Page 1

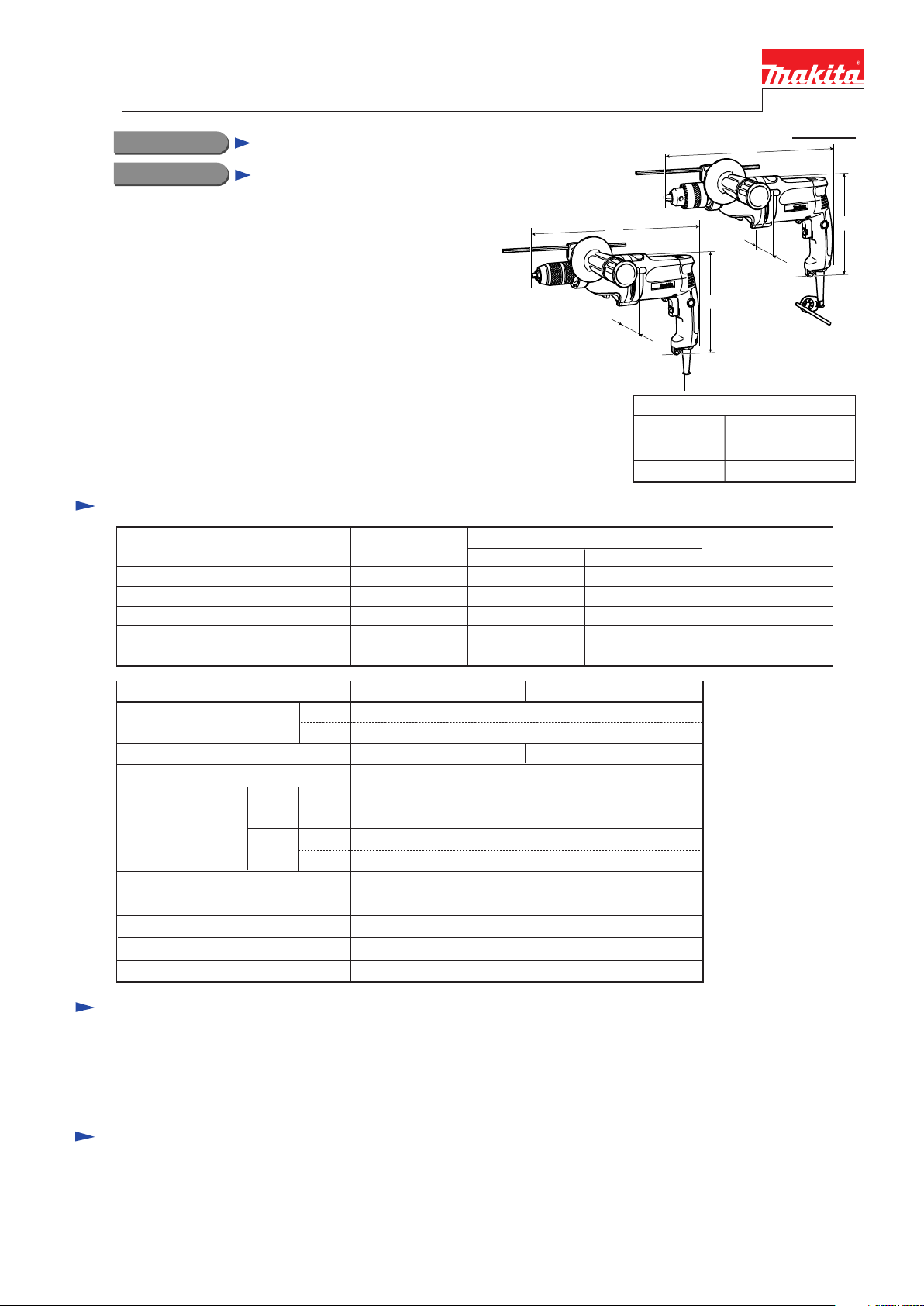

T

Description

ECHNICAL INFORMATION

Model No.

DP4010, DP4011

2-Speed Drill 13mm (1/2")

PRODUCT

P 1/ 8

L

CONCEPT AND MAIN APPLICATIONS

Models DP4010 and DP4011 have been developed as

13mm (1/2") Drill for professional users, featuring:

*2-speed gear selection with variable speed in each range

for a wide range of applications

*Extra-rigid cylindrical motor housing

*Sturdy aluminum gear housing

Specification

Voltage (V) Cycle (Hz)

110

120

220

230

240

Current (A)

6.9

6.6

3.4

3.3

3.2

50/60

50/60

50/60

50/60

50/60

L

W

DP4011

Length (L) 347 (13-5/8)

Width (W)

Height (H)

Continuous Rating (W)

Input Output

720

---

720

720

720

360

360

360

360

360

H

W

DP4010

H

Dimensions: mm (")

70 (2-3/4)

220 (8-5/8)

Max. Output (W)

660

660

660

660

660

Model

No load speed: min -1= rpm

Drill chuck type

Chuck capacity: mm (")

Steel

Capacities: mm (")

Wood

Reverse switch

Torque limiter Yes

Protection against electric shock

Power supply cord: m (ft)

Net weight: kg (lbs)

High

Low

High

Low

High

Low

DP4010

0 - 2,900

0 - 1,200

Keyed

1.5 - 13 (1/16 - 1/2)

8 (5/16)

13 (1/2)

25 (1)

40 (1-9/16)

Yes

Double insulation

2.5 (8.2)

2.2 (4.9)

Standard equipment

Chuck key S-13 ............... 1 (for DP4010)

Key holder 12 .................. 1 (for DP4010)

Side handle ...................... 1

Depth gauge ..................... 1

Note: The standard equipment for the tool shown above may differ by country.

DP4011

Keyless

Optional accessories

Metal drill bits 1.5 - 13 mm (1/16 - 1/2")

Wood drill bits 3 - 40 mm (1/8 - 1-9/16")

Center drill for hole saw

Hole saws 16 - 90 mm (5/8 - 3-1/2")

Metal borers 14 - 35 mm (9/16 - 1-3/8")

Depth gauge

Wrench 9

Side handle

Drill chuck

Chuck key S-13 (for DP4010)

Drill stand Type 43

Page 2

P 2 / 8

Repair

CAUTION: Remove the bit from the machine for safety before repair/ maintenance

in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

781024-2 Wrench 43

Gear extractor (large)1R045

1R139 Drill chuck extractor

1R223 Torque wrench shaft 20-90N.m

1R224 Ratchet head 12.7 for 1R223

1R298

1R316

Hex. bar 10 with square socket

Bearing extractor1R269

Wrench for bearing retainer

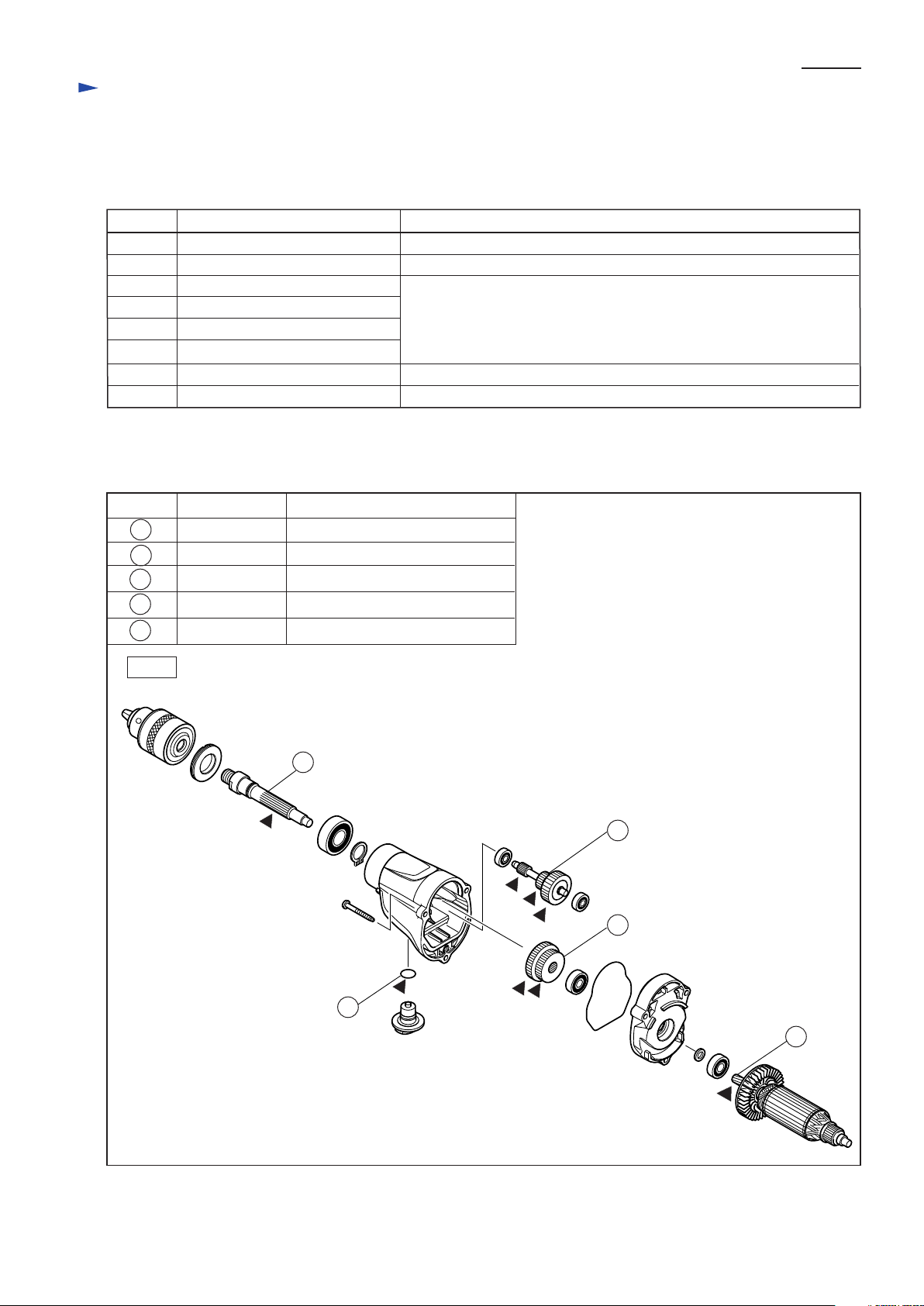

[2] LUBRICATION

Apply 30g in total of Makita grease N. No.1 to the following portions designated with the black triangle to protect parts

and product from unusual abrasion.

Item No. Description Portion to lubricate

3

13

15

30

19

Spindle

Gear complete Gear teeth

Spur gear 29-37 Gear teeth

Armature Gear teeth

O ring 12 Whole portion

Spline portion

Removing the damaged Keyed-drill chuck

Removing Armature

Removing / Assembling Drill chuck

Removing Ball bearings

Removing / Assembling Bearing retainer

Fig. 1

3

13

15

19

30

Page 3

P 3 / 8

Repair

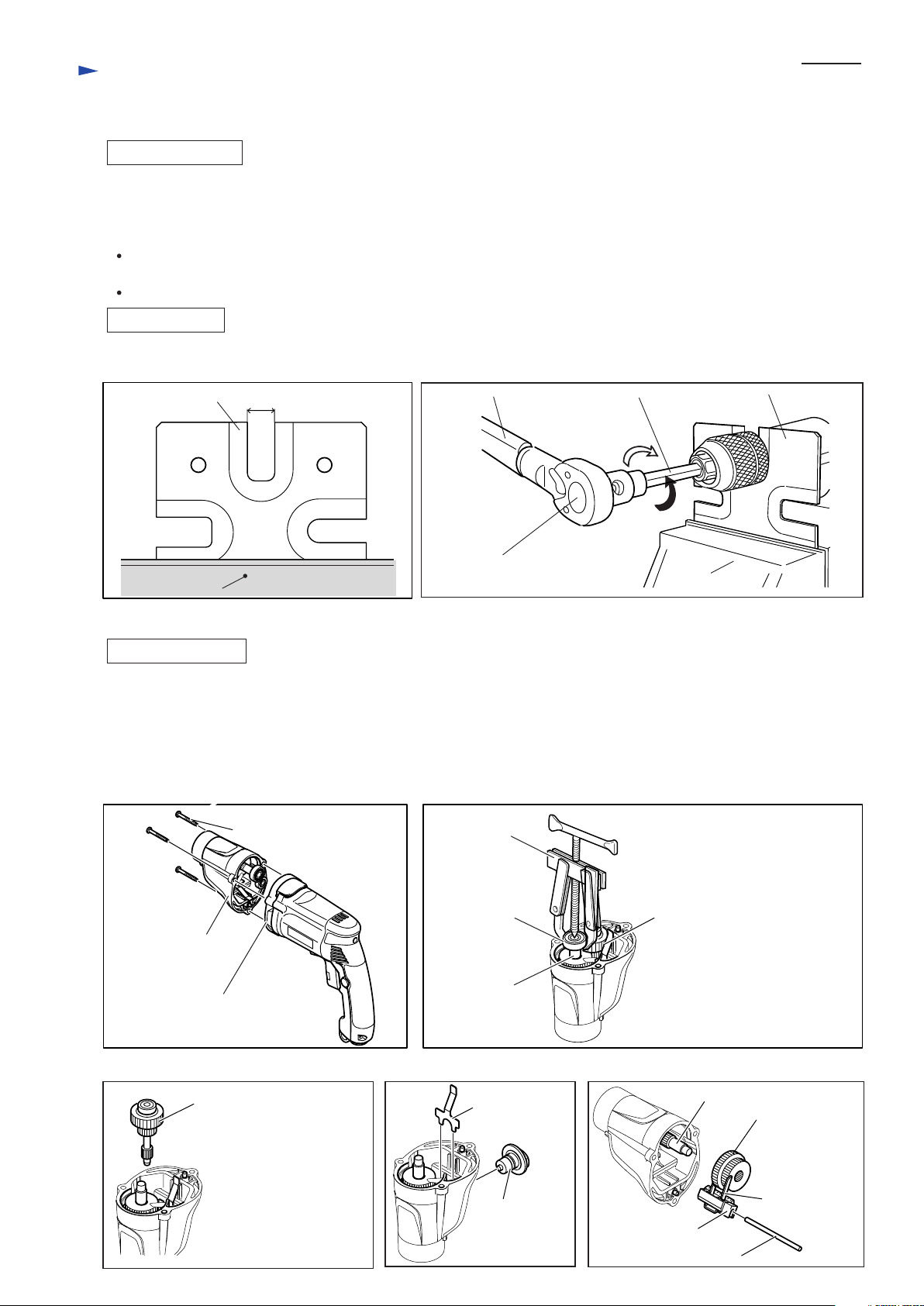

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Drill Chuck

DISASSEMBLING

1) Secure 1R139 firmly with Vise as illustrated in Fig. 2.

2) Fix Spindle on 1R139 by inserting Spindle into the U-shaped notch on 1R139 with the flat sides of the Spindle

facing the edges of the notch. And then remove Drill chuck by turning it counterclockwise with 1R223, 1R224 and

1R298. (Fig. 3)

Use Pipe wrench to remove the Drill chuck, if the sleeve of Drill chuck does not turn because of some troubles

with Drill chuck. Grip the periphery of the sleeve with wrench, and turn wrench counterclockwise.

The keyed Drill chuck of DP4010 can be removed using a Wrench 43 (781024-2).

ASSEMBLING

When fastening the Drill chuck to the Spindle, set the torque of 1R223 to 35.7 to 45.9 N.m.

Fig. 2

8419B

1R139

UT2201

6310

DP4700

17.0mm (11/16")

HP2031

8420V

8406C

8406

6300L

6300LR

6013BR

6300-4

Fig. 3

1R223

1R298

Fastening

1R139

Loosening

1R224

Vise

Vise

[3] -2. Gear Section

DISASSEMBLING

1) Remove three 4x35 Tapping screws, and Separate Gear housing from Gear housing cover complete. (Fig. 4)

2) Remove Ball bearing 608ZZ from Spindle with 1R269 (Fig. 5) and pull out Gear complete with Ball bearing 606ZZ.

(Fig. 6)

Note: Gear complete with Ball bearing 606ZZ can not be pulled out without removing Ball bearing 608ZZ in advance.

3) After removing Lock plate, pull off Change lever B. (Fig. 7)

4) Remove Spur gear 29-37 from Spindle. Change plate B, Rack 12 and Pin 4 can be removed. (Fig. 8).

Fig. 4

4x35 Tapping screw: 3 pcs.

Gear housing

Gear housing cover complete

Fig. 5

1R269

Ball bearing

608ZZ

Spindle

Gear complete with Ball

bearing 606ZZ

(A part of Gear complete is

caught on Ball bearing 608ZZ.)

Fig. 6 Fig. 7

Gear complete with

Ball bearing 606ZZ

Note: Do not disassemble

the Gear complete,

because it has torque

limiter function and

requires difficult

adjustment when

reassembled.

Lock plate

Change lever B

Fig. 8

Spindle

Spur gear 29-37

Change plate B

Rack 12

Pin 4

Page 4

P 4 / 8

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Gear Section (Cont.)

ASSEMBLING

1) Insert the arms of Change plate B through the slots in Rack 12, and then put Spur gear 29-37 between the arms of

Change plate B. (Fig. 9)

2) Insert the Pin 4 into Rack 12. Install Spur gear 29-37 to Spindle together with the parts you have assembled toRack 12.

(Fig. 10)

At this time, do not fail to set Leaf spring in place. (Fig. 10)

Fig. 9

Spur gear 29-37

Rack 12

arm

Change plate B

3) Push Rack 12 into Gear housing until it stops.

And then, install Change lever B on Gear housing

with its "I" mark which indicates low speed aligned

with the triangular mark on Gear housing. (Fig. 11)

4) Install Lock plate on Gear housing with its tail portion

inserted between the ribs on Gear housing as

illustrated in Fig. 11.

5) Assemble Gear complete with Ball bearing 606ZZ

to Gear housing as illustrated in Fig. 6.

Fig. 10

Gear housing

Fig. 11

Spur gear 29-37

Spindle

Leaf spring

Spur gear 29-37

Pin 4

Rack 12

with change plate B

Spindle

Rack 12

Change lever B

Align with I.

Ribs

Lock plate

Page 5

P 5 / 8

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Armature

DISASSEMBLY

1) Disassemble Handle cover by removing Tapping screws. Then remove Carbon brush with slotted screwdriver (Fig. 12)

2) Remove Gear housing cover complete from Motor housing after removing Gear housing. (Fig. 4)

Therefore, Armature comes out with Gear housing cover complete.

3) Remove Armature from Gear housing cover complete with 1R045. (Fig. 13)

4) The Ball bearings are removed from the both end of Armature shaft. (Figs. 14 and 15)

Fig. 12

Handle cover

Slotted

screwdriver

M4x25 Tapping screw

Carbon brush

Carbon brush

Fig. 13

Fig. 15

After removing Labyrinth rubber ring 19, Ball bearing 607LLB and Insulation washer are removed.

Labyrinth rubber ring 19

Armature

1R045

Gear housing

cover complete

Fig. 14

1R269

Note: When replacing Ball bearing 608DDW,

it is removed together with Ring 8.

This Ring 8 is easy to be deformed.

Therefore, do not reuse Ring 8

when removing it.

Ring 8

Ball bearing

608DDW

Ball bearing 607LLB Insulation washer

ASSEMBLY

Do the reverse of the disassemble step.

1R269

Page 6

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Bearing Retainer 19-36

DISASSEMBLY

(1) Remove Gear section from Gear housing. Refer to Figs. 4 to 8.

(2) Remove Bearing retainer 19-36 with 1R316. (Fig. 16)

(3) Ball bearing 6202LLB can be disassembled as illustrated in Fig. 17.

Fig. 16

1R316

P 6 / 8

Bearing retainer 19-36

Fit these pins of 1R316

to the groove of

Bearing retainer 19-36.

Fig. 17

Retaining ring S-15

Ball bearing 6202LLB

Spindle

Turn 1R316 clockwise,

and Bearing retainer 19-36

will be removed.

Retaining

ring S-15

ASSEMBLY

Do the reverse of the disassembling step.

Ball bearing 6202LLB

Page 7

Circuit diagram

Fig. D-1

P 7 / 8

Color index of lead wires' sheath

Black

White

Red

Purple

Blue

FA F'A

Brush

Holder A

FB

Brush

Holder B

F'B

Switch

Noise

suppressor

Power supply cord

Page 8

Wiring diagram

Fig. D-2

P 8 / 8

Fix the Lead wires with

Lead wire holder.

FA F'A

Fix the Lead wires with

Lead wire holder.

Brush

Holder A

FB F'B

Switch

Brush

Holder B

Route the Lead wires of

Power supply cord between

the inner wall and the Rib.

Noise suppressor

Noise Suppressor is not

used for some countries.

Power supply cord

Loading...

Loading...