Makita JS1600 REMPLACEMENT PARTS [nl]

GB

Shear Instruction Manual

F

Cisaille Manuel d’Instructions

D

Blechschere Betriebsanleitung

I

Cesoia Istruzioni d’Uso

NL

Plaatschaar Gebruiksaanwijzing

E

Tijera Electrica Manual de Instrucciones

P

Tesoura

DK

Pladesaks Brugsanvisning

S

Plåtsax Bruksanvisning

N

Platesaks Bruksanvisning

SF

Levyleikkuri Käyttöohje

GR Ισιο ψαλλίδι Οδηγίες χρήσεως

Manual de instruções

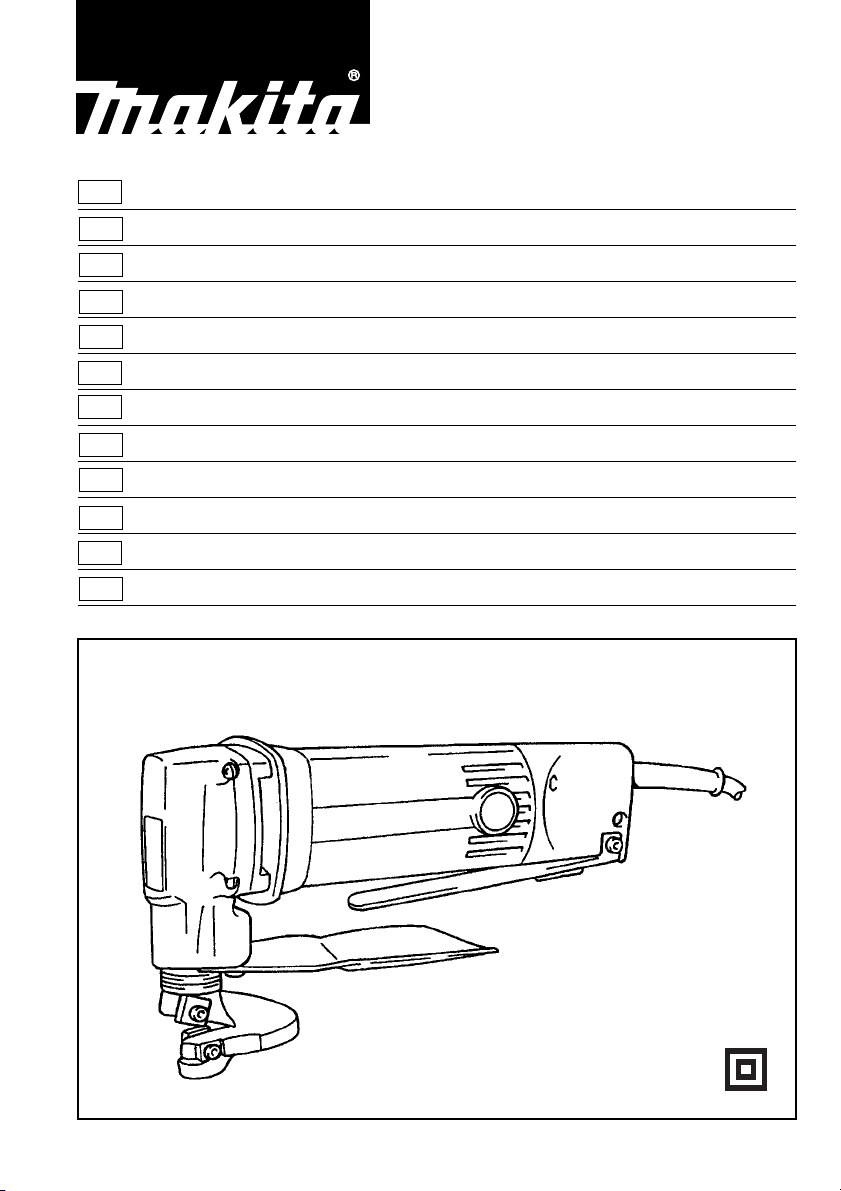

JS1600

12

34

56

78

2

910

11 12

13 14

3

ENGLISH

1 Lower blade

2 Loosen

3 Upper blade

4 Upper blade securing bolt

5 Hex wrench

6 Thin washers

7 Blade holder

8 Tighten

Explanation of general view

9 No gap allowed

10 Yoke

11 Lower blade positioning screw

12 Lock-off lever in the

FREE position

13 Switch lever (Paddle switch)

14 Lock-off lever in the

LOCK position

15 Lock-off lever

16 Gauge for stainless: 1.2 mm

17 Gauge for mild steel: 1.6 mm

18 Workholder

19 Limit ma rk

20 Screwdriver

21 Brush holder cap

SPECIFICATIONS

Model JS1600

Max. cutting capacities

Steel up to 400 N/mm

Steel up to 600 N/mm

Steel up to 800 N/mm

Aluminum up to 200 N/mm

Min. cutting radius ................................................ 30 mm

Strokes per minute .................... ..... ...... ..................4,000

Overall length ..................................................... 230 mm

Net weight .............................................................1.7 kg

• Due to our conti nuing program of rese arch and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Power supply

The tool should be connected o nly to a power s upply of

the same voltage as indicated on the nameplate, and can

only be operated on sing le-phase AC supply. They are

double-insulated in accor dance with E uropean Stand ard

and can, therefore, also be us ed from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed S afety

instructions.

2

........................... 1.6 mm/16 ga

2

........................... 1.2 mm/18 ga

2

........................... 0.8 mm/22 ga

2

................... 2.5 mm/13 ga

ADDITIONAL SAFETY RULES ENB011-2

1. Hold the tool firmly.

2. Secure the workpiece firmly.

3. Keep hands away from moving parts.

4. Edges and chips of the workpiece are sharp.

Wear gloves. It is also recommended that you

put on thickly bottomed shoes to pre vent injury.

5. Do not put the tool on the chips of the work-

piece. Otherwise it can cause damage and trouble on the tool.

6. Do not leave the to ol running. Operate th e tool

only when hand-held.

7. Always be sure you have a firm foot ing. Be sure

no one is below when using the tool in high locations.

8. Do not touch the blade or the workpiece immedi-

ately after operati on; they may be extremely hot

and could bu r n your skin.

9. Avoid cutting electrical wires. It can cause seri-

ous accident by electric shock.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

Blade inspe ct ion

Before using the tool, check the blades for wear. Dull,

worn blades will result in poor shearing action, and the

service life of the tool will be shortened.

Rotating or replacing blades

Important:

Always be sure that the tool is switched off and

unplugged before rotating or replacing the blades.

Both the upper a nd lower blades have four cutting edges

on each side (the front and back). When the cutting edge

becomes dull, rotate both the upper and the lower blades

90° to expose new cutting edges. When al l eight edges

are dull on both the upper and lower blades, replace both

blades with new ones. Each time blades are ro tated or

replaced, proceed as follows.

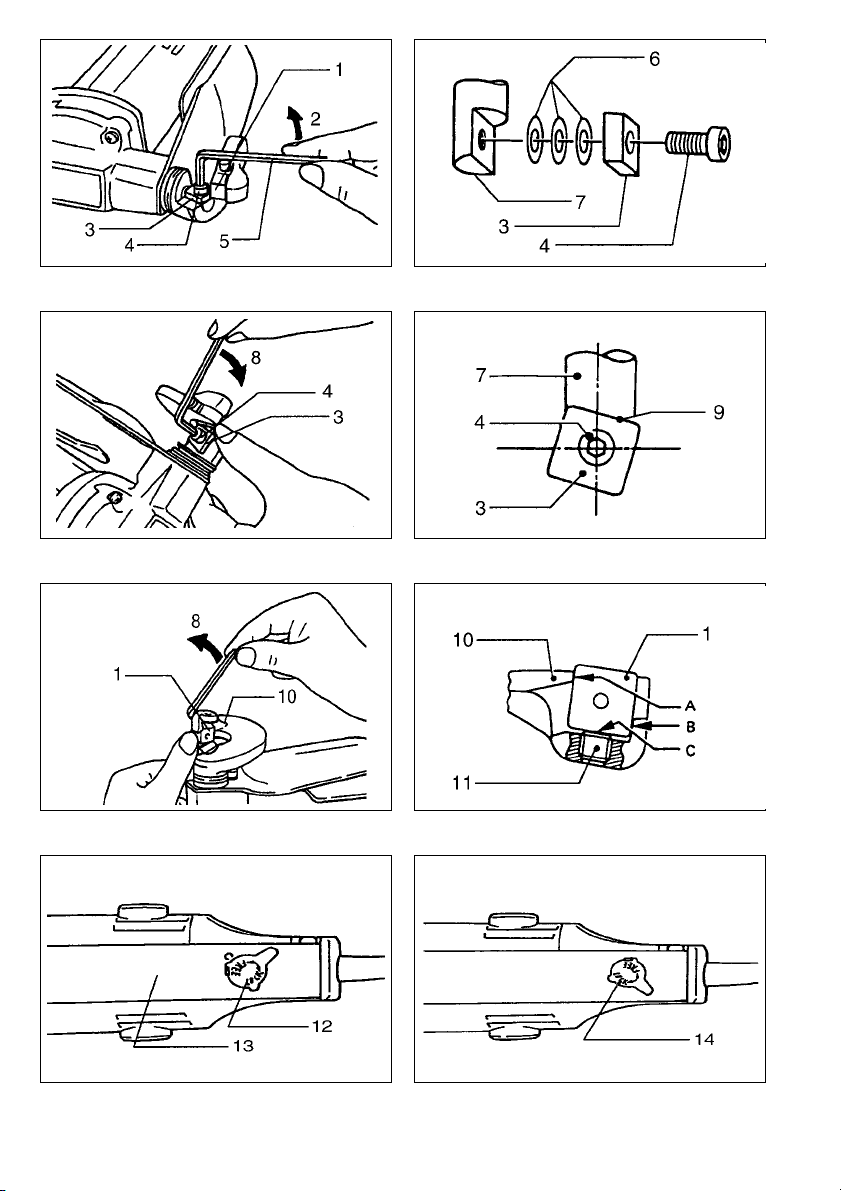

Remove the blade securi ng bolts with the hex wrench

provided and then rotate or replace the blades. (Fig.1)

Some tools have one or mor e thin washer s between the

upper blade and the blade holder. Be sure to use the

same number of thin washers when reassembling. (Note:

No thin washers are used for the lower blade.) (Fig. 2)

T o secure the upper blade, tighten the upper blade securing bolt with the hex wrench. Press up on the upper blade

while tightening it. (Fig. 3)

After securing the up per blade, be sure that ther e is no

gap left between the upp er blade and the bevelled surface of the blade holder. (Fig. 4)

When installing the lower blade onto the yoke, the lower

blade should be presse d against the yoke so as to be

contacting the bevelled portions A and B of the yoke and

the tip C of the lower blade positioning scr ew while you

tighten the lower blade se curing bolt. There must be no

clearance between A, B and C during installation.

(Fig. 5 & 6)

Note:

The lower blade positioning screw is factory-assembled.

Do not tamper with it.

4

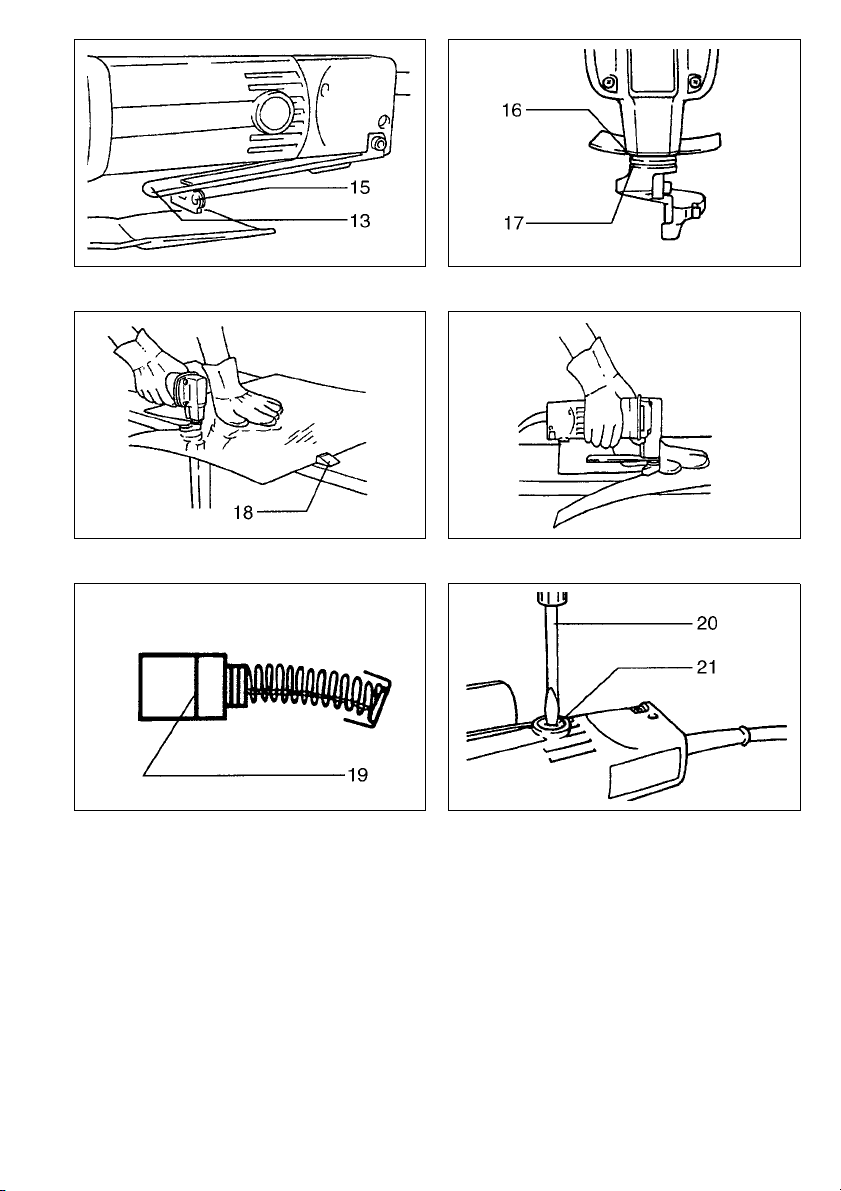

Switch action

For tools with pivot type lock-off lever

(Fig. 7 & 8)

CAUTION:

• B efore plugging in the tool, always check to see that

the paddle switch actuates p roperly an d return s to the

“OFF” position when released.

• The switch lever does not actuate when the lock-off

lever is in the LOCK position. Do no t try to actuate the

switch lever when the lock-off lev e r is in the LOCK position.

• When not operating the tool, keep the lock-off lever in

the LOCK position.

To prevent the switch from being accidentally a ctu ated , a

lock-off lever is provided. To start the tool, t urn the lockoff lever to the FREE position and then squeeze the

switch lever. Release the switch lever to stop.

For tools with slide type lock-off lever (Fig. 9)

CAUTION:

Before plugging in the too l, always check to see that the

paddle switch actuates prop er ly an d returns to the “OFF”

position when released.

To prevent the switch from being accidentally a ctu ated , a

lock-off lever is provided. To start the tool, slid e the lockoff lever in the direction of the arrow and squeeze the

switch lever. Release the switch lever to stop.

Holding materia l (Fig. 11)

The materials for cutting should be fastened to the work bench by means of workholders.

Shearing method (Fig. 12)

Keep the shear moving parallel with the material.

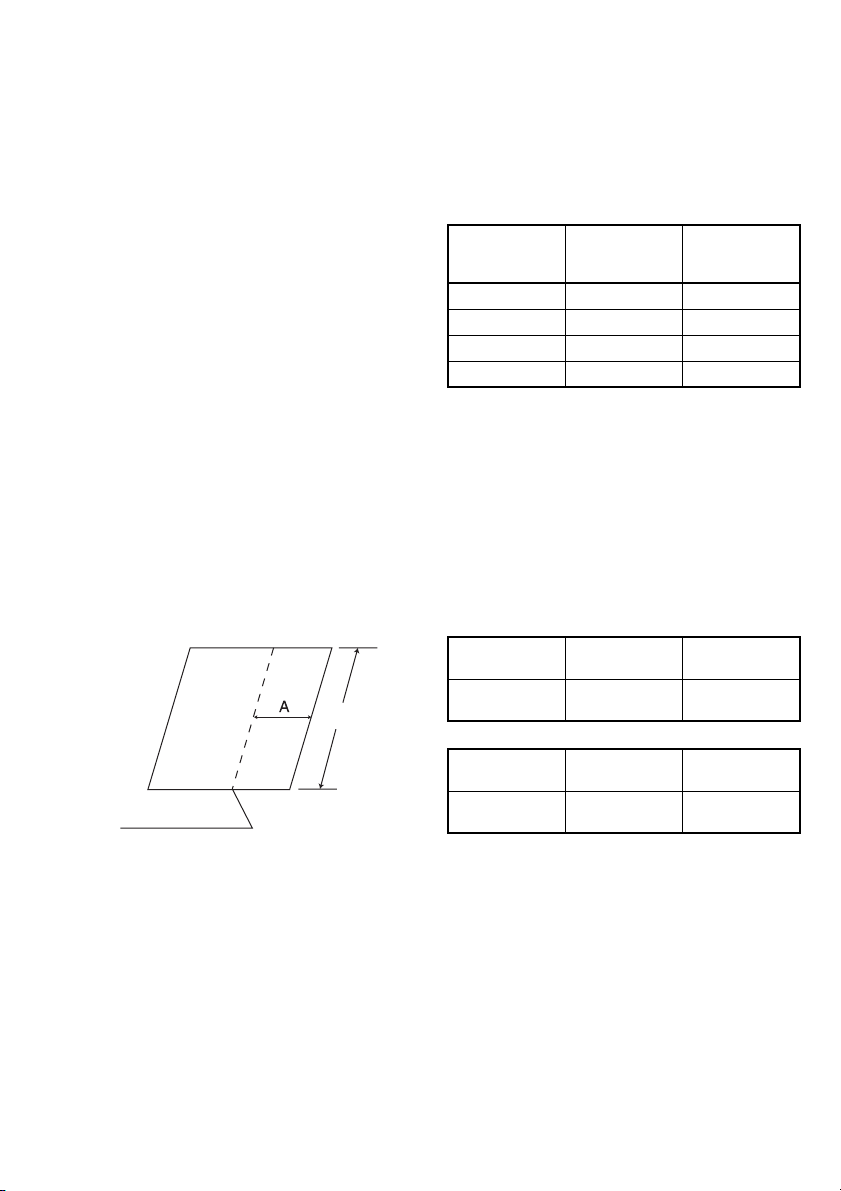

Maximum cutting width

Stay within the specified maximum cutting width (A): Case of length 1,800mm.

Permissible shearing thickness (F ig. 10)

The groove on the yoke serves as a thickness gauge for

shearing mild or stainless steel plate. If the material fits

within the groove, it is shearable.

The thickness of materia ls to be sheared depends upon

the type (strength) of the ma terial . The max imum shearing thickness is indicated in the table below in te rms of

various materials. Attemp ting to shear materials thicker

than indicated will result in tool breakdown and/or possible injury. Keep within the thickness shown below.

Material

Mild steel 35 1.6

Hard steel 50 1.2

Stainless steel 50 1.2

Aluminum plate 25 2.0

Tensile

strength

(kg/mm

2

)

Max. cutting

thickness (mm)

Mild steel

(thickness)

Max. cutting

1,800mm

Cutting line

Minimum cutting radius

Minimum cutting radius is 30 mm when cutting 1.0 mm mild steel.

width (A)

Stainless

(thickness)

Max. cutting

width (A)

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Replacement of carbon brushes

(Fig. 13 & 14)

Replace carbon brushes when they are worn down to the

limit mark. Both identical carbon brushes should be

replaced at the same time.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carr ied out by a Makita

Authorized Service Center.

1.6 mm Under 1.2 mm

100 mm No limit

1.2 mm Under 1.0 mm

80 mm No limit

5

Loading...

Loading...