger ou amplifier les termes de cette garantie, que ce soit verbalement,

par écrit ou par publicitaire.

MAKITA REFUSERA D’ENDOSSER, APRÈS L’EXPIRATION DU DÉLAI D’UN AN. UNE

GARANTIE IMPLICITE QUELCONQUE, `A L’INCLUSION DES GARANTIES

IMPLICITES DE VENDABILITE´ ET D’APTITUDE.

Cette garantie vous confiè

re certains droits et ses termes et conditions n’ont aucunement

pour objet de limiter, modifier, denier ou exclure les garanties promulguées par acte

législatif provincial. Tel qu’exige par la loi, toute provision législative fédérale ou

provinciale touchant aux garanties aura la présence sur celle contenues dans cette

garantie.

Makita Canada Inc.

1950 Forbes Street

Whitby, ON L1N 7B7

36

Page 37

CENTRES DE SERVICE EN USINE

SIEGE SOCIAL

BUREAU RÉGIONAL

BUREAU RÉGIONAL

1950 Forbes Street

11771 Hammersmith Way

6389 boul. Couture

Whitby, ON L1N 7B7

Richmond, BC V7A 5H6

St. Léonard, PQ H1P 3J5

(905) 571-2200

(604) 272-3104

(514) 323-1223

1-800-263-3734

1-800-663-0909

1-800-361-7049

Alberta

Nouvelle-Écosse

Québec

#8 – 6115 4th St. S.E.

202 Brownlow Avenue

1140 rue Begin

Calgary, AB T2H 2H9

Dartmouth, NS B3B 1T5

St. Laurent, PQ H4R 1X1

(403) 243-3995

(902) 468-7064

(514) 745-5025

1-800-267-0445

1-800-625-4821

1-888-745-5025

Ontario

1200 St. Jean Baptiste,

11614 – 149th Street

1950 Forbes Street

Unit # 106

Edmonton, AB T5M 3R5

Whitby, ON L1N 7B7

Les Saules, PQ G2E 5E8

(780) 455-6644

(905) 571-2200

(418) 871-5720

1-888-455-6644

1-800-263-3734

1-800-663-5757

Colombie-Britannique

6389 boul. Couture

11771 Hammersmith way

6350 Tomken Rd, Unit B

St. Léonard, PQ H1P 3J5

Richmond, BC V7A 5H6

Mississauga, ON L5T 1Y3

(514) 323-1223

(604) 272-3104

(905) 670-7255

1-800-361-7049

1-800-663-0909

1-800-221-9811

Saskatchewan

2284 Holdom Ave

210 Colonnade Rd., Unit 11

206A-2750 Faithful Ave

Burnaby, BC V5B 4Y5

Nepean (Ottawa), ON K2E 7K5

Saskatoon, SK S7K 6M6

(604) 291-1511

(613) 224-5022

(306) 931-0111

1-877-295-1511

1-888-560-2214

1-888-931-0111

Manitoba

1670 St. James Street

317 Adelaide St. S. Unit 117

Winnipeg, MB R3H 0L3

London, ON N5Z 3L3

(204) 694-0402

(519) 686-3115

1-800-550-5073

1-800-571-0899

En cas de besoin de service:

envoyer l’appareil (port payé)

à un Centre de service Makita

ou dans un Centre de service

Makita autoris

é

. S’assurer de

joindre une lettre

à

l’extérieur

de la boite mentionnant le

problème de votre outil en

détail.

Dâte de l’achat :

Nom et adresse du détaillant :

N du modèle :

N de série :

37

Page 38

MAC3001

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Misc.

Item Description Part # Qty

Compressor w/ Flywheel PV01A 1

Discharge Tube w/ Fittings TU-15-AL 1

Wiring Harness 12/3-42-TT50 1

Air Receiver 8TT35X5-M 1

Drain cock IH1850 2

V-Belt 4L530 1

Belt Guard BGC 1

Electric Motor EM0.0-36-1ODV 1

Pilot Unloader/Check Valve NDC29-M 1

Pressure Switch 21UCBDB-CH 1

Motor Pulley MA30X5/8 1

Unloader Tube w/ Fitting TU1/4BLK 3

Safety Valve PSV1/4-150 1

Handle Grip 435016 2

Vibration Damper TT-FOOT 4

Pneumatic Wheel TT-WHEEL 1

Axle WA1001 1

Power Cord w/ Plug 12/3-72-PT 1

Regulator 410029 1

Regulator Gauge 411029 1

Coupler 447013 3

Tank Gauge 411029 1

Triple Manifold Block CPL-MAN 1

Control Panel CNTRLPAN 1

1/8” NPT Elbow (for coupler) 10TT-12 3

¼” NPT Elbow (for Regulator) 10TT-13 1

Regulator Hose (Yellow) TT-HOSE 1

Page 39

PV01A

Item

Description

Part #

Qty

“C” INCLUDES

“B”

INCLUDES

“D” INCLUDES

RINGS + 5, 8, & 16

PARTS 3, 4, & 6

PARTS 5, 6, & 8

1 intake filter assembly MF2-RET 2

2 cylinder head 51121-0101 2

3 lift limiter - discharge valve plate 51121-3102 2

4 valve seat 51121-2101 2

5 valve seat to head gasket 51121-2105 2

6 discharge valve plate 51121-2103 4

8 valve seat to cylinder gasket 51121-2104 2

9 piston 52121-5101 2

10 piston pin c/w snap rings 51121-5112 2

12 connecting rod c/w dipper 51121-5120 2

14 cylinder 52121-4101 2

15 oil filler cap 51111-4719 1

16 cylinder to crankcase gasket 51121-4103 2

Page 40

Item Description Part # Qty

A

B

C

17 oil sight glass c/w gasket 51111-4770 1

18 crankcase 51121-4701 1

19 crankshaft 51121-4601 1

20 front bearing 83501-6205 1

21 rear bearing 83501-6204 1

22 crankcase to rear bearing housing gasket 51121-4704 1

23 rear bearing housing 51121-4703 1

24 oil seal 51121-4708 1

25 crankcase breather 51111-4761 1

26 flywheel c/w fasteners 51121-6601 1

29 connecting (interstage) tubing 51121-7710 1

Misc. 1/4" street elbow (oil drain) STREL1/4 1

Misc. rear bearing snap ring 83610-113025 1

Misc. interstage "Y" fitting 51121-7710 1

Misc. interstage "elbow" fitting 51112-7701 1

Intake filter element kit includes one (1) intake

filter element

Valve repair kit includes:

Valve seat to head gasket (item 5)

Two(2) outlet valve plates (item 6)

Intake valve plate (item 7)

Six(6) valve plate screws

Valve seat to cylinder gasket (item 8)

Ring repair kit includes:

Valve seat to head gasket (item 5)

Valve seat to cylinder gasket (item 8)

Two(2) compression rings

One(1) oil control ring

Cylinder to crankcase gasket (item 16)

D Valve plate assembly (not shown) 51121-2100 2

MAIF35E 2

101000-151 2

101000-255 2

Page 41

Your answers to the following questions are appreciated / Vos réponses aux questions suivantes sont appréciées.

1) This product was purchased from / Ce produit a été acheté dans un:

Home Centre / Centre de produit domestique

Tool distributor / Distributeur d’outil

Hardware – Lumber store / Quincaillerie – Centre de rénovation

Industrial supply / Fournisseur industriel

Construction supply / Fournisseur de matériel de construction

Other / Autre :

2) Use of this product is intended for / Cette appareil est utilise dans :

Construction Trade / Le domaine de la construction

Home maintenance / Entretien résidentiel

Industrial maintenance / Entretien industriel

Hobby / Loisir – passe-temps

Other / Autre :

3) How did you learn about this product / Comment avez-vous entendu parle de ce produit :

Magazine

Newspaper / Journal

Catalogue

Exhibition / Exposition

Dealer / Détaillant

Store Display / Magasin

Radio

Friend / Ami(e)

Previous Usage / Usage précédent

Other / Autre :

4) Most favored points are / Points favoris sont :

Design / Conception

Size / Taille

Repair Service / Service de réparation

Power / Puissance

Features / Caractéristiques

Price / Prix

Durability / Durabilité

Makita Brand / Marque Makita

Other / Autre :

5) Comments / Commentaires :

Telephone:

Age:

Model No. / N° du modèle:

Serial No. / N° de série:

Certificate of Warranty / Certificat de garantie

Mail to Makita / Envoyer a Makita

Month / Mois Day / Jour Year / Année

Date Purchased /

Date de l’achat: Status / Statut Sex / Sexe

Married Single Male Female

Intl. Last name / Company Name / Nom de famille / Nom de l’entreprise Marié Célibataire Homme Femme

Address / Adresse :

Postal Code /

City / Ville : Province : Code Postal :

Area Code /

Code Régional :

Occupation / Profession :

Dealer’s name and address /

Nom et adresse du détaillant :

Under 19 Over 60

19 et moins 20 – 29 30 – 39 40 – 49 50 – 59 60 et plus

Page 42

Stamp

Timbre

Makita Canada Inc.

1950 Forbes Street

Whitby, ON

L1N 7B7

Loading...

Loading...