Page 1

GB Angle Grinder Instruction manual

F Meuleuse d’Angle Manuel d’instructions

D Winkelschleifer Betriebsanleitung

I Smerigliatrice angolare Istruzioni per l’uso

NL Haakse slijpmachine Gebruiksaanwijzing

E Esmeriladora Angular Manual de instrucciones

P Esmerilhadeira Angular Manual de instruções

DK Vinkelsliber Brugsanvisning

GR Γωνιακός Τροχός Οδηγίες χρήσης

TR Taşlama Makinası Kullanım kılavuzu

M9002

M9003

015065

Page 2

1

2

4

5

6

7

8

9

10

1

3

1 015066 2 015067

3 015068 4 015069

5 015048 6 015049

11

A

7 015050 8 015071

2

15

B

12

Page 3

13

14

15

9 001145 10 015051

3

Page 4

ENGLISH (Original instructions)

Explanation of general view

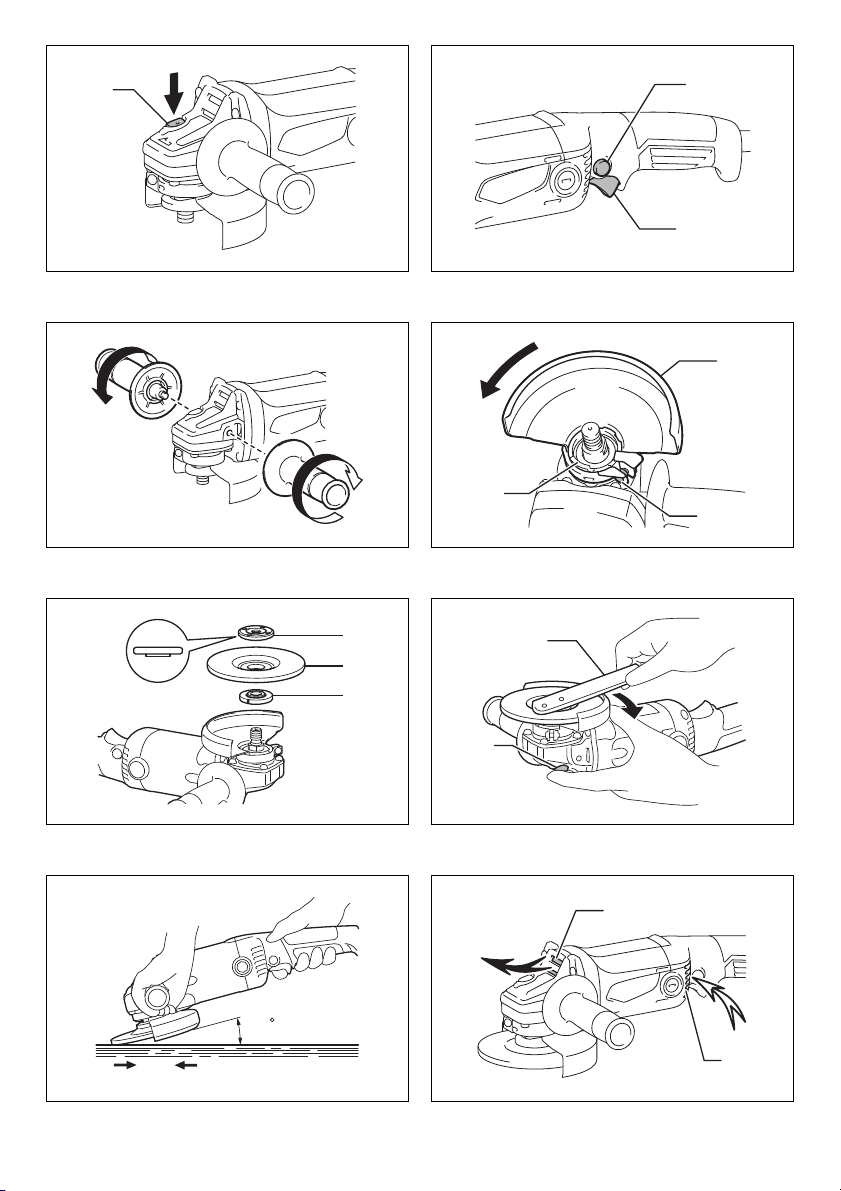

1. Shaft lock

2. Lock button

3. Switch trigger

4. Wheel guard

5. Screw

6. Bearing box

7. Lock nut

8. Depressed center grinding wheel/

Multi-disc

9. Inner flange

10. Lock nut wrench

11. Exhaust vent

12. Inhalation vent

13. Limit mark

14. Brush holder cap

15. Screwdriver

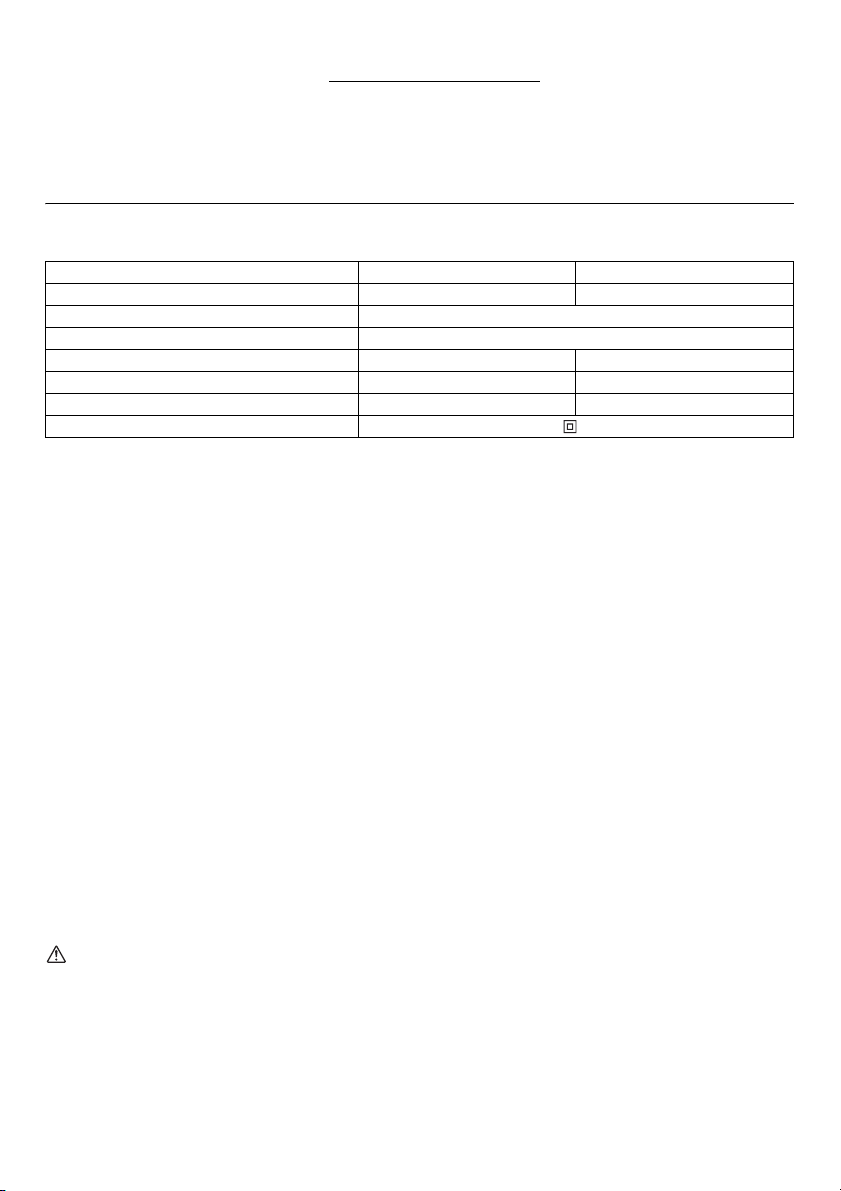

SPECIFICATIONS

Model M9002 M9003

Depressed center wheel diameter 125 mm 150 mm

Max. wheel thickness 6 mm

Spindle thread M14 or 5/8” (country specific)

Rated speed (n)/No load speed (n

Overall length 361 mm 361 mm

Net weight 2.8 kg 2.8 kg

Safety class /II

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for grinding of metal and stone

materials without the use of water.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated and can, therefore, also be used from

sockets without earth wire.

For public low-voltage distribution systems of

between 220 V and 250 V.

Switching operations of electric apparatus cause voltage

fluctuations. The operation of this device under

unfavorable mains conditions can have adverse effects to

the operation of other equipment. With a mains

impedance equal or less than 0.44 Ohms it can be

presumed that there will be no negative effects. The

mains socket used for this device must be protected with

a fuse or protective circuit breaker having slow tripping

characteristics.

) 11,000 min

0

ENE077-2

ENF002-2

ENF100-1

General Power Tool Safety

Warnings GEA010-1

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and

instructions for future reference.

-1

10,000 min

-1

GRINDER SAFETY WARNINGS

GEB110-3

Safety Warnings Common for Grinding Operations:

1. This power tool is intended to function as a

grinder. Read all safety warnings, instructions,

illustrations and specifications provided with this

power tool. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious

injury.

2. Operations such as sanding, wire brushing,

polishing or cutting-off are not recommended to

be performed with this power tool. Operations for

which the power tool was not designed may create a

hazard and cause personal injury.

3. Do not use accessories which are not specifically

designed and recommended by the tool

manufacturer. Just because the accessory can be

attached to your power tool, it does not assure safe

operation.

4. The rated speed of the accessory must be at least

equal to the maximum speed marked on the power

tool. Accessories running faster than their rated

speed can break and fly apart.

5. The outside diameter and the thickness of your

accessory must be within the capacity rating of

your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

6. Threaded mounting of accessories must match

the grinder spindle thread. For accessories

mounted by flanges, the arbour hole of the

accessory must fit the locating diameter of the

flange. Accessories that do not match the mounting

hardware of the power tool will run out of balance,

vibrate excessively and may cause loss of control.

4

Page 5

7. Do not use a damaged accessory. Before each use

inspect the accessory such as abrasive wheels for

chips and cracks, backing pad for cracks, tear or

excess wear. If power tool or accessory is

dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum noload speed for one minute. Damaged accessories

will normally break apart during this test time.

8. Wear personal protective equipment. Depending

on application, use face shield, safety goggles or

safety glasses. As appropriate, wear dust mask,

hearing protectors, gloves and workshop apron

capable of stopping small abrasive or workpiece

fragments. The eye protection must be capable of

stopping flying debris generated by various

operations. The dust mask or respirator must be

capable of filtrating particles generated by your

operation. Prolonged exposure to high intensity noise

may cause hearing loss.

9. Keep bystanders a safe distance away from work

area. Anyone entering the work area must wear

personal protective equipment. Fragments of

workpiece or of a broken accessory may fly away and

cause injury beyond immediate area of operation.

10. Hold the power tool by insulated gripping surfaces

only, when performing an operation where the

cutting accessory may contact hidden wiring or its

own cord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

11. Position the cord clear of the spinning accessory.

If you lose control, the cord may be cut or snagged

and your hand or arm may be pulled into the spinning

accessory.

12. Never lay the power tool down until the accessory

has come to a complete stop. The spinning

accessory may grab the surface and pull the power

tool out of your control.

13. Do not run the power tool while carrying it at your

side. Accidental contact with the spinning accessory

could snag your clothing, pulling the accessory into

your body.

14. Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing and

excessive accumulation of powdered metal may

cause electrical hazards.

15. Do not operate the power tool near flammable

materials. Sparks could ignite these materials.

16. Do not use accessories that require liquid

coolants. Using water or other liquid coolants may

result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other

accessory. Pinching or snagging causes rapid stalling of

the rotating accessory which in turn causes the

uncontrolled power tool to be forced in the direction

opposite of the accessory’s rotation at the point of the

binding.

For example, if an abrasive wheel is snagged or pinched

by the workpiece, the edge of the wheel that is entering

into the pinch point can dig into the surface of the material

causing the wheel to climb out or kick out. The wheel may

either jump toward or away from the operator, depending

on direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under these

conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to resist

kickback forces. Always use auxiliary handle, if

provided, for maximum control over kickback or

torque reaction during start-up. The operator can

control torque reactions or kickback forces, if proper

precautions are taken.

b) Never place your hand near the rotating

accessory. Accessory may kickback over your hand.

c) Do not position your body in the area where

power tool will move if kickback occurs. Kickback

will propel the tool in direction opposite to the wheel’s

movement at the point of snagging.

d) Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing have

a tendency to snag the rotating accessory and cause

loss of control or kickback.

e) Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create frequent

kickback and loss of control.

Safety Warnings Specific for Grinding Operation:

a) Use only wheel types that are recommended

for your power tool and the specific guard

designed for the selected wheel. Wheels for which

the power tool was not designed cannot be

adequately guarded and are unsafe.

b) The grinding surface of centre depressed

wheels must be mounted below the plane of the

guard lip. An improperly mounted wheel that projects

through the plane of the guard lip cannot be

adequately protected.

c) The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed towards

the operator. The guard helps to protect the operator

from broken wheel fragments, accidental contact with

wheel and sparks that could ignite clothing.

d) Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

e) Always use undamaged wheel flanges that are

of correct size and shape for your selected wheel.

Proper wheel flanges support the wheel thus

reducing the possibility of wheel breakage. Flanges

for cut-off wheels may be different from grinding

wheel flanges.

f) Do not use worn down wheels from larger

power tools. Wheel intended for larger power tool is

not suitable for the higher speed of a smaller tool and

may burst.

5

Page 6

Additional Safety Warnings:

17. When using depressed centre grinding wheels, be

sure to use only fiberglass-reinforced wheels.

18. NEVER USE Stone Cup type wheels with this

grinder. This grinder is not designed for these types of

wheels and the use of such a product may result in

serious personal injury.

19. Be careful not to damage the spindle, the flange

(especially the installing surface) or the lock nut.

Damage to these parts could result in wheel

breakage.

20. Make sure the wheel is not contacting the

workpiece before the switch is turned on.

21. Before using the tool on an actual workpiece, let it

run for a while. Watch for vibration or wobbling

that could indicate poor installation or a poorly

balanced wheel.

22. Use the specified surface of the wheel to perform

the grinding.

23. Do not leave the tool running. Operate the tool

only when hand-held.

24. Do not touch the workpiece immediately after

operation; it may be extremely hot and could burn

your skin.

25. Observe the instructions of the manufacturer for

correct mounting and use of wheels. Handle and

store wheels with care.

26. Do not use separate reducing bushings or

adaptors to adapt large hole abrasive wheels.

27. Use only flanges specified for this tool.

28. For tools intended to be fitted with threaded hole

wheel, ensure that the thread in the wheel is long

enough to accept the spindle length.

29. Check that the workpiece is properly supported.

30. Pay attention that the wheel continues to rotate

after the tool is switched off.

31. If working place is extremely hot and humid, or

badly polluted by conductive dust, use a shortcircuit breaker (30 mA) to assure operator safety.

32. Do not use the tool on any materials containing

asbestos.

33. Do not use cloth work gloves during operation.

Fibers from cloth gloves may enter the tool, which

causes tool breakage.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product (gained

from repeated use) replace strict adherence to safety

rules for the subject product. MISUSE or failure to

follow the safety rules stated in this instruction

manual may cause serious personal injury.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Shaft lock

CAUTION:

• Never actuate the shaft lock when the spindle is

moving. The tool may be damaged.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories. (Fig. 1)

Switch action

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released. (Fig. 2)

For tool without lock button

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

For tool with lock button

CAUTION:

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply caution

when locking tool in “ON” position and maintain firm

grasp on tool.

To start the tool, simply pull the switch trigger. Release

the switch trigger to stop.

For continuous operation, pull the switch trigger and then

push in the lock button.

To stop the tool from the locked position, pull the switch

trigger fully, and then release it.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing side grip (handle)

CAUTION:

• Always be sure that the side grip is installed securely

before operation.

Screw the side grip securely on the position of the tool as

shown in the figure. (Fig. 3)

Installing or removing wheel guard (For

depressed center wheel/Multi disc)

CAUTION:

• When using a depressed center grinding wheel/Multidisc, the wheel guard must be fitted on the tool so that

the closed side of the guard always points toward the

operator.

Mount the wheel guard with the protrusion on the wheel

guard band aligned with the notch on the bearing box.

Then rotate the wheel guard to such an angle that it can

protect the operator according to work. Be sure to tighten

the screw securely. (Fig. 4)

To remove wheel guard, follow the installation procedure

in reverse.

6

Page 7

Installing or removing depressed center

grinding wheel/Multi-disc (optional

accessory)

WARNING:

• Always use supplied guard when depressed center

grinding wheel/Multi-disc is on tool. Wheel can shatter

during use and guard helps to reduce chances of

personal injury.

Mount the inner flange onto the spindle. Fit the wheel/disc

on the inner flange and screw the lock nut onto the

spindle. (Fig. 5)

To tighten the lock nut, press the shaft lock firmly so that

the spindle cannot revolve, then use the lock nut wrench

and securely tighten clockwise. (Fig. 6)

To remove the wheel, follow the installation procedure in

reverse.

OPERATION

WARNING:

• It should never be necessary to force the tool. The

weight of the tool applies adequate pressure. Forcing

and excessive pressure could cause dangerous wheel

breakage.

• ALWAYS replace wheel if tool is dropped while

grinding.

• NEVER bang or hit grinding disc or wheel onto work.

• Avoid bouncing and snagging the wheel, especially

when working corners, sharp edges etc. This can

cause loss of control and kickback.

• NEVER use tool with wood cutting blades and other

sawblades. Such blades when used on a grinder

frequently kick and cause loss of control leading to

personal injury.

CAUTION:

• Never switch on the tool when it is in contact with the

workpiece, it may cause an injury to operator.

• Always wear safety goggles or a face shield during

operation.

• After operation, always switch off the tool and wait until

the wheel has come to a complete stop before putting

the tool down.

Grinding operation (Fig. 7)

ALWAYS hold the tool firmly with one hand on rear handle

and the other on the side handle. Turn the tool on and

then apply the wheel or disc to the workpiece.

In general, keep the edge of the wheel or disc at an angle

of about 15 degrees to the workpiece surface.

During the break-in period with a new wheel, do not work

the grinder in the B direction or it will cut into the

workpiece. Once the edge of the wheel has been rounded

off by use, the wheel may be worked in both A and B

direction.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

The tool and its air vents have to be kept clean. Regularly

clean the tool’s air vents or whenever the vents start to

become obstructed. (Fig. 8)

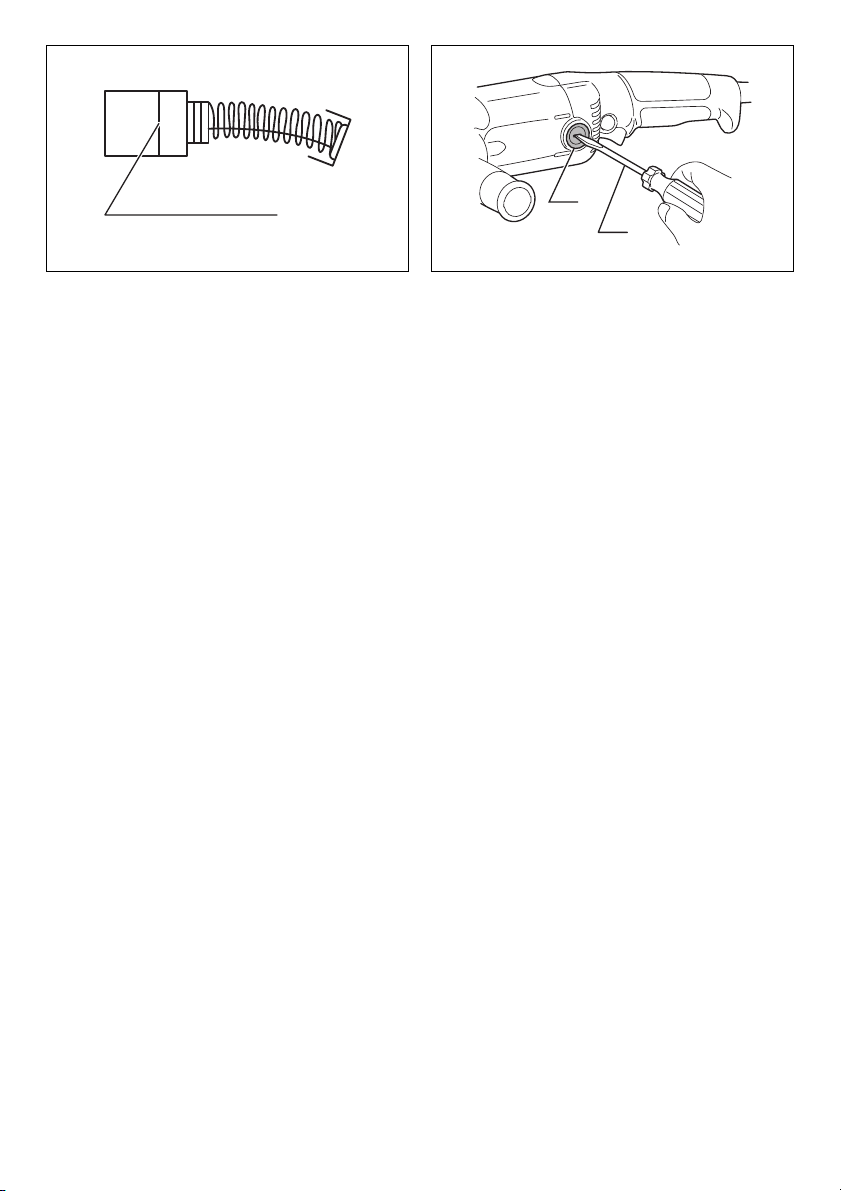

Replacing carbon brushes (Fig. 9)

Remove and check the carbon brushes regularly. Replace

when they wear down to the limit mark. Keep the carbon

brushes clean and free to slip in the holders. Both carbon

brushes should be replaced at the same time. Use only

identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps. (Fig. 10)

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers, always

using Makita replacement parts.

Noise

The typical A-weighted noise level determined according

to EN60745:

Model M9002

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

Model M9003

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

Wear ear protection.

Vibration

The vibration total value (tri-axial vector sum) determined

according to EN60745:

Work mode: surface grinding

Vibration emission (a

Uncertainty (K): 1.5 m/s

• The declared vibration emission value has been

measured in accordance with the standard test method

and may be used for comparing one tool with another.

• The declared vibration emission value may also be

used in a preliminary assessment of exposure.

• The declared vibration emission value is used for main

applications of the power tool. However if the power

tool is used for other applications, the vibration

emission value may be different.

WARNING:

• The vibration emission during actual use of the power

tool can differ from the declared emission value

depending on the ways in which the tool is used.

• Be sure to identify safety measures to protect the

operator that are based on an estimation of exposure in

the actual conditions of use (taking account of all parts

of the operating cycle such as the times when the tool

is switched off and when it is running idle in addition to

the trigger time).

): 91 dB (A)

pA

): 102 dB (A)

WA

): 90 dB (A)

pA

): 101 dB (A)

WA

): 9.0 m/s

h,AG

2

2

ENG905-1

ENG900-1

ENG902-1

7

Page 8

For European countries only

ENH101-18

EC Declaration of Conformity

Makita declares that the following Machine(s):

Designation of Machine:

Angle Grinder

Model No./Type: M9002, M9003

Conforms to the following European Directives:

2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents:

EN60745

The Technical file in accordance with 2006/42/EC is

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

2. 1. 2015

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

8

Page 9

FRANÇAIS (Instructions d’origine)

Descriptif

1. Blocage de l’arbre

2. Bouton de verrouillage

3. Gâchette

4. Carter de meule

5. Vis

6. Boîtier d’engrenage

7. Contre-écrou

8. Meule à moyeu déporté

/multidisque

9. Flasque intérieur

10. Clé à contre-écrou

11. Sortie d’air

12. Entrée d’air

13. Repère d’usure

14. Bouchon de porte-charbon

15. Tournevis

SPÉCIFICATIONS

Modèle M9002 M9003

Diamètre de la meule à moyeu déporté 125 mm 150 mm

Épaisseur maximale de la meule 6 mm

Filetage de l’axe M14 ou 5/8” (selon le pays)

Vitesse nominale (n)/Vitesse à vide (n

Longueur totale 361 mm 361 mm

Poids net 2,8 kg 2,8 kg

Niveau de sécurité /II

• Étant donné l’évolution constante de notre programme de recherche et de développement, les spécifications

contenues dans ce manuel sont sujettes à des modifications sans préavis.

• Les spécifications peuvent varier suivant les pays.

• Poids conforme à la procédure EPTA 01/2003

Utilisations

L’outil est conçu pour le meulage des métaux et pierres

sans utilisation d’eau.

Alimentation

L’outil ne doit être raccordé qu’à une alimentation de la

même tension que celle qui figure sur la plaque

signalétique, et il ne peut fonctionner que sur un courant

secteur monophasé. Réalisé avec une double isolation, il

peut de ce fait être alimenté sans mise à la terre.

Pour les systèmes d’alimentation électrique publics à

basse tension compris entre 220 et 250 V.

La mise sous/hors tension des appareils électriques

entraîne des fluctuations de la tension. L’utilisation de cet

appareil sur une source d’alimentation inadéquate peut

affecter le fonctionnement d’autres appareils. On peut

considérer qu’il n’y aura pas d’effets négatifs si

l’impédance de la source d’alimentation est inférieure ou

égale à 0,44 Ohms. La prise de courant utilisée pour cet

appareil doit être protégée par un fusible ou un

disjoncteur de protection à déclenchement lent.

)11000 min

0

ENE077-2

ENF002-2

ENF100-1

Consignes de sécurité générales

des outils électriques GEA010-1

AVERTISSEMENT Veuillez lire toutes les

consignes de sécurité et les instructions. Il y a un

risque de choc électrique, d’incendie et/ou de blessure

grave si les consignes et les instructions ne sont pas

toutes respectées.

Conservez toutes les consignes

et instructions pour référence

ultérieure.

-1

10 000 min

-1

AVERTISSEMENTS DE SÉCURITÉ

RELATIFS À LA MEULEUSE

Consignes de sécurité courantes pour les opérations

de meulage :

1. Cet outil électrique est conçu pour fonctionner

comme une meuleuse. Lisez tous les

avertissements concernant la sécurité, les

instructions, les illustrations et les

caractéristiques fournis avec cet outil électrique. Il

y a risque d’électrocution, d’incendie et/ou de

blessures graves si les instructions énumérées cidessous ne sont pas respectées.

2. Les opérations comme le ponçage, le brossage à

brosse métallique, le polissage ou le tronçonnage

sont déconseillées avec cet outil électrique. Les

opérations pour lesquelles l’outil électrique n’a pas été

conçu peuvent générer un danger et occasionner des

blessures.

3. N’utilisez pas d’accessoires qui ne sont pas

spécifiquement conçus et recommandés par le

fabricant de l’outil. Le simple fait que l’accessoire

puisse être fixé à votre outil électrique ne signifie pas

que le fonctionnement sera sécurisé.

4. La vitesse nominale de l’accessoire doit être au

moins égale à la vitesse maximale indiquée sur

l’outil électrique. Les accessoires fonctionnant plus

rapidement que leur vitesse nominale risquent de se

casser et de voler en éclats.

5. Le diamètre externe et l’épaisseur de votre

accessoire doivent correspondre à la puissance

nominale de votre outil électrique. Des accessoires

aux dimensions inappropriées ne peuvent pas être

protégés ou contrôlés correctement.

6. Le montage fileté d’accessoires doit correspondre

au filetage de la broche de la meuleuse. Pour les

GEB110-3

9

Page 10

accessoires montés à l’aide de flasques, l’orifice

de l’accessoire doit correspondre au diamètre du

flasque. Les accessoires qui ne correspondent pas

au matériel de montage de l’outil électrique seront

déséquilibrés et subiront des vibrations excessives,

susceptibles d’occasionner une perte de contrôle.

7. N’utilisez pas d’accessoire endommagé. Avant

chaque utilisation, vérifiez que les accessoires,

tels que les meules, ne sont pas écaillés et

craquelés, que les patins de renfort ne sont pas

fissurés, déchirés ou excessivement usés. En cas

de chute de l’outil électrique ou d’un accessoire,

assurez-vous qu’il n’est pas endommagé et

remplacez-le au besoin par un accessoire en bon

état. Après avoir inspecté et installé un

accessoire, positionnez-vous ainsi que les

spectateurs à distance de l’accessoire en rotation

et faites fonctionner l’outil électrique à la vitesse

maximale à vide pendant une minute.

Normalement, tout accessoire endommagé se brisera

au cours de ce temps d’essai.

8. Portez un équipement de protection corporelle. En

fonction du type de travail à effectuer, utilisez un

écran facial, des lunettes étanches ou des lunettes

de protection. Au besoin, portez un masque antipoussières, des protège-tympans, des gants et un

tablier d’atelier capable d’arrêter les petits

fragments abrasifs ou des morceaux de la pièce à

travailler. La protection pour les yeux doit pouvoir

stopper les projections de débris générées par

diverses opérations. Le masque anti-poussières ou le

masque filtrant doit pouvoir filtrer les particules

générées lors des travaux. L’exposition prolongée à

un bruit d’intensité élevée peut entraîner la surdité.

9. Gardez les spectateurs à une distance de sécurité

de la zone de travail. Quiconque pénètre dans la

zone de travail doit porter un équipement de

protection corporelle. Des fragments de la pièce à

travailler ou d’un accessoire cassé peuvent être

projetés hors de la zone de travail immédiate et

entraîner des blessures.

10. Ne tenez l’outil électrique que par ses surfaces de

poigne isolées lorsque vous effectuez une

opération au cours de laquelle l’accessoire de

coupe peut entrer en contact avec des fils

dissimulés ou avec le cordon de l’outil. Il est

possible que le contact de l’accessoire tranchant avec

un fil sous tension mette les parties métalliques

exposées de l’outil sous tension, risquant ainsi de

provoquer un choc électrique chez l’utilisateur.

11. Éloignez le cordon de l’accessoire rotatif. En cas

de perte de contrôle, le cordon risque d’être coupé ou

accroché et votre main ou votre bras happé(e) par

l’accessoire rotatif.

12. Ne posez jamais l’outil électrique à terre tant que

l’accessoire ne s’est pas complètement arrêté.

L’accessoire rotatif peut accrocher la surface et vous

risquez de perdre le contrôle de l’outil électrique.

13. Ne faites pas tourner l’outil électrique si vous le

transportez à côté de vous. Un contact accidentel

avec l’accessoire rotatif pourrait accrocher vos

vêtements et attirer l’accessoire vers votre corps.

14. Nettoyez régulièrement les aérations de l’outil

électrique. Le ventilateur du moteur tire la poussière

à l’intérieur du boîtier et une accumulation excessive

de poudre métallique peut entraîner des chocs

électriques.

15. Ne faites pas fonctionner l’outil électrique à

proximité de matériaux inflammables. Les

étincelles risquent d’enflammer ces matériaux.

16. N’utilisez pas d’accessoires qui nécessitent des

liquides de refroidissement. L’utilisation d’eau ou de

liquides de refroidissement peut entraîner une

électrocution ou un choc électrique.

Rebond et avertissements afférents

Le rebond est une réaction soudaine suite à un pincement

ou accrochage d’une meule en rotation, d’un patin de

renfort, d’une brosse ou d’un autre accessoire. Un

pincement ou un accrochage peut entraîner le calage

rapide de l’accessoire rotatif, ce qui peut alors forcer l’outil

électrique hors de contrôle à tourner dans la direction

opposée au sens de rotation de l’accessoire, jusqu’à ce

qu'il se bloque.

Par exemple, si une meule est accrochée ou pincée par la

pièce à travailler, le rebord de la meule qui pénètre dans

le point de pincement risque de creuser dans la surface

du matériau, ce qui peut faire sortir la meule. La meule

risque de sauter dans votre direction ou dans la direction

opposée, en fonction du sens de rotation de la meule au

niveau du point de pincement. Les meules peuvent

également se casser dans ces conditions.

Le rebond est dû à une mauvaise utilisation de l’outil et/ou

à des procédures ou conditions de travail inappropriées. Il

peut être évité en prenant les mesures appropriées, telles

que celles indiquées ci-dessous.

a) Maintenez une prise ferme sur l’outil électrique

et positionnez votre corps et vos bras de façon à

pouvoir résister aux forces du rebond. Utilisez

toujours une poignée auxiliaire, le cas échéant,

pour contrôler au maximum les rebonds ou la

réaction du couple au démarrage. Vous pouvez

contrôler les réactions du couple ou les forces du

rebond si vous prenez les précautions nécessaires.

b) Ne placez jamais la main à proximité de

l’accessoire rotatif. L’accessoire risque de rebondir

sur votre main.

c) Ne positionnez pas votre corps dans la zone où

l’outil électrique se déplacera en cas de rebond.

Le rebond va propulser l’outil dans la direction

opposée au mouvement de la meule, au point

d’accrochage.

d) Soyez particulièrement prudent lorsque vous

travaillez dans des recoins, sur des rebords

tranchants, etc. Évitez de faire rebondir ou

d’accrocher l’accessoire. Les recoins, les rebords

tranchants ou les rebonds ont tendance à accrocher

l’accessoire rotatif et à provoquer une perte de

contrôle ou un rebond.

e) Ne fixez pas une lame de sculpteur à chaîne

coupante ou une lame de scie dentée. De telles

lames peuvent créer de fréquents rebonds et pertes

de contrôle.

Consignes de sécurité spécifiques pour l’opération

de meulage :

a) N’utilisez que les types de meules qui sont

recommandées pour votre outil électrique et le

carter spécifique conçu pour la meule

10

Page 11

sélectionnée. Les meules pour lesquelles l’outil

électrique n’a pas été conçu ne peuvent pas être

protégées de manière adéquate et ne sont pas sûres.

b) La surface de meulage des meules à moyeu

déporté doit être installée sous le plateau de la

lèvre du carter. Une meule mal montée qui est

projetée à travers le plateau de la lèvre du carter ne

peut pas être correctement protégée.

c) Pour une sécurité maximale, le carter doit être

solidement fixé à l’outil électrique et positionné

pour une sécurité optimale, de manière à exposer

la meule au minimum dans votre direction. Le

carter contribue à vous protéger des fragments de

meule brisée, du contact accidentel avec la meule et

des étincelles susceptibles d’enflammer les

vêtements.

d) Les meules doivent être utilisées uniquement

pour les applications recommandées. Par

exemple : ne meulez pas avec la face latérale de

la meule à tronçonner. Les meules à tronçonner

sont conçues pour un meulage périphérique, les

forces latérales appliquées à ces meules peuvent les

briser.

e) Utilisez toujours des flasques de meule en bon

état dont la taille et la forme sont adaptées à la

meule que vous avez choisie. Des flasques de

meule appropriés soutiennent la meule, réduisant

ainsi le risque de cassure de celle-ci. Les flasques

pour les meules tronçonneuses peuvent être

différents des flasques de meule ordinaire.

f) N’utilisez pas de meules usées issues d’outils

électriques plus grands. Les meules conçues pour

de grands outils électriques ne conviennent pas en

cas de vitesse élevée d’un outil plus petit et elles

risquent d’exploser.

Autres avertissements de sécurité :

17. Lors de l’utilisation de meules à moyeu déporté,

assurez-vous d’utiliser exclusivement des meules

renforcées de fibre de verre.

18. N’UTILISEZ JAMAIS de meule pour couper la

pierre avec cette meuleuse. Cette meuleuse n’est

pas destinée à ce type de meule et l’utilisation de ce

genre de produit peut entraîner de graves blessures

corporelles.

19. Prenez garde de ne pas endommager l’axe, le

flasque (tout particulièrement la surface

d’installation) ou le contre-écrou. La meule risque

de casser si ces pièces sont endommagées.

20. Assurez-vous que la meule n’entre pas en contact

avec la pièce à travailler avant de mettre l’outil

sous tension.

21. Avant d’utiliser l’outil sur la pièce elle-même,

laissez-le tourner un instant. Soyez attentif à toute

vibration ou sautillement pouvant indiquer que la

meule n’est pas bien installée ou qu’elle est mal

équilibrée.

22. Utilisez la face spécifiée de la meule pour meuler.

23. N’abandonnez pas l’outil alors qu’il tourne. Ne

faites fonctionner l’outil qu’une fois que vous

l’avez bien en main.

24. Ne touchez jamais la pièce à travailler juste après

l’opération ; elle peut être extrêmement chaude et

vous risquez de vous brûler.

25. Pour installer et utiliser correctement la meule,

veuillez suivre les instructions du fabricant.

Manipulez les meules avec soin et rangez-les en

lieu sûr.

26. N’utilisez aucun raccord de réduction ou

adaptateur séparé pour adapter un trou de meule

trop grand.

27. Utilisez exclusivement les flasques spécifiés pour

cet outil.

28. Dans le cas des outils conçus pour l’utilisation

avec une meule à trou fileté, assurez-vous que la

longueur du filetage de la meule convient à la

longueur de l’axe.

29. Assurez-vous que la pièce à travailler est

correctement soutenue.

30. Gardez à l’esprit que la meule continue de tourner

même une fois le contact coupé sur l’outil.

31. Si le site de travail est extrêmement chaud et

humide ou s’il y a beaucoup de poussières

conductrices dans l’air, utilisez un coupe-circuit

(30 mA) pour assurer votre sécurité.

32. N’utilisez l’outil sur aucun matériau contenant de

l’amiante.

33. N’utilisez pas de gants de travail en tissu pendant

l’utilisation. Les fibres des gants en tissu pourraient

pénétrer dans l’outil et l’endommager.

CONSERVEZ CES

INSTRUCTIONS.

AVERTISSEMENT :

NE vous laissez PAS tromper (au fil d’une utilisation

répétée) par un sentiment d’aisance et de familiarité

avec le produit, en négligeant le respect rigoureux

des consignes de sécurité qui accompagnent l’outil.

Une UTILISATION INCORRECTE de l’outil ou le nonrespect des consignes de sécurité indiquées dans ce

manuel d’instructions peuvent causer de graves

blessures corporelles.

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION :

• Assurez-vous toujours que l’outil est éteint et

débranché avant de le régler ou vérifier son

fonctionnement.

Blocage de l’arbre

ATTENTION :

• N’activez jamais le blocage de l’arbre alors que l’axe

bouge. Vous pourriez endommager l’outil.

Appuyez sur le blocage de l’arbre pour empêcher l’axe de

tourner lors de l’installation ou du retrait des accessoires.

(Fig. 1)

Interrupteurs

ATTENTION :

• Avant de brancher l’outil, vérifiez toujours que la

gâchette fonctionne correctement et revient en position

d’arrêt « OFF » lorsqu’elle est relâchée. (Fig. 2)

11

Page 12

Pour les outils sans bouton de verrouillage

Pour mettre l’outil en marche, appuyez simplement sur la

gâchette. Pour l’arrêter, relâchez la gâchette.

Pour les outils avec bouton de verrouillage

ATTENTION :

• Pour votre confort, vous pouvez verrouiller le

commutateur en position de MARCHE en cas d’usage

prolongé. Soyez vigilant lorsque vous verrouillez l’outil

en position de MARCHE et gardez-le bien en main.

Pour mettre l’outil en marche, appuyez simplement sur la

gâchette. Pour l’arrêter, relâchez la gâchette.

Pour un fonctionnement continu, appuyez sur la gâchette

puis enfoncez le bouton de verrouillage.

Pour arrêter l’outil alors qu’il est en position verrouillée,

appuyez à fond sur la gâchette puis relâchez-la.

MONTAGE

ATTENTION :

• Avant d’effectuer toute intervention sur l’outil, assurezvous toujours qu’il est hors tension et débranché.

Installation de la poignée latérale

(manche)

ATTENTION :

• Avant d’utiliser l’outil, assurez-vous toujours que la

poignée latérale est installée de façon sûre.

Vissez la poignée latérale à fond sur la position prévue à

cet effet sur l’outil, comme illustré sur la figure. (Fig. 3)

Installation ou retrait du carter de meule

(pour les meules à moyeu déporté/

multidisques)

ATTENTION :

• Lors de l’utilisation d’une meule à moyeu déporté/d’un

multidisque, vous devez ajuster le carter de meule sur

l’outil, de sorte que la partie fermée du carter soit

toujours orientée vers vous.

Montez le carter de meule en alignant la partie saillante

de la bande du carter sur l’entaille du boîtier d’engrenage.

Faites ensuite pivoter le carter de meule selon un angle

qui permette de vous protéger selon le travail à exécuter.

Assurez-vous d’avoir serré la vis à fond. (Fig. 4)

Pour retirer le carter de meule, suivez la procédure

d’installation en sens inverse.

Installation ou retrait de la meule à moyeu

déporté/du multidisque (accessoire fourni

en option)

AVERTISSEMENT :

• Utilisez toujours le carter de meule fourni lorsque la

meule à moyeu déporté/le multidisque est installé(e)

sur l’outil. Comme la meule peut se rompre pendant

l’utilisation, le carter de meule réduit les risques de

blessure corporelle.

Montez le flasque intérieur sur l’axe. Ajustez la meule/le

disque sur le flasque intérieur et vissez le contre-écrou

sur l’axe. (Fig. 5)

Pour serrer le contre-écrou, appuyez fermement sur le

blocage de l’arbre pour empêcher l’axe de tourner, puis

12

utilisez la clé à contre-écrou pour serrer fermement dans

le sens des aiguilles d’une montre. (Fig. 6)

Pour retirer la meule, suivez la procédure d’installation en

sens inverse.

FONCTIONNEMENT

AVERTISSEMENT :

• Il ne doit jamais être nécessaire de forcer l’outil. Le

poids de l’outil lui-même suffit à assurer une pression

adéquate. Si vous forcez l’outil ou appliquez une

pression excessive sur celui-ci, vous risquez de casser

la meule, ce qui est dangereux.

• Remplacez TOUJOURS la meule si vous laissez

tomber l’outil pendant le meulage.

• Ne frappez JAMAIS le disque de meulage ou la meule

contre la pièce à travailler.

• Évitez de laisser la meule sautiller ou accrocher, tout

spécialement lorsque vous travaillez dans les coins,

sur les bords tranchants, etc. Cela peut causer une

perte de contrôle et un choc en retour.

• N’utilisez JAMAIS cet outil avec des lames à bois et

autres lames de scie. Les lames de ce type sautent

fréquemment lorsqu’elles sont utilisées sur une

meuleuse et risquent d’entraîner une perte de contrôle

pouvant causer des blessures corporelles.

ATTENTION :

• Pour éviter de vous blesser, ne mettez jamais l’outil en

marche alors qu’il se trouve en contact avec la pièce à

travailler.

• Pendant l’utilisation, portez toujours des lunettes de

sécurité ou un masque de protection.

• Après l’utilisation, mettez toujours l’outil hors tension et

attendez l’arrêt complet de la meule avant de reposer

l’outil.

Opération de meulage (Fig. 7)

Tenez TOUJOURS l’outil fermement en posant une main

sur le manche arrière et l’autre main sur le manche

latéral. Mettez l’outil en marche puis posez la meule ou le

disque sur la pièce à travailler.

En général, vous devez maintenir le bord de la meule ou

du disque sur un angle d’environ 15 degrés par rapport à

la surface de la pièce à travailler.

Pendant la période de rodage d’une meule neuve, ne

faites pas avancer la meuleuse dans le sens B, sinon elle

risque de couper la pièce à travailler. Une fois le tranchant

de la meule émoussé par son utilisation, la meule peut

être utilisée dans les sens A et B.

ENTRETIEN

ATTENTION :

• Assurez-vous toujours que l’appareil est éteint et

débranché avant d’effectuer tout travail d’inspection ou

d’entretien.

• N’utilisez jamais d’essence, de benzine, de diluant,

d’alcool ou de produit similaire. Ces produits risquent

de provoquer des décolorations, des déformations ou

des fissures.

L’outil et ses orifices d’aération doivent être maintenus

propres. Nettoyez les orifices d’aération de l’outil

régulièrement ou chaque fois qu’ils commencent à se

boucher. (Fig. 8)

Page 13

Remplacement des charbons (Fig. 9)

Retirez et vérifiez les charbons régulièrement.

Remplacez-les lorsqu’ils atteignent le repère d’usure.

Maintenez les charbons propres et en état de glisser

aisément dans les porte-charbons. Les deux charbons

doivent être remplacés en même temps. Utilisez

uniquement des charbons identiques.

Retirez les bouchons de porte-charbon à l’aide d’un

tournevis. Enlevez les charbons usés, insérez-en de

nouveaux et revissez solidement les bouchons de portecharbon. (Fig. 10)

Pour garantir la SÉCURITÉ et la FIABILITÉ du produit, les

réparations ainsi que tout autre travail d’entretien ou de

réglage doivent être effectués dans un centre d’entretien

Makita agréé, exclusivement avec des pièces de

rechange Makita.

Bruit

Les niveaux de bruit pondéré A typiques ont été mesurés

selon la norme EN60745 :

Modèle M9002

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

) : 91 dB (A)

pA

) : 102 dB (A)

WA

Modèle M9003

Niveau de pression sonore (L

Niveau de puissance sonore (L

Incertitude (K) : 3 dB (A)

) : 90 dB (A)

pA

) : 101 dB (A)

WA

Portez des protections auditives.

Vibrations

La valeur totale de vibration (somme du vecteur triaxial) a

été déterminée selon la norme EN60745 :

Mode de fonctionnement : meulage de surface

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

h, AG

2

) : 9,0 m/s

• La valeur de l’émission des vibrations déclarée a été

mesurée conformément à la méthode de test standard

et peut être utilisée afin de comparer des outils entre

eux.

• La valeur de l’émission des vibrations déclarée peut

également être utilisée lors d’une évaluation

préliminaire de l’exposition.

• La valeur de l’émission des vibrations déclarée est

utilisée pour les principales applications de l’outil

électrique. Cependant, si l’outil est utilisé pour d’autres

applications, la valeur de l’émission des vibrations peut

être différente.

AVERTISSEMENT :

• Selon la manière dont l’outil est utilisé, il est possible

que l’émission des vibrations pendant l’utilisation réelle

de l’outil électrique diffère de la valeur de l’émission

déclarée.

• Veillez à identifier les mesures de sécurité destinées à

protéger l’opérateur et établies à partir de l’estimation

de l’exposition dans les conditions réelles d’utilisation

(en prenant en compte toutes les étapes du cycle de

fonctionnement, telles que les périodes de mise hors

tension de l’outil, les périodes de fonctionnement au

ralenti et les périodes de mise en route).

ENG905-1

ENG900-1

2

ENG902-1

Pour les pays d’Europe uniquement

ENH101-18

Déclaration de conformité CE

Makita déclare que la/les machine(s) suivante(s) :

Nom de la machine :

Meuleuse d’Angle

N° de modèle/Type : M9002, M9003

sont conformes aux directives européennes

suivantes :

2006/42/CE

sont produites conformément aux normes ou documents

de normalisation suivants :

EN60745

Le dossier technique conforme à la norme 2006/42/CE

est disponible auprès de :

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

2. 1. 2015

Yasushi Fukaya

Directeur

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

13

Page 14

DEUTSCH (Originalanweisungen)

Erklärung der Gesamtdarstellung

1. Spindelarretierung

2. Arretiertaste

3. Ein/Aus-Schalter

4. Schutzhaube

5. Schraube

6. Lagergehäuse

7. Sicherungsmutter

8. Gekröpfte Trennschleifscheibe/

Multischeibe

9. Innenflansch

10. Sicherungsmutterschlüssel

11. Lüftungsschlitz

12. Schlitz für Lufteintritt

13. Verschleißgrenze

14. Bürstenhalterkappe

15. Schraubendreher

TECHNISCHE DATEN

Modell M9002 M9003

Durchmesser der gekröpften Scheibe 125 mm 150 mm

Max. Scheibendicke 6 mm

Spindelgewinde M14 oder 5/8 Zoll (länderspezifisch)

Nenndrehzahl (n)/Leerlaufdrehzahl (n

Gesamtlänge 361 mm 361 mm

Nettogewicht 2,8 kg 2,8 kg

Schutzklasse /II

• Aufgrund unserer beständigen Forschungen und Weiterentwicklungen sind Änderungen an den hier angegebenen

Technischen Daten ohne Vorankündigung vorbehalten.

• Die Technischen Daten können in den einzelnen Ländern voneinander abweichen.

• Gewicht entsprechend EPTA-Verfahren 01/2003

Verwendungszweck

Das Werkzeug ist für das Schleifen von Metall und Stein

ohne Verwendung von Wasser vorgesehen.

Stromversorgung

Das Werkzeug darf nur an eine Stromversorgung mit

Einphasen-Wechselstrom mit der auf dem Typenschild

angegebenen Spannung angeschlossen werden. Das

Werkzeug verfügt über ein doppelt isoliertes Gehäuse

und kann daher auch an einer Stromversorgung ohne

Schutzkontakt betrieben werden.

Für öffentliche NiederspannungsVersorgungssysteme mit einer Spannung zwischen

220 V und 250 V.

Schaltvorgänge von Elektrogeräten verursachen

Spannungsschwankungen. Der Betrieb dieses Gerätes

unter ungünstigen Netzstrombedingungen kann sich

nachteilig auf den Betrieb anderer Geräte auswirken. Bei

einer Netzstromimpedanz von 0,44 Ohm oder weniger ist

anzunehmen, dass keine negativen Effekte auftreten. Die

für dieses Gerät verwendete Netzsteckdose muss durch

eine Sicherung oder einen Schutzschalter mit trägen

Auslöseeigenschaften geschützt sein.

) 11.000 min

0

ENE077-2

ENF002-2

ENF100-1

Allgemeine Sicherheitshinweise

für Elektrowerkzeuge

WARNUNG Lesen Sie alle Sicherheitshinweise

und Anweisungen sorgfältig durch. Wenn die Hinweise

und Anweisungen nicht beachtet werden, besteht die

Gefahr eines Stromschlags, Brands und/oder das Risiko

von ernsthaften Verletzungen.

GEA010-1

-1

10.000 min

-1

Bewahren Sie alle Hinweise und

Anweisungen zur späteren

Referenz gut auf.

SICHERHEITSHINWEISE FÜR

SCHLEIFER

Allgemeine Sicherheitshinweise für Schleifarbeiten:

1. Dieses Elektrowerkzeug ist für den Einsatz als

Schleifer vorgesehen. Lesen Sie alle

Sicherheitshinweise, Anweisungen, Abbildungen

und Spezifikationen durch, die mit diesem

Elektrowerkzeug geliefert wurden. Werden nicht

alle der unten aufgeführten Anweisungen befolgt,

besteht die Gefahr eines Stromschlags, Brands und/

oder die Gefahr schwerer Verletzungen.

2. Arbeiten wie Schmirgeln, Drahtbürsten, Polieren

oder Abschneiden sollten mit diesem

Elektrowerkzeug nicht ausgeführt werden. Bei

Arbeiten, für die das Elektrowerkzeug nicht

vorgesehen ist, kann es zu gefährlichen Situationen

und zu Verletzungen kommen.

3. Verwenden Sie nur Zubehör, das vom Hersteller

des Geräts entwickelt oder vom Hersteller

ausdrücklich empfohlen wurde. Nur weil Sie ein

bestimmtes Zubehör am Werkzeug befestigen

können, bedeutet dies nicht, dass die Verwendung

gefahrlos möglich ist.

4. Die Nenndrehzahl des Zubehörs muss mindestens

der auf dem Elektrowerkzeug angegebenen

Höchstdrehzahl entsprechen. Zubehör, das mit

einer höheren Drehzahl als der zulässigen Drehzahl

betrieben wird, kann zerbersten, wobei Teile mit hoher

Geschwindigkeit durch die Luft fliegen.

GEB110-3

14

Page 15

5. Außendurchmesser und Dicke von Zubehör

müssen innerhalb der Nennwerte des

Elektrowerkzeugs liegen. Zubehör in unzulässiger

Größe kann nicht angemessen abgedeckt oder

betrieben werden.

6. Bei Gewindemontage muss das Zubehörteil auf

das Gewinde der Schleifspindel passen. Bei

Flanschmontage muss die Bohrung des

Zubehörteils die richtige Größe für den Flansch

besitzen. Zubehörteile, die nicht den Montageteilen

des Elektrowerkzeugs entsprechen, laufen

exzentrisch, schwingen stark und führen zum

Kontrollverlust.

7. Verwenden Sie kein beschädigtes Zubehör.

Überprüfen Sie vor jeder Verwendung das

Zubehör, beispielsweise die Schleifscheiben auf

Splitter und Risse, die Stützscheibe auf Risse,

Abrisse oder übermäßigen Verschleiß. Wenn das

Elektrowerkzeug oder ein Zubehör zu Boden

gefallen sein sollte, überprüfen Sie Werkzeug bzw.

Zubehör auf Beschädigungen und tauschen Sie

ggf. beschädigte Teile gegen unbeschädigte Teile

aus. Nachdem Sie das Zubehör überprüft und

montiert haben, halten Sie und Umstehende

Abstand vom rotierenden Zubehörteil und lassen

Sie das Elektrowerkzeug eine Minute mit

maximaler Leerlaufdrehzahl laufen. Beschädigtes

Zubehör zerbirst bei diesem Test für gewöhnlich.

8. Tragen Sie eine persönliche Schutzausrüstung.

Tragen Sie je nach Arbeitsaufgabe einen

Gesichtsschutz oder eine Schutzbrille. Soweit

angemessen, tragen Sie Staubmaske,

Gehörschutz, Schutzhandschuhe oder

Spezialschürze, um kleine Schleif- und

Materialpartikel von Ihnen fernzuhalten. Der

Augenschutz muss umherfliegende Fremdkörper

abhalten können, die bei verschiedenen Arbeiten

auftreten können. Die Staub- oder Atemschutzmaske

muss Partikel herausfiltern können, die bei

verschiedenen Arbeiten entstehen. Lange und

intensive Lärmeinwirkung kann zu Gehörverlust

führen.

9. Achten Sie darauf, dass Umstehende den

Sicherheitsabstand zum Arbeitsbereich einhalten.

Jeder, der den Arbeitsbereich betritt, muss eine

Schutzausrüstung tragen. Splitter des Werkstücks

oder eines geborstenen Zubehörteils können

umherfliegen und auch außerhalb des eigentlichen

Arbeitsbereichs noch zu Verletzungen führen.

10. Halten Sie das Elektrowerkzeug an den isolierten

Griffflächen, wenn Sie unter Bedingungen

arbeiten, bei denen das Schneidwerkzeug nicht

sichtbare Stromkabel oder das eigene Kabel

berühren kann. Bei Kontakt des Werkzeugs mit

einem stromführenden Kabel wird der Strom an die

Metallteile des Elektrowerkzeugs und dadurch an den

Bediener weitergeleitet, und der Bediener erleidet

einen Stromschlag.

11. Halten Sie das Netzkabel von rotierendem

Zubehör fern. Falls Sie die Kontrolle über das

Elektrowerkzeug verlieren, kann das Netzkabel

durchtrennt oder erfasst werden, oder Ihre Hand oder

Ihr Arm kann in das rotierende Zubehör geraten.

12. Legen Sie das Elektrowerkzeug erst ab, nachdem

rotierendes Zubehör zum völligen Stillstand

gekommen ist. Das rotierende Zubehör könnte

Kontakt zur Auflagefläche erhalten, sodass Sie die

Kontrolle über das Elektrowerkzeug verlieren.

13. Schalten Sie das Elektrowerkzeug immer aus,

bevor Sie es transportieren. Ihre Kleidung kann

durch unbeabsichtigten Kontakt mit dem sich

drehenden Zubehör erfasst werden, und das Zubehör

kann sich in Ihren Körper bohren.

14. Reinigen Sie die Lüftungsschlitze des

Elektrowerkzeugs regelmäßig. Der Motorventilator

zieht Staub in das Gehäuse hinein, wobei eine

übermäßige Ansammlung von Metallspänen Gefahren

durch elektrischen Strom verursachen kann.

15. Betreiben Sie das Elektrowerkzeug nicht in der

Nähe brennbarer Materialien. Diese Materialien

können durch Funken entflammt werden.

16. Verwenden Sie keine Zubehörteile, die flüssige

Kühlmittel benötigen. Bei Verwendung von Wasser

oder anderen flüssigen Kühlmitteln können Sie einen

Stromschlag erleiden.

Rückschläge und entsprechende Warnhinweise

Ein Rückschlag ist eine plötzliche Reaktion einer

verklemmten oder verfangenen rotierenden

Schleifscheibe, Stützscheibe, der Bürste oder anderen

Zubehörs. Durch Verklemmen oder Verfangen kommt es

zu einem plötzlichen Stillstand des rotierenden Zubehörs,

sodass das Elektrowerkzeug am Punkt des Festfahrens in

die der Rotationsrichtung des Zubehörs

entgegengesetzte Richtung gezwungen wird.

Verklemmt sich beispielsweise eine Schleifscheibe im

Werkstück, kann die Kante, die in den Punkt des

Verklemmens eindringt, in die Oberfläche des Materials

eindringen, sodass die Scheibe ausschlägt. Die Scheibe

springt entweder in Richtung des Bedieners oder vom

Bediener weg; dies hängt von der Richtung der

Scheibenbewegung am Punkt der Blockade ab. Unter

diesen Umständen können Schleifscheiben auch

zerbersten.

Ein Rückschlag ist auf eine Zweckentfremdung bzw.

inkorrekte Betriebsweise oder auf einen fehlerhaften

Zustand des Elektrowerkzeugs zurückzuführen und kann

durch die im Folgenden aufgeführten

Vorsichtsmaßnahmen verhindert werden.

a) Halten Sie das Elektrowerkzeug stets mit

beiden Händen gut fest und halten Sie Ihren

Körper und Ihre Arme so, dass Sie Rückschläge

abfangen können. Verwenden Sie immer den

Zusatzgriff, sofern vorhanden, um größtmögliche

Kontrolle über Rückschlagkräfte oder

Reaktionsmomente beim Hochlauf zu haben. Bei

geeigneten Vorsichtsmaßnahmen können

Rückschlag- und Reaktionskräfte sicher vom

Bediener beherrscht werden.

b) Bringen Sie Ihre Hand niemals in die Nähe von

rotierendem Zubehör. Das Zubehör könnte

zurückschlagen und Ihre Hand treffen.

c) Meiden Sie mit Ihrem Körper den Bereich, in

den sich das Elektrowerkzeug bei einem

Rückschlag bewegen würde. Das Elektrowerkzeug

wird am Punkt der Blockade in die der

Rotationsrichtung der Scheibe entgegengesetzte

Richtung zurückgeschlagen.

15

Page 16

d) Arbeiten Sie im Bereich von Ecken, scharfen

Kanten usw. besonders vorsichtig. Verhindern

Sie, dass das Zubehör vom Werkstück

zurückprallt und verklemmt. Ecken, scharfe

Kanten und sonstige Hindernisse neigen zum

Verklemmen des rotierenden Zubehörs und können

zum Verlust der Kontrolle oder zu einem

Rückschlagen führen.

e) Verwenden Sie kein Ketten- oder gezähntes

Sägeblatt. Derartige Blätter verursachen häufig ein

Rückschlagen und führen zum Kontrollverlust.

Spezielle Sicherheitshinweise für den Schleifbetrieb:

a) Verwenden Sie ausschließlich die für dieses

Elektrowerkzeug zugelassenen Scheibentypen

und die für diese Schleifscheiben vorgesehene

Schutzhaube. Schleifscheibe, die nicht für das

Elektrowerkzeug vorgesehen sind, können nicht

ausreichend abgeschirmt werden und stellen

Gefahrenquellen dar.

b) Die Schleifoberfläche von gekröpften

Schleifscheiben muss unterhalb der Ebene der

Schutzhaube montiert werden. Eine unsachgemäß

montierte Scheibe, die über die Ebene der

Schutzhaube hinausragt, kann nicht ausreichend

geschützt werden.

c) Zur optimalen Sicherheit muss die

Schutzhaube sicher am Elektrowerkzeug

angebracht und positioniert sein, sodass der

kleinstmögliche Teil der Scheibe in Richtung

Bediener frei liegt. Die Schutzabdeckung soll den

Bediener vor Bruchstücken und zufälligem Kontakt

mit der Scheibe und Funken, welche die Kleidung

entzünden könnten, schützen.

d) Schleifscheiben dürfen ausschließlich für die

vorgesehenen Arbeiten verwendet werden.

Beispiel: Schleifen Sie nie mit der Seitenfläche

einer Trennscheibe. Trennscheiben sind zum

Materialabtrag mit der Kante der Scheibe bestimmt.

Bei seitlicher Krafteinwirkung auf diese Scheiben

können sie zerbrechen.

e) Verwenden Sie immer unbeschädigte

Spannflansche in der richtigen Größe und Form

für die von Ihnen gewählte Schleifscheibe. Die

richtigen Scheibenflansche unterstützen die

Schleifscheibe, sodass die Möglichkeit des

Scheibenbruchs vermindert wird. Flansche für

Trennscheiben unterscheiden sich möglicherweise

von Flanschen für Schleifscheiben.

f) Verwenden Sie keine abgenutzten

Schleifscheiben von größeren

Elektrowerkzeugen. Schleifscheiben für größere

Elektrowerkzeuge sind nicht für die höheren

Drehzahlen von kleineren Elektrowerkzeugen

ausgelegt und können bersten.

Zusätzliche Sicherheitshinweise:

17. Verwenden Sie nur glasfaserverstärkte

Schleifscheiben als gekröpfte

Trennschleifscheiben.

18. Verwenden Sie mit diesem Schleifer NIEMALS

Steinschleiftöpfe. Dieser Schleifer ist nicht für diese

Art von Scheiben ausgelegt und die Verwendung

dieser Scheiben kann zu schweren Verletzungen

führen.

16

19. Achten Sie sorgfältig darauf, dass Spindel,

Flansch (insbesondere die Ansatzfläche) und

Sicherungsmutter nicht beschädigt werden. Eine

Beschädigung dieser Teile kann zu einem

Scheibenbruch führen.

20. Stellen Sie vor dem Einschalten des Werkzeugs

sicher, dass die Scheibe das Werkstück nicht

berührt.

21. Bevor Sie das Werkzeug auf das zu bearbeitende

Werkstück ansetzen, lassen Sie es einige Zeit

ohne Last laufen. Achten Sie auf Vibrationen und

Schlagen; beide Anzeichen können auf eine

schlecht ausgewuchtete oder nicht fachgerecht

eingebaute Schleifscheibe hindeuten.

22. Verwenden Sie für Schleifarbeiten ausschließlich

die dafür vorgesehene Fläche der Schleifscheibe.

23. Lassen Sie das Werkzeug nicht unbeaufsichtigt

eingeschaltet. Das Werkzeug darf nur dann in

Betrieb sein, wenn es von Hand festgehalten wird.

24. Vermeiden Sie eine Berührung des Werkstücks

unmittelbar nach der Bearbeitung, da es dann

noch sehr heiß sein und somit

Hautverbrennungen verursachen kann.

25. Befolgen Sie die Anweisungen des Herstellers zur

korrekten Montage und Verwendung von

Schleifscheiben. Behandeln und lagern Sie

Schleifscheiben mit Sorgfalt.

26. Verwenden Sie keine separaten Reduzierbuchsen

oder Adapter zur Anpassung von Schleifscheiben

mit großem Durchmesser.

27. Verwenden Sie ausschließlich die für dieses

Werkzeug vorgeschriebenen Flansche.

28. Wenn eine Trennscheibe mit Gewindebohrung am

Werkzeug montiert werden soll, achten Sie darauf,

dass das Gewinde der Trennscheibe tief genug für

die Spindellänge ist.

29. Vergewissern Sie sich, dass das Werkstück sicher

eingespannt ist.

30. Beachten Sie, dass sich die Schleifscheibe nach

dem Ausschalten des Werkzeugs noch

weiterdreht.

31. Falls der Arbeitsplatz sehr heiß, feucht oder durch

leitfähigen Staub stark verschmutzt ist, verwenden

Sie zum Schutz des Bedieners einen

Kurzschlussschalter (30 mA).

32. Verwenden Sie dieses Werkzeug nicht zum

Bearbeiten von asbesthaltigen Materialien.

33. Tragen Sie bei der Arbeit mit diesem Werkzeug

keine Arbeitshandschuhe aus Stoff. Fasern der

Stoffhandschuhe könnten in das Werkzeug gelangen

und zum Ausfall des Werkzeugs führen.

BEWAHREN SIE DIESE

ANLEITUNG SORGFÄLTIG AUF.

WARNUNG:

Lassen Sie sich NIE durch Bequemlichkeit oder (aus

fortwährendem Gebrauch gewonnener) Vertrautheit

mit dem Werkzeug dazu verleiten, die

Sicherheitsregeln für das Werkzeug zu missachten.

Bei MISSBRÄUCHLICHER Verwendung des

Werkzeugs oder bei Missachtung der in diesem

Handbuch enthaltenen Sicherheitshinweise kann es

zu schweren Verletzungen kommen.

Page 17

FUNKTIONSBESCHREIBUNG

ACHTUNG:

• Schalten Sie das Werkzeug stets aus und ziehen Sie

den Stecker, bevor Sie Einstellungen oder eine

Funktionsprüfung am Werkzeug vornehmen.

Spindelarretierung

ACHTUNG:

• Betätigen Sie die Spindelarretierung niemals bei

rotierender Spindel. Andernfalls kann das Werkzeug

beschädigt werden.

Drücken Sie die Spindelarretierung, um die Spindel bei

der Montage oder Demontage von Zubehör zu blockieren.

(Abb. 1)

Einschalten

ACHTUNG:

• Achten Sie vor dem Einstecken des

Werkzeugnetzsteckers in die Steckdose darauf, dass

sich der Ein/Aus-Schalter korrekt bedienen lässt und

beim Loslassen in die Position „OFF“ (AUS)

zurückkehrt. (Abb. 2)

Für Werkzeuge ohne Arretiertaste

Betätigen Sie zum Starten des Werkzeugs einfach den

Ein/Aus-Schalter. Lassen Sie zum Ausschalten des

Werkzeugs den Ein/Aus-Schalter los.

Für Werkzeuge mit Arretiertaste

ACHTUNG:

• Um die Bedienung bei längerem Gebrauch zu

vereinfachen, kann der Schalter in der Stellung „ON“

(EIN) arretiert werden. Seien Sie vorsichtig, wenn der

Schalter des Werkzeugs in der Position „ON“ (EIN)

arretiert ist, und halten Sie das Werkzeug gut fest.

Betätigen Sie zum Starten des Werkzeugs einfach den

Ein/Aus-Schalter. Lassen Sie zum Ausschalten des

Werkzeugs den Ein/Aus-Schalter los.

Für einen Dauerbetrieb betätigen Sie den Ein/AusSchalter, und drücken Sie dann die Arretiertaste hinein.

Zur Aufhebung der Arretierung müssen Sie den Ein/AusSchalter bis zum Anschlag betätigen und anschließend

loslassen.

MONTAGE

ACHTUNG:

• Schalten Sie das Werkzeug stets aus und ziehen Sie

den Netzstecker, bevor Sie irgendwelche Arbeiten am

Werkzeug durchführen.

Einsetzen des Seitengriffs (Handgriff)

ACHTUNG:

• Vergewissern Sie sich vor dem Betrieb stets, dass der

Seitengriff ordnungsgemäß montiert ist.

Schrauben Sie den Seitengriff an der in der Abbildung

gezeigten Position am Werkzeug fest. (Abb. 3)

Montage und Demontage der

Schutzhaube (für gekröpfte Scheiben/

Multischeiben)

ACHTUNG:

• Bei Verwendung einer gekröpften Trennschleifscheibe/

Multischeibe muss die Schutzhaube so am Werkzeug

angebracht werden, dass die geschlossene Seite stets

in Richtung Bediener zeigt.

Montieren Sie die Schutzhaube so, dass der Vorsprung

am Schutzhaubenring an der Nut im Lagergehäuse

ausgerichtet ist. Drehen Sie anschließend die

Schutzhaube in einen solchen Winkel, in dem der

Bediener bei seiner Arbeit entsprechend geschützt wird.

Achten Sie darauf, die Schraube fest anzuziehen.

(Abb. 4)

Zum Demontieren der Schutzhaube befolgen Sie die

Vorgehensweise zum Einbauen in umgekehrter

Reihenfolge.

Montage und Demontage der gekröpften

Trennschleifscheibe/Multischeibe

(Sonderzubehör)

WARNUNG:

• Wenn die gekröpfte Trennschleifscheibe/Multischeibe

am Werkzeug befestigt ist, muss stets die mitgelieferte

Schutzhaube verwendet werden. Die Scheibe kann

während des Gebrauchs zerbersten. Durch die

Schutzhaube wird die Verletzungsgefahr deutlich

verringert.

Setzen Sie den Innenflansch auf die Spindel. Setzen Sie

die Trenn-/Schleifscheibe auf den Innenflansch und

schrauben Sie die Sicherungsmutter auf die Spindel.

(Abb. 5)

Drücken Sie zum Anziehen der Sicherungsmutter die

Spindelarretierung fest, um die Spindel zu blockieren;

ziehen Sie dann die Mutter mit dem

Sicherungsmutterschlüssel im Uhrzeigersinn fest an.

(Abb. 6)

Zum Entnehmen der Scheibe befolgen Sie die

Vorgehensweise zum Einbauen in umgekehrter

Reihenfolge.

BETRIEB

WARNUNG:

• Es sollte nicht notwendig sein, Druck auf das

Werkzeug auszuüben. Das Eigengewicht des

Werkzeugs übt ausreichenden Druck aus.

Gewaltanwendung und übermäßiger Druck können zu

einem gefährlichen Schleifscheibenbruch führen.

• Wechseln Sie die Schleifscheibe IMMER aus, falls das

Werkzeug während der Arbeit fallen gelassen wurde.

• Eine Schleif- oder Trennscheibe darf NIEMALS gegen

das Werkstück geschlagen oder gestoßen werden.

• Achten Sie besonders beim Bearbeiten von Ecken,

scharfen Kanten usw. darauf, dass die Schleifscheibe

nicht springt oder hängen bleibt. Dies könnte den

Verlust der Kontrolle und Rückschläge verursachen.

• Verwenden Sie das Werkzeug NIEMALS mit

Holzschneide- oder anderen Sägeblättern. Solche

Sägeblätter verursachen bei Verwendung an einem

17

Page 18

Schleifer häufiges Rückschlagen und Verlust der

Kontrolle, was zu Verletzungen führen kann.

ACHTUNG:

• Schalten Sie das Werkzeug niemals ein, wenn es in

Kontakt mit dem Werkstück steht, da dies eine

Verletzungsgefahr für den Bediener darstellt.

• Tragen Sie bei der Arbeit stets eine Schutzbrille oder

einen Gesichtsschutz.

• Schalten Sie das Werkzeug nach der Arbeit stets aus

und warten Sie, bis die Scheibe zum völligen Stillstand

gekommen ist, bevor Sie das Werkzeug ablegen.

Schleifbetrieb (Abb. 7)

Halten Sie das Werkzeug IMMER mit einer Hand am

hinteren Griff und mit der anderen am Seitengriff fest.

Schalten Sie das Werkzeug ein und bringen Sie die

Trenn- oder Schleifscheibe an das Werkstück.

Halten Sie die Trenn- oder Schleifscheibe im Allgemeinen

in einem Winkel von etwa 15 Grad zur

Werkstoffoberfläche.

Bewegen Sie den Schleifer beim Einschleifen einer neuen

Schleifscheibe nicht in Richtung B, weil die Schleifscheibe

sonst in das Werkstück einschneidet. Sobald die

Schleifscheibenkante durch Gebrauch abgerundet ist,

kann die Schleifscheibe sowohl in Richtung A als auch in

Richtung B bewegt werden.

WARTUNG

ACHTUNG:

• Schalten Sie das Gerät aus und ziehen Sie immer den

Netzstecker, bevor Sie Inspektionen oder

Wartungsarbeiten am Gerät vornehmen.

• Verwenden Sie zum Reinigen niemals Kraftstoffe,

Benzin, Verdünner, Alkohol oder ähnliches. Dies kann

zu Verfärbungen, Verformungen oder Rissen führen.

Halten Sie das Werkzeug und die Lüftungsschlitze des

Werkzeugs stets sauber. Reinigen Sie die

Lüftungsschlitze des Werkzeugs regelmäßig oder bei

Beginn einer Verstopfung. (Abb. 8)

Ersetzen der Kohlebürsten (Abb. 9)

Entnehmen und überprüfen Sie die Kohlebürsten in

regelmäßigen Abständen. Wenn die Kohlebürsten bis zur

Verschleißgrenze abgenutzt sind, müssen die

Kohlebürsten durch neue ersetzt werden. Halten Sie die

Kohlebürsten sauber und sorgen Sie dafür, dass die

Bürsten locker in den Halterungen gleiten. Ersetzen Sie

immer beide Kohlebürsten gleichzeitig. Verwenden Sie

nur identische Kohlebürsten.

Nehmen Sie die Bürstenhalterkappen mit Hilfe eines

Schraubendrehers ab. Entnehmen Sie die verbrauchten

Kohlebürsten, setzen Sie neue Bürsten ein und bringen

Sie die Bürstenhalterkappen wieder fest an. (Abb. 10)

Zur Gewährleistung von SICHERHEIT und

ZUVERLÄSSIGKEIT des Produkts sollten Reparaturen,

Wartungsarbeiten und Einstellungen nur durch von

Makita autorisierte Servicecenter durchgeführt und

ausschließlich Makita-Ersatzteile verwendet werden.

Schallpegel

ENG905-1

Typischer A-bewerteter Schallpegel nach EN60745:

Modell M9002

Schalldruckpegel (L

Schallleistungspegel (L

Abweichung (K): 3 dB (A)

): 91 dB (A)

pA

): 102 dB (A)

WA

Modell M9003

Schalldruckpegel (L

Schallleistungspegel (L

Abweichung (K): 3 dB (A)

): 90 dB (A)

pA

): 101 dB (A)

WA

Tragen Sie Gehörschutz.

Schwingung

ENG900-1

Schwingungsgesamtwerte (Vektorsumme dreier Achsen)

nach EN60745:

Arbeitsmodus: Planschleifen

Vibrationsemission (a

Abweichung (K): 1,5 m/s

h,AG

2

): 9,0 m/s

2

ENG902-1

• Der hier angegebene Wert für die erzeugten

Schwingungen wurde gemäß dem genormten

Testverfahren ermittelt und kann als Vergleich zu

anderen Werkzeugen herangezogen werden.

• Der angegebene Wert für die erzeugten Schwingungen

ist außerdem für eine vorbeugende Bewertung der

Belastung zu verwenden.

• Der angegebene Wert für die erzeugten Schwingungen

gilt, wenn das Elektrowerkzeug für den vorgesehenen

Zweck verwendet wird. Wenn das Werkzeug für andere

Zwecke verwendet wird, kann der Wert für die

Schwingungsbelastung jedoch von dem hier

aufgeführten Wert abweichen.

WARNUNG:

• Die Schwingungsbelastung kann bei tatsächlichem

Gebrauch des Elektrowerkzeugs in Abhängigkeit von

der Handhabung des Elektrowerkzeugs von dem hier

aufgeführten Wert abweichen.

• Stellen Sie sicher, dass Schutzmaßnahmen für den

Bediener getroffen werden, die auf den unter den

tatsächlichen Arbeitsbedingungen zu erwartenden

Belastungen beruhen (beziehen Sie alle Bestandteile

des Arbeitsablaufs ein, also zusätzlich zu den

Arbeitszeiten auch Zeiten, in denen das Werkzeug

ausgeschaltet ist oder ohne Last läuft).

Nur für europäische Länder

ENH101-18

EG-Konformitätserklärung

Makita erklärt, dass die nachfolgende(n) Maschine(n):

Bezeichnung der Maschine(n):

Winkelschleifer

Nummer/Typ des Modells: M9002, M9003

den folgenden Richtlinien der Europäischen Union

genügt/genügen:

2006/42/EG

18

Page 19

Sie werden gemäß den folgenden Standards oder

Normen gefertigt:

EN60745

Die technischen Unterlagen gemäß 2006/42/EG sind

erhältlich von:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

2. 1. 2015

Yasushi Fukaya

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

Direktor

19

Page 20

Makita Jan-Baptist Vinkstraat 2, 3070, Belgium

Makita Corporation Anjo, Aichi, Japan

885412-993 www.makita.com

ALA

Loading...

Loading...