Cordless Impact

Driver

Equipped with Electric Brake

MODEL BTD040

MODEL BTD060

INSTRUCTION MANUAL

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

001249

SPECIFICATIONS

Model BTD040 BTD060

Machine screw

Capacities

No load speed (RPM) 0 - 2,500/min. 0 - 2,500/min.

Impacts per minute 0 - 3,500 0 - 3,000

Overall length 164 mm (6 - 7/16”) 164 mm (6-7/16”)

Net weight 1.0 kg (2.3 lbs) 1.0 kg (2.3 lbs)

Rated voltage D.C. 9.6 V

Standard battery cartridges BH9020A,BH9033A

• Manufacturer reserves the right to change specifications without notice.

• Specifications may differ from country to country.

Standard bolt

High tensile bolt

4 mm - 8 mm

(5/32” - 5/16”)

5 mm - 10 mm

(3/16” - 3/8”)

5 mm - 8 mm

(3/16” - 5/16”)

4 mm - 8 mm

(5/32” - 5/16”)

5 mm - 12 mm

(3/16” - 1/2”)

5 mm - 10 mm

(3/16” - 3/8”)

GENERAL SAFETY RULES USA003-1

(FOR All BATTERY OPERATED TOOLS)

WARNING:

Read and understand all instructions. Failure to follow all

instructions listed below, may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

Work A re a

1. Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

2

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust

or fumes.

3. Keep bystanders, children, and visitors

away while operating a power tool. Dis-

tractions can cause you to lose control.

Electrical Safety

4. A battery operated tool with integral batteries or a separate battery pack must be

recharged only with the specified charger

for the battery. A charger that may be suit-

able for one type of battery may create a risk

of fire when used with another battery.

5. Use battery operated tool only with specifically designated battery pack. Use of any

other batteries may create a risk of fire.

Personal Safety

6. Stay alert, watch what you are doing, and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication. A moment of inattention while

operating power tools may result in serious

personal injury.

7. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or

long hair can be caught in moving parts.

8. Avoid accidental starting. Be sure switch

is in the locked or off position before

inserting battery pack. Carrying tools with

your finger on the switch or inserting the battery pack into a tool with the switch on invites

accidents.

9. Remove adjusting keys or wrenches

before turning the tool on. A wrench or a

key that is left attached to a rotating part of

the tool may result in personal injury.

10. Do not overreach. Keep proper footing

and balance at all times. Proper footing and

balance enable better control of the tool in

unexpected situations.

11. Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Tool Use and Care

12. Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead

to loss of control.

13. Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

14. Do not use tool if switch does not turn it

on or off. A tool that cannot be controlled

with the switch is dangerous and must be

repaired.

15. Disconnect battery pack from tool or

place the switch in the locked or off position before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

16. Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

17. When battery pack is not in use, keep it

away from other metal objects like: paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a connection from one terminal to another.

Shorting the battery terminals together may

cause sparks, burns, or a fire.

18. Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools with sharp cutting edge are less likely to

bind and are easier to control.

19. Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tool’s

operation. If damaged, have the tool serviced before using. Many accidents are

caused by poorly maintained tools.

3

20. Use only accessories that are recommended by the manufacturer for your

model. Accessories that may be suitable for

one tool may create a risk of injury when

used on another tool.

SERVICE

21. Tool service must be performed only by

qualified repair personnel. Service or main-

tenance performed by unqualified personnel

may result in a risk of injury.

22. When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance instructions may create a risk of

shock or injury.

SPECIFIC SAFETY RULES USB024-2

DO NOT let comfort or familiarity with product (gained from

repeated use) replace strict adherence to cordless impact driver

safety rules. If you use this tool unsafely or incorrectly, you can

suffer serious personal injury.

1. Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring.

Contact with a “live” wire will also make

exposed metal parts of the tool “live” and

shock the operator.

2. Be aware that this tool is always in an

operating condition, because it does not

have to be plugged into an electrical outlet.

3. Always be sure you have a firm footing.

Be sure no one is below when using the

tool in high locations.

4. Hold the tool firmly.

5. Wear ear protectors.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety rules stated in this

instruction manual may cause serious personal injury.

4

SYMBOLS USD302-1

The followings show the symbols used for tool.

V .......................volts

................... direct current

................... no load speed

n

˚

.../min................revolutions or reciprocation per

minute

................number of blow

IMPORTANT SAFETY INSTRUCTIONS FOR

BATTERY CARTRIDGE

1. Before using battery cartridge, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

7. Do not incinerate the battery cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

8. Be careful not to drop or strike battery.

ENC005-1

SAVE THESE INSTRUCTIONS

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room tempera-

ture at 10°C - 40°C (50°F - 104°F). Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery car-

tridge when you do not use it for more than six

months.

5

FUNCTIONAL

DESCRIPTION

001251

2

1. Battery cartridge

2. Button

Indicating lamp

(C) E F

orange

Indicating lamp

EF

orange

1

001254

Capacity

80% - 100%

60% - 80%

40% - 60%

10% - 40%

0% - 10%

Capacity

80% - 100%

60% - 80%

40% - 60%

10% - 40%

0% - 10%

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

Installing or removing battery cartridge

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the tool

while pressing the buttons on both sides of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Checking the remaining battery capacity

When charging

When the charging begins, the first (far left) indicating lamp

begins to flicker. Then, as charging proceeds, the other

lamps light, one after the other, to indicate the battery capacity.

When using

When the tool is switched on, the lamps will light to indicate

the remaining battery capacity. When the tool is switched off,

the light goes out after approx. 5 seconds. If the battery has

not been used for a long time, or is needed refresh charging,

the orange lamp begins to flicker. Use Makita refreshing

adapter to refresh the battery.

CAUTION:

• A battery cartridge extracted from the charger that has

been unplugged with the battery cartridge inserted does

not work even if it is inserted in the tool. At this time,

recharge it for about five seconds before use.

6

001255

Switch action

CAUTION:

1

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

1. Switch trigger

To start the tool, simply pull the switch trigger. Tool speed is

increased by increasing pressure on the switch trigger.

Release the switch trigger to stop.

Electric brake

This tool is equipped with an electric brake. If the tool consistently fails to quickly stop after switch trigger release, have

tool serviced at a Makita service center.

001257

Reversing switch action

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the A side

1

AB

1. Reversing switch lever

for clockwise rotation or from the B side for counterclockwise

rotation.

When the reversing switch lever is in the neutral position, the

switch trigger cannot be pulled.

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation before

the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

001258

Auto-stop mechanism

(C) E F

The tool stops automatically after the battery capacity

reaches under 20% to prevent the lack of fastening torque.

Charge the battery or use a new fully charged one.

EF

7

ASSEMBLY

12 mm

(15/32”)

1 2

1. Bit

2. Sleeve

9 mm

(3/8”)

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out any

work on the tool.

001266

Installing or removing driver bit or socket bit

Use only the driver bit or socket bit shown in the figure. Do

not use any other driver bit or socket bit.

001267

To install the bit, pull the sleeve in the direction of the arrow

and insert the bit into the sleeve as far as it will go. Then

release the sleeve to secure the bit.

To remove the bit, pull the sleeve in the direction of the arrow

and pull the bit out firmly.

NOTE:

• If the bit is not inserted deep enough into the sleeve, the

sleeve will not return to its original position and the bit

will not be secured. In this case, try re-inserting the bit

according to the instructions above.

8

OPERATION

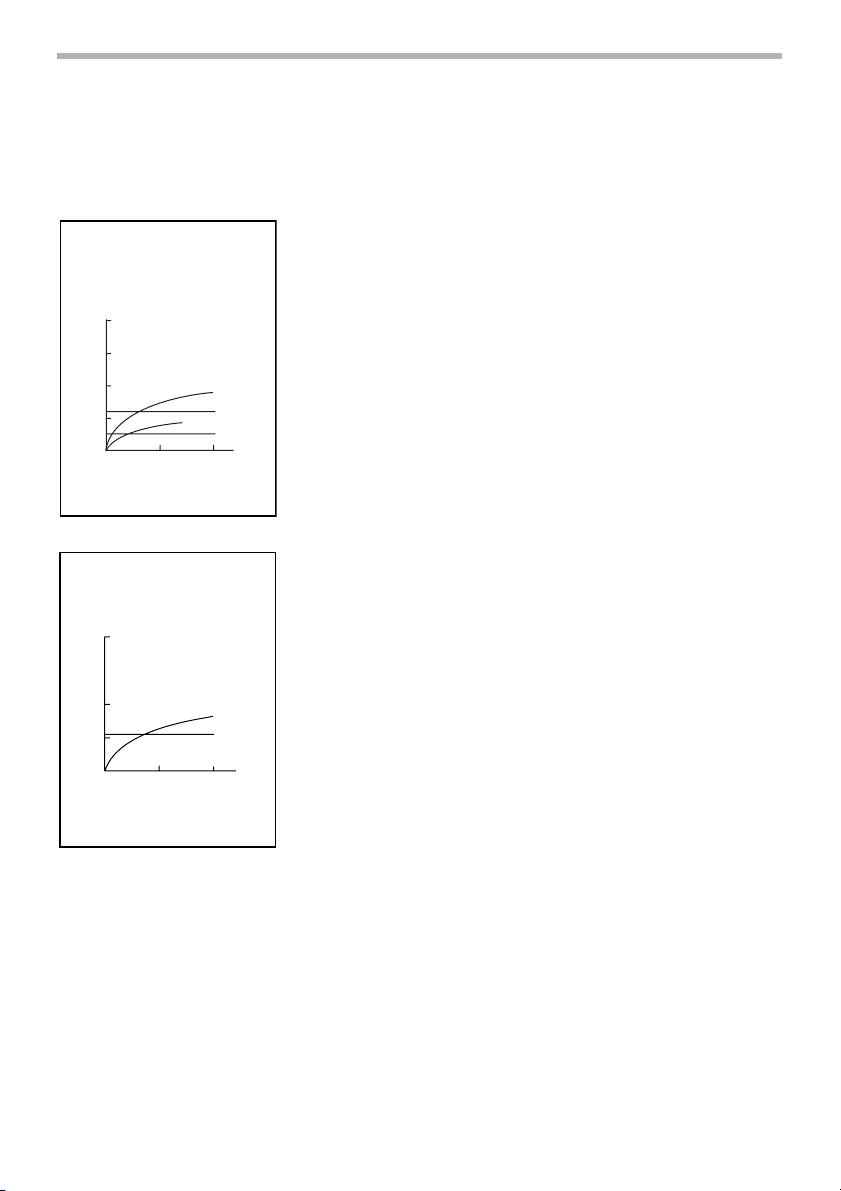

Standard bolt

N·m

(ft·lbs)

40

(29)

30

(21)

20

(14)

10

(7)

Fastening torque

0

Fastening time

High tensile bolt

N·m

(ft·lbs)

40

(29)

30

(21)

20

(14)

10

(7)

Fastening torque

0

Fastening time

M8 (5/16”)

M6 (1/4”)

0.5

BTD040

M6 (1/4”)

1.0

BTD040

(M8)

(M6)

1.0

(S)

(M6)

2.0

002844

Proper fastening torque

002845

Proper fastening torque

(S)

The proper fastening torque may differ depending upon the

kind or size of the screw/bolt, the material of the workpiece to

be fastened, etc. The relation between fastening torque and

fastening time is shown in the figures.

Hold the tool firmly and place the point of the driver bit in the

screw head. Apply forward pressure to the tool to the extent

that the bit will not slip off the screw and turn the tool on to

start operation.

NOTE:

• Use the proper bit for the head of the screw/bolt that you

wish to use.

• Hold the tool pointed straight at the screw.

• If you tighten the screw for a time longer than shown in

the figures, the screw or the point of the driver bit may be

overstressed, stripped, damaged, etc. Before starting

your job, always perform a test operation to determine

the proper fastening time for your screw.

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

The fastening torque is affected by a wide variety of factors

including the following. After fastening, always check the

torque with a torque wrench.

1. When the battery cartridge is discharged almost completely, voltage will drop and the fastening torque will be

reduced.

2. Driver bit or socket bit

Failure to use the correct size driver bit or socket bit will

cause a reduction in the fastening torque.

3. Bolt

• Even though the torque coefficient and the class of

bolt are the same, the proper fastening torque will

differ according to the diameter of bolt.

• Even though the diameters of bolts are the same, the

proper fastening torque will differ according to the

torque coefficient, the class of bolt and the bolt

length.

4. The manner of holding the tool or the material of driving

position to be fastened will affect the torque.

5. Operating the tool at low speed will cause a reduction in

the fastening torque.

9

MAINTENANCE

1

1. Limit mark

1

2

1. Brush holder cap

2. Screwdriver

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

001145

Replacing carbon brushes

Remove and check the carbon brushes regularly. Replace

when they wear down to the limit mark. Keep the carbon

brushes clean and free to slip in the holders. Both carbon

brushes should be replaced at the same time. Use only identical carbon brushes.

001268

Use a screwdriver to remove the brush holder caps. Take out

the worn carbon brushes, insert the new ones and secure

the brush holder caps.

After replacing brushes, insert the battery cartridge into the

tool and break in brushes by running tool with no load for

about 1 minute. Then check the tool while running and electric brake operation when releasing the switch trigger. If electric brake is not working well, ask your local Makita service

center for repair.

To maintain product SAFETY and RELIABILITY, repairs, any

other maintenance or adjustment should be performed by

Makita Authorized or Factory Service Centers, always using

Makita replacement parts.

10

Ni-Cd

EN0001-1

Recycling the Battery

The only way to dispose of a Makita battery is to recycle it.

The law prohibits any other method of disposal.

To recycle the battery:

1. Remove the battery from the tool.

2. a) Take the battery to your nearest Makita Factory

Service Center

or

b) Take the battery to your nearest Makita Authorized

Service Center or Distributor that has been designated as a Makita battery recycling location.

Call your nearest Makita Service Center or Distributor to

determine the location that provides Makita battery recycling.

See your local Yellow Pages under “Tools-Electric”.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended for

use with your Makita tool specified in this manual. The

use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory or

attachment for its stated purpose.

If you need any assistance for more details regarding these

accessories, ask your local Makita service center.

• Screw bits

• Protector (clear, red, blue)

• Automatic refreshing adapter

• Various type of Makita genuine battery cartridge

11

Memo

12

Cut

Makita Canada Inc.

1950 Forbes Street,

Whitby, Ontario

L1N 7B7

Fold

Stamp

Timbre

13

Your answers to the following questions are appreciated.

1. This product was purchased from?

Hardware/lumber Store

2. Use of the product is intended for?

Construction trade

5. Any comments?

Industrial Supply

Other ( )Tool Distributor

Home maintenance

Other ( )Industrial maintenance

3. How did you first learn of Makita Power Tools?

4. Most favored points are?

Certificate of Warranty

Mail to Makita

Date Purchased Model No.

Month Day Year 20

Serial No.

Magazine/Newspaper

Store display

Design

Price

Catalog

Other ( )From dealer

Makita Brand

Powe rFeatures

Other ( )Size

Initial Last Name

Street Address

City Province

AGE:

Under 19 20-29 30-39 40-49 Over 50

Occupation:

Dealer's Name & Address:

Paste Paste Paste Paste Paste Paste

14

Paste Paste Paste Paste Paste Paste Paste Paste

Male Female MarriedSingle

Postal Code

Paste Paste Paste Paste Paste Paste

Factory Service Centres

Head Office: 1950 Forbes St., Whitby, Ontario, L1N 7B7

Regional Office: 11771 Hammersmith Way, Richmond

Regional Office: 6389 boul. Couture, St. Leonard, Quebec

Dartmouth: 202 Brownlow Avenue

Ville St. Laurent: 1140 Rue Bégin, Ville St. Laurent, Quebec

Les Saules: 1200 St. Jean Baptiste, Unit 106, Les Saules,

Nepean: 210 Colonnade Road, Unit 11, Nepean,

Whitby: 1950 Forbes St., Whitby, Ontario, L1N 7B7

London: 317 Adelaide St. S., Unit 117, London,

Mississauga: 6350 Tomken Rd., Unit 8, Mississauga,

Calgary: #8-6115 Fourth St. S.E., Calgary

Edmonton: 11614-149 Street, Edmonton, Alberta,

Richmond: 11771 Hammersmith Way, Richmond, B.C.,

Winnipeg: 1670 St. James Street, Winnipeg, Manitoba,

Saskatoon: 206A-2750 Faithful Avenue Saskatoon,

For the authorized service centre nearest you please refer to the local yellow pages directory under “tools” or contact our customer service department (Tel) 1-800-263-3734

(905) 571 - 2200 1-800-263-3734

(604) 272 - 3104 1-800-663-0909B.C. V7A 5H6

(514) 323 - 1223 1-800-361-7049H1P 3J5(Montreal)

(902) 468 - 7064 1-888-625-4821Dartmouth, N.S., B3B 1T5

(514) 745 - 5025 1-888-745-5025H4R 1X1(Montreal)

(418) 871 - 5720 1-800-663-5757Quebec, G2E 5E8(Quebec)

(613) 224 - 5022 1-888-560-2214Ontario, K2E 7M1(Ottawa)

(905) 571 - 2200 1-800-263-3734

(519) 686 - 3115 1-800-571-0899Ontario, N5Z 3L3

(905) 670 - 7255 1-888-221-9811Ontario, L5T 1Y3

(403) 243 - 3995 1-800-267-0445Alberta, T2H 2H9

(780) 455 - 6644 1-888-455-6644T5M 3R3

(604) 272 - 3104 1-800-663-0909V7A 5H6

(204) 694 - 0402 1-800-550-5073R3H 0L3

(306) 931 - 0111 1-888-931-0111Saskatchewan, S7K 6M6

CUSTOMER RECORD

When you need service...

• Explain the problem in a letter

• Enclose the letter with the tool

• Package carefully and send prepaid

to the nearest Makita factory or

authorized service centre

DATE

PURCHASED:

DEALER’S NAME

& ADDRESS:

MODEL NO.:

SERIAL NO.:

15

MAKITA LIMITED ONE YEAR WARRANTY

Warranty Policy

Every Makita tool is thoroughly inspected and tested before leaving the factory. It is warranted to be free of defects from

workmanship and materials for the period of ONE YEAR from the date of original purchase. Should any trouble develop during

this one year period, return the COMPLETE tool, freight prepaid, to one of Makita’s Factory or Authorized Service Centres.

If inspection shows the trouble is caused by defective workmanship or material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply:

• where normal maintenance is required,

• repairs have been made or attempted by others,

• the tool has been abused, misused or improperly maintained,

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM

THE SALE OR USE OF THE PRODUCT. THIS DISCLAIMER APPLIES BOTH DURING AND AFTER THE TERM OF THIS

WARRANTY.

“The Makita Warranty is the only and the entire written warranty given by Makita for the Makita tools. No dealer or his agent

or employee is authorized to extend or enlarge upon this warranty by any verbal or written statement or advertisement.”

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED WARRANTIES INCLUDING IMPLIED WARRANTIES OF

“MERCHANTABILITY” AND FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF THIS WARRANTY.

“This Warranty gives you specific rights. The provisions contained in this warranty are not intended to limit, modify, take away

from, disclaim or exclude any warranties set forth in any provincial legislation. To the extent required by law, the provisions in

any provincial or federal legislation with respect to warranties take precedence over the provisions in this warranty.”

884334A235

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi 446-8502 Japan

Loading...

Loading...