Makita JR2601 Technical Information

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

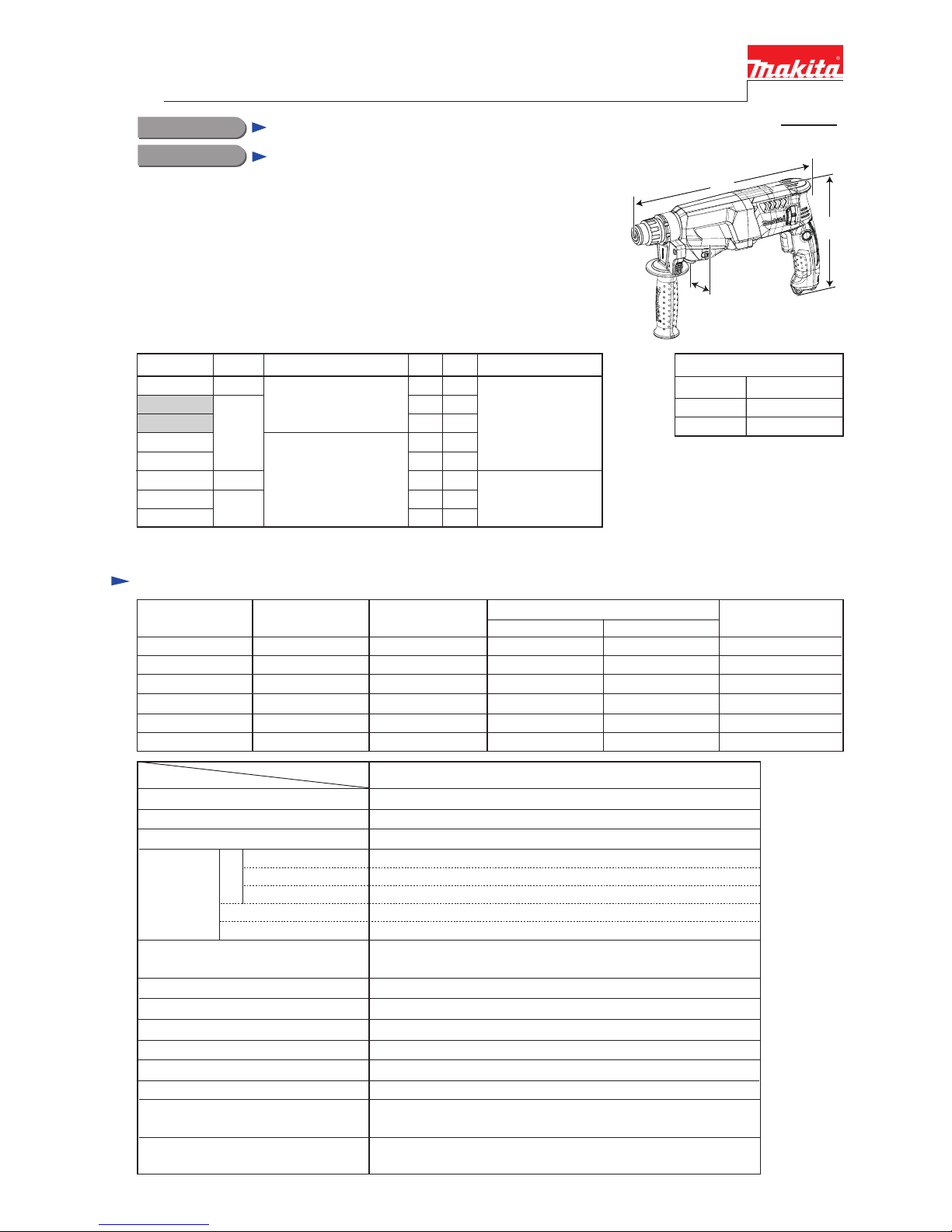

Specification

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

361 (14-1/4)

77 (3)

209 (8-1/4)

HR2600/ HR2601

Rotary Hammers 26mm (1")

Chuck type

Impacts per minute= minֿ¹

No load speed: minֿ¹= rpm

Specification

Double insulation

Weight according to

EPTA-Procedure 01/2003*2: kg (lbs)

Power supply cord: m (ft)

Variable speed control

Rotation reversing facility

Operation mode

Vibration absorption

Model

*1 AVT (Anti Vibration Technology); Counterweight mechanism + Damper spring

*2 with side grip

Concrete

TCT bit

Steel

Wood

Core bit

Diamond core bit

Capacities:

mm (")

Continuous Rating (W)

Voltage (V) Cycle (Hz)

Input Output

Max. Output (W)

110

120

220

230

240

7.7

7

3.8

3.7

3.5

50/ 60

50/ 60

50/ 60

50/ 60

50/ 60

800

---

800

800

800

400

400

400

400

400

550

550

550

550

550

127 6.6 50/ 60 800 400 550

Current (A)

Torque limiter

HR2600/ HR2601

Yes (by trigger)

Yes

Europe, North America: 4.0 (13.1), Australia, Brazil: 2.0 (6.6),

Other countries: 2.5 (8.2)

Yes

0 - 1,200

0 - 4,600

Adapted for SDS-PLUS shank bits

26 (1)

68 (2-11/16)

2.8/ 2.9

(6.2/ 6.3)

2 modes

(Rotation only/ Rotation with Hammering)

No/ Yes (AVT*1)

80 (3-1/8)

13 (1/2)

32 (1-1/4)

Yes

NoLED Job light

*Round shank bits can also be used by

replacing the factory-mounted chuck with

Quick change drill chuck (keyless).

PRODUCT

P 1/ 13

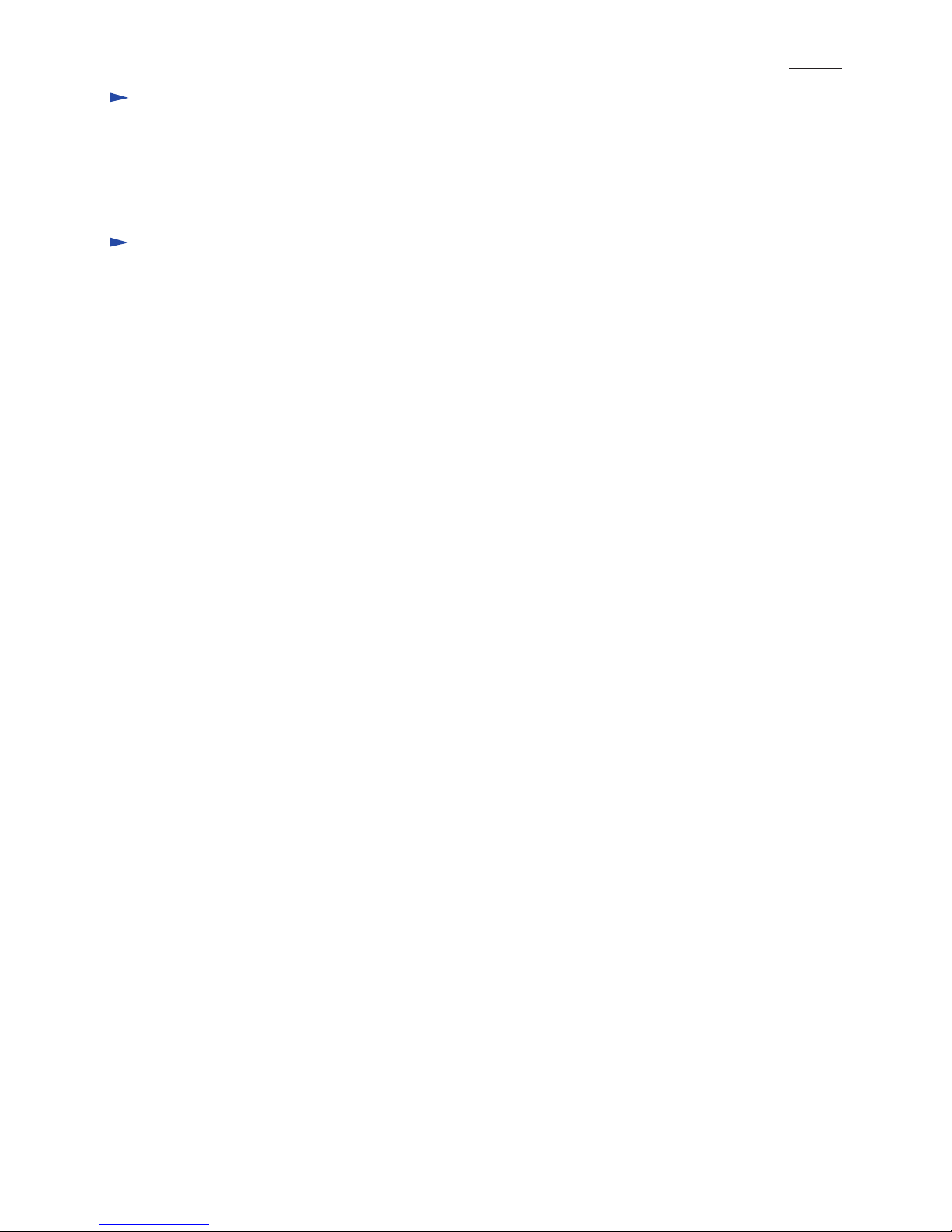

Model Operation Mode LED Chuck type

2 modes

(Rotation only/

Rotation with hammering)

3 modes

(Rotation only/

Rotation with hammering/

Hammering only)

No

No

26mm

Capacity

23mm

23mm

26mm

No

No

Adapted for

SDS-PLUS shank bits

Adapted for

SDS-PLUS shank bits

and Round shank bits*

Yes

No

AV T

No

No

No

Yes

Yes

NoNo

Yes

Yes

No

HR2300

HR2310T

HR2610T

HR2611FT

HR2600

HR2601

HR2611F

HR2610

H

W

L

T

ECHNICAL INFORMATION

HR2600/ HR2601 are 26mm (1") 2-mode rotary hammers adapted for

SDS-PLUS bits, featuring compact and lightweight design, enhanced comfort

and better control with ergonomic handle. Model HR2601 is equipped with AVT;

Anti Vibration Technology consisting of Active dynamic vibration absorber

with counterweight and Damper spring. AVT ensures operation with

extremely low vibration, which is much superior to the competitors.

HR2600 series models are available in the variations listed below, including

HR2300 and HR2610 series models developed on the same concept.

For information of HR2300 and HR2610 series models,

see “

TECHNICAL INFORMATION” of each series.

P 2/ 13

Standard equipment

Note: The standard equipment for the tool shown above may vary by country.

Depth gauge ............................... 1

Side grip .................................... 1

Dust cup set ................................ 1 (for some countries only)

Plastic carrying case ................... 1

Optional accessories

SDS-PLUS shank TCT hammer drill bits

Taper shank TCT hammer drill bits

Taper shank adaptor

Cotter

Core bits

Center bits

Core bit adaptor

Rod

Drill chuck ass'y

Chuck adapter assembly

Drill chuck S13

Chuck key S13

Tool holder set

Scraper assembly

Waterproof cover

Quick change drill chuck (keyless)

Dust cups 5 and 9

Hose

Joint 25

Dust cup set

Plastic carrying case

Hammer grease (30g)

Bit grease

Depth gauge

Blow out bulb

Safety goggles

Bull points

Cold chisels

Scaling chisels

Grooving chisels

Hammer service kit

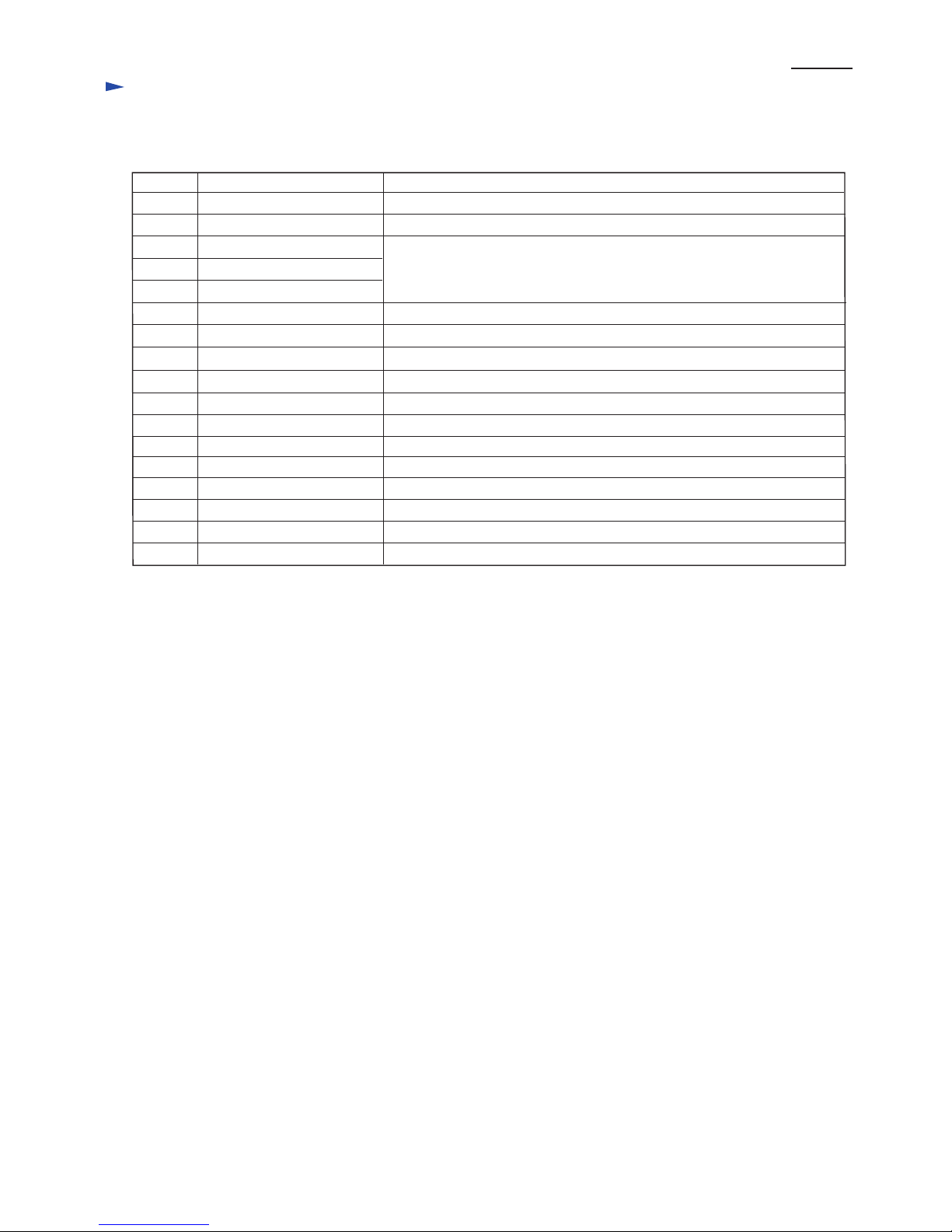

[1] NECESSARY REPAIRING TOOLS

Repair

DescriptionCode No. Use for

Retaining ring S pliers ST-2N1R003 removing Ring spring 14 and Ring spring 15 from Tool holder complete

Bearing setting pipe 16-8.21R026 assembling Bearing box

Bearing setting plate 10.21R033

Bearing setting plate 15.21R035

removing/ assembling Spiro lock washer 30Gear extractor (large)1R045

Tip for retaining ring pliers1R212

Use with 1R003

1/4" Hex. shank bit for M41R228

removing M4 Hex socket head bolt

Ring spring setting tool A1R164 assembling Oil seal 25

Bearing setting pipe 20-12.21R028

removing Helical gear 26

Pipe 301R232 assembling Oil seal 25

Round bar for arbor 30-1001R252 removing Oil seal 25

V block1R258 assembling Oil seal 25

Bearing extractor1R269 removing Ball bearing 6000LLB / 627DDW

Ring spring 26 setting tool B1R273 removing Cup sleeve / Ball bearing 6806LLU

Round bar for arbor 7-501R281 removing Helical gear 26

Jig for Spiro lock washer

1R369 removing/ assembling Spiro lock washer 30

Ring spring extractor

1R388 removing Ring spring 28

P 3/ 13

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Repair

P 4/ 13

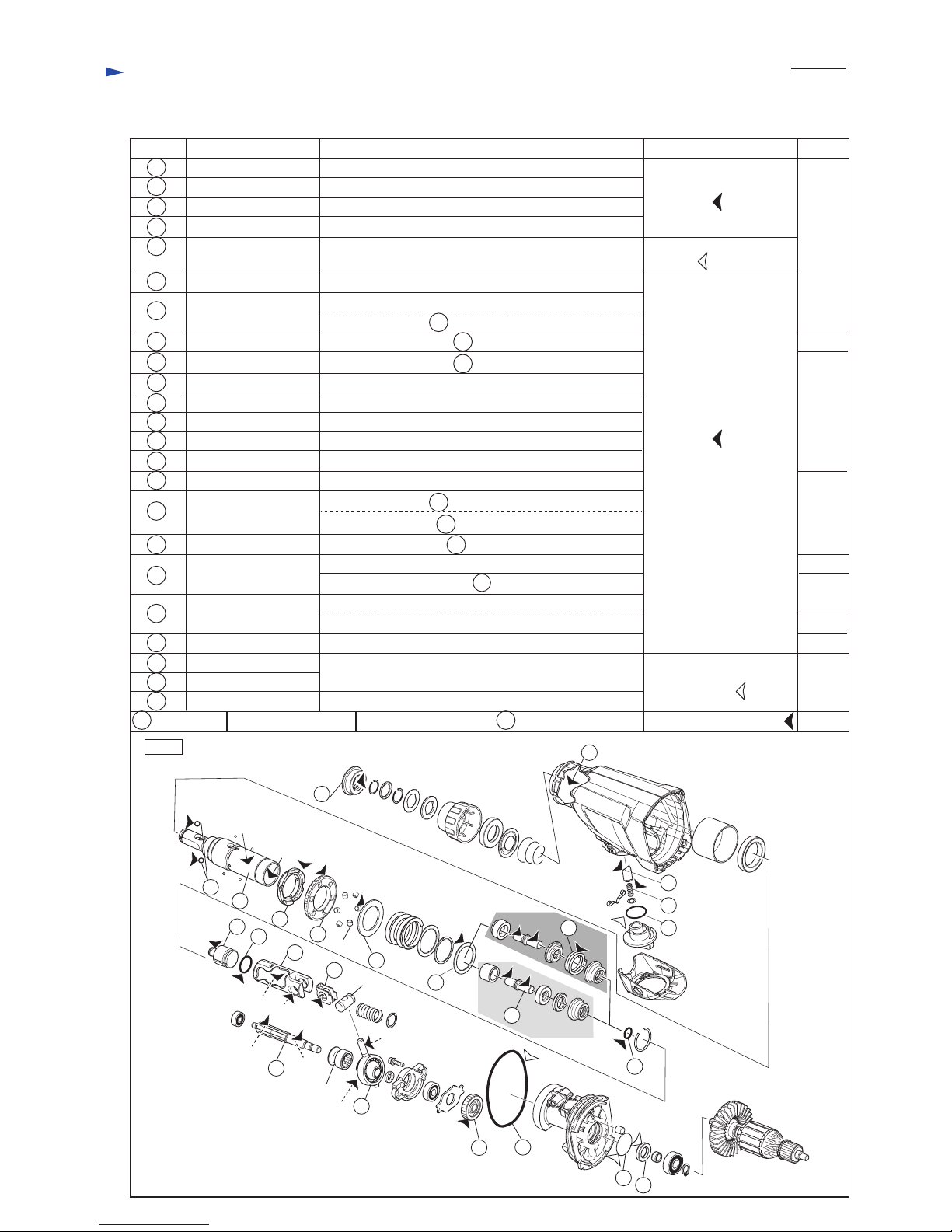

Apply the following grease/ lubricant to protect parts and product from unusual abrasion.

[2] LUBRICATION

Fig. 1

Item No. Description Grease/ Lubricant AmountPortion to lubricate

Makita lubricating

oil VG100

Makita lubricating oil

VG100

Makita grease RB

No. 00

Makita grease RB No. 00

Makita grease RB

No. 00

26

1 Cap 35

Gear housing complete Oil seal 25 on the inside of Gear housing complete

Lip portion where Bit is to be inserted

Entire surface

Entire surface

Entire surface

(h) Ball bearing portion

(g) Interleaved portion to Piston joint

Entire surface

Gear portion

2g

3g

3g

3g

19g

in total

29

Steel ball 7.0 (2 pcs.)

Whole portion

HR2601

HR2600

(c)

(d)

(a)

(b)

(e)

(f)

(g)

(h)

Portion that contacts Sleeve 9

32

28

a little

a little

a little

a little

a little

42

44

45

46

47

56

58

64

65

70

71

30

Driving flange

O ring 9

Tool holder complete

20

21

23

26

28

29

30

42

36

Pin 6

Piston

joint

44

45

46

47

56

58

64

65

70

71

32

1

30

Portion that contacts Spur gear 51/ Pins 6

30

Portion that contacts Spur gear 51/ Pins 6

16

Compression spring 20

(e) Gear portion

(f) Portion that contacts 58 Swash bearing 10

Gear portion that engages with Armature gear shaft

Inside that contacts 48 Piston joint

38 Impact bolt Entire surface

(b) Inside where 46 Piston cylinder reciprocates

16

2021Push corn Portion that contacts Clutch cam B

Compression spring 5 Periphery

23 O ring 21 Entire surface

Striker

HR2601 only40

O ring 17.5

Piston cylinder

(c) Inside where 44 Striker moves

(d) Periphery that 28 Tool holder complete contacts

Guide plate

Spur gear 10

Clutch cam B

Swash bearing 10

Helical gear 26

O-ring 68

O ring 26

Oil seal 12

Flat washer 30

36

Portion that contacts Inner housing complete

Flat washer 30

Spur gear 51

(a) Periphery that contacts Driving flange/ Spur gear 51

Periphery that contacts 28 Tool holder complete

38

40

Loading...

Loading...