Page 1

Air Compressor

Compresseur d’air

Manuel d’instructions

Compresor de aire

Manual de instrucciones

MAC100Q

MAC210Q

MAC320Q

Instruction Manual

Page 2

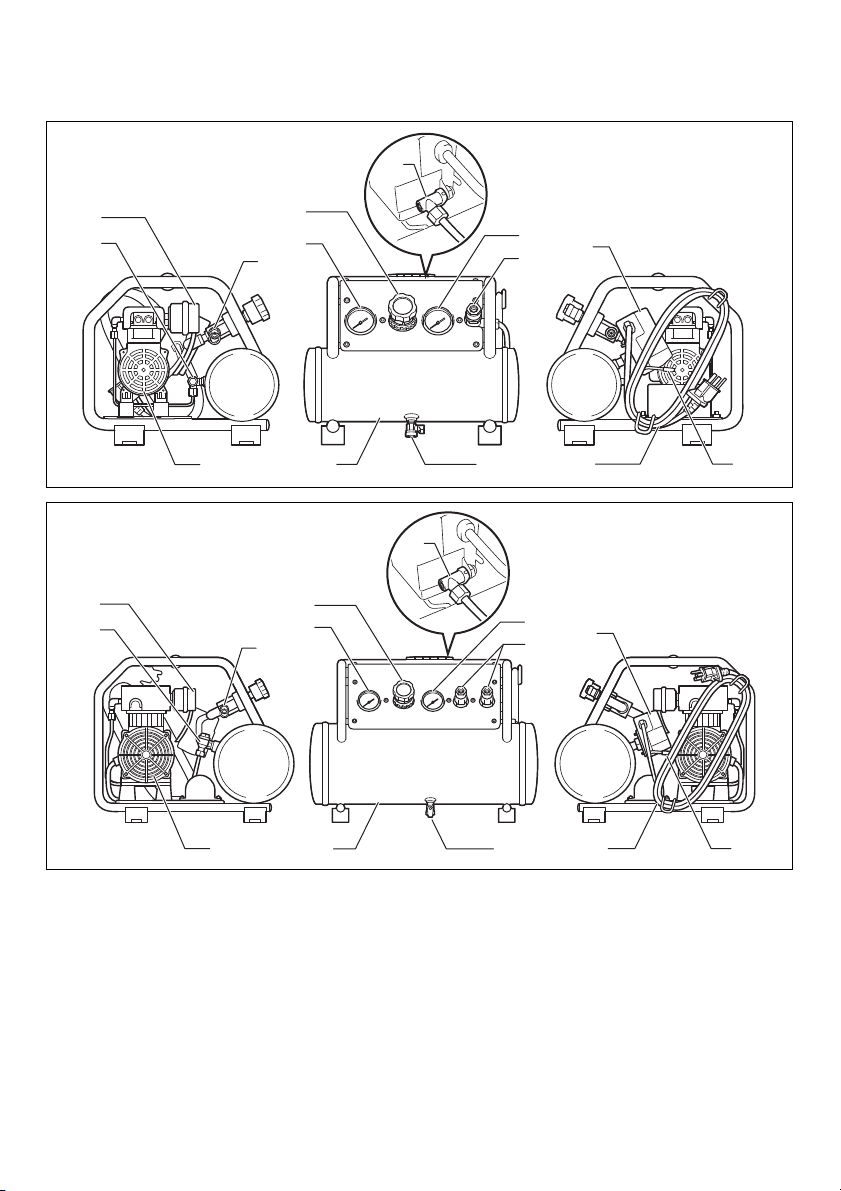

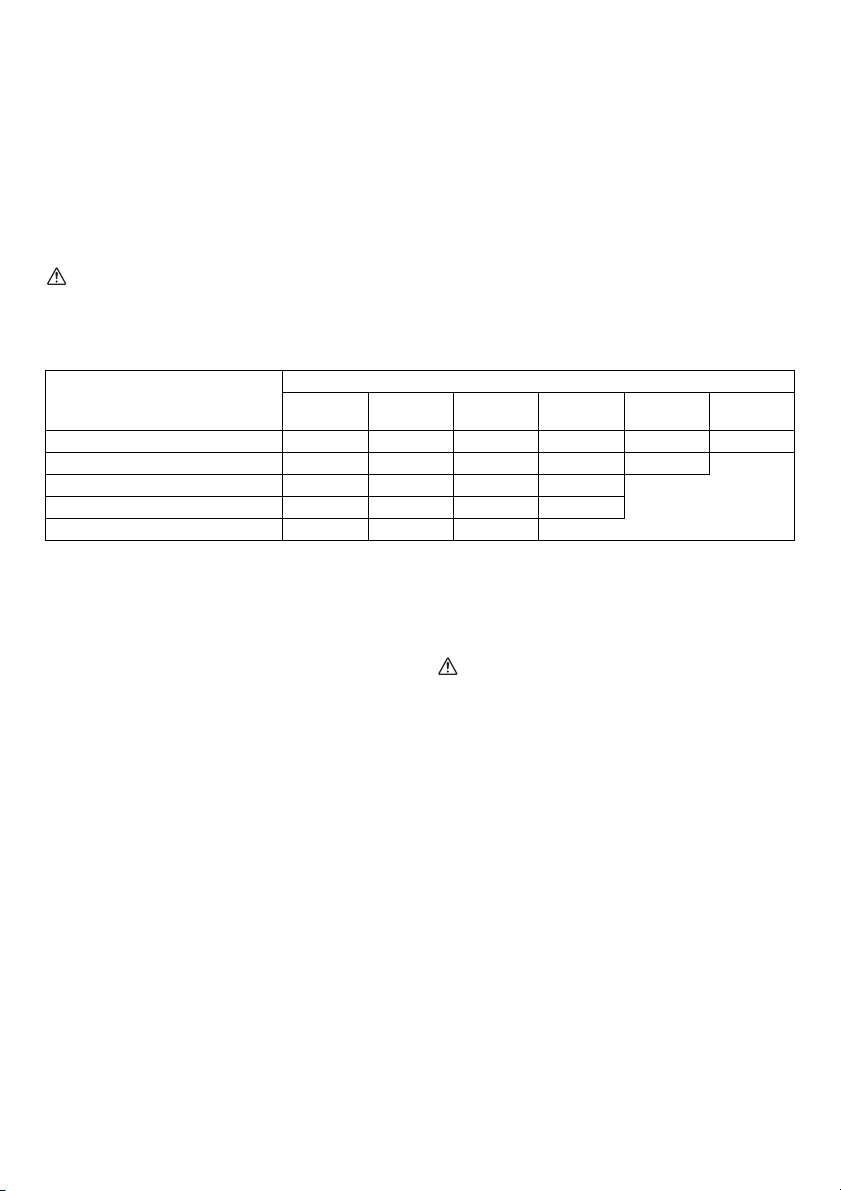

ENGLISH

2

1

3

6

5

7

8

9 10

11

1312

14

4

MAC100Q, MAC210Q

2

1

3

6

5

7

9 10

11

1312

14

8

4

MAC320Q

Parts description

1. Air filter (Air intake)

2. Check valve

3. Safety valve

4. Air compressor pump

5. Regulator

6. Tank pressure gauge

7. Outlet pressure gauge

Note:

The shape of the drain valve differs between MAC100Q and MAC210Q.

2

8. Quick coupler

9. Air tank

10. Drain valve

11. Pressure switch

12. Power cord

13. ON/AUTO-OFF switch

14. Pressure switch unloading valve

Page 3

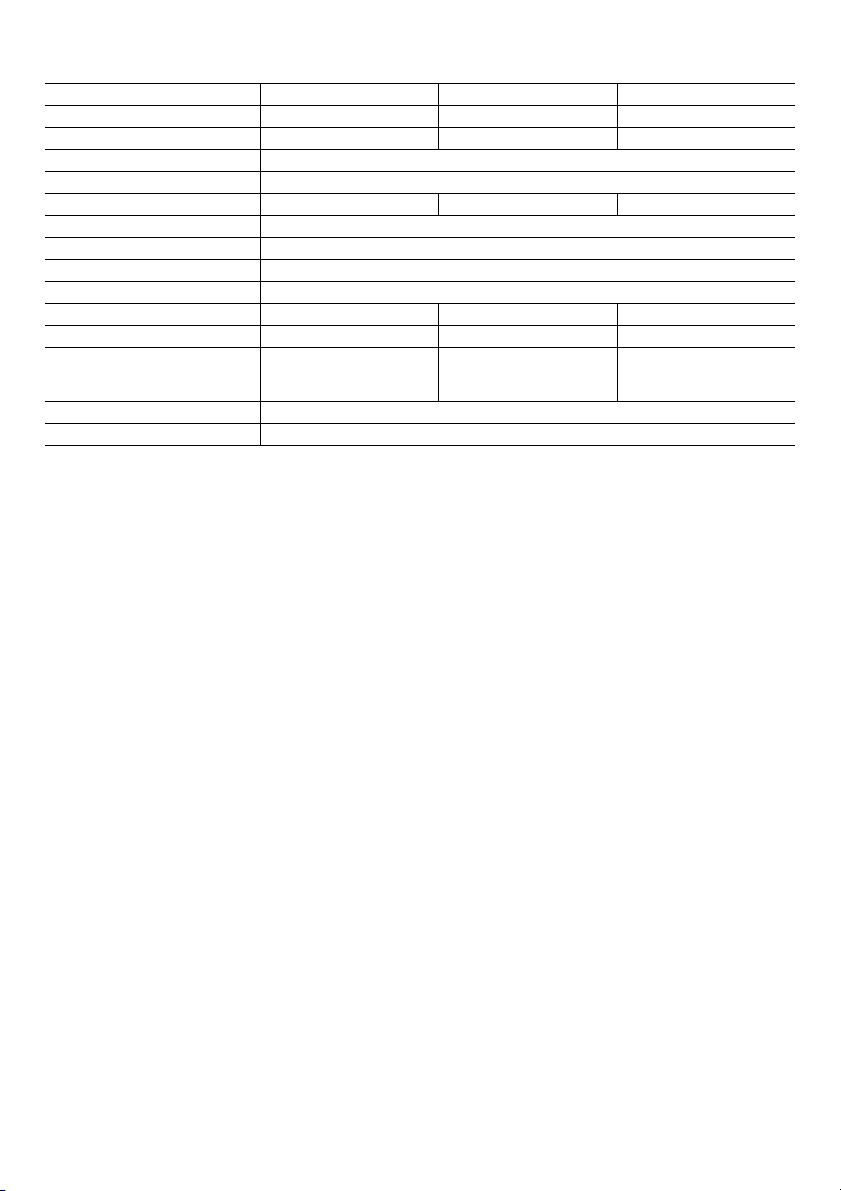

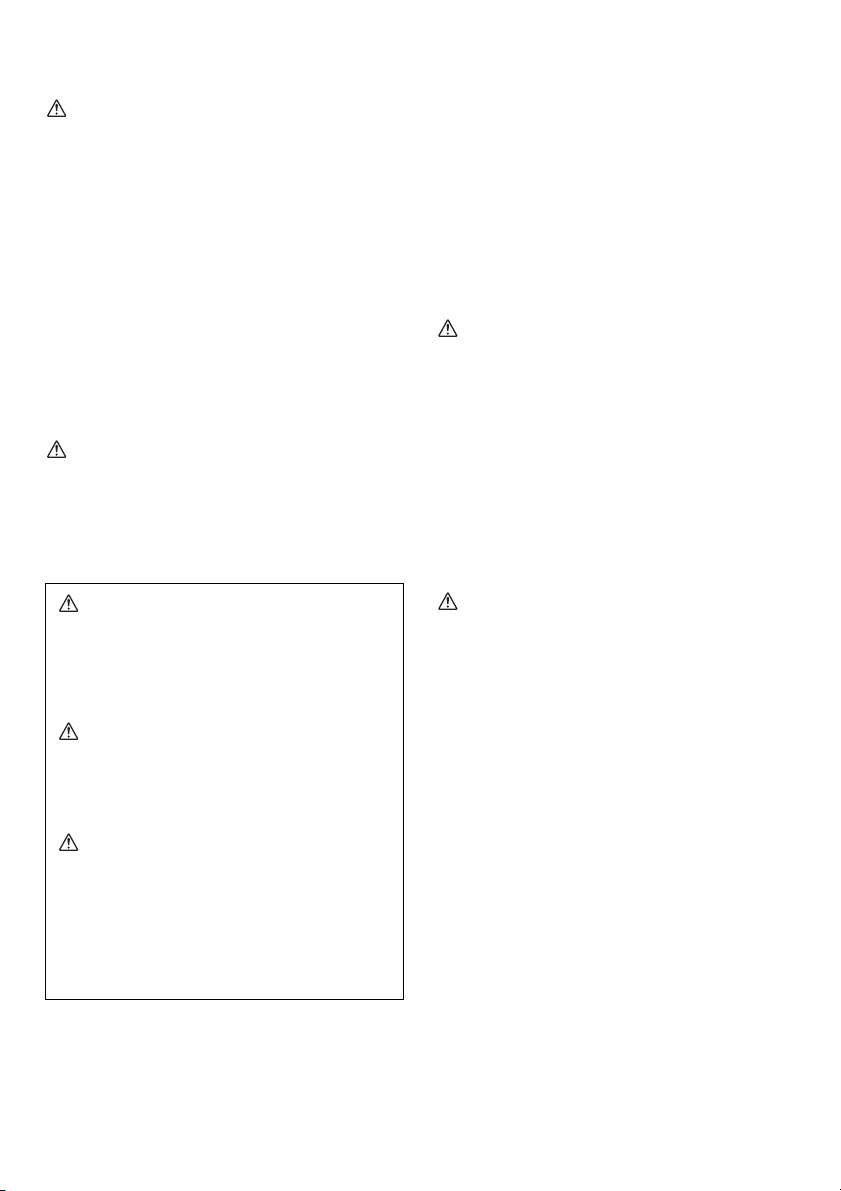

SPECIFICATIONS

Model MAC100Q MAC210Q MAC320Q

MAX Output Power 350 W 800 W 1100 W

SCFM @ 90 PSIG 0.7 2.0 2.6

Cut-In Pressure 105 PSIG (0.72 MPa)

Cut-Out Pressure 135 PSIG (0.93 MPa)

Bore x Stroke x Qty 51 mm x 8 mm x 2 64 mm x 14 mm x 2 64 mm x 17 mm x 2

Voltage -Single Phase 120 V AC

Hz 60 Hz

Motor RPM 1,750 min

Lubrication Oil-Less

Tank Size 1 gal (3.8 L) 2 gal (7.6 L) 3 gal (11.4 L)

Weight 12.5 kg (27.6 lbs) 20.5 kg (45.2 lbs) 23.8 kg (52.5 lbs)

Dimensions (L x H x W)

Outlet Max Pressure 135 PSIG (0.93 MPa)

CSA/US Listed Yes

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

Minimum Circuit Requirement: 15 AMPS

* A circuit breaker is preferred. Use only a fuse or circuit breaker that is the same rating as the branch circuit the air

compressor is operated on. If the air compressor is connected to a circuit protected by fuses, use time delay fuses.

L: 328 mm (12-7/8”)

W: 370 mm (14-1/2”)

H: 282 mm (11-1/8”)

L: 441 mm (17-3/8”)

W: 429 mm (16-7/8”)

H: 347 mm (13-5/8”)

IMPORTANT

Read the Safety Guidelines and ALL instructions carefully before operating.

www.makitatools.com

www.makita.ca

-1

L: 456 mm (18”)

W: 481 mm (19”)

H: 348 mm (13-3/4”)

3

Page 4

IMPORTANT SAFETY

INSTRUCTIONS

SAVE THESE INSTRUCTIONS.

WARNING

IMPROPER OPERATION OR MAINTENANCE OF THIS

PRODUCT COULD RESULT IN SERIOUS INJURY AND

PROPERTY DAMAGE.

READ AND UNDERSTAND ALL WARNINGS AND

OPERATING INSTRUCTIONS BEFORE USING THIS

EQUIPMENT.

WARNING

Risk of Unsafe Operation

WHAT CAN HAPPEN

Unsafe operation of your air compressor could lead to

serious injury to you or others.

HOW TO PREVENT IT

• Review and understand all instructions and warnings in

this manual.

• Become familiar with the operation and controls of the

air compressor.

• Keep operating area clear of all persons, pets, and

obstacles.

• Keep children away from the air compressor at all

times.

• Do not operate the product when fatigued or under the

influence of alcohol or drugs. Stay alert at all times.

• Never defeat the safety features of this product.

• Equip area of operation with a fire extinguisher.

• Do not operate machine with missing, broken, or

unauthorized parts.

WARNING

Risk of Attachments and Accessories

Bursting

WHAT CAN HAPPEN

Exceeding the pressure rating of air tools, spray guns, air

operated accessories, tires AND other inflatables can

cause them to explode or fly apart, and could result in

serious injury to you and others.

WARNING

Risk of Electric Shock

WHAT CAN HAPPEN

• Your air compressor is powered by electricity. Like any

other electrically powered device, if it is not used

properly, it may cause electrical shock.

• Electrical grounding: failure to provide adequate

grounding to this product could increase the risk of

electric shock.

HOW TO PREVENT IT

• Any electrical wiring or repairs required to this product

should be performed by qualified service personnel or

a licensed electrician, in accordance with national and

local electrical codes.

• Make certain that the electrical circuit to which the

compressor is connected provides proper electrical

grounding, correct voltage, and adequate fuse

protection.

• Never operate the compressor outdoors when it is

raining, or in a wet environment.

• Never operate the compressor with guards or covers

which are damaged or removed.

WARNING

Risk of Air Tank Bursting

WHAT CAN HAPPEN

The following conditions could lead to a weakening of the

tank, and RESULT IN A VIOLENT TANK EXPLOSION

RESULTING IN SERIOUS INJURY TO YOU OR

OTHERS:

• Failure to properly drain condensed water from the

tank, causing rust and thinning of the tank wall.

• Modifications or attempted repairs to the tank.

• Unauthorized modifications to the pressure switch,

safety valve, or any other components, which control

tank pressure.

HOW TO PREVENT IT

• Drain air tank daily or after each use. If air tank

develops a leak, replace it immediately with a new tank

or replace the entire compressor.

• Do not drill into, weld or otherwise modify air tank or it

will weaken. The tank can rupture or explode. Replace

with a new air tank.

• Follow the equipment manufacturers recommendation

and never exceed the maximum allowable pressure

rating of attachments. Never use the compressor to

inflate small low-pressure objects such as children’s

toys, footballs, basketballs, etc.

4

WARNING

Risk of Explosion or Fire

WHAT CAN HAPPEN

It is normal for electrical contacts within the motor and

pressure switch to spark, whenever the compressor starts

or stops. Never operate the compressor in an atmosphere

where flammable vapors are present. Doing so can result

in serious injury to you or others.

HOW TO PREVENT IT

• Always operate the compressor in a well-ventilated

area, free of gasoline or solvent vapors.

• If spraying flammable materials, locate compressor at

least 20 feet away from spray area.

• Store flammable materials in a secure location away

from compressor.

WARNING

Risk to Breathing

WHAT CAN HAPPEN

• The compressed air from your compressor is not safe

for breathing.

Page 5

The air stream may contain carbon monoxide or other

vapors, or particles from the tank or other components.

• Sprayed materials such as paint, paint solvents, paint

remover, insecticides, weed killers, etc., contain

harmful vapors and poisons.

• Breathing compressor or sprayed materials vapor can

result in serious injury.

HOW TO PREVENT IT

• Never inhale air from the compressor, either directly or

from a breathing device connected to the compressor.

Work in an area equipped with good cross ventilation.

• Read and follow the safety instructions provided on the

label or safety data sheet for the material you are

spraying.

Use an approved respirator designed for use with your

specific application.

WARNING: Risk from noise

Wear hearing protection to protect your ears against

exhaust noise and noise during operation.

WARNING

Risk from Compressed Air

WHAT CAN HAPPEN

The compressed air stream can cause soft tissue

damage, and can propel dirt, chips, loose particles and

small objects at high speed, resulting in property damage

or personal injury.

HOW TO PREVENT IT

• Always wear approved safety glasses with side shields

when using or maintaining the compressor.

• Never point any nozzle or sprayer toward any part of

the body or at other people or animals.

• Always turn the compressor off and bleed pressure

from the air line before attempting maintenance,

attaching tools or accessories.

WARNING

Risk from Moving Parts

WHAT CAN HAPPEN

The compressor cycles automatically when the pressure

switch is in the on/auto position. If you attempt repair or

maintenance while the compressor is operating or

plugged in, you can expose yourself to moving parts.

These moving parts can cause serious injury.

HOW TO PREVENT IT

• Always unplug the compressor and release air

pressure from the tank and any attachments before

attempting any maintenance or repair.

• Never operate the compressor with guards or covers

which are damaged or removed.

• Keep your hair, clothing, and gloves away from moving

parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

• Air vents may cover moving parts and should be

avoided as well.

WARNING

Risk of Burn

WHAT CAN HAPPEN

Contact with hot parts such as the compressor head or

outlet tubes could result in a serious skin burn.

HOW TO PREVENT IT

• Never touch hot components during or immediately

after operation of the compressor. Do not reach around

protective shrouds or attempt maintenance until unit

has been allowed to cool.

GLOSSARY

CFM: Cubic feet per minute.

SCFM: Standard cubic feet per minute; a unit of measure

of air delivery.

PSIG: Pounds per square inch gauge; a unit of measure

of pressure.

CUT-IN PRESSURE: While the motor is off, air tank

pressure drops as you continue to use your accessory or

air tool. When the tank pressure drops to a certain level

the motor will restart automatically re-started is called

“cut-in pressure”.

CUT-OUT PRESSURE: When you turn on your air

compressor, it begins to run, air pressure in the air tank

begins to build. It builds to a certain pressure before the

motor automatically shuts off - protecting your air tank

from pressure higher than its design rating. The pressure

at which the motor shuts off is called “cut-out pressure”.

DUTY CYCLE

All Makita manufactured air compressors are

recommended to be operated on not more than a 50%

duty cycle. This means an air compressor that pumps air

more than 50% in one hour is considered misuse because

the air compressor is undersized for the required air

demand.

GENERAL INFORMATION

This air compressor is equipped with an Oil-Less pump

designed for durability and no maintenance.

The compressor can be used for properly rated pneumatic

nailers and staplers. An air pressure regulator is supplied

for these applications.

WARNING

Never use compressor for applications other than to

operate a properly rated nailer or stapler. Use of the

compressor for other applications could result in property

damage and personal injury.

Separate air transformers which combine the functions of

air regulation and/or moisture and dirt removal should be

used where applicable.

ON-RECEIPT INSPECTION

DAMAGE: Each air compressor outfit is carefully tested

and checked before shipment. With improper handling,

damage may result in transit and cause problems with

compressor operation.

5

Page 6

Immediately upon arrival, check equipment for both

concealed and visible damages to avoid expenses being

incurred to correct such problems. This should be done

regardless of any visible signs of damage to the shipping

container. If this product was shipped directly to you,

report any damages to the carrier and arrange for

inspection of goods immediately.

STORAGE

Before you store the air compressor, make sure you do

the following:

1. Review the “Maintenance” and “Operating

Procedures” sections and perform maintenance as

necessary. Be sure to drain water from the air tank.

2. Protect the electrical cord and air hose from damage

(such as being stepped on or run over).

Store the air compressor in a clean and dry location.

DESCRIPTION OF OPERATION

DRAIN VALVE:

The drain valve is located at the bottom of the air tank and

is used to drain condensation at the end of each use.

AUTOMATIC SHUT OFF SYSTEM:

If the compressor automatically shuts off before reaching

its normal cutoff pressure :

1. Shut off all tools.

2. Unplug the compressor or turn off the pressure switch.

3. Wait until the compressor cools down. (about 10 min.)

4. Replug the compressor or turn on the pressure switch

to start the compressor.

5. Resume operation.

If you are using an extension cord, the compressor shuts

off even after performing above procedures. In this case,

the extension cord is too long or narrow. Replace the

extension cord with proper length and width.

ON/AUTO - OFF SWITCH:

Turn this switch to “on” to provide automatic power to the

pressure switch and to “off” to remove power when

finished using the compressor or when compressor will be

left unattended.

AIR FILTER (AIR INTAKE):

Keep the air filter clean at all times. Do not operate the

compressor with the air filter removed. The compressor

does not operate at full capacity if the air filter is dirty.

Before using the compressor, always check the air filter if

it is clean. If not, clean the air filter or replace the filter

element.

AIR COMPRESSOR PUMP:

To compress air, the piston moves up and down in the

cylinder. On the down stroke, air is drawn in through the

air intake valve. The exhaust valve remains closed.

On the upstroke of the piston, air is compressed. The

intake valve closes and compressed air is forced out

through the exhaust valve, through the outlet tube,

through the check valve and into the air tank. Useable air

is not available until the compressor has raised the air

tank pressure above that required at the air outlet.

CHECK VALVE:

When the air compressor is operating, the check valve is

“open”, allowing compressed air to enter the air tank.

When the air compressor reaches “cut-out” pressure, the

check valve “closes”, allowing air pressure to remain

inside the air tank.

PRESSURE SWITCH UNLOADING VALVE:

The pressure switch unloading valve located on the side

of the pressure switch, is designed to automatically

release compressed air from the compressor head and

the outlet tube when the air compressor reaches “cut-out”

pressure.

PRESSURE SWITCH:

The pressure switch automatically starts the motor when

the air tank pressure drops to the factory set “cut-in”

pressure. It stops the motor when the air tank pressure

reaches the factory set “cut-out” pressure.

SAFETY VALVE:

If the pressure switch does not shut off the air compressor

at its “cut-out” pressure setting, the safety valve will

protect against high pressure by “popping out” at its

factory set pressure which is slightly higher than the

pressure switch “cut-out” setting.

OUTLET PRESSURE GAUGE:

The outlet pressure gauge indicates the air pressure

available at the outlet side of the regulator. This pressure

is controlled by the regulator and is always less or equal

to the tank pressure. See “Operating Procedures”.

TANK PRESSURE GAUGE:

The tank pressure gauge indicates the air pressure in the

tank.

REGULATOR:

The air pressure coming from the air tank is controlled by

the regulator knob. Turn the knob clockwise to increase

pressure and counter-clockwise to decrease pressure. To

avoid minor re-adjustment after making a change in

pressure setting, always approach the desired pressure

from a lower pressure. When reducing from a higher to a

lower setting, first reduce to some pressure less than

desired pressure. Depending on the air requirements of

each particular accessory, the outlet regulated air

pressure may have to be adjusted while you are operating

the accessory.

COMPRESSED AIR OUTLET;

For Regular Pressure Pneumatic Tool Use

Outlet Max Pressure; 135 PSIG (0.93 MPa)

INSTALLATION AND BREAK-IN

PROCEDURES

LOCATION OF THE AIR COMPRESSOR

Locate the air compressor in a clean, dry and wellventilated area. The air filter must be kept clear of

obstructions, which could reduce air delivery of the air

compressor. The air compressor should be located at

least 12 inches away from the wall or other obstructions

6

Page 7

that will interfere with the flow of air. The air compressor

head and shroud are designed to allow for proper cooling.

If humidity is high, an air filter can be installed on the air

outlet adapter to remove excessive moisture. Follow the

instructions packaged with the air filter for proper

installation.

Place the air compressor on a flat surface so that it is

resting securely on the rubber feet.

OPERATING TEMPERATURE

The operating temperature of this compressor is between

0°C and 40°C (32°F and 104°F).

CAUTION

Never operate the compressor in the temperatures below

0°C (32°F) and above 40°C (104°F).

Please see the chart below for the MINIMUM extension cord gauge requirements:

Amp Rating Range (120 V)

0 - 5 A 161616141212

5 - 8 A 16 16 14 12 10

8 - 12 A 14 14 12 10

15 - 20 A 10 10 10

10 m

25 ft.

LUBRICATION

This air compressor is equipped with an Oil-Less pump

designed for durability and no maintenance.

Extension Cords

To avoid voltage drop, power loss, and overheating of the

motor, use extra air hose instead of an extension cord.

Low voltage can cause damage to the motor.

If an extension cord must be used:

• Use only an approved 3-wire extension cord that has a

3- blade grounding plug and a 3- slot receptacle that

will accept the plug on the air compressor.

• Make sure the extension cord is in good condition.

Total Length of Cord in Meter

15 m

50 ft.

20 m

75 ft.

30 m

100 ft.

50 m

150 ft.

Not Recommended12 - 15 A 12 12 10 10

60 m

200 ft.

Piping

Plastic or PVC pipe is not designed for use with

compressed air. Regardless of its indicated pressure

rating, plastic pipe can burst from air pressure. Use only

metal pipe for air distribution lines. If a pipe line is

necessary, use pipe that is the same size, or larger than,

the air tank outlet. Piping that is too small will restrict the

flow of air. If piping is over 100 feet long, use the next

larger size. Bury underground lines below the frost line

and avoid pockets where condensation can gather and

freeze. Apply pressure before underground lines are

covered to make sure all pipe joints are free of leaks.

Grounding Instruction

WARNING: Risk of electric shock! In the event of a short

circuit, grounding reduces the risk of shock by providing

an escape wire for the electric current. This air

compressor must be properly grounded.

The air compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug. The

plug must be used with an outlet that has been installed

and grounded in accordance with all local codes and

ordinances. The outlet must have the same configuration

as the plug. DO NOT USE AN ADAPTER.

Inspect the plug and cord before each use. Do not use if

there are signs of damage.

DANGER:

Improper grounding can result in electrical shock. Do not

modify the plug that has been provided. If it does not fit

the available outlet, the correct outlet should be installed

by a qualified electrician.

OPERATING PROCEDURES

Daily Start-up Checklist

INSTALLING HOSES

WARNING

Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose

whip. Losing control of the hose may result in

personal injury and property damage.

1. Before attaching air hose or accessories, make sure

the pressure switch lever is set to “OFF” and the air

regulator or shut-off valve is closed.

2. Attach hose and accessories. Too much air pressure

causes a hazardous risk of bursting. Check the

manufacturer’s maximum pressure rating for air tools

and accessories. The regulator outlet pressure must

never exceed the maximum pressure rating.

3. Turn the pressure switch lever to “ON/AUTO” and

allow tank pressure to build. Motor will stop when tank

pressure reaches “cut-out” pressure.

4. Open the regulator by turning it clockwise. Adjust the

regulator to the correct pressure setting. Your

compressor is ready for use.

5. Always operate the air compressor in well-ventilated

areas; free of gasoline or other solvent vapors. Do not

operate the compressor near the spray area.

7

Page 8

When you are finished:

DISCONNECTING HOSES

WARNING

Risk of unsafe operation. Firmly grasp hose in hand

when installing or disconnecting to prevent hose

whip. Losing control of the hose may result in

personal injury and property damage.

6. Set the pressure switch lever to “OFF”.

7. Using the air tool or accessory, bleed the tank

pressure down to zero.

8. Remove the air tool or accessory.

9. Drain water from air tank by opening drain cock valve

on bottom of tank. WATER WILL CONDENSE IN THE

AIR TANK. IF NOT DRAINED, WATER WILL

CORRODE AND WEAKEN THE AIR TANK CAUSING

A RISK OF AIR TANK RUPTURE.

Note:

If drain valve is plugged, release all air pressure. The

valve can then be removed, cleaned, then reinstalled.

10. After the water has been drained, close the drain

valve. The air compressor can now be stored.

WARNING

Drain Air Tank Properly. Improper draining of the air

tank can result in corrosion and possible bursting of

the tank. Tank bursting could lead to personal injury

and property damage.

MAINTENANCE

WARNING:

Never use the air compressor which is operating

abnormally.

If the air compressor appears to be operating

unusually, making strange noises or vibration,

stop using it immediately and arrange for repairs

by a Makita authorized service center.

WARNING:

Use only genuine Makita replacement parts.

Replacement parts not manufactured by Makita

may void your warranty and can lead to

malfunction and result in injuries. Genuine Makita

parts are available from an authorized dealer.

WARNING:

UNIT CYCLES AUTOMATICALLY WHEN

POWER IS ON. WHEN DOING MAINTENANCE,

YOU MAY BE EXPOSED TO VOLTAGE SOURCES,

COMPRESSED AIR OR MOVING PARTS.

PERSONAL INJURIES CAN OCCUR. BEFORE

PERFORMING ANY MAINTENANCE OR REPAIR,

UNPLUG THE COMPRESSOR AND BLEED OFF

ALL AIR PRESSURE.

be prepared and followed. The following routine

maintenance schedule is geared to a unit in a normal

working environment operating on a daily basis. If

necessary, the schedule should be modified to suit the

conditions under which your compressor is used. The

modifications will depend upon the hours of operation and

the working environment. Compressor units in an

extremely dirty and/or hostile environment will require a

greater frequency of all maintenance checks.

ROUTINE MAINTENANCE SCHEDULE

1. Drain water from the air tank, any moisture separators

or transformers.

2. Check for any unusual noise and/or vibration.

3. Manually check all safety valves to make sure they are

operating properly.

WARNING: Risk of bursting.

Check Safety Valve. If safety valve does not operate

properly over pressurization of the air tank may result

in rupture or explosion causing personal injury and

property damage.

4. Inspect air filter, replace if necessary.

5. Inspect air lines and fittings for leaks; correct as

necessary.

Each year of operation or if a problem is suspected:

• Check condition of air compressor pump intake and

exhaust valves.

• Check condition of check valve. Replace if

damaged or worn out.

6. Keep all screws, bolts, and covers tightly mounted.

Check their conditions periodically.

WARNING

Keep All Screws, Bolts and Covers Properly

Tightened. If screws plates or covers become loose

personal injury or property damage may occur.

MAKITA LIMITED WARRANTY

Please refer to the annexed warranty sheet for the most

current warranty terms applicable to this product. If

annexed warranty sheet is not available, refer to the

warranty details set forth at below website for your

respective country.

United States of America: www.makitatools.com

Canada: www.makita.ca

Other countries: www.makita.com

NOTICE:

Never use gasoline, benzine, thinner, alcohol or the like.

Discoloration, deformation or cracks may result.

To ensure efficient operation and longer life of the air

compressor unit, a routine maintenance schedule should

8

Page 9

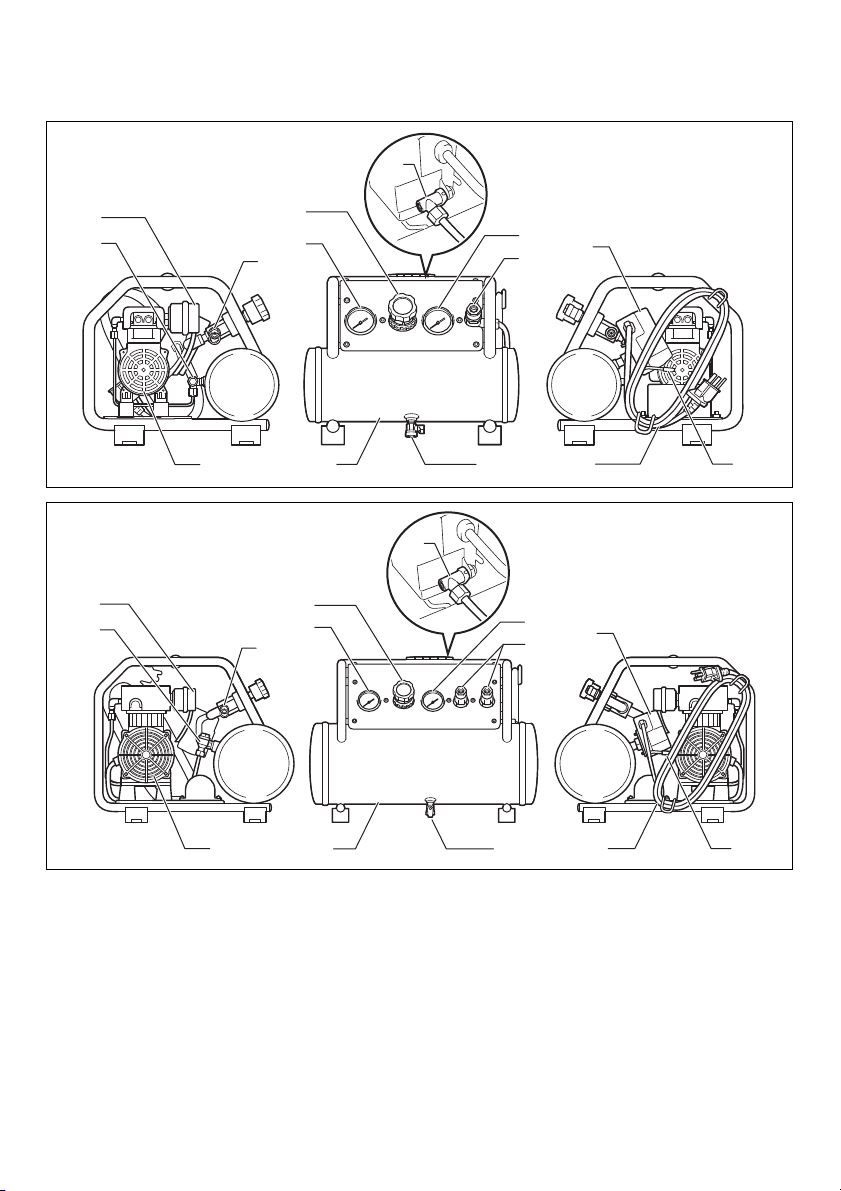

FRANÇAIS

2

1

3

6

5

7

8

9 10

11

1312

14

4

MAC100Q, MAC210Q

2

1

3

6

5

7

9 10

11

1312

14

8

4

MAC320Q

Description des pièces

1. Filtre à air (admission d’air)

2. Clapet antiretour

3. Soupape de sécurité

4. Pompe de compression d’air

5. Régulateur

6. Manomètre de réservoir

7. Manomètre de sortie

8. Raccord rapide

9. Réservoir d’air

10. Robinet de vidange

11. Manostat

12. Cordon d’alimentation

13. Interrupteur MARCHE/AUTOMATIQUE - ARRÊT

14. Valve de décompression de manostat

Remarque :

La forme du robinet de vidange des modèles MAC100Q et MAC210Q n’est pas la même.

9

Page 10

CARACTÉRISTIQUES TECHNIQUES

Modèle MAC100Q MAC210Q MAC320Q

Puissance de sortie MAX 350 W 800 W 1 100 W

3

Pi

/min std @ 90 PSIG 0,7 2,0 2,6

Pression d’enclenchement 105 PSIG (0,72 MPa)

Pression de déclenchement 135 PSIG (0,93 MPa)

Alésage x Course x Qté 51 mm x 8 mm x 2 64 mm x 14 mm x 2 64 mm x 17 mm x 2

Tension - monophasée 120 V CA

Hz 60 Hz

Régime du moteur 1 750 min

Lubrification Sans huile

Dimension du réservoir 1 gal (3,8 L) 2 gal (7,6 L) 3 gal (11,4 L)

Poids 12,5 kg (27,6 livres) 20,5 kg (45,2 livres) 23,8 kg (52,5 livres)

Dimensions (L x H x P)

Pression maximale de la sortie 135 PSIG (0,93 MPa)

Répertorié par CSA/US Oui

• Étant donné l’évolution constante de notre programme de recherche et de développement, les caractéristiques

techniques contenues dans ce manuel sont modifiables sans préavis.

• Remarque : Les caractéristiques techniques peuvent varier suivant les pays.

Exigences minimales pour le circuit : 15 ampères

* La présence d’un disjoncteur est recommandée. Utiliser uniquement un fusible ou un disjoncteur ayant la même valeur

nominale que celle du circuit de dérivation avec lequel le compresseur d’air est alimenté. Si le compresseur d’air est

branché à un circuit protégé par des fusibles, utiliser des fusibles temporisés.

L : 328 mm (12-7/8 po)

P : 370 mm (14-1/2 po)

H : 282 mm (11-1/8 po)

L : 441 mm (17-3/8 po)

P : 429 mm (16-7/8 po)

H : 347 mm (13-5/8 po)

IMPORTANT

Lire attentivement les recommandations de sécurité et TOUTES les instructions avant d’utiliser l’appareil.

www.makitatools.com

www.makita.ca

-1

L : 456 mm (18 po)

P : 481 mm (19 po)

H : 348 mm (13-3/4 po)

10

Page 11

CONSIGNES DE SÉCURITÉ

IMPORTANTES

CONSERVEZ LES PRÉSENTES

INSTRUCTIONS.

AVERTISSEMENT

UNE UTILISATION OU UN ENTRETIEN INADÉQUAT

DE CE PRODUIT PEUT ENTRAÎNER DES BLESSURES

GRAVES ET DES DOMMAGES MATÉRIELS.

S’ASSURER DE LIRE ET DE COMPRENDRE

L’ENSEMBLE DES AVERTISSEMENTS ET DES

INSTRUCTIONS D’UTILISATION AVANT D’UTILISER

CET ÉQUIPEMENT.

AVERTISSEMENT

Risques associés à une utilisation non

sécuritaire

CE QUI PEUT SE PRODUIRE

Une utilisation non sécuritaire de votre compresseur d’air

peut entraîner des blessures graves.

COMMENT L’ÉVITER

• S’assurer de consulter et de comprendre l’ensemble

des instructions et des avertissements contenus dans

le présent manuel.

• Se familiariser avec le fonctionnement et les

commandes du compresseur d’air.

• S’assurer que toute personne, tout animal ou tout

obstacle se trouve à l’écart de la zone de travail.

• Les enfants doivent se tenir à l’écart du compresseur

d’air en tout temps.

• Ne pas utiliser ce produit lorsque vous êtes fatigué ou

sous l’influence de l’alcool ou de la drogue. Toujours

rester vigilant.

• Ne jamais contourner les dispositifs de sécurité de ce

produit.

• Un extincteur doit être installé dans la zone

d’utilisation.

• Ne pas utiliser l’appareil si des pièces sont

manquantes, brisées, ou en présence de pièces non

homologuées.

AVERTISSEMENT

Risque d’éclatement du réservoir d’air

comprimé

CE QUI PEUT SE PRODUIRE

Les situations suivantes peuvent mener à un

affaiblissement du réservoir et PROVOQUER UNE

VIOLENTE EXPLOSION DU RÉSERVOIR, CE QUI

ENTRAÎNERAIT DES BLESSURES GRAVES :

• Ne pas vidanger correctement l’eau condensée dans le

réservoir, ce qui cause la corrosion et l’amincissement

de la paroi du réservoir.

• Toute modification ou tentative de réparations

effectuées sur le réservoir.

• Toute modification non autorisée du manostat, de la

soupape de sécurité ou de tout autre composant qui

contrôle la pression du réservoir.

COMMENT L’ÉVITER

• Vidanger le réservoir d’air quotidiennement ou après

chaque utilisation. Si le réservoir d’air présente une

fuite, le remplacer immédiatement par un nouveau

réservoir ou remplacer le compresseur au complet.

• S’abstenir de percer un trou dans le réservoir d’air, de

souder ce dernier ou de le modifier de quelque façon

que ce soit; cela l’affaiblirait. Le réservoir pourrait se

rompre ou exploser. Remplacer par un nouveau

réservoir d’air.

• Suivre les recommandations du fabricant des appareils

et ne jamais excéder la pression nominale maximale

autorisée pour les accessoires. Ne jamais utiliser le

compresseur pour gonfler de petits objets ayant une

faible pression comme les jouets pour enfants, les

ballons de soccer, les ballons de basketball, etc.

AVERTISSEMENT

Risque d’éclatement de l’équipement

et des accessoires

CE QUI PEUT SE PRODUIRE

Si la pression nominale des outils pneumatiques, pistolets

de pulvérisation, accessoires à commande pneumatique,

pneus ET autres objets gonflables est dépassée, il est

possible qu’ils explosent ou volent en éclats, ce qui peut

entraîner des blessures graves.

AVERTISSEMENT

Risque de décharge électrique

CE QUI PEUT SE PRODUIRE

• Votre compresseur d’air est alimenté par de

l’électricité. Comme tout autre appareil électrique, s’il

n’est pas utilisé correctement, il peut causer une

décharge électrique.

• Mise à la terre : si une mise à la terre adéquate n’est

pas réalisée, le risque de décharge électrique est

accru.

COMMENT L’ÉVITER

• Tout câblage électrique ou toute réparation pour ce

produit doit être réalisé par un technicien qualifié ou un

électricien agréé, conformément aux codes électriques

nationaux et locaux.

• S’assurer que le circuit électrique auquel le

compresseur est branché offre une mise à la terre

électrique correcte, une tension appropriée et une

protection par fusible adéquate.

• Ne jamais faire fonctionner le compresseur à l’extérieur

lorsqu’il pleut, ou dans un environnement humide.

• Ne jamais faire fonctionner le compresseur si les

dispositifs de protection ou les couvercles sont enlevés

ou endommagés.

AVERTISSEMENT

Risque d’explosion ou

d’incendie

CE QUI PEUT SE PRODUIRE

Il est normal que des contacts électriques dans le moteur

et le manostat produisent une étincelle lorsque le

11

Page 12

compresseur démarre ou s’arrête. Ne jamais faire

fonctionner le compresseur dans une atmosphère où sont

présentes des vapeurs inflammables. Cela pourrait

entraîner des blessures graves.

COMMENT L’ÉVITER

• Toujours utiliser le compresseur dans une zone bien

aérée, sans essence ou vapeurs de solvants.

• Si des matières inflammables sont pulvérisées, placer

le compresseur à une distance d’au moins 6,1 m

(20 pi) de la zone de projection.

• Entreposer les matières inflammables en lieu sûr, à

l’écart du compresseur.

AVERTISSEMENT

Risques respiratoires

CE QUI PEUT SE PRODUIRE

• Il est dangereux de respirer l’air comprimé sortant du

compresseur.

Le flux d’air peut contenir du monoxyde de carbone,

d’autres gaz ou des particules provenant du réservoir

ou d’autres composants.

• Les matériaux vaporisés comme la peinture, les

solvants de peinture, les décapants, les insecticides,

les herbicides, etc. contiennent des vapeurs nocives et

sont toxiques.

• L’inhalation du flux du compresseur ou des vapeurs

des matières pulvérisées peut entraîner des blessures

graves.

COMMENT L’ÉVITER

• Ne jamais inhaler l’air provenant du compresseur, que

ce soit directement ou par l’entremise d’un appareil de

ventilation branché au compresseur. Travailler dans un

endroit doté d’une bonne aération transversale.

• Lire et respecter les instructions de sécurité fournies

sur l’étiquette ou la fiche technique santé-sécurité du

produit pulvérisé.

Utiliser un respirateur homologué et conçu pour cette

application en particulier.

AVERTISSEMENT: Risques associés au

bruit

Porter un dispositif de protection de l’ouïe pour protéger

vos oreilles contre le bruit de l’échappement et le bruit

durant le fonctionnement.

AVERTISSEMENT

Risques associés à l’air comprimé

CE QUI PEUT SE PRODUIRE

Le flux d’air comprimé peut endommager les tissus mous

de la peau et peut projeter de la poussière, des

fragments, des particules détachées et des petits objets à

haute vitesse, ce qui pourrait entraîner des dommages

matériels ou des blessures.

COMMENT L’ÉVITER

• Toujours utiliser des lunettes de sécurité homologuées

munies d’écrans latéraux durant l’utilisation ou

l’entretien du compresseur.

• Ne jamais diriger la buse ou le pulvérisateur vers une

partie du corps ou vers une autre personne ou un

animal.

• Toujours mettre le compresseur hors tension et

évacuer la pression de la canalisation d’air avant

d’effectuer l’entretien ou encore de fixer des outils ou

des accessoires.

AVERTISSEMENT

Risques associés aux pièces

mobiles

CE QUI PEUT SE PRODUIRE

Le compresseur se met automatiquement en marche

lorsque le manostat est à la position marche/automatique.

S’il tente de réaliser une réparation ou un entretien

pendant que le compresseur fonctionne ou qu’il est

branché, l’utilisateur risque de s’exposer aux pièces

mobiles. Ces pièces mobiles peuvent causer des

blessures graves.

COMMENT L’ÉVITER

• Toujours débrancher le compresseur et évacuer la

pression d’air du réservoir et de tout équipement avant

d’effectuer l’entretien ou la réparation.

• Ne jamais faire fonctionner le compresseur si les

dispositifs de protection ou les couvercles sont enlevés

ou endommagés.

• Gardez vos cheveux, vos vêtements et vos gants à

distance des pièces mobiles. Des vêtements amples,

des bijoux ou de longs cheveux peuvent se prendre

dans les pièces mobiles.

• Les évents peuvent camoufler des pièces mobiles; il

convient donc de s’en tenir à l’écart aussi.

AVERTISSEMENT

Risque de brûlure

CE QUI PEUT SE PRODUIRE

Tout contact avec les pièces chaudes, comme la tête du

compresseur ou la tubulure d’échappement, peut

entraîner de graves brûlures.

COMMENT L’ÉVITER

• Ne jamais toucher les pièces chaudes pendant ou

immédiatement après l’utilisation du compresseur. Ne

pas toucher aux déflecteurs de protection ni effectuer

des réparations avant le refroidissement de l’appareil.

GLOSSAIRE

Pi³/min : pied cube par minute.

Pi³/min standard : pied cube standard par minute; une

unité de mesure du débit de l’air.

PSIG : Pression manométrique en livres par pouce carré;

une unité de mesure de la pression.

PRESSION DE RÉALIMENTATION : Quand le moteur est

arrêté, la pression du réservoir d’air chute pendant que

vous continuez à utiliser votre accessoire ou outil

pneumatique. Lorsque la pression du réservoir d’air chute

sous un certain niveau, le moteur redémarre

12

Page 13

automatiquement. C’est ce qu’on appelle la « pression de

réalimentation ».

PRESSION DE COUPURE : Lorsque vous démarrez le

compresseur d’air, il commence à fonctionner et la

pression du réservoir d’air commence à augmenter. Elle

augmente jusqu’à un certain niveau, puis le moteur

s’arrête automatiquement - ce qui évite que le réservoir

d’air soit soumis à une pression supérieure à celle pour

laquelle il a été conçu. La pression à laquelle le moteur

s’arrête est appelée « pression de coupure ».

CYCLE DE TRAVAIL

Tout compresseur fabriqué par Makita devrait être utilisé à

moins de 50 % du cycle de travail. Ainsi, si le

compresseur d’air pompe l’air pendant plus de 50 % du

temps pendant une heure d’utilisation, on considère qu’il

s’agit d’une mauvaise utilisation; le compresseur d’air est

insuffisant pour la demande d’air requise.

INFORMATIONS GÉNÉRALES

Ce compresseur d’air est doté d’une pompe sans huile,

conçue pour être durable sans nécessiter d’entretien.

Le compresseur peut être utilisé avec des cloueuses et

agrafeuses pneumatiques correctement calibrées. Un

régulateur de pression d’air est fourni pour ces

applications.

AVERTISSEMENT

Ne jamais utiliser un compresseur pour des applications

autres que l’utilisation de cloueuses ou agrafeuses

correctement calibrées. L’utilisation du compresseur pour

d’autres applications peut entraîner des dommages

matériels et des blessures.

Des transformateurs d’air distincts combinant des

fonctions de réglage d’air et/ou d’enlèvement de la saleté

et de l’humidité peuvent être utilisés le cas échéant.

INSPECTION À LA RÉCEPTION

DOMMAGES : Chaque ensemble compresseur d’air est

soigneusement testé et vérifié avant l’expédition. Il est

toutefois possible qu’une manutention incorrecte

provoque des dommages durant le transport et entraîne

des problèmes de fonctionnement du compresseur.

Dès l’arrivée de l’équipement, vérifier la présence de

dommages cachés ou visibles, afin d’éviter les dépenses

associées à la correction de tels problèmes. Cette

opération doit être effectuée même si l’emballage de

l’expédition ne présente aucun signe visible de

dommages. Si ce produit a été envoyé directement,

signaler les dommages au transporteur et prévoir

immédiatement une inspection du produit.

ENTREPOSAGE

Avant l’entreposage du compresseur d’air, s’assurer de

prendre les mesures suivantes :

1. Passer en revue les sections « Entretien » et

« Consignes d’utilisation » et réaliser les opérations

d’entretien nécessaires. Bien s’assurer de vidanger

l’eau du réservoir d’air.

2. Protéger le cordon électrique et le tuyau à air contre

les dommages (pour éviter qu’on y trébuche ou qu’on

marche dessus).

Entreposer le compresseur d’air dans un endroit propre et

sec.

DESCRIPTION DU FONCTIONNEMENT

ROBINET DE VIDANGE :

Le robinet de vidange est situé au bas du réservoir d’air. Il

est utilisé pour vidanger la condensation après chaque

utilisation.

SYSTÈME D’ARRÊT AUTOMATIQUE :

Si le compresseur s’arrête automatiquement avant

d’atteindre sa pression de coupure normale :

1. Éteindre l’ensemble des outils.

2. Débrancher le compresseur ou désactiver le

manostat.

3. Laisser le compresseur se refroidir (environ 10 min.)

4. Rebrancher le compresseur ou activer le manostat

pour faire démarrer le compresseur.

5. Reprendre le travail.

Si vous utilisez un cordon prolongateur, le compresseur

peut s’éteindre même après la réalisation des procédures

ci-dessus. Si tel est le cas, le cordon prolongateur est trop

long ou trop étroit. Remplacer le cordon prolongateur

avec un autre, de la longueur et largeur adéquate.

INTERRUPTEUR MARCHE/

AUTOMATIQUE - ARRÊT :

Mettre cet interrupteur à la position Marche (On) afin de

fournir automatiquement l’alimentation au manostat et à

Arrêt (Off) pour retirer l’alimentation lorsque vous avez

terminé d’utiliser le compresseur ou lorsque le

compresseur sera laissé sans surveillance.

FILTRE À AIR (ADMISSION D’AIR) :

Le filtre à air doit être propre en tout temps. Ne pas mettre

le compresseur en marche quand le filtre à air n’est pas

en place. Le compresseur ne fonctionne pas au maximum

de sa capacité si le filtre à air est sale. Avant d’utiliser le

compresseur, vérifier toujours si le filtre à air est propre.

Dans le cas contraire, nettoyer le filtre à air ou remplacer

l’élément filtrant.

POMPE DE COMPRESSION D’AIR :

Pour comprimer l’air, le piston se déplace vers le haut et

vers le bas du cylindre. Dans la course vers le bas, l’air

est aspiré par la soupape d’admission d’air. La soupape

d’échappement demeure fermée.

Dans la course du piston vers le haut, l’air est comprimé.

La soupape d’admission se ferme et l’air comprimé est

poussé à travers la soupape d’échappement, dans la

tubulure d’échappement jusqu’au clapet antiretour et

enfin dans le réservoir d’air. L’air utilisable n’est pas

disponible tant que le compresseur n’a pas augmenté la

pression du réservoir d’air au-delà de la pression requise

à la sortie d’air.

CLAPET ANTIRETOUR :

Quand le compresseur d’air est en fonction, le clapet

antiretour est « ouvert » et permet à l’air compressé de

13

Page 14

pénétrer dans le réservoir d’air. Lorsque le compresseur

d’air atteint la pression de « coupure », le clapet antiretour

se « ferme», ce qui permet à la pression d’air de

demeurer à l’intérieur du réservoir d’air.

VALVE DE DÉCOMPRESSION DE

MANOSTAT:

La valve de décompression de manostat, située sur le

côté du manostat, est conçue pour libérer

automatiquement l’air comprimé de la tête du

compresseur et de la tubulure d’échappement lorsque l’air

comprimé atteint la pression de « coupure ».

MANOSTAT:

Le manostat démarre automatiquement le moteur lorsque

la pression du réservoir d’air descend au-dessous de la

« pression de réalimentation ». Il arrête le moteur lorsque

la pression du réservoir d’air atteint la pression de

« coupure ».

SOUPAPE DE SÉCURITÉ :

Si le manostat n’arrête pas le compresseur d’air lorsque la

pression de « coupure » réglée est atteinte, la soupape

de sécurité protègera le réservoir contre la haute pression

en se « déclenchant » quand la pression définie en usine

sera atteinte (cette pression est légèrement supérieure à

la pression de « coupure » du manostat).

MANOMÈTRE DE SORTIE :

Le manomètre de sortie indique la pression d’air

disponible du côté de la sortie du régulateur. Cette

pression est contrôlée par le régulateur et est toujours

inférieure ou égale à la pression du réservoir. Consulter la

section « Consignes d’utilisation ».

MANOMÈTRE DE RÉSERVOIR :

Le manomètre de réservoir indique la pression de l’air

dans le réservoir.

RÉGULATEUR :

La pression de l’air provenant du réservoir d’air est réglée

à l’aide du bouton du régulateur. Tourner le bouton dans

le sens des aiguilles d’une montre pour augmenter la

pression, et dans le sens inverse pour la diminuer. Afin

d’éviter de devoir procéder à des réajustements mineurs

après avoir effectué un changement du réglage de la

pression, il faut toujours approcher la pression souhaitée

à partir d’une pression inférieure. Pour diminuer le réglage

de la pression, depuis un réglage supérieur vers un

réglage inférieur, commencer par réduire la valeur à une

pression inférieure à celle souhaitée. Selon les exigences

de chaque accessoire particulier, la pression d’air réglée à

la sortie pourrait devoir être ajustée pendant que

l’accessoire est en fonction.

SORTIE D’AIR COMPRIMÉ;

À utiliser avec les outils pneumatiques à pression

régulière

Pression maximale de la sortie; 135 PSIG (0,93 MPa)

PROCÉDURES D’INSTALLATION

ET DE RODAGE

EMPLACEMENT DU COMPRESSEUR

D’AIR

Placer le compresseur dans un endroit propre, sec et bien

aéré. Le filtre à air doit être libre d’obstruction pouvant

réduire l’approvisionnement de l’air dans le compresseur

d’air. Le compresseur d’air doit être placé à une distance

d’au moins 12 po (30,4 cm) du mur ou d’autres

obstructions qui pourraient entraver le débit de l’air. La

tête et le déflecteur du compresseur d’air sont conçus

pour permettre un refroidissement adéquat. Si le taux

d’humidité est élevé, il est possible d’installer un filtre à air

sur l’adaptateur de sortie d’air pour éliminer l’humidité

excessive. Suivre les instructions incluses dans

l’emballage du filtre à air pour une installation adéquate.

Placer le compresseur d’air sur une surface plane afin

qu’il soit solidement installé sur ses pieds de caoutchouc.

TEMPÉRATURE DE

FONCTIONNEMENT

Ce compresseur a une température de fonctionnement de

0 °C à 40 °C (32 °F à 104 °F).

ATT ENTI ON

Ne jamais faire fonctionner le compresseur si la

température est inférieure à 0 °C (32 °F) ou supérieure à

40 °C (104 °F).

LUBRIFICATION

Ce compresseur d’air est doté d’une pompe sans huile,

conçue pour être durable sans nécessiter d’entretien.

Cordons prolongateurs

Pour éviter les chutes de tension, pertes de puissance ou

surchauffes du moteur, utiliser un tuyau à air

supplémentaire au lieu d’un cordon prolongateur. Une

basse tension peut endommager le moteur.

Si l’utilisation d’un cordon prolongateur est requise :

• Utiliser uniquement un cordon prolongateur homologué

à trois fils, doté d’une fiche de mise à la terre à trois

broches, ainsi qu’une prise de courant à trois

ouvertures dans laquelle brancher cette fiche.

• S’assurer que le cordon prolongateur est en bon état.

14

Page 15

Consulter le tableau ci-dessous pour connaître les exigences MINIMALES relatives au cordon prolongateur :

Valeurs nominales en ampères -

plage (120 V)

0 à 5 A 16 16 16 14 12 12

5 à 8 A 16 16 14 12 10

8 à 12 A 14 14 12 10

15 à 20 A 10 10 10

10 m

25 pi

Longueur totale du cordon en mètres

15 m

50 pi

20 m

75 pi

30 m

100 pi

50 m

150 pi

Non recommandé12 à 15 A 12 12 10 10

60 m

200 pi

Tuyauterie

Les tuyaux de plastique ou de PVC ne sont pas conçus

pour être utilisés avec l’air comprimé. Quelle que soit la

pression nominale indiquée, les tuyaux de plastique

peuvent éclater sous la pression de l’air. Utiliser

uniquement des tuyaux métalliques pour les conduites de

distribution d’air. Si une conduite est nécessaire, utiliser

un tuyau de la même dimension que la sortie du réservoir

d’air, ou d’une dimension supérieure. Si la canalisation est

trop petite, le flux de l’air sera entravé. Si la longueur de la

canalisation est supérieure à 100 pieds (30,5 m), utiliser

la grandeur immédiatement supérieure. Enterrer les

conduites souterraines sous la profondeur de pénétration

du gel et éviter les poches où la condensation peut

s’accumuler et geler. Exercer une pression avant

d’enterrer les conduites pour s’assurer que les joints ne

présentent aucune fuite.

Instructions de mise à la terre

AVERTISSEMENT : Risque de décharge électrique! Au

cas où un court-circuit se produirait, la mise à la terre

réduit le risque de décharge électrique en fournissant un

fil d’échappement pour le courant électrique. Le

compresseur d’air doit être correctement mis à la terre.

Le compresseur d’air est équipé d’un cordon muni d’un fil

de mise à la terre et d’une fiche de mise à la terre. Cette

fiche doit être branchée dans une prise installée

correctement et mise à la terre conformément à tous les

codes et règlements en vigueur. La prise doit avoir la

même configuration que la fiche. NE PAS UTILISER UN

ADAPTATEUR.

Inspecter la fiche et le cordon avant chaque utilisation. Ne

pas les utiliser en présence de signes de dommages.

DANGER :

Une mise à la terre incorrecte peut provoquer une

décharge électrique. Ne pas modifier la fiche fournie. Si

elle ne s’insère pas dans la prise disponible, une prise

adéquate doit être installée par un électricien qualifié.

CONSIGNES D’UTILISATION

Liste de vérification quotidienne au

démarrage

INSTALLATION DES TUYAUX

AVERTISSEMENT

Risques associés à une utilisation non sécuritaire.

Saisir fermement le tuyau dans la main lors de son

installation ou de son débranchement, pour éviter

tout « coup de fouet ». Perdre le contrôle du tuyau

peut entraîner des blessures et des dommages

matériels.

1. Avant de raccorder un tuyau à air ou des accessoires,

s’assurer que le levier du manostat est à la position

Arrêt (« OFF ») et que le régulateur d’air ou la

soupape d’arrêt est fermé.

2. Raccorder le tuyau et les accessoires. Une pression

d’air excessive peut entraîner un danger d’éclatement.

Vérifier la pression nominale maximale spécifiée par

le fabricant des outils pneumatiques et des

accessoires. La pression de sortie du régulateur ne

doit jamais excéder la pression nominale maximale.

3. Mettre le levier du manostat à la position Marche/Auto

(« ON/AUTO ») et laisser à la pression du réservoir le

temps de monter. Le moteur s’arrêtera lorsque la

pression du réservoir atteindra la pression de

« coupure ».

4. Ouvrir le régulateur en le tournant dans le sens des

aiguilles d’une montre. Régler le régulateur jusqu’à la

configuration de pression requise. Le compresseur est

prêt à être utilisé.

5. Toujours utiliser le compresseur d’air dans des zones

bien aérées, sans essence ou vapeurs de solvants.

Ne pas utiliser le compresseur près de la zone de

projection.

Lorsque vous avez terminé :

DÉBRANCHEMENT DES TUYAUX

AVERTISSEMENT

Risques associés à une utilisation non sécuritaire.

Saisir fermement le tuyau dans les mains lors de son

installation ou de son débranchement pour éviter tout

« coup de fouet ». Perdre le contrôle du tuyau peut

entraîner des blessures et des dommages matériels.

6. Régler le levier du manostat à la position Arrêt

(« OFF »).

7. En utilisant l’outil pneumatique ou l’accessoire, porter

la pression du réservoir à zéro.

8. Retirer l’outil pneumatique ou l’accessoire.

9. Vidanger l’eau du réservoir d’air en ouvrant le robinet

de vidange au bas du réservoir. DE L’EAU SE

CONDENSE DANS LE RÉSERVOIR D’AIR. SI ELLE

N’EST PAS VIDANGÉE, CETTE EAU ENTRAÎNERA

LA CORROSION ET UN AFFAIBLISSEMENT DU

RÉSERVOIR D’AIR, CE QUI PEUT CAUSER UN

RISQUE DE RUPTURE DU RÉSERVOIR D’AIR.

15

Page 16

Remarque :

Si le robinet de vidange est obstrué, évacuer toute la

pression d’air. Le robinet peut ensuite être enlevé, nettoyé

et réinstallé.

10. Lorsque l’eau a été vidangée, refermer le robinet de

vidange. Le compresseur d’air peut alors être rangé.

AVERTISSEMENT

Vidanger le réservoir d’air correctement. Une vidange

inadéquate du réservoir d’air peut entraîner de la

corrosion et un éclatement du réservoir est possible.

L’éclatement du réservoir peut entraîner des

blessures et des dommages matériels.

ENTRETIEN

AVERTISSEMENT:

Ne jamais utiliser le compresseur d’air s’il

fonctionne de manière anormale.

Si le compresseur d’air semble fonctionner de

manière inhabituelle, ou qu’il émet un bruit ou des

vibrations étranges, cesser de l’utiliser

immédiatement et programmer sa réparation dans

un centre de service Makita agréé.

AVERTISSEMENT:

Utilisez uniquement des pièces de rechange

Makita authentiques. Le remplacement par des

pièces non fabriquées par Makita peut annuler

votre garantie et entraîner un mauvais

fonctionnement pouvant provoquer des

blessures. Les pièces Makita authentiques sont

disponibles auprès de revendeurs autorisés.

AVERTISSEMENT:

L’APPAREIL SE MET AUTOMATIQUEMENT EN

MARCHE QUAND

L’ALIMENTATION EST ACTIVÉE (ON). LORSQUE

L’ENTRETIEN EST RÉALISÉ, L’UTILISATEUR

PEUT ÊTRE EXPOSÉ À DES SOURCES DE

TENSION ÉLECTRIQUE, À DE L’AIR COMPRIMÉ

OU À DES PIÈCES MOBILES. CELA PEUT

ENTRAÎNER DES BLESSURES. AVANT DE

RÉALISER TOUT TRAVAIL D’ENTRETIEN OU DE

RÉPARATION, DÉBRANCHER LE COMPRESSEUR

ET ÉVACUER TOUTE LA PRESSION D’AIR.

REMARQUE :

N’utilisez jamais d’essence, de benzine, de solvant,

d’alcool ou tout autre produit similaire. Cela pourrait

provoquer une décoloration, une déformation ou la

formation de fissures.

d’entretien visant les compresseurs se trouvant dans un

environnement extrêmement sale et/ou rude devront être

plus fréquentes.

CALENDRIER D’ENTRETIEN RÉGULIER

1. Vidanger l’eau du réservoir d’air, des séparateurs

d’humidité ou des transformateurs.

2. Vérifier la présence de tout bruit inhabituel et/ou

vibration.

3. Vérifier manuellement le bon fonctionnement de

toutes les soupapes de sécurité.

AVERTISSEMENT: Risque d’éclatement.

Vérifier la soupape de sécurité. Si la soupape de

sécurité ne fonctionne pas correctement, une

pressurisation excessive du réservoir d’air peut

entraîner la rupture du réservoir ou son explosion, et

provoquer des blessures ou d’autres dommages

matériels.

4. Inspecter le filtre à air et le remplacer au besoin.

5. Inspecter les conduites d’air et les raccords pour

s’assurer qu’il n’y a pas de fuite; apporter les

corrections au besoin.

Après chaque année d’utilisation, ou encore si on

soupçonne la présence d’un problème :

• Vérifier les conditions d’entrée de la pompe de

compression d’air et des soupapes d’échappement.

• Vérifier l’état du clapet antiretour. Le remplacer s’il

est endommagé ou trop usé.

6. Maintenir l’ensemble des vis, boulons et couvercles

fermement en place. Vérifier périodiquement leur état.

AVERTISSEMENT

Maintenir l’ensemble des vis, boulons et couvercles

fermement en place. Si des vis ou couvercles se

desserrent, cela pourrait entraîner des blessures ou

des dommages matériels.

GARANTIE LIMITÉE MAKITA

Consulter le certificat de garantie joint pour connaître les

plus récentes conditions de la garantie applicable à ce

produit. Si le certificat de garantie n’est pas disponible, se

reporter aux détails de la garantie énoncés sur le site Web

ci-dessous et applicable à votre pays.

États-Unis : www.makitatools.com

Canada : www.makita.ca

Autres pays : www.makita.com

Pour assurer un fonctionnement efficace et une durée de

vie prolongée du compresseur d’air, il convient de

préparer et de suivre un calendrier d’entretien courant. Le

calendrier d’entretien suivant est conçu pour un appareil

dans un environnement de fonctionnement normal, utilisé

quotidiennement. Au besoin, le calendrier devrait être

modifié pour répondre aux conditions réelles dans

lesquelles le compresseur est utilisé. Les modifications

dépendront du nombre d’heures d’utilisation, et de

l’environnement de travail. Toutes les vérifications

16

Page 17

ESPAÑOL

2

1

3

6

5

7

8

9 10

11

1312

14

4

MAC100Q, MAC210Q

2

1

3

6

5

7

9 10

11

1312

14

8

4

MAC320Q

Descripción de las piezas

1. Filtro de aire (admisión de aire)

2. Válvula de retención

3. Válvula de seguridad

4. Bomba del compresor de aire

5. Regulador

6. Manómetro del tanque

7. Manómetro de la toma

Nota:

La forma de la válvula de drenado es diferente entre MAC100Q y MAC210Q.

8. Acople rápido

9. Tanque de aire

10. Válvula de drenado

11. Interruptor de presión

12. Cable eléctrico

13. Interruptor de Encendido/Auto/Apagado

14. Válvula de descarga del interruptor de presión

17

Page 18

ESPECIFICACIONES

Modelo MAC100Q MAC210Q MAC320Q

Producción máxima de energía 350 W 800 W 1 100 W

SCFM @ 90 PSIG 0,7 2,0 2,6

Presión de activación 105 PSIG (0,72 MPa)

Presión de desactivación 135 PSIG (0,93 MPa)

Calibre x Ciclo x Cantidad 51 mm x 8 mm x 2 64 mm x 14 mm x 2 64 mm x 17 mm x 2

Voltaje - Monofásico 120 V CA

Hz 60 Hz

RPM - Motor 1.750 min

Lubricación Sin aceite

Capacidad del tanque 1 gal (3,8 L) 2 gal (7,6 L) 3 gal (11,4 L)

Peso 12,5 kg (27,6 lb) 20,5 kg (45,2 lb) 23,8 kg (52,5 lb)

Dimensiones (La x An x Al)

Presión máxima de la toma 135 PSIG (0,93 MPa)

Clasificación CSA/US Sí

• Debido a nuestro programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a

cambios sin previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

Requisito mínimo del circuito: 15 amperes

* Se prefiere el uso de un cortacircuitos (“breaker”). Utilice solamente un fusible o cortacircuitos que sea de la misma

clasificación que el circuito en el que opera el módulo del compresor de aire. Si el compresor de aire está conectado a

un circuito protegido por fusibles, utilice fusibles con retardo de tiempo.

Largo: 328 mm (12-7/8”)

Ancho: 370 mm (14-1/2”)

Alto: 282 mm (11-1/8”)

Largo: 441 mm (17-3/8”)

Ancho: 429 mm (16-7/8”)

Alto: 347 mm (13-5/8”)

IMPORTANTE

Lea con atención las Normas de Seguridad, así como TODAS las instrucciones antes de utilizar el equipo.

www.makitatools.com

www.makita.ca

-1

Largo: 456 mm (18”)

Ancho: 481 mm (19”)

Alto: 348 mm (13-3/4”)

18

Page 19

INSTRUCCIONES IMPORTANTES

DE SEGURIDAD

CONSERVE ESTAS

INSTRUCCIONES.

ADVERTENCIA

LA OPERACIÓN Y EL MANTENIMIENTO

INCORRECTOS DE ESTE PRODUCTO PUEDE

GENERAR LESIONES GRAVES A LA PERSONA O

DAÑOS AL EQUIPO.

LEA Y COMPRENDA TODAS LAS ADVERTENCIAS E

INSTRUCCIONES DE OPERACIÓN ANTES DE USAR

ESTE EQUIPO.

ADVERTENCIA

Riesgo de operación insegura

LO QUE PUEDE PASAR

La operación insegura de su compresor de aire puede

generar graves lesiones hacia usted u otras personas.

CÓMO PUEDE PREVENIR ESTO

• Revise y comprenda todas las instrucciones y

advertencias que se indican en este manual.

• Familiarícese con la operación y los controles del

compresor de aire.

• Mantenga el área de operación despejada de

personas, mascotas y obstáculos.

• Mantenga a los niños alejados del compresor de aire

en todo momento.

• No opere el equipo si está cansado o bajo la influencia

los efectos del alcohol, medicinas u otras sustancias.

Manténgase alerta en todo momento.

• Nunca anule la funcionalidad de seguridad que ofrece

el producto.

• Equipe el área de operación con un extintor de

incendios.

• No opere el equipo si nota que faltan piezas, si alguna

pieza está dañada, ni con piezas no autorizadas.

ADVERTENCIA

Riesgo de que el tanque de aire

explote

LO QUE PUEDE PASAR

Las siguientes condiciones podrían originar un

debilitamiento del tanque, lo cual GENERARÁ UNA

EXPLOSIÓN VIOLENTA DEL TANQUE OCASIONANDO

GRAVES LESIONES A USTED Y A OTRAS PERSONAS:

• Negligencia por no drenar el agua condensada del

tanque, ocasionando oxidación y adelgazamiento de la

pared del tanque.

• Alteraciones o intentos de reparar el tanque.

• Alteraciones no autorizadas al interruptor de presión,

válvula de seguridad o de cualquier otro componente

que controle la presión del tanque.

CÓMO PUEDE PREVENIR ESTO

• Drene el tanque de aire diariamente o después de

cada uso. Si se origina una fuga en el tanque, cambie

de inmediato el tanque con un nuevo, o reemplace el

compresor de aire por completo.

• No taladre, suelde ni modifique en alguna forma el

tanque de aire o este se debilitará. El tanque podrá

romperse o explotar. Cambie el tanque por uno nuevo.

• Siga las recomendaciones del fabricante del equipo y

nunca exceda la clasificación de la presión máxima

permitida de los aditamentos. No use nunca un

compresor para inflar objetos de baja presión como

juguetes para niños, pelotas o balones, etc.

ADVERTENCIA

Riesgo de que los aditamentos o

accesorios exploten

LO QUE PUEDE PASAR

Exceder la clasificación de presión para herramientas de

aire, pistolas de aire (o atomizadores), accesorios que

funcionan a base de presión de aire, neumáticos Y de

cualquier otro objeto inflable puede ocasionar que se

revienten o salgan proyectados lo cual podría generar

graves lesiones para usted y otras personas.

ADVERTENCIA

Riesgo de descarga eléctrica

LO QUE PUEDE PASAR

• Su compresor de aire funciona con electricidad. Así

como con cualquier otro dispositivo eléctrico, si no se

usa correctamente, puede ocasionarse una descarga

eléctrica.

• Conexión a tierra: si no se proporciona una conexión a

tierra adecuada para este producto, se podría

aumentar el riesgo de descargas eléctricas.

CÓMO PUEDE PREVENIR ESTO

• Cualquier cableado eléctrico o reparación requerida

para este equipo deberá realizarse por personal de

servicio calificado o electricista con licencia, de

acuerdo a los criterios eléctricos nacionales y locales.

• Cerciórese de que el circuito eléctrico al cual está

conectado el compresor proporciona una conexión

eléctrica a tierra adecuada, el voltaje correcto y la

protección que corresponda mediante fusibles.

• Nunca opere el compresor al aire libre si está

lloviendo, ni en un entorno mojado.

• Nunca opere el compresor con protectores o cubiertas

que tengan daños o que hayan sido quitados del

equipo.

ADVERTENCIA

Riesgo de explosión o incendio

LO QUE PUEDE PASAR

Es normal que haya un chispazo debido a los contactos

eléctricos dentro del motor y el interruptor de presión

cada vez que se prenda o apague el compresor. Nunca

opere el compresor ante entornos donde haya presencia

de gases inflamables. Hacer esto puede generar graves

lesiones hacia usted u otras personas.

CÓMO PUEDE PREVENIR ESTO

• Siempre opere el compresor en un área bien ventilada

donde no haya gasolina ni otros gases solventes.

19

Page 20

• Si se está rociando material inflamable, coloque el

compresor a una distancia de al menos 6 metros (20

pies) de donde haciendo el rociado.

• Almacene los materiales inflamables en un lugar

seguro alejado del compresor.

ADVERTENCIA

Riesgo de inhalación

LO QUE PUEDE PASAR

• El aire comprimido de su compresor no es seguro para

ser respirado.

Puede que dicho torrente de aire contenga monóxido

de carbono, otros vapores o partículas del tanque u

otros componentes.

• Los materiales rociados como pintura, solventes de

pintura, eliminadores de pintura, insecticidas,

eliminadores de maleza, etc. contienen gases dañinos

y venenosos.

• La inhalación de los materiales usados con el

compresor o gases expedidos puede generar graves

lesiones.

CÓMO PUEDE PREVENIR ESTO

• Nunca respire el aire desde el compresor, ya sea de

forma directa o de algún dispositivo de ventilación

conectado al compresor. Trabaje en un lugar que

cuente con buenos puntos de ventilación.

• Lea y siga las instrucciones de seguridad que se

incluyen en la etiqueta o en la hoja de datos de

seguridad para el material a ser rociado.

Use un respirador aprobado diseñado para usarse con

la aplicación específica.

ADVERTENCIA: Riesgo de ruidos

Use protección auditiva para proteger sus oídos contra el

ruido del escape y el ruido durante la operación.

ADVERTENCIA

Riesgo debido al aire comprimido

LO QUE PUEDE PASAR

La corriente de aire comprimido puede causar daño a los

tejidos suaves, así como proyectar partículas, astillas y

pequeños objetos con gran fuerza.

CÓMO PUEDE PREVENIR ESTO

• Use siempre gafas protectoras aprobadas con

cubiertas laterales cuando use o realice mantenimiento

al compresor.

• Nunca apunte la boquilla o el rociador hacia ninguna

parte del cuerpo, ni hacia otra persona o animal.

• Apague siempre el compresor y drene la presión del

conducto de aire antes de realizar algún servicio de

mantenimiento, colocar aditamentos o accesorios.

ADVERTENCIA

Riesgo debido a las piezas

móviles

LO QUE PUEDE PASAR

El compresor se alterna automáticamente cuando el

interruptor de la presión está en la posición de encendido

20

o en la posición automática. Si va a hacer algún servicio

de reparación o mantenimientos mientras el compresor

está siendo utilizado o está conectado, puede exponerse

a las piezas móviles. Estas piezas móviles pueden causar

graves lesiones.

CÓMO PUEDE PREVENIR ESTO

• Desconecte siempre el compresor y libere la presión

de aire del tanque y de cualquier aditamento antes de

realizar cualquier servicio de mantenimiento o

reparación.

• Nunca opere el compresor con protectores o cubiertas

que tengan daños o que hayan sido quitados del

equipo.

• Mantenga su cabello, prendas de vestir y guantes

alejados de las piezas móviles. Las ropas sueltas, al

igual que las alhajas y el cabello largo, pueden

engancharse en las piezas móviles.

• Las aberturas para la ventilación puede que encubran

las piezas móviles, por lo que deberá evitar exponerse

a ellas también.

ADVERTENCIA

Riesgo de quemaduras

LO QUE PUEDE PASAR

El contacto con piezas calientes como la cabeza del

compresor o los tubos de la toma podría generar

quemaduras graves de la piel.

CÓMO PUEDE PREVENIR ESTO

• Nunca toque los componentes calientes durante o

inmediatamente tras la operación del compresor. No

trate de alcanzar las piezas que quedan más allá de

las cubiertas o protectores, ni realice servicio de

mantenimiento hasta que el equipo se haya enfriado.

GLOSARIO

CFM: pies cúbicos por minuto.

SCFM: pies cúbicos por minuto estándar; una unidad de

medición en el suministro de aire.

PSIG: libras por pulgada cuadrada de presión de

manómetro.

PRESIÓN DE ACTIVACIÓN: mientras el motor está

apagado, la presión del aire en el tanque baja a medida

que continúa utilizando el equipo. Cuando la presión baja

alcanzando cierto nivel, el motor se reactivará

automáticamente. A esta activación se le conoce como

“presión de activación”.

PRESIÓN DE DESACTIVACIÓN: Al encender el

compresor de aire, éste comenzará a funcionar y la

presión en el tanque de aire comenzará a acumularse. La

presión se acumulará hasta cierto punto antes de que el

motor se apague automáticamente con el fin de proteger

el tanque de aire contra una mayor presión para el cual

está diseñado. La presión en la cual el motor se apaga se

le conoce como “presión de desactivación”.

CICLO DE SERVICIO

Se recomienda que todos los compresores de aire

fabricados por MAKITA sean utilizados sobre un ciclo de

Page 21

servicio a no más del 50% del mismo. Esto significa que

un compresor de aire que bombea más del 50% del aire

en una hora se consideraría como uso indebido ya que el

compresor de aire estaría subdimensionado para la

demanda de aire requerida.

INFORMACIÓN GENERAL

Este compresor de aire está equipado para usarse con

una bomba sin aceite para su durabilidad y para que esta

no requiera mantenimiento.

Puede usar el compresor con clavadoras y grapadoras

neumáticas que cuenten con la clasificación

correspondiente. Se proporciona un regulador de presión

para el uso de estas aplicaciones.

ADVERTENCIA

Nunca use el compresor para aplicaciones distintas a las

del compresor para hacer funcionar clavadoras y

grapadoras neumáticas con la clasificación

correspondiente. Usar el compresor para otras

aplicaciones puede generar daños a la propiedad y

lesiones personales.

Se deberán usar transformadores de aire por separado

los cuales combinen las funciones de regulación de aire

y/o humedad y eliminación de residuos en los casos en

los que corresponda.

INSPECCIÓN DURANTE LA RECEPCIÓN

DAÑOS: cada artefacto del compresor de aire es

sometido a pruebas y revisiones exhaustivas antes de su

envío. Con un manejo inapropiado durante el envío del

equipo, puede que se generen daños que podrían causar

problemas en la operación.

Al recibir el equipo, compruebe inmediatamente si hay

daños ocultos o visibles para evitar los gatos que se

incurren para corregir dichos problemas. Esto deberá

hacerse desde el contenedor en donde viene el equipo,

independientemente de cualquier signo visible de daños.

Si el producto le fue enviado directamente, reporte

cualquier daño al transportador y coordine una inspección

de los bienes inmediatamente.

ALMACENAMIENTO

Antes de almacenar su compresor de aire, asegúrese de

hacer lo siguiente:

1. Revise las secciones de “Mantenimiento” y

“Procedimientos de operación” y realice el

mantenimiento según sea necesario. Asegúrese de

drenar el agua del tanque de aire.

2. Proteja el cable eléctrico y la manguera de aire contra

daños (como el evitar que alguien los pise o aplaste).

Almacene el compresor de aire en un lugar limpio y seco.

DESCRIPCIÓN DE LA OPERACIÓN

VÁLVULA DE DRENADO:

La válvula de drenado se ubica en la parte inferior del

tanque de aire y se utiliza para drenar la condensación al

final de cada uso.

SISTEMA DE APAGADO AUTOMÁTICO:

Si el compresor se apaga automáticamente antes de

alcanzar la presión de desactivación normal:

1. Apague todas las herramientas.

2. Desconecte el compresor o apague el interruptor de

presión.

3. Espere hasta que el compresor se enfríe. (Cerca de

10 min.)

4. Vuelva a conectar el compresor o encienda el

interruptor de presión para arrancar el compresor.

5. Reanude la operación.

Si utiliza un cable de extensión, el compresor se apagará

incluso después de realizar los procedimientos

anteriores. En este caso, el cable de extensión es

demasiado largo o angosto. Cambie el cable de extensión

por uno del ancho y largo adecuados.

INTERRUPTOR DE ENCENDIDO / AUTO /

APAGADO:

Ponga este interruptor en la posición de encendido (“on”)

para suministrar energía automática al interruptor de la

presión, y póngalo en la posición de apagado (“off”) para

eliminar el suministro al terminar de usar el compresor o

cuando no esté bajo su completa atención.

FILTRO DE AIRE (ADMISIÓN DE AIRE):

Mantenga limpio el filtro de aire en todo momento. No

haga funcionar el compresor sin el filtro de aire. El

compresor no funciona a la máxima capacidad si el filtro

de aire está sucio. Antes de usar el compresor, revise

siempre si el filtro de aire está limpio. Si no lo está, limpie

el filtro de aire o cambie el elemento del filtro.

BOMBA DEL COMPRESOR DE AIRE:

Para comprimir el aire, el pistón se mueve de arriba para

abajo en el cilindro. Estando en la posición baja del ciclo,

el aire es absorbido a través de la válvula de entrada de

aire. La válvula de escape permanece cerrada.

Estando en la posición elevada del pistón, el aire es

comprimido. La válvula de entrada se cierra y el aire

comprimido es forzado a través de la válvula de escape, a

través del tubo de la toma, a través de la válvula de

retención y hacia el tanque de aire. El aire utilizable no

está disponible hasta que el compresor ha elevado la

presión del tanque de aire por encima del requerido en la

toma de aire.

VÁLVULA DE RETENCIÓN:

Cuando el compresor de aire está funcionando, la válvula

de retención se “abre”, permitiendo el paso del aire

comprimido hacia el tanque de aire. Cuando el compresor

alcanza la presión de “desactivación”, la válvula de

retención se “cierra”, permitiendo que la presión de aire

permanezca dentro del tanque de aire.

VÁLVULA DEL INTERRUPTOR DE

DESCARGA DE PRESIÓN:

La válvula del interruptor de descarga de la presión, que

se encuentra sobre el costado del interruptor de la

presión, está diseñada para liberar automáticamente el

aire desde la cabeza del compresor y de la toma del tubo

cuando el compresor de aire alcance presión de

“desactivación”.

21

Page 22

INTERRUPTOR DE LA PRESIÓN:

El interruptor de la presión activa automáticamente el

motor cuando la presión del tanque de aire baja a presión

de “activación” establecida de fábrica. Detiene el motor

cuando la presión del tanque de aire alcanza la presión

de “desactivación” establecida de fábrica.

VÁLVULA DE SEGURIDAD:

Si el interruptor de la presión no apaga el compresor de

aire en su ajuste de presión de “desactivación”, la válvula

de seguridad ofrecerá protección contra la presión

elevada al “salirse” en su ajuste de presión de fábrica

(levemente mayor al ajuste de “desactivación” del

interruptor de presión).

MANÓMETRO DE LA TOMA:

El manómetro de la toma indica la presión de aire

disponible en el lado de la toma del regulador. Esta

presión es controlada por el regulador y siempre es

menor o igual a la presión del tanque. Consulte

“Procedimientos de operación”.

MANÓMETRO DEL TANQUE:

El manómetro del tanque indica la presión de aire en el

tanque.

REGULADOR:

La presión de aire que viene del tanque de aire es

controlada por la perilla del regulador. Gírela en dirección

de las manijas del reloj para incrementar la presión, y en

dirección contraria para reducirla. Para evitar tener que