Page 1

T

ECHNICAL INFORMATION

PRODUCT

P 1/ 15

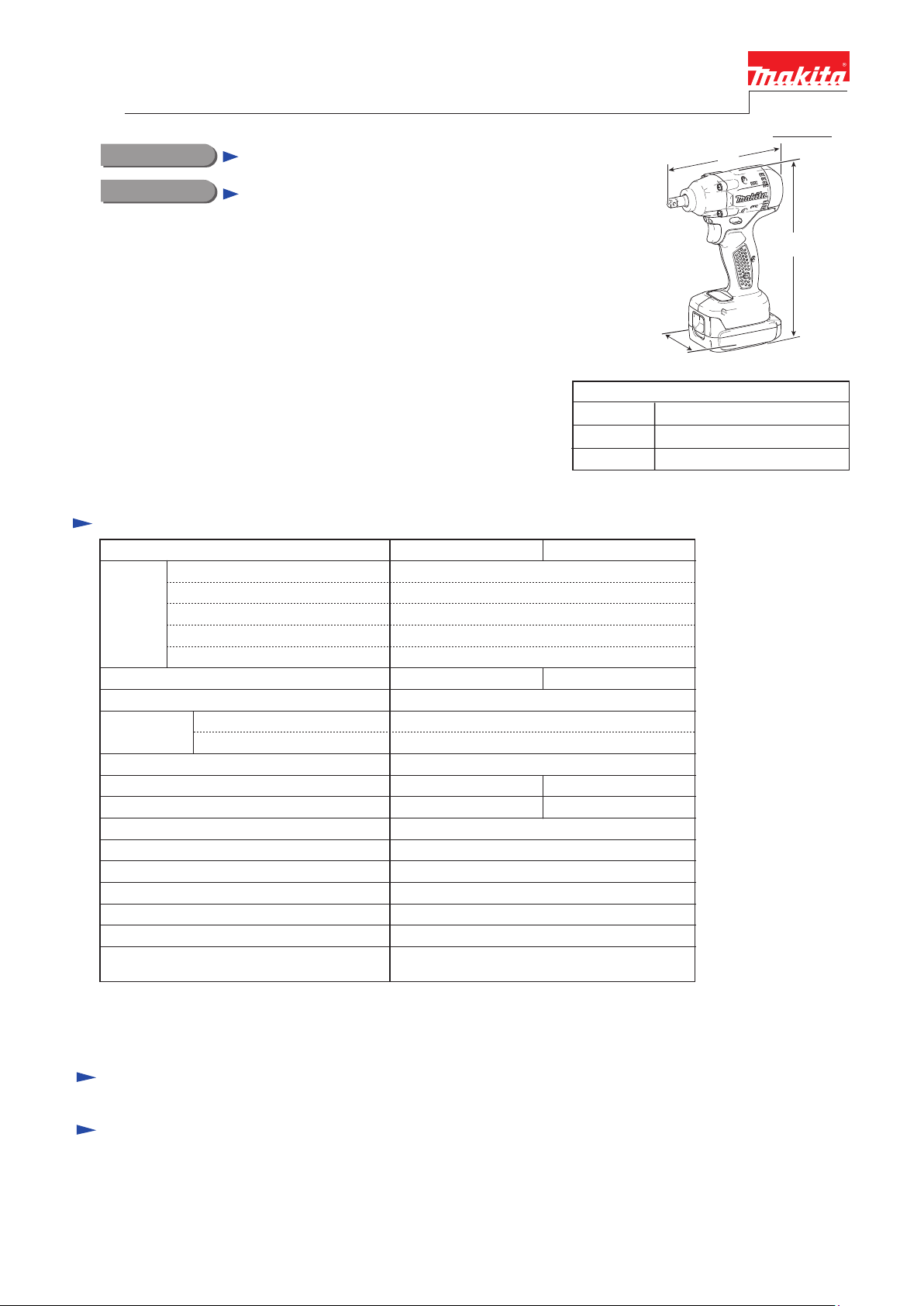

Models No.

Description

BTW074, BTW104

Cordless Impact Wrench

CONCEPT AND MAIN APPLICATIONS

These cordless impact wrenches for manufacturing industry as

the successors of BTW072 series models.

Their main features are:

• Extra compact design with a short overall length of 144mm (5-5/8")*

• Powered by our new 14.4V Li-ion batteries with battery fuel gauge:

BL1415NA (1.5Ah)/ BL1415NP (1.5Ah)/

BL1430A (3.0Ah)/ BL1430AP (3.0Ah)

• Automatic impact stop system to avoid under-tightening and

over-tightening

• Torque stabilization system to stabilize the torque of each fastening

• Automatic battery shut-off system to avoid incomplete fastenings

Specification

Model No.

Cell

Voltage: V

Battery

Max output (W)

Driving shank

Capacities

Impacts per min.: min.

No load speed: min.

Max. fastening torque: N.m [kgf·cm] (in.lbs)

Battery fuel gauge*

Automatic battery shut-off system

Electric brake

LED job light

Variable speed control by trigger

Reverse switch

Weight according to

EPTA-Procedure 01/2003*

*4 The fastening torque at 3 seconds after seating, when fastening M10 (grade 10.9) high tensile bolt.

*5 The fastening torque at 3 seconds after seating, when fastening M12 (grade 10.9) high tensile bolt.

*6 located on battery BL1415NA/ BL1415NAP/ BL1430A/ BL1430AP, not on the tool body

*7 with battery

Capacity: Ah

Energy capacity: Wh 22/ 44

Charging time (approx.): min.

Standard bolt

High tensile bolt

ˉ¹=ipm

ˉ¹=rpm

6

7: kg (lbs)

BTW074 BTW104

15/ 22 with DC18RC

140 150

9.5mm (3/8") Square drive

M5 - M12 (3/16 - 1/2")

M5 - M10 (3/16 - 3/8")

0 - 2,500 0 - 2,700

65 [660] (575)*

1

W

(The image above is Model BTW074.)

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

*1 149mm (5-7/8”) for Anti-wobble anvil version

*2 with 1.5Ah Li-ion battery BL1415NA

*3 with 3.0Ah Li-ion battery of BL1430A

Li-ion

14.4

1.5/ 3.0

0 - 3,500

4 95 [970] (841)*5

Yes

Yes

Yes

Yes

Yes

Yes

1.1/ 1.3

(2.4/ 2.9)

144 (5-5/8)*

74 (2-15/16)

216 (8-1/2)

L

H

1

*1/ 234 (9-1/4)*2

Standard equipment

No

Optional accessories

Li-ion Battery BL1415NA

Li-ion Battery BL1415NAP

Li-ion Battery BL1430A

Li-ion Battery BL1430AP

Battery protector

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Fast charger DC18RA (for USA, Canada, Guam, Panama, Mexico, Colombia)

Fast charger DC18RC (for all countries except the countries above)

Protectors (blue/ white/ red)

Automatic refreshing adapter ADP03

Page 2

P 2/ 15

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. Description Use for

1R004 Retaining Ring S Pliers disassembling / assembling Ring spring 7

1R045 Gear extractor disassembling / assembling Hammer section

1R222

1R288

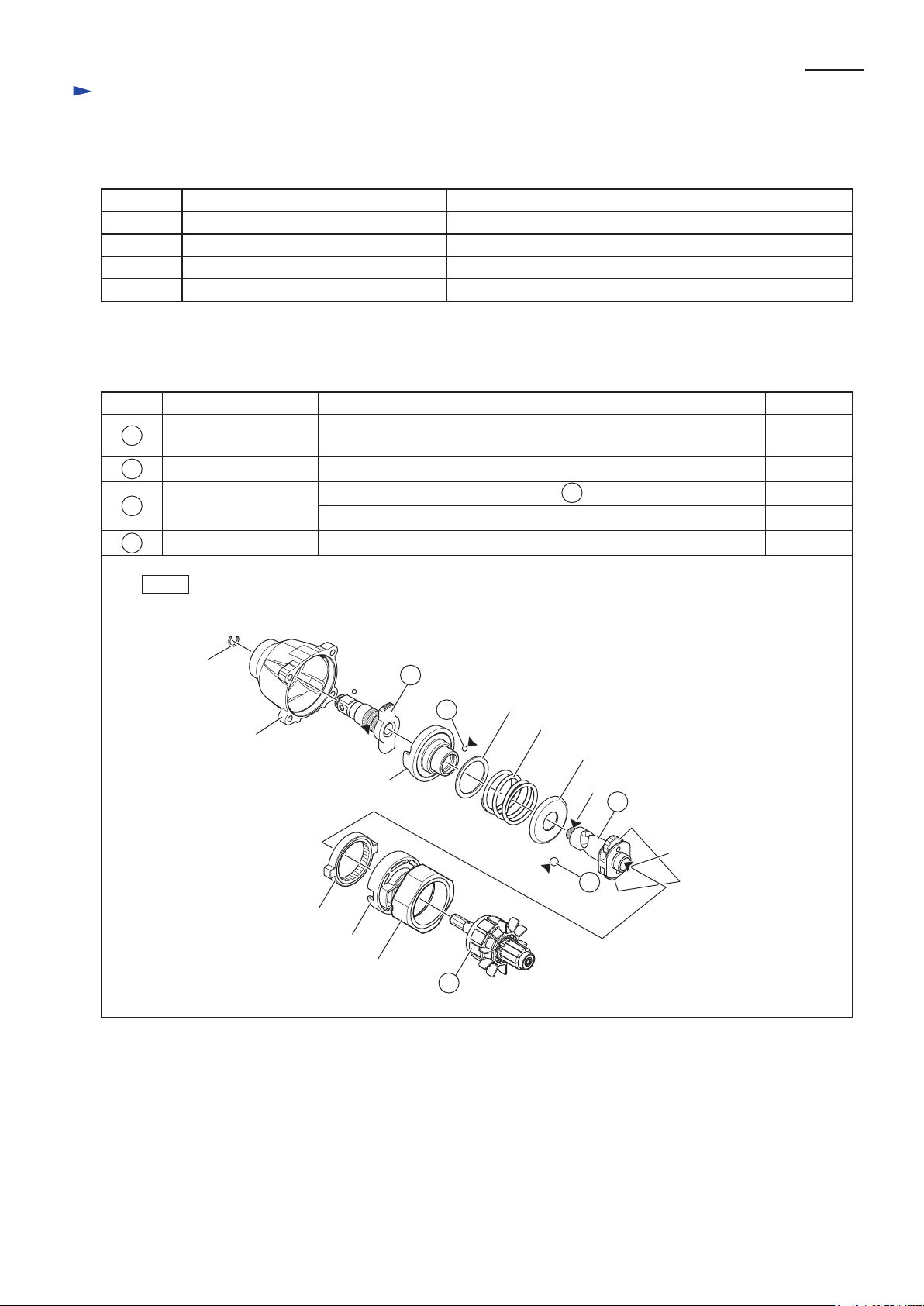

[2] LUBRICATION

Apply Makita grease FA No.2 to the following portions designated with the black triangle to protect parts and product

from unusual abrasion.

Socket Adapter

Screwdriver magnetizer removing Steel ball 5.6 from Spindle

securing Ring spring 7

Item No. Description

Anvil

14

Steel ball 3.5 (24 pcs.) Whole portion

16

Spindle

20

Steel ball 5.6 (2 pcs.)

25

Fig. 1

Ring spring 7

Hammer case

Drum portion which is accepted by Needle bearing 1412 mounted in

Hammer case complete

(a) Tip portion which is inserted into 14 Anvil

(b) in the hole where Spur gear 16 engages with Armature’s gear

Whole portion

14

16

Hammer

Washer 24

Compression spring 26

Cup washer 14

(a)

20

(b)

AmountPortion to lubricate

a little

a little

a little

approx. 2 g

a little

Internal gear 39

Internal gear case

Yoke unit

29

25

Spur gear 16

(2pcs.)

Page 3

Repair

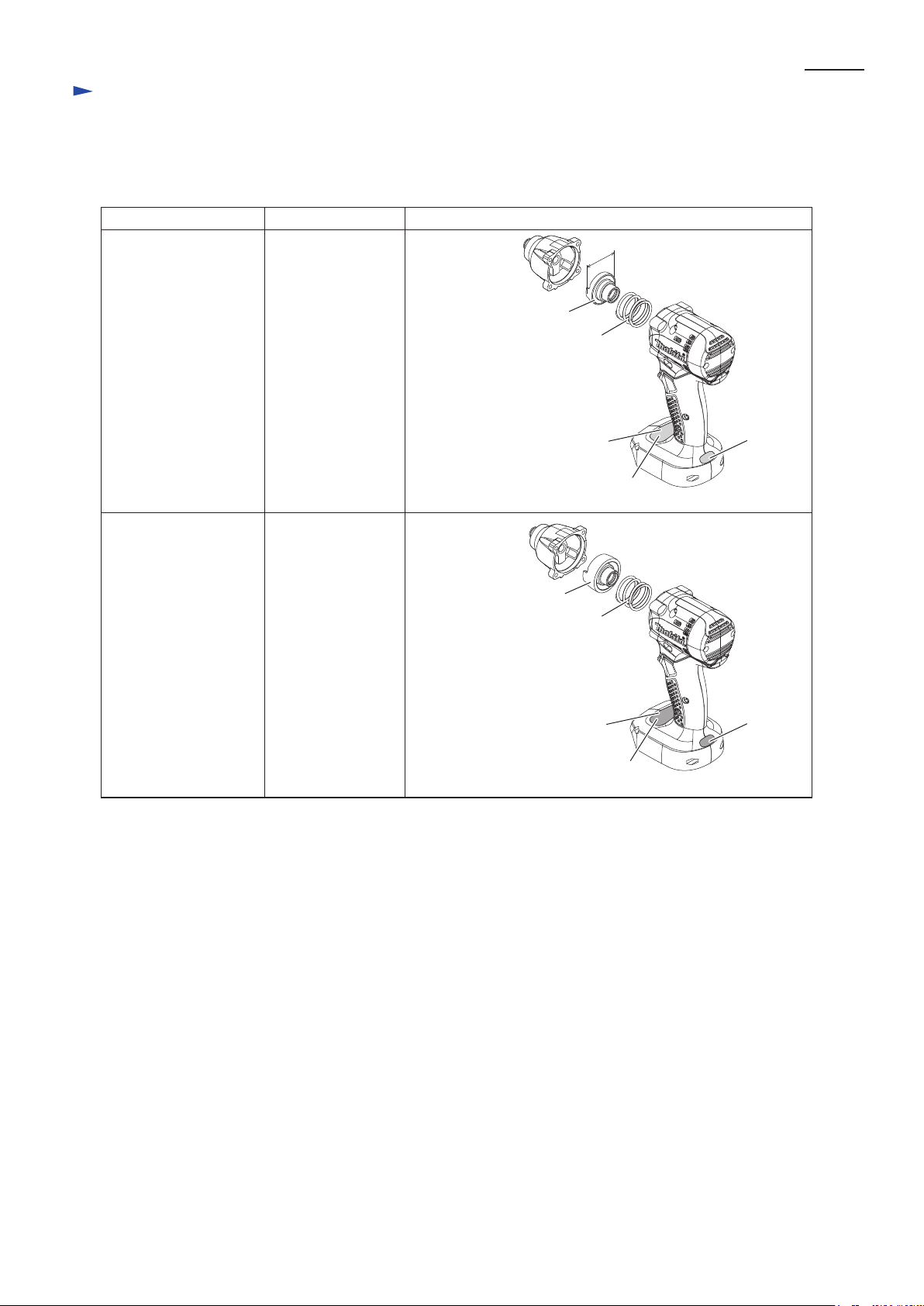

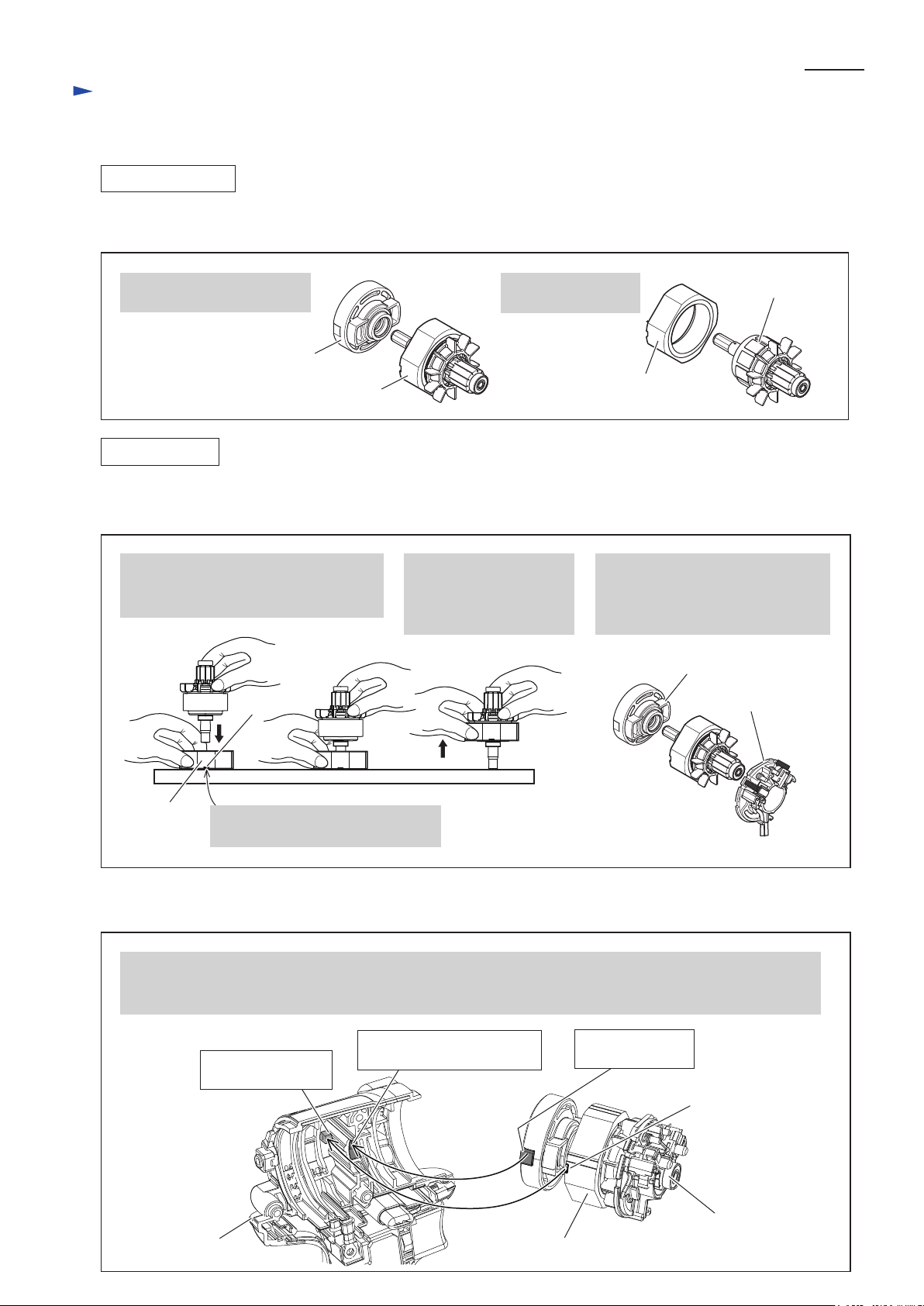

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Note for Assembly/Disassembly

The models can be distinguished depending on the max. fastening torque. See Fig. 2.

Fig. 2

Model No.Max. fastening torque Distinctive Parts

ø39

Hammer B

Compression spring

(orange)

65 N.m

BTW073

BTW074

P 3/ 15

ID plate

(white)

ID plate

(red)

95 N.m

BTW103

BTW104

BTD063: Cover complete

(white)

BTD064: Switch plate complete

(white)

Hammer C

Compression spring

(green)

BTD103: Cover complete

(red)

BTD104: Switch plate complete

(red)

When repairing the products, be sure to assemble Hammer, Compression spring and Switch plate complete or

Cover complete as shown in Fig.2.

Page 4

P 4/ 15

Repair

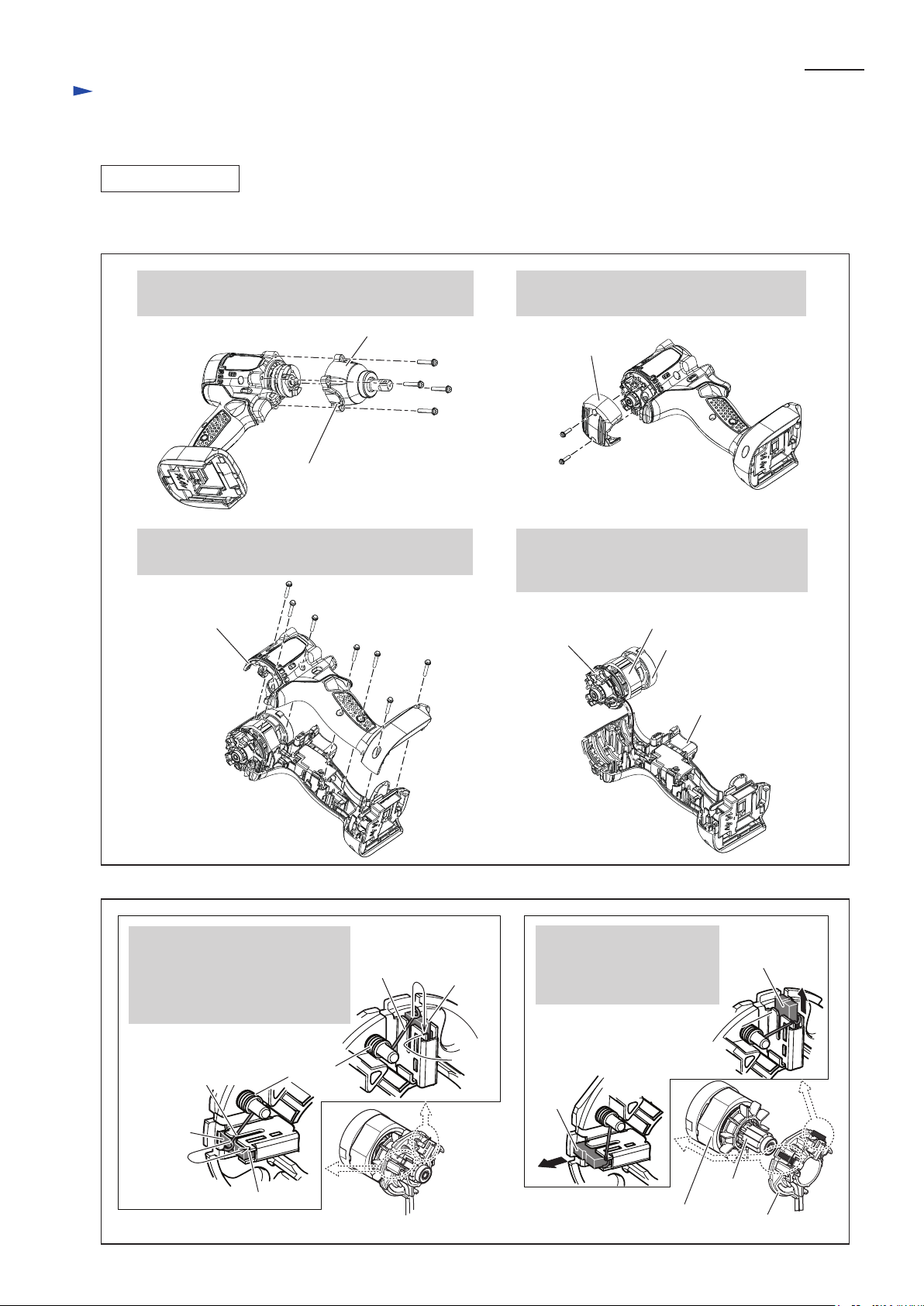

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature

DISASSEMBLING

(1) Remove Armature section from Housing set as drawn in Fig. 3, and remove Brush holder from Armature in Fig. 4.

Fig. 3

1. Loosen four M4x22 Pan head screws and separate

Hammer case complete from Housing set.

Hammer case complete

M4x22

Pan head screw

Hammer case

(4 pcs.)

complete

3. Loosen seven M3x20 Pan head screws and

separate Housing set (R) from Housing set (L).

M3x20

Housing set (R)

Pan head screw

(7 pcs.)

2. Loosen two M3x12 Pan head screws and

separate Rear cover from Housing set.

Rear cover

M3x12

Pan head screw

4. Take out Brush holder and Motor section

(Armature and Yoke unit) together with

Internal gear case from Housing set (L).

Motor section

Brush holder

Internal gear case

Housing set (L)

Fig. 4

1. Shift the tail of Torsion spring

from the top of Carbon brush to

the notch of Brush holder.

Then, Carbon brush is free from

the pressure of Torsion spring.

Tail of

Torsion Spring

Carbon

Brush

Notch

Torsion

Spring

Tail of

Torsion spring

Carbon

Brush

Notch

2. Take out Carbon brushes.

Then, disassemble

Armature and Yoke unit

from Brush holder.

Carbon

Brush

Yoke unit

Carbon brush

Armature

Brush holder

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature (cont.)

DISASSEMBLING

(1) Remove Armature as drawn in Fig. 5.

Fig. 5

P 5/ 15

1. Remove Internal gear case

from Motor section.

Internal gear case

Motor section

ASSEMBLING

(1) Insert Armature into Yoke unit so as not to damage the wiring of Armature and not to be pinched your fingers

between yoke unit and Armature fan. And insert the drive end of Armature into Internal gear case as drawn in Fig. 6.

Fig. 6

1. Hold Yoke unit on workbench and

slowly insert Armature into Yoke unit

until the drive end reaches workbench.

Notch

2. When the drive end

of Armature reaches

worktable, lift up Yoke

unit slowly.

2. Remove Armature

from Yoke unit.

3. Insert the drive end of Armature

into Internal gear case. And insert

the commutator end of Armature

into Brush holder.

Armature

Yoke unit

Internal gear case

Brush holder

Yoke unit

(2) Assemble Motor section (Armature, Yoke unit ), Internal gear case and Brush holder as drawn in Fig. 7.

Fig. 7

Assemble Internal gear case, Yoke unit, Armature and Brush holder to Housing set (L) by the following points.

* setting the slip stopper of Internal gear case to the box portion of Housing set (L)

* setting the notch of Yoke unit to the projection of Housing set

Housing set (L)

Note: Set Yoke unit with its Notch

facing to the workbench side.

Box portion for Slip

Projection for

Notch of Yoke unit

stopper of Internal gear case

Slip stopper of

Internal gear case

Notch of

Yoke unit

Brush holder

Motor section

Page 6

P 6/ 15

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature (cont.)

ASSEMBLING

(3) Assemble Motor section (Armature, Yoke unit ), Internal gear case and Brush holder to Housing set (L) as drawn

in Fig. 8.

Fig. 8

Yoke unit

Housing Set (L)

The flat surface of Brush

holder complete has to be

mounted perpendicularly.

90°

The edge of Yoke unit

has to be set inside of

the rib.

The marking on Yoke

unit should be facing

upward.

Rib

Mark

(4) Mount Pig tails and Spacers as drawn in Fig. 9.

Fig. 9

1. Spacer has to be set inside

the housing wall.

projection

Spacer

2. Aligning this groove with

the projection of Brush holder,

push Spacer toward Armature

until it stops.

(5) Assemble F/R change lever as drawn in Fig. 10.

Fig. 10

1. Set F/R change lever to Switch with aligning

the prong portion with the projection.

Pig tails

Note: Make sure that the loosening of

Pig tail is within 9 mm from

the edge of Brush holder.

9mm

2. Assemble Switch with F/R change lever

to Housing set (L).

Prong portion of

Projection

of Switch

(6) Be sure to assemble ID plate and Cover complete or Switch plate complete to Housing set (L) in accordance with

[3] -1. Note for Assembly/Disassembly

F/R change lever

and the drawings in Fig. 2. And then, assemble Housing set (R).

Page 7

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -3. Ball bearing 6801LLB in Internal gear case

DISASSEMBLING

(1) Disassemble Brush holder and Motor section together with Internal gear case as drawn in Fig. 3.

(2) Remove Internal gear case from Armature as drawn on the left in Fig. 5.

(3) Remove Ball bearing 6801LLB from Internal gear case as drawn in Fig. 11.

Fig. 11

Tap Internal gear case on the workbench to remove Ball bearing 6801LLB from the gear case.

Internal gear case

Ball bearing 6801LLB

P 7/ 15

Note: Should be tapped perpendicularly.

Page 8

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -4. Bit holder section, Anvil

DISASSEMBLING

(1) Loosen four M4x22 Pan head screws and separate Hammer case complete from Housing set.

See the drawing on the upper left in Fig. 3.

(2) Remove Ring spring 7 as drawn in Fig. 12. And then, remove Anvil as drawn in Fig. 13.

*For Anvil without Ring spring 7, Anvil can be removed as drawn in Fig. 13 skipping Fig. 12.

Fig. 12

Use 1R232 for stabilizing Anvil in the position

where Ring spring 7 can be removed easily.

Ring spring 7

Anvil

Remove Ring spring 7 with 1R004.

Ring spring 7

1R004

Anvil

P 8/ 15

1R232

Fig. 13

Anvil and Nylon washer 14 are removed from

Hammer case complete.

Hammer Case Complete

ASSEMBLING

(1) Pass Anvil through Nylon Washer 14 and mount them to Hammer case complete. Refer to Fig. 13.

*For Anvil without Ring spring 7, Hammer case section can be assembled to Housing set. Refer to Fig. 3

(2) To stabilize Anvil in the position where Ring spring 7 can be assembled easily, set Hammer case complete

on 1R232. Refer to the drawing on the left in Fig. 12.

(3) Assemble Ring spring 7 as drawn in Fig. 14.

Fig. 14

1. Aligning the cut of Ring

spring 7 with the groove

on Anvil, push the opposite

side of the cut portion

with pliers.

2. The mounted Ring

spring 7 is widened

by just fitting it.

So fasten it with pliers

as shown below.

Nylon Washer 14

Anvil

3. For final adjustment, repeatedly

attach and detach a 9.5 mm square

socket such as 1R222 to/from Anvil

to fit Ring spring 7 into the groove

on Anvil.

.

Ring spring 7

9.5 mm

1R222

Page 9

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Hammer section

DISASSEMBLING

(1) Loosen four M4x22 Pan head screws and separate Hammer case complete from Housing set.

See the drawing on the upper left in Fig. 3.

(2) Remove Hammer section from Housing set. See Fig. 15.

Fig. 15

Hammer section

P 9/ 15

(3) Take out Steel ball 5.6 with 1R045 as drawn in Fig. 16.

Fig. 16

1. Pull Hammer downwards using 1R045

to align the opening for Steel ball insertion

with the top of the cam grooving on Spindle,

and then remove Steel balls 5.6 from Spindle.

Steel Ball 5.6

(2pcs.)

Top of

Cam groove

on Spindle

Opening for

Steel ball

insertion

Spindle

Hammer

2. Hold Hammer section as shown below in Fig. 16R,

and then release it from 1R045.

Caution: Do not hold Hammer section as shown below

in Fig. 16F when releasing Hammer section

from 1R045. Failure to follow this instruction

could cause Steel balls 3.5 to fall out from it.

Fig. 16R Fig. 16F

1R045

Handle

Page 10

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Hammer section (cont.)

DISASSEMBLING

(4) Disassemble Hammer section as drawn in Fig. 17.

Fig. 17

P 10/ 15

Compression spring 26

Hammer

Steel ball 3.5 (24 pcs.)

Flat washer 24

Spindle

ASSEMBLING

Assemble Hammer section by reversing the disassembly procedure. (Refer to Fig. 17)

Note for Assembling:

Before putting Flat washer 24 in Hammer, make sure that twenty-four Steel balls 3.5 are put in the groove of Hammer

as shown in Fig. 18.

Fig. 18

Hammer and Steel balls 3.5,

viewed from above

Hammer

Cup washer 14

There will appear a space equivalent to

one Steel ball 3.5 in the groove of Hammer

when twenty-four Steel balls 3.5 are put

in place.

Page 11

Circuit diagram

Fig. D-1

Black

Red

P 11/ 15

BTW073, BTW103

(without Automatic Impact Stop System)

Color index of lead wires' sheath

Yellow

Brush holder

Line filter*

Brush holder complete

*Line filter is not used for some countries.

LED Circuit

LED

Switch

Connector

Connector

Terminal

Wiring diagram

Fig. D-2

Wiring to M1 Terminal of Switch

1. Secure Insulated terminal to

M1 Terminal with a screw

as shown below.

Viewed from

Housing set (L) side

BTW073, BTW103

(without Automatic Impact Stop System)

2. Bend the Terminal 90º

toward M2 Terminal side

so that Line filter can be

placed on Switch.

M1

M1

M2

Viewed from

Rear side

Wiring to M2 Terminal of Switch

Secure Insulated terminal to M2 Terminal

tilting approx. 30º±5º as shown below.

30°±5º

M1

M2

Viewed from

Housing set (R) side

Page 12

Wiring diagram

Fig. D-3

Wiring of LED Lead Wire (before setting Switch)

Route Lead wires (black, red) between

Rib A and the inner wall of Housing set (L).

Route lead wires (black, red) between Rib A

and Rib B so that they are not pinched

with Switch.

Route Lead wires (black, red) between Rib B

and the inner wall of Housing set (L).

If Connectors are put in Connector box A, route

Lead wires (black, red) through Connector box A

and secure them with Lead wire holder A .

Connectors in Connector Box A

(without Automatic Impact Stop System)

BTW073, BTW103

Rib C

P 12/ 15

LED

Rib A

Rib B

Rib D

Lead wire holder A

Connectors in

Connector box B

Lead wire

holder B

Wiring in Housing set (L) (after setting Switch)

Be careful not to route

any Lead wires on this Rib.

Rib E

Line filter

Place Line filter between Rib E and Rib F.

Note for Wiring:

If Line filter interferes with Housing set (R)

in assembling, check that Insulated terminal

is tilted enough to save the space for Line

filter referring to Fig. D-2.

Connectors can be also routed

through Connector box B.

In this case, Lead wires

have to be secured with Lead

wire holder B.

Rib F

LED

Switch

Route Lead wires connected to Switch

between Boss and the inner wall of

Housing set (L).

Boss

Page 13

Circuit diagram

Fig. D-4

Black

Blue

BTW074, BTW104

(equipped with Automatic Impact Stop System)

Color index of lead wires' sheath

Gray

Green

Orange

Red

P 13/ 15

White

Yellow

Brush holder complete

Brush holder

Line filter*

Switch

Terminal

LED Circuit

(Warning of Power Reduce)

LED Warning

Light

Connector

(4 pin)

Connector

(6 pin)

LED Light

Circuit

Controller

*Line filter is not used for some countries.

Wiring diagram

Fig. D-5

Wiring to M1 Terminal of Switch

1. Secure Insulated terminal to

M1 Terminal with a screw

as shown below.

(equipped with Automatic Impact Stop System)

M1

BTW074, BTW104

2. Bend the Terminal 90º

toward M2 Terminal side

so that Line filter can be

placed on Switch.

M1

M2

Wiring to M2 Terminal of Switch

Secure Insulated terminal to M2 Terminal

tilting approx. 30º±5º as shown below.

30°±5º

M1

M2

Viewed from

Housing set (L) side

Viewed from

Rear side

Viewed from

Housing set (R) side

Page 14

Wiring diagram

Fig. D-6

P 14/ 15

BTW074, BTW104

(equipped with Automatic Impact Stop System)

Wiring of LED Lead Wire (before setting Switch)

Route Lead wires (black, red) between

Rib A and the inner wall of Housing set (L).

Route lead wires (black, red) between

Rib A and Rib B so that they are not pinched

with Switch.

Route Lead wires (black, red) between Rib B

and the inner wall of Housing set (L).

Route Lead wires (black, red) between

the following Ribs.

* Rib of the Boss for Screw hole

* Rib of the Connector box

Wiring of Lead wire of LED Warning Lamp (before setting Switch)

Rib C

Boss

Rib F

LED

Rib A

Rib B

Connector (6 pin) for

connecting to Switch

Connector (4 pin) for

connecting to

LED Warning Light

Rib D

Connector box

LED warning lamp

Route the bundle of Lead wires (blue,

black, red and gray) between Rib A

and the inner wall of Housing set (L).

Route the bundle of Lead wires (blue,

black, red and gray) between Rib B

and the inner wall of Housing set (L).

Route Lead wires (blue, red and gray)

of LED Warning lamp and the

connecting Lead wire (black) between

Rib C and Rib D.

Secure Lead wires of both Connectors

(4 pin) with Lead wire holders.

Rib C

Rib F

LED

Rib A

Rib B

Connector 6 pin for

connecting to Switch

Rib D

Boss

Connector

(4 pin)

Page 15

Wiring diagram

Fig. D-7

Be careful not to route

any Lead wires on this Rib.

P 15/ 15

BTW074, BTW104

(equipped with Automatic Impact Stop System)

Wiring in Housing set (L) (after setting Switch)

Rib E

Route Lead wires of

LED warning lamp

between the Ribs.

LED warning lamp

Be careful not to route

any Lead wires on this Rib.

Secure lead wires of

both Connectors (6 pin)

with Lead wire holders.

Switch

Rib F

LED light

Note for Wiring:

If Line filter interferes with Housing set (R)

in assembling, check that Insulated terminal

is tilted enough to save the space for Line

filter referring to Fig. D-5.

Route Lead wires for connecting

to Switch between Boss and

the inner wall of Housing set (L).

Boss

Line filter

Route Line filter

between Ribs E and F.

Loading...

Loading...