Page 1

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Cordless Impact Wrench

Boulonneuse sans fil

Llave de Impacto

BTW200

002299

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

Page 2

ENGLISH

SPECIFICATIONS

Model BTW200

Capacities

Square drive 12.7 mm (1/2”)

No load speed (RPM)

Impacts per minute

Max. fastening torque

Overall length 226 mm (8-7/8”)

Net weight 2.8 kg (6.1 lbs)

Battery Charger DC24SA DC24WA

Input A.C. only 50 Hz - 60 Hz

Output D.C. 7.2 V - 24 V

Battery Cartridge BH2420 BH2433 BH2420 BH2433

Voltage 24 V

Charging time 30 min. 60 min. 55 min. 90 min.

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Standard bolt M10 - M16 (3/8” - 5/8”)

High tensile bolt M10 - M12 (3/8” - 1/2”)

High 0 - 2,000/min.

Low 0 - 1,600/min.

High 0 - 3,000

Low 0 - 2,500

High 200 N.m (144 ft.lbs)

Low 150 N.m (108 ft.lbs)

GENERAL SAFETY RULES

USA003-2

(FOR ALL BATTERY OPERATED TOOLS)

WARNING:

Read and understand all instructions.

Failure to follow all instructions listed below,

may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

4. A battery operated tool with integral batteries or

a separate battery pack must be recharged only

with the specified charger for the battery. A

charger that may be suitable for one type of battery

may create a risk of fire when used with another battery.

5. Use battery operated tool only with specifically

designated battery pack. Use of any other batter-

ies may create a risk of fire.

Personal Safety

6. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in

serious personal injury.

2

Page 3

7. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

8. Avoid accidental starting. Be sure switch is in

the locked or off position before inserting battery pack. Carrying tools with your finger on the

switch or inserting the battery pack into a tool with

the switch on invites accidents.

9. Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

10. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enables better control of the tool in unexpected situations.

11. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

Tool Use and Care

12. Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable and may lead to loss of control.

13. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

14. Do not use tool if switch does not turn it on or

off. Any tool that cannot be controlled with the

switch is dangerous and must be repaired.

15. Disconnect battery pack from tool or place the

switch in the locked or off position before making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

16. Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

17. When battery pack is not in use, keep it away

from other metal objects like: paper clips, coins,

keys, nails, screws, or other small metal objects

that can make a connection from one terminal to

another. Shorting the battery terminals together

may cause sparks, burns, or a fire.

18. Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edges are less likely to bind and are

easier to control.

19. Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

20. Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool may create a risk of

injury when used on another tool.

SERVICE

21. Tool service must be performed only by qualified

repair personnel. Service or maintenance per-

formed by unqualified personnel could result in a risk

of injury.

22. When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unau-

thorized parts or failure to follow Maintenance

instructions may create a risk of shock or injury.

SPECIFIC SAFETY RULES

USB025-2

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to cordless

impact wrench safety rules. If you use

this tool unsafely or incorrectly, you can

suffer serious personal injury.

1. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will also make exposed metal parts of the tool

“live” and shock the operator.

2. Be aware that this tool is always in an operating

condition, because it does not have to be

plugged into an electrical outlet.

3. Wear ear protectors.

4. Check the socket carefully for wear, cracks or

damage before installation.

5. Hold the tool firmly.

6. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

7. The proper fastening torque may differ depending upon the kind or size of the bolt. Check the

torque with a torque wrench.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

3

Page 4

SYMBOLS

The followings show the symbols used for tool.

V............................volts

.......................direct current

.......................no load speed

.../min....................revolutions or reciprocation per

..................number of blow

minute

USD302-1

IMPORTANT SAFETY INSTRUCTIONS FOR CHARGER & BATTERY CARTRIDGE

1. SAVE THESE INSTRUCTIONS; This manual contains important safety and operating instructions for battery charger.

2. Before using battery charger, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

USC002-3

3. CAUTION - To reduce risk of injury, charge only

MAKITA rechargeable batteries marked on the

charger label. Other types of batteries may burst

causing personal injury and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended or sold

by the battery charger manufacturer may result

in a risk of fire, electric shock, or injury to persons.

6. To reduce risk of damage to electric plug and

cord, pull by plug rather than cord when disconnecting charger.

7. Make sure cord is located so that it will not be

stepped on, tripped over, or otherwise subjected

to damage or stress.

8. An extension cord should not be used unless

absolutely necessary. Use of improper extension

cord could result in a risk of fire and electric

shock. If extension cord must be used, make

sure:

a. That pins on plug of extension cord are the

same number, size, and shape as those of

plug on charger;

b. That extension cord is properly wired and in

good electrical condition; and

c. That wire size is at least as large as the one

specified in the table below.

Table 1: RECOMMENDED MINIMUM AWG SIZE FOR EXTENSION CORDS FOR BATTERY CHARGERS

Length of Cord (Feet) 25 50 100 150

AWG Size of Cord 18 18 18 16

9. Do not operate charger with damaged cord or

plug - replace them immediately.

10. Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in

any way; take it to a qualified serviceman.

11. Do not disassemble charger or battery cartridge;

take it to a qualified serviceman when service or

repair is required. Incorrect reassembly may

result in a risk of electric shock or fire.

12. To reduce risk of electric shock, unplug charger

from outlet before attempting any maintenance

or cleaning. Turning off controls will not reduce

this risk.

13. The battery charger is not intended for use by

young children or infirm persons without supervision.

14. Young children should be supervised to ensure

that they do not play with the battery charger.

15. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

16. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

ADDITIONAL SAFETY RULES

FOR CHARGER & BATTERY CARTRIDGE

1. Do not charge the battery cartridge when temperature is BELOW 10°C (50°F) or ABOVE 40°C

(104°F)

2. Do not attempt to use a step-up transformer, an

engine generator or DC power receptacle.

3. Do not allow anything to cover or clog the

charger vents.

4. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as nails,

coins, etc.

4

Page 5

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

5. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

6. Do not incinerate the Battery Cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

7. Be careful not to drop or strike battery.

8. Do not charge inside a box or container of any

kind. The battery must be placed in a well ventilated area during charging.

SAVE THESE INSTRUCTIONS

SYMBOLS

The following show the symbols used for the equipment.

Be sure that you understand their meaning before use.

............Ready to charge

...............Charging

...............Charging complete

...........Delay charge (Cooling)

...........Defective battery

...........Conditioning

............Cooling abnormality

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

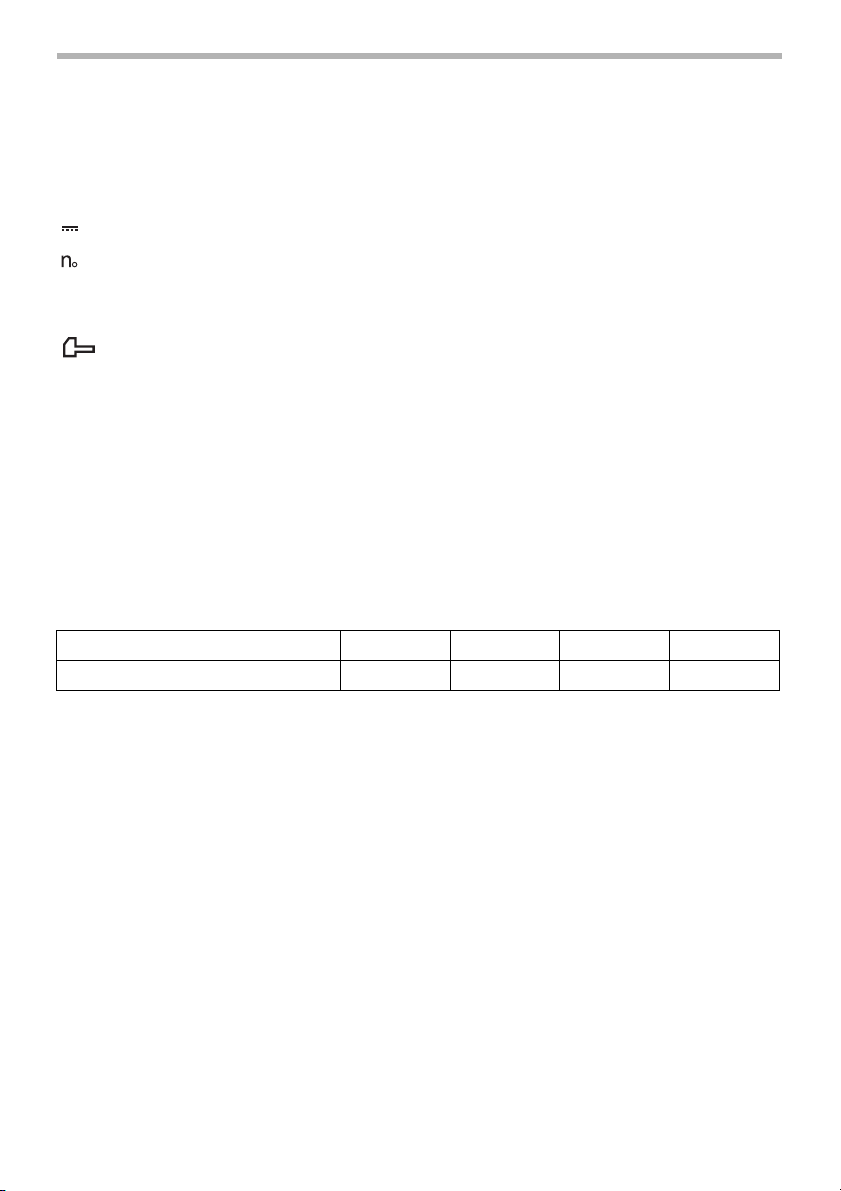

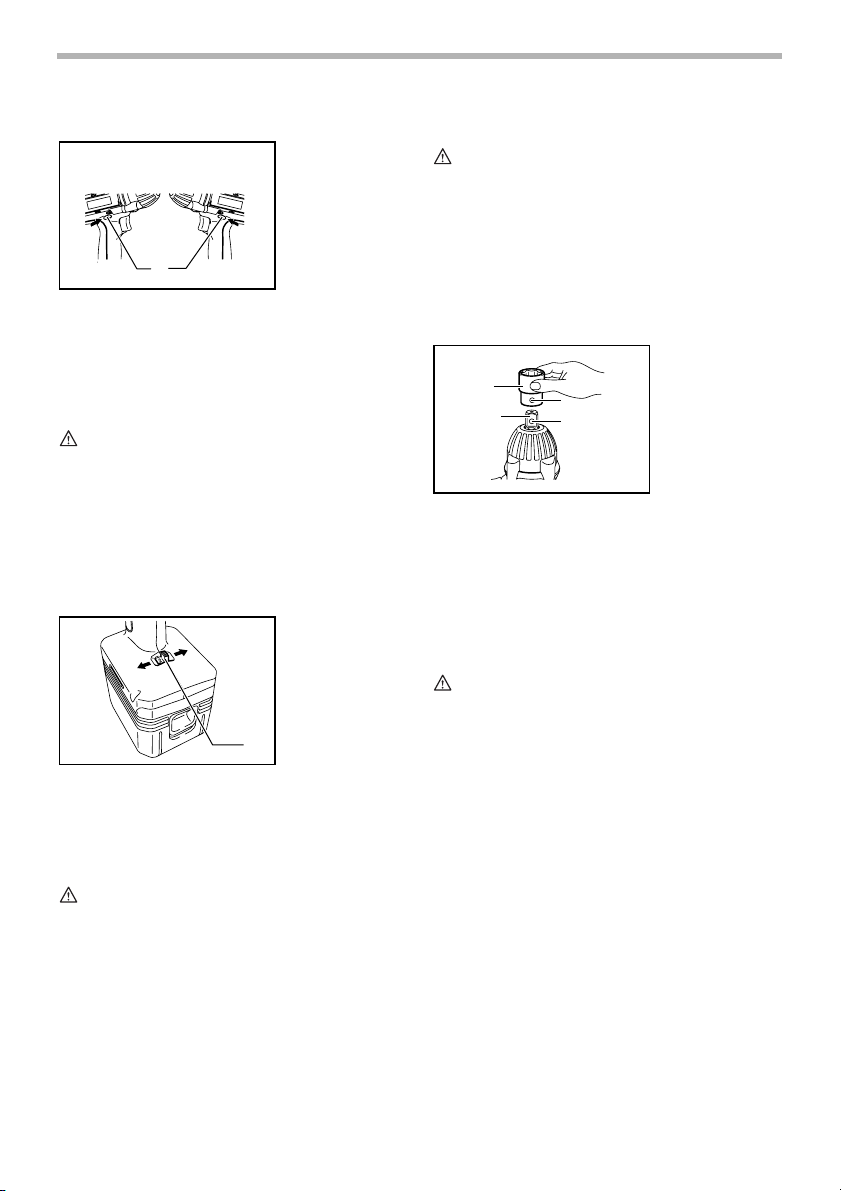

Installing or removing battery cartridge

1

2

• Always switch off the tool before insertion or

removal of the battery cartridge.

002306

1. Red part

2. Button

3. Battery cartridge

3

• To remove the battery cartridge, withdraw it from

the tool while sliding the button on the side of the

cartridge.

• To insert the battery cartridge, align the tongue on

the battery cartridge with the groove in the housing

and slip it into place. Always insert it all the way

until it locks in place with a little click. If you can see

the red part on the upper side of the button, it is not

locked completely. Insert it fully until the red part

cannot be seen. If not, it may accidentally fall out of

the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery car-

tridge. If the cartridge does not slide in easily, it is

not being inserted correctly.

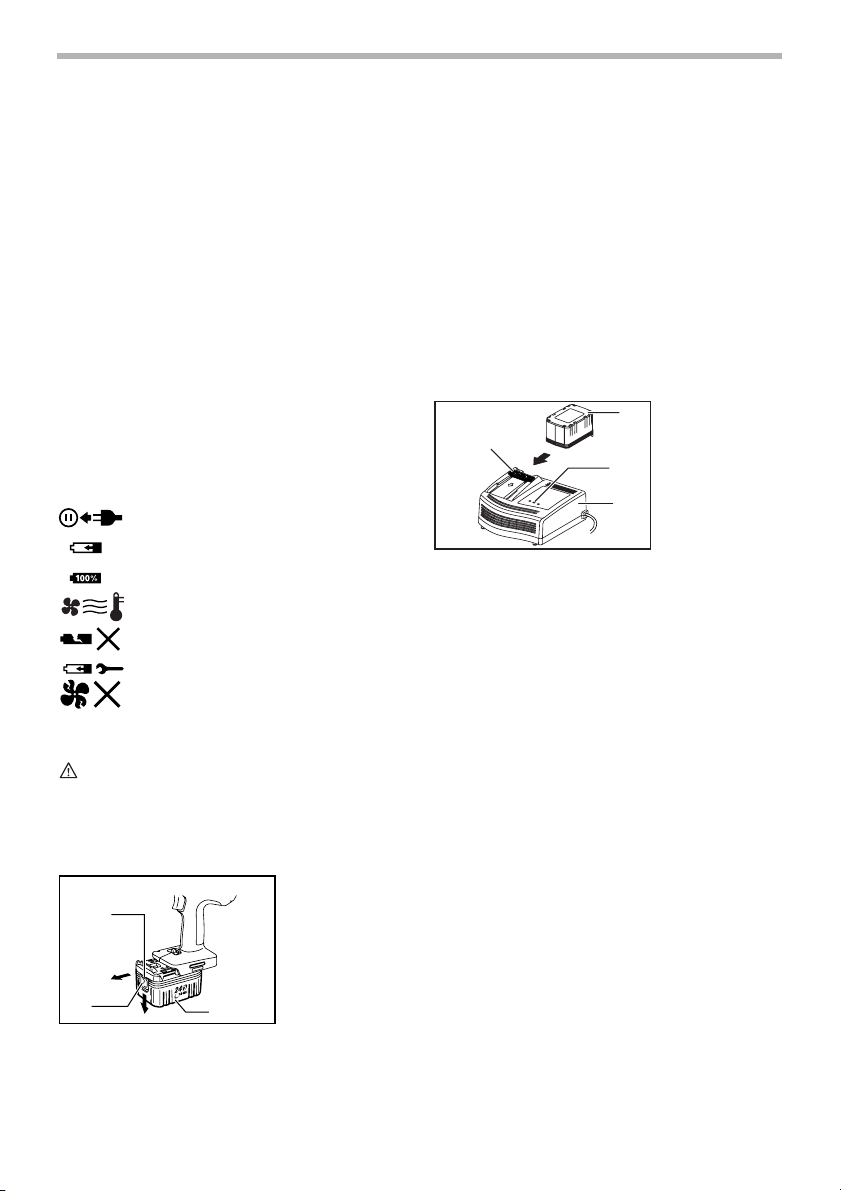

Charging

1

1. Plug the battery charger into the proper AC voltage

source. Two charging lights will flash in green color

repeatedly.

2. Insert the battery cartridge into charger until it stops

adjusting to the guide of charger. Terminal cover of

charger can be opened with inserting and closed

with pulling out the battery cartridge.

3. When the battery cartridge is inserted, the charging

light color will change from green to red and charging will begin. The charging light will keep lighting

up lit steadily during charging. One red charging

light indicates charged condition in 0 - 80% and two

red ones indicates 80 - 100%.

4. With finish of charge, the charging lights will

change from two red ones to two green ones.

5. If you leave the battery cartridge in the charger

after the charging cycle is complete, the charger

will switch into its “trickle charge (maintenance

charge)” mode which will last approximately 24

hours.

6. After charging, unplug the charger from the power

source.

NOTE:

• The battery charger is for charging Makita battery

cartridge. Never use it for other purposes or for

other manufacturer’s batteries.

• When you charge a new battery cartridge or a bat-

tery cartridge which has not been used for a long

period of time, it may not accept a full charge. This

001336

2

3

4

1. Terminal cover

2. Battery cartridge

3. Charging light

4. Battery charger

5

Page 6

is a normal condition and does not indicate a problem. You can recharge the battery cartridge fully

after discharging it completely and recharging a

couple of times.

• If you charge a battery cartridge from a just oper-

ated tool or battery cartridge which has been left in

a location exposed to direct sunlight for a long time,

the charging light may flash in red color. If this

occurs, wait for a while. Charging will begin after

the battery cartridge is cooled by the cooling fan

installed in the charger. (DC24SA only) When the

temperature on battery is more than approx. 70°C,

two charging lights may flash in red color, and when

approx. 50°C - 70°C, one charging light in red color.

• If the charging light flashes alternately in green and

red color, charging is not possible. The terminals on

the charger or battery cartridge are clogged with

dust or the battery cartridge is worn out or damaged.

Cooling system (DC24SA only)

• This charger is equipped with cooling fan for heated

battery in order to enable the battery to prove its

own performance. Sound of cooling air comes out

during cooling, which means no trouble on the

charger.

• Yellow light will flash for warning in the following

cases.

- Trouble on cooling fan

- Incomplete cool down of battery, such as, being

clogged with dust

The battery can be charged in spite of the yellow

warning light. But the charging time will be longer

than usual in this case. Check the sound of cooling

fan, vent on the charger and battery, which can be

sometime clogged with dust.

• The cooling system is in order although no sound of

cooling fan comes out, if the yellow warning light

will not flash.

• Always keep clean the vent on charger and battery

for cooling.

• The products should be sent to repair or mainte-

nance, if the yellow warning light will frequently

flash.

Conditioning charge (DC24SA only)

Conditioning charge can extend the life of battery by

automatically searching the optimum charging condition

for the batteries in every situations.

The battery employed in the following conditions repeatedly, will be worn out shortly, and yellow warning light

may flash.

1. Recharge of battery with its high temperature

2. Recharge of battery with its low temperature

3. Recharge of full charged battery

4. Over-discharge of battery (continue to discharge

battery in spite of down of power.)

The charging time of such battery is longer than usual.

Trickle charge (Maintenance charge)

If you leave the battery cartridge in the charger to prevent

spontaneous discharging after full charge, the charger

will switch into its “trickle charge (maintenance charge)”

mode and keep the battery cartridge fresh and fully

charged.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely dis-

charged.

Always stop tool operation and charge the battery

cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature

at 10°C - 40°C (50°F - 104°F).

Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge

when you do not use it for more than six months.

Refresh charging

Refreshing adapter (optional accessory) can refresh an

inactive battery cartridge.

• Refresh charging should be done once a week.

• When you charge a new battery cartridge or a bat-

tery cartridge that has not been used for a long

time, it may not accept a full charge. In this case,

refresh charging must be done. The battery cartridge my decrease the tool performance, because

the chemical substance of the battery cartridge is

inactive.

Switch action

1

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

002320

1. Switch trigger

Electric brake

This tool is equipped with an electric brake. If the tool

consistently fails to quickly stop after switch trigger

release, have tool serviced at a Makita service center.

6

Page 7

Reversing switch action

AB

1

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the A

side for clockwise rotation or from the B side for counterclockwise rotation.

When the reversing switch lever is in the neutral position,

the switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before opera-

tion.

• Use the reversing switch only after the tool comes

to a complete stop. Changing the direction of rotation before the tool stops may damage the tool.

• When not operating the tool, always set the revers-

ing switch lever to the neutral position.

Speed change

B

To change the speed, first switch off the tool and then

slide the speed change lever to the “A” side (2) for high

speed or “B” side (1) for low speed. Be sure that the

speed change lever is set to the correct position before

operation. Use the right speed for your job.

CAUTION:

• Always set the speed change lever fully to the cor-

rect position. If you operate the tool with the speed

change lever positioned halfway between the “A”

side (2) and “B” side (1), the tool may be damaged.

• Do not use the speed change lever while the tool is

running. The tool may be damaged.

002328

1. Reversing

switch lever

002330

1. Speed change

lever

A

1

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out

any work on the tool.

Selecting correct socket

Always use the correct size socket for bolts and nuts. An

incorrect size socket will result in inaccurate and inconsistent fastening torque and/or damage to the bolt or nut.

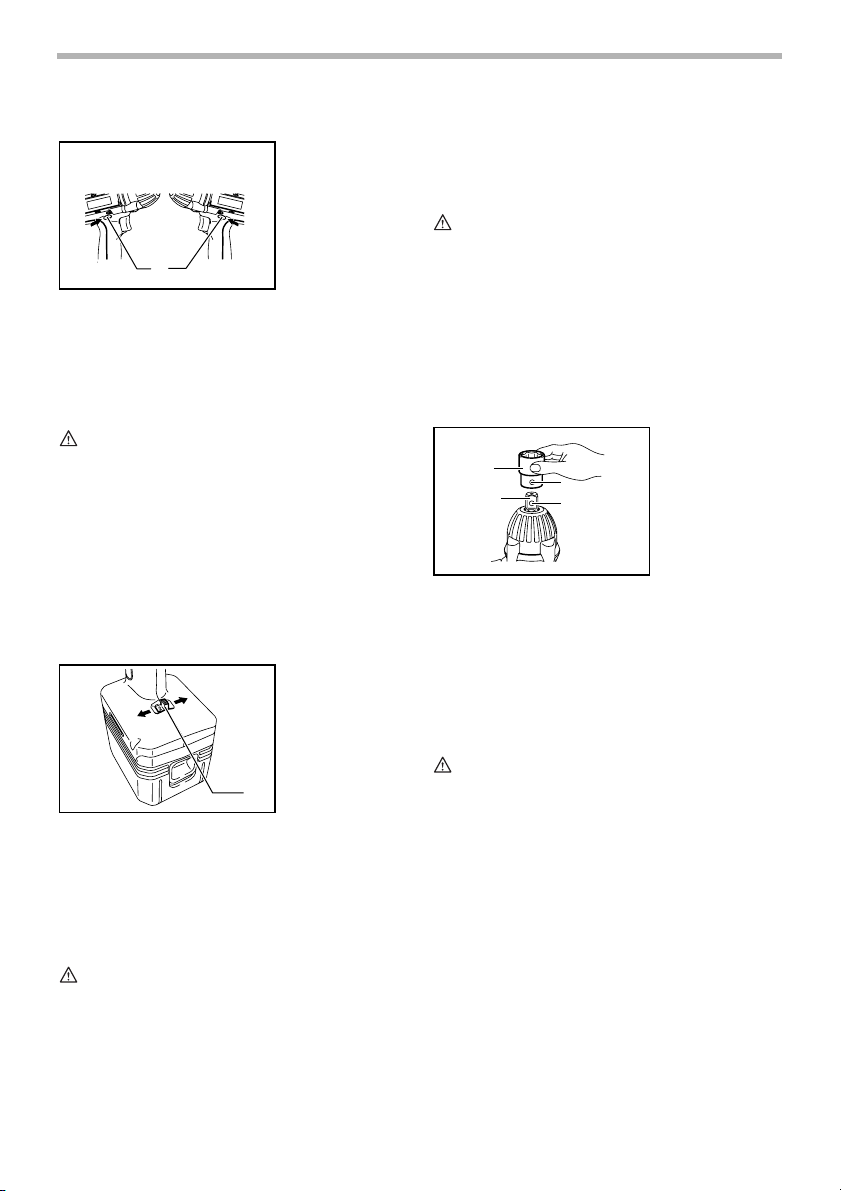

Installing or removing socket

1

2

To install the socket, align the hole in the side of the

socket with the detent pin on the anvil.

Push the socket onto the anvil until it snaps into place.

Tap it lightly if required.

To remove the socket, depress the detent pin through the

hole in the socket and pull the socket off the anvil.

002343

1. Socket

2. Anvil

3

4

3. Hole

4. Detent pin

OPERATION

CAUTION:

• Always insert the battery cartridge all the way until

it locks in place. If you can see the red part on the

upper side of the button, it is not locked completely.

Insert it fully until the red part cannot be seen. If

not, it may accidentally fall out of the tool, causing

injury to you or someone around you.

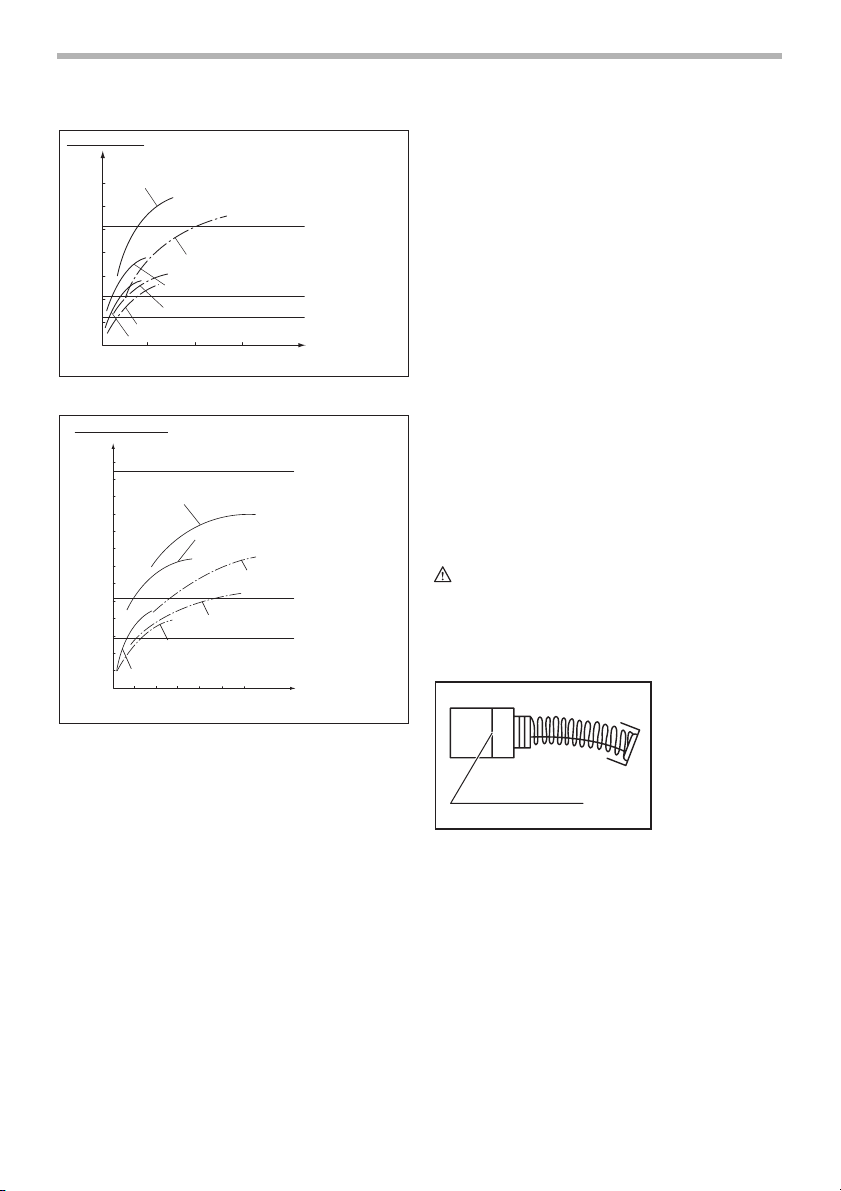

The proper fastening torque may differ depending upon

the kind or size of the bolt, the material of the workpiece

to be fastened, etc. The relation between fastening

torque and fastening time is shown in the figures.

7

Page 8

Standard bolt

N.m

(ft.lbs)

Fastening torque

M16X50 (5/8” X 2”) at high speed

140

(101)

120

(87)

100

(72)

80

(58)

60

(43)

40

(29)

20

M10X50 (3/8” X 2”) at low speed

(14)

M10X50 (3/8” X 2”) at high speed

01 2

High tensile bolt

N.m

260

(188)

240

(174)

220

M16X50 (5/8” X 2”) at high speed

(159)

200

(145)

180

(130)

160

(116)

140

(101)

120

(87)

Fastening torque

100

(72)

80

(58)

60

(43)

40

(29)

20

M10X50 (3/8” X 2”) at high speed

(14)

012

M16X50 (5/8” X 2”) at low speed

M12X50 (1/2” X 2”) at high speed

M12X50 (1/2” X 2”) at low speed

3

Fastening time

M12X50 (1/2” X 2”) at high speed

M16X50 (5/8” X 2”) at low speed

M12X50 (1/2” X 2”) at low speed

M10X50 (3/8” X 2”) at low speed

3

45 6

Fastening time

M16 (5/8”)

M12 (1/2”)

M10 (3/8”)

(S)

M16 (5/8”)

M12 (1/2”)

M10 (3/8”)

(S)

002369

2. Socket

• Failure to use the correct size socket will cause

a reduction in the fastening torque.

• A worn socket (wear on the hex end or square

end) will cause a reduction in the fastening

torque.

3. Bolt

• Even though the torque coefficient and the

class of bolt are the same, the proper fastening

Proper fastening torque

torque will differ according to the diameter of

bolt.

• Even though the diameters of bolts are the

same, the proper fastening torque will differ

according to the torque coefficient, the class of

bolt and the bolt length.

4. The use of the universal joint or the extension bar

002370

somewhat reduces the fastening force of the impact

wrench. Compensate by fastening for a longer

period of time.

5. The manner of holding the tool or the material of

driving position to be fastened will affect the torque.

6. Operating the tool at low speed will cause a reduc-

tion in the fastening torque.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

Proper fastening torque

battery cartridge is removed before attempting to

perform inspection or maintenance.

Replacing carbon brushes

001145

1. Limit mark

Hold the tool firmly and place the socket over the bolt or

nut. Turn the tool on and fasten for the proper fastening

time.

NOTE:

• Hold the tool pointed straight at the bolt or nut.

• Excessive fastening torque may damage the bolt/

nut or socket. Before starting your job, always perform a test operation to determine the proper fastening time for your bolt or nut.

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

The fastening torque is affected by a wide variety of factors including the following. After fastening, always check

the torque with a torque wrench.

1. When the battery cartridge is discharged almost

completely, voltage will drop and the fastening

torque will be reduced.

1

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

8

Page 9

002376

1

2

After replacing brushes, insert the battery cartridge into

the tool and break in brushes by running tool with no load

for about 1 minute. Then check the tool while running and

electric brake operation when releasing the switch trigger. If electric brake is not working well, ask your local

Makita service center for repair.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

1. Brush holder

cap

2. Screwdriver

ACCESSORIES

CAUTION:

• These accessories or attachments are recom-

mended for use with your Makita tool specified in

this manual. The use of any other accessories or

attachments might present a risk of injury to persons. Only use accessory or attachment for its

stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Extension bar

• Universal joint

• Bit adapter

• Screw bits

• Automatic refreshing adapter

• Shoulder strap

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

EN0006-1

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

9

Page 10

FRANÇAIS

SPÉCIFICATIONS

Modèle BTW200

Capacités

Tournevis carré 12.7 mm (1/2”)

Vitesse à vide (T/MIN)

Percussions par minute

Couple de serrage max.

Longueur totale 226 mm (8-7/8”)

Poids net 2.8 kg (6.1 lbs)

Chargeur de batterie DC24SA DC24WA

Entrée C.A. 50 Hz - 60 Hz uniquement

Sortie C.C. 7.2 V - 24 V

Batterie BH2420 BH2433 BH2420 BH2433

Tension 24 V

Temps de charge 30 min. 60 min. 55 min. 90 min.

• Le fabricant se réserve le droit de modifier sans avertissement les spécifications.

• Note: Les spécifications peuvent varier selon les pays.

Boulon standard M10 - M16 (3/8” - 5/8”)

Boulon à haute résistance M10 - M12 (3/8” - 1/2”)

Grande 0 - 2,000/min.

Bas 0 - 1,600/min.

Grande 0 - 3,000

Bas 0 - 2,500

Grande 200 N.m (144 ft.lbs)

Bas 150 N.m (108 ft.lbs)

RÈGLES DE SÉCURITÉ

GÉNÉRALES

USA003-2

(POUR TOUS LES OUTILS ALIMENTÉS

PAR BATTERIE)

AVERTISSEMENT:

MISE EN GARDE ! Assurez-vous d’avoir

lu et compris toutes les instructions. Il y

a risque de choc électrique, d’incendie et/ou

de blessure grave si les instructions cidessous ne sont pas respectées.

CONSERVEZ CE MODE

D’EMPLOI

Zone de travail

1. Maintenez votre aire de travail propre et bien

éclairée. Les établis encombrés et les aires de

travail sombres ouvrent la porte aux accidents.

2. N’utilisez pas les outils électriques dans les

atmosphères explosives, par exemple en

présence de liquides, gaz ou poussières

inflammables. Les outils électriques produisent des

étincelles au contact desquelles la poussière ou les

vapeurs peuvent s’enflammer.

3. Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillez avec un

outil électrique. Ils pourraient vous distraire et vous

faire perdre la maîtrise de l’outil.

Sécurité en matière d’électricité

4. Un outil alimenté par des batteries intégrées ou

par un bloc-piles séparé doit toujours être

rechargé au moyen du chargeur spécifié pour la

batterie en question. L’utilisation d’un chargeur

10

Page 11

conçu pour un type donné de batterie peut

comporter un risque d’incendie avec un autre type

de batterie.

5. En utilisant un outil alimenté par batterie,

servez-vous uniquement du bloc-piles

spécialement conçu à cet effet. L’emploi d’autres

batteries risquerait de provoquer un d’incendie.

Sécurité personnelle

6. Restez alerte, attentif à vos gestes, et faites

preuve de bon sens lorsque vous utilisez un

outil électrique. Évitez d’utiliser l’outil lorsque

vous êtes fatigué ou sous l’influence de

drogues, d’alcool ou de médicaments. Tou t

moment d’inattention pendant l’utilisation d’un outil

électrique comporte un risque de blessure grave.

7. Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les

cheveux longs. N’approchez jamais les cheveux,

les vêtements ou les gants des pièces en

mouvement. Des vêtements flottants, des bijoux ou

des cheveux longs risquent d’être happés par des

pièces en mouvement.

8. Prévenez tout démarrage accidentel. Assurezvous que l’interrupteur est en positon d’arrêt ou

en position verrouillée avant d’insérer le blocpiles. En transportant l’outil avec le doigt sur

l’interrupteur ou en insérant le bloc-piles alors que

l’interrupteur est en position de marche, vous ouvrez

toute grande la porte aux accidents.

9. Enlevez les clés de réglage ou de serrage avant

de démarrer l’outil. Une clé laissée dans une pièce

tournante de l’outil peut provoquer des blessures.

10. Ne vous penchez pas trop en avant. Maintenez

un bon appui et restez en équilibre en tout

temps. Un bonne stabilité vous permet de mieux

réagir à une situation inattendue.

11. Utilisez des accessoires de sécurité. Portez

toujours un protecteur pour la vue. Selon les

conditions, portez aussi un masque antipoussière,

des bottes de sécurité antidérapantes, un casque

protecteur et/ou une protection d’oreille.

Utilisation et entretien des outils

12. Immobilisez le matériau sur une surface stable

au moyen de brides ou de toute autre façon

adéquate. Le fait de tenir la pièce avec la main ou

contre votre corps offre une stabilité insuffisante et

peut entraîner une perte de maîtrise de l’outil.

13. Ne forcez pas l’outil. Utilisez un outil qui

convient au travail à effectuer. Si vous utilisez le

bon outil et respectez le régime pour lequel il a été

conçu, il effectuera un travail de meilleure qualité et

de façon plus sûre.

14. N’utilisez pas un outil si son interrupteur est

bloqué. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux et

doit être réparé.

15. Retirez le bloc-piles de l’outil ou placez

l’interrupteur en position de verrouillage ou

d’arrêt avant d’effectuer tout réglage, de changer

d’accessoire ou de ranger l’outil. De telles

mesures préventives réduisent les risques de

démarrage accidentel de l’outil.

16. Une fois l’utilisation de l’outil terminée, rangez-le

hors de portée des enfants et personnes qui en

ignorent le fonctionnement. Les outils

représentent un danger entre les mains de

personnes qui n’en connaissent pas le mode

d’utilisation.

17. Lorsque vous n’utilisez pas le bloc-piles, rangezle à l’écart des objets tels que les trombones,

pièces de monnaie, clés, clous, vis et autres

petits objets métalliques qui risquent d’établir la

connexion entre les bornes. Il y a risque

d’étincelles, de brûlures et d’incendie si les bornes

de la batterie sont court-circuitées.

18. Prenez soin de bien entretenir les outils. Les

outils de coupe doivent être toujours bien

affûtés et propres. Des outils bien entretenus, dont

les arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à diriger.

19. Assurez-vous que les pièces mobiles ne sont

pas désalignées ou coincées, qu’aucune pièce

n’est cassée et que l’outil n’a subi aucun

dommage affectant son bon fonctionnement. Le

cas échéant, faites réparer l’outil avant de

l’utiliser. De nombreux accidents sont causés par

des outils mal entretenus.

20. Utilisez uniquement les accessoires

recommandés par le fabricant pour le modèle

utilisé. Des accessoires qui conviennent à un outil

donné peuvent comporter un risque de blessure

lorsque utilisés sur un autre outil.

Service

21. La réparation des outils électriques doit être

confiée à un réparateur qualifié. La réparation ou

l’entretien effectué par du personnel non qualifié

risque d’entraîner des blessures.

22. Seules des pièces de rechange identiques aux

pièces originales doivent être utilisées lors de la

réparation d’un outil. Suivez les instructions de

la section Entretien du présent manuel.

L’utilisation de pièces non spécifiées ou l’ignorance

des instructions d’entretien comporte un risque de

choc électrique ou de blessure.

RÈGLES DE SÉCURITÉ

PARTICULIÈRES

USB025-2

NE vous laissez PAS tromper (au fil d’une

utilisation répétée) par un sentiment

d’aisance et de familiarité avec l’outil, en

11

Page 12

négligeant le respect rigoureux des

règles de sécurité qui accompagnent la

clé à chocs sans fil. L’utilisation non

sécuritaire ou incorrecte de cet outil

comporte un risque de blessure grave.

1. Tenez l’outil par ses surfaces de prise isolées

pendant toute opération où l’outil de coupe

pourrait venir en contact avec un câblage

dissimulé. En cas de contact avec un conducteur

sous tension, les pièces métalliques à découvert de

l’outil transmettraient un choc électrique à

l’utilisateur.

2. Soyez bien conscient du fait que l’outil est

constamment en état de marche, car il n’a pas à

être raccordé à une prise d’alimentation.

3. Portez une protection d’oreilles.

4. Avant installation, vérifiez soigneusement que la

douille ne porte ni marque d’usure, ni fissures

ou tout autre dommage.

5. Tenez l’outil fermement.

6. Adoptez toujours une position de travail vous

assurant d’un bon équilibre.

Assurez-vous qu’il n’y a personne plus bas

lorsque vous utilisez l’outil en position élevée.

7. Le couple de serrage correct peut varier selon le

type ou la taille du boulon. Vérifiez-le à l’aide

d’une clé dynamométrique.

CONSERVEZ CE MODE

D’EMPLOI

AVERTISSEMENT:

La MAUVAISE UTILISATION de l’outil ou

l’ignorance des Une MAUVAISE

UTILISATION de l’outil ou l’ignorance des

consignes de sécurité du présent manuel

d’instructions peuvent entraîner une

grave blessure.

SYMBOLES

Les symboles utilisés pour l’outil sont présentés cidessous.

V............................volts

.......................courant continu

.......................vitesse à vide

USD302-1

PRECAUTIONS TRES

IMPORTANTES POUR LE

CHARGEUR ET LA PILECARTOUCHE

1. CONSERVEZ CES INSTRUCTIONS. Ce manuel

contient d’importantes instructions relatives à la

sécurité et au fonctionnement du chargeur.

2. Avant de vous servir du chargeur, lisez toutes

les instructions et précautions relatives 1) au

chargeur, 2) à la pile, et 3) à l’outil utilisant la

pile.

3. PRECAUTION – Pour réduire les risques de

blessures, n'utiliser que des batteries

rechargeables MAKITA marquées sur l'étiquette

du chargeur. Tout autre type de batterie risque

d'exploser en provoquant des blessures et des

dommages.

4. N’exposez pas le chargeur à la pluie ou à la

neige.

5. L’utilisation d’un accessoire non recommandé ni

vendu par le fabricant du chargeur peut

entraîner un risque d’incendie, de décharge

électrique ou de blessure.

6. Pour ne pas risquer d’endommager le câble ou

la prise, débranchez en tenant la prise plutôt

quele câble.

7. Assurez-vous que la position du câble ne

l’expose pas à faire trébucher, à être foulé aux

pieds, ou à forcer de quelque manière que ce

soit.

8. Ne pas utiliser de cordon de rallonge à moins de

nécessité absolue. L'emploi d'un cordon de

rallonge inadéquate risque d'entraîner un

incendie et une électrocution. S'il est impossible

de s'en passer, s'assurer:

a. Que les broches de la fiche du cordon de

rallonge soient en nombre égal, et

correspondant en grandeur et en forme à la

prise du chargeur.

b. Que le cordon de rallonge soit

convenablement connecté et en bon état du

point de vue électrique.

c. Que les dimensions du câblage soient au

moins de caractéristiques équivalentes à

celles spécifiées dans le tableau ci-dessous.

USC002-3

.../min....................tours ou alternances par minute

..................nombre de frappes

12

Page 13

TABLEAU 1: GRANDEUR AWG MINIMUM RECOMMENDEE POUR LES CORDONS DE

RALLONGE DES CHARGEURS DE BATTERIE.

Longueur du cordon (Pieds) 25 50 100 150

Grandeur AWG du cordon 18 18 18 16

9. Ne pas utiliser le chargeur avec une fiche ou un

cordon endommagé – Les remplacer

immédiatement si besoin.

10. Si le chargeur a subi un choc, a tombé, ou a été

endommagé de manière quelconque, ne pas

s’en servir; l’apporter pour réparation chez un

technicien qualifié.

11. Ne pas désassembler le chargeur ni la cartouche

de batterie; l’apporter pour réparation chez un

technicien qualifié si besoin. Un réassemblage

inadéquate risquerait d’entraîner une

électrocution ou un incendie.

12. Pour réduire le risque d’électrocution,

débrancher le chargeur de la prise

d’alimentation avant d’entreprendre toute

opération d’entretien ou de nettoyage. La

coupure des interrupteurs s’avère insuffisante

pour réduire ce risque.

13. Le chargeur de batterie ne doit pas être

manipulé par les jeunes enfants ou les

personnes infirmes sans surveillance.

14. Il convient de veiller à ce que les jeunes enfants

ne jouent pas avec le chargeur de batterie.

15. Si la durée de fonctionnement est devenue

excessivement courte, arrêter le fonctionnement

immédiatement. Autrement, cela risquerait de

provoquer le surchauffement, voire des brûlures

et même une déflagration.

16. Si par inadvertance de l’électrolyte atteignait les

yeux, il faudrait les rincer aussitôt à l’eau propre

et consulter un médecin le plus vite possible,

autrement, la faculté oculaire risquerait d’être

compromise.

PRECAUTIONS

SUPPLEMENTAIRES POUR LE

CHARGEUR ET LA PILECARTOUCHE

1. Ne retirez pas la batterie lorsque la température

est INFÉRIEURE À 10°C (50°F) ou SUPÉRIEURE

À 40°C (104°F)

2. Ne tentez pas d’utiliser un transformateurélévateur, un groupe électrogène ou une prise de

courant continu.

3. Ne laissez rien recouvrir ou obturer les

ouvertures du chargeur.

4. Ne pas causer de court-circuit à la cartouche de

batterie:

(1) Ne jamais toucher les bornes de

raccordement avec des matériaux

conducteurs.

(2) Ne pas conserver la batterie dans un

récipient contenant des objets métalliques

tels que des clous, des pièces métalliques,

etc.

(3) Ne pas exposer la batterie à l’eau ni à la

pluie.

Un court-circuit à la batterie risque de causer

une surintensité de courant, un surchauffement,

voire une calcination et même une panne.

5. Ne rangez pas l’outil ou la batterie dans des

endroits où la température risque d’atteindre ou

de dépasser 50°C (122°F).

6. Ne brûlez pas la pile-cartouche même si elle est

sévèrement endommagée ou complètement

hors d’usage, car elle risque d’exploser au feu.

7. Prenez garde d'échapper ou de heurter la

batterie.

8. Ne pas charger à l’intérieur d’une boîte ou d’un

containeur de toutes sortes. La batterie doit être

placée dans un endroit bien ventilé durant

l’opération de charge.

SUIVEZ STRICTEMENT CES

INSTRUCTIONS

SYMBOLES

Les symboles utilisés pour l’appareil sont indiqués cidessous. Assurez-vous d’avoir bien compris leur

signification avant d’utiliser l’outil.

............Prêt à la charge

...............Charge

...............Charge terminée

...........Délai de charge (Refroidissement)

...........Batterie défectueuse

...........Conditionnement

............Anomalie de refroidissement

13

Page 14

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

que sa batterie est retirée avant de l’ajuster ou de

vérifier son fonctionnement.

Installation ou retrait de la batterie

1

2

• Mettez toujours l’outil hors tension avant d’insérer

ou de retirer la batterie.

• Pour retirer la batterie, sortez-la de l’outil tout en

faisant glisser le bouton sur le côté de la batterie.

• Pour insérer la batterie, alignez sa languette sur

l’entaille qui se trouve à l’intérieur du carter, puis

glissez la batterie pour la mettre en place. Insérez-

la toujours bien à fond, jusqu’à ce qu’elle se

verrouille en émettant un léger clic. Si vous pouvez

voir la partie rouge de la face supérieure du bouton,

la batterie n’est pas parfaitement verrouillée.

Insérez-la à fond, jusqu’à ce que la partie rouge ne

soit plus visible. Sinon, elle risque de tomber

accidentellement de l’outil, en vous blessant ou en

blessant une personne se trouvant près de vous.

• N’appliquez pas une force excessive lors de

l’insertion de la batterie. Si la batterie ne glisse pas

aisément, c’est qu’elle n’est pas insérée

correctement.

Charge

1

1. Branchez le chargeur sur une source d’alimentation

secteur dont la tension est adéquate. Deux témoins

de charge clignotent en vert de manière répétée.

2. Insérez la batterie dans le chargeur jusqu’à ce

qu’elle s’arrête, alignée sur le guide du chargeur.

002306

1. Partie rouge

2. Bouton

3. Batterie

3

001336

1. Couvre-bornes

2

2. Batterie

3. Voyant de

3

4

charge

4. Chargeur de

batterie

Le couvre-bornes du chargeur peut être ouvert en

insérant la batterie, et fermé en la retirant.

3. Lorsque la batterie est insérée, la couleur du

témoin de charge passe du vert au rouge et la

charge commence. Le témoin de charge demeure

allumé en permanence pendant la charge. Un

témoin de charge rouge indique une charge de 0 à

80%, et deux témoins rouges une charge de 80 à

100%.

4. Lorsque la charge est terminée, la couleur des

deux témoins de charge passe du rouge au vert.

5. Si vous laissez la batterie dans le chargeur une fois

le cycle de charge terminé, le chargeur passe en

mode de “charge de compensation (charge

d’entretien)”.

6. Après la charge, débranchez le chargeur de la

source d’alimentation.

NOTE:

• Ce chargeur de batterie est conçu pour la charge

des batteries Makita. Ne l’utilisez jamais à d’autres

fins ou avec les batteries des autres fabricants.

• Lorsque vous chargez une batterie neuve ou une

batterie restée inutilisée pendant une période

prolongée, il se peut que la charge complète ne soit

pas possible. Il s’agit d’un phénomène normal qui

n’indique aucune anomalie. La batterie pourra de

nouveau être complètement chargée après avoir

été complètement déchargée puis rechargée à

quelques reprises.

• Lorsque vous chargez la batterie d’un outil qui vient

tout juste d’être utilisé, ou une batterie qui a été

laissée dans un endroit exposé directement aux

rayons du soleil pendant une période prolongée, il

se peut que le témoin de charge clignote en rouge.

Si cela se produit, veuillez patienter un instant. La

charge commencera une fois la batterie refroidie

par le ventilateur de refroidissement installé dans le

chargeur. (DC24SA uniquement) Lorsque la

température de la batterie est supérieure à environ

70°C, deux témoins de charge peuvent clignoter en

rouge, tandis qu’à une température d’environ 50°C

à 70°C, un seul témoin clignote en rouge.

• Si le témoin de charge clignote alternativement en

vert et en rouge, la charge n’est pas possible. Les

bornes du chargeur ou de la batterie sont alors

bloquées par la poussière, ou bien la batterie est

soit usée, soit endommagée.

Système de refroidissement (DC24SA uniquement)

• Ce chargeur est équipé d’un ventilateur de

refroidissement pour batterie chaude afin de

permettre à la batterie de fournir son plein

rendement. Un son de refroidissement d’air

s’échappe pendant le refroidissement, et ce son

n’indique aucun problème de fonctionnement du

chargeur.

• Un témoin jaune d’avertissement clignote dans les

cas suivants.

- Problème de ventilateur de refroidissement.

14

Page 15

- Refroidissement insuffisant de la batterie, causé

par une accumulation de poussière, etc.

La batterie peut être chargée même si le témoin

jaune d’avertissement est allumé. Dans ce cas, le

temps de charge sera toutefois plus long que

d’ordinaire. Vérifiez le son du ventilateur de

refroidissement, ainsi que les évents du chargeur et

de la batterie, où s’accumule parfois de la

poussière.

• Le système de refroidissement fonctionne

normalement si le témoin jaune d’avertissement ne

clignote pas, et ce même si aucun son ne provient

du ventilateur de refroidissement.

• Maintenez toujours les évents du chargeur et de la

batterie propres pour permettre le refroidissement.

• Si le témoin jaune d’avertissement clignote

souvent, les produits devraient être envoyés pour

réparation ou entretien.

Charge de régénération (DC24SA uniquement)

La charge de régénération peut faire augmenter la durée

de vie d’une batterie en effectuant automatiquement une

recherche du niveau de charge optimale des batteries

dans toute situation.

Les batteries utilisées à plusieurs reprises dans les

conditions suivantes s’useront rapidement, et le témoin

jaune d’avertissement peut se mettre alors à clignoter.

1. Recharge de la batterie alors qu’elle est chaude

2. Recharge de la batterie alors qu’elle est froide

3. Recharge d’une batterie déjà complètement

chargée

4. Décharge excessive de la batterie (continuer de

décharger la batterie bien qu’elle soit déjà faible).

Le temps de charge d’une telle batterie est plus long que

d’ordinaire.

Charge de compensation (charge d’entretien)

Si vous laissez la batterie dans le chargeur pour éviter

qu’elle ne se décharge naturellement après une charge

complète, le chargeur passera en mode de “charge de

compensation (charge d’entretien)”, maintenant la

batterie fraîche et complètement chargée.

Conseils pour obtenir la durée de service maximale

de la batterie

1. Chargez la batterie avant qu’elle ne soit

complètement déchargée.

Lorsque vous constatez une baisse de puissance,

arrêtez toujours l’outil et chargez la batterie.

2. Ne rechargez jamais une batterie complètement

chargée.

La surcharge réduit la durée de service de la

batterie.

3. Rechargez la batterie à une température ambiante

comprise entre 10°C et 40°C (50°F et 104°F).

Avant de charger une batterie chaude, laissez-la

refroidir.

4. Chargez la batterie à hydrure métallique de nickel

lorsqu’elle est restée inutilisée pendant plus de six

mois.

Charge de remise en condition

L’adaptateur de remise en condition (accessoire en

option) permet de rétablir la charge d’une batterie qui

n’est plus active.

• La charge de remise en condition doit être

effectuée une fois par semaine.

• Lorsque vous chargez une batterie neuve ou une

batterie restée inutilisée pendant une période

prolongée, il se peut que la charge complète ne soit

pas possible. Dans ce cas, une charge de remise

en condition doit être effectuée. Sinon, il se peut

que l’utilisation de cette batterie entraîne une

diminution de la performance de l’outil, puisque la

substance chimique qu’elle contient est inactive.

Interrupteur

002320

1. Gâchette

1

ATTENTION:

• Avant d’insérer la batterie dans l’outil, vérifiez

toujours que la gâchette fonctionne bien et revient

en position d’arrêt lorsque relâchée.

Pour mettre l’outil en marche, appuyez simplement sur la

gâchette. La vitesse de l’outil augmente à mesure que

l’on accroît la pression exercée sur la gâchette. Pour

l’arrêter, relâchez la gâchette.

Frein électrique

Cet outil est équipé d’un frein électrique. Si à plusieurs

reprises l’outil ne s’arrête pas rapidement après le

relâchement de la gâchette, faites-le réparer dans un

centre de service après-vente Makita.

Inverseur

AB

1

L’outil possède un inverseur qui permet de changer le

sens de rotation. Enfoncez le levier inverseur du côté A

pour une rotation dans le sens des aiguilles d’une

002328

1. Levier inverseur

15

Page 16

montre, ou du côté B pour une rotation dans le sens

inverse des aiguilles d’une montre.

La pression sur la gâchette n’est pas possible lorsque le

levier inverseur se trouve en position neutre.

ATTENTION:

• Vérifiez toujours le sens de rotation avant de mettre

l’outil en marche.

• N’actionnez l’inverseur qu’une fois que l’outil est

complètement arrêté. Si vous changez le sens de

rotation avant l’arrêt de l’outil, vous risquez de

l’endommager.

• Lorsque vous n’utilisez pas l’outil, placez toujours le

levier inverseur en position neutre.

Changement de vitesse

002330

1. Levier de

changement de

A

vitesse

B

1

Pour changer de vitesse, commencez par éteindre l’outil,

puis déplacez le levier de changement de vitesse sur le

côté (2) “A” pour faire marcher l’outil à grande vitesse, ou

sur le côté (1) “B” pour le faire marcher à vitesse réduite.

Vérifiez que le levier de changement de vitesse est réglé

sur la bonne position avant de réutiliser l’outil. Utilisez la

vitesse qui convient pour le travail.

ATTENTION:

• Réglez toujours le levier de changement de vitesse

à fond sur la position correcte. Si vous actionnez

l’outil alors que le levier est placé à mi-chemin entre

la position (2) “A” et la position (1) “B”, vous risquez

d’endommager l’outil.

• Ne modifiez pas la position du levier de

changement de vitesse pendant que l’outil tourne.

Vous risqueriez de l’endommager.

ASSEMBLAGE

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

que sa batterie est retirée avant d’effectuer tout

travail dessus.

Sélection de la douille

Pour certains modèles il existe différents types de

douilles ou embouts, suivant le travail à effectuer.

Veuillez choisir et installer une douille ou un embout qui

convient au travail à effectuer.

Installation et retrait de la douille

002343

1. Douille

1

2

3

4

2. Enclume

3. Orifice

4. Broche de

détente

Pour installer la douille, enfoncez-la sur le piton de l’outil

jusqu’à ce qu’elle se verrouille en position.

Pour retirer la douille, tirez simplement dessus.

UTILISATION

ATTENTION:

• Insérez toujours la batterie jusqu’au fond, jusqu’à

ce qu’elle verrouille en place. Si vous pouvez voir la

partie rouge de la face supérieure du bouton, la

batterie n’est pas parfaitement verrouillée. Insérezla à fond, jusqu’à ce que la partie rouge ne soit plus

visible. Sinon, elle risque de tomber

accidentellement de l’outil, en vous blessant ou en

blessant une personne se trouvant près de vous.

Le couple de serrage adéquat peut varier suivant la sorte

ou taille de boulon, suivant le matériau dont se compose

la pièce faisant l’objet du serrage, etc. La relation entre le

couple de serrage et le temps de serrage est indiquée

dans les figures.

Boulon standard

N.m

(ft.lbs)

Couple de serrage

M16X50 (5/8” X 2”) à grande vitesse

140

(101)

120

(87)

100

(72)

80

(58)

60

(43)

40

(29)

20

M10X50 (3/8” X 2”) à vitesse réduite

(14)

M10X50 (3/8” X 2”) à grande vitesse

01 2

M16X50 (5/8” X 2”) à vitesse réduite

M12X50 (1/2” X 2”) à grande vitesse

M12X50 (1/2” X 2”) à vitesse réduite

3

Temps de serrage

M16 (5/8”)

M12 (1/2”)

M10 (3/8”)

(S)

002369

Couple de serrage adéquat

16

Page 17

Boulon à haute résistance

N.m

260

(188)

240

(174)

220

M16X50 (5/8” X 2”) à grande vitesse

(159)

200

(145)

180

(130)

160

(116)

140

(101)

120

(87)

Couple de serrage

100

(72)

80

(58)

60

(43)

40

(29)

20

M10X50 (3/8” X 2”) à grande vitesse

(14)

012

Saisissez fermement l’outil et placez la douille sur le

boulon ou l’écrou. Mettez l’outil en marche et procédez

M12X50 (1/2” X 2”) à grande vitesse

M12X50 (1/2” X 2”) à vitesse réduite

M10X50 (3/8” X 2”) à vitesse réduite

3

45 6

Temps de serrage

M16 (5/8”)

M16X50 (5/8” X 2”) à vitesse

réduite

M12 (1/2”)

M10 (3/8”)

(S)

002370

au serrage, en appliquant le temps de serrage adéquat.

NOTE:

• Tenez votre outil bien droit sur le boulon ou l’écrou.

• Un couple de serrage excessif risque

d’endommager le boulon/l’écrou ou la douille. Avant

de commencer le travail, effectuez toujours un

essai pour vérifier que le temps de serrage

conviennent pour le boulon ou l’écrou en question.

• Si l’outil est utilisé de manière continue jusqu’à ce

que la batterie soit déchargée, laissez-le reposer

15 minutes avant de poursuivre l’opération avec

une batterie fraîche.

Le couple de serrage dépend d’un certain nombre de

facteurs, comme suit. Une fois le serrage terminé,

vérifiez toujours le couple avec une clé dynamométrique.

1. Lorsque la batterie est presque complètement

déchargée, la tension tombe et le couple de

serrage diminue.

2. Douille

• L’utilisation d’une douille de mauvaise

dimension entraînera une réduction du couple

de serrage.

• Une douille usée (usure sur l’extrémité

hexagonale ou l’extrémité carrée) entraînera

une réduction du couple de serrage.

3. Boulon

• Même si le coefficient du couple et la catégorie

du boulon sont les mêmes, le couple de

serrage variera en fonction du diamètre de

boulon.

• Même si les diamètres des boulons sont les

mêmes, le couple de serrage variera en

fonction du coefficient de couple, de la

catégorie du boulon et de la longueur du

boulon.

4. L’utilisation d’un joint universel ou d’une barre de

rallonge réduit quelque peu la force de serrage de

la boulonneuse. Compenser en serrant plus

longtemps.

5. Le couple de serrage est affecté par la façon dont

vous tenez l’outil ou la pièce, ou par la position de

vissage.

6. Le fonctionnement de l’outil à vitesse réduite

entraîne une diminution du couple de serrage.

ENTRETIEN

Couple de serrage adéquat

ATTENTION:

• Assurez-vous toujours que l’outil est hors tension et

que la batterie est retirée avant d’y effectuer tout

travail d’inspection ou d’entretien.

Remplacement des charbons

001145

1. Trait de limite

d’usure

1

Retirez et vérifiez régulièrement les charbons.

Remplacez-les lorsqu’ils sont usés jusqu’au trait de limite

d’usure. Maintenez les charbons propres et en état de

glisser aisément dans les porte-charbon. Les deux

charbons doivent être remplacés en même temps.

N’utilisez que des charbons identiques.

Utilisez un tournevis pour retirer les bouchons de portecharbon. Enlevez les charbons usés, insérez-en de

nouveaux et revissez solidement les bouchons de portecharbon.

002376

1

1. Bouchon de

porte-charbon

2. Tournevis

2

Après avoir remplacé les charbons, insérez la batterie

dans l’outil et rodez les brosses en faisant fonctionner

l’outil à vide pendant environ 1 minute. Vérifiez ensuite le

bon fonctionnement de l’outil, ainsi que l’activation du

frein électrique lors du relâchement de la gâchette. Si le

frein électrique ne fonctionne pas bien, faites une

demande de réparation auprès du centre de service

après-vente Makita le plus près.

17

Page 18

Pour maintenir la SÉCURITÉ et la FIABILITÉ du produit,

les réparations, tout autre travail d’entretien ou de

réglage doivent être effectués dans un centre de service

Makita agréé ou un centre de service de l’usine Makita,

exclusivement avec des pièces de rechange Makita.

ACCESSOIRES

ATTENTION:

• Ces accessoires ou pièces complémentaires sont

recommandés pour l’utilisation avec l’outil Makita

spécifié dans ce mode d’emploi. L’utilisation de tout

autre accessoire ou pièce complémentaire peut

comporter un risque de blessure. N’utilisez les

accessoires ou pièces qu’aux fins auxquelles ils ont

été conçus.

Si vous désirez obtenir plus de détails concernant ces

accessoires, veuillez contacter le centre de service

après-vente Makita le plus près.

• Barre de rallonge

• Joint universel

• Adaptateur à embout

• Forets de vis

• Adaptateur de régénération automatique

• Bandoulière

GARANTIE LIMITÉE D’UN AN MAKITA

Politique de garantie

Chaque outil Makita est inspecté rigoureusement et testé

avant sa sortie d’usine. Nous garantissons qu’il sera

exempt de défaut de fabrication et de vice de matériau

pour une période d’UN AN à partir de la date de son

achat initial. Si un problème quelconque devait survenir

au cours de cette période d’un an, veuillez retourner

l’outil COMPLET, port payé, à une usine ou à un centre

de service après-vente Makita. Makita réparera l’outil

gratuitement (ou le remplacera, à sa discrétion) si un

défaut de fabrication ou un vice de matériau est

découvert lors de l’inspection.

Cette garantie ne s’applique pas dans les cas où:

• des réparations ont été effectuées ou tentées par

un tiers:

• des réparations s’imposent suite à une usure

normale:

• l’outil a été malmené, mal utilisé ou mal entretenu:

• l’outil a subi des modifications.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ POUR

TOUT DOMMAGE ACCESSOIRE OU INDIRECT LIÉ À

LA VENTE OU À L’UTILISATION DU PRODUIT. CET

AVIS DE NON-RESPONSABILITÉ S’APPLIQUE À LA

FOIS PENDANT ET APRÈS LA PÉRIODE COUVERTE

PAR CETTE GARANTIE.

MAKITA DÉCLINE TOUTE RESPONSABILITÉ QUANT

À TOUTE GARANTIE TACITE, INCLUANT LES

GARANTIES TACITES DE “QUALITÉ MARCHANDE” ET

“ADÉQUATION À UN USAGE PARTICULIER” APRÈS

EN0006-1

LA PÉRIODE D’UN AN COUVERTE PAR CETTE

GARANTIE.

Cette garantie vous donne des droits spécifiques

reconnus par la loi, et possiblement d’autres droits, qui

varient d’un État à l’autre. Certains États ne permettant

pas l’exclusion ou la limitation des dommages

accessoires ou indirects, il se peut que la limitation ou

exclusion ci-dessus ne s’applique pas à vous. Certains

États ne permettant pas la limitation de la durée

d’application d’une garantie tacite, il se peut que la

limitation ci-dessus ne s’applique pas à vous.

18

Page 19

ESPAÑOL

ESPECIFICACIONES

Modelo BTW200

Capacidades

Adaptador cuadrado 12,7 mm (1/2”)

Revoluciones por minuto (r.p.m.)

Impactos por minuto

To rs i ón de fijación máxima

Longitud total 226 mm (8-7/8”)

Peso neto 2,8 kg (6,1 lbs)

Cargador de batería DC24SA DC24WA

Entrada Sólo corriente alterna (AC) 50 Hz - 60 Hz.

Salida 7,2 V - 24 V c.d.

Cartucho de batería BH2420 BH2433 BH2420 BH2433

Voltaje 24 V

Tiempo de carga 30 min. 60 min. 55 min. 90 min.

• Debido a un programa continuo de investigación y desarrollo, las especificaciones aquí dadas están sujetas a

cambios sin previo aviso.

• Nota: Las especificaciones pueden ser diferentes de país a país.

Perno estándar M10 - M16 (3/8” - 5/8”)

Perno de gran resistencia M10 - M12 (3/8” - 1/2”)

Alta 0 - 2 000/min.

Baja 0 - 1 600/min.

Alta 0 - 3 000

Baja 0 - 2 500

Alta 200 N.m (144 ft.lbs)

Baja 150 N.m (108 ft.lbs)

NORMAS DE SEGURIDAD

GENERALES

USA003-2

(PARA TODAS LAS HERRAMIENTAS DE

FUNCIONAMIENTO A BATERÍA)

AVISO:

Lea y entienda todas las instrucciones.

El no seguir todas las instrucciones listadas

abajo, podrá resultar en una descarga

eléctrica, incendio y/o heridas personales

graves.

GUARDE ESTAS

INSTRUCCIONES

Área de trabajo

1. Mantenga su área de trabajo limpia y bien

iluminada. Los bancos de trabajo atestados y las

áreas oscuras son una invitación a accidentes.

2. No utilice las herramientas eléctricas en

atmósferas explosivas, tal como en la presencia

de líquidos, gases o polvo inflamables. Las

herramientas eléctricas crean chispas que pueden

prender fuego al polvo o los humos.

3. Mantenga a los curiosos, niños, y visitantes

alejados mientras utiliza una herramienta

eléctrica. Las distracciones le pueden hacer perder

el control.

Seguridad eléctrica

4. Una herramienta de funcionamiento a batería

con baterías integrales o una batería separada

deberán ser cargada solamente con el cargador

especificado para la batería. Un cargador que

19

Page 20

pueda ser apropiado para un tipo de batería podrá

crear un riesgo de incendio cuando se utilice con

otra batería.

5. Utilice la herramienta de funcionamiento a

batería solamente con la batería designada

específicamente para ella. La utilización de otras

baterías podrá crear un riesgo de incendio.

Seguridad personal

6. Manténgase alerta, mire lo que está haciendo y

use el sentido común cuando esté utilizando

una herramienta. No utilice la herramienta si

está cansado, o si se encuentra bajo los efectos

de drogas, alcohol o medicamentos. Un momento

de distracción durante el manejo de las

herramientas puede ocasionarle graves heridas.

7. Vístase apropiadamente. No se ponga ropa

holgada ni joyas. Recójase el pelo si lo tiene

largo. Mantenga su pelo, ropa y guantes

alejados de las partes en movimiento. La ropa

holgada, las joyas, o el pelo largo pueden

engancharse en las partes en movimiento.

8. Evite puestas en marcha no deseadas.

Asegúrese de que el interruptor esté en la

posición bloqueada o desactivada antes de

insertar la batería. El transportar herramientas con

el dedo en el interruptor o insertar la batería en una

herramienta con el interruptor activado invita a

accidentes.

9. Retire las llaves de ajuste y de apriete antes de

encender la herramienta. Una llave de ajuste o

llave de apriete que sea dejada puesta en una parte

giratoria de la herramienta podrá resultar en heridas

personales.

10. No utilice la herramienta donde no alcance.

Mantenga los pies sobre suelo firme y el

equilibrio en todo momento. El mantener los pies

sobre suelo firme y el equilibrio permiten un mejor

control de la herramienta en situaciones

inesperadas.

11. Utilice equipo de seguridad. Póngase siempre

protección para los ojos. Las mascaras contra el

polvo, botas antideslizantes, casco rígido, o

protección para los oídos deberán ser utilizados

para las condiciones apropiadas.

Utilización y cuidado de las herramientas

12. Utilice mordazas u otros medios de sujeción

prácticos para sujetar y apoyar la pieza de

trabajo en una plataforma estable. El sujetar la

pieza de trabajo con la mano o contra su cuerpo es

inestable y puede llevar a la pérdida del control.

13. No fuerce la herramienta. Utilice la herramienta

adecuada para su tarea. La herramienta correcta

realizará la tarea mejor y de forma más segura a la

potencia para la que ha sido diseñada.

14. No utilice la herramienta si ésta no se enciende

o apaga accionando el interruptor. Una

herramienta que no se puede controlar mediante el

interruptor es peligrosa y debe ser reparada.

15. Desconecte la batería de la herramienta o ponga

el interruptor en la posición bloqueada o

desactivada antes de hacer cualquier ajuste,

cambiar accesorios, o guardar la herramienta.

Tales medidas de seguridad preventiva reducirán el

riesgo de que la herramienta pueda ser puesta en

marcha por descuido.

16. Guarde las herramientas que no esté utilizando

fuera del alcance de los niños y otras personas

no preparadas. Las herramientas son peligrosas en

manos de personas no preparadas.

17. Cuando la batería no esté siendo utilizada,

manténgala alejada de otros objetos metálicos

como: sujetapapeles, monedas, llaves, clavos,

tornillos, u otros objetos metálicos pequeños

que pueden hacer una conexión de un terminal a

otro. Si se cortocircuitan entre sí los terminales de

la batería podrán producirse chispas, quemaduras,

o un incendio.

18. Mantenga las herramientas con cuidado.

Mantenga los implementos de corte afilados y

limpios. Las herramientas bien mantenidas con el

borde de corte afilado son menos propensas a

estancarse y más fáciles de controlar.

19. Compruebe que no haya partes móviles

desalineadas o estancadas, partes rotas, y

cualquier otra condición que pueda afectar al

funcionamiento de la herramienta. Si la

herramienta está dañada, haga que se la reparen

antes de utilizarla. Muchos accidentes son

ocasionados por herramientas mal mantenidas.

20. Utilice solamente accesorios que estén

recomendados por el fabricante para su modelo.

Los accesorios que puedan ser apropiados para

una herramienta podrán crear un riesgo de incendio

o heridas cuando se utilicen con otra herramienta.

Servicio

21. La reparación de la herramienta debe ser

realizada sólo por personal de reparaciones

calificado. La reparación o el mantenimiento

realizados por personal no calificado puede

significar el riesgo de sufrir heridas.

22. Cuando haga el servicio a la herramienta, utilice

solamente piezas de repuesto idénticas. Siga las

instrucciones de la sección de Mantenimiento de

este manual. La utilización de piezas no

autorizadas o el no seguir las instrucciones de

mantenimiento podrá crear un riesgo de descargas

eléctricas o heridas.

20

Page 21

NORMAS ESPECÍFICAS DE

SEGURIDAD

USB025-2

NO deje que la comodidad o familiaridad

con el producto (a base de utilizarlo

repetidamente) sustituya la estricta

observancia de las normas de seguridad

para el llave de impacto. Si utiliza esta

herramienta de forma no segura o

incorrecta, podrá sufrir graves heridas

personales.

1. Cuando realice una operación en la que la

herramienta de corte pueda entrar en contacto

con cableado oculto, sujete la herramienta por

las superficies de asimiento aisladas. El contacto

con un cable con corriente también hará que la

corriente circule por las partes metálicas expuestas

de la herramienta y podrá electrocutar al operador.

2. Tenga presente que esta herramienta está

siempre en condición de operación, porque no

tiene que ser enchufada a una toma de corriente.

3. Póngase protectores de oídos.

4. Compruebe con cuidado que el enchufe no esté

desgastado, agrietado ni dañado antes de la

instalación.

5. Sostenga la herramienta con firmeza.

6. Asegúrese siempre de que tiene suelo firme.

Asegúrese de que no haya nadie debajo cuando

utilice la herramienta en lugares altos.

7. El par de apriete de torsión apropiado podrá

variar en función del tipo o tamaño del perno.

Compruebe el par de apriete con una llave de

torsión.

GUARDE ESTAS

INSTRUCCIONES

AVISO:

El mal uso o incumplimiento de las

reglas de seguridad descriptas en el

presente manual de instrucciones puede

ocasionar graves lesiones personales.

SÍMBOLOS

A continuación se muestran los símbolos utilizados para

la herramienta.

V............................voltios

USD302-1

.......................corriente directa

.......................velocidad en vacío

.../min ...................revoluciones o alternaciones por

.................. número de percusiones

minuto

INSTRUCCIONES IMPORTANTES

DE SEGURIDAD PARA EL

CARGADOR Y EL CARTUCHO DE

BATERÍA

1. GUARDE ESTAS INSTRUCCIONES; este manual

contiene información e instrucciones

importantes de seguridad para el cargador de la

batería.

2. Antes de usar el cargador de batería, lea todas

las instrucciones y notas de precaución sobre

(1) el cargador de batería, (2) la batería y (3) el

producto al usarlo con la batería.

3. PRECAUCIÓN. Para reducir el riesgo de lesión,

cargue solamente baterías recargables MAKITA

marcadas sobre la etiqueta del cargador. Otros

tipos de baterías podrían estallar causando

lesión personal y daños.

4. No exponga el cargador a la lluvia ni a la nieve.

5. El uso de un aditamento no recomendado ni

vendido por el fabricante de la batería podría

resultar en un riesgo de incendio, choque

eléctrico o lesiones personales.

6. Para reducir el riesgo de daño al cordón y

enchufe eléctrico, jale el enchufe en vez del

cordón al desconectar el cargador.

7. Asegúrese que el cordón está colocado de tal

forma que no se pisará ni causará tropiezos o

que de alguna otra forma esté sujeto a daños o

tensiones.

8. El uso de una extensión eléctrica debe evitarse a

menos que sea estrictamente necesaria. El uso

inapropiado de una extensión eléctrica podría

resultar en riesgo de incendio y choque

eléctrico. Si se requiere usar una extensión

eléctrica, asegúrese de:

a. Que las clavijas en el enchufe de la

extensión eléctrica sean del mismo número,

tamaño y forma que las del enchufe del

cargador.

b. Que la extensión eléctrica esté

adecuadamente cableada y en buena

condición eléctrica.

c. Y que el tamaño sea al menos de grande

como se especifica en la tabla a

continuación.

21

USC002-3

Page 22

TABLA 1:

TAMA ÑO AWG MÍNIMO RECOMENDADO PARA CABLES PROLONGADORES PARA

CARGADORES DE BATERÍA

Longitud del cable (en pies) 25 50 100 150

Tama ño AWG del cable 18 18 18 16

9. No opere el cargador con un cordón o enchufe

dañado y sustituya de inmediato.

10. No opere el cargador si éste ha recibido un

golpe fuerte, se ha dejado caer o se ha dañado

de cualquier otra forma; llévelo con un técnico

de servicio calificado.

11. No desarme el cargador o el cartucho de batería;

llévelo a un técnico de servicio calificado

cuando se requiera de servicio o reparación. Un

ensamblado incorrecto podría resultar en riesgo

de choque eléctrico o incendio.

12. Para reducir el riesgo de choque eléctrico,

desenchufe el cargador del tomacorriente antes

de intentar dar cualquier mantenimiento o

limpieza. El apagar los controles no basta para

reducir este riesgo.

13. El cargador de la batería no está diseñado para