Makita Construction Coil Nailer AN621 Instruction Manual

Construction Coil Nailer

0.44 - 0.83

MPa

I65 - 120

PSIG)

MODEL

AN621

200, 250, 300

pcs.

45

mm,

50 mm, 57 mm, 65 mm

11-3/4",

2".

2-114". 2-112")

INSTRUCTION MANUAL

SPECIFICATIONS

Air

pressure

I

Applicable length

I

Nail capacity

Min.

hose diameter

I

Dimensions

IL

x

W

x

H)

I

Net weight

6,5

mm

1114,,)

I

310

mm

x

133

mm

x

305

mm

(12.3/16" x 5.1/4" x 12")

I

kg

16''

Ibs)

*

Manufacturer reserves the right to change specifications without notice.

Note: Specifications may differ from country to country.

WARNING: For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS

FOR

FUTURE REFERENCE.

IMPORTANT

SAFETY INSTRUCTIONS

WARNING:

WHEN USING THIS TOOL, BASIC SAFETY PRECAUTIONS

SHOULD ALWAYS BE FOLLOWED

TO

REDUCE THE

RISK

OF PERSONAL

INJURY, INCLUDING THE FOLLOWING:

READ ALL INSTRUCTIONS.

For personal safety and proper operation

and maintenance of the

tool,

read this

instruction manual carefully before using

the tool.

Always wear safety glasses to protect your

eyes from dust or nail injury. The safety

glasses should conform with the requirements of ANSI 287.

1

-

1979.

WARNING:

n

It

is an employer’s responsibility to enforce

the use of safety eye protection equipment

by the tool operators and by other persons

in the immediate working area.

Wear hearing protection to protect your

ing. Sleeves should be buttoned or rolled

up. No necktie should be worn.

ears against exhaust noise and head pro-

~

protection

tection.

Also

wear light but not loose cloth-

v-,,

Hearing

protection

Rushing the job or forclng the tool is dangerous. Handle the tool carefully.

Do

not

operate when under the influence of alcohol, drugs or the like.

2

General

Tool

Handling Guidelines:

1.

Always assume that the tool contains fasteners.

2.

Do

not point the tool toward yourself or anyone whether it contains fasteners or not.

3.

Do

not actuate the tool unless the tool is placed firmly against the workpiece.

4.

Respect the tool as a working implement.

5.

No horseplay.

6.

Do

not hold or carry the tool with a finger on the trigger.

7.

Do

not load the tool with fasteners when any one of the operating controls is

8.

Do

not operate the tool with any power source other than that specified in the

activated.

tool operatingkafety instructions.

An improperly functioning tool must not be

used.

Sparks sometimes fly when the tool is

used. Do not use the tool near volatile,

flammable materials such as gasoline, thinner, paint, gas, adhesives, etc.; they will

ignite and explode, causing serious injury.

The area should be sufficiently illuminated

to assure safe operations.

The area should be clear and litter- free. Be

especially careful to maintain good footing

and balance.

3

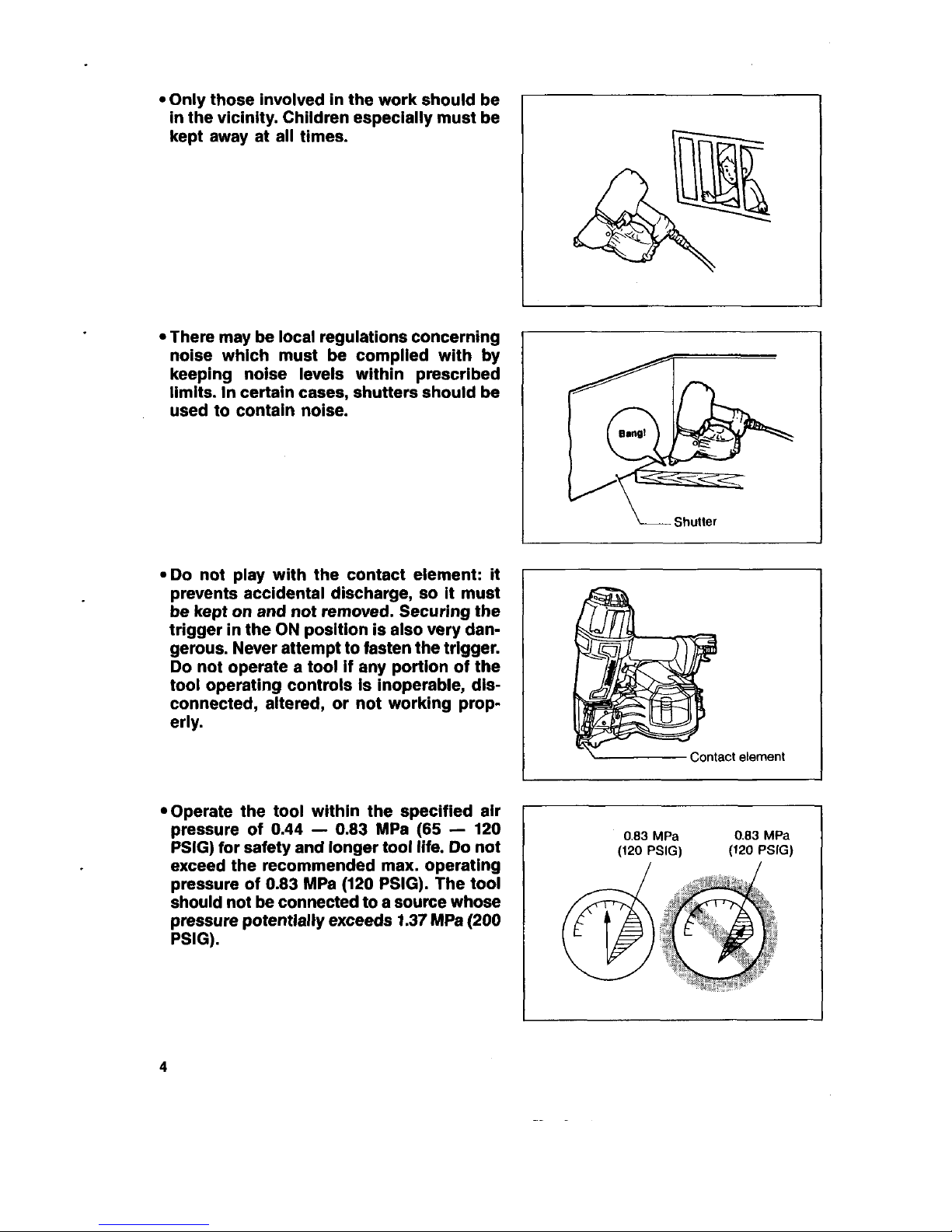

Only those involved in the work should be

in

the vicinity. Children especially must be

kept away at all times.

There may be local regulations concerning

noise which must be complied with by

keeping noise levels within prescribed

limits.

In

certain cases, shutters should be

used to contain noise.

*Do

not play with the contact element:

it

prevents accidental discharge,

so

it must

be kept on

and

not removed. Securing the

trigger in the

ON

position is also very dangerous. Never attempt to fasten the trigger.

Do

not operate a tool if any portion of the

tool

operating controls is inoperable,

dis-

connected, altered, or not working properly.

Operate the tool within the specified air

pressure of

0.44

-

0.83

MPa

(65

-

120

PSIG) for safety and longer tool life.

Do

not

exceed the recommended max. operating

pressure of

0.83

MPa

(120

PSIG). The tool

should not be connected to a source whose

pressure potentlally exceeds

1.37

MPa

(200

PSIG).

Shutter

I

-~

Contact element

0.83

MPa

0.83

MPa

(120

PSIG)

(120

PSIG)

4

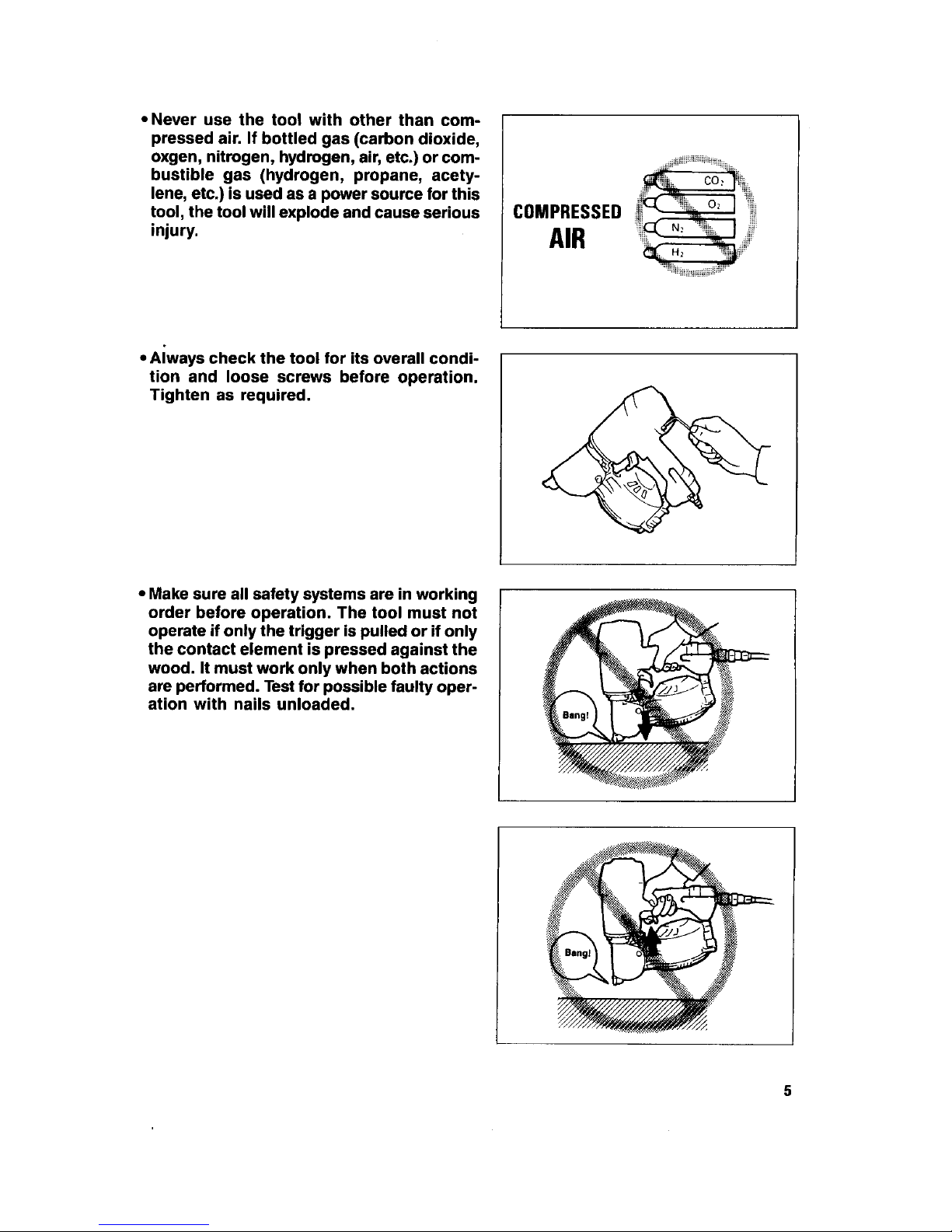

*Never use the tool with other than com-

pressed air. If bottled gas (carbon dioxide,

oxgen, nitrogen, hydrogen, air, etc.) or combustible gas (hydrogen, propane, acetylene, etc.)

is

used as a power source for this

tool, the tool will explode and cause serious

injury.

Always check the tool for its overall condition and loose screws before operation.

Tighten as required.

Make sure all safety systems are

in

working

order before operation. The tool must not

operate if only the trigger

is

pulled or if only

the contact element is pressed against the

wood.

It

must work only when both actions

are performed. Test for possible faulty operation with nails unloaded.

COMPRESSED

AIR

5

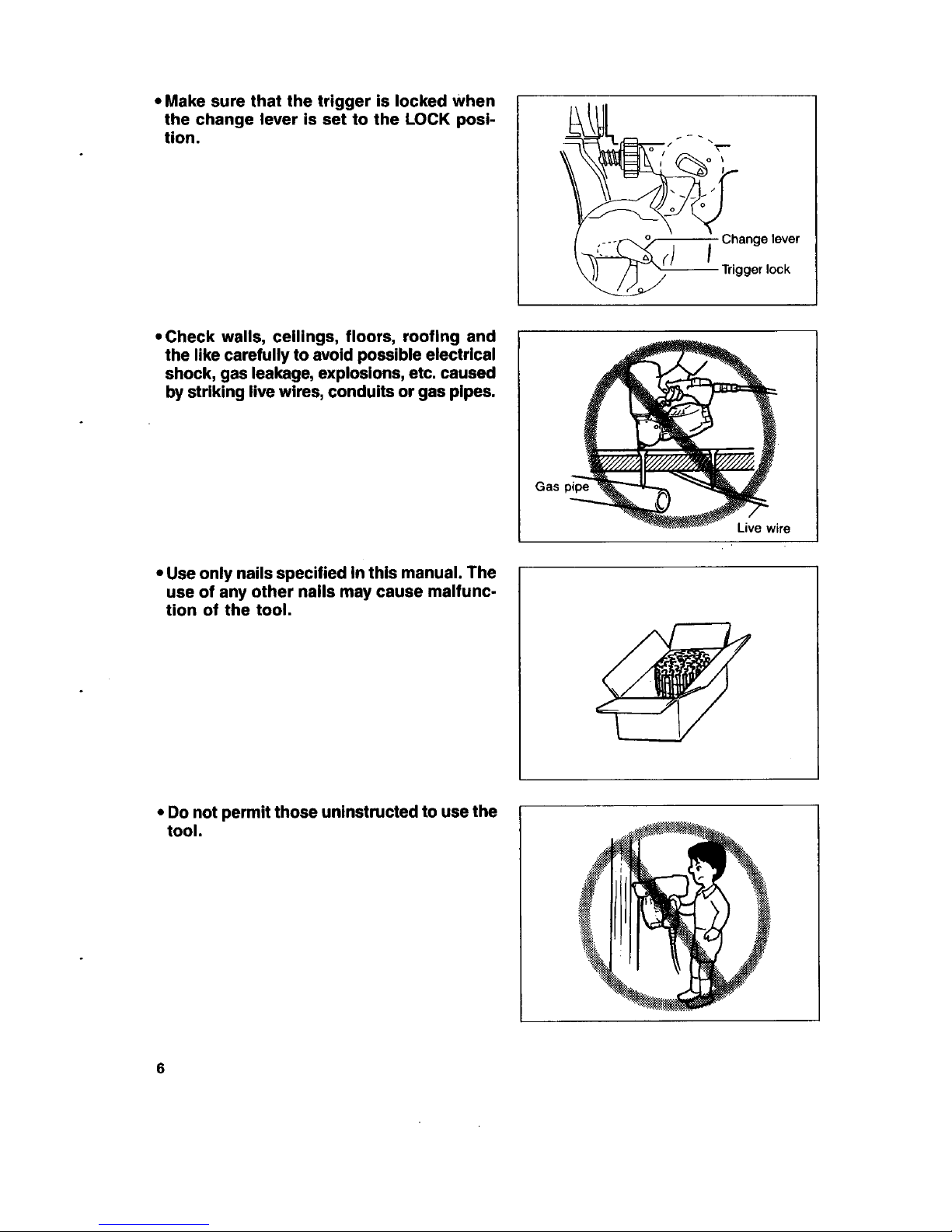

Make sure that the trigger is locked when

the change lever is set to the LOCK position.

Change

lever

Trigger

lock

Check walls, ceilings, floors, roofing and

the like carefully to avoid possible electrical

shock, gas leakage, explosions, etc. caused

by striking live wires, conduits or gas pipes.

Use only nails specified

in

this manual. The

use of any other nails may cause malfunc-

tion of the tool.

6

Loading...

Loading...