Page 1

Chain Saw

Safety Instructions

Maintenance

Information

Page 2

Checking the safety chain brake

Checking the chain lubrication

6

M

Do not work with the saw without first checking the chain

brake!

- Start the engine as described (make sure you have a good

footing, and place the saw on the ground in such a way that

the blade is free of contact).

- Grasp the tubular handle

grip with the other.

- With the engine running at moderate speed, press the hand

guard (C/1) in the direction of the arrow

hand until the chain brake engages. The chain should stop

immediately.

- Immediately release the throttle and release the chain

brake.

IMPORTANT: If the chain does not stop immediately when

you test the chain brake, do NOT use the saw! Take the saw

to a MAKITA service center.

firmly with one hand and hold the

with the back of your

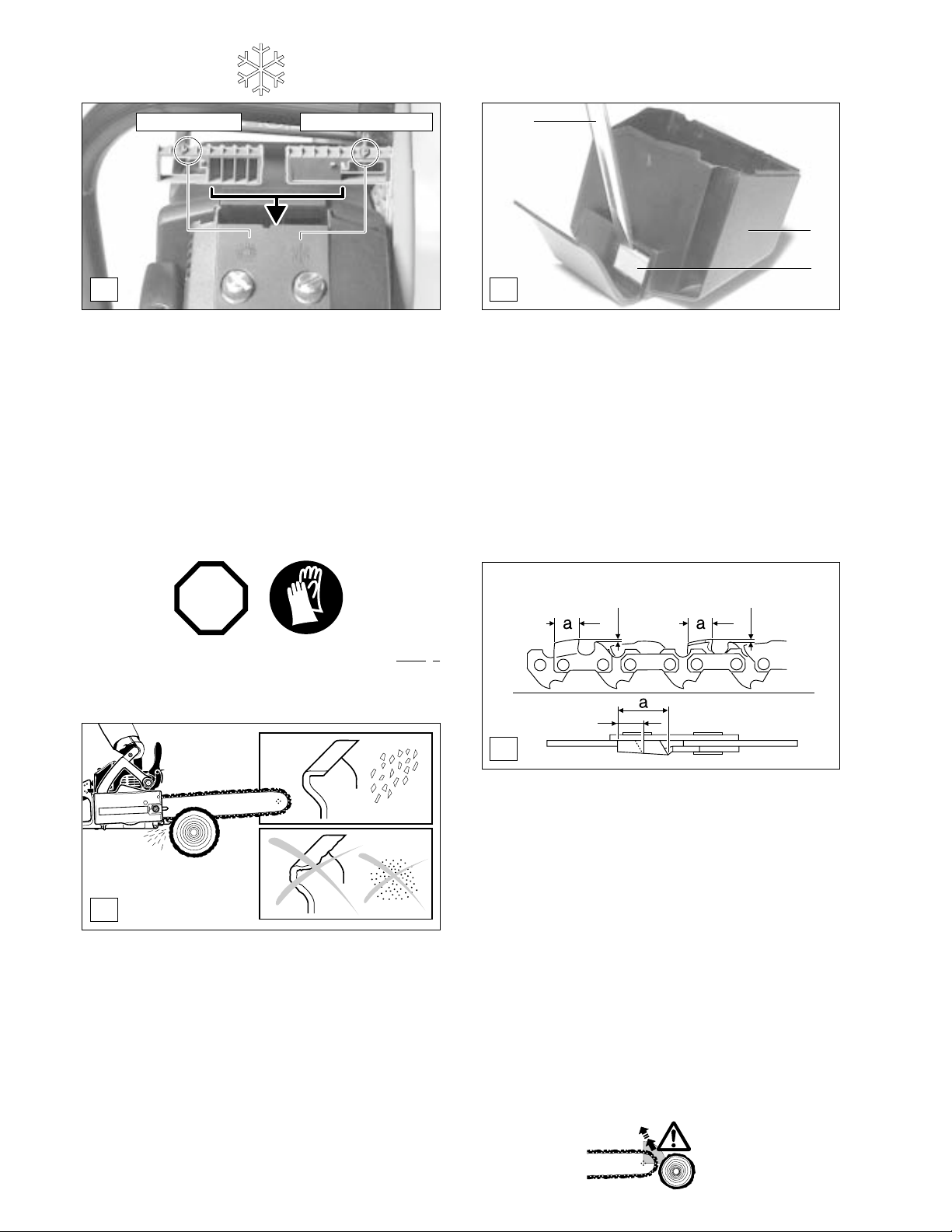

Adjusting the carburetor

CAUTION:

Optimum perfornance can only be achieved if the carbure-

tor is adjusted correctly. For this work, which should be

carried out by an expert, the engine must be warmed up for

a period of 3-5 min. and the air filter must be clean.

The carburetor has been adjusted by MAKITA on the basis of

atmosheric pressure conditions at sea level. Other atmospheric pressure conditions or the running-in process of a new

engine may require readjustment of the carburetor.

It is urgently recommended to use a revolution indicator (O/1)

(order number 950 233 210) in order to achieve a correct

adjustment of the carburetor. Adjust the carburetor using a 4

mm screwdriver.

The screwdriver shown (O/2) (order number 944 340 001) has

a molded-on lug to assist in adjustment.

For adjusting the carburetor correctly the following steps

must be carried out:

1. Warm up engine

2. Switch off engine

3. Basic adjustment

4. Start engine

5. Set idle speed

6. Adjust speed

7. Check idling speed

8. Check acceleration

9. Check max. speed or output

10. Repeat adjustment procedure starting with step 5, until

idling speed, max. speed and acceleration are reached

with the adjustment made.

2

1

STOP

N

Never work with the chain saw withoute sufficient chain lubrication. Otherwise the service life of the chain and guide bar will be

reduced.

Before starting work check the oil level in the tank and the oil feed.

Check the oil feed rate as described below:

- Start the chain saw.

- Hold the running chain saw approx. 15 cm above a trunk or

the ground (use an appropriate base).

If the lubrication is sufficient, you will see a light oil trace because

oil will be flung off the sawing device.

3

2

O

Basic adjustment (step 3)

- First, carefully turn the 2 adjusting screws for the main jet

(O/3) and the idle jet (O/4) to the right (clockwise) until you

feel them stop.

- Now turn both screws one turn to the left (counter-clockwise).

Set idle speed (step 5)

- If the chain turns when the engine is idling, unscrew the

throttle-valve stop screw (O/speed) until the chain stops. If

the engine runs unevenly, screw the screw (O/speed) back

in.

- Idling speed should be 2,600 rpm.

Adjust speed (output) (step 6)

- Adjust the speed by adjusting the main jet screw (O/3) to

11,500 rpm (DCS 340, 341), 12,000 rpm (DCS 400, 401).

Check idle speed (item 7)

- After having adjusted the max. speed ensure the idle speed

is set to 2,600 1rpm. (the chain must not turn). Use the idle

jet screw (O/4) to regulate it. Turn in the screw (O/4) to speed

up, and turn out the screw (O/4) to speed down the engine.

Check acceleration (item 8)

- Now check the acceleration, i. e. the time necessary for

speeding up from idle speed to max. speed. To do this,

press the throttle lever hard.

- If the acceleration is too low, turn out the idle jet screw

(O/4) approx. 1/8 rotation.

Do not run the engine without load a high speed, open

throttle fully only, if you are sawing!

speed

1

4

STOP

2

1

23

Page 3

Working in winter

normal operation

A

In order to prevent carburetor icing in conditions of low temperature combined with high humidity, and in order to get up to

operating temperature faster in subfreezing temperatures,

heated air can be taken from the cylinder (marking (circled) on

insert in "snowflake" position).

At temperatures above freezing the carburetor must NOT be

fed heated air (marking (circled) on insert in "sun" position).

Failure to follow these instructions can lead to damage

to the cylinder and piston!

subfreezing operation

MAINTENANCE

Sharpening the saw chain

2

1

3

B

- Remove the filter cover (B/1).

- Position the universal wrench (B/2) as shown above and

push the insert (B/3) out by tapping the wrench.

- Put the insert (B/3) back in in the appropriate position, i.e. with

the marking next to the sun symbol for normal operation or

the snowflake symbol for subfreezing operation.

- Replace filter cover (B/1).

STOP

CAUTION:

Before doing any work on the guide bar or chain,

switch off the engine and pull the plug cap off the

spark plug (see "Replacing the spark plug"). Always wear

protective gloves!

always

✓

✓

C

The chain needs sharpening when:

- The sawdust produced when sawing damp wood looks

like wood flour.

- The chain penetrates the wood only under great pressure.

- The cutting edge is visibly damaged.

- The saw is pulled to the left or right when sawing. This is

caused by uneven sharpening of the chain.

Important: Sharpen frequently, but without removing

too much metal!

Generally, 2 or 3 strokes of the file will be enough.

Have the chain resharpened at a service center when you

have already sharpened it yourself several times.

0.65 mm

(.025")

0.65 mm

(.025")

min.

3 mm (0.11”)

D

Proper sharpening:

CAUTION:

Use only chains and guide bars designed for this saw (see

the Extract from the spare-parts list)!

- All cutters must be of the same length (dimension a).

Cutters with different lengths result in rough running of the

chain and can cause cracks in the chain.

- Minimum cutter length is 0.11" (3 mm). Do not resharpen

the chain when the minimum cutter length has been

reached; at this point, the chain must be replaced (see the

Extract from the spare-parts list and "Replacing the chain").

- The depth of the cut is determined by the difference in

height between the depth limiter (round nose) and the

cutting edge.

- The best results are obtained with a depth-limiter depth

of 0.65 mm (.025").

CAUTION:

Excessive depth increases the risk of kickback!

24

Page 4

E

F

- All cutters must be sharpened to the same angle, 30°.

Different angles result in a roughly, irregularly running

chain, increase wear and tear and cause chain breakage.

- The 85° front rake of the cutter results from the cut depth

of the round file. If the proper file is used in the right manner,

the correct front rake will be obtained automatically.

4/5

30°

G

- The file holder makes file guidance easier. It is marked for

the correct 30° sharpening angle (keep the marks parallel

with the chain when filing, see illustration) and limits the cut

depth to the correct 4/5 of the file diameter. See "Accessories" for the order number.

Files and how to work with them

- Use a special round file for chains (dia. 4 mm) for sharpening the chain. Normal round files are not appropriate for

this work. See "Accessories" for the order number.

- The file should cut only when pushed forwards (arrow).

Lift the file when leading it backwards.

- First sharpen the shortest cutter. The length of this cutter

is then the standerd for all other cutters of the chain.

o

- Always guide the file horizontally (90

H

- After having sharpened the chain, the height of the depth

limiter must be checked by means of a chain gauge. See

"Accessories" for the order number.

- Correct even the smallest excess height with a special flat

file (H). See "Accessories" for the order number.

- Round off the front of the depth limiter (I).

to the guide bar).

I

Cleaning the guide bar,

lubricating the sprocket nose

CAUTION:

Protective gloves must be worn.

J

Regularly inspect the bearing surfaces of the guide bar for

damage, and clean them with a suitable tool.

If the saw is used intensively it will be necessary to lubricate

the return sprocket bearings regularly (once a week). To do

this, first

bar, and then press in a small amount of multi-purpose grease.

Multi-purpose grease and grease guns are available as

accessories.

Multi-purpose grease (order no. 944 360 000)

Grease gun (order no. 944 350 000)

thoroughly clean the 2 mm hole at the tip of the guide

25

Page 5

Cleaning the brake band and sprocket interior

Replacing the saw chain

STOP

6

7

A

CAUTION: Before doing any work on the guide bar or

CAUTION: Start the chain saw only after having assem-

- Remove the sprocket guard (A/1) (See "PUTTING INTO

OPERATION" figs. A and B).

- Turn the chain tightener screw (A/2) to the left (counterclockwise) until you feel resistance.

- Remove the chain (A/3) and guide bar (A/4).

- Clean the interior with a brush, in particular the brakeband

area (A/5).

NOTE:

Make sure that no residue or contaminants remain in the oil

guide groove (A/6) and the chain tightener (A/7).

- For replacing the guide bar, chain, and sprocket see

"PUTTING INTO OPERATION".

NOTE:

The chain brake is a very important safety device and like

any other component subject to normal wear and tear.

Regular inspection and maintenance are important for your

own safety and must be done by a MAKITA service center.

5

chain,

always switch off the engine and pull

the plug cap off the spark plug (see "Replacing

the spark plug"). Always wear protective gloves!

bled it completely and inspected!

1

2

3

4

CAUTION:

Use only chains and guide bars designed for this saw (see

the Extract from the spare-parts list)!

1

C

Check the sprocket (C/1) before mounting a new chain.

The sprocket is located underneath the clutch drum (C/2).

CAUTION:

Worn out sprockets (D) may damage the new chain and must

therefore be replaced.

Do not attempt to replace the sprocket yourself. Sprocket

replacement requires special training and tools and must be

done at a MAKITA service center.

2

D

Replacing / cleaning the spark arrester screen

2

4

3

5

6

E

1

Replacing the suction head

1

B

The felt filter (B/1) of the suction head can become clogged. It

is recommended to replace the suction head once every three

months in order to ensure unimpeded fuel flow to the carburetor. To remove the suction head for replacement, pull it

out through the tank filler neck using a piece of wire bent at

one end to form a hook.

26

The spark arrester screen should be checked and cleaned

regularly.

- Unscrew the muffler bolts (E/1) and remove the protective

screen (E/2).

- Carefully remove the muffler (E/3).

NOTE: If the muffler gasket (E/4) is damaged, replace it.

- Unscrew bolt (E/6) and remove the spark arrester screen

(E/5).

CAUTION:

Do not use sharp or pointed objects for screen cleaning.

Damaged or misformed screen wires may result.

- Reassemble the spark arrester screen (E/5) and tighten the

screw (E/6).

- Tighten muffler bolts (E/1) to 5.6

+0.07

ft. lbs. (8.0

+0.1

Nm).

Page 6

Cleaning the air filter

E

1

3

2

STOP

F

- Remove the filter cover (E/1) (2 screws).

CAUTION:

Press the choke (E/2) up to shut the choke valve and to prevent

dirt particles from entering the carburetor.

- Pull the air filter (E/3) off the carburetor.

- Cover the carburetor with a clean cloth.

Replacing the spark plug

STOP

1

- Grasp the top and bottom sections of the air filter as shown

in figure F and pull apart.

CAUTION: To prevent injury to the eyes, do NOT blow out

dirt particles!

Do not use fuel to clean the air filter.

- Clean the air filter with a soft brush.

- If the filter is very dirty, clean it in lukewarm water with

dishwashing detergent.

- Let the air filter dry completely.

- Put the top and bottom sections back together.

- Before re-installing the air filter, check the choke valve for dirt

particles. If there are any, remove them with a brush.

If the filter is very dirty, clean it frequently (several times a day),

because only a clean air filter provides full engine power.

CAUTION: Replace damaged air filters immediately.

Pieces of cloth or large dirt particles can destroy the

engine!

G

CAUTION:

Do not touch the spark plug or plug cap if the engine is

running (high voltage).

Switch off the engine before starting any maintenance work.

A hot engine can cause burns. Wear protective gloves!

The spark plug must be replaced in case of damage to the

insulator, electrode erosion (burn) or if the electrodes are very

dirty or oily.

- Remove the filter cover (see "Cleaning the air filter" above,

Fig. E/1).

- Pull the plug cap (G/1) off the spark plug. Use only the

combination wrench supplied with the saw to remove the

spark plug.

CAUTION: Use only the following spark plugs:

NGK BPMR 6F or CHAMPION RDJ-7Y.

.020" (0.5 mm).

H

Electrode gap

The electrode gap must be .020" (0.5 mm).

Checking the ignition spark

- Press the loosened spark plug with the ignition cable firmly

connected against the cylinder using insulated pliers

(not near the spark plug opening).

- ON/OFF switch in the "I" (ON) position.

- Pull the starter cable hard.

If the function is correct, an ignition spark must be visible

near the electrodes.

27

Page 7

Instructions for daily and periodic maintenance

To ensure a long servicelife and to prevent any damage the maintenance work described in the following must be performed

regularly. The product guarantee will be automatically invalidated if this maintenance is not carried out regularly and according to

the instructions.

Perform the following servicing work daily after use. Make a habit of it, it does not require much time and your saw will always function

properly.

Possibly hidden faults can be detected in this manner before causing expensive and annoying interruptions of your work. In case

you should detect a fault in the safety equipment when performing daily servicing, the saw must not be used before elimination of

the fault. The user of the chain saw must not perform maintenance work which is not described in the instruction manual. All such

work must be carried out by a MAKITA service center.

Page

General Chain saw Clean exterior, check for damage. In case of damage,

Saw chain Sharpen regulary, replace in good time 24-25

Chain brake Have inspected regularly at an authorized service center

Guide bar Turn over to ensure even wear of bearing surfaces

Before each start Saw chain Inspect for damage and sharpness 24

Guide bar Check for damage

Chain lubrication Functional check 23

Chain brake Functional check 20

OFF switch,

Safety locking button,

Throttle lever Functional check 22

Fuel/oil tank

plug Check for tightness

Every day Air filter Clean 27

Guide bar Check for damage, clean oil intake bore 22

Guide bar support Clean, in particular the oil guide groove 22, 26

Idle speed Check that a sufficient difference is existing between

Every week Fan housing Clean to ensure proper air cooling

Carburetor interior Clean (remove filter cover for access) 27

Chain brake Clean the brake band (sawdust, oil) 26

Spark plug Check and replace if necessary 27

Muffler Check tightness of mounting, clean spark arrester screen 26

Chain guide Check 25

have repaired by a qualified service center immediately

Replace in good time 19

Check chain tension 19

idlind speed and engaging speed, to ensure that the chain

is in standstill while the engine is idling. 23

Every 3 months Suction head Replace 26

Fuel, oil tanks Clean

Storage Chain saw Clean exterior, check for damage. In case of damage,

Guide bar/chain Demount, clean and oil slightly

Fuel, oil tanks Empty and clean

Carburetor Run empty

have repaired by a qualified service center immediately

Clean the guide groove 26

Service, spare parts and guarantee

Maintenance and repair

The maintenance and repair of modern engines as well as all safety devices require qualified technical training and a special

workshop equipped with special tools and testing devices.

We therefore recommend that you consult a MAKITA service center for all work not described in this instruction manual.

The MAKITA service centers have all the necessary equipment and skilled and experienced personnel, who can work out cost-

effective solutions and advise you in all matters.

Please contact the general agent or importer indicated on the back cover of this Instruction Manual, who will gladly provide you with

the address of your nearest MAKITA service center.

28

Page 8

Spare parts

Reliable long-term operation, as well as the safety of your chain saw, depend among other things on the quality of the spare parts

used. Use only original MAKITA parts, marked

Only original spare parts and accessories guarantee the highest quality in material, dimensions and function.

Original spare parts and accessories can be obtained from your local dealer. He will also have the spare part lists to determine the

required spare part numbers, and will be constantly informed about the latest improvements and spare part innovations.

Please bear in mind that if parts other than original MAKITA spare parts are used, this will automatically invalidate the MAKITA product

guarantee.

Guarantee

MAKITA guarantees the highest quality and will therefore reimburse all costs for repair by replacement of damaged parts resulting

from material or production faults occurring within the guarantee period after purchase. Please note that in some countries particular

guarantee conditions may exist. If you have any questions, please contact your salesman, who is responsible for the guarantee of

the product.

Please note that we cannot accept any responsibility for damage caused by:

• Disregard of the instruction manual.

• Non-performance of the required maintenance and cleaning.

• Incorrect carburetor adjustment.

• Normal wear and tear.

• Obvious overloading due to permanent exceeding of the upper performance limits.

• Use of guide bars and chains which have not been approved.

• Use of guide bar and chain lengths which have not been approved.

• Use of force, improper use, misuse or accidents.

• Damage from overheating due to dirt on the fan housing.

• Work on the chain saw by unskilled persons or inappropriate repairs.

• Use of unsuitable spare parts or parts which are not original MAKITA parts, insofar as they have caused the damage.

• Use of unsuitable or old oil.

• Damage related to conditions arising from lease or rent contracts.

Cleaning, servicing and adjustment work is not covered by the guarantee. All repairs covered by the guarantee must be performed

by a MAKITA service center.

Troubleshootig

Malfunction System Observation Cause

Chain does not run Chain brake Engine runs Chain brake actuated.

Engine does not start or Ignition system Ignition spark Malfunction in fuel supply system, comonly with difficulty pression system, mechanical malfunction.

No ignition spark Switch on STOP, fault or short-circuit in the

Fuel supply Fuel tank is filled Choke in wrong position, carburetor defective,

Compression Inside Cylinder base packing ring defective, radial

system shaft packings defective, cylinder or piston rings

Outside Spark plug does not seal.

Mechanical Starter does not engage Spring in starter broken, broken parts

malfunction inside the engine.

Warm start difficulties Carburetor Fuel tank is filled Wrong carburetor adjustment.

Ignition spark

Engine starts, but Fuel supply Fuel tank is filled Wrong idling adjustment, suction head or

dies immediately carburetor dirty. Tank venting defective, fuel line

Insufficient power Several systems Engine is idling Air filter dirty, wrong carburetor adjustment,

may be involved muffler clogged,exhaust channel in cylinder

simultaneously clogged.

wiring, plug cap or spark plug defective.

suction head dirty, fuel line bent or interrupted.

defective

interrupted, cable defective, STOP switch

defective. Starting valve dirty (DCS 341/401).

No chain lubrication Oil tank/pump No oil on the chain Oil tank empty.

Oil guide groove dirty.

Oil-pump adjusting screw incorrectly adjusted.

29

Page 9

Extract from the spare parts list

Use only original MAKITA parts. For repairs and replacement of other parts, see

your MAKITA service center.

3

2

1

DCS 340 / DCS 341

DCS 400 / DCS 401

Pos. MAKITA-No. Qty. Denomination

1 442 030 661 1 Sprocket nose bar 30 cm (12")

442 035 661 1 Sprocket nose bar 35 cm (14")

442 040 661 1 Sprocket nose bar 40 cm (16")

2 522 092 646 1 Saw chain 3/8" for 30 cm

522 092 652 1 Saw chain 3/8" for 35 cm

522 092 656 1 Saw chain 3/8" for 40 cm

3 952 100 633 1 Chain protection for 30-40 cm

4 028 213 670 1 Sprocket guard, cpl.

5 923 208 004 1 Hexagonal nut M8

6 941 716 131 1 Universal wrench SW 13/16

7 010 114 010 1 Suction head

8 965 603 018 1 Spark plug NGK BPMR 6F

9 028 173 141 1 Air filter

10 010 114 050 1 Fuel tank plug, cpl.

11 963 224 035 1 O-Ring 24 x 3.5

12 965 450 040 1 Oil tank plug, cpl.

13 963 100 041 1 Gasket

14 965 524 062 1 Gasket

15 928 405 000 2 Spring washer

16 908 205 605 2 Fillister screw

17 021 174 111 1 Protective screen

18 915 135 100 1 Screw 3.5 x 9.5

19 021 174 340 1 Spark arrester screen

20 021 174 320 1 Muffler

10

9

20

8

19

18

16

(2)

11

17

15

(2)

12

13

14

7

5

4

6

30

27

22

21

23

24

25

Accessories (not delivered with the chain saw)

21 953 100 090 1 Chain gauge

22 953 004 010 1 File handle

23 953 003 090 1 Round file, dia. 4 mm

24 953 003 060 1 Flat file

25 953 030 010 1 File holder

(with 4 mm dia. round file)

26 944 340 001 1 Carburetor screwdriver

27 950 233 210 1 Tachometer

- 949 000 031 1 Combined can

(for 5l fuel, 2.5l oil)

26

Loading...

Loading...