Page 1

ENGLISH: Original instructions

INSTRUCTION MANUAL

Cordless Random Orbit Polisher

DPO500

DPO600

Read before use.

Page 2

SPECIFICATIONS

Ni-MH

Model: DPO500 DPO600

Backing pad diameter 123 mm 148 mm

Orbits per minute Normal mode 0 - 6,800 min

Finishing mode 0 - 5,200 min

Overall length 530 mm

Rated voltage D.C. 18 V

Net weight 3.1 - 3.6 kg

•

Due to our continuing program of research and development, the specications herein are subject to change without notice.

• Specications and battery cartridge may differ from country to country.

• The weight may differ depending on the attachment(s), including the battery cartridge. The lightest and heavi-

est combinations, according to EPTA-Procedure 01/2014, are shown in the table.

Applicable battery cartridge and charger

-1

-1

Battery cartridge BL1815N / BL1820 / BL1820B / BL1830 / BL1830B / BL1840 /

Charger DC18RC / DC18RD / DC18RE / DC18SD / DC18SE / DC18SF

Some of the battery cartridges and chargers listed above may not be available depending on your region of residence.

•

BL1840B / BL1850 / BL1850B / BL1860B

WARNING: Only use the battery cartridges and chargers listed above. Use of any other battery cartridges

and chargers may cause injury and/or re.

Symbols

The followings show the symbols used for the equipment.

Be sure that you understand their meaning before use.

Read instruction manual.

Only for EU countries

Do not dispose of electric equipment or

battery pack together with household waste

material!

In observance of the European Directives,

on Waste Electric and Electronic

Equipment and Batteries and Accumulators

and Waste Batteries and Accumulators

and their implementation in accordance

with national laws, electric equipment and

batteries and battery pack(s) that have

reached the end of their life must be col-

lected separately and returned to an environmentally compatible recycling facility.

Li-ion

Intended use

The tool is intended for polishing.

Noise

The typical A-weighted noise level determined according to EN62841-2-4:

Model DPO500

Sound pressure level (L

Sound power level (LWA) : 93 dB (A)

Uncertainty (K) : 3 dB(A)

Model DPO600

Sound pressure level (L

Sound power level (LWA) : 94 dB (A)

Uncertainty (K) : 3 dB(A)

) : 82 dB(A)

pA

) : 83 dB(A)

pA

NOTE: The declared noise emission value(s) has

been measured in accordance with a standard test

method and may be used for comparing one tool with

another.

NOTE: The declared noise emission value(s)

may also be used in a preliminary assessment of

exposure.

WARNING: Wear ear protection.

WARNING: The noise emission during actual

use of the power tool can differ from the declared

value(s) depending on the ways in which the

tool is used especially what kind of workpiece is

processed.

WARNING: Be sure to identify safety mea-

sures to protect the operator that are based on an

estimation of exposure in the actual conditions of

use (taking account of all parts of the operating

cycle such as the times when the tool is switched

off and when it is running idle in addition to the

trigger time).

Vibration

The vibration total value (tri-axial vector sum) determined according to EN62841-2-4:

Model DPO500

Work mode: polishing

Vibration emission (a

Uncertainty (K) : 1.5 m/s

h, P

Model DPO600

Work mode: polishing

Vibration emission (a

Uncertainty (K) : 1.5 m/s

h, P

) : 9.5 m/s

) : 10.0 m/s

2

2

2

2

2 ENGLISH

Page 3

NOTE: The declared vibration total value(s) has been

measured in accordance with a standard test method

and may be used for comparing one tool with another.

NOTE: The declared vibration total value(s) may also

be used in a preliminary assessment of exposure.

WARNING: The vibration emission during

actual use of the power tool can differ from the

declared value(s) depending on the ways in which

the tool is used especially what kind of workpiece

is processed.

WARNING: Be sure to identify safety mea-

sures to protect the operator that are based on an

estimation of exposure in the actual conditions of

use (taking account of all parts of the operating

cycle such as the times when the tool is switched

off and when it is running idle in addition to the

trigger time).

EC Declaration of Conformity

For European countries only

The EC declaration of conformity is included as Annex A

to this instruction manual.

SAFETY WARNINGS

General power tool safety warnings

WARNING:

tions, illustrations and specications provided with this

power tool. Failure to follow all instructions listed below

may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause

you to lose control.

Electrical Safety

1. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodied plugs and matching outlets will

reduce risk of electric shock.

2. Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of elec-

tric shock if your body is earthed or grounded.

Read all safety warnings, instruc-

3. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

4. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges

or moving parts. Damaged or entangled cords

increase the risk of electric shock.

5. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

6. If operating a power tool in a damp location

is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

7.

Power tools can produce electromagnetic elds

(EMF) that are not harmful to the user. However,

users of pacemakers and other similar medical

devices should contact the maker of their device and/

or doctor for advice before operating this power tool.

Personal Safety

1. Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the inuence of drugs, alcohol or medication. A moment of inattention while operating

power tools may result in serious personal injury.

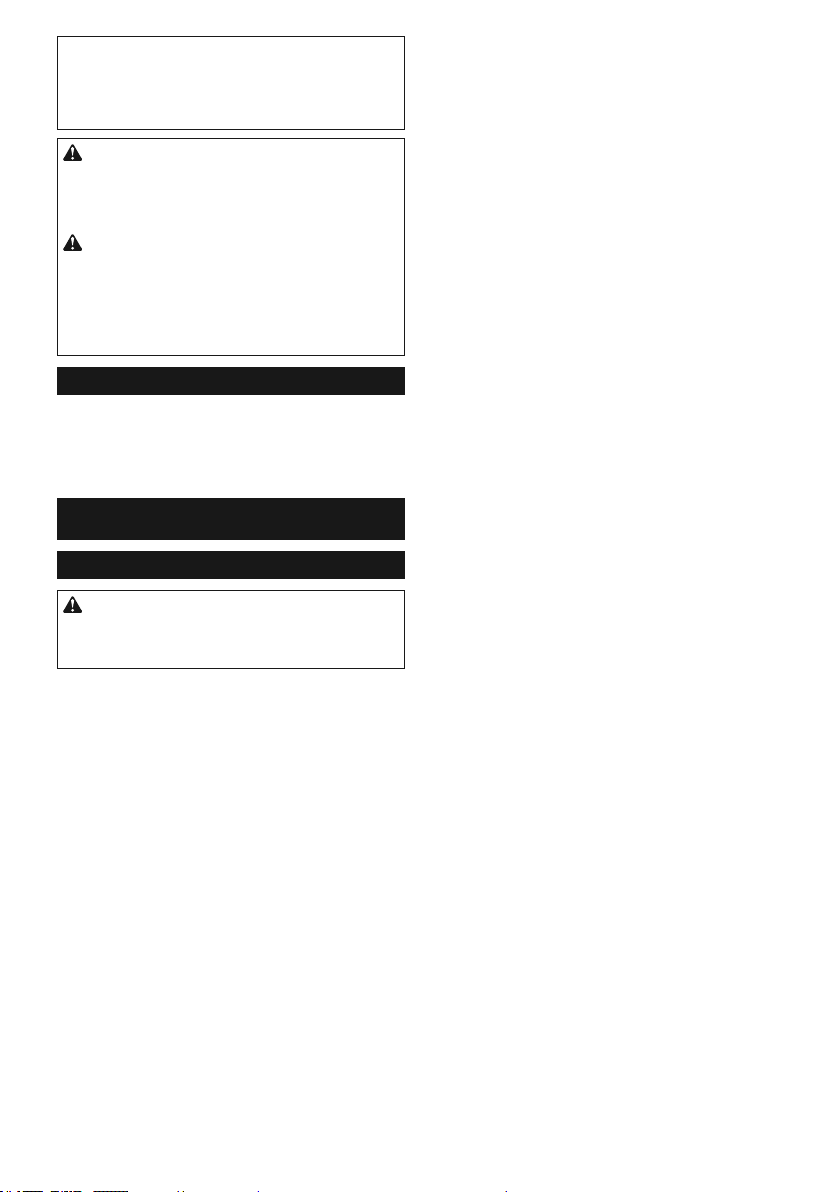

2. Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat or

hearing protection used for appropriate conditions

will reduce personal injuries.

3. Prevent unintentional starting. Ensure the

switch is in the off-position before connecting

to power source and/or battery pack, picking

up or carrying the tool. Carrying power tools with

your nger on the switch or energising power tools

that have the switch on invites accidents.

4. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

5. Do not overreach. Keep proper footing and

balance at all times. This enables better control

of the power tool in unexpected situations.

6. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away

from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

7. If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dust-related hazards.

8.

Do not let familiarity gained from frequent use

of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

9. Always wear protective goggles to protect

your eyes from injury when using power tools.

The goggles must comply with ANSI Z87.1 in

the USA, EN 166 in Europe, or AS/NZS 1336

in Australia/New Zealand. In Australia/New

Zealand, it is legally required to wear a face

shield to protect your face, too.

3 ENGLISH

Page 4

It is an employer's responsibility to enforce

the use of appropriate safety protective equipments by the tool operators and by other persons in the immediate working area.

Power tool use and care

1. Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at the

rate for which it was designed.

2. Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and

must be repaired.

3. Disconnect the plug from the power source

and/or remove the battery pack, if detachable,

from the power tool before making any adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce

the risk of starting the power tool accidentally.

4. Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

5. Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If damaged, have the power tool repaired before use.

Many accidents are caused by poorly maintained

power tools.

6. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

7. Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking into account the working conditions and

the work to be performed. Use of the power tool

for operations different from those intended could

result in a hazardous situation.

8. Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unexpected

situations.

9. When using the tool, do not wear cloth work

gloves which may be entangled. The entangle-

ment of cloth work gloves in the moving parts may

result in personal injury.

Battery tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

one type of battery pack may create a risk of re

when used with another battery pack.

2. Use power tools only with specically desig-

nated battery packs. Use of any other battery

packs may create a risk of injury and re.

3. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nals together may cause burns or a re.

4. Under abusive conditions, liquid may be

ejected from the battery; avoid contact. If con-

tact accidentally occurs, ush with water. If

liquid contacts eyes, additionally seek medical

help. Liquid ejected from the battery may cause

irritation or burns.

5. Do not use a battery pack or tool that is dam-

aged or modied. Damaged or modied batteries

may exhibit unpredictable behaviour resulting in

re, explosion or risk of injury.

6. Do not expose a battery pack or tool to re or

excessive temperature. Exposure to re or temperature above 130 °C may cause explosion.

7. Follow all charging instructions and do not

charge the battery pack or tool outside the

temperature range specied in the instructions. Charging improperly or at temperatures

outside the specied range may damage the

battery and increase the risk of re.

Service

1.

Have your power tool serviced by a qualied repair

person using only identical replacement parts. This

will ensure that the safety of the power tool is maintained.

2. Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

3. Follow instruction for lubricating and chang-

ing accessories.

Cordless random orbit polisher

safety warnings

1. Do not leave the tool running. Operate the tool

only when hand-held.

2. Check that the workpiece is properly

supported.

3. Do not use the tool on any materials containing asbestos.

4. Do not touch the bolt on the backing pad

immediately after operation. It may be extremely

hot and could burn your skin.

5. Make sure that there is no crack or breakage

on the pad before use. If you drop the tool,

check that there is no breakage and run the

tool for approximately 1 minute at the maximum speed at no load to check that there is no

abnormality with the tool. Cracks or breakage

may cause a personal injury.

SAVE THESE INSTRUCTIONS.

4 ENGLISH

Page 5

WARNING:

product (gained from repeated use) replace strict adherence to safety rules for the subject product. MISUSE or

failure to follow the safety rules stated in this instruction manual may cause serious personal injury.

DO NOT let comfort or familiarity with

Important safety instructions for

battery cartridge

1.

Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4.

If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10.

The contained lithium-ion batteries are subject to

the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on pack-

aging and labeling must be observed.

For preparation of the item being shipped, consulting an

expert for hazardous material is required. Please also

observe possibly more detailed national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to dis-

posal of battery.

12. Use the batteries only with the products

specied by Makita. Installing the batteries to

non-compliant products may result in a re, excessive heat, explosion, or leak of electrolyte.

SAVE THESE INSTRUCTIONS.

CAUTION:

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will also

void the Makita warranty for the Makita tool and charger.

Only use genuine Makita batteries.

Tips for maintaining maximum

battery life

Charge the battery cartridge before completely dis-

1.

charged. Always stop tool operation and charge the

battery cartridge when you notice less tool power.

2.

Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3.

Charge the battery cartridge with room tempera-

ture at 10 °C - 40 °C (50 °F - 104 °F). Let a hot

battery cartridge cool down before charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

FUNCTIONAL

DESCRIPTION

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery

cartridge

CAUTION: Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip off your hands

and result in damage to the tool and battery cartridge

and a personal injury.

1

2

3

► 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

5 ENGLISH

Page 6

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

Indicating the remaining battery

capacity

Only for battery cartridges with the indicator

1

2

► 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indicate the remaining battery capacity. The indicator lamps

light up for a few seconds.

Indicator lamps Remaining

Lighted Off Blinking

capacity

75% to 100%

Overload protection

When the tool or battery is operated in a manner that

causes it to draw an abnormally high current, the tool automatically stops without any indication. In this situation, turn

the tool off and stop the application that caused the tool to

become overloaded. Then turn the tool on to restart.

Overheat protection

When the tool or battery is overheated, the tool stops automatically. In

this case, let the tool and battery cool before turning the tool on again.

Overdischarge protection

When the battery capacity is not enough, the tool stops automatically.

In this case, remove the battery from the tool and charge the battery.

Switch action

CAUTION: Before installing the battery car-

tridge into the tool, always check to see that the

switch trigger actuates properly and returns to

the "OFF" position when released.

CAUTION: Switch can be locked in "ON" posi-

tion for ease of operator comfort during extended

use. Apply caution when locking tool in "ON"

position and maintain rm grasp on tool.

CAUTION: Do not install the battery cartridge

with the lock button engaged.

CAUTION: When not operating the tool,

depress the trigger-lock button from

lock the switch trigger in the OFF position.

1

side to

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

Tool / battery protection system

The tool is equipped with a tool/battery protection system. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will automatically stop during operation if the tool or battery is

placed under one of the following conditions:

A

► 1. Trigger-lock button

B

3

1

1. Switch trigger 2. Lock button 3. Trigger-lock button

►

6 ENGLISH

2

Page 7

To prevent the switch trigger from accidentally pulled, the

trigger-lock button is provided. To start the tool, depress

the trigger-lock button from A (

trigger. Tool speed is increased by increasing pressure on

the switch trigger. Release the switch trigger to stop. After

use, depress the trigger-lock button from B (

For continuous operation, depress the lock button while

pulling the switch trigger, and then release the switch trigger.

To stop the tool, pull the switch trigger fully, then release it.

) side and pull the switch

) side.

Speed adjusting dial

Selecting the action mode

Turn the change knob to alter the rotation mode.

1

4

► 1. Speed adjusting dial

The rotating speed can be changed by turning the

speed adjusting dial to a given number setting from 1 to

5. Higher speed is obtained when the dial is turned in

the direction of number 5. And lower speed is obtained

when it is turned in the direction of number 1.

Refer to the table for the relationship between the number

settings on the dial and the approximate rotating speed.

Normal mode

Number Orbits per min. Pad rotating speed per

1 1,600 180

2 2,500 290

3 4,000 460

4 5,600 650

5 6,800 780

Finishing mode

Number Orbits per min. Pad rotating speed per

1 1,600 180

2 2,200 250

3 3,300 380

4 4,400 500

5 5,200 600

2

3

minute in random orbit with

forced rotation mode

minute in random orbit with

forced rotation mode

NOTICE: If the tool is operated continuously

at low speeds for a long time, the motor will get

overloaded, resulting in tool malfunction.

NOTICE:

only as far as 5 and back to 1. Do not force it past 5 or

1, or the speed adjusting function may no longer work.

The speed adjusting dial can be turned

1

► 1. Change knob

NOTICE:

in the middle position, you cannot turn on the tool.

Always turn the knob fully. If the knob is

NOTICE: You cannot change the action mode

when the tool is switched on.

Random orbit with forced rotation mode

► 1. Change knob

Random orbit with forced rotation mode is orbital action with forced

rotation of the pad for rough polishing such as surface treatment.

Rotate the change knob counterclockwise for random

orbit with forced rotation mode.

Random orbit mode

► 1. Change knob

7 ENGLISH

1

1

Page 8

Random orbit mode is orbital action with free rotation of

the pad for ne polishing.

Rotate the change knob clockwise for random orbit mode.

Finishing mode

In the nishing mode, you can operate the tool without applying

excessive load. This mode is suitable for nishing operation.

To use the tool in the nishing mode, pull the switch trigger and

release it to turn on the tool, and then press the mode switching

button. The lamp lights up in green. To return to the normal mode,

press the mode switching button while the tool is turned on.

1

2

► 1. Lamp 2. Mode switching button

NOTE: You cannot change the mode when the tool

is running.

Accidental restart preventive function

If you install the battery cartridge while pulling the switch trigger

or locking the switch trigger, the tool does not start. To start the

tool, release the switch trigger, and then pull the switch trigger.

Electronic function

The tools equipped with electronic function are easy to

operate because of the following features.

Installing the backing pad

1

2

3

► 1. Hex wrench 2. Bolt 3. Backing pad

Put the backing pad on the shaft then turn the bolt

clockwise with a hex wrench.

CAUTION: Make sure that the backing pad is

secured properly. Loose attachment will run out of

balance and cause an excessive vibration which may

cause loss of control.

Installing side grip

Optional accessory

CAUTION:

Otherwise, the front cover may fall and cause an injury.

Tighten the caps or side grip rmly.

1

Constant speed control

Possible to get ne nish, because the rotating speed is

kept constant even under the loaded condition.

Soft start feature

Soft start because of suppressed starting shock.

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before carrying out any work on the tool.

2

► 1. Cap 2. Side grip

8 ENGLISH

Page 9

Remove the cap and screw the side grip on the tool securely.

The side grip can be installed on either side of the tool.

Installing or removing pad

Optional accessory

CAUTION: Only use hook-and-loop system

pads for polishing.

1

NOTICE: Never force the tool. Excessive pressure

may lead to decreased polishing efciency, damaged

pad, or shorten tool life.

NOTICE: Continuous operation at high speed

may damage work surface.

Polishing operation

► 1. Pad

To install the pad, rst remove all dirt and foreign matter from the hook-and-loop system of the pad and the

backing pad. Attach the pad to the backing pad so that

their edges are aligned.

To remove the pad from the backing pad, just pull up

from its edge.

CAUTION: Make sure that the pad and

backing pad are aligned and securely attached.

Otherwise the pad will cause an excessive vibration

which may cause loss of control or the pad may be

thrown out from the tool.

OPERATION

CAUTION: Only use Makita genuine pads for

polishing (optional accessories).

CAUTION: Make sure the work material is

secured and stable. Falling object may cause

personal injury.

CAUTION: Hold the tool rmly with one hand

on the switch handle and the other hand on the

front grip (or side handle) when performing the

tool.

CAUTION: Do not run the tool at high load

over an extended time period. It may result in tool

malfunction which causes electric shock, re and/or

serious injury.

CAUTION: Be careful not to touch the rotating

part.

CAUTION: Before operating the tool, make

sure that the side grip or caps are not loose. If the

side grip or caps are loose, the front cover may fall

and cause an injury.

1. Surface treatment (Random orbit with forced

rotation mode)

Use a wool pad for rough nishing then use a sponge

pad for ne nishing.

2. Applying wax (Random orbit mode)

Use a sponge pad. Apply wax to the sponge pad or

work surface. Run the tool at low speed to smooth out

wax.

CAUTION: Do not apply excessive wax or

polishing agent. It will generate more dust and may

cause eye or respiratory diseases.

NOTE: First, perform a test waxing on an inconspicuous portion of the work surface. Make sure that the

tool will not scratch the surface or result in uneven

waxing before.

3. Removing wax (Random orbit mode)

Use another sponge pad. Run the tool to remove wax.

4. Polishing (Random orbit mode)

Apply a felt pad gently to the work surface.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

To maintain product SAFETY and RELIABILITY,

repairs, any other maintenance or adjustment should

be performed by Makita Authorized or Factory Service

Centers, always using Makita replacement parts.

9 ENGLISH

Page 10

Cleaning dust covers

1

1

► 1. Dust cover

Regularly clean the dust covers on the inhalation vents

for smooth air circulation. Remove the dust covers and

clean the mesh.

OPTIONAL

ACCESSORIES

CAUTION: These accessories or attachments

are recommended for use with your Makita tool

specied in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or attachment

for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service

Center.

• Side grip

• Backing pad

• Wool pad

• Sponge pad

• Felt pad

• Makita genuine battery and charger

NOTE: Some items in the list may be included in the

tool package as standard accessories. They may

differ from country to country.

10 ENGLISH

Page 11

11

Page 12

Makita Europe N.V.

Makita Corporation

n

Jan-Baptist Vinkstraat 2,

www.makita.com

3070 Kortenberg, Belgium

3-11-8, Sumiyoshi-cho,

Anjo, Aichi 446-8502 Japa

885667A229

EN

20181226

Loading...

Loading...