Makita EY2650H, EY2650HG Instruction Manual

Instruction Manual

Manuel d’instructions

Manual de instrucciones

Manual de Instruções

WARNING:

Read this instruction manual carefully before putting the Telescopic Petrol Pole Saw into operation and strictly observe the safety regulations!

Save instruction manual for future reference.

AVERTISSEMENT :

Veuillez lire attentivement ce mode d’emploi avant d’utiliser l’élagueuse thermique à perche télescopique et respectez strictement les

consignes de sécurité !

Conservez ce mode d’emploi pour vous y reporter ultérieurement.

ADVERTENCIA:

Lea esta manual de instrucciones con atención antes de utilizar la Sierra de Extensión Telescópica a Gasolina y ¡observe estrictamente las

regulaciones de seguridad!

Guarde el manual de instrucciones para futuras referencias.

AVISO:

Leia com atenção este manual de instruções antes de colocar o podador telescópico a gasolina em funcionamento e cumpra estritamente

com os regulamentos de segurança!

Guarde o manual de instruções para consulta futura.

EY2650H

EY2650HG

English

(Original instructions)

Thank you very much for purchasing the MAKITA Telescopic Petrol Pole Saw.

We are pleased to recommend to you the MAKITA Telescopic Petrol Pole

Saw which is the result of a long development programme and many years of

knowledge and experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the best

possible result from your MAKITA Telescopic Petrol Pole Saw.

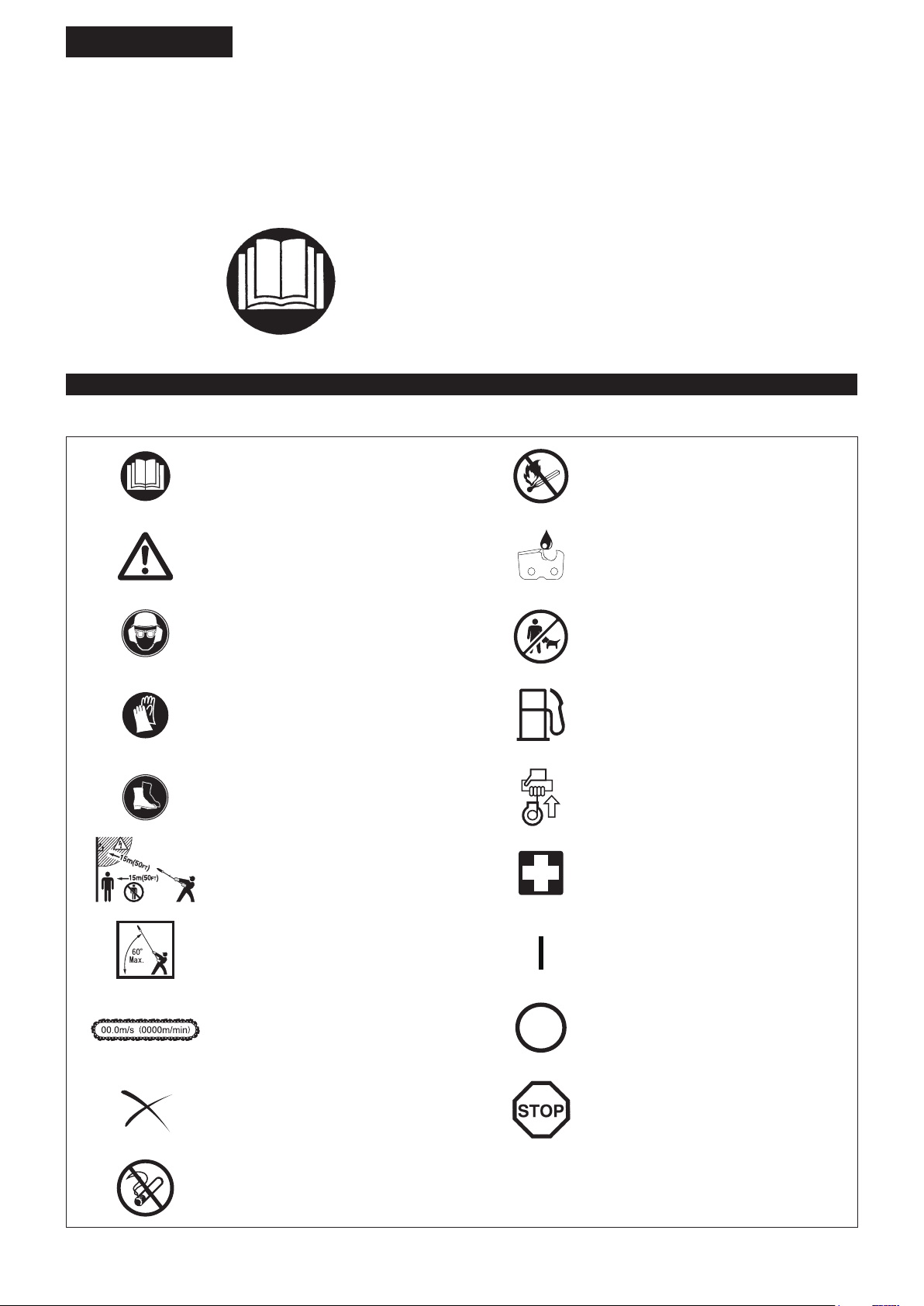

SYMBOLS

You will note the following symbols when reading the instructions manual.

Read instruction manual and follow the

warnings and safety precautions!

Table of Contents Page

Symbols .........................................................................2

Safety instructions .........................................................3

Technical data................................................................8

Designation of parts.......................................................9

Assembly and adjustment ...........................................10

Before start of operation ..............................................13

Points in operation and how to stop ............................15

Operation .....................................................................17

Servicing instructions...................................................17

Storage ........................................................................23

No open flame!

Take particular care and attention! Chain oil.

Wear protective helmet, eye and ear

protection.

Protective gloves must be worn! Fuel (Gasoline)

Wear sturdy boots with non-slip soles. Engine-manual start

Keep a distance of at least 15 m (50 ft)

between the equipment and bystanders

and/or electrical line (including any

branches contacting it). Risk of electrical

shock and/or personal injury.

Never hold the pole saw at an angle of

more than 60°.

Keep the area of operation clear of all

persons and pets!

First Aid

ON/START

Chain speed. OFF/STOP

Forbidden! Emergency stop

No smoking!

2

SAFETY INSTRUCTIONS

General instructions

To ensure correct operation, user has to read this instruction manual to -

make himself familiar with the handling of the equipment. Users insufciently

informed will risk danger to themselves as well as others due to improper

handling.

It is recommended only to lend the equipment to people who have proven to be experienced with equipment.

Always hand over the instruction manual.

First users should ask the dealer for basic instructions to familiarize oneself with the handling of an engine powered cutter.

Children and young persons aged under 18 years must not be allowed to operate the equipment. Persons over the age of 16 years may however use

the device for the purpose of being trained only whilst under supervision of a

qualied trainer.

Use the equipment with the utmost care and attention. Operate the equipment only if you are in good physical condition. Perform all -

work calmly and carefully. The user has to accept liability for others.

Never use the equipment after consumption of alcohol or drugs, or if feeling -

tired or ill.

Never attempt to modify the equipment. National regulations may restrict of the use of the equipment. Follow the -

regulations about handling of pole saws and chain saws in your country.

Intended use of the machine

This equipment is designed only for the purpose of pruning branches and limbs

less than 15 cm in diameter. Never use the equipment for the other purpose.

Abusing the equipment may cause serious injury.

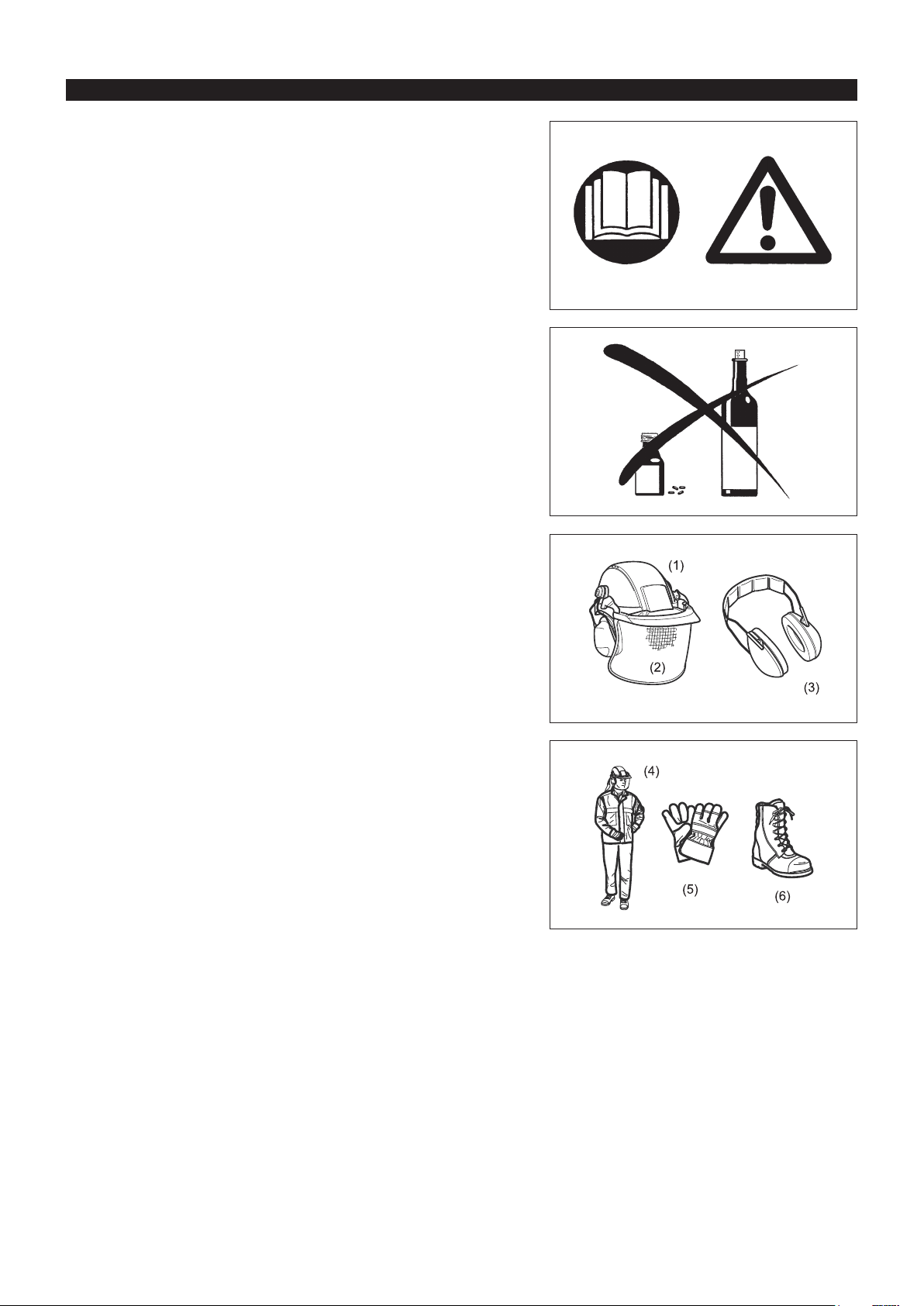

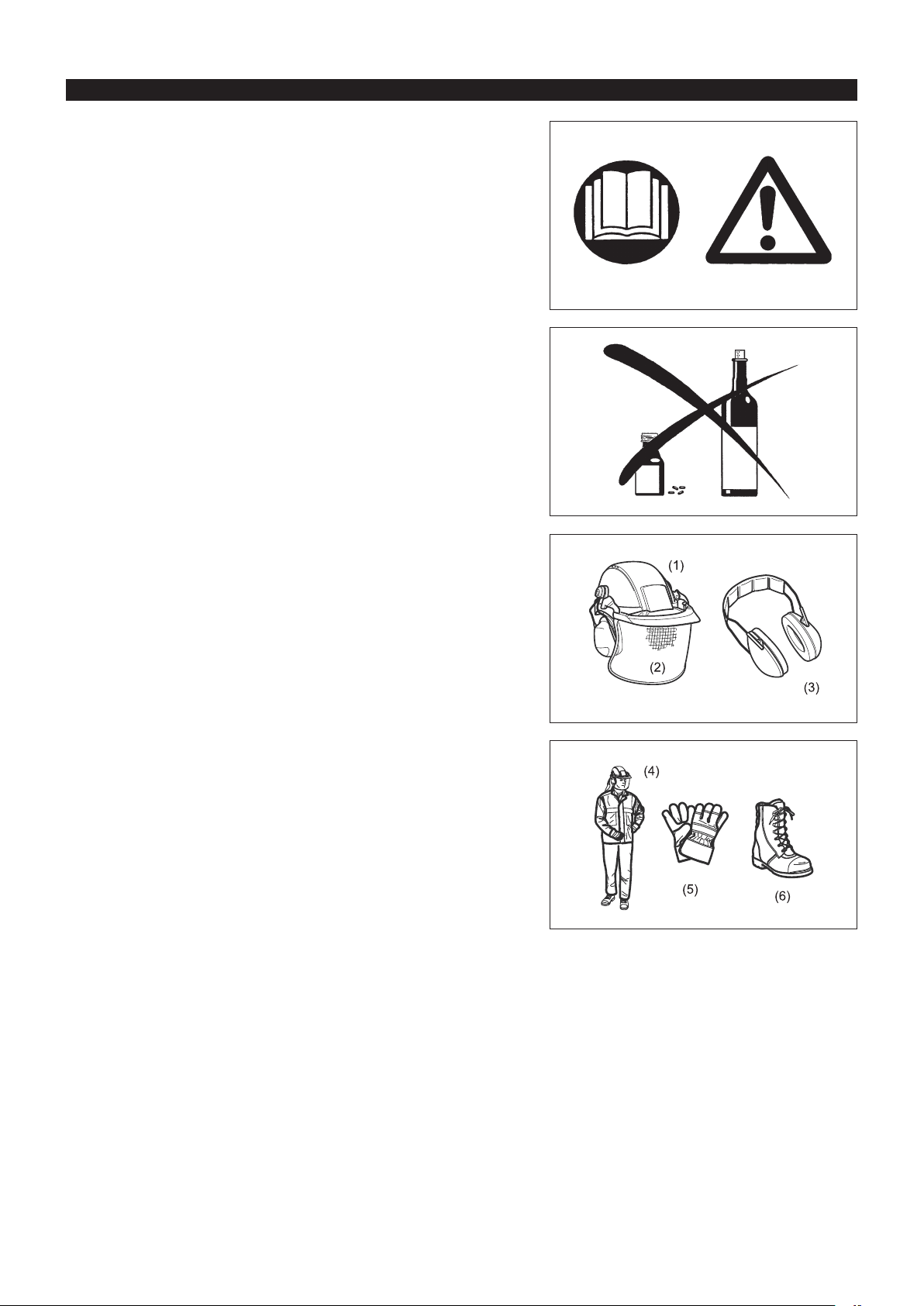

Personal protective equipment

The clothing worn should be functional and appropriate, i.e. it should be tight- -

tting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

In order to avoid either head-, eye-, hand-or foot injuries as well as to protect -

your hearing the following protective equipment and protective clothing must

be used during operation.

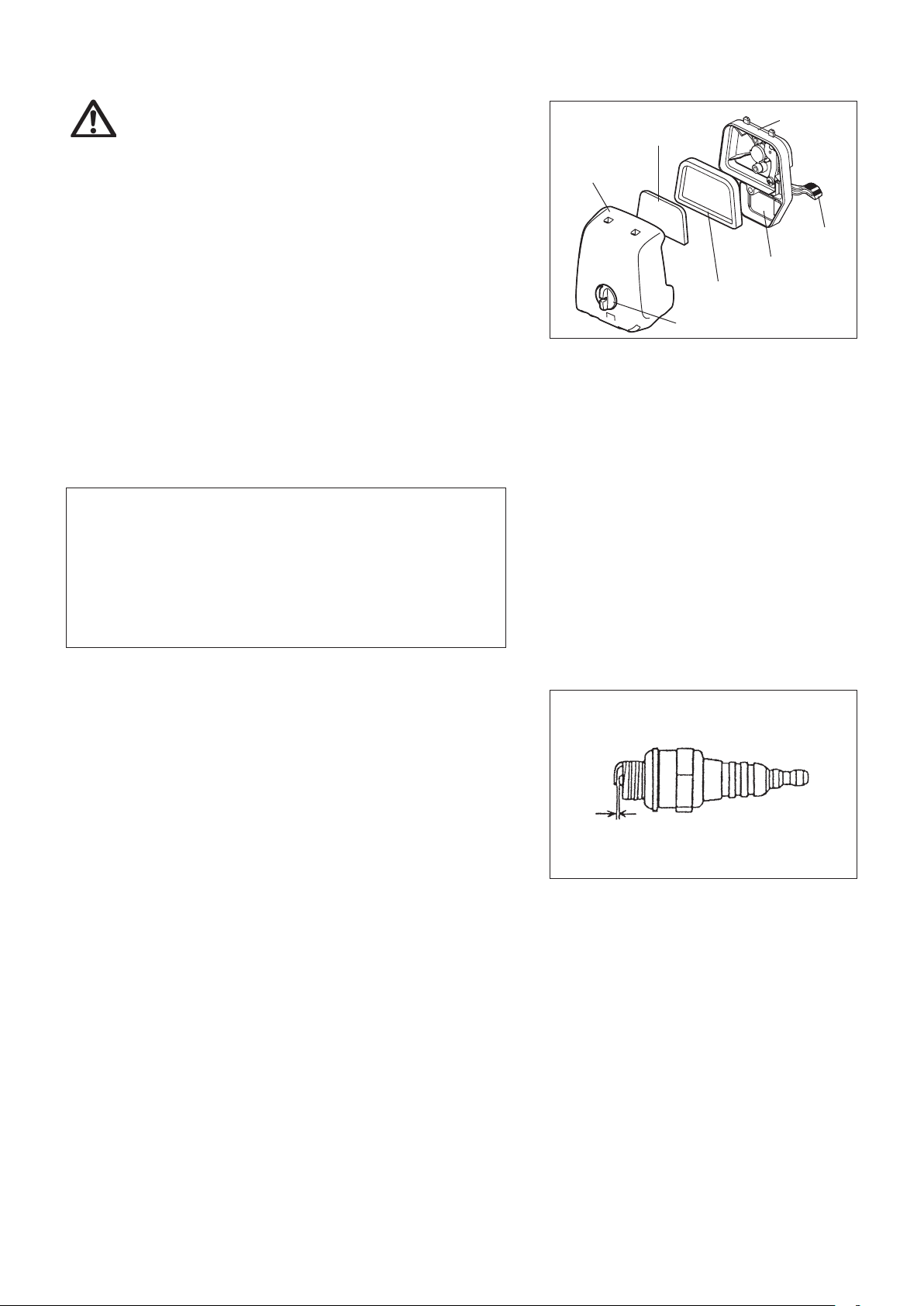

Always wear a helmet where there is a risk of falling objects. The protective helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

The visor (2) of the helmet (or alternatively goggles) protects the face from -

flying debris and stones. During operation always wear goggles, or a visor to

prevent eye injuries.

Wear adequate noise protection equipment to avoid hearing impairment (ear -

muffs (3), ear plugs etc.).

The work overalls (4) protect against flying stones and debris. -

We strongly recommend that the user wears work overalls.

Special gloves (5) made of thick leather are part of the prescribed equipment -

and must always be worn during operation.

When using the equipment, always wear sturdy shoes (6) with a non-slip -

sole. This protects against injuries and ensures a good footing.

When handling the saw chain or adjusting the chain tension, wear protective -

gloves. Saw chain can cut bare hands severely.

3

Work area safety

- Danger: Keep the pole saw at least 15 m away from electric lines and

communication cables (including any branches contacting them). Touching

or approaching high-voltage lines with the pole saw can result in death or

serious injury. Watch power lines and electrical fences around the work area

before starting operation.

Operate the pole saw under good visibility and daylight conditions only. Do not operate the pole saw in darkness or fog.

Start and operate the engine only outdoors in a well ventilated area. -

Operation in a conned or poorly ventilated area can result in death due to

suffocation or carbon monoxide poisoning.

During operation, never stand on an unstable or slippery surface or a steep -

slope. During the cold season, beware of ice and snow and always ensure

secure footing.

During operation, keep bystanders or animals at least 15 m away from the pole saw. Stop the engine as soon as someone approaches.

Before operation, examine the work area for wire fences, walls, or other solid objects. They can damage the saw chain.

- WARNING: Use of this product can create dust containing chemicals

which may cause respiratory or other illnesses. Some examples of these

chemicals are compounds found in pesticides, insecticides, fertilizers and

herbicides. Your risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to lter out microscopic

particles.

Putting into operation

Before assembling or adjusting the equipment, switch off the engine and remove the spark plug cap.

Before starting the engine, inspect the equipment for damages, loose screws/ nuts or improper assembly. Sharpen blunt saw chain. If the saw chain is bent

or damaged, replace it. Check all control levers and switches for easy action.

Clean and dry the handles.

Never attempt to start the engine if the equipment is damaged or not fully assembled. Otherwise serious injury may result.

Adjust the chain tension properly. Rell the chain oil, if necessary. -

Starting up the engine

Please make sure that there are no children or other people, also pay attention to any animals in the working vicinity.

Wear the personal protective equipment before starting the engine. Make sure that the attachment is attached in place, the control lever for easy -

action and check for proper functioning of the lock-off lever.

If the saw chain moves at idle, stop the engine and adjust the idle speed -

down. Ask authorized service center for adjustment if in doubt. Check for

clean and dry handles and test the function of the start/stop switch.

4

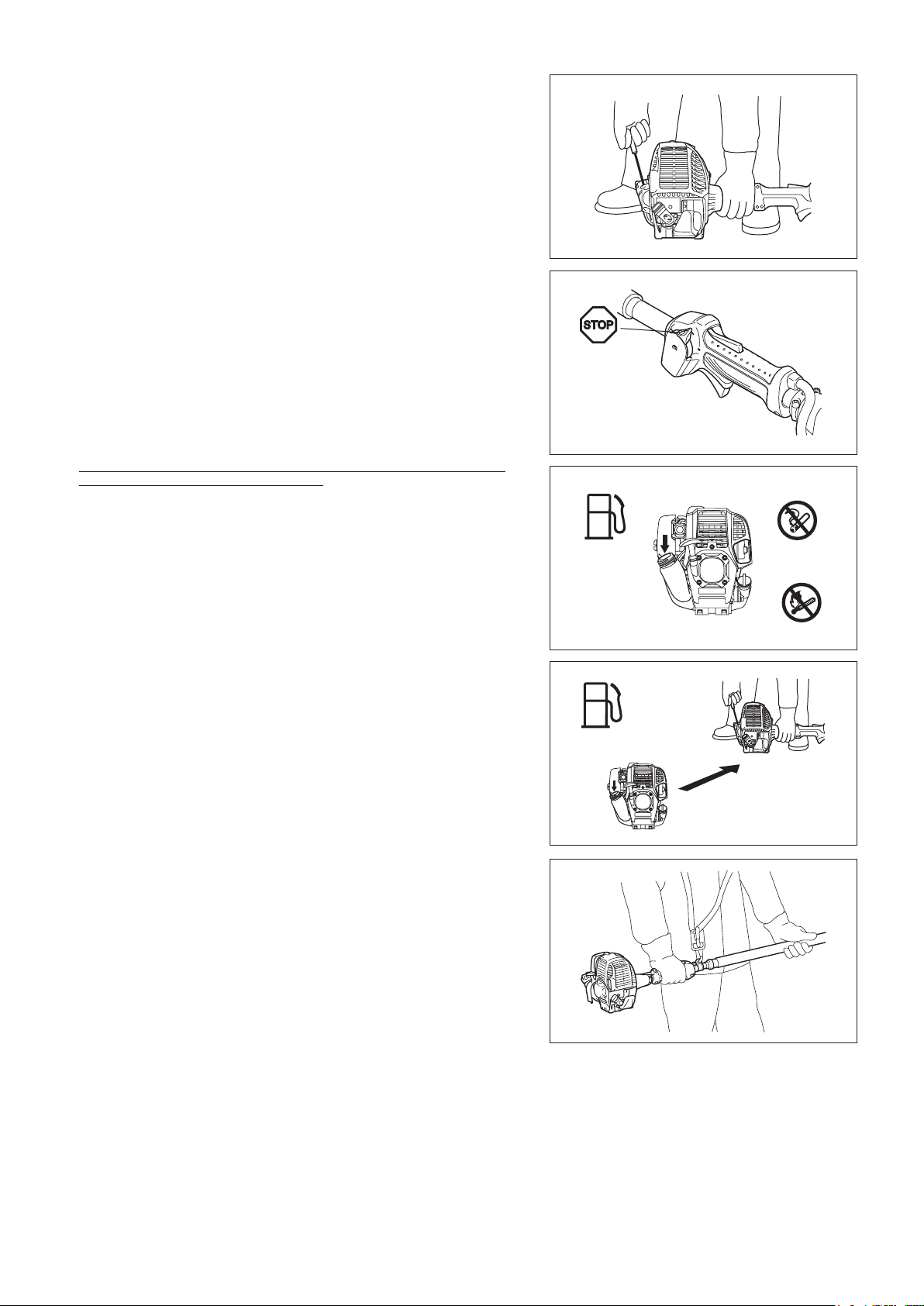

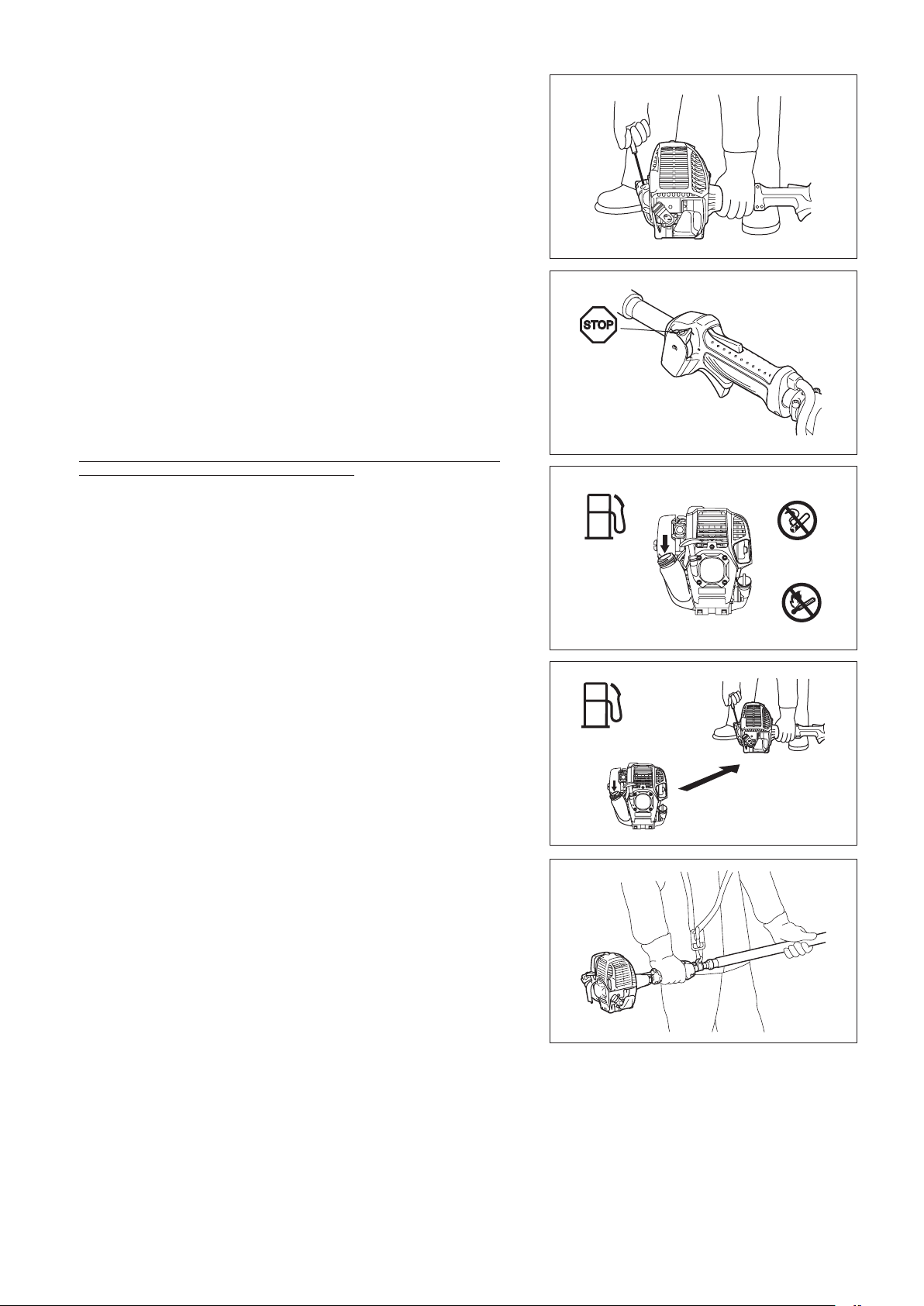

Start the engine only in accordance with the instructions.

Do not use any other methods for starting the engine! Place the equipment on rm ground. Maintain good balance and secure -

footing.

When pulling the starter knob, hold the equipment rmly against the ground -

by your left hand. Never step on the drive shaft.

Before starting the engine, make sure that there is no person or animal in the -

work area.

When starting the engine, keep the saw chain and guide bar clear of your -

body and other object, including the ground. The saw chain may move when

starting and may cause serious injury or damage to the saw chain and/or

property.

The engine is to be switched off immediately in case of any engine problems. Should the saw chain hit stones or other hard objects, immediately switch off -

the engine and inspect the equipment.

Operate the equipment only with the shoulder strap attached which is to be -

suitably adjusted before putting the equipment into operation. It is essential

to adjust the shoulder strap according to the user size to prevent fatigue

occurring during use. Never hold the cutter with one hand during use.

With the engine running only at idle, attach the shoulder harness. During -

operation, keep the equipment on your right side rmly.

All protective installations and guards supplied with the machine must be used during operation.

Never operate the engine with faulty exhaust muffler. Except in case of emergency, never drop or cast the equipment to the ground -

or this may severely damage the equipment.

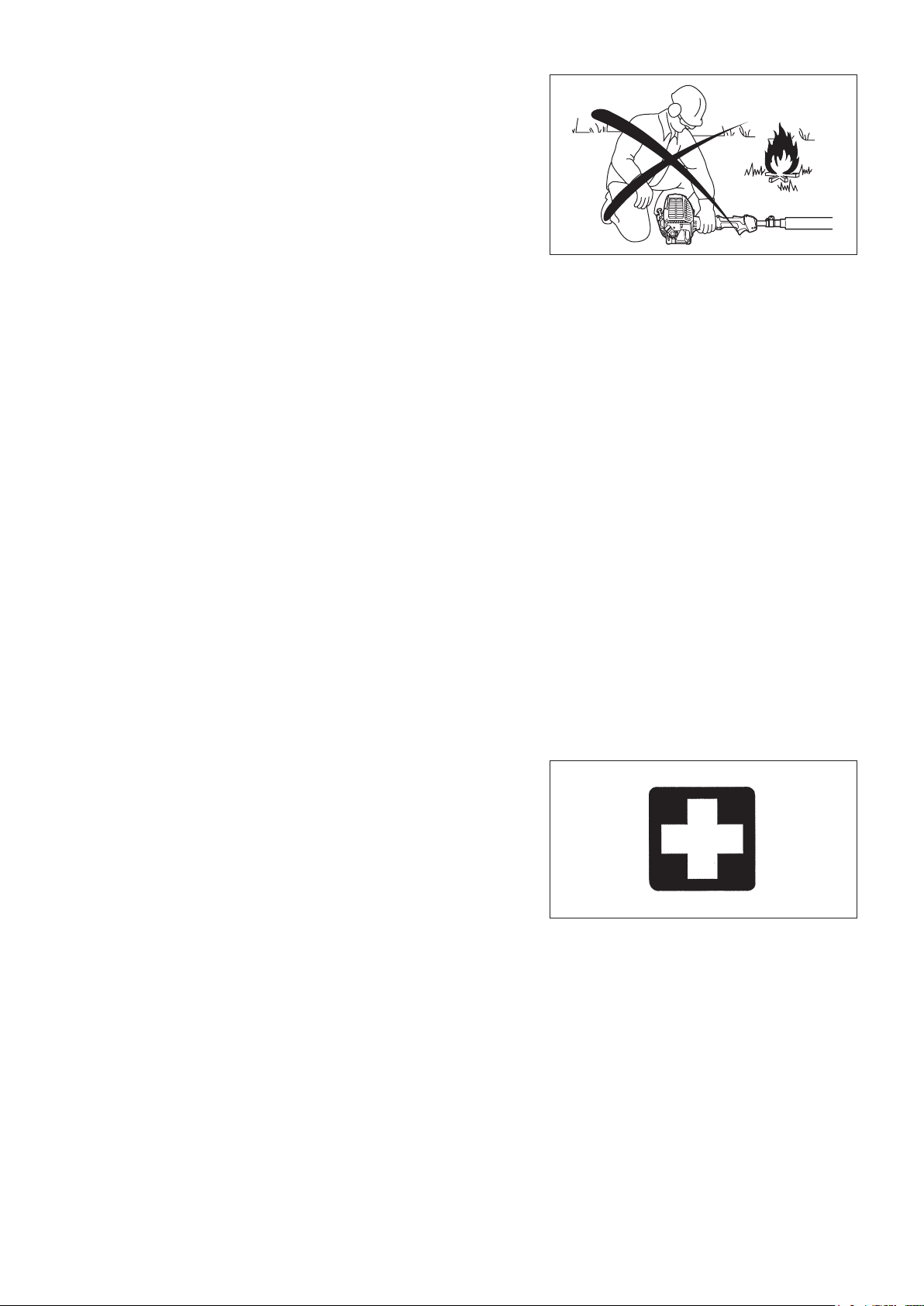

Refuelling

Shut off the engine during refuelling, keep away from open flames and do not smoke.

Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always wear protective gloves during refuelling. Change and clean protective clothing

at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination (environmental protection). Clean the equipment immediately after fuel has

been spilt.

Avoid any fuel contact with your clothing. Change your clothing instantly if -

fuel has been spilt on it (to prevent clothing catching re).

Inspect the fuel cap at regular intervals making sure that it can be securely fastened and does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at least 3 meters away from the place of refuelling).

Never refuel in closed rooms. Fuel vapors accumulate at ground level (risk of explosions).

Only transport and store fuel in approved containers. Make sure the fuel stored is not accessible to children.

Method of operation

In the event of an emergency, switch off the engine immediately. If you feel any unusual condition (e.g. noise, vibration) during operation, -

switch off the engine. Do not use the equipment until the cause is recognized

and solved.

The saw chain continues to move for a short period after releasing the throttle trigger. Don’t rush to contact the saw chain.

Hold the front grip with the left hand and the rear grip with the right hand, no -

matter you are right-hander or left-hander. Wrap your ngers and thumbs

around the grips.

Never attempt to operate the equipment with one hand. Loss of control may -

result in serious or fatal injury. To reduce the risk of injury, keep your hands

and feet away from the blades.

Do not overreach. Keep proper footing and balance at all times. Watch for hidden obstacles such as tree stumps, roots and ditches to avoid -

stumbling. Clear fallen branches and other objects away.

If the equipment gets heavy impact or fall, check the condition before -

continuing work. Check the fuel system for fuel leakage and the controls and

safety devices for malfunction. If there is any damage or doubt, ask Makita

authorized service center for the inspection and repair.

Do not touch the gear case. The gear case becomes hot during operation. When you leave the equipment, even if it is a short time, always stop the -

engine. The equipment unattended with the engine running may be used by

unauthorized person and cause serious accident.

• Resting

• Transport

• Refuelling

• Maintenance

• Tool replacement

3 meters

5

Pay attention to the environment. Avoid unnecessary throttle operation for less pollution and noise emissions. Adjust the carburetor correctly.

During or after operation, do not put the hot equipment onto dry grass or combustible materials.

Do not hold your right hand above shoulder height. During operation, never hit the saw chain against hard obstacles such stones -

and nails. Take particular care when cutting branches next to walls, wire

fences or the like.

If branches get caught in the saw chain, always stop the engine and remove the spark plug cap. Otherwise unintentional start may cause serious injury.

If the saw chain becomes clogged, always stop the engine and remove the spark plug cap before cleaning.

Accelerating the engine with the saw chain blocked increases the load and will damage the engine and/or clutch.

Before cutting limbs, keep an escape area away from the falling limb. First, clear obstructs such as limbs and branches from the work area. Move all

tools and goods from the escape area to another safe place.

Before cutting branches and limbs, check the falling direction of them, considering the condition of branches and limbs, adjoining trees, wind

direction, etc. Pay full attention to the falling direction, and the rebound of the

branch, which hit the ground.

Never hold the pole saw at an angle of more than 60°. Otherwise falling objects can hit the operator and cause serious injury. Never stand underneath

the limb being cut.

Pay attention to broken or bent branches. They may bounce back in cutting, causing unexpected injury.

Before cutting limbs that you intend to cut, remove branches and leaves around them. Otherwise the saw may be caught by them.

To prevent the saw from being caught in the kerf, do not release the throttle lever before pulling the saw out of the kerf.

If the saw chain is bound in the kerf, immediately stop the engine, carefully move the branch to open the kerf and release the saw.

Avoid kickback (rotational reactive force towards the operator). To prevent kickback, never use the guide bar nose or perform a penetrating cut. Always

beware of the position of the guide bar nose.

Check the chain tension frequently. When checking or adjusting the chain tension, stop the engine and remove the spark plug cap. If the tension is

loose, tighten it.

Operate the equipment with as little noise and contamination as possible. In particular check the correct setting of the carburetor.

Never stand on a ladder and run the equipment. Never climb up into trees to perform cutting operation. Wait until the chain reaches its full working speed before cutting. Take a rest to prevent loss of control caused by fatigue. We recommend to -

take a 10 to 20-minute rest every hour.

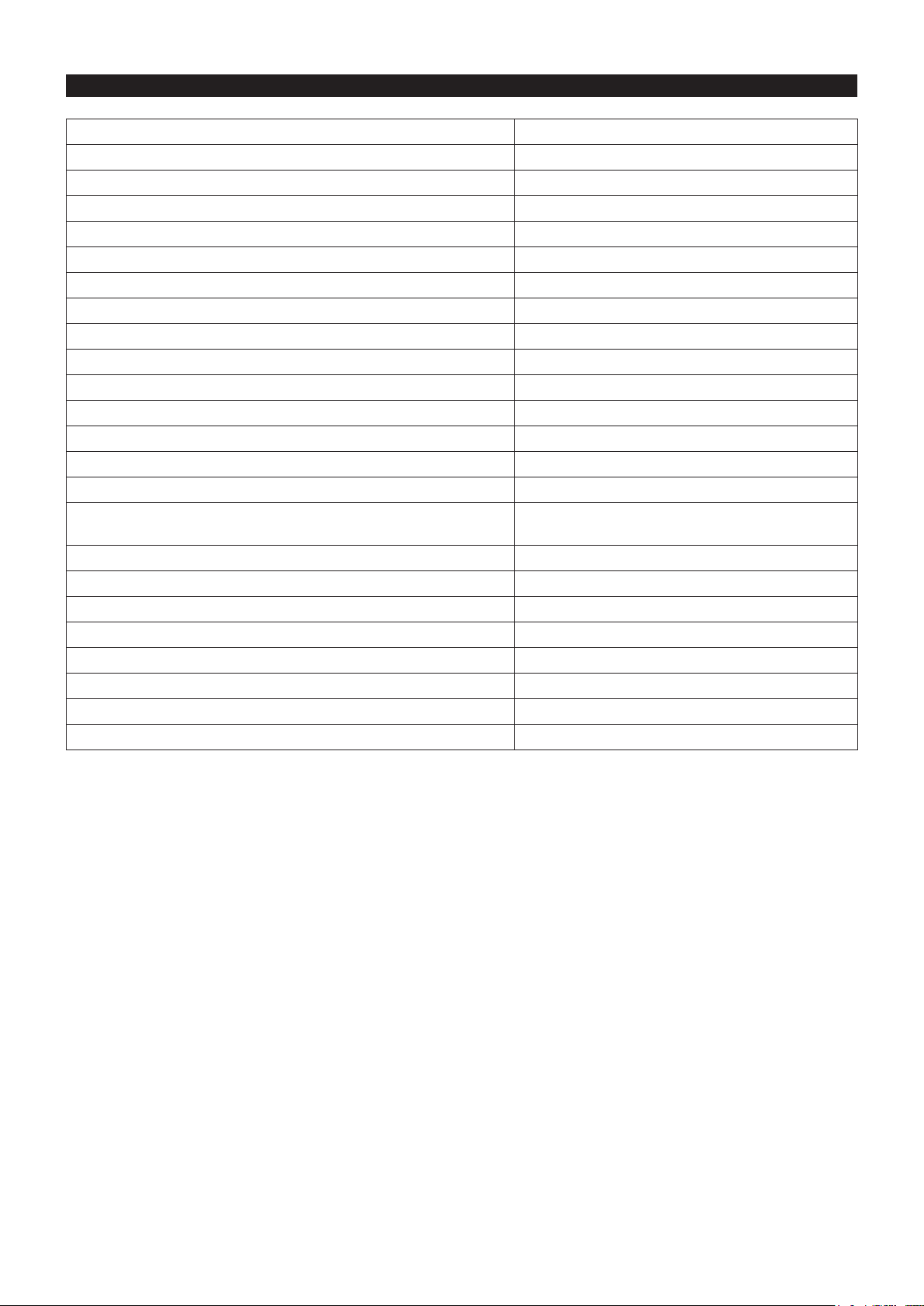

Transport

Before transporting the equipment, switch off the engine and remove the spark plug cap.

Always t the guide bar cover during transportation. Always use the tool protection included with the equipment. Carry it in a horizontal position by holding the shaft. Keep the hot muffler -

away from your body.

When transporting the equipment in a vehicle, properly secure it to avoid -

turnover. Otherwise fuel spillage and damage to the equipment and other

baggage may result.

Shut off the engine during transport. Ensure that the fuel tank is completely empty. When unloading the equipment from the truck, never drop the engine to the -

ground or this may severely damage the fuel tank.

Remember to lift the entire equipment from the ground when moving the -

equipment. Dragging the fuel tank is highly dangerous and will cause damage

and leakage of fuel, possibly causing re.

6

Maintenance instructions

Have your equipment serviced by our authorized service center, always using only genuine replacement parts. Incorrect repair and poor maintenance can

shorten the life of the equipment and increase the risk of accidents.

Before doing any maintenance or repair work or cleaning the equipment, always stop the engine and remove the spark plug cap. Wait until the engine

gets cold.

To reduce the risk of re, never service or store the equipment in the vicinity of re.

Always wear protective gloves when handling the saw chain. Always clean dust and dirt off the equipment. Never use gasoline, benzine, -

thinner, alcohol or the like for the purpose. Discoloration, deformation or

cracks of the plastic components may result.

After each use, tighten all screws and nuts, except for adjustment screws. Keep the saw chain sharp. If the saw chain has become blunt and cutting -

performance is poor, ask Makita authorized service center to sharpen it or

replace it with new one.

Do not attempt any maintenance or repair not described in this instruction manual. Ask Makita authorized service center for such work.

Clean the equipment at regular intervals and check that all screws and nuts are well tightened.

Always store the equipment in locked rooms and with an emptied fuel tank. -

Storage

Before storing the equipment, perform full cleaning and maintenance. Fit the guide bar cover. Remove the spark plug cap. Drain the fuel and chain oil after

the engine gets cold.

Store the equipment in a dry and high or locked location out of reach of children.

Do not prop the equipment against something, such as a wall. Otherwise it may fall suddenly and cause an injury.

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modications on the equipment as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other work is

to be done by an Authorized Service Center. Use only genuine spare parts and accessories released and supplied by MAKITA.

Use of non-approved accessories and tools means increased risk of accidents.

MAKITA will not accept any liability for accidents or damage caused by the use of non-approved attachments and xing devices of attachments,

or accessories.

First aid

In case of accident make sure that a rst-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the rst aid box.

When asking for help, please give the following

information:

Place of accident What happened Number of injured persons Kind of injuries Your name -

Vibration

People with poor circulation who are exposed to excessive vibration may experience injury to blood vessels or the nervous system. Vibration -

may cause the following symptoms to occur in the ngers, hands or wrists: “Falling asleep” (numbness), tingling, pain, stabbing sensation,

alteration of skin color or of the skin. If any of these symptoms occur, see a physician!

To reduce the risk of “white nger disease”, keep your hands warm during operation and well maintain the equipment and accessories. -

7

TECHNICAL DATA

Model EY2650H/EY2650HG

Dimension: L x W x H mm 2,720-3,920 x 223 x 240

Weight kg 7.2

Fuel tank volume cm

Chain oil tank volume cm

Engine displacement cm

3

3

3

Max. chain speed m/s 21.0

Maximum engine performance 0.77 kW at 7,000 min

Engine speed at recommended max, spindle speed min

Idling speed min

Clutch engagement speed min

-1

-1

-1

Carburetor Diaphragm type

Spark plug Type NGK CMR4A

Electrode gap mm 0.7 - 0.8

Fuel Automobile gasoline (petrol)

Engine oil

API grade SF class or higher, SAE 10W-30 oil

(automobile 4-stroke engine oil)

Cutting length mm 255

Guide bar length mm (inch) 255 (10”)

Saw chain 91VXL-39E

Chain pitch inch 3/8”

Chain gauge mm (inch) 1.3 (0.05”)

Number of sprocket teeth 7

Chain oil Makita genuine chain oil

Chain oil pump Plunger pump (Self lubricating type)

600

120

25.4

-1

10,000

3,000

4,400

• Due to our continuing program of research and development, the specications herein are subject to change without notice.

• Specications may differ from country to country.

EY2650HG: This model adapts for use with Brazilian gasoline (E20 and E25).

8

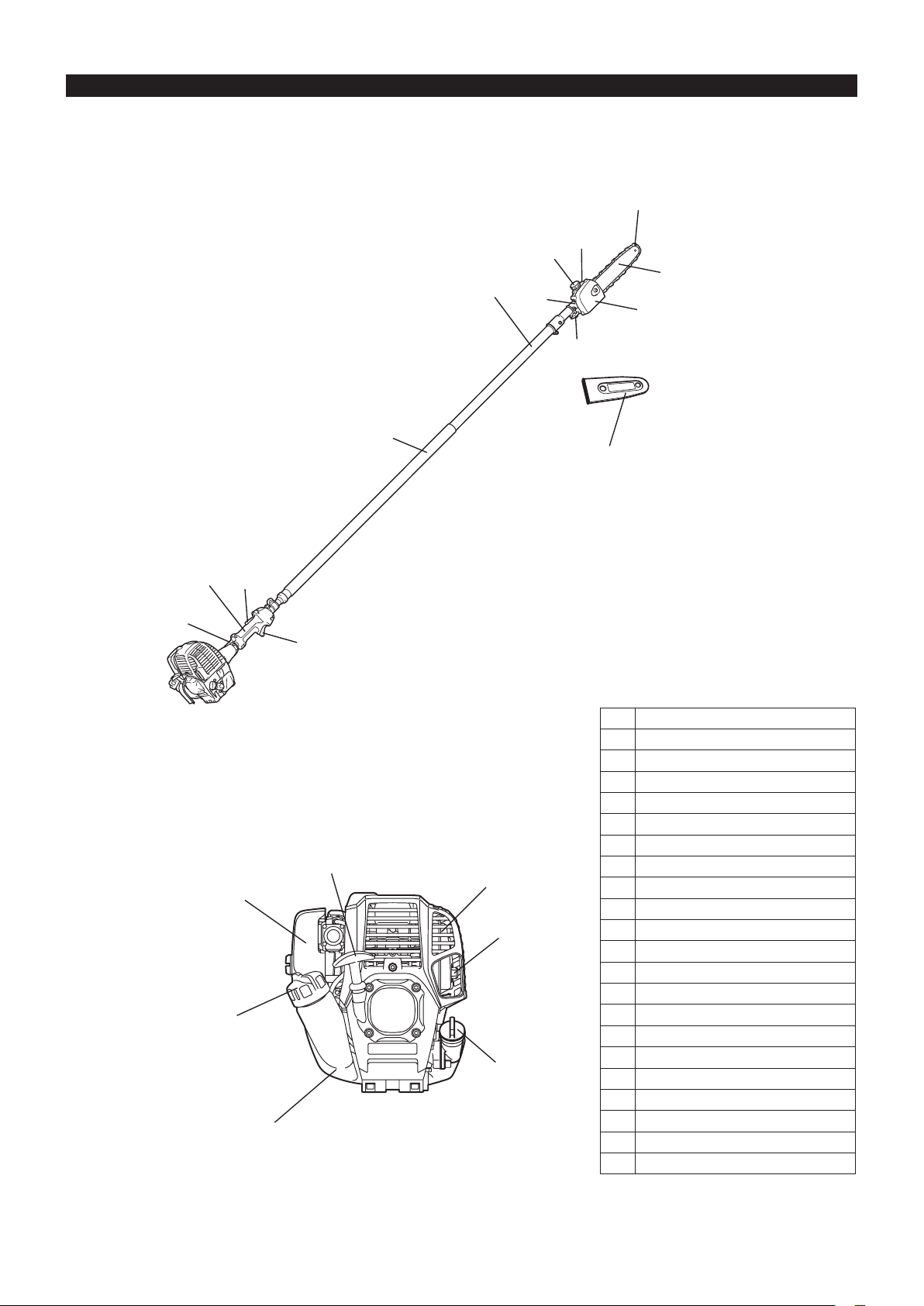

20

21

18

14

19

17

15

16

1

2

3

4

5

6

7

8

9

10

13

11

12

DESIGNATION OF PARTS

EY2650H

EY2650HG

GB DESIGNATION OF PARTS

1 Saw chain

2 Guide bar

3 Oil tank

4 Oil tank cap

5 Bar holder

6 Gear case

7 Knob

8 Telescopic shaft

9 Front grip

10 Throttle lever

11 Lock-off lever

12 Rear grip

13 Control cable

14 Exhaust muffler

15 Exhaust pipe

16 Oil cap

17 Starter knob

18 Air cleaner

19 Fuel tank cap

20 Fuel tank

21 Guide bar cover

9

ASSEMBLY AND ADJUSTMENT

A

D

B

C

E

A

B

C

WARNING:

Before assembling, adjusting or checking, switch off the engine and remove the spark plug cap.•

Always wear protective gloves when handling saw chain.•

Wait until the saw chain cools down before assembling, adjusting or checking. The saw chain become very hot during the operation, and may •

cause burn.

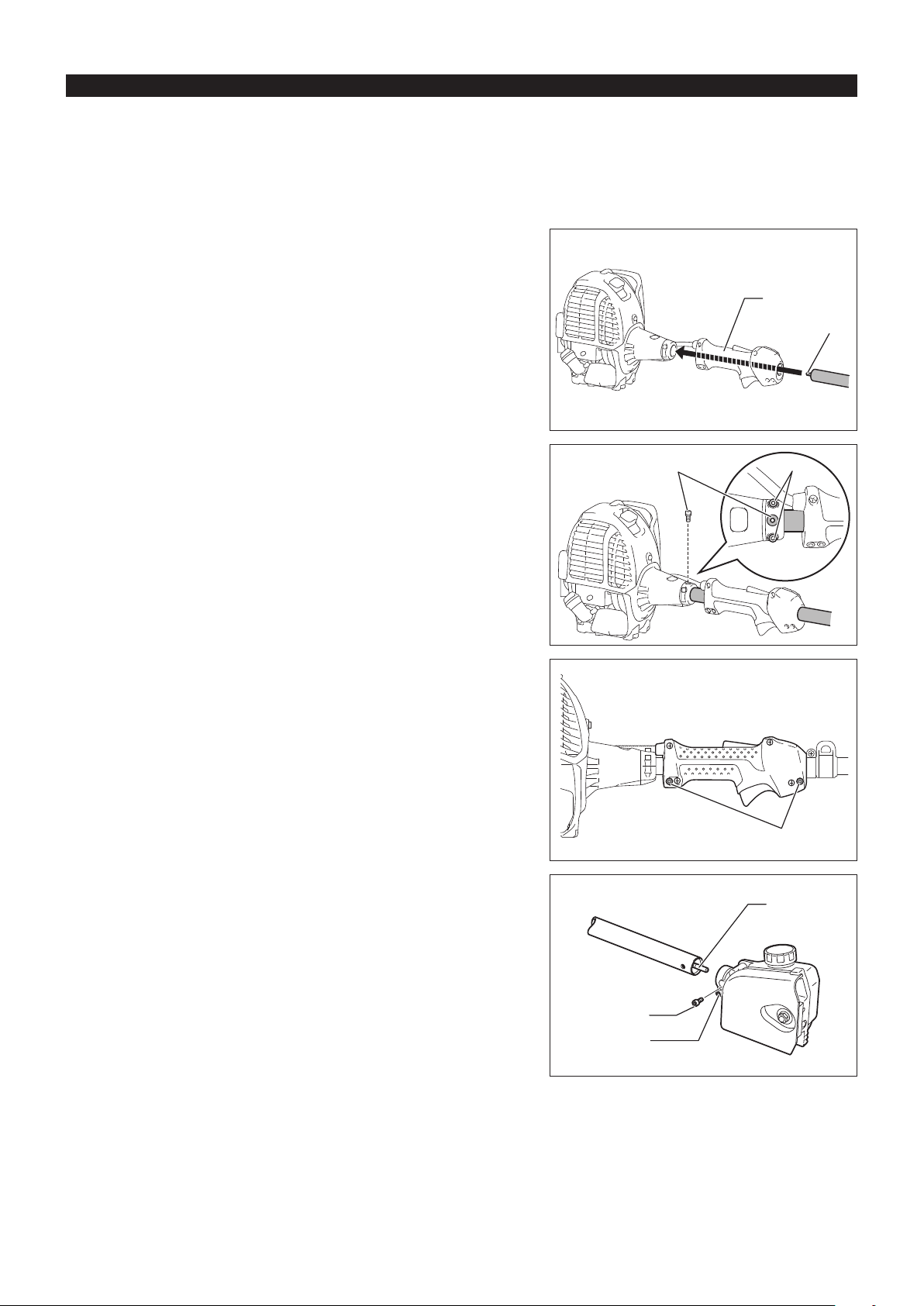

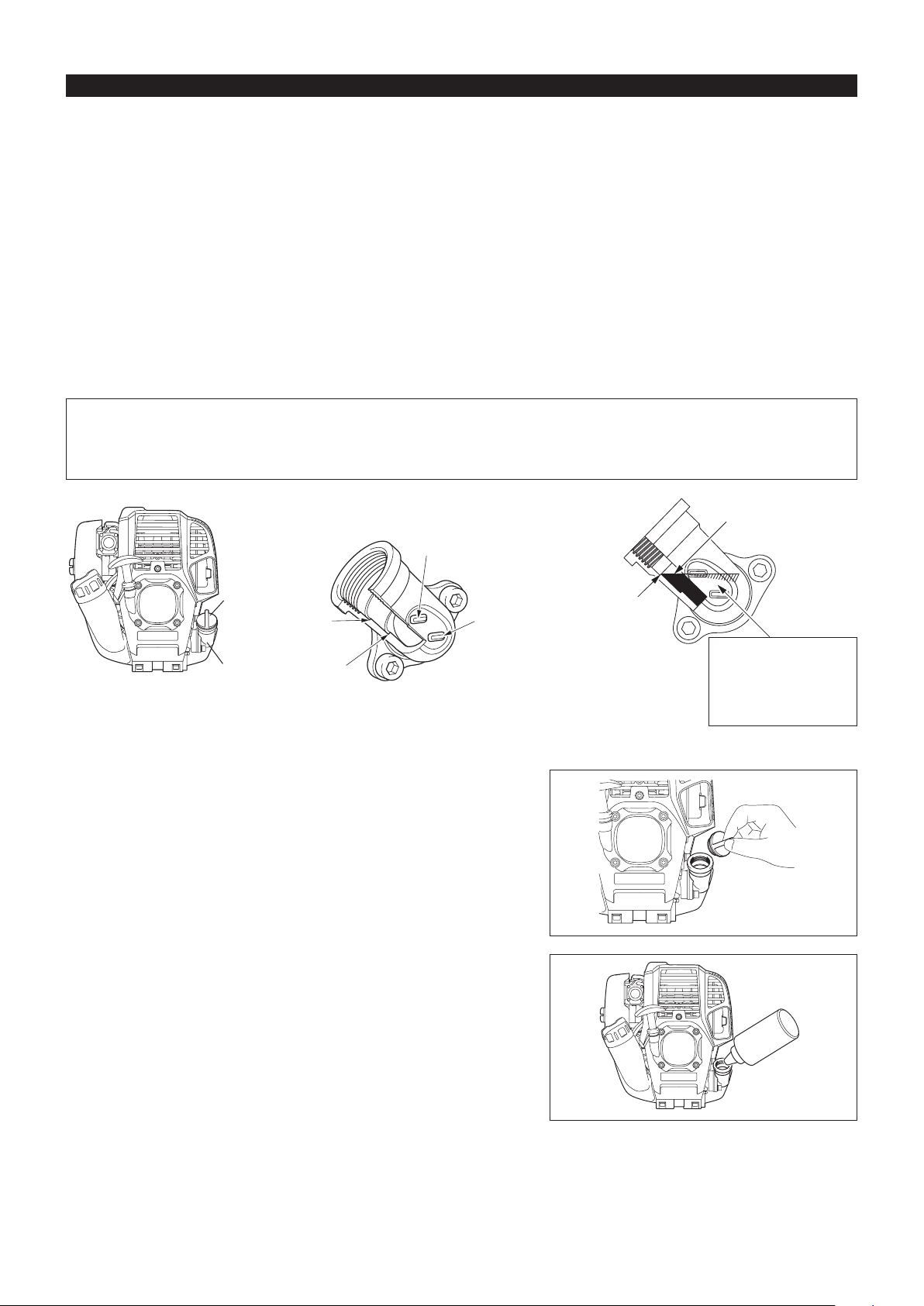

Assembling shaft and clutch case

Assemble the shaft with the rear grip and the engine unit as follows:

1. Insert the shaft through the rear grip (A).

2. Loosen two fastening bolts (B) and remove the center bolt (C) on the clutch

case.

3. Insert the shaft into the clutch case. If it is difcult to fully insert, turn the

spline (D) a little.

4. Align the hole on the shaft with the hole of the center bolt.

5. Tighten the center bolt.

6. Tighten two fastening bolts evenly.

7. Adjust the position of the rear grip, then tighten it by two bolts (E).

Assembling shaft and gear case

Assemble the shaft with the gear case as follows:

1. Loosen the bolt (A). And remove the bolt (B).

2. Insert the shaft into the gear case. If it is difcult to fully insert it, turn the

spline (C) a little.

3. Align the hole on the shaft with the bolt (B) hole.

4. Tighten the bolt (B) rst and then tighten the bolt (A).

10

A

B

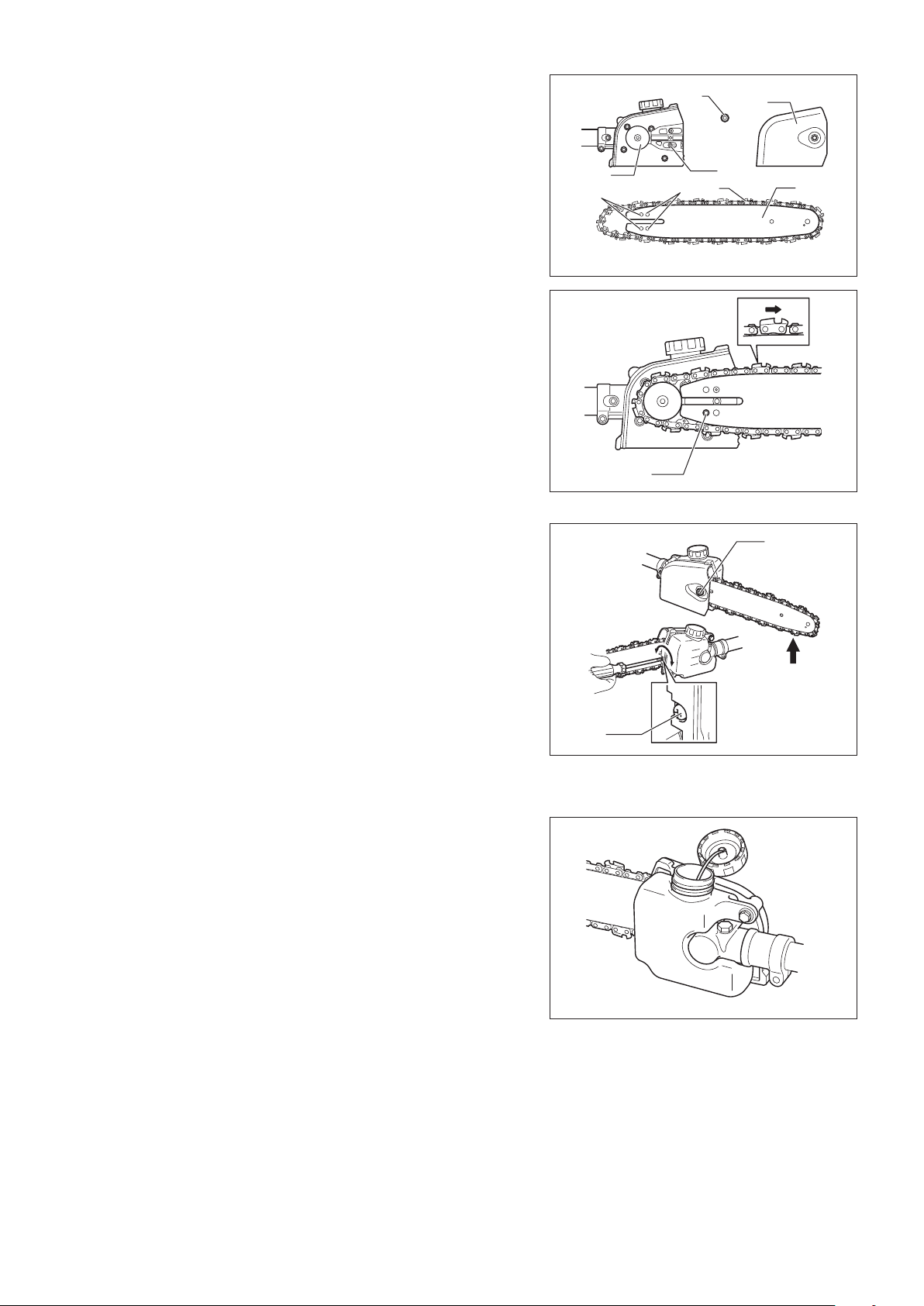

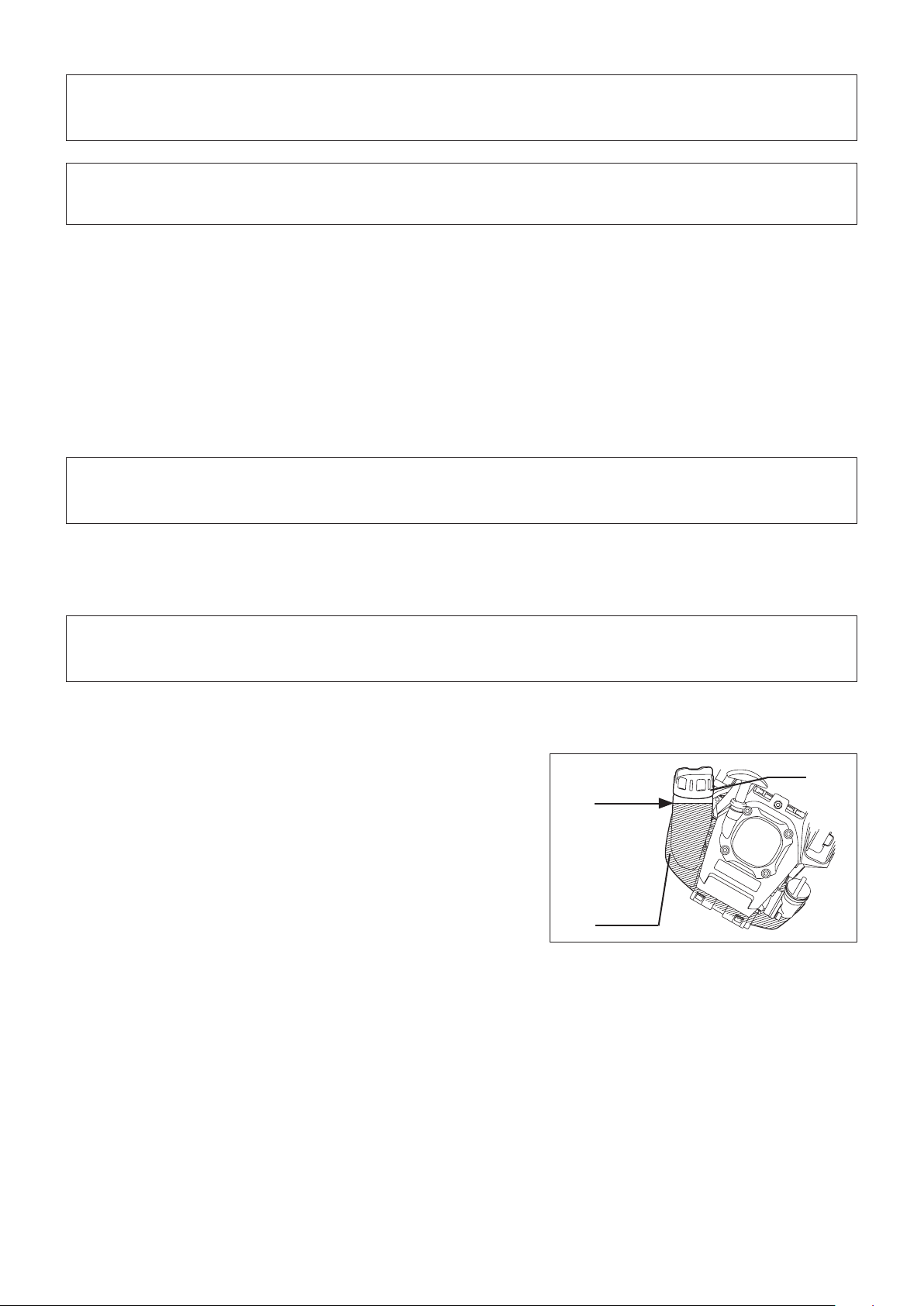

Assembling saw chain and guide bar

A

B

C

D

E

F

G

H

F

CAUTION: Make sure that the saw chain, guide bar and sprocket match

Assemble the saw chain and guide bar as the following steps.

1. Loosen the nut (A) and remove the bar holder (B).

2. Fit the saw chain (C) into the groove of guide bar (D). Start at the bar nose.

3. Fit the saw chain (C) onto the sprocket (E).

4. Install the guide bar (D) so that the tensioning nut (F) ts into the hole (G)

5. Fit the bar holder (B) and tighten the nut (A) securely. Then loose the nut a

6. Adjust the chain tension. Refer to the section “Adjusting the chain tension.”

each other in gauge and pitch.

on the guide bar. Holes (H) are not used.

half turn as a provision of the chain tension adjustment.

Adjusting the chain tension

CAUTION:

Keep the applicable chain tension. Loose tension can cause the saw chain •

to come off during operation. Too tight tension can damage the saw chain or

guide bar.

During operation, check the chain tension frequently. The saw chain stretches •

and becomes loose during operation. When use a new saw chain, adjust the

tension more frequently.

Adjust the chain tension as the following steps.

1. Loose the nut (A) a half turn.

2. Hold the bar nose up. Turn the tensioning screw (B) clockwise until the saw

chain ts the underside of the guide bar snugly.

3. Grasp the saw chain in the middle of the guide bar and lift up. The gap

between the guide bar and the tie strap of the saw chain should be

approximately 3 - 4 mm (0.118”-0.157”). If it is not, turn the tensioning

screw counterclockwise slightly and do the step 2 again.

4. Tighten the nut (A) securely.

5. If necessary, tighten the tensioning screw a little to prevent it from falling.

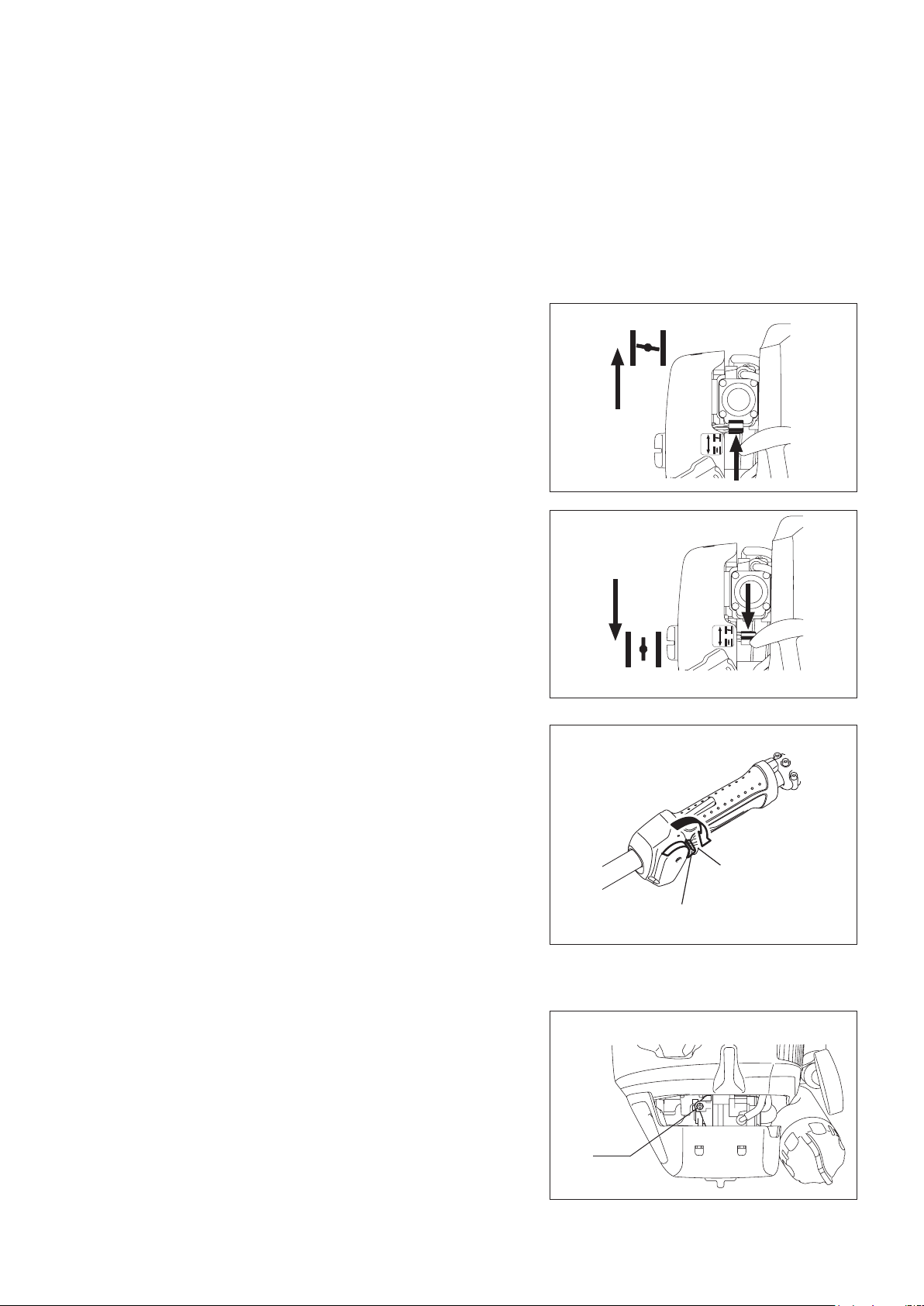

Filling the chain oil tank

The saw chain must be lubricated with chain oil during operation.

Before operation, ll the chain oil tank. After supplying the oil, tighten the oil cap

securely.

Use Makita genuine chain oil only.

NOTICE:

Never use waste oil. It may damage the oil pump.•

Avoid dusty environment when lling the chain oil. Dust and other foreign •

materials may damage the oil feed system.

During operation, always pay attention to the oil level. Rell the tank if the oil

level becomes low. The tank becomes empty in approximately 40 minutes of

operation (depending on the setting of the chain lubrication).

11

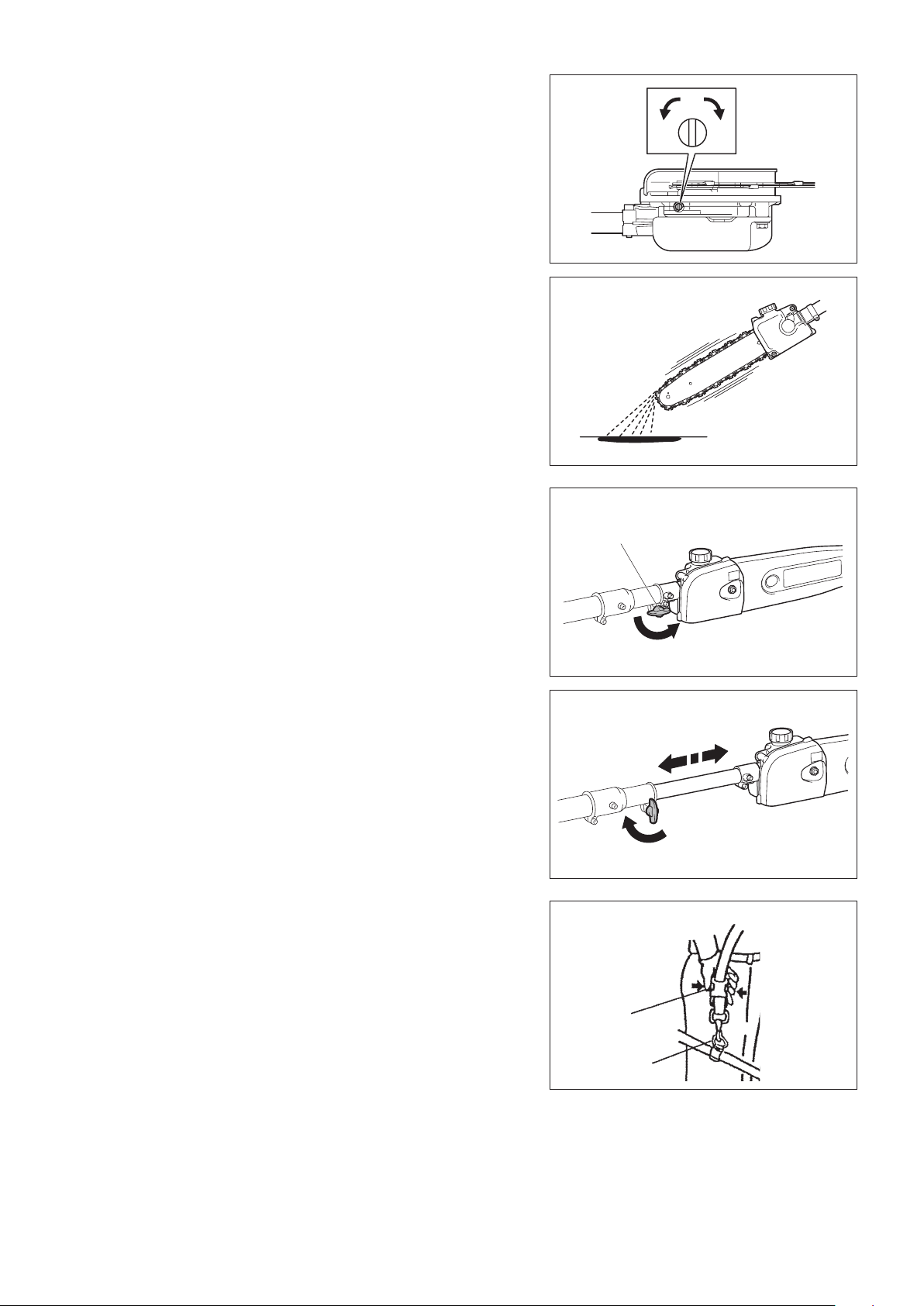

Adjusting the chain-oil feeding rate

A

B

A

The chain-oil feeding rate is adjustable in three steps. According to the

operation, for example cutting hard limbs, adjust the feeding rate.

To adjust the chain-oil feeding rate, use a flat-bladed screwdriver. Push in the

adjusting screw and turn it. To increase feeding rate, turn the adjusting screw

counterclockwise (A). To reduce feeding rate, turn it clockwise (B).

After adjusting the chain-oil feeding rate, check the feeding rate by driving the

equipment at medium speed.

Adjusting the length of pole saw

Adjust the length of the pole saw as follows:

1. Turn the knob (A) counterclockwise.

2. Adjust the length of the pole.

3. Turn the knob clockwise to fasten the gear head.

Shoulder strap

Adjusting the shoulder strap

Adjust the strap to the suitable length for your operation.

Detachment

In case of emergency, push the notches (A) at both sides, and detach the

equipment.

Be extremely careful to maintain control of the equipment at this time. Do not

allow the equipment to be deflected toward you or anyone in your vicinity.

WARNING: Failure to maintain complete control of the machine at all could

Note: In some countries, shoulder strap does not have this detachment function.

result in serious injury or DEATH.

12

A

Hanger

BEFORE START OF OPERATION

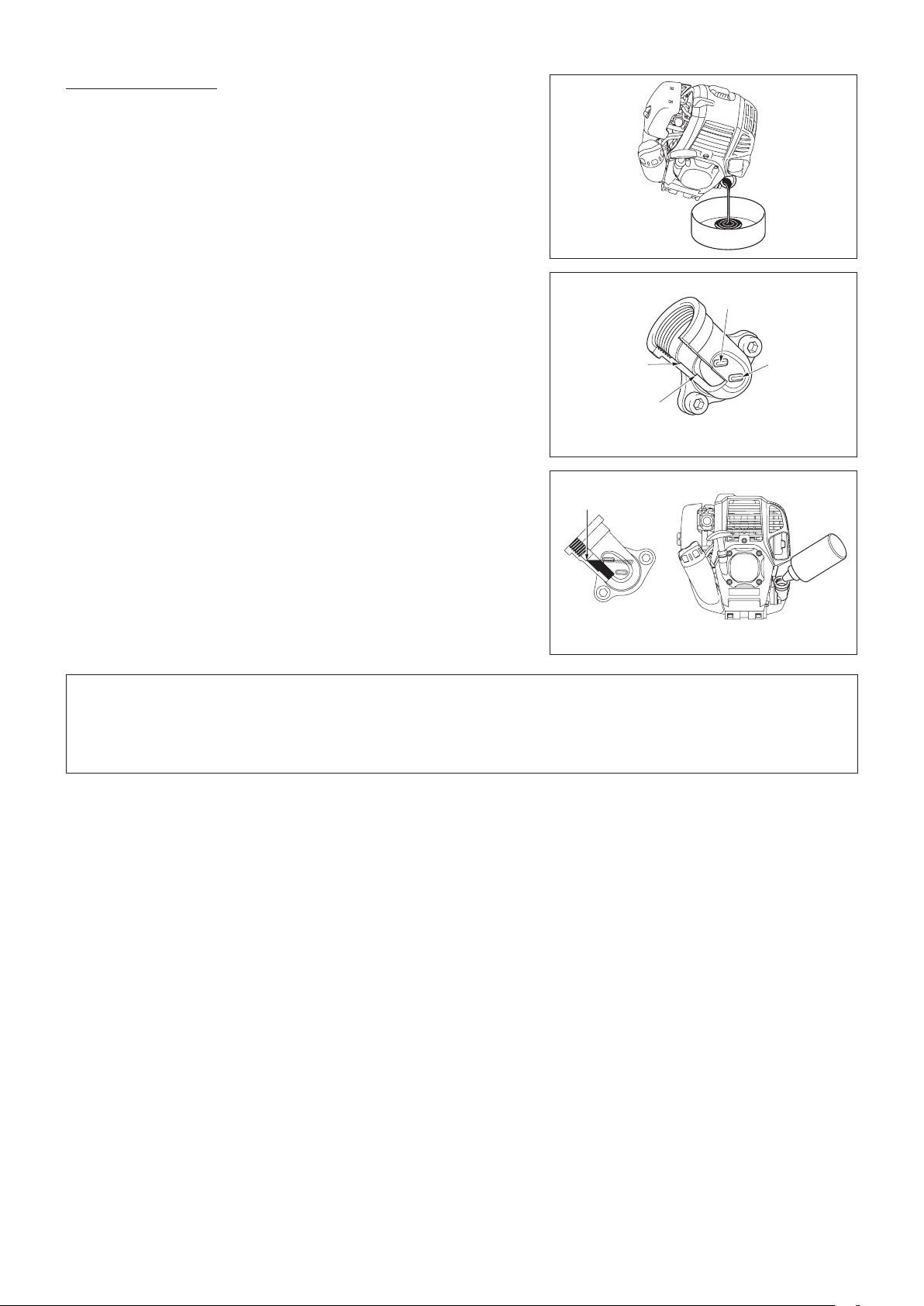

Inspection and rell of engine oil

Perform the following procedure, with the engine cooled down. Set the engine level, remove oil cap (Fig. 1), and check to see whether or not there is oil in the range between the upper limit and lower limit -

marks of the oil pipe (Fig. 2).

Top up with oil to upper limit mark if oil is insufcient (oil level is close to lower limit mark) (Fig. 3). The area surrounding the external marks is transparent, so the amount of oil inside can be checked without having to remove the oil cap. -

However, if oil pipe becomes extremely dirty, visibility may be lost, and oil level will have to be checked against stepped section on inside of

oil pipe.

For reference, the oil rell time is about 10h (every 10 refuellings). If the oil changes in color or mixes with dirt, replace it with new one. (For the interval and method of replacement, refer to P 18)

Recommended oil: SAE 10W-30 oil of API Classication, Class SF or higher (4-stroke engine for automobile)

Oil volume: Approx. 0.08L

Note: If the engine is not kept upright, oil may go into around the engine, and may be relled excessively.

If the oil is lled above the limit, the oil may be contaminated or may catch re with white smoke.

Point 1 in Replacement of oil: “Oil cap”

Remove dust or dirt near the oil rell port, and detach the oil cap. Keep the detached oil cap free of sand or dust. Otherwise, any sand or dust adhering to the oil cap may cause irregular oil circulation or -

wear on the engine parts, which will result in troubles.

Oil cap

Internal stepped

section (upper

limit)

Oil pipe

Fig. 1

(1) Keep the engine level, and detach the oil cap.

(2) Fill with oil to upper limit mark. (see Fig. 3)

Use oil bottle when lling.

Internal stepped

section (lower

limit)

External mark

(upper limit)

External mark

(lower limit)

Fig. 2 Oil pipe Fig. 3

Top up with oil until

oil level reaches

internal stepped

section (upper

limit).

Oil

The area between the

external upper and lower

limits is transparent, so

oil level can be checked

externally against these

marks.

(3) Securely tighten the oil cap. Insufcient tightening may cause oil leakage.

13

Note

Do not replace oil with the engine in a tilted position.•

Filling with oil while engine is tilted leads to overlling which causes oil contamination and/or white smoke.•

Point 2 in Replacement of oil: “If oil spills out”

If oil spills out between the fuel tank and engine main unit, the oil is sucked into through the cooling air intake port, which will contaminate the engine. Be sure to wipe out spilt oil before start of operation.

REFUELLING

Handling of fuel

It is necessary to handle fuel with utmost care. Fuel may contain substances similar to solvents. Refuelling must be performed in a sufciently

ventilated room or in the open air. Never inhale fuel vapor, and keep fuel away from you. If you touch fuel repeatedly or for a long time, the

skin becomes dry, which may cause skin disease or allergy. If fuel enters into the eye, clean the eye with fresh water. If your eye remains still

irritated, consult your doctor.

Do not perform refuelling in the dusk or on unstable surface.

Storage period of fuel

Fuel should be used up within a period of 4 weeks, even if it is kept in a special container in a well-ventilated shade.

If a special container is not used or if the container is not covered, fuel may deteriorate in one day.

STORAGE OF MACHINE AND REFILL TANK

Keep the machine and tank at a cool place free from direct sunshine. Never keep the fuel in the cabin or trunk. -

Fuel

The engine is a four-stroke engine. Be sure to use an automobile gasoline (regular gasoline or premium gasoline).

EY2650HG:This model adapts for use with Brazilian gasoline (E20 and E25).

Points for fuel

Never use a gasoline mixture which contains engine oil. Otherwise, it will cause excessive carbon accumulation or mechanical troubles. Use of deteriorated oil will cause irregular startup. -

Refuelling

WARNING: INFLAMMABLES STRICTLY PROHIBITED

CAUTION: Do not forget to close the fuel tank cap after refuelling. Never start

Gasoline used: Automobile gasoline (unleaded gasoline)

1. Loosen the fuel tank cap (A) a little to avoid the fuel spilling.

2. Detach the fuel tank cap. And tilt the engine so that the refuel port faces

3. Refuel carefully with discharging air from the fuel tank (B). (Do not refuel

4. Wipe well the periphery of the fuel tank cap to prevent foreign matter from

5. After refuelling, securely tighten the fuel tank cap.

If there is any flaw or damage on the tank cap, replace it.•

The tank cap wears out in course of time. Replace it every two to three years.•

the engine with the fuel tank cap opened.

C

upwards.

over the fuel upper limit (C).)

entering into the fuel tank.

B

A

14

POINTS IN OPERATION AND HOW TO STOP

C

D

CAUTION:

Observe the applicable accident prevention regulations!

NOTICE:

Remove the guide bar cover before starting the engine.

STARTING

Move at least 3 m away from the place of refuelling. Place the equipment on a clean piece of ground taking care that the attachment does not

come into contact with the ground or any other objects.

A: Cold start

1) Set this machine on a flat space.

2) Set the I-O switch (A) to OPERATION.

OPERATION

STOP

A

3) Primer pump

Continue to push the primer pump (B) until fuel enters into the primer

pump.

(In general, fuel enters into the primer pump by 7 to 10 pushes.)

If the primer pump is pushed excessively, an excess of gasoline returns to

the fuel tank.

4) Recoil starter

Pull the start knob gently until it is hard to pull (compression point). Then,

return the start knob, and pull it strongly.

Never pull the rope to the full. Once the start knob is pulled, never release

your hand immediately. Hold the start knob until it returns to its original

point.

5) The handle equips with lock-off lever (C) to prevent accidental start. To

pull the throttle lever (D), grasp the handle to release the lock (the lock-off

button is pressed by hand pressure).

B

6) Warm-up operation

Continue warm-up operation for 2 to 3 minutes.

Note: In case of excessive fuel intake, remove the spark plug and pull the starter handle slowly to remove excess fuel. Also, dry the electrode

section of the spark plug.

15

Caution during operation:

If the throttle lever is opened fully in a no-load operation, the engine rotation is increased to 10,000 min-1 or more. Never operate the engine at a

higher speed than required and at an approximate speed of 6,000 - 8,500 min

-1

.

B: Startup after warm-up operation

1) Push the primer pump repeatedly.

2) Keep the throttle lever at the idling position.

3) Pull the recoil starter strongly.

4) If it is difcult to start the engine, open the throttle by about 1/3.

Pay attention to the attachment which may rotate.

At times, such as winter, when starting the engine

is difcult

Operate choke lever with the following procedure when starting engine.

After implementing startup steps 1) to 3), set choke lever to the CLOSE •

position.

Implement startup step 4) and start engine.•

Once engine starts, set choke lever to the OPEN position.•

Implement startup step 5) and complete warm up.•

CAUTION: If a bang (explosive sound) is heard and the engine stops, or the

just-started engine stalls before the choke lever is operated, return

the choke lever to the OPEN position, and pull the starter knob a

few times again to start the engine.

CAUTION: If the choke lever is left in the CLOSE position, and the starter knob

merely pulled repeatedly, too much fuel will be sucked in, and the

engine will become difcult to start.

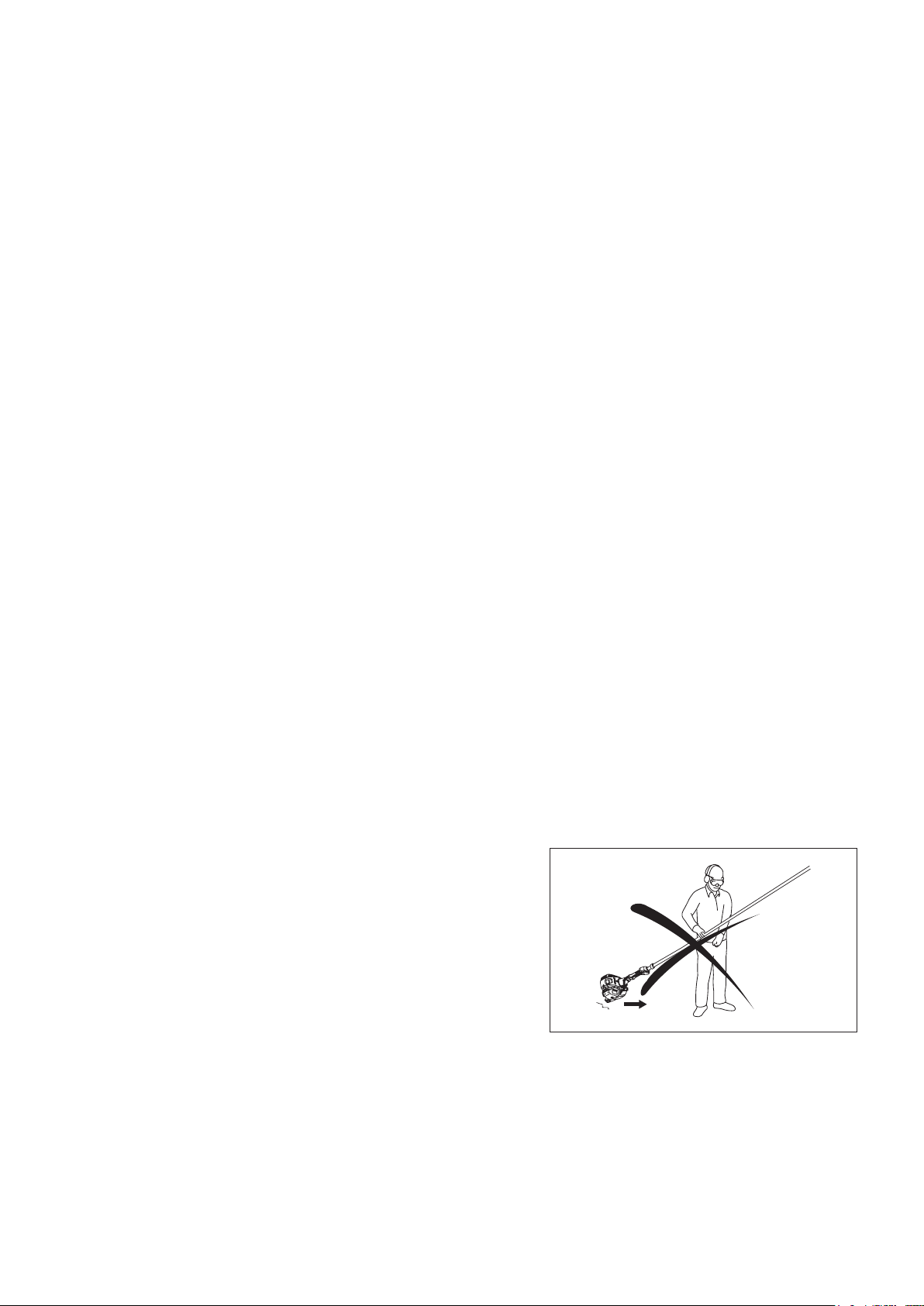

STOPPING

1) Release the throttle lever (B) fully, and when the engine rpm has lowered,

set the I-O switch (A) to STOP the engine will now stop.

2) Be aware that the attachment may not stop immediately and allow it to slow

down fully.

CLOSE

OPEN

ADJUSTMENT OF LOW-SPEED ROTATION (IDLING)

When it is necessary to adjust the low-speed rotation (idling), perform it by the carburetor adjusting screw (A).

CHECKUP OF LOW-SPEED ROTATION

Set the low-speed rotation to 3,000 min If it is necessary to change the rotation speed, regulate the adjusting screw,

with Phillips screwdriver.

Turn the adjusting screw to the right, and the engine rotation will increase. Turn the adjusting screw to the left, and the engine rotation will drop.

The carburetor is generally adjusted before shipment. If it is necessary to readjust it, please contact Authorized Service Center.

-1

.

A

16

STOP

B

A

OPERATION

1

2

3

4

Standing position

Stand on stable surface. Make the angle of the pole saw become 60° against •

the horizontal ground.

Cut lower branches rst so that the branches fall easier. •

Always keep escape route in case a cut branch falls towards the operator.•

Method

Start the engine, and pull the throttle until the saw chain reaches its full •

speed.

Press the saw chain onto the branch lightly. Do not force the equipment, •

otherwise it may damage the equipment.

Never use the tip of the bar for cutting. Otherwise dangerous kickback may •

occur, and it may result in personal injury.

Tips for cutting thick branch

When you cut a thick branch, use the following method.

1. Make a small notch on the under side of the branch where is a bit distance

from you intend to cut.

2. Cut the branch from the upper side of where you notched.

3. Make another small notch on the under side of the branch where you

intend to cut.

4. Cut where you intend to cut from the upper side.

SERVICING INSTRUCTIONS

CAUTION: Before doing any work on the equipment, always stop the engine and pull the plug cap off the spark plug (see “checking the spark

Always wear protective gloves!

When inspecting or maintaining the equipment, always put it down. Assembling or adjusting the equipment in an upright position

Always put the guide bar cover when servicing.

To ensure a long service life and to avoid any damage to the equipment, the following servicing operations should be performed at regular

intervals.

Daily checkup and maintenance

Before operation, check the machine for loose screws or missing parts. Pay particular attention to a specied attachment for mounting in place securely.

Before operation, always check for clogging of the cooling air passage and the cylinder ns. Clean them if necessary.

Perform the following work daily after use: -

• Clean the equipment externally and inspect for damage.

• Clean the air lter. When working under extremely dusty conditions, clean the lter several times a day.

• Check that there is sufcient difference between idling and engagement speed to ensure that the attachment is at a standstill while the

Check the functioning of the I-O switch, the lock-off lever and the control lever. -

plug”).

may result in serious injury.

engine is idling (if necessary reduce idling speed).

If under idling conditions the tool should still continue to run, consult your nearest Authorized Service Agent.

17

B

A

B

A

B

C

Cleaning the chain-oil feed port

A

Clean the chain-oil feed port (A) daily. To access it, remove the bar holder and

guide bar.

Cleaning and inspecting the guide bar

Clean the guide bar daily. Remove saw dust from the groove (A) and chain-oil

feed port (B).

To avoid one side wear of the guide bar, turn it over every time you replace or

sharpen the saw chain.

If the groove is worn, bent, cracked or deformed, replace the guide bar.

Inspecting the saw chain

When you feel the saw chain is worn, deformed, cracked or you need more

effort for the cutting, replace it or ask Makita authorized service center to

sharpen it.

Lubricating moving parts

NOTICE: Follow the instruction of the frequency and amount of grease

supplied. Otherwise insufcient lubrication may damage moving parts.

Gear case:

Remove the grease plug (A) and ll lithium-base grease through the grease

hole (B) every 25 hours of operation.

Guide bar nose:

Apply grease (Shell Alvania No. 2 or equivalent) from the grease hole (C) every

10 hours of operation.

REPLACEMENT OF ENGINE OIL

Deteriorated engine oil will shorten the life of the sliding and rotating parts to a great extent. Be sure to check the period and quantity of

replacement.

ATTENTION: In general, the engine main unit and engine oil still remain hot just after the engine is stopped. In replacement of oil,

Note: If the oil lled above the limit, it may be contaminated or may catch re with white smoke.

Interval of replacement: Initially, after 20 operating hours, and subsequently every 50 operating hours

Recommended oil: SAE10W-30 oil of API Classication SF Class or higher (4-stroke engine oil for automobile)

In replacement, perform the following procedure.

1) Conrm that the fuel tank cap (A) is tightened securely.

2) Place large container (pan, etc.) under drain hole (C).

conrm that the engine main unit and engine oil are sufciently cooled down. Otherwise, there may remain a risk of

scald.

B

A

3) Remove drain bolt (E) and then remove oil cap (B) to drain out oil from drain

hole.

At this time, be sure not to mislay drain bolt’s gasket (D), or to make dirty

any of the removed components.

4) Once all the oil has been drained, combine gasket and drain bolt, and tightly

secure drain bolt, so that it will not loosen and cause leaks.

* Use cloth to fully wipe off any oil attached to bolt and equipment.

18

B

C

D

E

Alternative draining method

Remove oil cap, tilt the equipment toward oil ller hole, and drain out oil.

Collect oil in container.

5) Set the engine level, and gradually ll up to upper limit mark (F) with new

oil.

6) After lling, tightly secure oil cap, so that it will not loosen and cause leaks.

If oil cap is not tightly secured, it may leak.

Internal stepped

section (upper

limit)

Internal stepped

section (lower

limit)

POINTS ON OIL

Never discard replaced engine oil in garbage, earth or sewage ditch. Disposal of oil is regulated by law. In disposal, always follow the relevant laws and regulations. For any points remaining unknown, contact Authorized Service Agent.

Oil will deteriorate even when it is kept unused. Perform inspection and replacement at regular intervals (replace with new oil every 6 months).

External mark

(upper limit)

External mark

(lower limit)

F

19

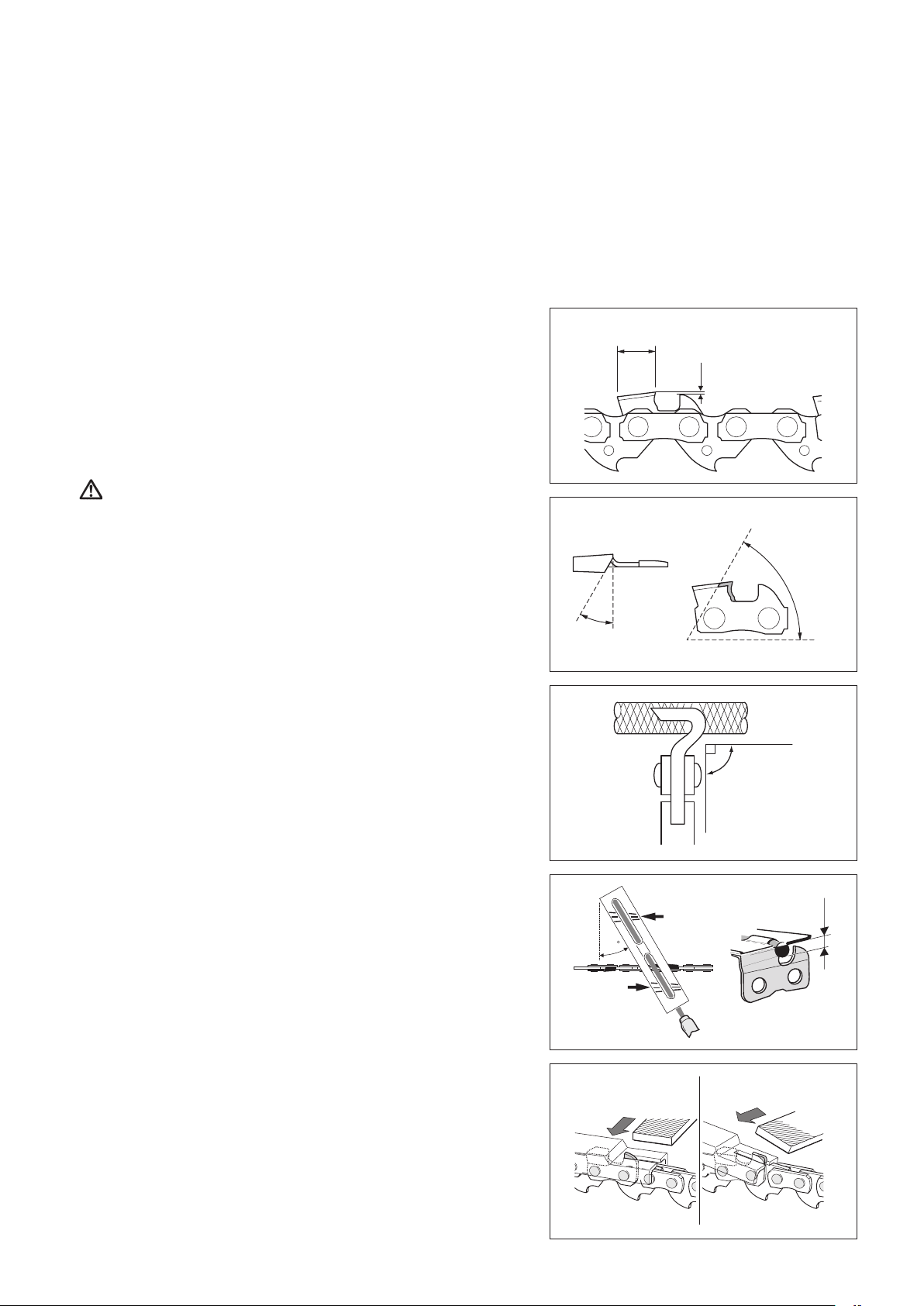

CLEANING OF AIR CLEANER

DANGER: INFLAMMABLES STRICTLY PROHIBITED

Interval of cleaning and inspection: Daily (every 10 operating hours)

Turn the choke lever - (D) to the full close side, and keep the carburetor off

from dust or dirt.

Loosen the xing bolt - (G).

Remove the air cleaner cover - (A) by pulling its bottom side.

Remove the elements - (B) (F) and tap them to remove dirt.

If the elements are heavily contaminated: -

Remove the elements, immerse them in warm water or in water-diluted

neutral detergent, and dry them completely. Do not squeeze or rub them

when washing.

Before attaching the elements, be sure to dry them completely. Insufcient drying of the elements may lead to difcult startup.

Wipe out oil adhering around the air cleaner cover and the breather part - (E)

with waste cloth.

Fit the element (sponge) - (B) into the element (felt) (F).

Fit the elements into the plate (C) so that the sponge faces the air cleaner

cover.

Immediately attach the cleaner cover and tighten it with xing bolts. (In remounting, rst place the upper claw, and then the lower claw.)

NOTICE:

Clean the elements several times a day, if excessive dust adheres to it. -

Dirty elements reduce engine power and make starting engine difcult.

Remove oil on the elements. If operation continues with the elements remaining not cleared of oil, oil in the air cleaner may fall outside, resulting

in contamination of the environment.

Do not put the elements on the ground or dirty place. Otherwise they pick up dirt or debris and it may damage the engine.

Never use fuel for cleaning the elements. Fuel may damage them. -

C

B

A

D

E

F

G

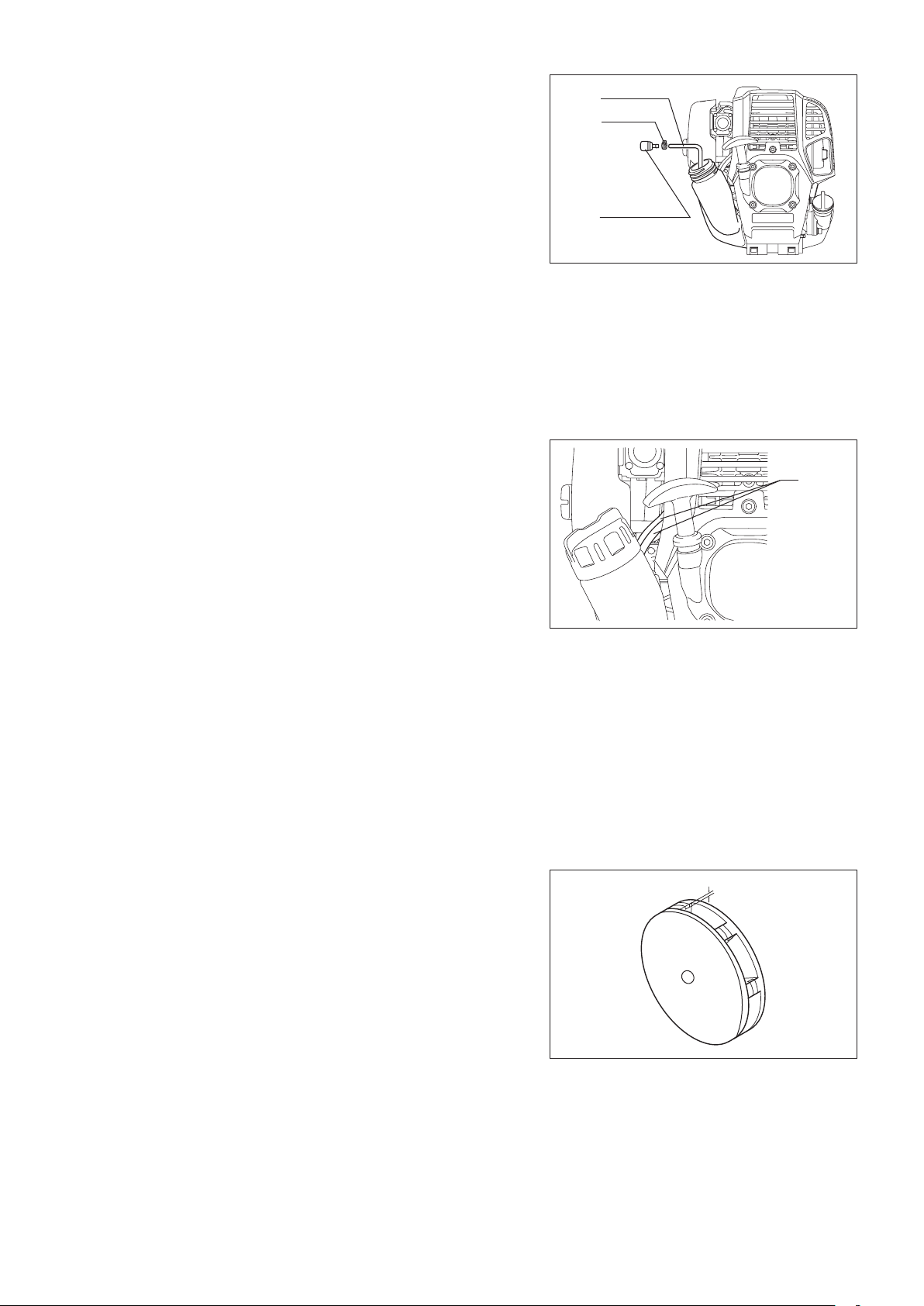

CHECKING THE SPARK PLUG

Only use the supplied universal wrench to remove or to install the spark plug. The gap between the two electrodes of the spark plug should be 0.7 - 0.8 mm -

(0.028” - 0.032”). If the gap is too wide or too narrow, adjust it. If the spark

plug is clogged or contaminated, clean it thoroughly or replace it.

CAUTION: Never touch the spark plug connector while the engine is running

(danger of high voltage electric shock).

0.7 mm - 0.8 mm

(0.028” - 0.032”)

20

CLEANING OF FUEL FILTER

0.3 mm

WARNING: INFLAMMABLES STRICTLY PROHIBITED

Interval of cleaning and inspection: Monthly (every 50 operating hours)

Suction head in the fuel tank

Check the fuel lter (A) periodically. To check the fuel lter, follow the steps

below:

(1) Remove the fuel tank cap, drain the fuel to empty the tank. Check the tank

inside for any foreign materials. If any, remove them.

(2) Pull out the suction head by using a wire hook through the tank opening.

(3) If the fuel lter clogged slightly, clean it. To clean it, gently shake and tap

it in fuel. To avoid damage, do not squeeze or rub it. The fuel used for the

cleaning must be disposed in accordance with the method specied by

regulations in your country.

If the fuel lter became hard or heavily clogged up, replace it.

(4) After checking, cleaning or replacing, insert the fuel lter into the fuel pipe

(B) and x it by the hose clamp (C). Push the fuel lter in all the way to the

bottom of the fuel tank.

Clogged or damaged fuel lter can cause insufcient fuel supply and reduce

engine power. Replace the fuel lter at least quarterly to ensure satisfactory fuel

supply to the carburetor.

REPLACEMENT OF FUEL PIPE

CAUTION: INFLAMMABLES STRICTLY PROHIBITED

Interval of cleaning and inspection: Daily (every 10 operating hours)

Replacement: Annually (every 200 operating hours)

Replace the fuel pipe (A) every year, regardless of operating frequency. Fuel

leakage may lead to re.

If any leakage is detected during inspection, replace the fuel pipe immediately.

B

C

A

A

INSPECTION OF BOLTS, NUTS AND SCREWS

Retighten loose bolts, nuts, etc. Check for fuel and oil leakage. Replace damaged parts with new ones for safety operation. -

CLEANING OF PARTS

Keep the engine always clean. Keep the cylinder ns free of dust or dirt. Dust or dirt adhering to the ns will cause piston seizure. -

REPLACEMENT OF GASKETS AND PACKINGS

In reassembling after the engine is dismounted, be sure to replace the gaskets and packings with new ones.

Any maintenance of adjustment work that is not included and described in this manual is only to be performed by Authorized Service Agents.

INSPECTING SPROCKET

Check the sprocket for wear every 50 hours of use. Replace it if the wear marks

becomes 0.3 mm or deeper.

21

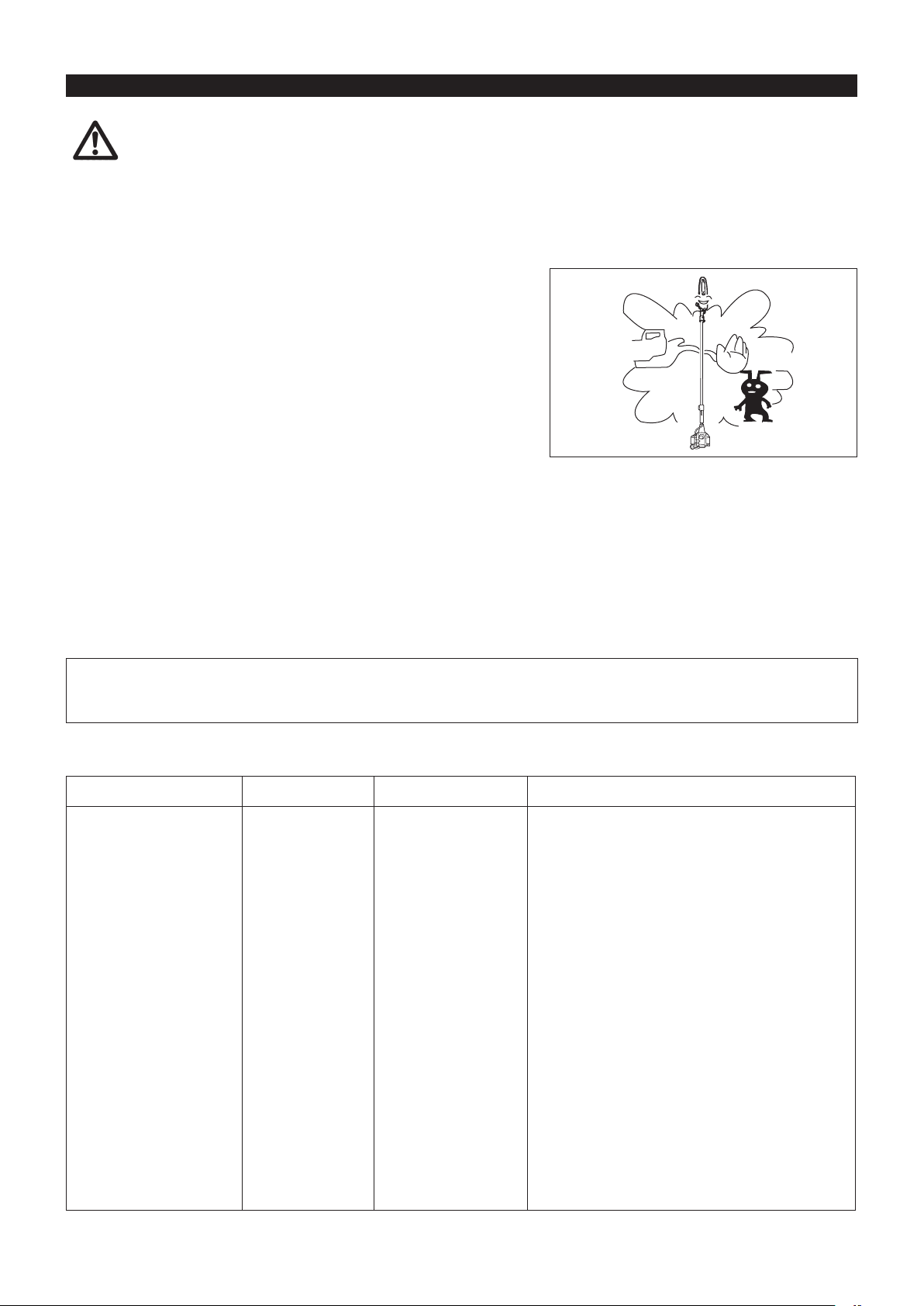

Sharpening the saw chain

B

A

55°

30°

90°

30

4/5

Sharpen the saw chain when:

Mealy sawdust is produced when damp wood is cut; The chain penetrates the wood with difculty, even when heavy pressure is -

applied;

The cutting edge is obviously damaged; The saw pulls to the left or right in the wood. The reason for this behavior is -

uneven sharpening of the saw chain, or damage to one side only.

Sharpen the saw chain frequently, but remove only a little material each

time.

Two or three strokes with a le are usually sufcient for routine resharpening.

When the saw chain has been resharpened several times, have it sharpened in

MAKITA authorized service center.

Sharpening criteria:

All cutter length - (A) must be equal. Cutters of different length prevent the

chain from running smoothly, and may cause the chain to break.

The chip thickness is determined by the distance between the depth gauge (round nose) and the cutting edge (B).

The best cutting results are obtained with following distance between cutting edge and depth gauge.

Chain blade 91VXL: 0.64 mm (0.025”)

WARNING: An excessive distance increases the risk of kick-back.

The sharpening angle of 30° must be the same on all cutters. Differences in angle cause the chain to run roughly and unevenly, accelerate wear, and lead

to chain breaks.

The side plate angle of the cutter is determined by the depth of penetration of -

the round le. If the specied le is used properly, the correct side plate angle

is produced automatically.

Proper angle for each saw chain are as follows: -

Chain blade 91VXL: 55°

File and le guiding

Use a special round le (optional accessory) for saw chains to sharpen the chain. Normal round les are not suitable.

Diameter of the round le for each saw chain is as follows: -

Chain blade 91VXL: 4.0 mm (5/32”)

The le should only engage the cutter on the forward stroke. Lift the le off -

the cutter on the return stroke.

Sharpen the shortest cutter rst. Then the length of this shortest cutter -

becomes the standard for all other cutters on the saw chain.

Guide the le as shown. The le can be guided more easily if a le holder (optional accessory) is -

employed. The le holder has markings for the correct sharpening angle

of 30° (align the markings parallel to the saw chain) and limits the depth of

penetration (to 4/5 of the le diameter).

After sharpening the chain, check the height of the depth gauge using the chain gauge tool (optional accessory).

Remove any projecting material, however small, with a special flat le (optional accessory).

Round off the front of the depth gauge again. -

22

STORAGE

WARNING: When draining the fuel, be sure to stop the engine and conrm that the engine cools

down.

The engine is still hot just after stopping the engine. Wait until it cools down,

otherwise it may cause burns or re.

When the machine is kept out of operation for a long time, perform the

followings:

Drain up fuel from the fuel tank and carburetor according to the following procedure:

1) Remove the fuel tank cap, and drain fuel completely. If there is any foreign

matter remaining in the fuel tank, remove it completely.

2) Pull out the fuel lter from the rell port using a wire.

3) Push the primer pump until fuel is drained from there, and drain fuel

coming into the fuel tank.

4) Reset the lter to the fuel tank, and securely tighten the fuel tank cap.

5) Then, continue to operate the engine until it stops.

Drain up the chain oil. Remove the saw chain and the guide bar. Clean the guide groove of the guide bar. Lubricate slightly on the saw chain and the guide bar. Remove the spark plug, and drip several drops of engine oil through the -

spark plug hole.

Gently pull the starter handle so that engine oil will spread over the engine, -

and attach the spark plug.

In general, store the machine in horizontal position. If it is not possible, -

place the machine as the motor unit comes below the cutting tool. Otherwise

engine oil may leak from inside.

Always pay attention to storing the machine in a safe place to prevent machine damage and personal injury.

Keep the drained fuel in a special container in a well-ventilated shade. -

Drain fuel

Humidity

Attention after long-time storage

Before startup after long-time storage, be sure to replace engine oil (refer to “REPLACEMENT OF ENGINE OIL”). Oil will deteriorate while the machine is kept out of operation.

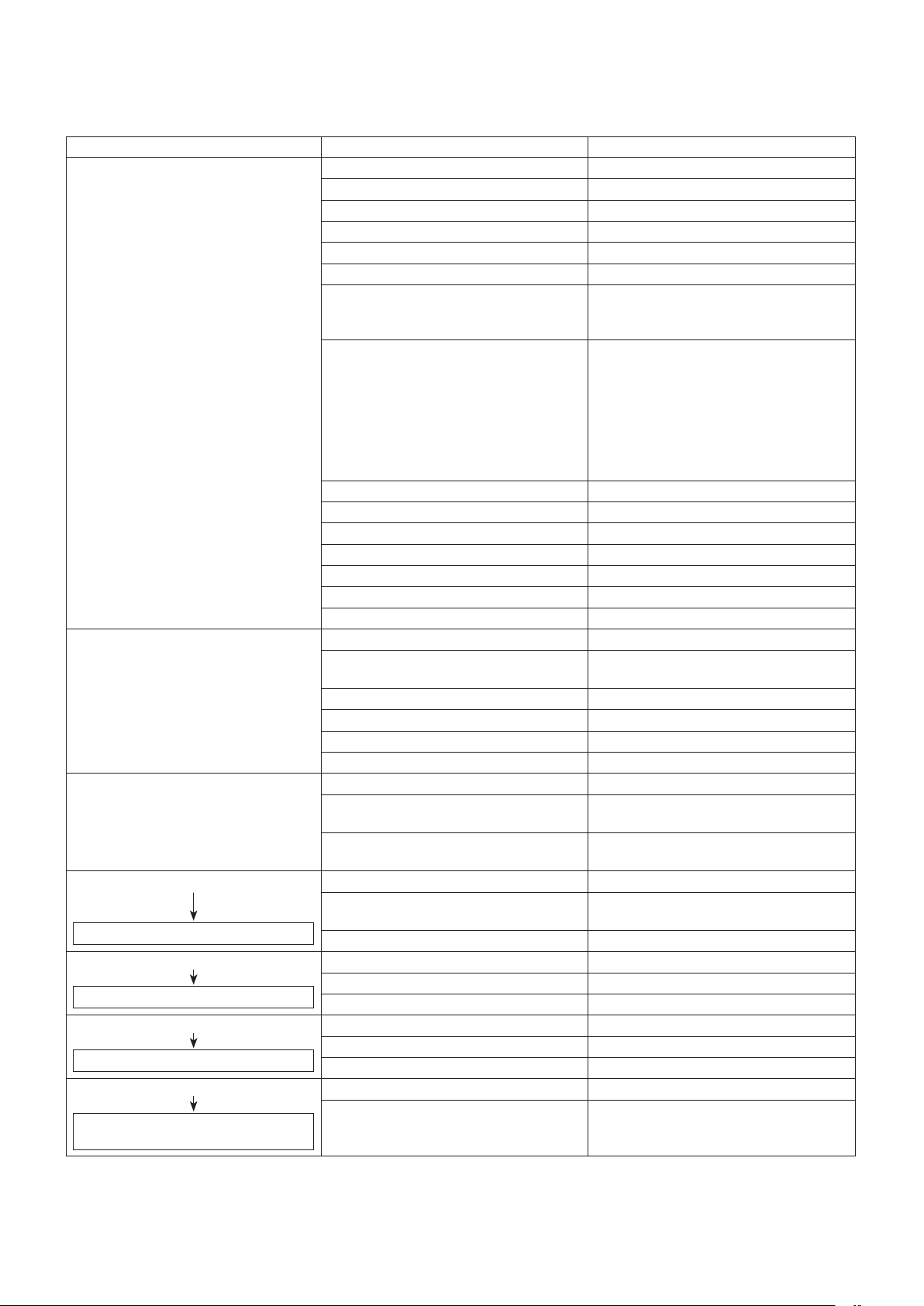

Fault location

Fault System Observation Cause

Engine not starting or with

difculty

Warm start problems Tank lled ignition spark

Engine starts but dies Fuel supply Tank lled Incorrect idling adjustment, carburetor contaminated

Ignition system Ignition spark O.K. Fault in fuel supply or compression system, mechanical

defect

No ignition spark STOP-switch operated, wiring fault or short circuit, spark

plug or connector defective, ignition module faulty

Fuel supply Fuel tank lled Incorrect choke position, carburetor defective, fuel supply

line bent or blocked, fuel dirty

Compression No compression when

pulled over

Mechanical fault Starter not engaging Broken starter spring, broken parts inside of the engine

existing

Cylinder bottom gasket defective, crankshaft seals

damaged, cylinder or piston rings defective or improper

sealing of spark plug

Carburetor contaminated, have it cleaned

Fuel tank vent defective, fuel supply line interrupted,

cable or STOP-switch faulty

Insufcient performance Several systems may

simultaneously be

affected

Engine idling poor Air lter contaminated, carburetor contaminated, muffler

clogged, exhaust duct in the cylinder clogged

23

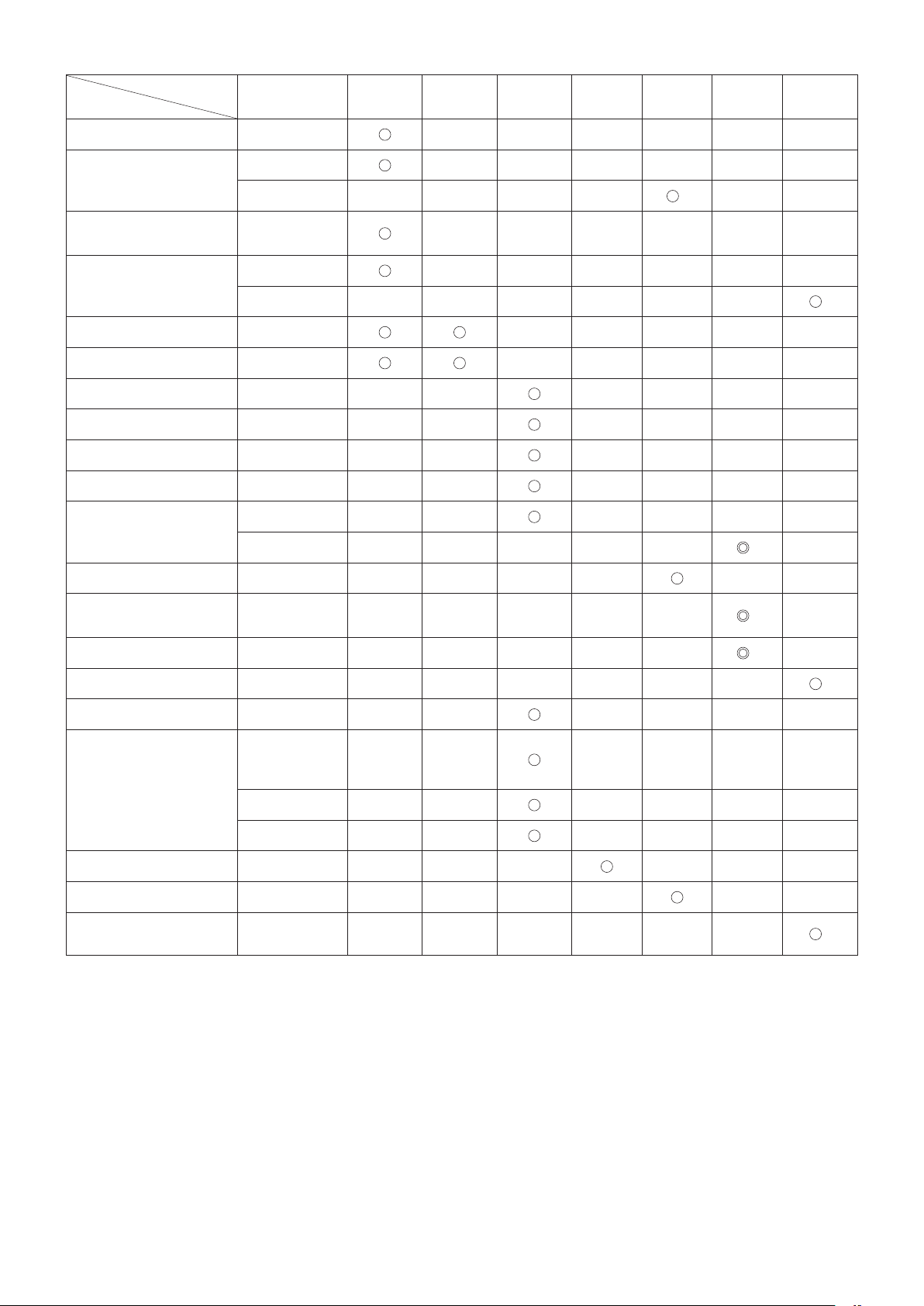

Operating time

Item

Whole unit Visually inspect

Before

operation

After

lubrication

Daily

(10h)

25h 50h 200h

Shutdown/

rest

Engine oil

Tightening parts

(bolt, nut)

Replace *

Inspect

1

Inspect

Fuel tank

Drain fuel *

Throttle control Check function

Stop switch Check function

Idle speed Inspect/adjust

Air cleaner Clean

Ignition plug Inspect

Cooling air duct Clean/inspect

Inspect

Inspect

Fuel pipe

Replace *

2

Fuel lter Clean/replace

Valve clearance (intake valve

and exhaust valve)

Inspect/adjust

Engine overhaul *

2

*

2

Carburetor Drain fuel *

3

3

Chain oil feed port Clean

Clean the groove

and the chain oil

feed port

Guide bar

Inspect

Supply grease

Gear case Supply grease

Sprocket Inspect

Saw chain

Replace or ask for

sharpening

*1 Perform initial replacement after 20h operation.

*2 For the 200 operating hour inspection, request authorized service center.

*3 After emptying the fuel tank, continue to run the engine and drain fuel in the carburetor.

*4 If required.

4

*

24

TROUBLESHOOTING

Before making a request for repairs, check a trouble for yourself. If any abnormality is found, control your machine according to the description

of this manual. Never tamper or dismount any part contrary to the description. For repairs, contact Authorized Service Agent or local dealership.

State of abnormality Probable cause (malfunction) Remedy

Failure to operate primer pump. Push 7 to 10 times.

Low pulling speed of starter rope. Pull strongly.

Lack of fuel. Feed fuel.

Clogged fuel lter. Clean it.

Disconnected fuel tube. Connect fuel tube properly.

Bent fuel tube. Straighten fuel tube.

Deteriorated fuel. Deteriorated fuel makes starting more difcult.

Replace with new fuel. (Recommended

replacement: 1 month).

Excessive suction of fuel. Set throttle control to medium or high speed,

and pull starter handle until engine starts.

Engine does not start

Engine stops soon

Engine speed does not increase

Chain oil is not supplied.

Saw chain does not rotate

Stop engine immediately

The equipment vibrates abnormally

Stop engine immediately

Saw chain does not stop

Stop engine immediately

Engine does not stop

Run engine at idling, and set choke lever

to CLOSE

Detached plug cap. Attach securely.

Contaminated spark plug. Clean it.

Abnormal clearance of spark plug. Adjust clearance.

Other abnormality of spark plug. Replace it.

Abnormal carburetor. Make request for inspection and maintenance.

Starter rope cannot be pulled. Make request for inspection and maintenance.

Abnormal drive system. Make request for inspection and maintenance.

Insufcient warm-up. Perform warm-up operation.

Choke lever is set to “CLOSE” although

engine is warmed up.

Clogged fuel lter. Clean it.

Contaminated or clogged air cleaner. Clean it.

Abnormal carburetor. Make request for inspection and maintenance.

Abnormal drive system. Make request for inspection and maintenance.

The oil tank is empty. Fill the oil tank with chain oil.

The chain oil feed port is dirty. Clean the chain oil feed port on the unit and

The adjusting screw of the chain oil feed rate

is improperly set.

The guide bar is bent or damaged. Replace the guide bar.

Foreign matter caught by saw chain. Remove foreign matter while the engine

Abnormal drive system. Make request for inspection and maintenance.

Broken, bent or worn guide bar. Replace guide bar.

Loosened saw chain. Adjust the saw chain tension.

Abnormal drive system. Make request for inspection and maintenance.

High idling rotation. Adjust idle speed.

Throttle control wire problem. Ask service center to replace it.

Abnormal drive system. Make request for inspection and maintenance.

Detached connector to the I-O switch. Attach securely.

Abnormal electric system. Make request for inspection and maintenance.

Once engine starts, saw chain starts rotating.

Pay full attention to saw chain.

If engine still does not start, remove spark

plug, dry the electrode, and reassemble

them as they originally were. Then, start as

specied.

Set to “OPEN”.

guide bar.

Set the adjusting screw properly.

stopped.

When the engine does not start after warm-up operation:

If there is no abnormality found for the checked items, open the throttle by about 1/3 and start the engine.

25

Français

(Instructions d’origine)

Merci beaucoup d’avoir choisi l’élagueuse thermique à perche télescopique

MAKITA. Nous sommes ravis de vous recommander l’élagueuse thermique

à perche télescopique de MAKITA, résultat d’un long programme de

développement et de nombreuses années d’expérience et de connaissances.

Veuillez lire ce livret qui explique en détail les nombreuses caractéristiques

qui en font un outil d’une performance exceptionnelle. Il vous aidera à obtenir

les meilleurs résultats possibles de votre élagueuse thermique à perche

télescopique MAKITA.

SYMBOLES

Le mode d’emploi contient les symboles suivants.

Lisez le mode d’emploi et suivez les

mises en garde et précautions de sécurité !

Table des matières Page

Symboles .....................................................................26

Consignes de sécurité .................................................27

Caractéristiques techniques ........................................32

Nomenclature des pièces ............................................33

Assemblage et réglage ................................................34

Avant de commencer ................................................... 37

Avertissements concernant le fonctionnement

et la procédure d’arrêt .................................................39

Fonctionnement ...........................................................41

Instructions d’entretien ................................................41

Entreposage ................................................................47

Pas de flamme nue !

Faites preuve de prudence et de vigilance ! Huile de chaîne.

Portez un casque protecteur, des lunettes de

protection et des protège-oreilles.

Portez des gants de protection ! Carburant (essence)

Portez des bottes de sécurité équipées de

semelles antidérapantes.

Respectez une distance d’au moins 15 m (50 pi.)

entre l’appareil et les spectateurs et/ou les ls

électriques (y compris les branches susceptibles

d’entrer en contact avec l’outil). Risque de choc

électrique et/ou de blessure corporelle.

Ne tenez jamais l’élagueuse à perche selon

un angle supérieur à 60°.

Éloignez les personnes et les animaux du lieu

de travail !

Démarrage manuel du moteur

Premiers secours

SOUS TENSION/DÉMARRAGE

Vitesse de la chaîne. HORS TENSION/ARRÊT

Interdit ! Arrêt d’urgence

Ne fumez pas !

26

CONSIGNES DE SÉCURITÉ

Instructions générales

Pour une utilisation correcte, lisez ce mode d’emploi an de vous familiariser avec le fonctionnement de l’appareil. Sans ces informations, vous risquez

de vous mettre en danger ou de blesser d’autres personnes à cause d’une

utilisation incorrecte.

Il est recommandé de prêter l’appareil uniquement aux personnes ayant déjà utilisé ce type d’appareil.

Transmettez-leur toujours ce mode d’emploi.

Les personnes utilisant l’outil pour la première fois doivent demander au -

revendeur de leur fournir des instructions de base an de se familiariser avec

le maniement d’une élagueuse thermique.

Les enfants et jeunes gens âgés de moins de 18 ans ne doivent pas utiliser -

cet appareil. Toutefois, les personnes âgées de plus de 16 ans peuvent

utiliser l’appareil à des ns de formation uniquement sous la supervision d’un

formateur qualié.

Utilisez l’appareil avec la plus grande prudence et vigilance. Faites fonctionner l’appareil uniquement si vous êtes en bonne forme -

physique. Effectuez tout le travail avec calme et prudence. Vous êtes

responsable des autres personnes.

N’utilisez jamais l’appareil après avoir consommé de l’alcool ou de la drogue, ou bien si vous vous sentez fatigué ou malade.

N’essayez jamais de modier l’appareil. Les règlementations nationales peuvent restreindre l’utilisation de l’appareil. -

Respectez les réglementations de votre pays relatives au maniement des

élagueuses à perche et des tronçonneuses.

Utilisation prévue de l’appareil

Cet appareil est destiné uniquement à tailler des petites branches et des

branches maîtresses de moins de 15 cm de diamètre. N’utilisez jamais

l’appareil à d’autres ns. L’utilisation inappropriée de l’appareil peut provoquer

des blessures graves.

Équipement de protection individuelle

Les vêtements que vous portez doivent être fonctionnels et adaptés, c’est- à-dire qu’ils doivent être ajustés, sans pour autant gêner vos mouvements.

Ne portez pas de bijoux ou de vêtements qui pourraient s’emmêler dans les

taillis ou les petits arbustes.

L’équipement de protection suivant ainsi que les vêtements de protection -

doivent être utilisés an d’éviter des blessures au pied, à la main, aux yeux et

à la tête ainsi que pour protéger votre ouïe durant l’utilisation.

Portez toujours un casque en cas de risque de chute d’objets. Le casque -

de protection (1) doit être vérié régulièrement pour parer à d’éventuels

dommages et il doit être remplacé au plus tard tous les 5 ans. N’utilisez que

des casques de protection agréés.

La visière (2) du casque (ou alternativement les lunettes) protège le visage des débris et des pierres qui volent. Pendant l’utilisation, portez toujours des

lunettes de protection ou une visière pour éviter toute blessure aux yeux.

Portez un équipement de protection antibruit adéquat an d’éviter toute perte auditive (coquilles antibruit (3), bouchons d’oreille etc.).

Les combinaisons de travail (4) protègent contre les pierres et débris qui volent.

Il est fortement recommandé de porter une combinaison de travail.

Les gants spéciaux (5) en cuir épais font partie de l’équipement prescrit et doivent toujours être portés lors de l’utilisation de l’appareil.

Lorsque vous utilisez l’appareil, portez toujours des chaussures de sécurité (6) dotées d’une semelle antidérapante. Elles vous protègent d’éventuelles

blessures et vous garantissent une bonne stabilité.

Lors de la manipulation de la chaîne ou du réglage de la tension de la chaîne, portez des gants de protection. Vous risqueriez de vous couper

grièvement les mains.

27

Sécurité de la zone de travail

- Danger : Éloignez d’au moins 15 m l’élagueuse à perche des ls

électriques et des câbles de communication (y compris des branches

susceptibles d’entrer en contact avec ceux-ci). Le contact ou la proximité de

lignes haute tension avec l’élagueuse à perche peut entraîner la mort ou des

blessures graves. Avant de commencer à utiliser l’appareil, recherchez les

lignes et clôtures électriques situées autour de la zone de travail.

N’utilisez l’élagueuse à perche que lorsque les conditions de visibilité et de luminosité sont bonnes. N’utilisez pas l’élagueuse à perche dans l’obscurité

ou en cas de brouillard.

Ne démarrez le moteur et n’utilisez l’appareil qu’en extérieur dans une -

zone bien ventilée. L’utilisation de l’appareil dans une zone connée ou

mal ventilée peut entraîner la mort par suffocation ou l’empoisonnement au

monoxyde de carbone.

Lors du fonctionnement de l’outil, ne vous tenez jamais sur une surface -

instable ou glissante ou sur une pente abrupte. En hiver, méez-vous du gel

et de la neige et veillez à garder votre équilibre.

Lors du fonctionnement de l’outil, éloignez les spectateurs et les animaux -

de l’élagueuse à perche d’au moins 15 m. Arrêtez le moteur dès qu’une

personne s’approche.

Avant l’utilisation, recherchez les éventuels murs, clôtures en ls de fer ou autres objets solides présents dans la zone de travail. Ils risqueraient

d’endommager la chaîne.

- AVERTISSEMENT : L’utilisation de ce produit peut entraîner la création

de poussière contenant des produits chimiques susceptibles de provoquer

des maladies respiratoires ou autres. Parmi ces produits chimiques gurent

les composés présents dans les pesticides, les insecticides, les engrais et

les herbicides. Les risques liés à l’exposition à ces produits varient suivant la

fréquence d’exécution de ce type de travaux. Pour réduire votre exposition

à ces produits chimiques : travaillez dans une zone bien ventilée et avec un

équipement de sécurité agréé, tel qu’un masque à poussière spécialement

conçu pour ltrer les particules microscopiques.

Mise en marche

Avant d’assembler ou de régler l’appareil, éteignez le moteur et retirez le protecteur de bougie.

Avant de démarrer le moteur, assurez-vous que l’appareil n’est pas endommagé, que les vis et écrous sont bien serrés et que l’assemblage a été

effectué correctement. Affûtez la chaîne si elle est émoussée. Si la chaîne

est déformée ou endommagée, remplacez-la. Vériez que tous les leviers de

commande et interrupteurs peuvent être actionnés sans forcer. Nettoyez et

séchez les poignées.

Ne tentez jamais de démarrer le moteur si l’appareil est endommagé ou s’il n’est pas entièrement assemblé. Dans le cas contraire, vous risqueriez de

vous blesser grièvement.

Réglez correctement la tension de la chaîne. Ajoutez de l’huile de chaîne au besoin.

Démarrage du moteur

Assurez-vous qu’aucun enfant ou adulte ne se trouve à proximité et faites attention aux animaux situés dans la zone de travail.

Avant de démarrer le moteur, enlez votre équipement de protection corporel. Assurez-vous que l’accessoire est bien en place, que le levier de commande -

peut être actionné aisément et que le levier de verrouillage fonctionne

correctement.

Si la chaîne tourne au ralenti, coupez le moteur et diminuez la vitesse. En cas de doute, demandez à un centre d’entretien agréé de procéder au

réglage. Vériez que les poignées sont propres et sèches et que l’interrupteur

marche/arrêt fonctionne correctement.

28

Ne démarrez le moteur qu’en conformité avec les instructions.

Ne démarrez pas le moteur selon une autre méthode ! Placez l’appareil sur un sol stable. Gardez une bonne position d’équilibre et -

une bonne stabilité.

Au moment de tirer sur le bouton de démarreur, maintenez fermement le -

matériel contre le sol avec votre main gauche. Ne montez jamais sur l’arbre

d’entraînement.

Avant de démarrer le moteur, assurez-vous qu’aucun individu ou animal ne se trouve dans la zone de travail.

Lorsque vous démarrez le moteur, maintenez la chaîne et le guide-chaîne éloignés de votre corps et de tout objet, y compris du sol. La chaîne pourrait

bouger au démarrage et provoquer des blessures graves, être endommagée

et/ou endommager d’autres objets.

En cas de problème avec le moteur, éteignez-le immédiatement. Si la chaîne heurte des pierres ou d’autres objets durs, coupez -

immédiatement le moteur et examinez l’appareil.

N’utilisez l’appareil qu’avec la bandoulière, que vous devez régler -

correctement avant de mettre l’appareil en marche. Il est très important de

régler la bandoulière selon votre taille, an d’éviter toute fatigue pendant

l’utilisation. Ne tenez jamais l’outil d’une seule main pendant l’utilisation.

Après avoir réglé la vitesse du moteur au ralenti, xez les bretelles de -

sécurité. Pendant l’utilisation, tenez fermement l’appareil sur votre côté droit.

Vous devez utiliser toutes les installations protectrices et tous les carters -

fournis avec l’outil durant l’utilisation.

Ne faites jamais fonctionner le moteur si le pot d’échappement est endommagé. Sauf en cas d’urgence, ne laissez jamais tomber l’appareil et ne le jetez pas -

sur le sol, au risque de l’endommager grièvement.

Ravitaillement en carburant

Lors du ravitaillement en carburant, coupez le moteur, éloignez-le des -

flammes nues et ne fumez pas.

Évitez tout contact entre la peau et l’essence. Ne respirez pas les vapeurs de carburant. Portez toujours des gants de protection pendant le ravitaillement

en carburant. Changez et nettoyez régulièrement les vêtements de

protection.

Veillez à ne pas renverser de carburant ou d’huile, an d’éviter toute contamination du sol (protection environnementale). Nettoyez immédiatement

l’appareil en cas d’écoulement de carburant.

Évitez tout contact entre vos vêtements et le carburant. Si vous renversez du carburant sur vos vêtements, changez-en immédiatement (pour éviter que

vos vêtements ne prennent feu).

Vériez régulièrement le bouchon du réservoir de carburant pour vous assurer qu’il est bien fermé et ne fuit pas.

Serrez soigneusement le bouchon du réservoir de carburant. Déplacez-vous avant de démarrer le moteur (à au moins 3 mètres de l’endroit où vous avez

fait le plein).

Ne faites jamais le plein dans une pièce connée. Les vapeurs d’essence s’accumulent au niveau du sol (risque d’explosions).

Transportez et stockez le carburant uniquement dans des récipients agréés. Assurez-vous que les enfants ne peuvent pas accéder au carburant.

Mode d’emploi

En cas d’urgence, coupez immédiatement le moteur. En cas de situation anormale (par exemple du bruit, des vibrations) pendant -

le fonctionnement, éteignez le moteur. N’utilisez pas l’appareil avant d’avoir

déterminé et corrigé la cause du problème.

Lorsque vous relâchez la commande d’accélérateur, la chaîne continue à tourner quelques instants. Ne touchez pas immédiatement la chaîne.

Tenez la poignée avant avec la main gauche et la poignée arrière avec la main droite, que vous soyez droitier ou gaucher. Enserrez les poignées avec

vos doigts et votre pouce.

Ne tentez jamais d’utiliser l’appareil avec une seule main. Une perte de contrôle peut entraîner des blessures graves ou mortelles. Pour réduire les

risques de blessures, éloignez vos mains et vos pieds des lames.

Maintenez une bonne position. Gardez une bonne prise au sol et d’une bonne position d’équilibre à tout moment.

Pour éviter de trébucher, prenez garde aux obstacles cachés, tels que les souches d’arbres, les racines et les fossés. Retirez les branches et autres

objets au sol.

En cas de chute ou d’impact de l’appareil, vériez qu’il est en bon état avant de poursuivre le travail. Vériez qu’il n’y a pas de fuite de carburant dans

le circuit d’alimentation et que les commandes et dispositifs de sécurité

fonctionnent correctement. En cas de dommage ou de doute, demandez à un

centre d’entretien agréé Makita d’examiner et de réparer l’outil.

Ne touchez pas le carter d’engrenage. Le carter d’engrenage devient chaud lors du fonctionnement.

• Au repos

• Transport

• Ravitaillement en carburant

• Entretien

• Remplacement d’outil

3 mètres

29

Lorsque vous vous éloignez de l’appareil, même pendant un court instant, coupez toujours le moteur. Ne laissez pas l’appareil sans surveillance avec le

moteur allumé car il pourrait être utilisé par des personnes non autorisées et

causer des accidents graves.

Respectez l’environnement. Pour réduire la pollution et les émissions sonores, évitez tout fonctionnement inutile du papillon des gaz. Réglez

correctement le carburateur.

Pendant ou après l’utilisation, ne posez pas l’appareil chaud sur de l’herbe sèche ou sur des matériaux combustibles.

Ne placez pas votre main droite au-dessus de la hauteur des épaules. Pendant l’utilisation, ne heurtez jamais la chaîne contre des obstacles durs, tels -

que des pierres et des clous. Soyez particulièrement vigilant(e) lors de l’élagage

de branches situées près de murs, de clôtures en ls de fer ou similaires.

Si des branches sont happées par la chaîne, coupez toujours le moteur et retirez le protecteur de bougie. Dans le cas contraire, un démarrage

accidentel pourrait provoquer de graves blessures.

Si la chaîne est encombrée, coupez toujours le moteur et retirez le protecteur de bougie avant de procéder au nettoyage.

Si vous accélérez alors que la chaîne est bloquée, vous augmentez la charge et endommagez le moteur et/ou l’embrayage.

Avant de couper des branches maîtresses, prévoyez une zone de repli éloignée du point de chute des branches. Commencez par retirer les obstacles,

tels que les branches maîtresses et autres branches, de la zone de travail.

Éloignez tous les outils et objets de la zone de repli dans une autre zone sûre.

Avant de couper des branches et des branches maîtresses, vériez le sens de leur chute en prenant en compte l’état des branches et des branches

maîtresses, les arbres voisins, le sens du vent, etc. Soyez très attentif/

attentive quant au sens de la chute, ainsi qu’au rebond de la branche qui

heurte le sol.

Ne tenez jamais l’élagueuse à perche selon un angle supérieur à 60°. En tombant, les objets pourraient vous heurter et vous blesser grièvement. Ne

vous tenez jamais sous la branche qui va être coupée.

Méez-vous des branches cassées ou pliées. Elles pourraient rebondir lors de la coupe et provoquer des blessures soudaines.

Avant de couper des branches maîtresses, retirez les autres branches et les feuilles qui se trouvent autour de celle-ci. Dans le cas contraire, elles

pourraient happer la chaîne.

Pour éviter que la chaîne se coince dans le trait d’abattage, ne relâchez pas le levier d’accélérateur avant d’avoir retiré la chaîne du trait d’abattage.

Si la chaîne est coincée dans le trait d’abattage, coupez immédiatement le moteur, déplacez la branche avec précaution pour ouvrir le trait d’abattage et

dégagez la chaîne.

Évitez tout rebond (force réactive rotative vers l’utilisateur). Pour éviter les rebonds, n’utilisez jamais le nez du guide-chaîne et n’effectuez pas de coupe

pénétrante. Restez toujours vigilant(e) quant à la position du nez du guidechaîne.

Vériez fréquemment la tension de la chaîne. Lorsque vous vériez ou réglez la tension de la chaîne, arrêtez le moteur et retirez le protecteur de bougie. Si

la chaîne est détendue, tendez-la.

Faites fonctionner l’appareil en émettant le moins de bruit et de contamination -