Makita DCS3500, DCS3501, DCS4300, DCS4301, EA3500F Repair Manual

...

___

Reparaturanleitung PS-4600 / PS-5000 1

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

www.dolmar.de

Repair Manual

Caution:

Before doing any maintenance or service work, the combination switch must be engaged in the service position, in

order to prevent unintended starting by the easy start system!

DCS3500

DCS3501

DCS4300

DCS4301

EA3500F

EA3501F

EA4300F

EA4301F

MEA3500L

MEA3500M

MEA4300G

MEA4300L

___

Reparaturanleitung PS-4600 / PS-5000 2

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

Page

Technical data ........................................................................................................................................................................... 3

Troubleshooting ........................................................................................................................................................................ 4

00 Special tools.......................................................................................................................................................................... 5 - 7

01 Sprocket guard / Chain tensioning system ................................................................................................................................ 8

02 Clutch drum with chain sprocket ...............................................................................................................................................9

03 Chain brake / Guide bar bolt ............................................................................................................................................ 10 - 11

04 Clutch................................................................................................................................................................................ 12 - 13

05 Oil pump...................................................................................................................................................................................14

06 Starter ...................................................................................................................................................................................... 15

07 Ignition system (trouble-shooting)............................................................................................................................................ 16

07 Ignition system................................................................................................................................................................. 17 – 18

08 Carburetor........................................................................................................................................................................ 19 – 20

09 Vibration damper...................................................................................................................................................................... 21

10 Tank................................................................................................................................................................................. 22 – 23

11 Cylinder / Piston .............................................................................................................................................................. 24 – 26

12 Crankcase / Crankshaft ........................................................................................................................................................... 27

13 Torques ................................................................................................................................................................................... 28

CONTENTS

___

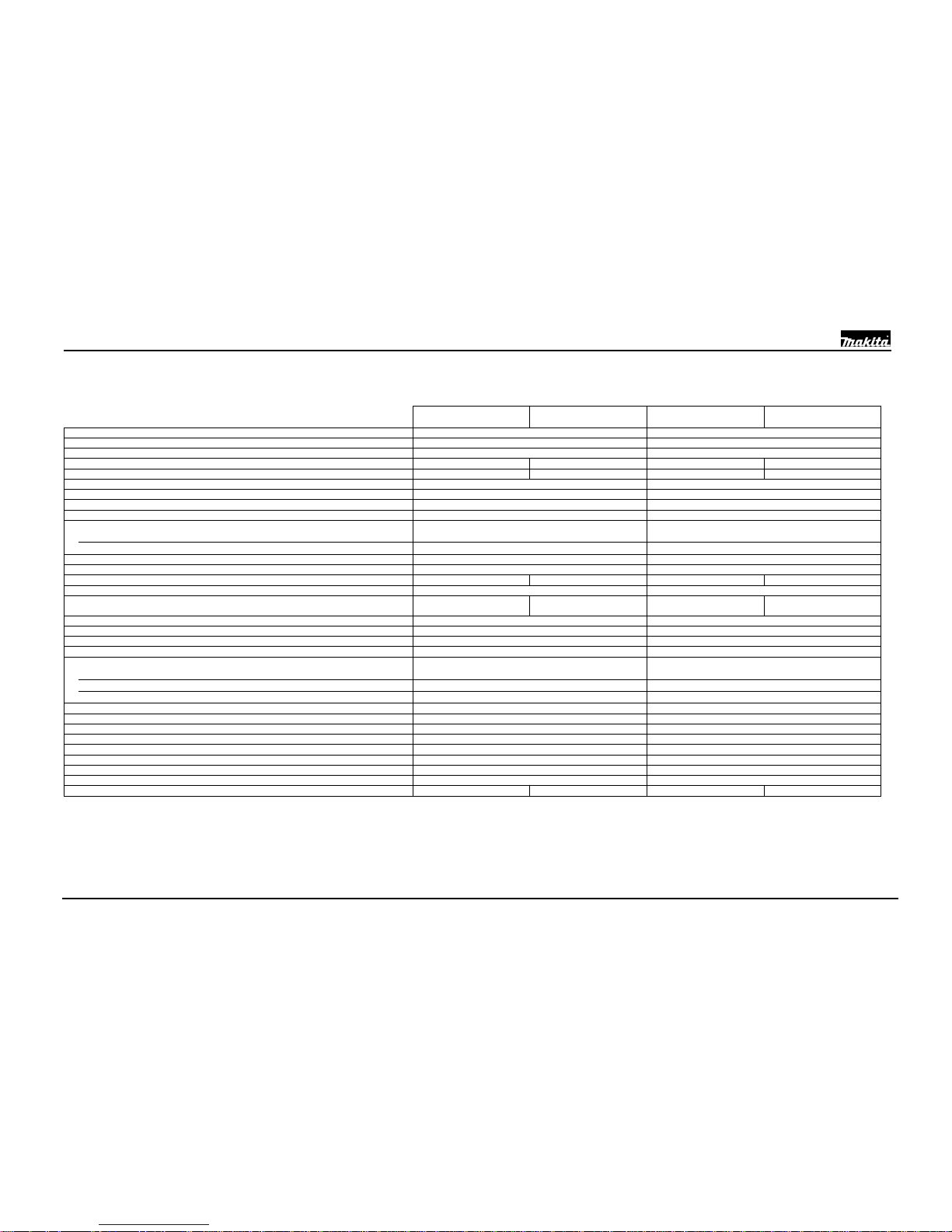

Reparaturanleitung PS-4600 / PS-5000 3

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

DCS3500 / DCS3501

EA3500F / EA3501F

MEA3500M / MEA 3500L

DCS4300 / DCS4301

EA4300F / EA4301F

MEA4300G / MEA4300L

Stroke volume cm3 34.7 42.4

Bore mm 38 42

Stroke mm 30.6 30.6

Max. power at speed kW / 1/min 1.5 / 9,500 1.7 / 9,500 2.0 / 9,500 2.2 / 9,500

Max. torque at speed Nm / 1/min 1.9 / 6,500 2.1 / 6,500 2.4 / 6,500 2.6 / 6,500

Idling speed / max. engine speed with bar and chain 1/min 2,800 / 13,500 2,800 / 13,500

Clutch engagement speed 1/min 5,100 5,100

Sound pressure level at the workplace L

pA av

per ISO/CD 22868 1) dB (A) 100.8 100.8

Sound power level L

WA av

per ISO/CD 22868 1) dB (A) 110 110

Vibration acceleration a

h,w eq

per ISO 22867 1)

- Tubular handle m/s2

4.3

3.6

- Rear handle m/s2 3.6 3.2

Carburetor (diaphragm, choke flap carburetor) Typ membrane carburetor membrane carburetor

Ignition system Typ electronic electronic

Spark plug Typ NGK BPMR 7A NGK CMR7A-5 NGK BPMR 7A NGK CMR7A-5

Electrode gap mm 0.5 0.5

or spark plug Typ

BOSCH WSR 6F,

CHAMPION RCJ 6Y

- -

BOSCH WSR 6F,

CHAMPION RCJ 6Y

- -

Fuel consumption at max. load per ISO 7293 kg/h 0.79 0.96

Specific consumption at max. load per ISO 7293 g/kWh 526 480

Fuel tank capacity l 0.48 0.48

Chain oil tank capacity l 0.28 0.28

Mixture ratio (fuel/two-stroke oil)

- when using DOLMAR oil

50 : 1 / 100: 1 (HP-100)

50 : 1 / 100: 1 (HP-100)

- when using Aspen Alkalyt (two-stroke fuel) 50 : 1 (2%) 50 : 1 (2%)

- when using other oils 50 : 1 (quality grade JASO FC or ISO EGD) 50 : 1 (Qualitätsstufe JASO FC oder ISO EGD)

Chain brake engages manually or in case of kickback engages manually or in case of kickback

Chain speed at max. power m/s 18.1 18.3

Sprocket pitch inch 3/8 .325

Number of teeth Z 6 7

Chain type see the spare-parts list see the spare-parts list

Pitch / gauge inch 3/8 / 0.050 (1.3) .325 / 0.050 (1.3)

Guide bar, length of a cut cm 30, 35, 40 33, 38, 45

Guide-bar type see the spare-parts list see the spare-parts list

Weight (fuel tank empty, without chain, guide bar and accessories) kg 4.7 / 4.8 2) 4.8 / 4.9 2) 4.7 / 4.8 2) 4.8 / 4.9 2)

1)

Figures derived in equal part from idling, full-load and racing speed.

2)

On models with catalytic converter.

TECHNICAL DATA

___

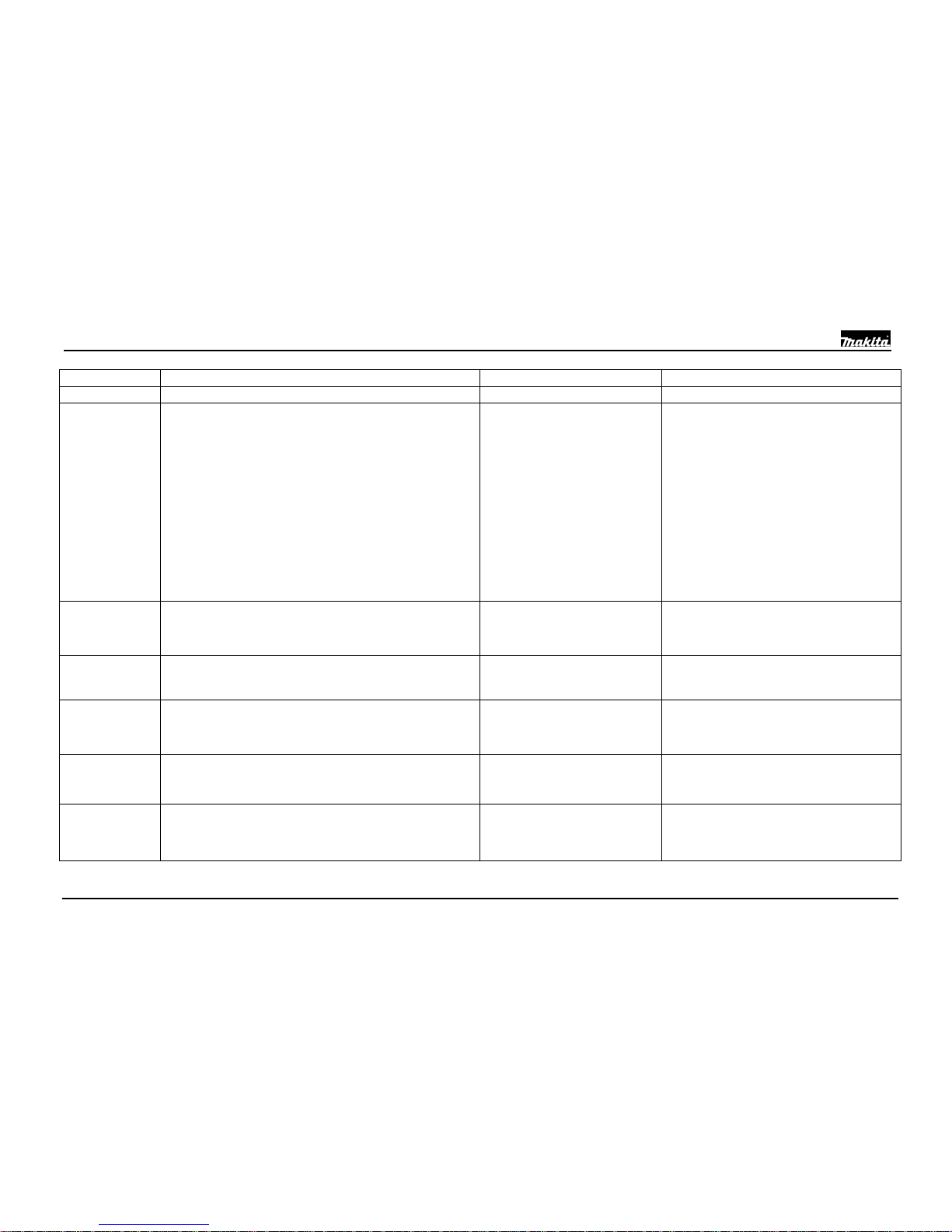

Reparaturanleitung PS-4600 / PS-5000 4

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

Malfunction System Observation Cause

Chain does not run Chain brake Engine runs Chain brake actuated, Chain too tight

Engine does not start

or

only with difficulty

Ignition system

Ignition spark

No ignition spark

Malfunction in fuel supply system, pressure system,

mechanical malfunction.

STOP switch stuck in service position, fault or short-

circuit in the wiring,

plug cap or spark plug defective,

gap between ignition module and flywheel uneven or too

wide

Fuel supply

Compression

Mechanical malfunction

Fuel tank is filled

Inside system

Outside

Starter does not engage

Combination switch in Choke position,

carburetor defective, suction head dirty,

fuel line bent, leaky or interrupted.

Cylinder base packing ring defective, radial shaft

packings defective,

cylinder or piston rings defective

Spark plug does not seal.

Spring in starter broken, broken parts inside the engine.

Engine speed gets

“stuck”

Multiple systems Engine speed about

4,500 - 6,000 rpm

Carburetor too lean

Bleed air at cylinder and/or rubber induction piece

Fuel line bent, throttle link stuck

Warm engine won’t

start

Carburetor Fuel tank is filled

Ignition spark

Wrong carburetor adjustment

Flooded from choke use

Piston ring worn (max. thrust play 0.5 mm)

Engine starts, but

dies immediately

Fuel supply Fuel tank is filled Wrong idling adjustment, suction head or carburetor dirty,

tank venting defective, fuel line interrupted, cable

defective, Choke flap closed, decompression valve dirty

Insufficient power Several systems

may be involved

simultaneously

Engine is idling

Air filter dirty, incorrect carburetor setting, muffler

clogged, exhaust channel in cylinder clogged, spark

arrester screen clogged.

No chain lubrication

Oil tank/pump

No oil on the chain

Oil tank empty

Oil guide groove dirty, Oil suction head dirty

Oil pump adjusting screw incorrectly adjusted

Oil pump worm drive gear defective

TROUBLESHOOTING

___

Reparaturanleitung PS-4600 / PS-5000 5

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

1

2

3

4

5

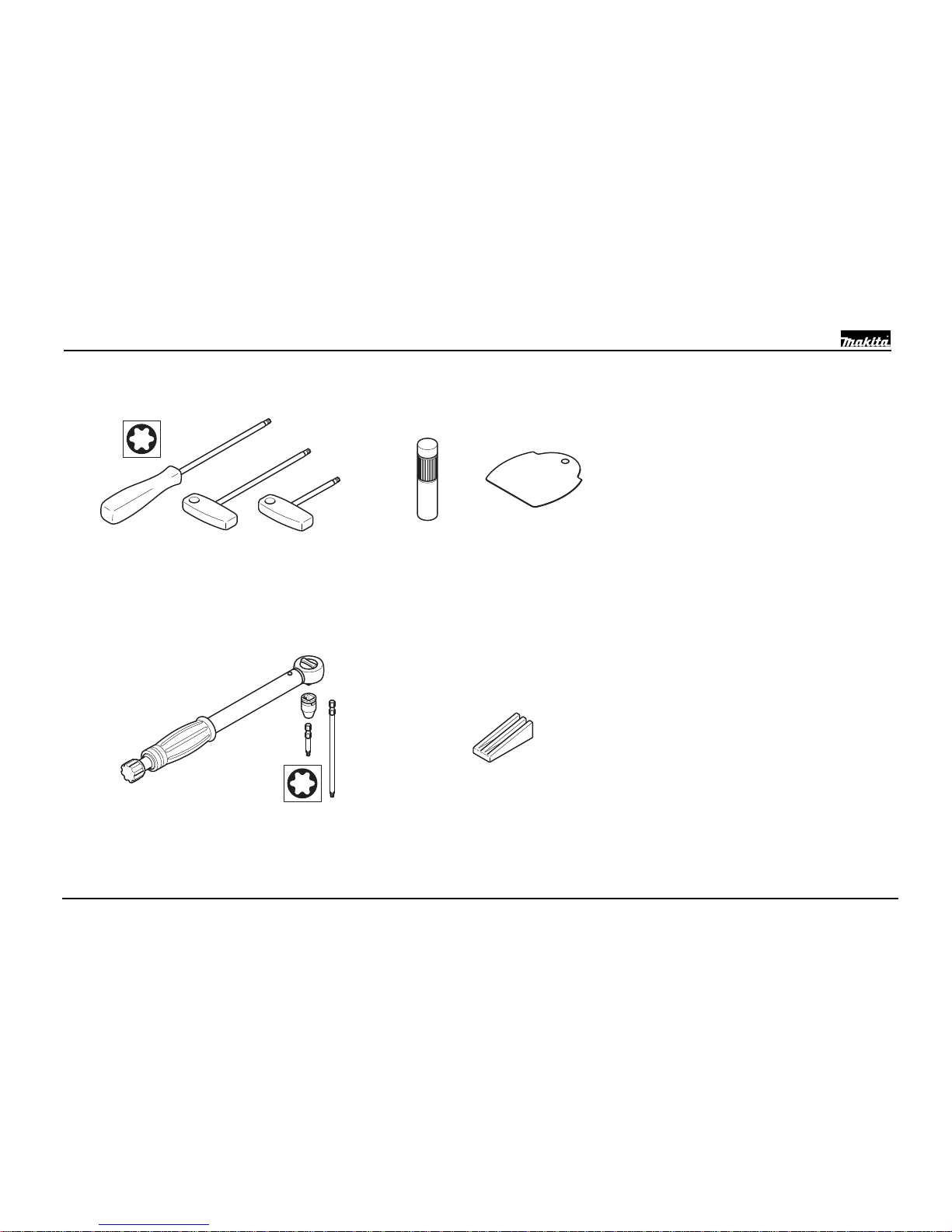

00 SP

ECIAL TOOLS

1 Torx screwdriver

Grip (944.500.860)

T-grip 200 mm (944.500.862)

T-grip 100 mm (944.500.861)

2 Mandrel

Disassembly mandrel for

tapping out the flywheel

without damage to

the crankshaft thread (944.500.880)

3 Setting gauge

Gauge for measuring the gap

between flywheel and

armature (944.500.891)

4 Torque wrench

3/8” Drive socket (944.500.864)

Bit 152 mm (944.500.865)

Bit 49 mm (944.500.866)

Torque wrench

3/8” Drive (950.230.000)

5 Piston stop wedge

Wedge for blocking

the engine through the

exhaust port (944.602.001)

___

Reparaturanleitung PS-4600 / PS-5000 6

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

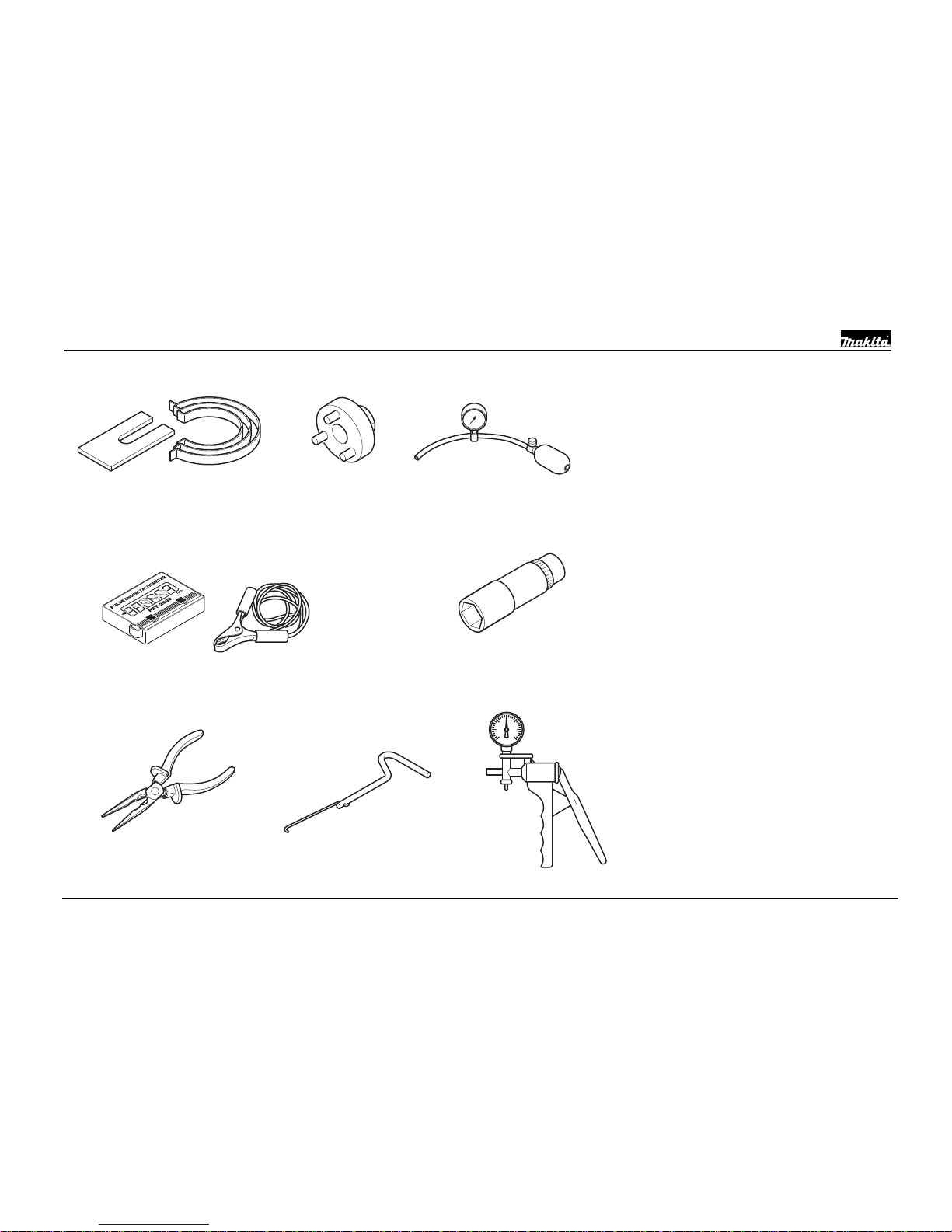

6 7

9

8

10

11 12 13

00 SPECIAL TOOLS

6 Piston ring tensioner

Piston ring band and

assembly tool for cylinders (944.600.001)

7 Assembly and disassembly wrench

Wrench for disassembling and

assembling the centrifugal

clutch (944.500.590)

8 Pressure gauge

Pressure guage for checking

the carburetor fuel valve (956.004.000)

9 Tachometer

Electronic tachometer for measuring

the engine speed of

2- and 4-stroke engines (950.233.220)

10 3/8” socket

Installation/removal of

Spark plug, clutch (944.500.864)

11 Needle-nose pliers

Various assembly/

Disassembly tasks (944.603.400)

12 Disassembly hook

Removal/installation

Brake band spring (950.237.000)

13 Over/underpressure pump

For checking sealing of

radial rings and gaskets (957.004.001)

___

Reparaturanleitung PS-4600 / PS-5000 7

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

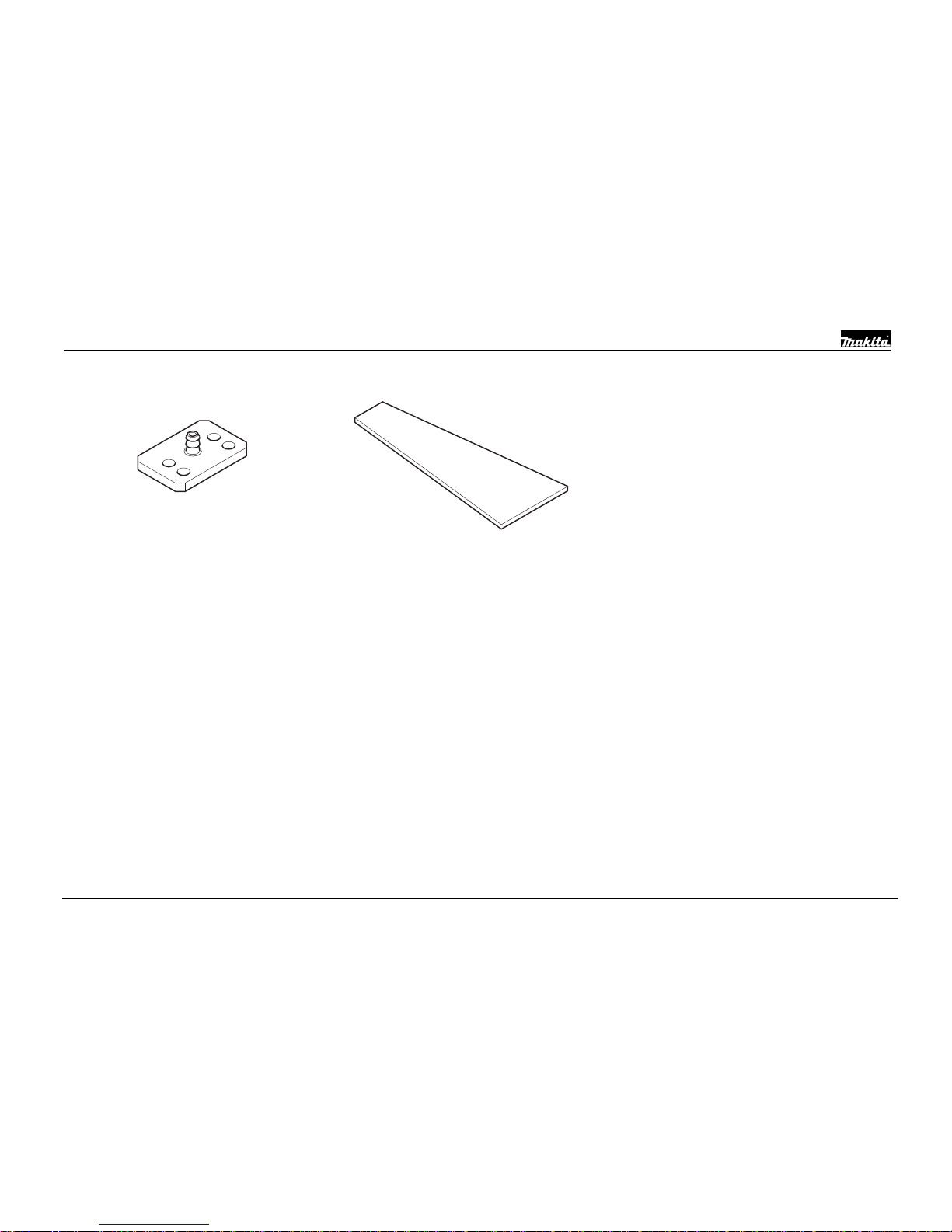

14 15

00 SPECIAL TOOLS

14 Sealing plate

For sealing intake side (944.603.020)

15 Sealing plate

For sealing exhaust side (944.603.170)

___

Reparaturanleitung PS-4600 / PS-5000 8

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

1

01 SPROCKET GUARD / CHA

IN TENSIONING SYSTEM

Remove the sprocket guard, bar, and chain.

CAUTION: Do not work on the chain brake

unless the spring is detensioned!

Chain tensioner

Carefully take the chain guide cover off the

guide bar bolts.

Unscrew 4 screws, and remove the spike bar

and the cover.

Chain tensioner function

An angled worm drive converts the turns of

the adjustment screw 1 to forward or

backward motion of the tensioning pin.

If necessary, turn adjusting screw 1

clockwise,

until the fastening screw is accessible.

Unscrew the fastening screw and pull the

chain tensioner up and out.

Assembly

Grease spindle and worm gear with multipurpose grease (944.360.000).

___

Reparaturanleitung PS-4600 / PS-5000 9

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

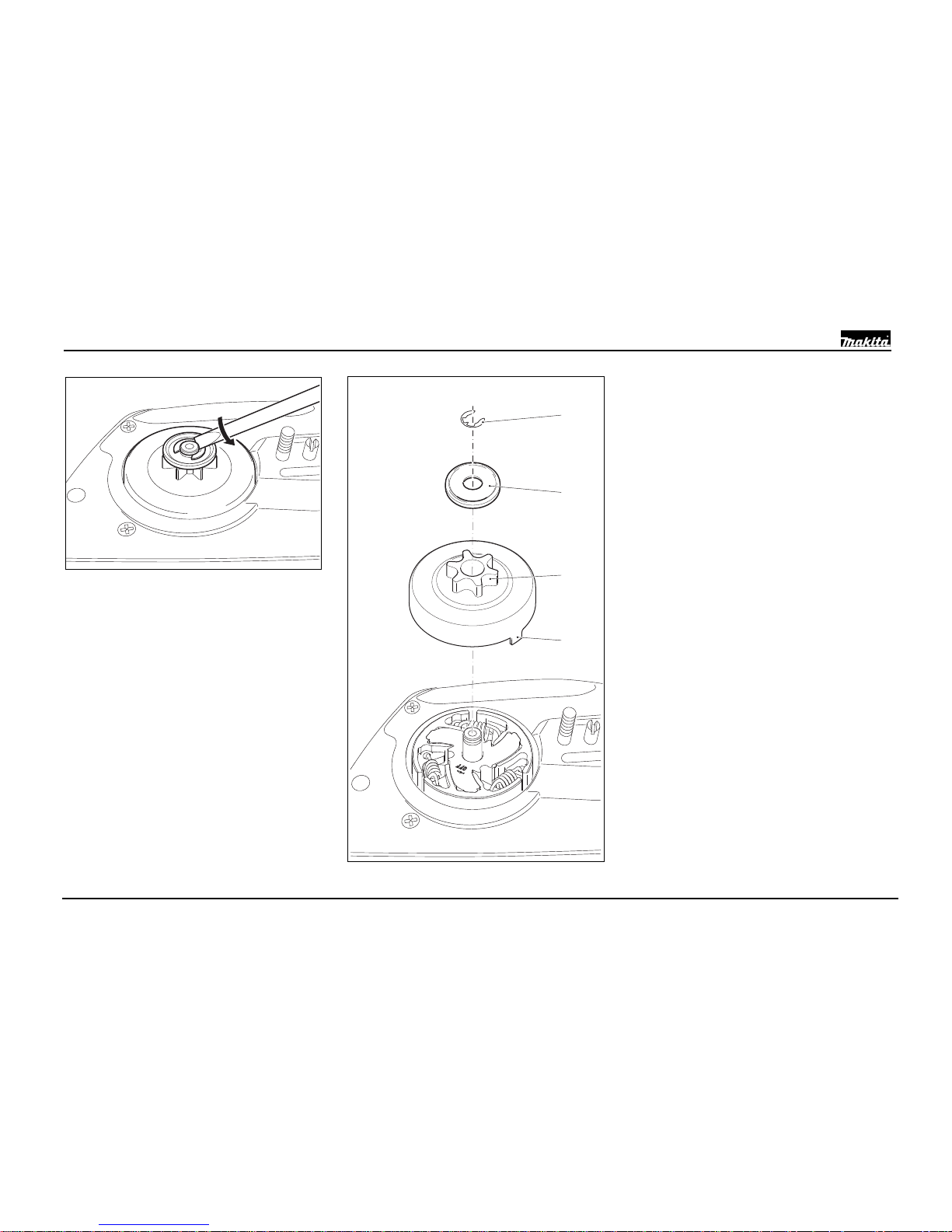

4

3

2

1

02 CLUTCH DRUM AND CHAIN SPROCKET

Remove the sprocket guard, bar, and chain.

Remove the circlip 4 with the universal

wrench.

Remove cup washer 3.

Pull the handguard towards the front grip only

as far as necessary so the clutch drum can be

removed.

Clutch drum with sprocket and needle

bearing

Check the chain sprocket 2 for damage and

wear.

Important customer information:

Before installing a new saw chain, always

check the condition of the chain sprocket. A

worn chain sprocket will damage a new saw

chain, and must be replaced.

Check the clutch drum needle bearing for

wear and damage.

Assembly the bearing with multi

-purpose high-

performance grease (944.360.000).

Check the inside of the clutch drum for

damage and wear.

Replace the clutch drum if damaged or worn.

Note: Always use a new circlip 4

(927.408.000)!

When assembling the clutch drum, make

sure that the lug of the oil pump drive 1 is

not positioned on the oil pump drive.

When

inserting, turn the clutch drum slightly.

___

Reparaturanleitung PS-4600 / PS-5000 10

Repair manual DCS3500 / DCS3501 / DCS4300 / DCS4301 / EA3500F / EA3501F / EA4300F / EA4301F / MEA3500L / MEA3500M / MEA4300G / MEA4300L

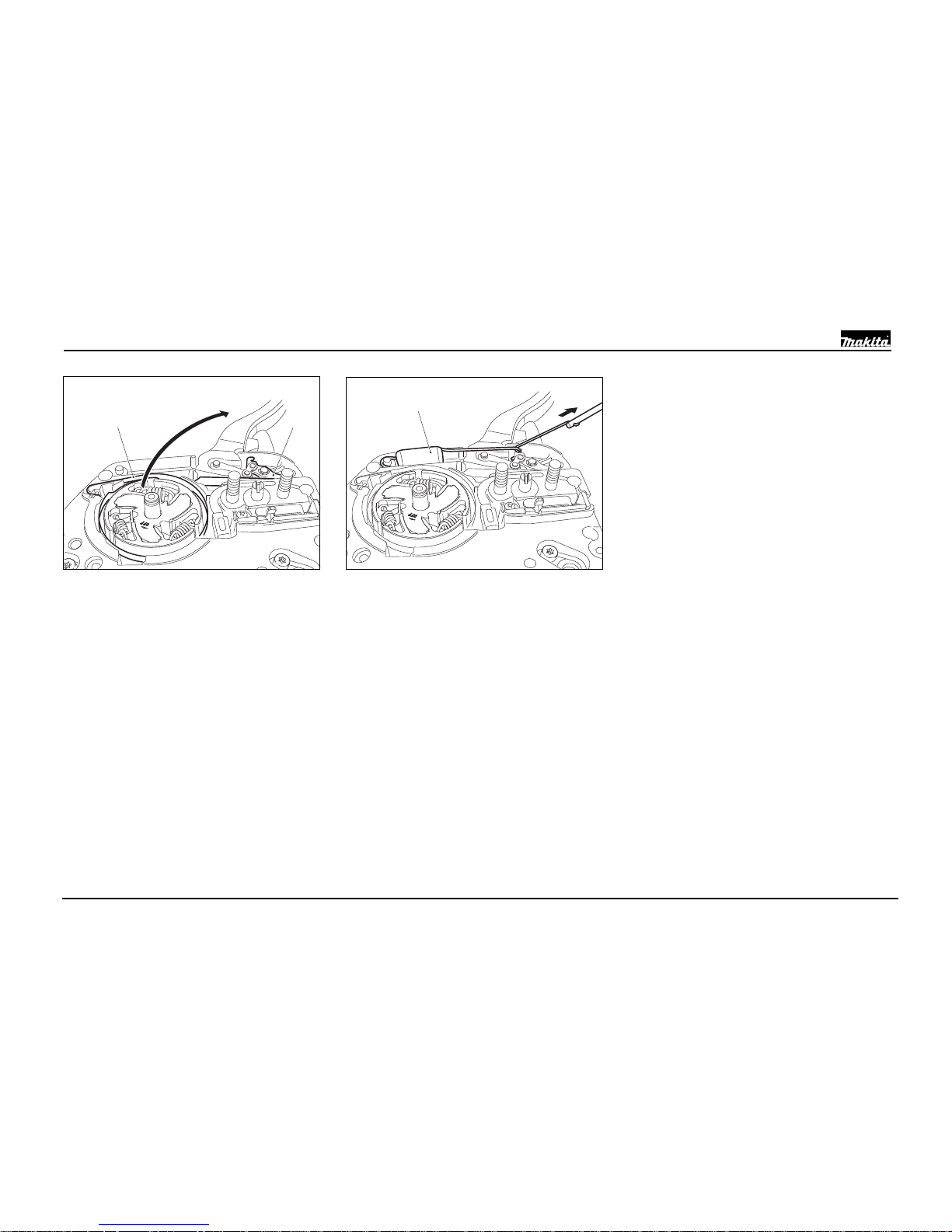

Secure the chain saw from slipping (vise).

Using the disassembly hook (Chap. 00, Pos.

12), disengage the brake band spring 3.

1

2

3

03 CHAIN BR

AKE / GUIDE BAR BOLT

Removing the brake band

CAUTION: Wear protective gloves to

prevent cuts!

Remove the sprocket guard, bar, and chain.

Remove the clutch drum, see Chapter 02.

Push the hand guard forward to engage the

chain brake. This tensions the brake band

spring.

Remove the cover plate, see Chapter 01.

Fold the brake band 1 upward and turn it out

of the disengagement mechanism 2.

Loading...

Loading...