Page 1

GB Hammer Drill Instruction Manual

M8100

M8101

F Perceuse à Percussion Manuel d’instructions

D Schlagbohrmaschine Betriebsanleitung

I Trapano a percussione Istruzioni per l’uso

NL Hamerboor Gebruiksaanwijzing

E Rotomartillo Manual de instrucciones

P Furadeira de Impacto Manual de instruções

DK Borehammer Brugsanvisning

GR Κρουστικό τρυπάνι Οδηγίες χρήσεως

TR Darbeli matkap Kullanma kılavuzu

Page 2

12

4

1

2

3

5

6

7

8

9

10

12

1

11

13

14

15

A

B

16

011089 011090

34

56

78

2

011095 011091

011092 011093

011094 015487

Page 3

ENGLISH (Original instructions)

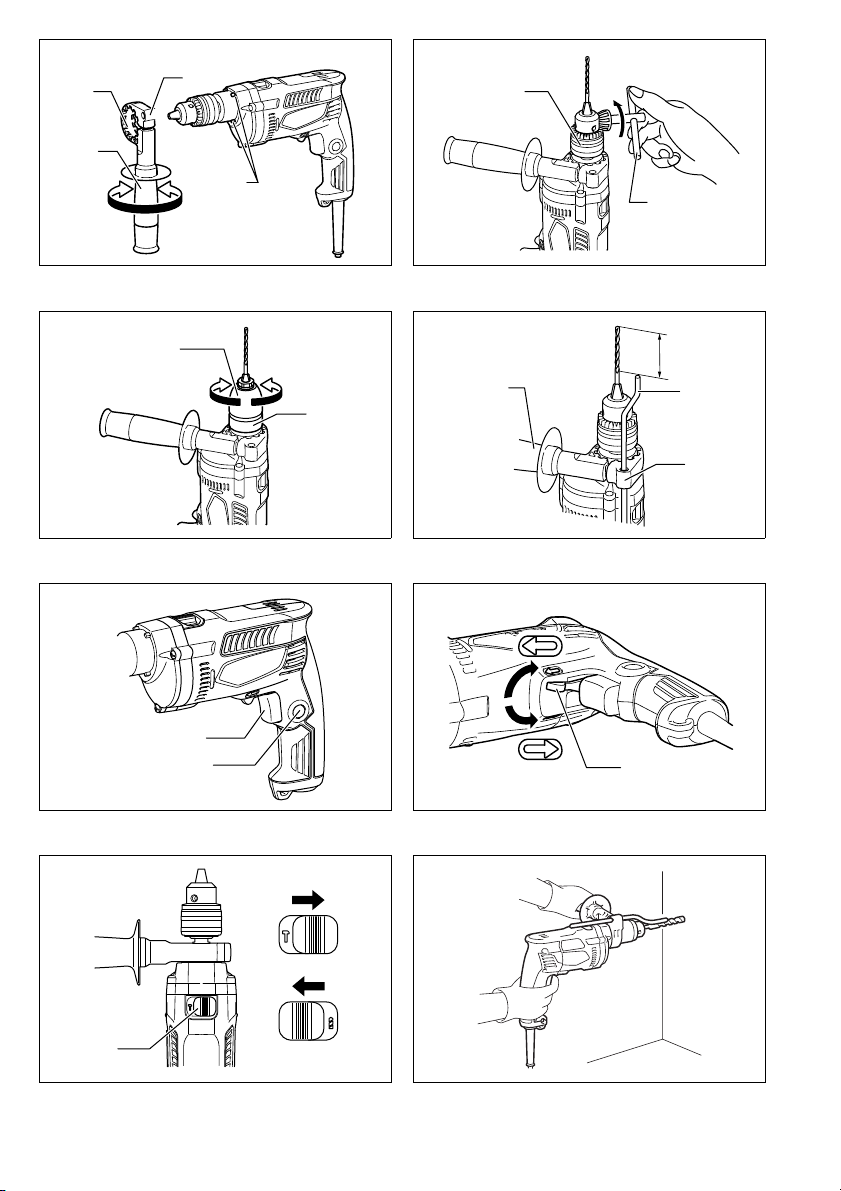

Explanation of general view

1Grip base

2 Teeth

3 Side grip (auxiliary handle)

4Protrusion

5 Loosen

6Tighten

SPECIFICATIONS

Model M8100 M8101

Capacities

No load speed (min

Blows per minute 0 – 48,000

Overall length 296 mm 295 mm

Net weight 2.1 kg 2.0 kg

Safety class /II

• Due to our continuing program of research and

development, the specifications herein are subject to

change without notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

Intended use

The tool is intended for impact drilling in brick, concrete

and stone as well as for drilling without impact in wood,

metal, ceramic and plastic.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated and can, therefore, also be used from

sockets without earth wire.

General Power Tool Safety Warnings

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and instructions for future

reference.

HAMMER DRILL SAFETY WARNINGS

1. Wear ear protectors when impact drilling.

Exposure to noise can cause hearing loss.

2. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool “live”

and could give the operator an electric shock.

7 Drill chuck

8 Chuck key

9Sleeve

10 Ring

11 Si de g rip

12 Depth gauge

Concrete 16 mm

Wood 30 mm

Steel 13 mm

–1

) 0–3,200

ENE039-1

ENF002-2

GEA010-1

GEB003-5

13 Switch trigger

14 Lock button

15 Reversing switch lever

16 Action mode changing lever

4. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

5. Hold the tool firmly with both hands.

6. Keep hands away from rotating parts.

7. Do not leave the tool running. Operate the tool

only when hand-held.

8. Do not touch the bit or the workpiece

immediately after operation; they may be

extremely hot and could burn your skin.

9. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to safety rules for the subject product. MISUSE or

failure to follow the safety rules stated in this

instruction manual may cause serious personal

injury.

ASSEMBLY

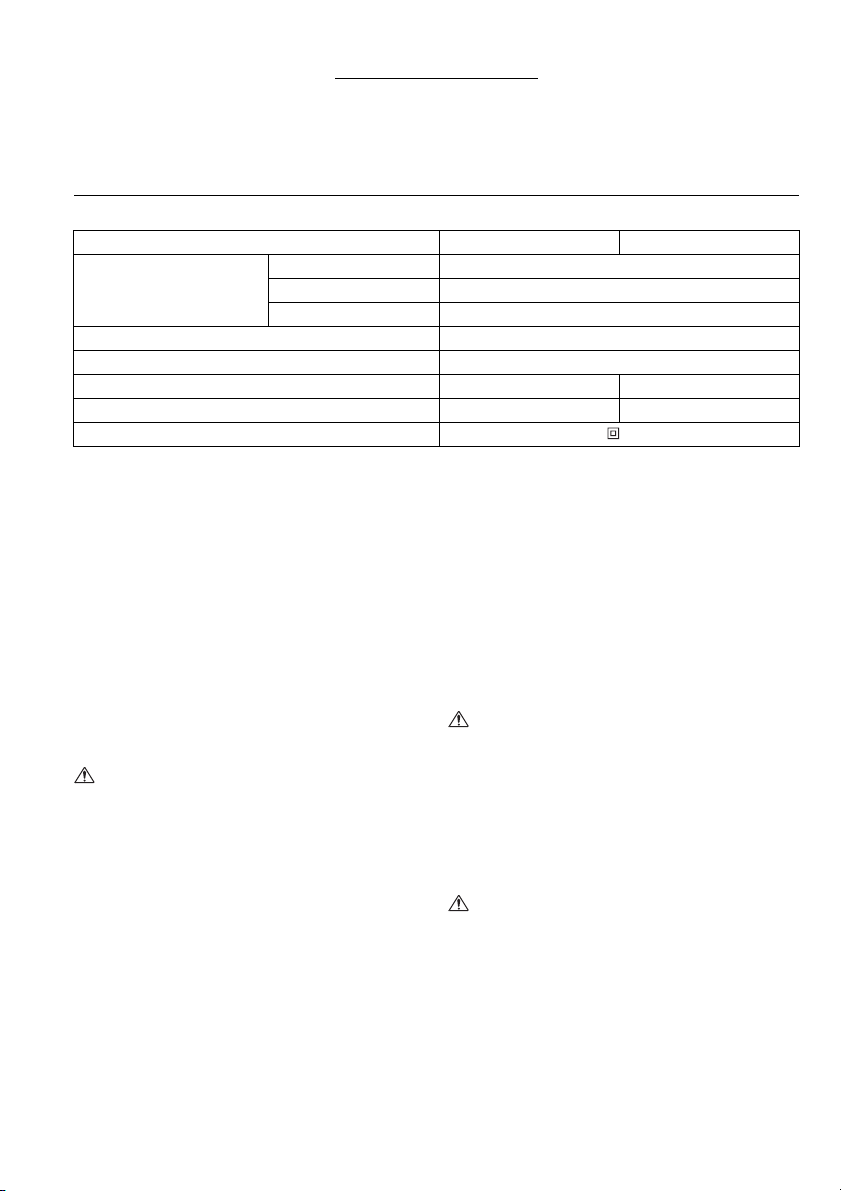

Installing side grip (auxiliary handle) (Fig. 1)

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the side grip.

Always use the side grip to ensure operating safety.

Install the side grip so that the teeth on the grip fit in

between the protrusions on the tool barrel. Then tighten

the grip by turning clockwise at the desired position. It

may be swung 360° so as to be secured at any position.

3

Page 4

Installing or removing drill bit

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the bit.

For Model M8100 (Fig. 2)

To install the bit, place it in the chuck as far as it will go.

Tighten the chuck by hand. Place the chuck key in each

of the three holes and tighten clockwise. Be sure to

tighten all three chuck holes evenly. To remove the bit,

turn the chuck key counterclockwise in just one hole,

then loosen the chuck by hand.

After using the chuck key, be sure to return it to the

original position.

For Model M8101 (Fig. 3)

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws. Place the bit in the chuck as far as

it will go. Hold the ring firmly and turn the sleeve

clockwise to tighten the chuck.

To remove the bit, hold the ring and turn the sleeve

counterclockwise.

Depth gauge (Fig. 4)

The depth gauge is convenient for drilling holes of

uniform depth. Loosen the side grip and insert the depth

gauge into the hole in the grip base. Adjust the depth

gauge to the desired depth and tighten the side grip.

NOTE:

• The depth gauge cannot be used at the position where

the depth gauge strikes against the gear housing.

FUNCTIONAL DESCRIPTION

Switch action (Fig. 5)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop. For continuous

operation, pull the switch trigger, push in the lock button

and then release the switch trigger. To stop the tool from

the locked position, pull the switch trigger fully, then

release it.

Reversing switch action (Fig. 6)

This tool has a reversing switch to change the direction

of rotation. Move the reversing switch lever to the D

position (A side) for clockwise rotation or to the E

position (B side) for counterclockwise rotation.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

Selecting the action mode (Fig. 7)

This tool has an action mode change lever. For rotation

with hammering, slide the action mode change lever to

the right (g symbol). For rotation only, slide the action

mode change lever to the left (m symbol).

CAUTION:

• Always slide the action mode change lever all the way

to your desired mode position. If you operate the tool

with the lever positioned halfway between the mode

symbols, the tool may be damaged.

OPERATION (Fig. 8)

Always hold the tool only by the handle when performing

an operation. Do not touch the metal part.

Hammer drilling operation

CAUTION:

• There is tremendous and sudden twisting force exerted

on the tool/bit at the time of hole break-through, when

the hole becomes clogged with chips and particles, or

when striking reinforcing rods embedded in the

concrete. Always use the side grip (auxiliary handle)

and firmly hold the tool by both side grip and switch

handle during operations. Failure to do so may result in

the loss of control of the toll and potentially serve injury.

When drilling in concrete, granite, tile, etc., slide the

action mode change lever to the position of g symbol to

use “rotation with hammering” action. Be sure to use a

tungsten-carbide tipped bit. Do not apply more pressure

when the hole becomes clogged with chips or particles.

Instead, run the tool at an idle, then remove the bit

partially from the hole. By repeating this several times,

the hole will be cleaned out.

After drilling the hole, use the blow-out bulb to clean the

dust out of the hole.

Drilling operation

When drilling in wood, metal or plastic materials, slide the

action mode change lever to the position of m symbol to

use “rotation only” action.

Drilling in wood

When drilling in wood, the best results are obtained with

wood drills equipped with a guide screw. The guide

screw makes drilling easier by pulling the bit into the

workpiece.

Drilling in metal

To prevent the bit from slipping when starting a hole,

make an indentation with a center-punch and hammer at

the point to be drilled. Place the point of the bit in the

indentation and start drilling. Use a cutting lubricant when

drilling metals. The exceptions are iron and brass which

should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool

performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole break through. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back

out. However, the tool may back out abruptly if you do

not hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

4

Page 5

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

• Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by a

Makita Authorized Service Center.

Noise

The typical A-weighted noise level determined according

to EN60745:

L

Sound pressure level (

Sound power level (

Uncertainty (K): 3 dB (A)

Vibration

The vibration total value (tri-axial vector sum) determined

Wear ear protection

): 98 dB (A)

pA

L

): 109 dB (A)

WA

according to EN60745:

Work mode: impact drilling into concrete

Vibration emission (

Uncertainty (K): 2.0 m/s

Work mode: drilling into metal

Vibration emission (

Uncertainty (K): 1.5 m/s

a

h, ID

a

h, D

)

: 16.5 m/s

2

): 3.0 m/s

2

2

2

• The declared vibration emission value has been

measured in accordance with the standard test method

and may be used for comparing one tool with another.

• The declared vibration emission value may also be

used in a preliminary assessment of exposure.

WARNING:

• The vibration emission during actual use of the power

tool can differ from the declared emission value

depending on the ways in which the tool is used.

• Be sure to identify safety measures to protect the

operator that are based on an estimation of exposure in

the actual conditions of use (taking account of all parts

of the operating cycle such as the times when the tool

is switched off and when it is running idle in addition to

the trigger time).

ENG905-1

ENG900-1

ENG901-1

For European countries only

ENH101-18

EC Declaration of Conformity

Makita declares that the following Machine(s):

Designation of Machine:

Hammer Drill

Model No./ Type: M8100, M8101

Conforms to the following European Directives:

2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents:

EN60745

The technical file in accordance with 2006/42/EC is

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

1.12.2014

Yasushi Fukaya

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

Director

5

Page 6

FRANÇAIS (Instructions originales)

Descriptif

1 Embase de la poignée

2Crans

3 Poignée latérale

(poignée auxiliaire)

4 Saillie

5 Desserrer

SPÉCIFICATIONS

Modèle M8100 M8101

Capacités

Vitesse à vide (min

Cadence de frappe/mn 0 – 48 000

Longueur totale 296 mm 295 mm

Poids net 2,1 kg 2,0 kg

Catégorie de sécurité

• Étant donné l’évolution constante de notre programme

de recherche et de développement, les spécifications

contenues dans ce manuel sont sujettes à modification

sans préavis.

• Les spécifications peuvent varier suivant les pays.

• Poids selon la procédure EPTA 01/2003

Utilisations

L’outil est conçu pour le perçage avec chocs dans la

brique, le béton et la pierre, ainsi que pour le perçage

sans choc dans le bois, le métal, la céramique et le

plastique.

Alimentation

L’outil ne devra être raccordé qu’à une alimentation de la

même tension que celle qui figure sur la plaque

signalétique, et il ne pourra fonctionner que sur un

courant secteur monophasé. Réalisé avec une double

isolation, il peut de ce fait être alimenté sans mise à la

terre.

Consignes de sécurité générales pour outils

électriques

AVERTISSEMENT Veuillez lire toutes les mises

en garde et toutes les instructions. Il y a risque de

choc électrique, d’incendie et/ou de blessure grave si les

mises en garde et les instructions ne sont pas

respectées.

Conservez toutes les mises en garde et instructions

pour référence ultérieure.

CONSIGNES DE SÉCURITÉ POUR LA

PERCEUSE À PERCUSSION

1. Portez des protections d’oreilles lorsque vous

utilisez une perceuse à percussion. L’exposition

au bruit peut entraîner la surdité.

6 Serrer

7 Mandrin porte-foret

8 Clé de mandrin

9 Manchon

10 Anneau

11 Poignée latérale

Béton 16 mm

Bois 30 mm

Acier 13 mm

–1

) 0–3200

ENE039-1

ENF002-2

GEA010-1

GEB003-5

12 Tige de profondeur

13 Gâchette de l’interrupteur

14 Bouton de blocage

15 Levier inverseur

16 Levier de changement de mode

/II

2. Utilisez la ou les poignée(s) auxiliaire(s), si l’outil

en possède. La perte de contrôle comporte un

risque de blessure.

3. Saisissez l’outil électrique par ses surfaces de

poigne isolées lorsque vous effectuez une

opération au cours de laquelle l’outil tranchant

peut entrer en contact avec un câble caché ou

avec son propre cordon d’alimentation. Le

contact de l’outil tranchant avec un fil sous tension

peut mettre les parties métalliques de l’outil

électrique sous tension et causer un choc électrique

chez l’utilisateur.

4. Assurez-vous toujours de travailler en position

stable.

Lorsque vous utilisez l’outil dans un endroit

élevé, assurez-vous qu’il n’y a personne en bas.

5. Tenez l’outil fermement à deux mains.

6. Gardez les mains éloignées des pièces en

mouvement.

7. Ne laissez pas l’outil tourner. Ne le faites

fonctionner que lorsque vous le tenez.

8. Ne touchez pas le foret ou le matériau

immédiatement après l’utilisation ; ils peuvent

être extrêmement chauds et brûler votre peau.

9. Certains matériaux contiennent des produits

chimiques qui peuvent être toxiques. Prenez les

précautions nécessaires pour éviter que la

poussière dégagée lors du travail ne soit inhalée

ou n’entre en contact avec la peau. Suivez les

consignes de sécurité du fournisseur du

matériau.

CONSERVEZ CES INSTRUCTIONS.

6

Page 7

AVERTISSEMENT :

NE vous laissez PAS tromper (au fil d’une utilisation

répétée) par un sentiment d’aisance et de familiarité

avec le produit, en néglige, ant le respect rigoureux

des consignes de sécurité qui accompagnent le

produit en question. La MAUVAISE UTILISATION de

l’outil ou l’ignorance des consignes de sécurité

indiquées dans ce manuel d’instructions peut

entraîner une blessure grave.

ASSEMBLAGE

Pose de la poignée latérale (poignée auxiliaire)

(Fig. 1)

ATTENTION :

• Assurez-vous toujours que l’outil est hors tension et

débranché avant de poser ou de retirer la poignée

latérale.

Pour garantir un travail en toute sécurité, utilisez toujours

la poignée latérale. Installez la poignée latérale de façon

que les crans de la poignée s’insèrent entre les saillies

du collet de l’outil. Puis, serrez la poignée en la tournant

vers la droite sur la position voulue. Elle pivote sur 360°,

ce qui permet de la fixer à n’importe quelle position.

Installation et retrait du foret

ATTENTION :

• Vérifiez toujours que l’outil est arrêté et que son câble

d’alimentation est débranché avant d’installer ou de

retirer le foret.

Pour le modèle M8100 (Fig. 2)

Pour installer le foret, introduisez-le à fond dans le

mandrin. Serrez le mandrin à la main. Puis introduisez la

clé de mandrin dans chacun des trois trous et serrez en

tournant en sens des aiguilles d’une montre. Veillez à

bien serrer les trois trous de façon uniforme. Pour retirer

le foret, tournez la clé de mandrin en sens inverse des

aiguilles d’une montre dans l’un des trois trous

seulement, puis desserrez à la main.

Après avoir utilisé la clé de mandrin, replacez-la dans le

porte-clé.

Pour le modèle M8101 (Fig. 3)

Saisissez l’anneau et tournez le manchon en sens

inverse des aiguilles d’une montre pour ouvrir les

mâchoires du mandrin. Placez le foret dans le mandrin

en l’enfonçant le plus loin possible. Saisissez fermement

l’anneau et tournez le manchon en sens des aiguilles

d’une montre pour serrer le mandrin.

Pour retirer le foret, saisissez l’anneau et tournez le

manchon en sens inverse des aiguilles d’une montre.

Tige de profondeur (Fig. 4)

La tige de profondeur vous permet de percer des trous

de longueur uniforme. Desserrez la poignée latérale et

insérez la tige de profondeur dans l’orifice à la embase

de la poignée. Réglez la tige à la profondeur voulue puis

serrez la poignée latérale.

NOTE :

• La tige de profondeur ne pourra pas être utilisée à

l’endroit où elle bute sur le carter d’engrenage.

DESCRIPTION DU FONCTIONNEMENT

Interrupteur (Fig. 5)

ATTENTION :

• Avant de brancher l’outil, vérifiez toujours que la

gâchette de l’interrupteur fonctionne et qu’elle revient

sur la position “OFF” une fois relâchée.

Pour mettre l’outil en route, il suffit de tirer sur la gâchette

de l’interrupteur. Plus vous appuyez sur la gâchette de

l’interrupteur, plus la vitesse de l’outil augmente. Pour

arrêter l’outil, relâchez la gâchette de l’interrupteur. Pour

obtenir un fonctionnement continu, tirez sur la gâchette

de l’interrupteur, appuyez sur le bouton de blocage et

relâchez la gâchette de l’interrupteur. Pour arrêter l’outil

lorsqu’il fonctionne en continu, tirez à fond sur la

gâchette de l’interrupteur et relâchez-la.

Inverseur (Fig. 6)

Cet outil est muni d’un inverseur pour modifier le sens de

rotation. Déplacez le levier inverseur sur la position D

(côté A) pour une rotation en sens des aiguilles d’une

montre, et sur la position E (côté B) pour une rotation

en sens inverse.

ATTENTION :

• Vérifiez toujours le sens de la rotation avant d’utiliser

l’outil.

• N’utilisez l’inverseur qu’une fois l’outil parfaitement

arrêté. Sinon, vous risquez d’endommager l’outil.

Sélection du mode de fonctionnement (Fig. 7)

Cet outil est muni d’un levier de changement de mode.

Pour une rotation avec frappe, glissez ce levier vers la

droite (symbole g). Pour une rotation seulement,

glissez-le vers la gauche (symbole m).

ATTENTION :

• Glissez toujours le levier de changement de mode

complètement sur la position du mode désiré. Si vous

faites fonctionner l’outil en plaçant le levier entre les

symboles de mode, vous risquez d’endommager l’outil.

PERCAGE (Fig. 8)

Tenez toujours l’outil uniquement par sa poignée pour

travailler. Ne touchez pas la partie métallique.

Perçage avec frappe

ATTENTION :

• Une force énorme s’exerce sur le foret et l’outil lorsque

le foret émerge sur la face opposée, lorsque le trou est

encombré de copeaux ou de particules, ou lors de la

frappe sur des barres d’armature encastrées dans le

béton. Utilisez toujours la poignée latérale (poignée

auxiliaire) et tenez fermement l’outil par la poignée

latérale et par la poignée revolver lors des travaux.

Sinon, vous risquez de perdre le contrôle de l’outil et

de subir une blessure grave.

Lorsque vous percez du béton, granite, carrelage, etc.,

glissez le levier de changement de mode sur la position

du symbole g pour obtenir un mouvement de “rotation

avec frappe”. Assurez-vous d’utiliser un foret à pointe en

carbure de tungstène. N’appliquez pas davantage de

pression lorsque le trou est bouché par les copeaux et

particules. Faites plutôt tourner l’outil au ralenti, puis

retirez partiellement la mèche du trou. En répétant cette

opération quelques fois, le trou se débouchera.

Une fois le trou percé, utilisez la poire soufflante pour

retirer la poussière du trou.

7

Page 8

Perçage

Lorsque vous percez dans les matériaux de bois, de

métal ou de plastique, glissez le levier de changement de

mode sur la positon du symbole m pour obtenir un

mouvement de “rotation seulement”.

Perçage du bois

Lorsque vous percez dans du bois, vous obtiendrez de

meilleurs résultats avec des forets munis d’une vis-guide.

Celle-ci rend le perçage plus aisé en tirant le foret à

l’intérieur de la pièce.

Perçage du métal

Pour empêcher le foret de glisser en début de perçage,

faites une indentation au point de perçage à l’aide d’un

poinçon et d’un marteau. Placez ensuite la pointe du

foret dans l’indentation et commencez à percer. Quand

vous percez dans du métal, utilisez un lubrifiant. Seuls le

fer et le laiton peuvent se percer à sec.

ATTENTION :

• Une pression excessive sur l’outil n’accélère pas le

perçage. Au contraire, elle risque d’endommager la

pointe du foret, de réduire le rendement de l’outil et

donc sa durée de service.

• Une force énorme s’exerce sur le foret et l’outil quand

le premier émerge sur la face postérieure. Tenez votre

outil fermement et faites bien attention dès que le foret

commence à approcher de la face opposée du

matériau que vous percez.

• Un foret coincé peut se retirer en plaçant l’inverseur sur

la direction opposée. Il faut alors faire très attention car

l’outil risque de reculer brusquement si vous ne le

tenez pas fermement.

• Assurez toujours les petites pièces à percer à l’aide

d’un étau ou d’un mode de fixation analogue.

ENTRETIEN

ATTENTION :

• Assurez-vous toujours que l’outil est hors tension et

hors secteur avant toute intervention.

• N’utilisez jamais d’essence, benzine, diluant, alcool ou

autre produit similaire. Cela risquerait de provoquer la

décoloration, la déformation ou la fissuration de l’outil.

Pour maintenir la sécurité et la fiabilité du produit, les

réparations, l’entretien ou les réglages doivent être

effectués par le Centre d’Entretien Makita.

ENG905-1

Bruit

Niveau de bruit pondéré A typique, déterminé selon

EN60745 :

Niveau de pression sonore (

Niveau de puissance sonore (

Incertitude (K) : 3 dB (A)

Porter des protecteurs anti-bruit

Vibrations

Valeur totale de vibrations (somme de vecteur triaxial)

déterminée selon EN60745 :

Mode de travail : Perçage avec chocs dans le béton

Émission de vibrations (

Incertitude (K) : 2,0 m/s

Mode de travail : Perçage dans le métal

Émission de vibrations (

Incertitude (K) : 1,5 m/s

a

h, ID

2

a

h, D

2

L

) : 98 dB (A)

pA

L

) : 109 dB (A)

WA

) : 16,5 m/s

) : 3,0 m/s

ENG900-1

2

2

• La valeur d’émission de vibrations déclarée a été

mesurée conformément à la méthode de test standard

et peut être utilisée pour comparer les outils entre eux.

• La valeur d’émission de vibrations déclarée peut aussi

être utilisée pour l’évaluation préliminaire de

l’exposition.

ENG901-1

AVERTISSEMENT :

• L’émission de vibrations lors de l’usage réel de l’outil

électrique peut être différente de la valeur d’émission

déclarée, suivant la façon dont l’outil est utilisé.

• Les mesures de sécurité à prendre pour protéger

l’utilisateur doivent être basées sur une estimation de

l’exposition dans des conditions réelles d’utilisation (en

tenant compte de toutes les composantes du cycle

d’utilisation, comme par exemple le moment de sa

mise hors tension, lorsqu’il tourne à vide et le moment

de son déclenchement).

ENH101-18

Pour les pays d’Europe uniquement

Déclaration de conformité CE

Makita déclare que la (les) machine(s) suivante(s) :

Désignation de la machine :

Perceuse à Percussion

N° de modèle / Type : M8100, M8101

sont conformes aux directives européennes

suivantes :

2006/42/CE

et sont fabriquées conformément aux normes ou aux

documents normalisés suivants :

EN60745

La documentation technique conforme à la norme 2006/

42/CE est disponible auprès de :

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

1.12.2014

Yasushi Fukaya

Directeur

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

8

Page 9

DEUTSCH (Originale Anleitungen)

Übersicht

1 Griffbasis

2 Zähne

3 Seitengriff (Zusatzgriff)

4 Vorsprung

5 Lösen

6 Anziehen

TECHNISCHE DATEN

Modell M8100 M8101

Bohrleistungen

Leerlaufdrehzahl (min

Schlagzahl/min. 0 – 48.000

Gesamtlänge 296 mm 295 mm

Nettogewicht 2,1 kg 2,0 kg

Sicherheitsklasse /II

• Wir behalten uns vor, Änderungen im Zuge der

Entwicklung und des technischen Fortschritts ohne

vorherige Ankündigung vorzunehmen.

• Die technischen Daten können von Land zu Land

abweichen.

• Gewicht nach EPTA-Verfahren 01/2003

Vorgesehene Verwendung

Die Maschine ist für Schlagbohren in Ziegel, Beton und

Stein sowie für Bohren in Holz, Metall, Keramik und

Kunststoff vorgesehen.

Stromversorgung

Die Maschine darf nur an die auf dem Typenschild

angegebene Spannung angeschlossen werden und

arbeitet nur mit Einphasen-Wechselspannung. Diese

sind doppelt schutzisoliert und können daher auch an

Steckdosen ohne Erdleiter verwendet werden.

Allgemeine Sicherheitswarnungen für

Elektrowerkzeuge

WARNUNG Lesen Sie alle Sicherheitswarnungen

und Anweisungen durch. Eine Missachtung der unten

aufgeführten Warnungen und Anweisungen kann zu

einem elektrischen Schlag, Brand und/oder schweren

Verletzungen führen.

Bewahren Sie alle Warnungen und Anweisungen für

spätere Bezugnahme auf.

FÜR SCHLAGBOHRMASCHINESICHERHEITSWARNUNGEN

1. Tragen Sie Gehörschützer beim Arbeiten mit

Schlagbohrmaschinen. Lärmeinwirkung kann zu

Gehörverlust führen.

2. Benutzen Sie (einen) Zusatzgriff(e), sofern er

(sie) mit dem Werkzeug geliefert wurde(n).

Verlust der Kontrolle kann Verletzungen

verursachen.

7Bohrfutter

8 Bohrfutterschlüssel

9 Werkzeugaufnahme

10 Klemmring

11 Seitengriff

12 Tiefenanschlag

Beton 16 mm

Holz 30 mm

Stahl 13 m m

–1

)0–3.200

ENE039-1

ENF002-2

GEA010-1

GEB003-5

13 Ein-Aus-Schalter

14 Arretierknopf

15 Drehrichtungsumschalter

16 Betriebsart-Umschalthebel

3. Halten Sie Elektrowerkzeuge nur an den

isolierten Griffflächen, wenn Sie Arbeiten

ausführen, bei denen die Gefahr besteht, dass

verborgene Kabel oder das eigene Kabel

kontaktiert werden. Bei Kontakt mit einem Strom

führenden Kabel können die freiliegenden

Metallteile des Elektrowerkzeugs ebenfalls Strom

führend werden, so dass der Benutzer einen

elektrischen Schlag erleiden kann.

4. Achten Sie stets auf sicheren Stand.

Vergewissern Sie sich bei Einsatz der Maschine

an hochgelegenen Arbeitsplätzen, dass sich

keine Personen darunter aufhalten.

5. Die Maschine sicher mit beiden Händen

festhalten.

6. Halten Sie die Hände von rotierenden Teilen fern.

7. Lassen Sie die Maschine nicht unbeaufsichtigt

laufen. Benutzen Sie die Maschine nur mit

Handhaltung.

8. Vermeiden Sie eine Berührung des

Bohrereinsatzes oder des Werkstücks

unmittelbar nach der Bearbeitung, weil sie dann

noch sehr heiß sind und Hautverbrennungen

verursachen können.

9. Manche Materialien können giftige Chemikalien

enthalten. Treffen Sie Vorsichtsmaßnahmen, um

das Einatmen von Arbeitsstaub und Hautkontakt

zu verhüten. Befolgen Sie die Sicherheitsdaten

des Materialherstellers.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

WARNUNG:

Lassen Sie sich NICHT durch Bequemlichkeit oder

Vertrautheit mit dem Produkt (durch wiederholten

Gebrauch erworben) von der strikten Einhaltung der

Sicherheitsregeln für das vorliegende Produkt

abhalten. MISSBRAUCH oder Missachtung der

Sicherheitsvorschriften in dieser Anleitung können

schwere Verletzungen verursachen.

9

Page 10

MONTAGE

Montieren des Seitengriffs (Zusatzgriffs) (Abb. 1)

VORSICHT:

• Vergewissern Sie sich vor der Montage oder

Demontage des Seitengriffs stets, dass die Maschine

ausgeschaltet und vom Stromnetz getrennt ist.

Verwenden Sie stets den Seitengriff, um

Betriebssicherheit zu gewährleisten. Montieren Sie den

Seitengriff so, dass die Verzahnungen von Griff und

Maschinengehäuse ineinander eingreifen. Ziehen Sie

dann den Griff fest, indem Sie ihn an der gewünschten

Position im Uhrzeigersinn drehen. Der Griff kann um

360° geschwenkt und in jeder beliebigen Position

gesichert werden.

Montage und Demontage des Bohrers

VORSICHT:

• Vergewissern Sie sich vor der Montage oder

Demontage des Einsatzwerkzeugs stets, dass die

Maschine ausgeschaltet und vom Stromnetz getrennt

ist.

Für Modell M8100 (Abb. 2)

Führen Sie das Einsatzwerkzeug zum Montieren bis zum

Anschlag in das Bohrfutter ein. Ziehen Sie das Bohrfutter

von Hand an. Setzen Sie den Bohrfutterschlüssel in

jedes der drei Löcher ein, und drehen Sie ihn im

Uhrzeigersinn. Ziehen Sie das Bohrfutter in allen drei

Löchern mit gleicher Kraft an. Führen Sie den

Bohrfutterschlüssel zum Demontieren des

Einsatzwerkzeugs nur in ein Loch ein, und drehen Sie

ihn entgegen dem Uhrzeigersinn, bevor Sie das

Bohrfutter von Hand lösen.

Bringen Sie den Bohrfutterschlüssel nach Gebrauch

wieder an seinem ursprünglichen Platz an.

Für Modell M8101 (Abb. 3)

Halten Sie den Klemmring fest, und drehen Sie die

Werkzeugverriegelung entgegen dem Uhrzeigersinn, um

die Bohrfutterbacken zu öffnen. Führen Sie das

Einsatzwerkzeug bis zum Anschlag in das Spannfutter

ein. Halten Sie den Klemmring fest, und drehen Sie die

Werkzeugverriegelung im Uhrzeigersinn, um das

Bohrfutter festzuziehen.

Zum Entfernen des Einsatzwerkzeugs halten Sie den

Klemmring und drehen die Werkzeugverriegelung

entgegen dem Uhrzeigersinn.

Tiefenanschlag (Abb. 4)

Der Tiefenanschlag ist praktisch, um Löcher von gleicher

Tiefe zu bohren. Lösen Sie den Seitengriff, und führen

Sie den Tiefenanschlag in das Loch in der Griffbasis ein.

Stellen Sie den Tiefenanschlag auf die gewünschte

Bohrtiefe ein, und ziehen Sie den Seitengriff an.

HINWEIS:

• Der Tiefenanschlag kann nicht in einer Position

verwendet werden, in der er gegen das

Getriebegehäuse stößt.

FUNKTIONSBESCHREIBUNG

Schalterfunktion (Abb. 5)

VORSICHT:

• Vergewissern Sie sich vor dem Anschließen der

Maschine an das Stromnetz stets, dass der Ein-AusSchalter ordnungsgemäß funktioniert und beim

Loslassen in die AUS-Stellung zurückkehrt.

Zum Einschalten der Maschine einfach den Ein-AusSchalter drücken. Die Drehzahl erhöht sich durch

verstärkte Druckausübung auf den Ein-Aus-Schalter.

Zum Ausschalten lassen Sie den Ein-Aus-Schalter los.

Für Dauerbetrieb betätigen Sie den Ein-Aus-Schalter,

drücken Sie den Arretierknopf hinein und lassen Sie

dann den Ein-Aus-Schalter los. Zum Ausrasten des

Arretierknopfes drücken Sie den Ein-Aus-Schalter bis

zum Anschlag hinein und lassen ihn dann los.

Drehrichtungsumschalterbedienung (Abb. 6)

Diese Maschine besitzt einen Drehrichtungsumschalter.

Stellen Sie den Drehrichtungsumschalthebel für

Rechtsdrehung auf die Stellung D (Seite A) oder für

Linksdrehung auf die Stellung E (Seite B).

VORSICHT:

• Prüfen Sie stets die Drehrichtung, bevor Sie mit der

Arbeit beginnen.

• Betätigen Sie den Drehrichtungsumschalter erst,

nachdem die Maschine völlig zum Stillstand gekommen

ist. Durch Umschalten der Drehrichtung bei noch

laufender Maschine kann die Maschine beschädigt

werden.

Wahl der Betriebsart (Abb. 7)

Diese Maschine besitzt einen BetriebsartUmschalthebel. Schieben Sie den BetriebsartUmschalthebel für Schlagbohren nach rechts

(Symbol g). Schieben Sie den BetriebsartUmschalthebel für Bohren nach links (Symbol m).

VORSICHT:

• Schieben Sie den Betriebsart-Umschalthebel immer

bis zum Anschlag auf die gewünschte Position. Wird

die Maschine bei einer Zwischenstellung des Hebels

zwischen den Betriebsartpositionen betrieben, kann sie

beschädigt werden.

BETRIEB (Abb. 8)

Halten Sie die Maschine bei der Arbeit immer nur am

Handgriff. Berühren Sie nicht den Metallteil.

Schlagbohren

VORSICHT:

• Beim Durchbruch der Bohrung, bei Verstopfung der

Bohrung mit Spänen und Partikeln, oder beim

Auftreffen auf Betonstahl wirkt eine starke, plötzliche

Drehkraft auf Maschine und Bohrer. Montieren Sie

stets den Seitengriff (Zusatzgriff), und halten Sie die

Maschine während der Arbeit mit beiden Händen an

Seitengriff und Schaltergriff fest. Eine Missachtung

dieser Vorsichtsmaßnahme kann den Verlust der

Kontrolle über die Maschine und mögliche schwere

Verletzungen zur Folge haben.

10

Page 11

Schieben Sie den Betriebsart-Umschalthebel zum

Bohren in Beton, Granit, Fliesen usw. zur Position des

Symbols g, um die Betriebsart “Schlagbohren” zu

verwenden. Verwenden Sie unbedingt einen Bohrer mit

Hartmetallspitze. Üben Sie keinen stärkeren Druck aus,

wenn das Bohrloch mit Spänen oder Bohrmehl zugesetzt

wird. Lassen Sie statt dessen die Maschine leer laufen,

und ziehen Sie dann den Bohrer teilweise aus dem

Bohrloch heraus. Durch mehrmaliges Wiederholen

dieses Vorgangs wird das Bohrloch ausgeräumt.

Blasen Sie den Staub nach dem Bohren des Lochs mit

einer Ausblaspipette aus dem Loch.

Bohren

Schieben Sie den Betriebsart-Umschalthebel zum

Bohren in Holz, Metall oder Kunststoff zur Position des

Symbols m, um die Betriebsart “Bohren” zu verwenden.

Bohren in Holz

Beim Bohren in Holz lassen sich die besten Ergebnisse

mit Holzbohrern erzielen, die mit einer Zentrierspitze

ausgestattet sind. Die Zentrierspitze erleichtert das

Bohren, da sie den Bohrer in das Werkstück hineinzieht.

Bohren in Metall

Um Abrutschen des Bohrers beim Anbohren zu

vermeiden, empfiehlt es sich, die Bohrstelle mit einem

Zentrierkörner anzukörnen. Setzen Sie dann die Spitze

des Bohrers in die Vertiefung, und beginnen Sie mit dem

Bohren. Verwenden Sie Schneidflüssigkeit beim Bohren

von Metall. Eisen und Messing sollten jedoch trocken

gebohrt werden.

VORSICHT:

• Übermäßige Druckausübung auf die Maschine bewirkt

keine Beschleunigung der Bohrleistung. Im Gegenteil;

übermäßiger Druck führt zu einer Beschädigung der

Bohrerspitze und damit zu einer Verringerung der

Bohrerstandzeit sowie zu einer Verkürzung der

Lebensdauer der Maschine.

• Beim Bohrungsdurchbruch wirkt ein hohes

Rückdrehmoment auf Maschine und Bohrer. Halten Sie

daher die Maschine mit festem Griff und lassen Sie

Vorsicht walten, wenn der Bohrer im Begriff ist, aus

dem Werkstück auszutreten.

• Ein festsitzender Bohrer lässt sich durch einfaches

Umschalten der Drehrichtung wieder herausdrehen.

Dabei sollten Sie aber die Maschine gut festhalten,

damit sie nicht ruckartig herausgestoßen wird.

• Spannen Sie kleine Werkstücke stets in einen

Schraubstock oder eine ähnliche Aufspannvorrichtung

ein.

ENG905-1

Geräusch

Typischer A-bewerteter Geräuschpegel ermittelt gemäß

EN60745:

L

Schalldruckpegel (

Schalleistungspegel (

Ungewissheit (K): 3 dB (A)

Vibration

Vibrationsgesamtwert (Drei-Achsen-Vektorsumme)

): 98 dB (A)

pA

L

): 109 dB (A)

WA

Gehörschutz tragen

ENG900-1

ermittelt gemäß EN60745:

Arbeitsmodus: Schlagbohren in Beton

Vibrationsemission (

Ungewissheit (K): 2,0 m/s

Arbeitsmodus: Bohren in Metall

Vibrationsemission (

Ungewissheit (K): 1,5 m/s

a

h, ID

a

h, D

): 16,5 m/s

2

): 3,0 m/s

2

• Der angegebene Vibrationsemissionswert wurde im

Einklang mit der Standardprüfmethode gemessen und

kann für den Vergleich zwischen Maschinen

herangezogen werden.

• Der angegebene Vibrationsemissionswert kann auch

für eine Vorbewertung des Gefährdungsgrads

verwendet werden.

WARNUNG:

• Die Vibrationsemission während der tatsächlichen

Benutzung des Elektrowerkzeugs kann je nach der

Benutzungsweise der Maschine vom angegebenen

Emissionswert abweichen.

• Identifizieren Sie Sicherheitsmaßnahmen zum Schutz

des Benutzers anhand einer Schätzung des

Gefährdungsgrads unter den tatsächlichen

Benutzungsbedingungen (unter Berücksichtigung aller

Phasen des Arbeitszyklus, wie z. B. Ausschalt- und

Leerlaufzeiten der Maschine zusätzlich zur

Betriebszeit).

2

2

ENG901-1

WARTUNG

VORSICHT:

• Vergewissern Sie sich vor der Ausführung von Arbeiten

an der Maschine stets, dass sie ausgeschaltet und vom

Stromnetz getrennt ist.

• Verwenden Sie auf keinen Fall Benzin, Benzol,

Verdünner, Alkohol oder dergleichen. Solche Mittel

können Verfärbung, Verformung oder Rissbildung

verursachen.

Um die Sicherheit und Zuverlässigkeit des Produkts zu

gewährleisten, sollten Reparatur-, Wartungs- oder

Einstellarbeiten nur von einem MakitaKundendienstzentrum ausgeführt werden.

11

Page 12

ENH101-18

Nur für europäische Länder

EG-Übereinstimmungserklärung

Makita erklärt, dass die folgende(n) Maschine(n):

Bezeichnung der Maschine:

Schlagbohrmaschine

Modell-Nr./ Typ: M8100, M8101

den folgenden europäischen Richtlinien

entsprechen:

2006/42/EG

gemäß den folgenden Standards oder standardisierten

Dokumenten hergestellt werden:

EN60745

Die technische Akte in Übereinstimmung mit 2006/42/EG

ist erhältlich von:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

1.12.2014

Yasushi Fukaya

Direktor

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgien

12

Page 13

Makita

Jan-Baptist Vinkstraat 2, 3070, Belgium

885407-996

IDE

Makita Corporation

www.makita.com

Anjo, Aichi, Japan

Loading...

Loading...