Page 1

T

ECHNICAL INFORMATION

Models No.

Description

BHR241

Cordless Combination Hammer

CONCEPT AND MAIN APPLICATIONS

The cordless version of HR2470 has been launched

with D-handle for operator's comfort.

This new product is available in the following variations.

Model No.

BHR241RFE

BHR241RF

BHR241Z

The variations for USA, Canada, Mexico and Panama are as follows.

Model No.

BHR241

BHR241Z

Battery

Type Quantity

BL1830

No No No

Battery

Type Quantity

BL1830

No No No

2

1

---

2

---

Charger

DC18RA

Charger

DC18RA

carrying case

carrying case

Plastic

Yes

Yes

Plastic

Yes

PRODUCT

P 1/ 14

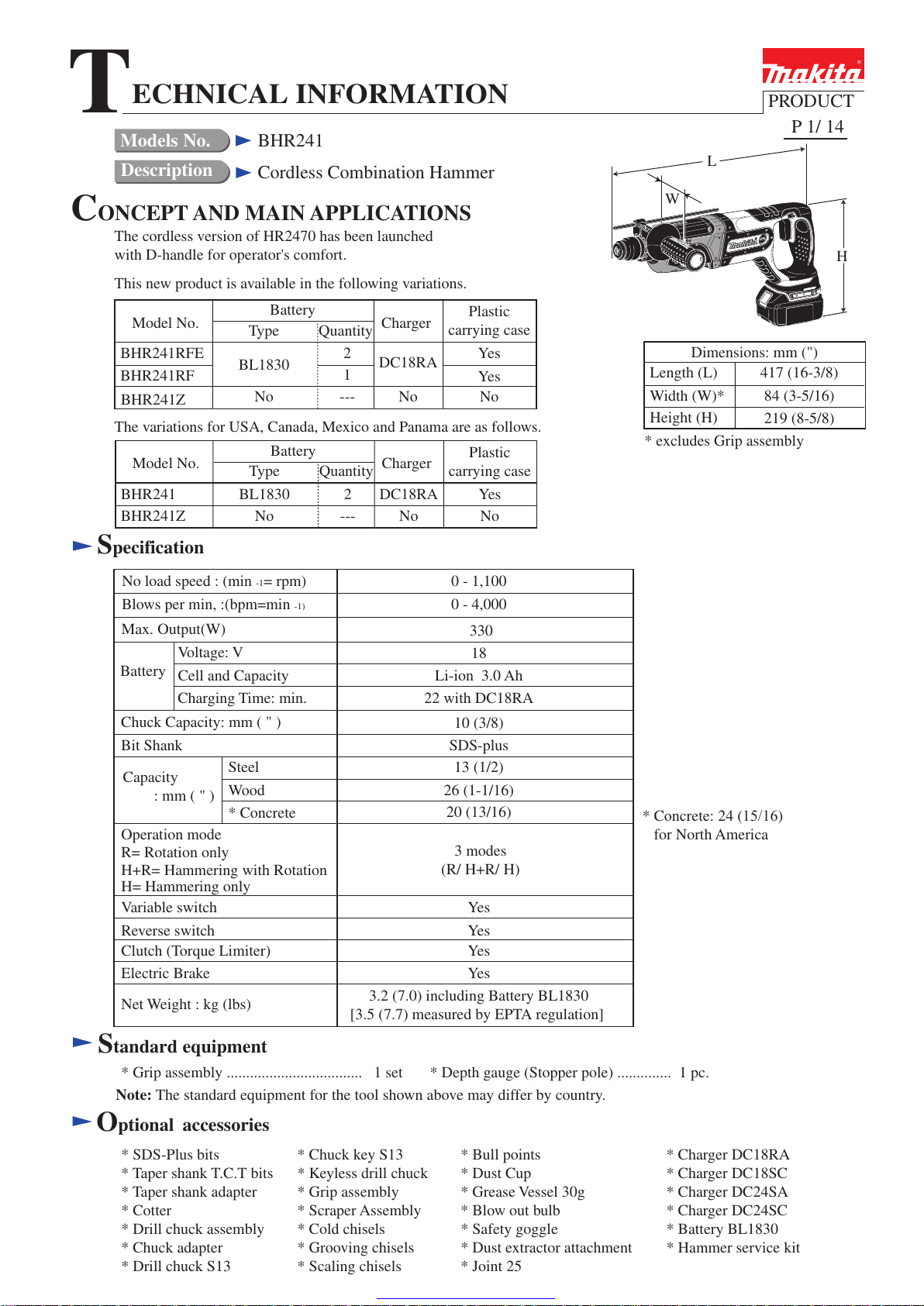

L

W

Dimensions: mm (")

Length (L)

Width (W)*

Height (H)

* excludes Grip assembly

417 (16-3/8)

84 (3-5/16)

219 (8-5/8)

H

Specification

No load speed : (min -1= rpm)

Blows per min, :(bpm=min

Max. Output(W)

Voltage: V

Battery

Chuck Capacity: mm ( " )

Bit Shank

Capacity

: mm ( " )

Operation mode

R= Rotation only

H+R= Hammering with Rotation

H= Hammering only

Variable switch

Reverse switch

Clutch (Torque Limiter)

Electric Brake

Net Weight : kg (lbs)

Cell and Capacity

Charging Time: min.

Steel

Wood

* Concrete

0 - 1,100

-1)

3.2 (7.0) including Battery BL1830

[3.5 (7.7) measured by EPTA regulation]

0 - 4,000

330

18

Li-ion 3.0 Ah

22 with DC18RA

10 (3/8)

SDS-plus

13 (1/2)

26 (1-1/16)

20 (13/16)

3 modes

(R/ H+R/ H)

Yes

Yes

Yes

Yes

* Concrete: 24 (15/16)

for North America

Standard equipment

* Grip assembly ................................... 1 set * Depth gauge (Stopper pole) .............. 1 pc.

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

* SDS-Plus bits

* Taper shank T.C.T bits

* Taper shank adapter

* Cotter

* Drill chuck assembly

* Chuck adapter

* Drill chuck S13

* Chuck key S13

* Keyless drill chuck

* Grip assembly

* Scraper Assembly

* Cold chisels

* Grooving chisels

* Scaling chisels

* Bull points

* Dust Cup

* Grease Vessel 30g

* Blow out bulb

* Safety goggle

* Dust extractor attachment

* Joint 25

* Charger DC18RA

* Charger DC18SC

* Charger DC24SA

* Charger DC24SC

* Battery BL1830

* Hammer service kit

Page 2

P 2/ 14

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the battery and the bit from the machine for safety before

repair/ maintenance in accordance with the instruction manual!

Repair

DescriptionCode No.

1R003 Retaining ring S pliers SR-2 Removing / Installing Ring spring 19

Removing Ring spring 29

Removing Helical gear 25 from Cam shaft

Disassemble Oil seal 25 and Needle bearing complete from Gear housing

complete

Disassemble Ball bearing 608ZZ from Cam shaft

Installing Helical gear 25 to Cam shaft

Installing Oil seal 25 to Gear housing complete

Installing Oil seal 25 to Gear housing complete

Installing Needle bearing complete to Gear housing complete

Holding Tool holder complete

1R004 Retaining ring S pliers ST-2N

1R022

1R023

Bearing plate for Arbor press

Pipe ring (for Arbor press)

1R033

1R032

Bearing setting plate 10.2

Bearing setting plate 8.2

1R038 Armature holder 32 set for vise

1R164 Ring spring setting tool A

1R165 Ring spring setting tool B

1R212

Tip for Retaining ring pliers Attaching to 1R003 for removing Ring spring 19

1R232 Pipe 30

1R252 Round bar for Arbor 30-100

1R269 Bearing extractor

1R281 Round bar for Arbor 7-50

Removing Striker from Tool holder complete

Removing Ring 8 from Cam shaft

Removing / Installing Retaining ring S-7 from / to Cam shaft

Removing / Installing Ring spring 29 from / to Tool holder complete

1R291 Retaining ring S and R pliers

1R306 Ring spring removing jig

Use for

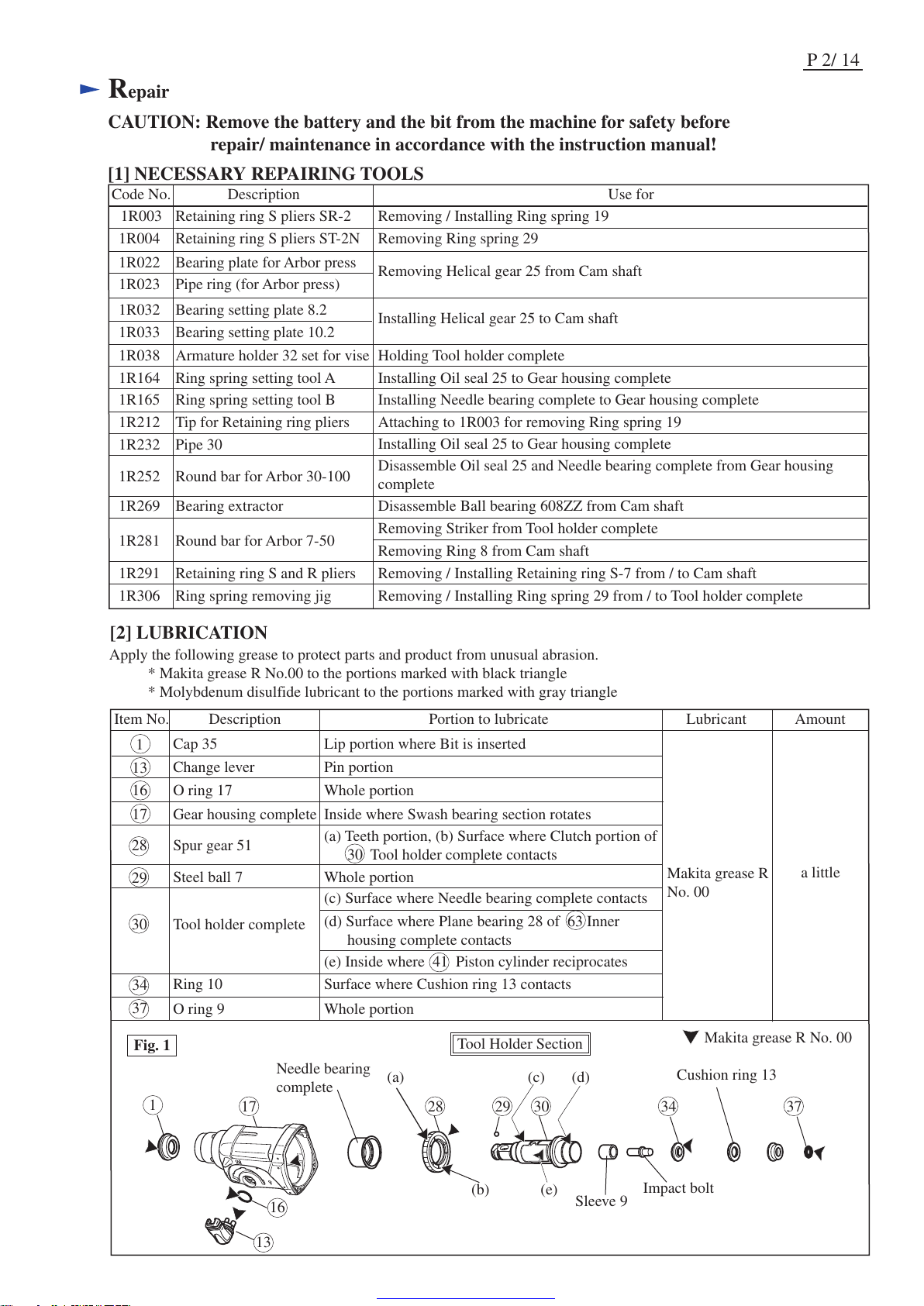

[2] LUBRICATION

Apply the following grease to protect parts and product from unusual abrasion.

* Makita grease R No.00 to the portions marked with black triangle

* Molybdenum disulfide lubricant to the portions marked with gray triangle

Fig. 1

Item No. Description Portion to lubricate Lubricant Amount

a little

1

(a) (c) (d)

(e)

16

17 28

Needle bearing

complete

29 30

13

34 37

Sleeve 9

Impact bolt

Cushion ring 13

(b)

Cap 35

O ring 17

1

16

Change lever

13

Gear housing complete

Spur gear 51

17

28

Steel ball 7

29

Tool holder complete

30

Lip portion where Bit is inserted

Whole portion

Pin portion

Inside where Swash bearing section rotates

(a) Teeth portion, (b) Surface where Clutch portion of

30 Tool holder complete contacts

Whole portion

(c) Surface where Needle bearing complete contacts

(d) Surface where Plane bearing 28 of 63 Inner

housing complete contacts

(e) Inside where 41 Piston cylinder reciprocates

Ring 10

34

O ring 9

Surface where Cushion ring 13 contacts

Whole portion

37

Tool Holder Section

Makita grease R No. 00

Makita grease R

No. 00

Page 3

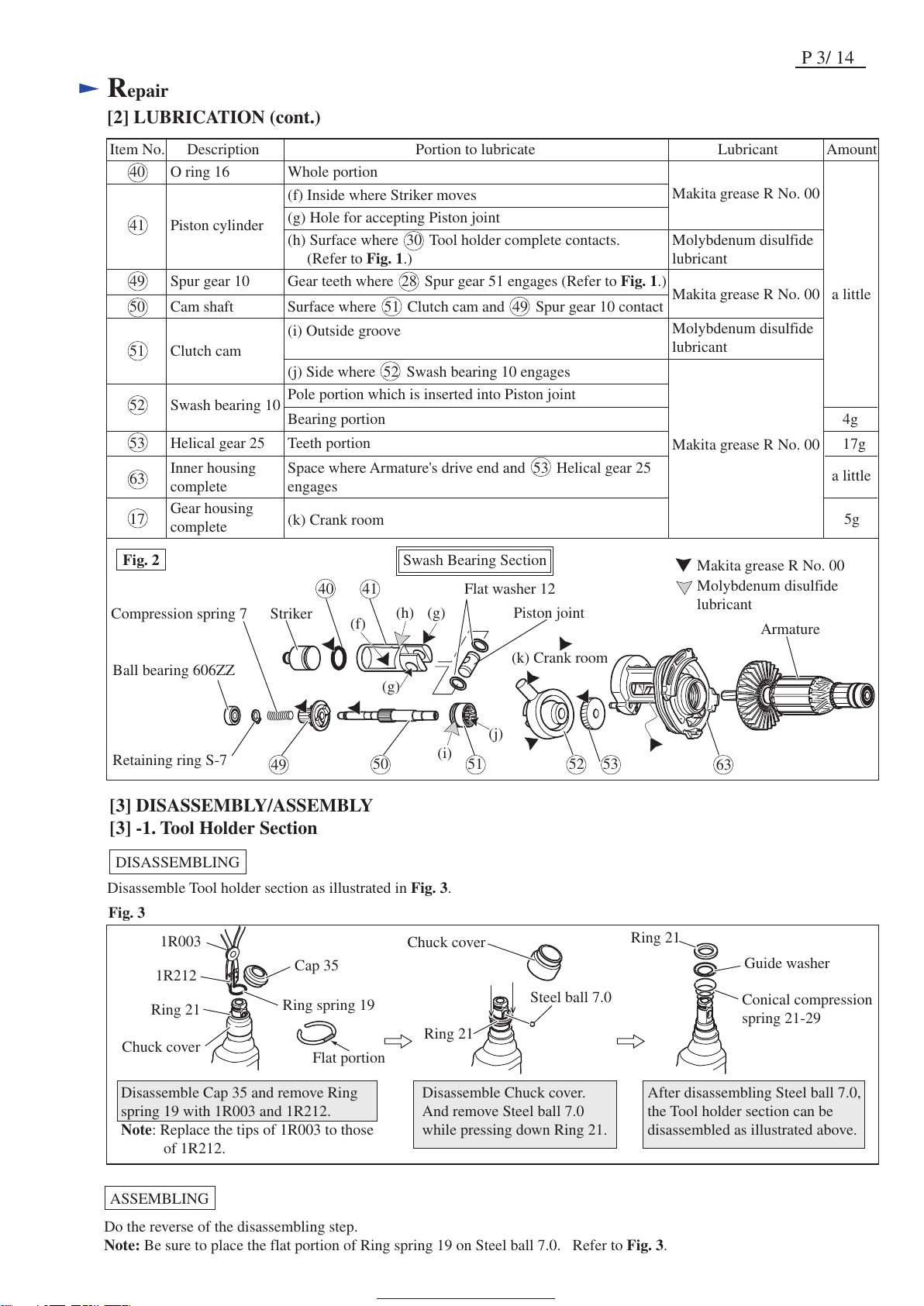

[2] LUBRICATION (cont.)

Repair

P 3/ 14

Fig. 2

Item No. Description Portion to lubricate Lubricant Amount

Striker

Ball bearing 606ZZ

Compression spring 7

Disassemble Tool holder section as illustrated in Fig. 3.

Retaining ring S-7

Piston joint

Armature

Flat washer 12

Swash Bearing Section

40

41

51

52 53

63

(f)

(g)

(h)

(g)

(k) Crank room

(i)

(j)

50

49

51

52

53

63

17

40

41

Clutch cam

Bearing portion

(k) Crank room

4g

17g

Swash bearing 10

Helical gear 25

Gear housing

complete

Inner housing

complete

O ring 16

Piston cylinder

Whole portion

Makita grease R No. 00

Makita grease R No. 00

Makita grease R No. 00

Molybdenum disulfide

lubricant

Molybdenum disulfide

lubricant

Molybdenum disulfide

lubricant

Makita grease R No. 00

a little

a little

5g

Pole portion which is inserted into Piston joint

49 Spur gear 10 Gear teeth where 28 Spur gear 51 engages (Refer to Fig. 1.)

Teeth portion

Space where Armature's drive end and 53 Helical gear 25

engages

(f) Inside where Striker moves

(g) Hole for accepting Piston joint

(h) Surface where 30 Tool holder complete contacts.

(Refer to Fig. 1.)

(i) Outside groove

(j) Side where 52 Swash bearing 10 engages

50 Cam shaft Surface where 51 Clutch cam and 49 Spur gear 10 contact

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Tool Holder Section

DISASSEMBLING

Ring 21

Ring 21

Guide washer

Conical compression

spring 21-29

Cap 35

Steel ball 7.0

Chuck cover

Ring spring 19

Chuck cover

1R003

1R212

Disassemble Cap 35 and remove Ring

spring 19 with 1R003 and 1R212.

Note: Replace the tips of 1R003 to those

of 1R212.

Ring 21

Disassemble Chuck cover.

And remove Steel ball 7.0

while pressing down Ring 21.

After disassembling Steel ball 7.0,

the Tool holder section can be

disassembled as illustrated above.

Fig. 3

ASSEMBLING

Do the reverse of the disassembling step.

Note: Be sure to place the flat portion of Ring spring 19 on Steel ball 7.0. Refer to Fig. 3.

Flat portion

Page 4

Repair

P 4/ 14

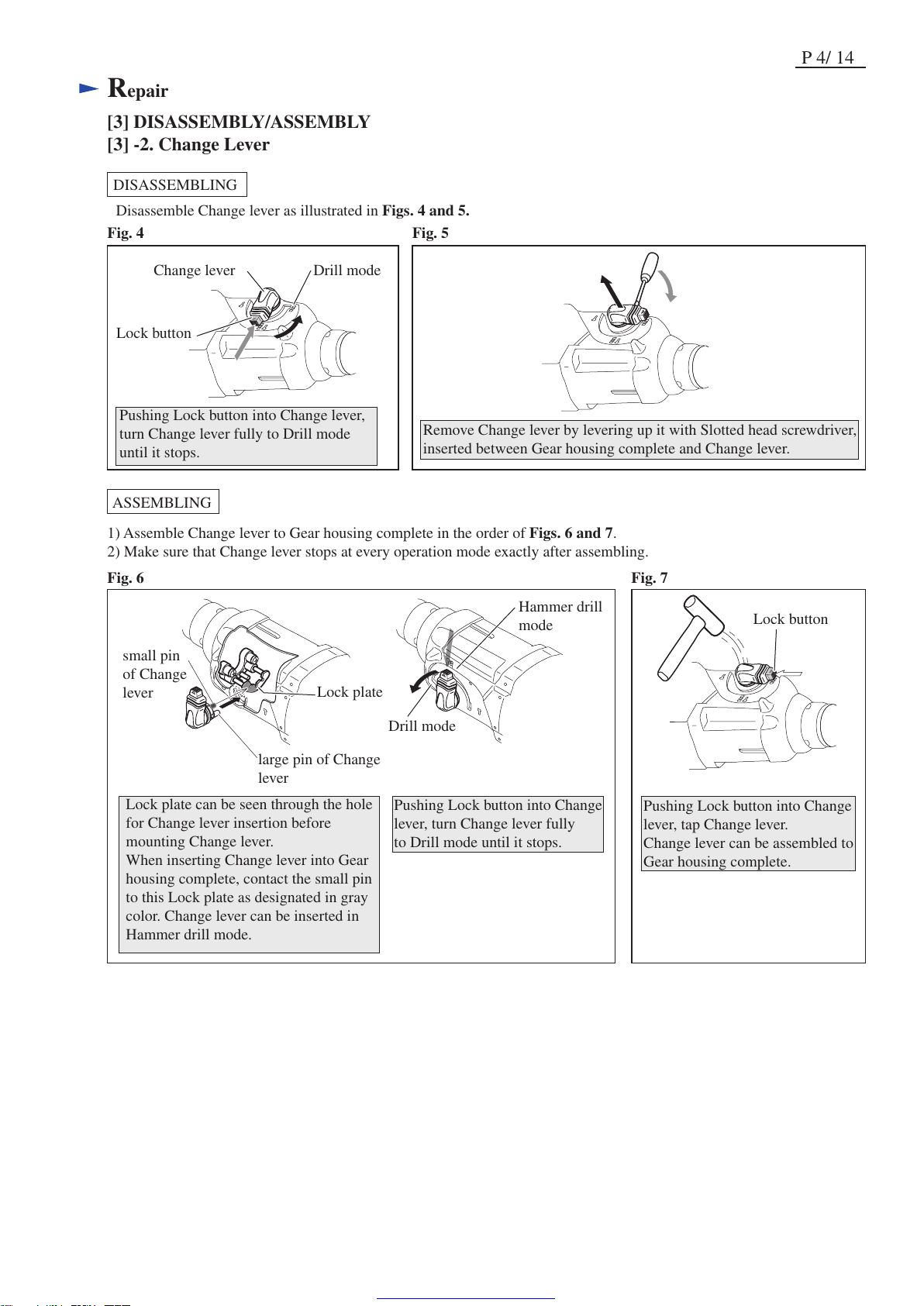

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Change Lever

DISASSEMBLING

ASSEMBLING

Change lever Drill mode

Lock button

Pushing Lock button into Change lever,

turn Change lever fully to Drill mode

until it stops.

Remove Change lever by levering up it with Slotted head screwdriver,

inserted between Gear housing complete and Change lever.

Fig. 4 Fig. 5

Fig. 6 Fig. 7

Disassemble Change lever as illustrated in Figs. 4 and 5.

1) Assemble Change lever to Gear housing complete in the order of Figs. 6 and 7.

2) Make sure that Change lever stops at every operation mode exactly after assembling.

Lock plate

Drill mode

Hammer drill

mode

large pin of Change

lever

small pin

of Change

lever

Lock plate can be seen through the hole

for Change lever insertion before

mounting Change lever.

When inserting Change lever into Gear

housing complete, contact the small pin

to this Lock plate as designated in gray

color. Change lever can be inserted in

Hammer drill mode.

Pushing Lock button into Change

lever, turn Change lever fully

to Drill mode until it stops.

Pushing Lock button into Change

lever, tap Change lever.

Change lever can be assembled to

Gear housing complete.

Lock button

Page 5

Repair

P 5/ 14

bearing room of

Gear housing complete

4x40 Tapping screws (4 pcs.)

Gear housing

complete

Holder cap cover Motor housing

complete

Ball bearing 6000DDW

of Armature (behind the Fan)

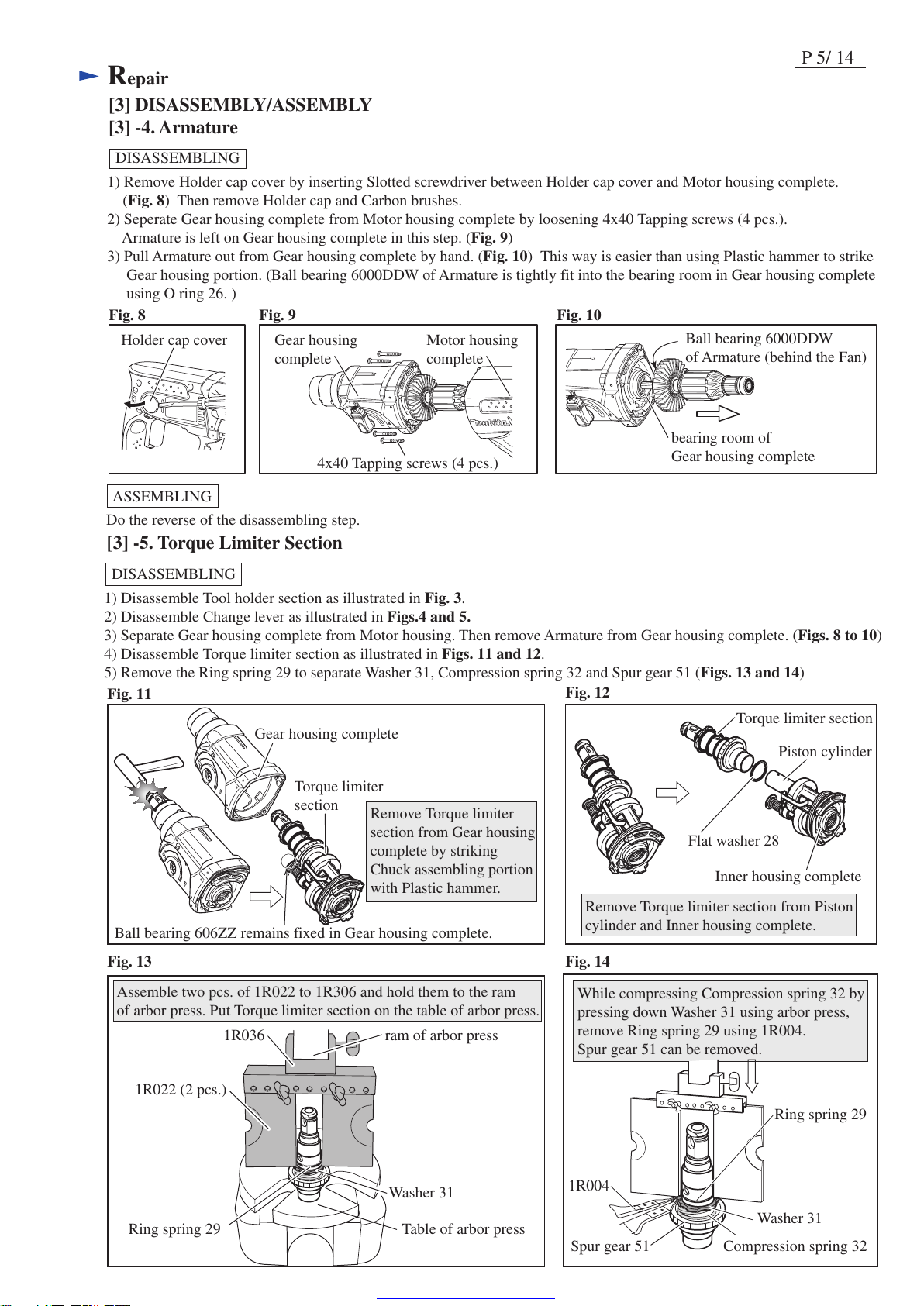

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Armature

1) Remove Holder cap cover by inserting Slotted screwdriver between Holder cap cover and Motor housing complete.

(Fig. 8) Then remove Holder cap and Carbon brushes.

2) Seperate Gear housing complete from Motor housing complete by loosening 4x40 Tapping screws (4 pcs.).

Armature is left on Gear housing complete in this step. (Fig. 9)

3) Pull Armature out from Gear housing complete by hand. (Fig. 10) This way is easier than using Plastic hammer to strike

Gear housing portion. (Ball bearing 6000DDW of Armature is tightly fit into the bearing room in Gear housing complete

using O ring 26. )

Do the reverse of the disassembling step.

DISASSEMBLING

ASSEMBLING

Fig. 10Fig. 9Fig. 8

DISASSEMBLING

Fig. 11

Fig. 12

1) Disassemble Tool holder section as illustrated in Fig. 3.

2) Disassemble Change lever as illustrated in Figs.4 and 5.

3) Separate Gear housing complete from Motor housing. Then remove Armature from Gear housing complete. (Figs. 8 to 10)

4) Disassemble Torque limiter section as illustrated in Figs. 11 and 12.

5) Remove the Ring spring 29 to separate Washer 31, Compression spring 32 and Spur gear 51 (Figs. 13 and 14)

[3] -5. Torque Limiter Section

Remove Torque limiter section from Piston

cylinder and Inner housing complete.

Remove Torque limiter

section from Gear housing

complete by striking

Chuck assembling portion

with Plastic hammer.

Flat washer 28

Piston cylinder

Inner housing complete

Torque limiter section

Gear housing complete

Torque limiter

section

Ball bearing 606ZZ remains fixed in Gear housing complete.

Assemble two pcs. of 1R022 to 1R306 and hold them to the ram

of arbor press. Put Torque limiter section on the table of arbor press.

While compressing Compression spring 32 by

pressing down Washer 31 using arbor press,

remove Ring spring 29 using 1R004.

Spur gear 51 can be removed.

Washer 31

Washer 31

Ring spring 29

Compression spring 32

Ring spring 29

1R004

Table of arbor press

Fig. 13 Fig. 14

1R022 (2 pcs.)

1R036 ram of arbor press

Spur gear 51

Page 6

Repair

P 6/ 14

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Torque Limiter Section (cont.)

ASSEMBLING

Do the reverse of disassembling steps.

Note: Do not forget to assemble Flat washer 28 between Torque limiter section and Inner housing complete. Refer to Fig. 12.

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Needle Bearing Complete and Oil Seal 25

DISASSEMBLING

Applying 1R252, press it with Arbor press.

Needle bearing complete is removed

together with Oil seal 25 from Gear

housing complete.

1R252

1R252

Oil seal 25

Needle bearing

complete

Fig. 16

Fig. 15

1) Disassemble Torque limiter section and Inner housing complete from Gear housing complete.

See Disassembly of [3] -5. Torque Limiter Section.

2) Insert Inner housing complete into Gear housing complete. (Fig. 15)

3) Remove Needle bearing complete and Oil seal 25. (Fig. 16)

Inner housing complete

Gear housing complete

As the side for joining to Motor

housing is not flat, Gear housing

complete can not stand vertically

without support.

Therefore, insert Inner housing

complete into Gear housing

complete as a support.

ASSEMBLING

Fig. 20

Fig. 19

1) Assemble Oil seal 25 to Gear housing complete in the order of Figs. 17 and 18.

2) Assemble Needle bearing complete as illustrated in Figs. 19 and 20.

1R164

1R164

1R164

outer diameter: 30mm

outer diameter: 34mm

1R232

Oil seal 25

With 1R232 and arbor press, insert Oil seal 25 until it stops.

Oil seal 25 is not yet inserted completely in this step,

because the outer diameter of 1R232 is bigger than that of

Oil seal setting hole.

The initial position of Oil seal 25

Oil seal 25

The diameter of Oil seal 25 setting

hole is less than 36mm.

outer diameter: 36mm

back side

Gear housing complete

belly side

Needle bearing complete

Press Needle bearing with

arbor press and the outer

diameter 34mm end

surface of 1R164 until

Needle bearing complete

stops.

Fig. 17 Fig. 18

Face the flat portion of Needle bearing complete to

the belly side of Gear housing complete.

Needle bearing complete

flat portion

Press Oil seal 25 to the initial position with arbor press

and the outer diameter 34mm end surface of 1R164.

Page 7

Repair

P 7/ 14

DISASSEMBLI NG

1) Referring to "[3] -5. Torque Limiter Section", disassemble Ring spring 29, Washer 31, Compression spring 32

and Spur gear 51 from Tool holder complete. Refer to Figs. 11 to 14.

2) Holding Gear housing complete in vise and 1R038, Tap Ring spring 28 in Tool holder complete as illustrated in Figs. 21

and 22.

3) Remove Ring spring 28 from Tool holder complete and disassemble Impact bolt section. (Figs. 23 to 24)

Ring spring 28

Ring spring 28 can be pulled off from Tool holder

complete when completely removed from the

groove.

Disassemble Impact bolt

section by striking Tool

holder complete against

workbench.

Note: Be sure to replace Ring spring 28

when assembling Tool holder section.

Fig. 23

Fig. 24

Tool holder

complete

Sleeve 9

Impact bolt

Ring 10

Cushion ring 13

O ring case

Impact bolt section

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Impact Bolt Section

Fig. 22

Fig. 21

end of Ring spring 28 Ring spring 28

When the end of Ring spring

28 is in the hole of Tool holder

complete, slide the end to the

blind side using a slotted

screwdriver.

Ring spring 28

1R038

Vise

Tap Ring spring 28 from

the two holes alternately

to push downward.

Tool holder

complete

ASSEMBLING

Fig. 25 Fig. 26 Fig. 27

Fig. 28

Tool holder

complete

1) Referring to Figs. 25, 26 and 27 assemble the Impact bolt section to Tool holder complete as illustrated in Fig. 28.

O Ring 9

O ring 9

O ring case

Note: Make sure O ring 9

is mounted to O ring

case in advance.

Note: Do not put the end of the ring spring 28 into

the two holes on Tool holder complete.

end of

Ring spring 28

hole

Correct

Wrong

Ring 10

Sleeve 9 Impact bolt

O ring case Ring spring 28

Cushion ring 13

15.5mm20mm

Note: This end has to be inserted

into Sleeve 9.

Incorrect assembling causes

trouble in hammering.

Impact bolt

Impact Bolt Section

assembled in Tool holder

complete

Page 8

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Impact Bolt Section (cont.)

DISASSEMBLING

ASSEMBLING

Fig. 29

Note: Use an extra Piston cylinder as a jig. Never use Piston cylinder that is to be

assembled to the machine.

2) Push Ring spring 28 with Piston cylinder until it fits to the inner groove of Tool holder complete. (Fig. 29)

1) Disassemble Tool holder section as illustrated in Fig. 3.

2) Disassemble Change lever as illustrated in Figs. 4 and 5.

3) Separate Gear housing complete from Motor housing complete. And then, remove Armature from Gear housing complete.

(Refer to Figs. 8 to 10.)

4) Remove Stop ring E-4, Flat washer 5 and Compression spring 6 from pin of Inner housing complete. (Fig. 30)

5) Remove two M4x12 Hex socket bolts that fasten Bearing retainer to Inner housing complete. (Fig. 31)

[3] -8. Swash Bearing Section

Flat washer 5

Stop ring E-4

Compression spring 6

Change plate

Pin of Inner housing complete

M4x12 Hex socket

head bolt (2 pcs.)

Fig. 30 Fig. 31

Repair

P 8/ 14

Piston cylinder

as a repairing jig

Piston cylinder

as a repairing jig

Tool holder

complete

Ring spring 28

Inner groove of

Tool holder complete

Ring spring 28

O ring case

Page 9

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Swash Bearing Section (cont.)

DISASSEMBLING

Fig. 32 Fig. 33

6) Move Piston cylinder to the rear dead center position (Fig. 32).

7) Remove Swash bearing section from Inner housing by pulling in the direction of the arrow. Then, remove Change plate

from the groove of Clutch cam. (Fig. 33).

Piston

cylinder

Swash bearing section

Piston cylinder

in the rear dead center position

Swash bearing section Inner housing complete

Change plate

Change plate

Clutch cam

Repair

P 9/ 14

8) Remove Ball bearing 606ZZ from Gear housing complete using the removed Swash bearing section as a jig as follows;

* Insert Cam shaft of Swash bearing section into the Ball bearing again.

* Tilt the Ball bearing a little bit by moving Swash bearing section as illustrated to left in Fig. 34.

* Ball bearing 606ZZ can now be removed by lightly tapping the edge of Gear housing complete with plastic

hammer as illustrated to right in Fig. 34.

Fig. 34

Swash bearing section

used as a jig

Ball bearing 606ZZ

Gear housing

complete

9) Remove Ring 8 using 1R022, 1R023, 1R281 and arbor press as illustrated in Fig. 35.

10) Remove Ball bearing 608ZZ using 1R269. Flat washer 8 and Bearing retainer can now be removed by hand. (Fig. 36)

Fig. 36Fig. 35

Ring 8

Ball bearing 608ZZ

Ball bearing

608ZZ

1R269

Ring 8

1R023

1R281

Bearing retainer

Flat washer 8

1R022

1R022

Page 10

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Swash Bearing Section (cont.)

DISASSEMBLING

ASSEMBLING

1R032 1R033

Fig. 39

Swash

bearing 10

Helical gear 26

Retaining ring S-7

Compression spring 7

Spur gear 10

Cam shaft

Cam shaft

Clutch cam

1) Assemble Swash bearing section using 1R032, 1R033, 1R291 and arbor press as illustrated in Fig. 39.

Note: Be sure to put Flat washer 8 in place, or else Bearing retainer will be clamped between Ball bearing 608ZZ

and Helical gear 26.

Repair

P 10/ 14

11) Remove Helical gear 26 using 1R022, 1R023 and 1R281.

as illustrated to left in Fig. 37. Swash bearing 10 and Clutch cam can now be removed by hand (right in Fig. 37).

12) Remove Retaining ring S-7 using 1R291 (left in Fig. 38). Compression spring 7 and Spur gear 10 can now be removed

by hand. (right in Fig. 38).

Fig. 38

Fig. 37

Swash

bearing 10

Clutch cam

Retaining

ring S-7

Compression

spring 7

Spur gear 10

Cam shaft

Helical gear 26

1R023

1R281

1R022

1R291

Ring 8

Flat washer 8

Ball bearing

608ZZ

Bearing retainer

Page 11

[[3] DISASSEMBLY/ASSEMBLY

[3] -8. Swash Bearing Section (cont.)

Repair

ASSEMBLING

P 11/ 14

4) Move Piston cylinder to the rear dead center position. (Fig. 42)

5) Insert the pole of Swash bearing 10 into the hole of Piston joint as illustrated in Fig. 43.

6) Insert Ring 8 (the end of Swash bearing section) into Inner housing complete. (Fig. 44)

7) Fitting the tip of Change plate in the groove on Clutch cam, insert Change plate over the pins of Inner housing complete.

(Fig. 45)

Note: Ball bearing 608ZZ of Swash bearing section is not yet inserted into Inner housing complete in this step.

Fig. 44

Fig. 45

Fig. 42 Fig. 43

Piston cylinder at

rear dead center

position

Front Rear

Piston cylinder

Tilt Swash bearing 10 to insert the pole.

hole of Piston joint

tip of Clutch cam

Swash bearing section Ring 8

Clutch cam

groove

Inner housing complete pins of Inner housing complete

Ball bearing

608ZZ

Change plate

Piston joint

hole for the pole of

Swash bearing 10

Flat

washer 12

Flat

washer 12

Fig. 40 Fig. 41

2) Assemble Piston joint and two Flat washers 12 to Piston cylinder as illustrated in Fig. 40.

Note: Do not forget to apply Makita grease R No.00. Refer to Fig. 2.

3) Insert Piston cylinder into Inner housing complete. (Fig. 41).

Flat washer 12

Flat washer 12

Piston joint

Piston cylinder

Inner housing

Correct Wrong

pole of Swash

bearing 10

Ring 8

Ball bearing 608ZZ

M4x12 Hex socket head bolt ( 2 pcs.)

(with threadlocker coated)

Note: If reusing M4x12 hex.

socket head bolts, be sure

to apply ThreeBond 1321B

or 1342, or Loctite 242

to the threads before

fastening.

Stop ring E-4

Upper pin of

Inner housing complete

Flat washer 5 Compression spring 5

8) Insert Ball bearing 608ZZ of Swash bearing section into Inner housing complete, and fasten Swash bearing section to

Inner housing complete with two M4x12 hex socket head bolts. Then, put Compression spring 6 and Flat washer 5

through the upper pin of Inner housing complete, and secure them with Stop ring E-4 (Fig. 46)

Fig. 46

Ball bearing 608ZZ Ring 8

Page 12

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-9. F/R change lever, Wave washer, Cushion and Rubber pin 5 in Housing set

ASSEMBLING

Refer to Fig. 47.

Fig. 47

Fit the protrusion of Switch into Oval hole of F/R

change lever and assemble them to Housing L.

protrusion of

Switch

oval hole of

F/R change

lever

Wave washer 15

Do not forget to put Wave

washer 15 in place for

holding Ball bearing

607DDW on the commutator

end of Armature.

P 12/ 14

Housing set (L)

Battery housing set (L)

Terminal

Pass Pin 1.5 through Rubber pin 5.

And then, assemble them to Battery

housing set (L) as illustrated right.

Assemble Cushion to Battery

housing set (L) at the rear side of

Terminal.as illustrated above.

Pin 1.5

Rubber pin 5

Page 13

P 13/ 14

Maintenance program

It is recommended to replace the following parts shown below and apply lubricant to the specific parts designated in

Figs.2 and 3 when replacing Carbon brushes.

1 Cap 35

29 Steel

ball 7.0

40 O ring 16

Circuit diagram

Fig. D-1

Color index of lead wires' sheath

Black

Red

Blue

Yellow

Housing (L)

Side

Housing (R)

Side

Switch

35 Cushion

ring 13

37 O ring 9

Housing (L)

Side

Housing (R)

Side

38 Ring spring

28

Brush holder (L)

Yoke unit

Brush holder (R)

Heat sink

Housing (L)

Side

Terminal

Housing (R)

Side

Tape for

binding

Lead wires

FET

Page 14

Wiring diagram

Fig. D-2

Connecting terminal

Housing set (L)

P 14/ 14

Switch

Bend Connecting terminal to Housing set (L) side as

illustrated above.

Switch

Put the extra portion

of Lead wires in this

area.

Fix the Brush holder’s Lead wires

(red and black) with Lead wire holder.

Yoke unit

Heat sink

FET

Brush holder

Rib A

Route all of the FET lead wires

on the right side of Rib A.

Terminal

Fix the FET Lead wires

with Lead wire holder.

Loading...

Loading...