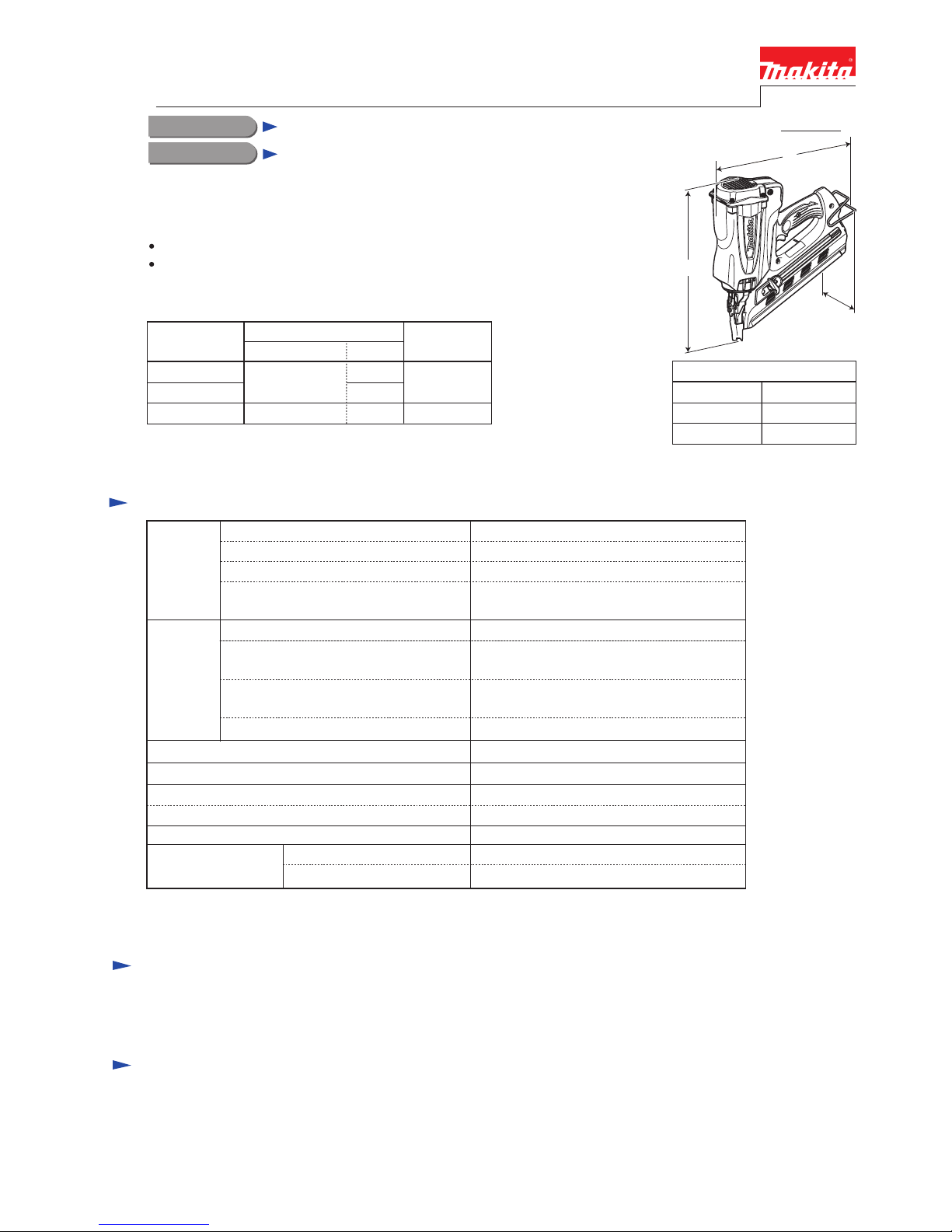

Makita GN900SE, GN900S, GN900ZK Technical Information

Models No.

Description

PRODUCT

T

ECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

P 1/ 16

Standard equipment

Dimensions: mm (")

Width*2 (W)

*2 with Hook

Height (H)

Length*2 (L)

108 (4-1/4)

321 (12-5/8)

368 (14-1/2)

Note: The standard equipment for the tool shown above may differ by country.

GN900

Cordless Clipped Head Framing Nailer

Model GN900 is a cordless clipped head nailer developed for a wide range of

framing applications. The main features are as follows:

Using fuel gas as the power source to provide freedom from hoses and compressors

Equipped with LED indication lamp with battery power warning and trouble detection

functions for convenience of operation and repair

Safety goggles ............................ 1

Hex wrench 4 ............................. 1

Plastic carrying case ................... 1

Magazine capacity

Nail

44 nails (1 strip)

50 - 90

(2 - 3-1/2)

2.9 - 3.3

(0.113 - 0.131)

Clipped-head

Length: mm (")

Gauge (Shank diameter): mm (")

Head type

34 degreeNail collation angle

Optional accessories

Nail fuel pack

Fuel cell

Cleaner kit (contains the following accessories in a special Tool bag: Cleaner/ 1, Lubricating oil/ 1,

Hex wrench 4/ 1, Brush/ 1, Cotton waste/ 1)

Charger DC07SA

Charger DC10WA

Battery BL7010

7.2

1.0

30

with DC07SA/DC10WA

Li-ion

Charging time (approx.): min.

Battery

YesAnti-dry-fire mechanism

Cell

Voltage: V

Capacity: Ah

Battery life*4

Fuel cell life*5

4,000 nails (approx.)

Motor*3 Coreless DC motor

1,200 nails (approx.)

3.2 (7.0)

3.4 (7.5)

without Battery and Fuel cell

with Battery and Fuel cell

Net weight: kg (lbs)

W

H

L

This product is available in the following variations.

The model also includes the accessories listed below in "Standard equipment".

GN900SE

GN900S

DC07SA

Model No.

type

No

Charger

No

quantity

No

1

2

BL7010

(Li-ion 1.0Ah)

Battery*1

GN900ZK

*3 The motor is used for gas mixing, air intake/exhaust, supply of cooling air.

*4 Battery life: the number of nails on a single full battery charge

*5 Fuel cell life: the number of nails per Fuel cell

*1 Battery is used as the power source for ignition spark,

gas mixing, air intake/exhaust and supply of cooling air.

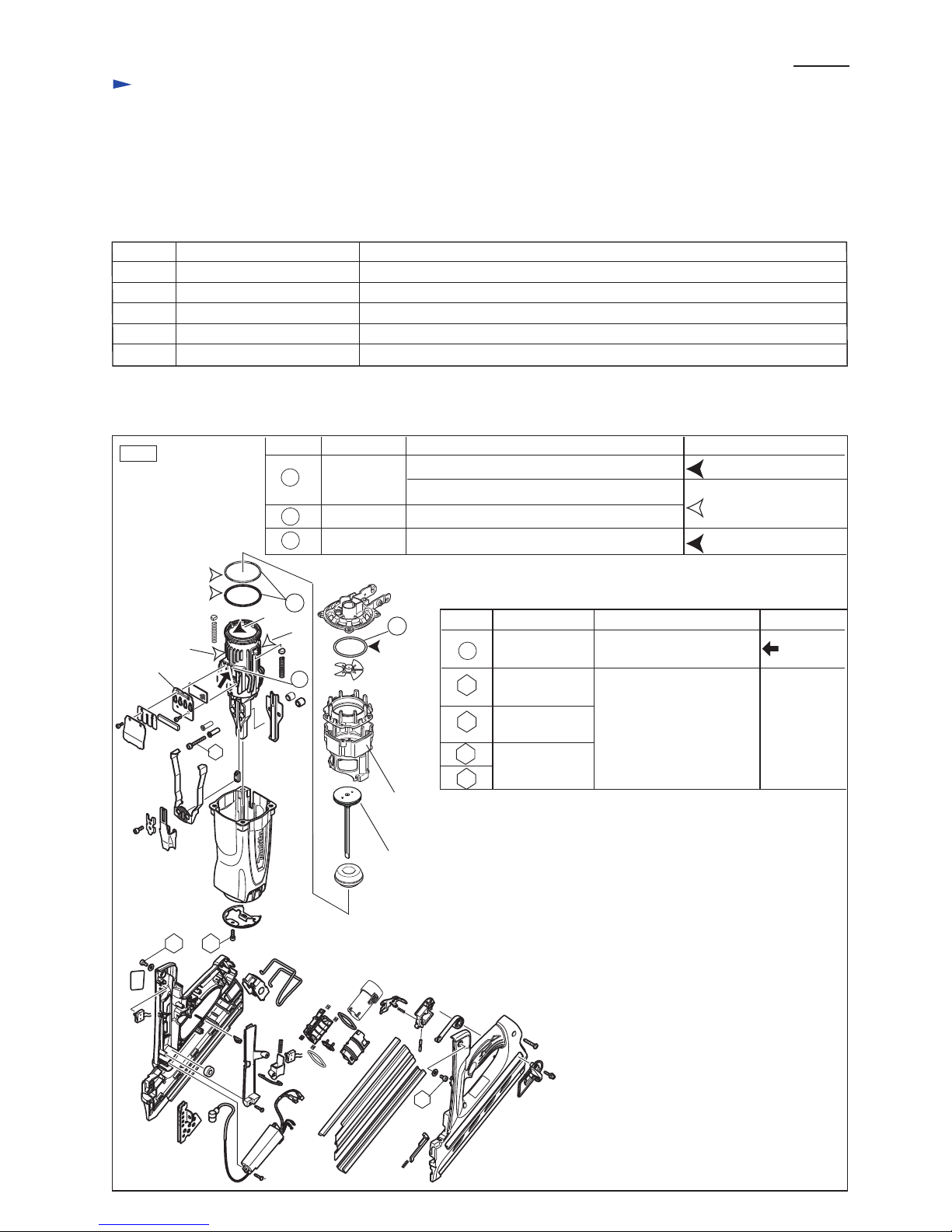

P 2/ 16

R

epair

CAUTION: 1) Remove Battery, Fuel cell, Nail from the machine for safety before repair/ maintenance

in accordance with the instruction manual!

2) Loosen Hex socket head bolts with L-shape wrench in advance before removing them

using cordless impact driver with 1R228/ 1R229, or the top of 1R228/ 229 will damage.

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS AND ADHESIVES

Fig. 1

Code No. Description Use for

1R005 Retaining ring pliers RT-2N Disassembling / Assembling Retaining ring R-58

1R228 1/4” Hex shank bit for M4 Disassembling / Assembling M4 Hex socket head bolt

1R229 1/4” Hex shank bit for M5 Disassembling / Assembling M5 Hex socket head bolt

1R268 Spring pin extractor 3 Disassembling / Assembling Spring pin 3-32

1R291 Retaining ring S and R pliers Disassembling / Assembling Retaining ring R-24

Item No.

Apply a little amount of Lubricant and Adhesives illustrated in Fig. 1.

Description Portion to lubricate Lubrication

Lubrication oil VG100

Lubrication oil VG100

Molybdenum

disulfide

a: Inside with which Driver complete contacts

b: Outside with which Chamber contacts

24

42

23

Cylinder ring Whole portion

O ring 60 Whole portion

Cylinder

24

b

b

42

23

17

9

c

67

97

a

ThreeBond1342

or

Loctite272

c: Rib portion on which

Exhaust plate is attached

23 Cylinder

Item No. Description Adhesive

ThreeBond

1215

Portion to glue

Thread

Driver complete

Exhaust plate

Chamber

M5x10 Hex

socket head bolt

M5x16 Hex

socket head bolt

M5x35 Hex

socket head bolt

9

97

17

67

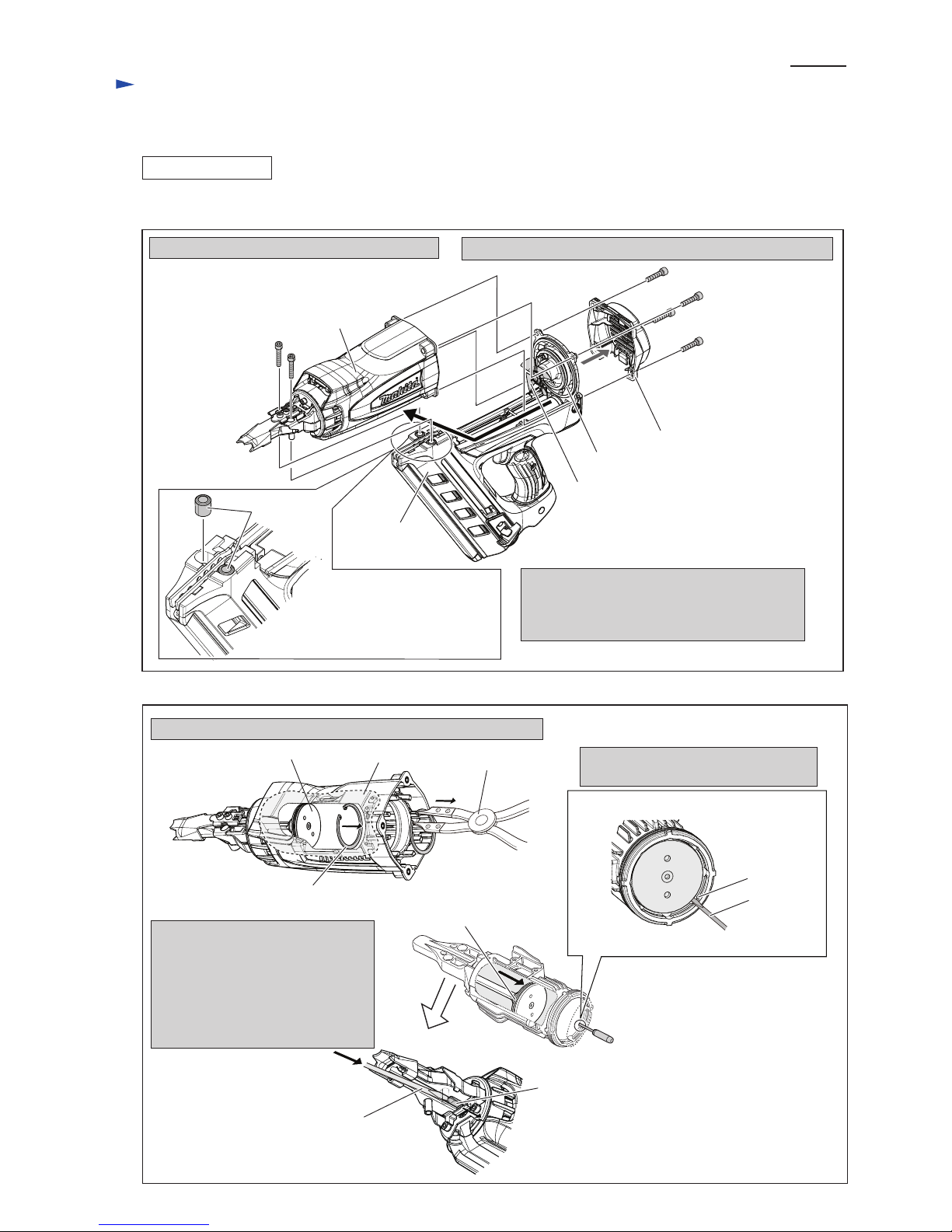

P 3/ 16

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Driver, Front cushion

DISASSEMBLING

1) Remove M5x35 Hex socket head bolt (2pcs.)

Note: Sleeve 8 (2pcs.) may be

fallen from Handle set

in the disassembling step.

Therefore, pay attention

not to lose Sleeve 8.

1) Remove Retaining ring (INT) R-58 from Cylinder with 1R005.

2) Remove M5x25 Hex socket head bolt (4pcs.) and Top cap.

3) Hold Housing by hand and slide it straightly

and gently in order not to hook with Fan 60,

then lift Housing obliquely as designated in

black arrow.

Note: Do not deform Fan 60.

Handle set

Top cap

Cylinder head

Fan 60

M5x35 Hex socket

head bolt (2pcs.)

M5x25 Hex socket

head bolt (4pcs.)

Housing

(1) Disassemble Driver complete as illustrated in Figs. 2 and 3.

Fig. 2

Fig. 3

Sleeve 8

cylinder

1R005

Driver complete

Retaining ring (INT) R-58 on Cylinder

3) While holding Piston ring (2pcs.)

with the slotted screwdriver to

prevent them from being caught

in the groove for Retaining ring

(INT) R-58, push Driver complete

with another slotted screwdriver

toward Top cap side.

2) Insert slotted screwdriver along with

an vertical groove of Cylinder.

slotted

screwdriver

vertical groove

of Cylinder

Cylinder viewed from top cap side

Inside view

slotted screwdriver

end of Driver complete

Piston ring (2pcs.)

on Driver complete

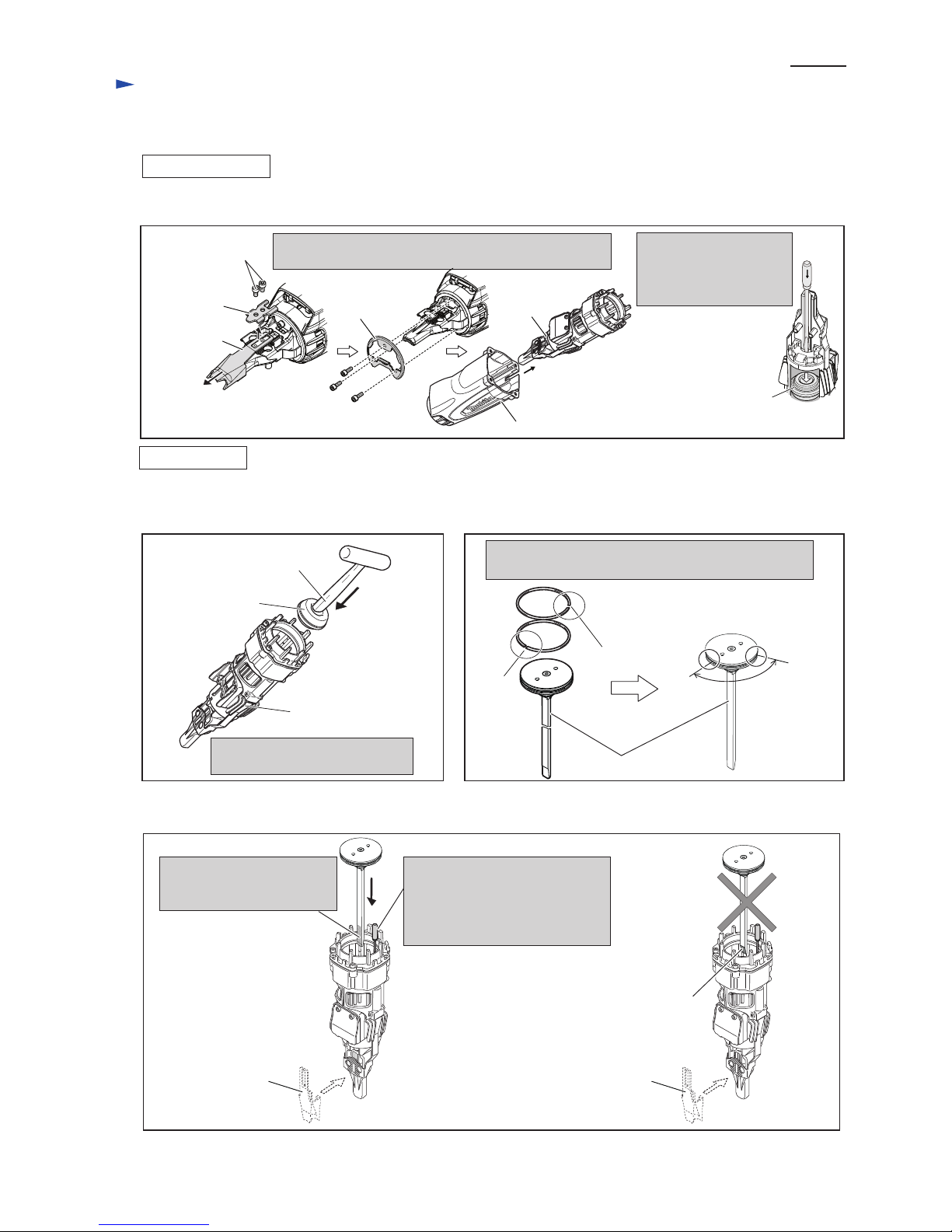

P 4/ 16

R

epair

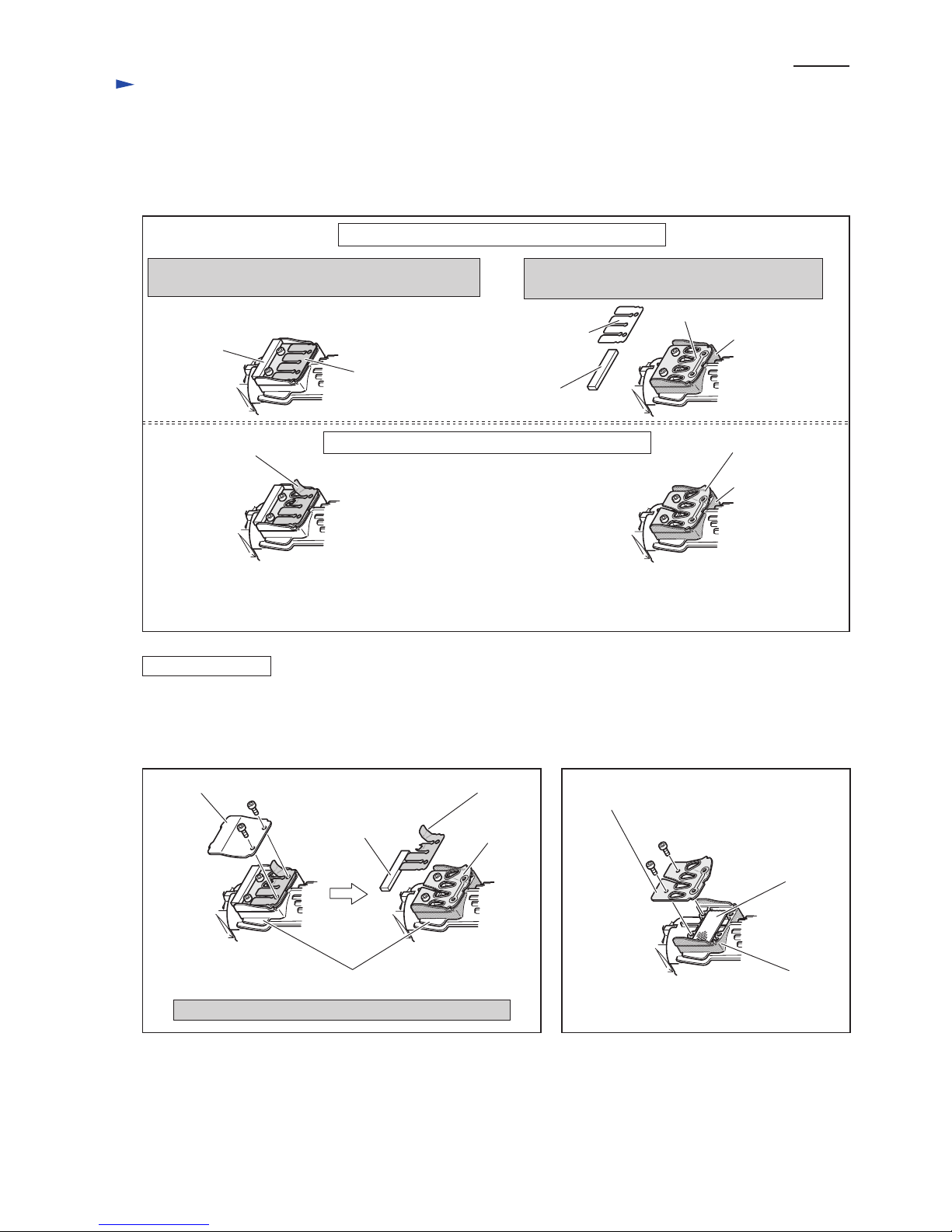

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Driver, Front cushion (cont.)

DISASSEMBLING

ASSEMBLING

M5x10 Hex socket

head bolt (2pcs.)

Separate Cylinder section from Housing after removing

Arm plate, Contact top and Front plate.

(2) Separate Cylinder section from Housing. And then disassemble Front cushion. (Fig. 4)

(1) Assemble Front cushion to Cylinder as illustrated in Fig. 5.

(2) Mount two Piston rings to Driver complete. (Fig. 6)

M5x16 Hex socket

head bolt (3pcs.)

Arm plate

Contact top

Front plate

Housing

Front cushion

Push Front cushion into Cylinder

with hammer until it stops.

Insert slotted screwdriver

from the nail exit side,

and push Front cushion

out of Cylinder section.

Fig. 4

Cylinder

section

Front cushion

hammer

more than

90 degrees

Assemble Piston ring (2pcs.) to Driver complete

so that the angle of their slits is more than 90 degrees.

slit

slit

slit

slit

Cylinder

Driver complete

Fig. 5 Fig. 6

Contact top Contact top

Use slotted screwdriver to prevent

Piston rings from being caught in

the groove of Cylinder for

Retaining ring (INT) R-58.

(Refer to Fig. 3.)

Set Driver complete in place

so that the flat tip faces

Contact top installation side.

Note: Do not face the chamfered tip

of Driver complete to Contact top

installation side

(3) Insert Driver complete into Cylinder as illustrated in Fig. 7.

(4) Inserting Cylinder section into Housing, tighten Front plate with M5x16 Hex socket head bolt (3pcs.).

Assemble Contact top and Arm plate. (Fig. 4)

(5) Assemble Retaining ring (INT) R-58 to the groove in Cylinder. (Fig. 3)

(6) Assemble Handle set to Housing. (Fig. 2)

Fig. 7

P 5/ 16

R

epair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Exhaust valve section

DISASSEMBLING

When the tip of Driver complete does not hit the nail head in use, disassemble exhaust valve section to check malfunctions

as illustrated in Fig. 8.

Fig. 8

Exhaust valve is attached to four holes on Exhaust plate

when Driver complete moves to the lowest position.

Exhaust plate under Exhaust valve seals Cylinder

at the frame on Cylinder.

Exhaust plate

Exhaust valve

Exhaust valve

Punching metal

Exhaust plate

Exhaust plate

Exhaust cover

M4x10 Hex socket

head bolt (2pcs.)

M4x10 Hex socket

head bolt (2pcs.)

Exhaust valve

Silencer

Silencer

Cylinder

Disassemble Exhaust cover, Silencer and Exhaust valve.

Silencer

frame on Cylinder

frame on Cylinder

frame on Cylinder

Exhaust plate

It causes the wrong driving like dry fire and the leakage of gas.

Note: It is possible that the tip of Driver complete does not hit the nail head in use because of the corrosion of adhesive

even if Exhaust valve and Exhaust plate do not look deformed/ damaged.

Scrape away the adhesive and apply fresh ThreeBond to treat such a case. (Refer to next page.)

Exhaust valve

Deformed and damaged Exhaust valve / Exhaust plate

Normal condition of Exhaust valve and Exhaust plate

(1) Disassemble Handle set from Housing. (Fig. 2.)

(2) Remove Contact top, Arm plate and Front plate from Cylinder. And separate Cylinder section from Housing. (Fig.4)

(3) Disassemble Exhaust mechanism as illustrated in Figs. 9 and 10.

Fig. 9 Fig. 10

Loading...

Loading...