Page 1

T

ECHNICAL INFORMATION

Models No.

Description

BHR242 (LXRH01*1), BHR243 (LXRH02*1)

Cordless Combination Hammer 24mm (15/16")

*1 Model number for North and Central American countries.

CONCEPT AND MAIN APPLICATIONS

The subject models are 24mm (15/16") Cordless Combination Hammers

powered by 18V Li-ion Battery, featuring:

• Efficient Brushless DC motor provides higher productivity than that of

18V Cordless Combination Hammer model BHR202.

• Able to drill in concrete as fast or faster than 24V Cordless Combination

Hammer model BHR200.

• 3 operation modes (rotation only/ rotation with hammering/ hammering only)

• Quick change drill chuck for models BHR243 (LXRH02*

• Makita’s first Cordless Combination Hammers with Dust extraction system.

Note: • These products are not compatible with 1.3Ah battery BL1815.

DX01, DX02

These are the accessories as Makita’s first Dust extracting system exclusively

for model BHR242 (LXRH01*1), BHR243 (LXRH02*1).

This system is designed to collect dust effectively with on-off operation

of the tool’s on-off trigger switch interlocked with this system.

Note: • This system can be applied for concrete drilling only and comes with

Dust case, Filter and 5 pcs. of extra Sealing caps.

• The following parts are available optionally:

Dust case set, Filter set, Plastic carrying case (can be stored with BHR242

or BHR243)

For Model and its Chuck systemDust extraction system

DX01

BHR242 (LXRH01*1)

BHR243 (LXRH02*

1)

Quick change chuckDX02

Specification

Model

Voltage: V

Cell

Battery

Capacity: mm (")

No load speed: (min

Chuck capacity: mm (")

Bit shank

Quick change drill chuck No Yes

Operation mode

Variable speed control

by switch trigger

Reverse switch

Clutch (Torque limiter)

Weight of Dust

extracting system: kg (lbs)

Weight according to EPTA-

Procedure 01/2003: kg (lbs)

*2: for North and Central American countries only

Capacity: Ah

Energy capacity: W

Charging time: min.

Concrete

Steel

Wood

-1= rpm)

-1)

BHR242

(LXRH01*

22 with DC18RC (DC18RA*

(Rotation only/ Rotation with Hammering/

1)

18

Li-ion

3.0

54

24 (15/16)

13 (1/2)

27 (1-1/16)

0 - 950

0 - 4,700Blows per min.: (bpm=min

10 (3/8)

Adapted for SDS-PLUS

3 modes

Hammering only)

Yes

YesConstant speed control

Yes

Yes

1.3 (3.0) for DX01,

1.4 (3.0) for DX02

1) only

Normal chuck

BHR243

(LXRH02*1)

2)

3.4 (7.6)3.3 (7.2)

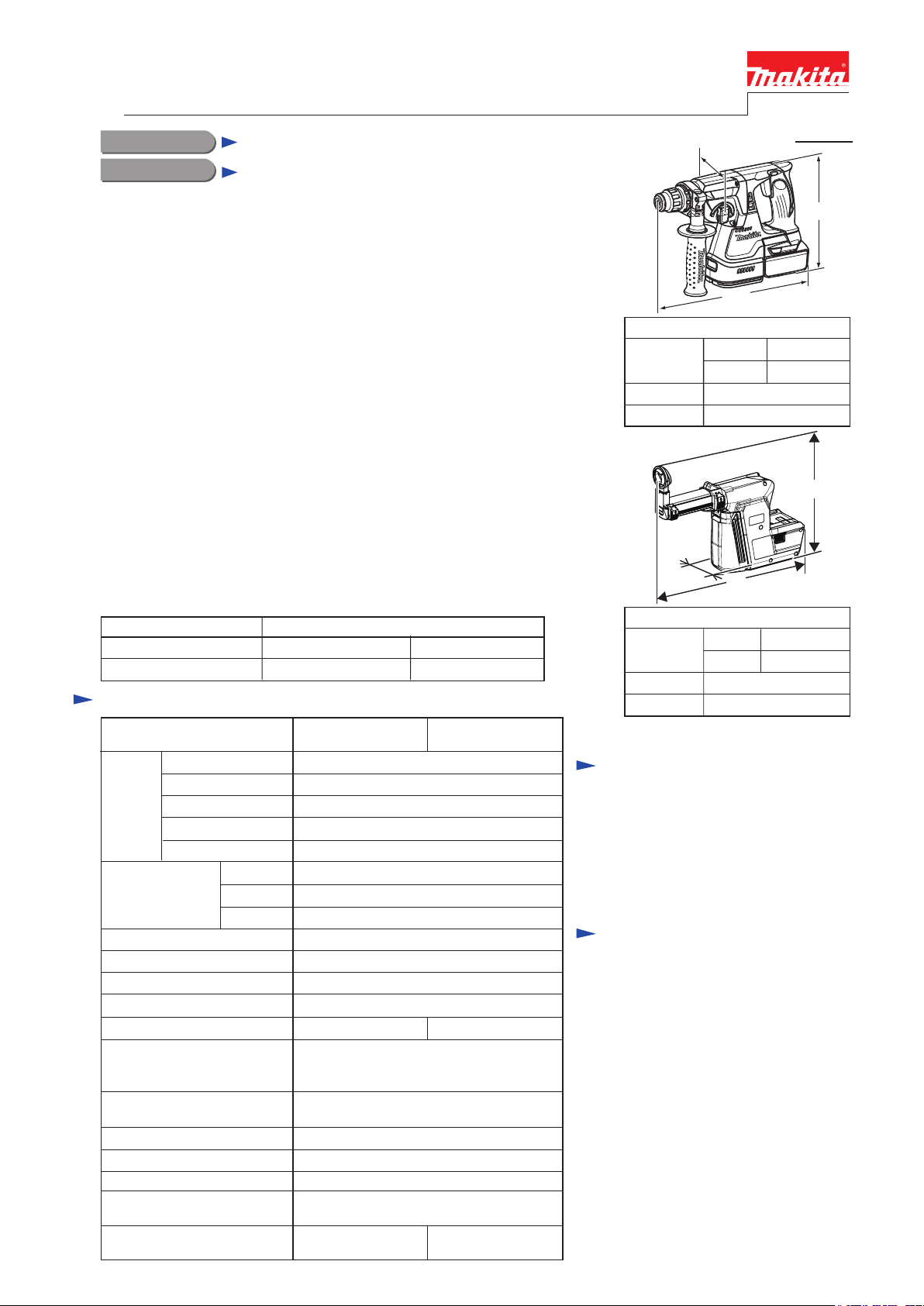

PRODUCT

P 1/ 25

W

H

L

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

Length (L)

Width (W) 88 (3-1/2)

Height (H)

BHR242

BHR243

W

Dimensions: mm (")

DX01

DX02

328(12-7/8)

353(13-7/8)

85 (3-3/8)

213 (8-3/8)

H

L

372(14-5/8)

397(15-5/8)

287 (11-1/4)

Standard equipment

Side grip assembly ............................ 1

Depth gauge (Stopper pole) .............. 1

Plastic carrying case

Quick change drill chuck set

for BHR243 (LXRH02*1) only ....... 1

Note: The standard equipment for the tool

shown above may vary by country.

......................... 1

Optional accessories

SDS-PLUS bits, Taper shank T.C.T bits,

Taper shank adapter, Cotter, Center bit,

Core bit adapter, Drill chuck assembly,

Chuck adapter, Drill chuck S13,

Chuck key S13, Keyless drill chuck,

Tool holder set, Dust cup 5 & 9,

Dust cup set, Bull point, Cold chisel,

Grooving chisel, Scaling chisel,

Scraper assembly, Grease vessel 30g,

Blow out bulb, Safety goggles,

Bit grease, Plastic carrying case,

Battery BL1830,

Fast charger; DC18RA*2, DC18RC,

Charger; DC18SC, DC24SC,

Automotive charger DC18SE,

Dust extraction system (DX01, DX02)

Page 2

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

DescriptionCode No. Use for

Retaining ring pliers ST-2N1R003 removing Ring spring 19 from Tool holder complete/ Tool holder guide complete

Retaining ring pliers ST-21R004

Drill chuck extractor1R139 removing Spiral bevel gear 32

Ring spring setting tool A1R164 assembling Oil seal 25 to Gear housing complete

T-type hex wrench 3-1271R170 removing M4 hex socket head bolts

Tip for Retaining ring pliers1R212 attachment of 1R003

1/4" hex shank bit for M41R228 removing M4 hex socket head bolts (if the bolt head damages.)

Pipe 301R232 assembling Oil seal 25 to Gear housing complete

Round bar for arbor 30-1001R252 removing Oil seal 25 from Gear housing complete

V block1R258 assembling Oil seal 25 to Gear housing complete

Bearing extractor1R269 removing Ball bearing 626DDW

Ring spring 26 setting tool B1R273 assembling Cup sleeve / Ball bearing 6806LLU to Gear housing complete

Round bar for arbor 7-501R281 removing Spiral bevel gear 32

1R356 removing Ball bearings from Rotor

1R369 removing / assembling Spiro lock washer 30

Bearing plate 10mm for

arbor press

Jig for Spiro lock washer for

spring type models

Ring spring extractor1R388 removing Ring spring 28

removing Retaining ring 21 for BHR243 from Armature shaft

assembling Ring 8Bearing setting plate 10.21R033

assembling Cam shaftBearing setting plate 15.21R035

removing / assembling Spiro lock washer 30Gear extractor (large)1R045

P 2/ 25

Page 3

Repair

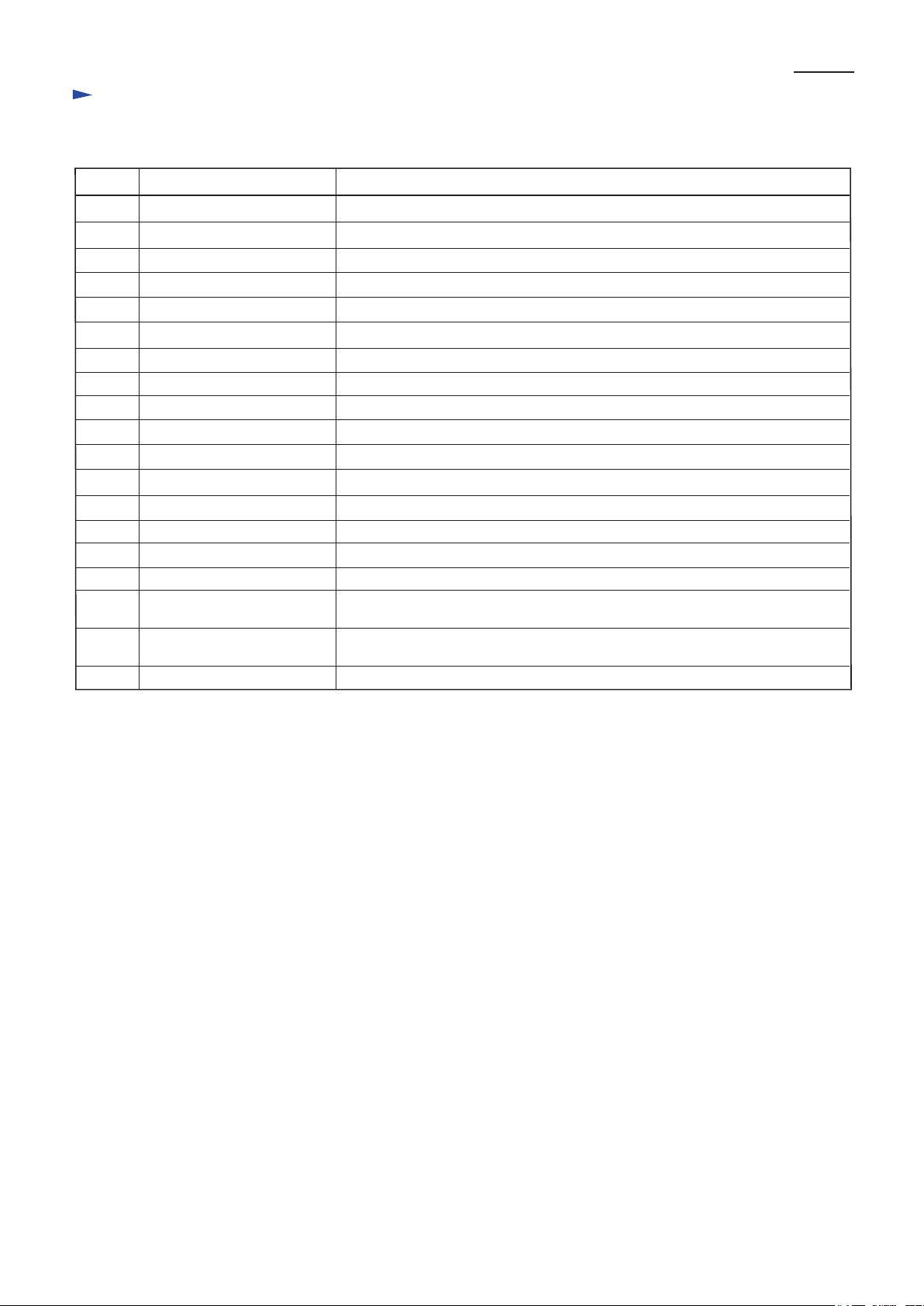

[2] LUBRICATION

Apply the following grease to protect parts and product from unusual abrasion.

Item No. Description Portion to lubricate Lubricant

Striker

46

O ring 17.5 Whole surface

47

48

Piston cylinder

49

Guide plate Inside that contacts 50 Piston joint

50

Piston joint Grooves that contact 49 Guide plate

51

Compression spring14End to be fixed to the boss in Inner housing complete

Spur gear 10 Gear portion that engages with Spur gear 51

56

57

Clutch cam A

58 Cam shaft

Swash bearing 10

59

Spiral bevel gear 32

60

73

Flat fillister HD pin 6

74 76

Weight holder guide

75 Counter weight

Spiral bevel gear 11

80

complete

Whole surface of projection

(a) Inside where Striker moves

(b) Outside that contacts Tool holder (guide) complete

(See Fig. 3.)

Gear portion that engages with 58 Cam shaft

(c) Gear portion that engages with 57 Clutch cam A

(d) Portion to be inserted into 59 Swash bearing 10

(e) Cylindrical portion to be inserted into 56 Spur gear 10

(f) Pole portion to be inserted into 50 Piston joint

(g) Ball bearing portion

(h) Inside of hole

Gear portion that engages with Armature shaft gear

Portion that contacts the hinge of Inner housing complete

Gear portion that engages with 60 Spiral bevel gear 32

[in the room of Inner housing complete for Spiral bevel gear 32]

Makita grease RB No.00

Makita grease RB No.00

and

Molybdenum disulfide

Makita grease RB No.00

Makita Grease FA No. 2

P 3/ 25

Amount

a little

3g

a little

See

Fig. 3.

a little

3g

Fig. 1

47 48

(a)

56

46

57

Transmission parts

(b)

49

(c) (d)

(e)

50 51

58

(f)

(g)

(h)

59

60

Counterweight

section

73

74

75

76

hinge of Inner

housing complete

80

Page 4

Repair

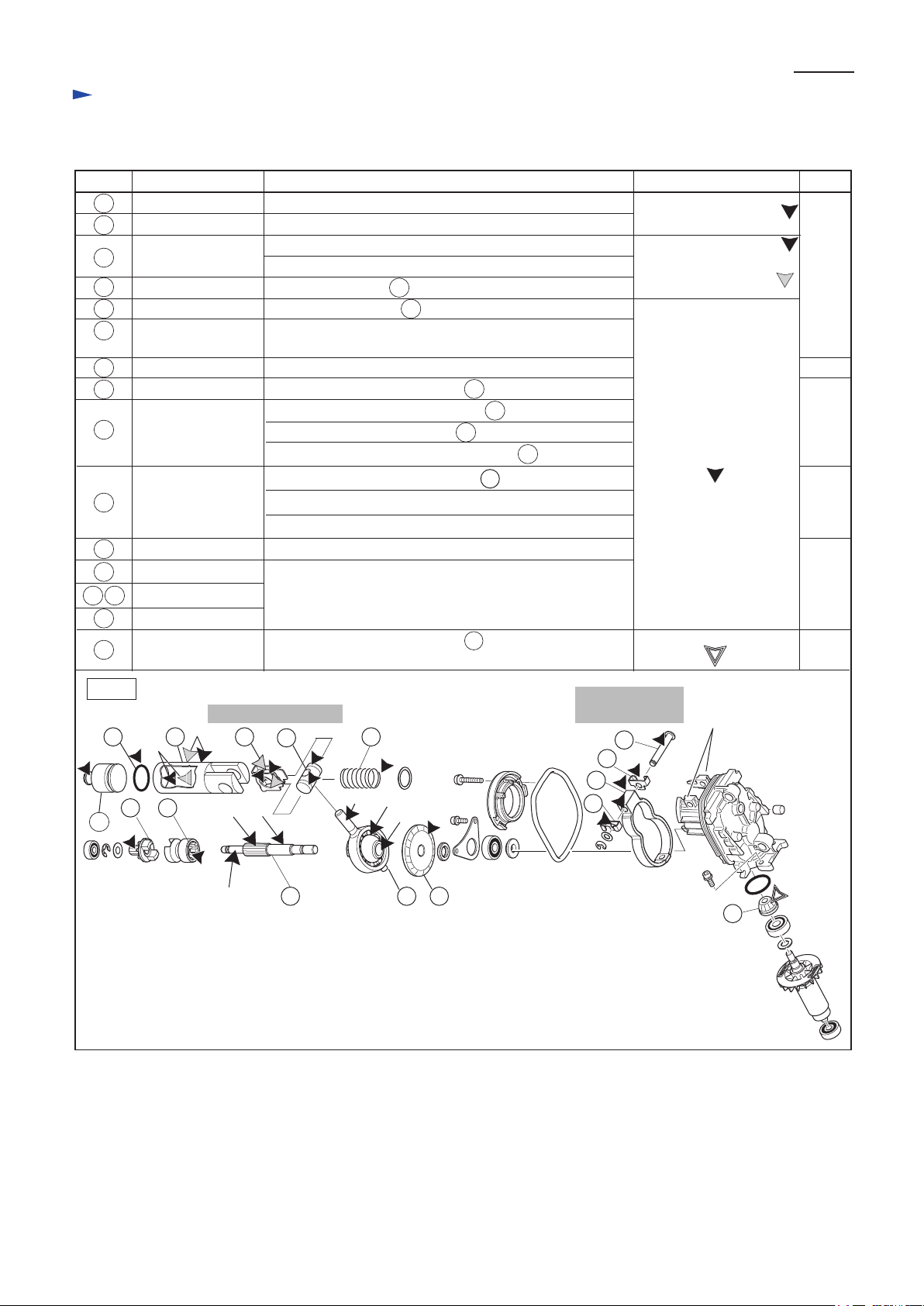

[2] LUBRICATION (cont.)

Apply the following grease/ oil to protect parts and product from unusual abrasion.

Item No.

BHR242 BHR243

1

105

6

8

108

114 Steel ball 6 Entire surface

118 Steel ball 5.0 Entire surface

15

22

32

28

109

30

30

39

Description Portion to lubricate Lubricant Amount

Cap 35

Lip portion where Bit is to be inserted

Rubber washer 16 Inner periphery

Ring 21 Inner periphery

Stopper Inner periphery

(a) Oil seal 25 in Gear housing complete

Gear housing complete

(b) Inside where Swash bearing section rotates

(See Fig. 3.)

O ring 21

Entire surface

Push corn25 Outer surface

(c) Gear portion

Spur gear 51

(d) Surface where Clutch portion of 30 Tool

holder (guide) complete contacts

Steel ball 7.0

Tool holder complete

Tool holderguide complete

Sleeve 9B

Washer 1041

O ring 944

Entire surface

Inside where 48 Piston cylinder reciprocates

Inside where Impact bolt A/ B reciprocates

Entire surface

P 4/ 25

Makita grease

RB No.00

a little

Makita lubricating oil

VG100

2g

Makita grease

RB No.00

a little

Fig. 2

Fig. 3

Quick change drill chuck: Apply Makita grease RB No. 00 to

two Steel balls 6 and one Steel ball 5.

(a)

22

15

Steel ball 5

Steel ball 6

(2 pcs.)

(b)

25

1

6

105

30

BHR242

(c)

108

109

32

8

28

(d)

BHR243

114

39

Impact bolt A

118

Impact bolt B

40

41

44

Cross section around

Swash bearing 10

boss for fixing

Compression

spring 14

Inside view of

Inner housing

Put 16g Makita grease RB No 00 by using the space

(designated by the black dot) to lubricate

Swash bearing section and Cam shaft section.

Page 5

Repair

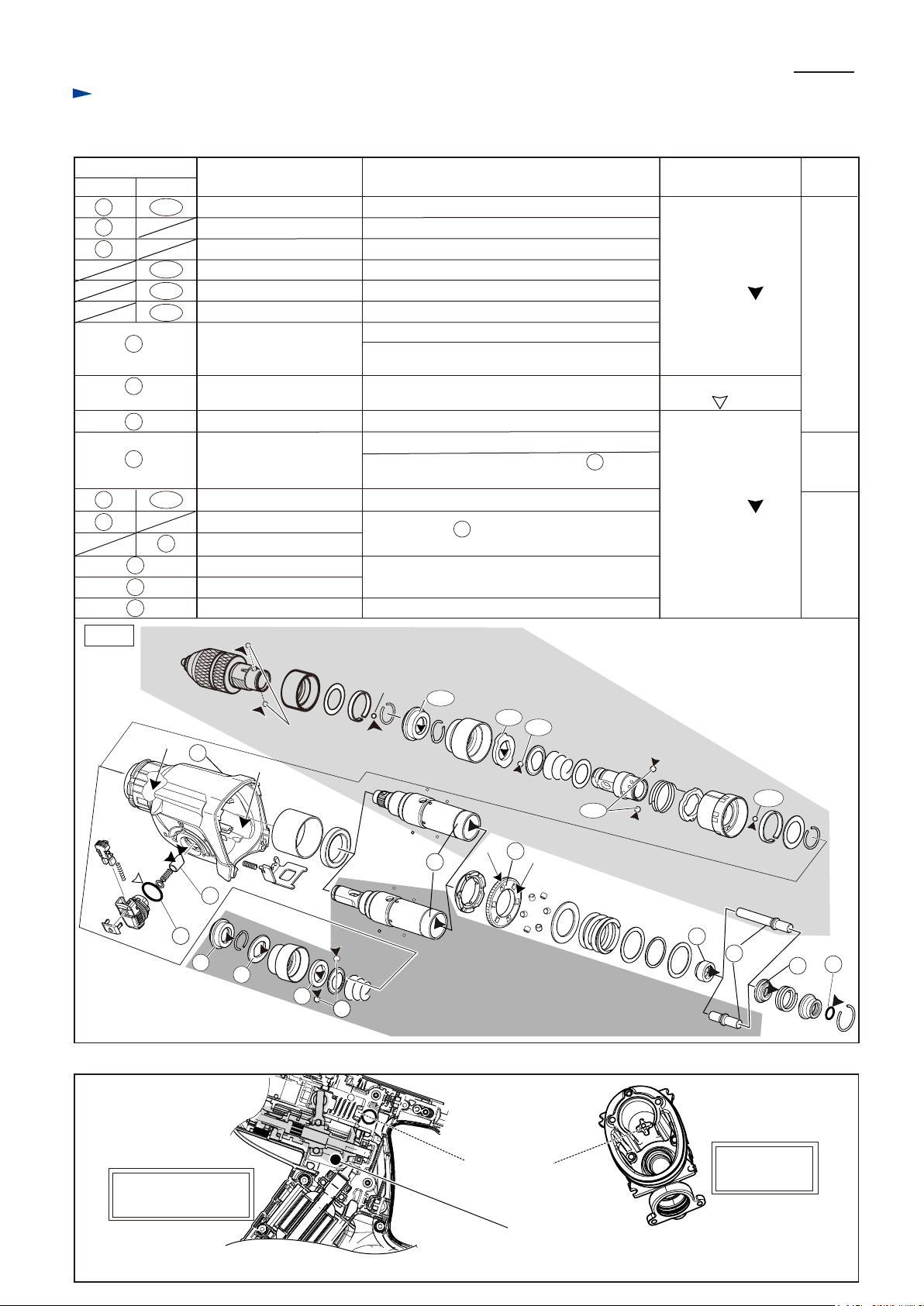

[3] DISASSEMBLY/ASSEMBLY

[3] -1A. Bit holder section for BHR242

DISASSEMBLING for BHR242

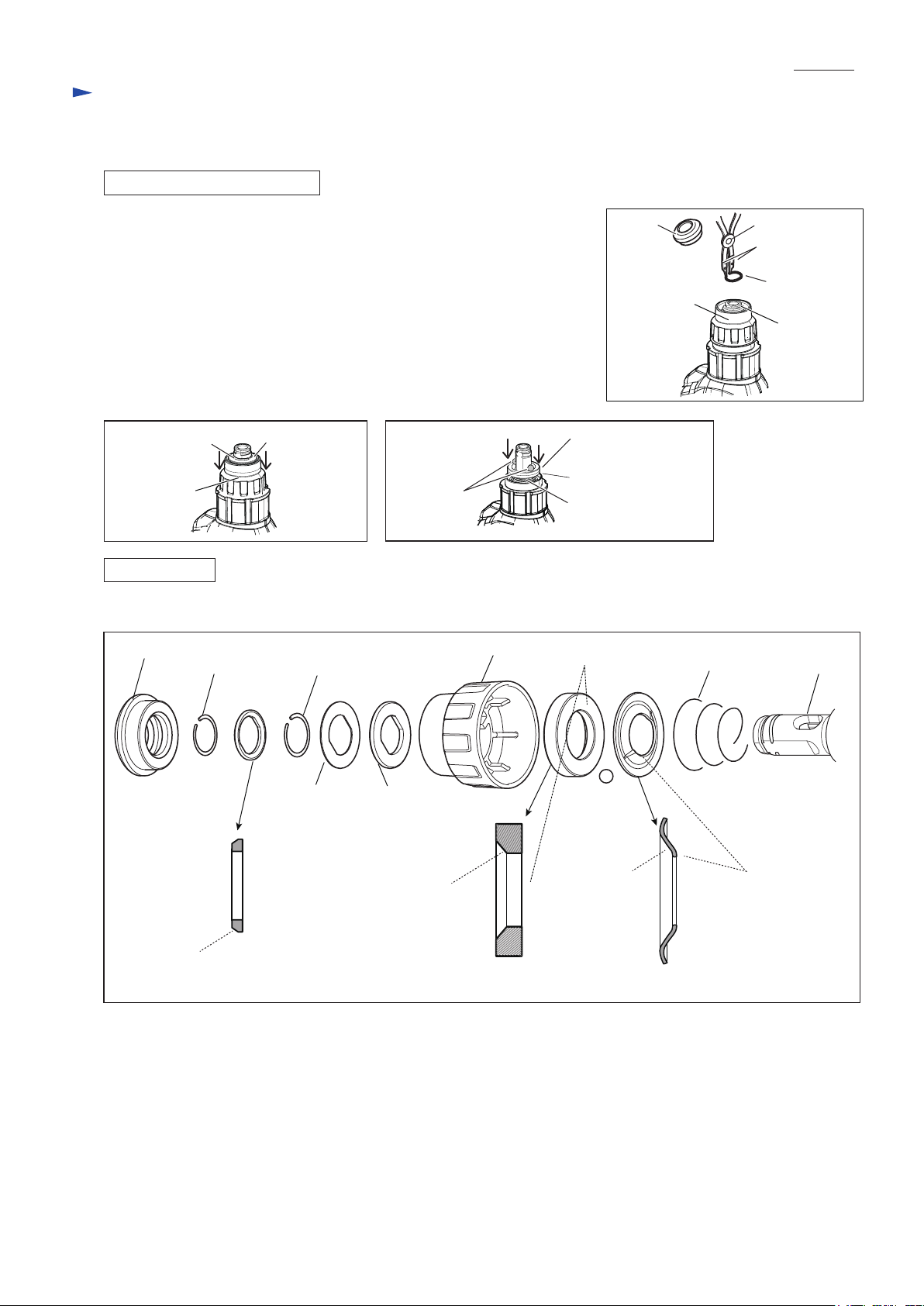

Fig. 4

(1) Remove Cap 35.

(2) Separate Ring spring 14 from the groove of Tool holder complete using

1R003 with 1R212. (Fig. 4)

Washer 16 on Ring spring 15 is removed.

(3) Remove Ring spring 15 in the same way while pressing down Chuck cover.

(Fig. 5) Then pick up Flat washer 17 and Rubber washer 16

from the space between Chuck cover and Tool holder complete.

Chuck cover is removed.

(4) Remove two Steel balls 7.0 while pressing down Ring 21. (Fig. 6)

Ring 21, Guide washer and Conical compression spring 21-29 are removed.

Cap 35

Chuck cover

P 5/ 25

1R003

1R212

Ring spring 14

(black)

Groove of

Tool holder

complete

Fig. 5

Ring spring 15

(silver)

Chuck cover

ASSEMBLING

Assemble by reversing the disassembly procedure. Refer to Fig. 7 for the directions of the components.

Fig. 7

Ring spring 14

(black)

Flat washer 17

Ring spring 15

(silver)

Flat washer 17 Rubber

Fig. 6

Steel ball 7.0

(2 pcs.)

washer 16

Ring 21

Guide washer

Conical compression

spring 21-29

Chuck coverCap 35

flat side

Steel ball

7.0 (2 pcs.)

Conical compression

spring 21-29

Tool holder

complete

chamfered

portion

chamfered

portion

Ring 21

concave

side

Guide washerWasher 16

convex

side

Page 6

P 6/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1B. Holder section for BHR243

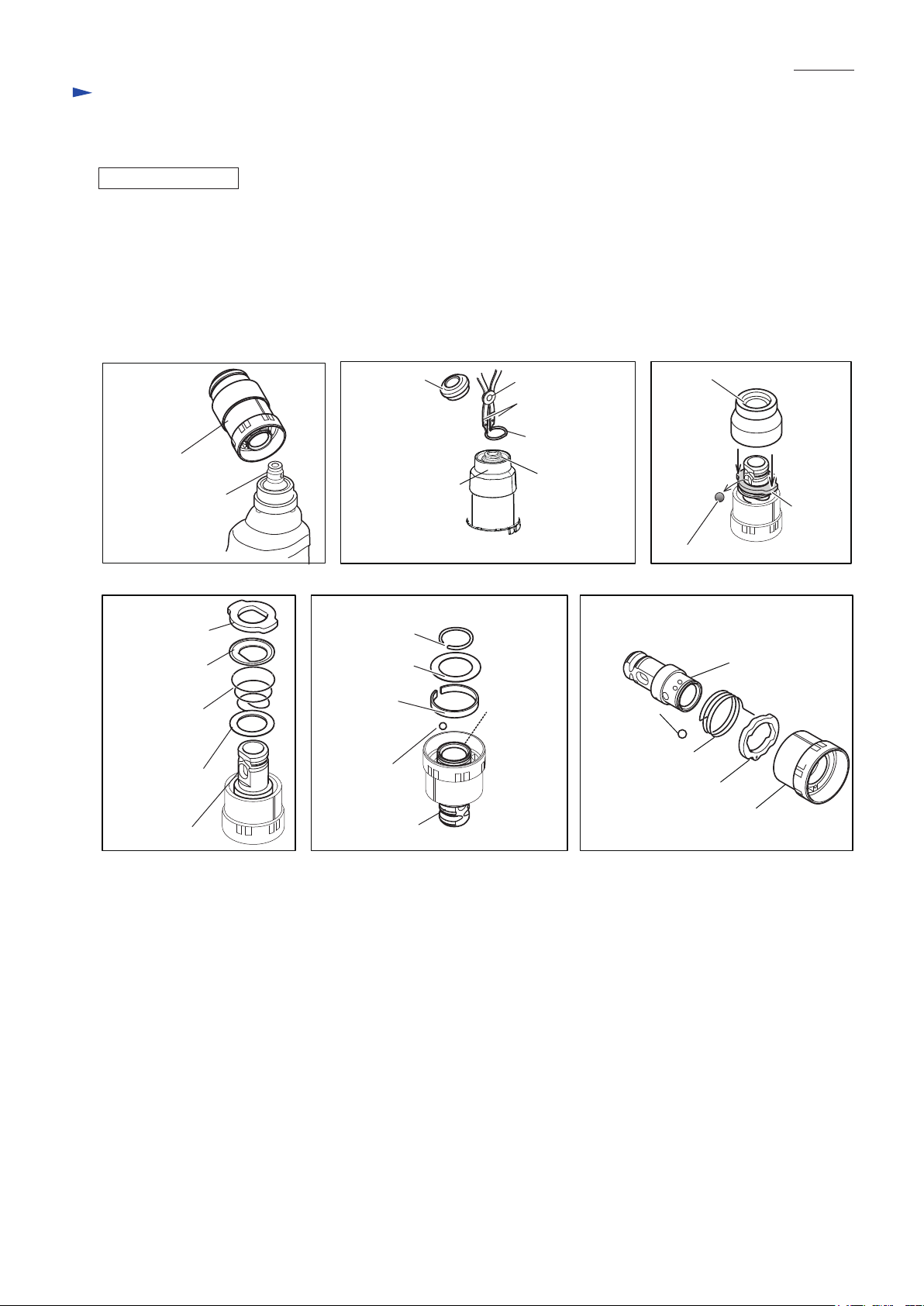

DISASSEMBLING

(1) Remove Tool holder set from Tool holder guide complete. (Fig. 8)

(2) Remove Cap 35, then separate Ring spring 19 from the groove of Tool holder using 1R003 with 1R212. (Fig. 9)

(3) Remove Chuck cover, then remove Steel ball 7.0 while pressing down Stopper. (Fig. 10)

Stopper, Guide washer, Conical compression spring 21-29 and Flat washer 21 are removed. (Fig. 11)

(4) Remove Ring spring 21 with 1R004 from Tool holder guide complete side.

Flat washer 24, Leaf spring and Steel ball 5 are removed. (Fig. 12)

(5) Remove two Steel balls 6, Torsion spring 31 and Change ring from Tool holder. (Fig. 13)

Fig. 8

Tool holder set

Tool holder guide

complete

Fig. 11 Fig. 13Fig. 12

Stopper

Guide washer

Conical

compression

spring 21-29

Flat washer 21

Fig. 9 Fig. 10

Ring spring 21

Flat washer 24

Leaf spring

Steel ball 5

Cap 35

Chuck cover

Tool holder set

1R003

1R212

Ring spring 19

Groove of

Tool holder

Tool holder

guide

complete

side

Chuck cover

Stopper

Steel ball 7.0

Tool holder

Steel ball 6

(2 pcs.)

Torsion spring 31

Change ring

Tool holder

Tool holder

Change cover

Page 7

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-1B. Holder section for BHR243 (cont.)

P 7/ 25

ASSEMBLING

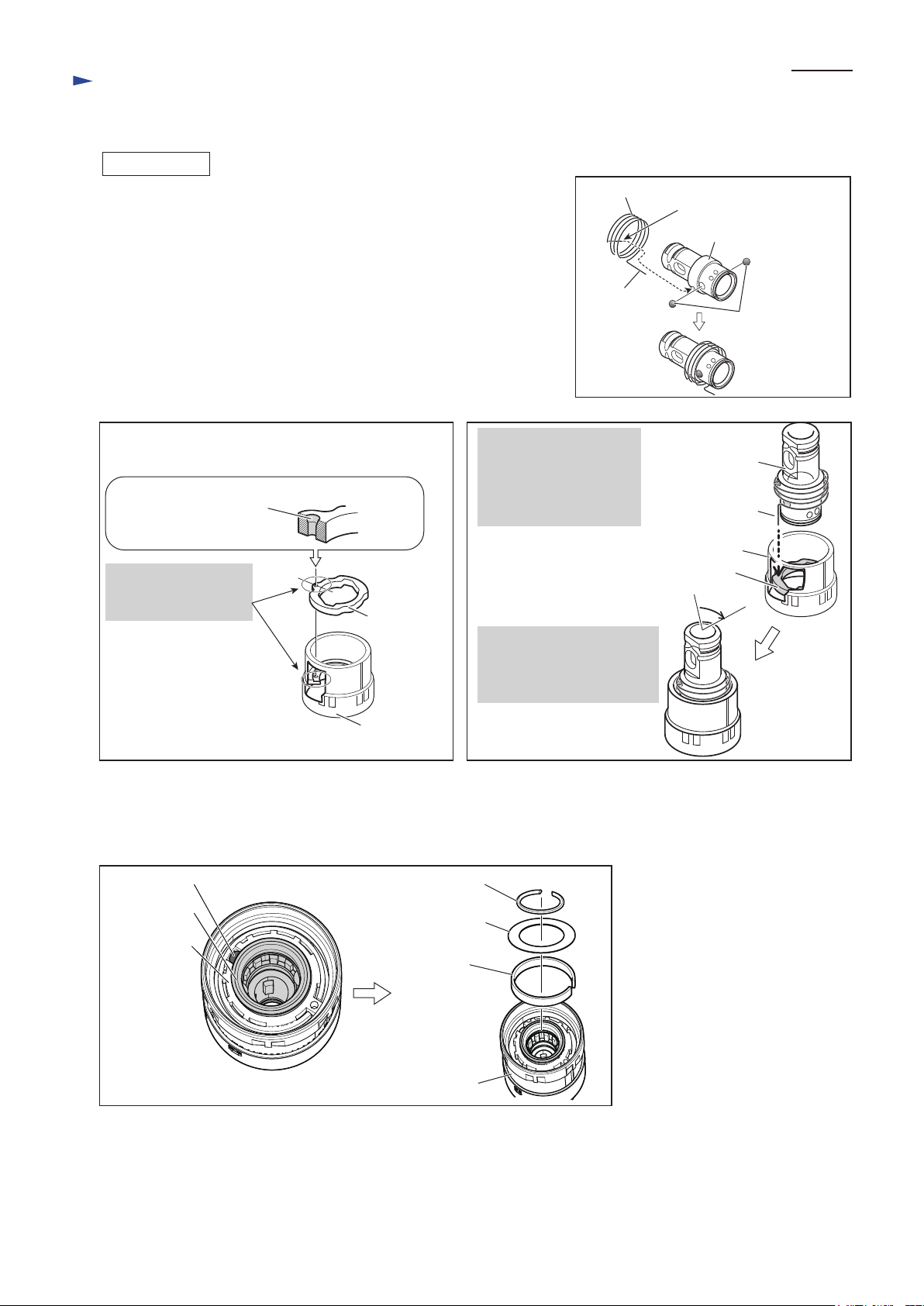

(1) Assemble Torsion spring 31 to Tool holder as follows:

• Set two Steel balls 6 on the holes of Tool holder.

• Insert the short arm of Torsion spring 31 into the hole of Tool holder.

Note: Apply Makita grease No. RB No. 00 to two Steel balls 6 to prevent

them from falling. (Fig. 14)

(2) Assemble Change ring to Change cover. (Fig. 15)

(3) Assemble Tool holder to Change cover. (Fig. 16)

Fig. 15 Fig. 16

Insert the long arm of

Torsion spring 31 into

Note:

Face the chamfered end

of the hole upward.

Align the hole of

Change ring with

that of Change cover.

[Section a - a']

a

a'

Change ring

the hole of Change cover

through the hole of

Change ring.

By turning Tool holder

approx. 75

Tool holder can be fastened

to Change cover.

Fig. 14

Torsion spring 31

long arm

°

clockwise,

short arm

Tool holder

Steel ball 6 (2pcs.)

Tool holder

long arm of

Torsion spring 31

Change cover

Change ring

75

°

Change cover

(4) Put Steel ball 5.0 in the groove surrounded by Change cover and Tool holder. (left in Fig. 17)

(5) Set Leaf spring and Flat washer 24 in change cover, then secure them with Ring spring 21. (right in Fig. 17)

(6) As for Cap 35 side, assemble the components by reversing disassembly procedure. Refer to the previous page.

Fig. 17

Steel ball 5.0

Change cover

Tool holder

Ring spring 21

Flat washer 24

Leaf spring

Change cover

Page 8

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Drill chuck assembly for BHR243

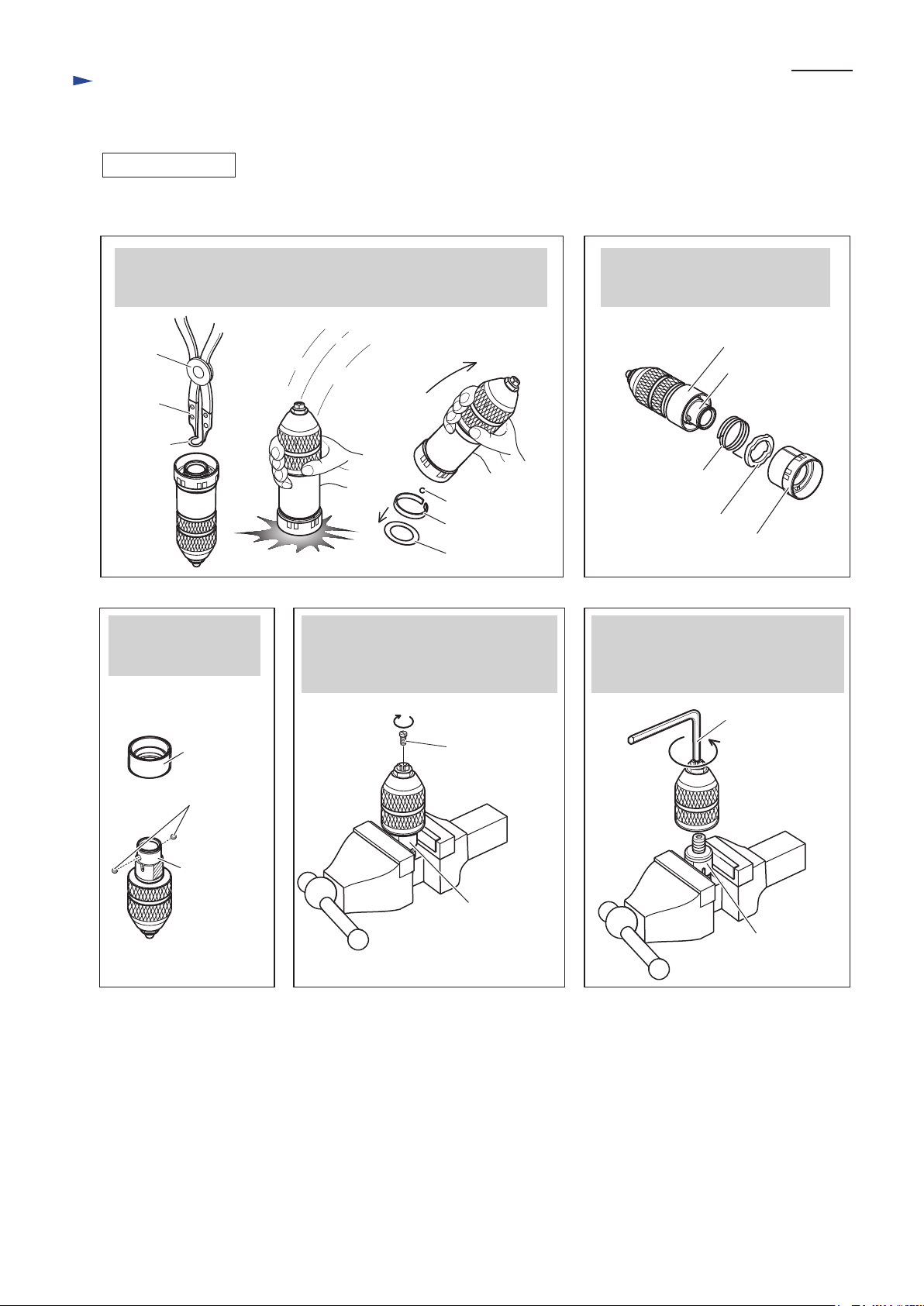

DISASSEMBLING

Drill chuck assembly can be disassembled as drawn in Figs. 18 to 22.

Fig. 18 Fig. 19

P 8/ 25

After Removing Ring spring 21, strike Drill chuck assembly against

workbench which is covered with a cloth as a cushion.

Flat washer 24, Leaf spring and Steel ball 5.0 can be removed.

1R003

1R212

Ring

spring 21

Steel ball 5.0

Leaf spring

Flat washer 24

Remove Spacer and

two Steel balls 6 from

Chuck holder.

Clamp the flats of Chuck holder in vise,

then unscrew M6x22 Flat head screw

by turning it clockwise using Impact

driver.

Pull off Change cover.

Change ring and Torsion spring 31

can be removed.

Spacer

Chuck holder

Torsion spring 31

Change ring

Change cover

Fig. 22Fig. 21Fig. 20

Clamp the flats of Chuck holder in vise,

then separate Drill chuck from Chuck

holder by turning it counterclockwise

using Hex wrench 10.

Spacer

Steel ball 6 (2 pcs.)

Chuck holder

Hex wrench 10

M6x22

Flat head screw

Chuck holder

Chuck holder

Page 9

P 9/ 25

Repair

[3] DISASSEMBLY/ ASSEMBLY

[3] -2. Drill chuck assembly for BHR243 (cont.)

ASSEMBLING

(1) Holding the flat portions of Chuck holder in vise, assemble Drill chuck to Chuck holder by turning it clockwise

using Hex wrench 10.

(2) Secure Drill chuck with M6x22 Flat head screw by turning it counterclockwise using Impact driver.

(3) Assemble Drill chuck to Spacer. (Fig. 23) Then mount two Steel balls 6. (Fig. 24)

(4) Mount Torsion spring 31. Then assemble Drill chuck to Change cover. (Fig. 25)

(5) Mount Steel ball 5, Leaf spring and Flat washer 24 to Chuck holder, then secure them with Ring spring 21. (Fig. 26)

Fig. 23 Fig. 24

Steel ball 6 (2 pcs.)

While fitting the flat portions

of Chuck holder to Spacer,

mount Drill chuck to Spacer.

Spacer

Fig. 25

Insert the short arm of Torsion

spring 31 into the hole of

Chuck holder using small pliers.

hole for

Torsion spring 31

Spacer

Chuck holder

short arm of

Torsion spring 31

Chuck holder

Chuck holder

Insert the long arm of Torsion spring 31

into the hole of Change cover through

the hole of Change ring, then assemble

Change ring to Change cover. (See Fig. 6.)

Torsion spring 31

long arm of

Torsion spring 31

Change ring

Change cover

Spacer

Note: Apply Makita grease RB No.00 to Steel balls 6

to protect them from falling.

By turning Drill chuck

approx. 75

Drill chuck can be fastened

to Change cover.

Drill

chuck

Change

cover

°

clockwise,

75

°

Fig. 26

Leaf spring

Flat washer 24

Ring spring 21

Steel ball 5

Page 10

P 10/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-3. Change lever

DISASSEMBLING

(1) Remove dust and dirt from Change lever and the grooved area on Motor housing.

(2) Set Change lever to Hammer mode. (Fig. 27)

Note: If it is hard to set Change lever to Hammer mode because of getting stuck in the halfway,

turn the bit holder section / holder section of the machine by hand and then try again.

(3) While pushing Lock button into Change lever, turn Change lever to the right fully over the position of Hammer mode.

(Fig. 28)

(4) Pull out Change lever from the position drawn in Fig. 29. If it is impossible to remove Change lever by hand, lever it up

with slotted screwdriver.

Note: Be careful not to remove Change lever without placing as drawn in Fig. 29.

The exact positioning prevents Change lever from breakage.

(5) Disassemble Change lever section as drawn in Fig. 2.

Fig. 27

Hammer mode

Fig. 28 Fig. 29

Change lever Lock button

ASSEMBLING

(1) Assemble the following parts to Change lever.

▪ Lock button ▪ Compression spring 3 ▪ Change lever cover ▪ O ring 21 (Apply Makita lubricating oil VG100.)

▪ Thin washer 16 ▪ Compression spring 5 ▪ Push corn

(2) Apply Makita grease RB No. 00 to Push corn.

(3) Fit the top of Push corn into the groove of Clutch cam A, and insert the hinge of Change lever into the hole of

Motor housing while keeping the exact position drawn in Fig. 29. (Refer to Fig. 30.)

(4) While pushing Lock button, turn Change lever to the left.

Note: Make sure that Change lever works properly by setting it to Drill mode/ Rotary hammer mode/ Hammer mode.

If it is hard to set Change lever to each mode because of getting stuck in the halfway; try 1 or 2 as follows:

1. Turn the bit holder section / holder section of the machine by hand and then try again.

2. Install battery and pull Switch very slightly a second to run the machine.

Fig. 30

Change lever section

Page 11

P 11/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Rotor

DISASSEMBLING

(1) Loosen four 4x35 Tapping screws, and then remove Battery housing R and Housing R in order from their housings L.

(Fig. 31)

(2) Remove Gear housing section as drawn in Fig. 32.

Inner housing in Gear housing section comes with Rotor.

(3) Loosen two M4x12 Hex socket head bolts with 1R170, and then remove Bearing retainer A. (Fig. 33)

(4) Pull Rotor section out straight from Inner housing by hand.

Note: Due to the effect of O ring 22.4 in the groove in Bearing room, pulling is preferable to tapping for removing Rotor

section.

(5) Insert a set of 1R356 under Ball bearing 608LLU, and press the shaft of Rotor in the center of Spiral bevel gear 11

complete with 1R281. (Fig. 34)

Ball bearing 608LLU, Flat washer 8 and Spiral bevel gear 11 complete are removed.

Remove 626DDW from Rotor with 1R269.

Fig. 31

Housing R

Gear housing section

Fig. 32

Two holes of Inner housing

for inserting two bosses of

Housing L

Battery

housing R

4x18 Tapping

screw (10 pcs.)

Fig. 33

1R170

Bearing retainer A

M4x12 Hex

socket head bolt

4x35 Tapping

screw (4 pcs.)

Rotor section

Fig. 34

Arbor press

1R281

1R356

Spiral bevel gear

11 complete

Rotor section

Stator

Ball bearing 608LLU

on Flat washer 8

Shaft of Rotor

Ball bearing 626DDW

ASSEMBLING

Assemble by reversing the disassembly procedure.

Note: Be sure to set Flat washer 8 in place between Fan and Ball bearing 608LLU.

Page 12

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-5. Torsion spring 6 for Connector, Battery housing

ASSEMBLING

See Fig. 35.

Set Torsion spring 6 into Housing L, and then assemble Connector to Compression spring 6. Refer to A .

Set Opener in place. Refer to B .

When Battery housing L and R are matched, do not fail to assemble the parts shown in C .

Fig. 35

A

Hold one end of Torsion spring 6

with the inner wall of Housing L.

Insert the hinge of Connector

into the coil of Torsion spring 6.

P 12/ 25

Hook the opposite end

of Torsion spring with

the step of Housing L.

C

B

Align the chamfered side

of Opener with the walls

of Housing L.

(Housing set)

Opener

Cushion

rubber (R)

Rubber pin 5

Pin 1.5

Battery housing set

Cushion rubber (L)

(behind Terminal)

Cushion

Page 13

P 13/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Torque limiter section

DISASSEMBLING

(1) Disassemble Tool holder section. (Figs. 4 to 6 for BHR242/ Figs. 8 to 13 for BHR243.)

(2) Disassemble Change lever. (Figs. 27 to 29)

(3) Remove Gear housing section from Motor housing, and then remove Rotor section from Gear housing section.

(Figs. 31 to 33)

(4) While holding Gear housing section by hand, tap the top of Tool holder (guide) complete with plastic hammer. (Fig. 36)

Note: 1. Grease falls from Gear housing section. Receive the grease with cloths.

2. Do not lose Flat washer 30 between

(5) Remove Stop ring EXT U-6 from Cam shaft. (Fig. 37)

The ring tends to be caught by Spur gear 51, and therefore, it interferes in the disassembling step.

(6) Remove Tool holder section. (Fig. 37)

(7) Set 1R045 and 1R369 to Tool holder section. (Fig. 38)

(8) Compress Compression spring 31 of Tool holder section by turning the handle of 1R045 clockwise. (Fig. 39)

(9) Remove Spiro lock washer 30 from Tool holder (guide) complete by gradually sliding it on Tool holder (guide) complete

with Thin-slotted screwdriver. (Fig. 40) Tool holder (guide) section are disassembled as drawn in Fig. 41.

Tool holder section

and Inner housing.

Fig. 36

Tool

holder

section

Fig. 39 Fig. 40

Spiro lock washer 30

1R045

1R369

(Compression

spring 31)

Fig. 37 Fig. 38

Super gear 51

Stop ring

EXT U-6

Flat washer 7

Swash bearing section

Magnified view of Fig. 39

Thin-slotted

screwdriver

Tool holder section Tool holder section

1R369

Tool holder (guide) complete

1R045

Ends of Spiro lock

washer 30

1R369

1R045

Fig. 41

Pin 6 (6 pcs.)Driving flangeTool holder (guide)

complete

Spur gear 51Steel ball 3 (4 pcs.)

ASSEMBLING

Assemble by reversing the disassembly procedure.

Note: 1. Set Spiro lock washer 30 in place with 1R369 and 1R045.

2. After assembling the components of Tool holder section, set Flat washer 7 and Stop ring EXT U-6 to Cam shaft.

(Refer to Fig. 37)

Flat washer 30

(thick shape)

Flat washer 30

(thin shape 2 pcs.)

Spiro lock washer 30Compression spring 31

Page 14

P 14/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Impact bolt in Torque limiter section

DISASSEMBLING

(1) Put 1R388 into Tool holder (guide) complete, then push 1R388 in vise with the access holes on Tool holder (guide)

complete parallel to Vise. (Fig. 42)

O-ring case B is moved toward the top of Tool holder (guide) complete, and therefore, Ring spring 28 can be relieved

from O-ring case B.

(2) When the end gap of Ring spring 28 is in the access hole, slide it with slotted screwdriver until it is completely hidden.

(3) Using slotted screwdriver, tap Ring spring 28 through the two access holes alternately to push it out of the inner groove

of Tool holder (guide) complete.

Note: As soon as a part of Ring spring 28 is removed from the inner groove of Tool holder (guide) complete, insert another

slotted screwdriver in between Ring spring 28 and the inner groove of Tool holder (guide) complete to prevent

returning the removed portion back to the inner groove.

(4) The components are removed by tapping with Phillips screwdriver and Plastic hammer from bit installation side of

Tool holder (guide) complete. (Fig. 43)

Fig. 42

The directions of two access holes on Tool holder (guide) complete

have to be parallel to Vise.

Vise Vise

1R388

1R388 O-ring case B

holes on both side of Tool holder (guide)

complete to access inside

Fig. 43

°

90

slotted

screwdriver

Ring spring 28

inner groove of Tool holder (guide) complete

Bit installation side

BHR242: Impact bolt A

Sleeve 9B

BHR243: Impact bolt B

O ring 9O ring case B

Washer 10

Compression spring 20

Ring spring 28

Inner housing

side

Page 15

P 15/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-6. Impact bolt in Torque limiter section (cont.)

ASSEMBLING

(1) Assemble Impact bolt section to Tool holder (guide) complete as drawn in Fig. 44A/ 44B.

Fig. 44A

Impact bolt section in Tool holder complete for BHR242

Tool holder complete (140265-3)

Bit installation side Inner housing side

Sleeve 9B

Impact bolt A

Washer 10 Compression

spring 20

O ring case B with

O ring 9 fit inside

Note: These components

are directional.

Fig. 44B

Impact bolt section in Tool holder guide complete for BHR243

Tool holder guide complete (140266-1)

Bit installation

side

Note: These components

are directional.

(2) Push Ring spring 28 into the inner groove of Tool holder (guide) complete as drawn in Fig. 45.

Note: Do not reuse the removed Ring spring 28 if it is deformed or damaged.

Fig. 45

Note: 1. Use an extra Piston cylinder as a jig. Never use Piston cylinder that is

to be assembled to the machine.

Piston cylinder

as a jig

2. The end gap of Ring spring 28 must not be placed at the two holes of

Tool holder (guide) complete.

ø9mm

[cross-sectional view]

Sleeve 9B Washer 10 Compression

Impact bolt B

long short

[cross-sectional view]

ø9.5mm

spring 20

O ring case B with

O ring 9 fit inside

Inner housing side

end gap

Ring spring 28

Tool holder (guide)

complete

hole

Note: 2

Tool holder Guide)

complete

Ring spring 28

end gap

Note: 1

hole

Inner groove of

Tool holder (guide)

complete

[Correct] [Wrong]

Piston cylinder as a jig

Ring spring 28

O ring case B

Page 16

P 16/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-7. Swash bearing section, Piston cylinder section

DISASSEMBLING

(1) Disassemble Motor housing section, Gear housing section and Inner housing section.

(2) Remove Flat fillister HD pin 6, two Weight holder guides, Flat washer 6, Stop ring E-5, Inner support complete and

two M4x25 Hex socket head bolts from Inner housing. (Fig. 47)

(3) While pushing Piston cylinder, remove Counter weight from Swash bearing section as drawn in Fig. 48.

(4) Remove two M4x12 Hex socket head bolts with 1R170 or 1R228. (Fig. 49)

- Then pull Swash bearing section and Piston cylinder section out of Inner housing. (Fig. 49)

- Swash bearing section can be removed from Piston cylinder section with Inner housing attached as drawn in Fig. 50.

(5) Remove Ball bearing 606ZZ from Gear housing complete using the removed Swash bearing section. (Fig. 51)

Fig. 47

Flat fillister HD pin 6

M4x25 Hex socket

head bolt (2 pcs.)

Inner support complete

Fig. 49

M4x12 Hex socket head bolt (2 pcs.)

Note: These are thread locking screws.

Do not reuse them without applying

ThreeBond 1321B/ 1342 or

Loctite 242.

Weight holder guide

(2 pcs.)

Fig. 48

Flat washer 6

Stop ring E-5

Inner housing

Piston cylinder section

Swash bearing section

Piston cylinder

Counter

weight

Swash bearing

section

Fig. 50

Inner housing

Piston

cylinder

Push Piston cylinder into Inner housing

to tilt Swash bearing 10.

Fig. 51

Insert the shaft of Swash bearing section to the hole

of Ball bearing 606ZZ, and tilt it back and forth.

Ball bearing 606ZZ

in Gear housing complete

Swash bearing 10

Pull Swash bearing section horizontally

with Swash bearing 10 kept tilted, and

remove the pole of Swash bearing 10

toward the tilted direction.

Swash bearing section

Tap Gear housing complete with plastic hammer.

Ball bearing 606ZZ is removed together with

Swash bearing section.

Ball bearing 606ZZ

Page 17

P 17/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-7. Swash bearing section (cont.)

DISASSEMBLING

(6) Remove Stop ring EXT U-6 from Can shaft, then separate Flat washer 7, Spur gear 10 and Clutch cam A from Can shaft.

(7) Receive Spiral bevel gear 32 on 1R139 put on U-groove of Arbor press table and press out Cam shaft with 1R281

(ø7mm round bar) as drawn in Fig. 52.

The swash bearing section can be removed as drawn in Fig. 53.

Fig. 52

Arbor press

1R281

1R139

Spiral bevel gear 32

Arbor press table

Fig. 53

Flat washer 7 Bearing retainer BSpur gear 10

Stop ring

EXT U-6

ASSEMBLING

Assemble the Swash bearing section carefully to the directions of each part and the order shown in Fig. 53.

(1) Pass Cam shaft through Clutch cam A, and then receive Clutch cam A on 1R035.

(2) Pass Cam shaft through Swash bearing 10 and press-fit Spiral bevel gear 32 to Cam shaft until Spiral bevel gear stops.

(3) Pass Cam shaft through Ring 8 and Bearing retainer B, and then press-fit Ball bearing 608ZZ and Ring 8 to Cam shaft

with 1R033 carefully. Do not pinch Bearing retainer B by Ball bearing 608ZZ and Spiral bevel gear 32.

Note: When 1mm height of Cam shaft is projected out over Ring 8, the assembling work is successful. (Fig. 54) Check

the height at this time.

(4) Set Spur gear 10 and Flat washer 7 in place on Cam shaft, and secure them with Stop ring EXT U-6.

Fig. 54

Clutch cam A Swash bearing 10 Spiral bevel gear 32

Cam shaft Ring 8

(Flat shape)

Arbor press

1R033

Ball bearing 608ZZ

Ring 8

(stepped)

Clutch cam A

Cam shaft

1mm height

Top of Ring 8

Bearing retainer B Spiral bevel gear 32

1R035

Page 18

P 18/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-7. Swash bearing section, Piston cylinder section (cont.)

ASSEMBLING

(5) Set Compression spring 14 and Flat washer 14 to the projection of Inner housing as drawn in Fig. 55.

Insert Guide plate and Piston joint into Piston cylinder, and then pass the pole of Swash bearing 10 through Piston joint.

(Fig. 56)

(6) Assemble Inner support complete to Inner housing with two M4x25 Hex socket head bolts. (Refer to Fig. 47)

(7) Make sure that the gear teeth of Clutch cam A engage those of Swash bearing 10. (Fig. 57)

(8) Assemble Compression spring 4 and Lock plate to Gear housing. (Fig. 58)

Note: Apply Makita grease RB No. 00 to the end of Compression spring 4 on Lock plate mating side in order to do

the next step smoothly.

(9) While holding Lock plate by a finger so as not to drop from the guides of Gear housing, assemble Gear housing to

Inner housing. (Figs. 58 and 59)

Fig. 55

Fig. 56

Fig. 57

Compression spring 14

Flat washer 14

Projection of

Inner housing

Guide plate Inner housingPiston cylinder

It is not necessary

to position this hole.

Pole of

Swash bearing 10

Fig. 58

Gear housing complete Compression spring 4 Lock plate

Piston joint

Note: Apply Makita grease RB No. 00

to the specific portions of Piston joint

designated by .

Clutch cam A

Correct assembling

Fig. 59

Swash bearing 10

Guides of Gear housing

Apply Makita grease RB No. 00 to the portion

of Compression spring 4 designated by .

Page 19

P 19/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-8. Oil seal 25, Cup sleeve, Ball bearing 6806LLU

DISASSEMBLING

(1) Assemble Inner housing complete to Gear housing complete.

(2) Put Inner housing complete on U-groove table portion of arbor press, then press Oil seal 25, Cup sleeve and Ball

bearing 6806LLU out of Gear housing complete using 1R252.

ASSEMBLING

(1) Press-fit Ball bearing 6806LLU into Cup sleeve. (Fig. 60)

(2) While receiving the stepped collar of Gear housing complete on 1R258 as drawn in Fig. 61,

press-fit Oil seal 25 with 1R232 until it stops. (Fig. 62)

Oil seal 25 is not yet inserted completely because the outer diameter of 1R232 is larger than

that of Oil seal setting hole.

(3) Press-fit Oil seal 25 to the original position with 1R164 until it stops. (Fig. 63)

(4) Press-fit Cup sleeve with Ball bearing 6806LLU into the place using 1R273. (Fig. 64)

Note: Too much pressure will deform Oil seal 25 and Cup sleeve. Press-fit them with gentle

pressure.

Fig. 61 Fig. 62

Gear housing

complete

the stepped collar

(gray color portion)

to be put on 1R258

Oil seal 25

Fig. 60

Ball bearing

6806LLU

Cup sleeve

1R232

36mm

1R258

Fig. 63 Fig. 64

30mm

1R164

34mm

Oil seal 25

1R273

37mm

37mm

100mm

Cup sleeve with Ball bearing 6806LLU

at the bottom

Note: Be careful to the direction.

1R258

Page 20

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-9. Motor of Dust extraction system DX01, DX02

Note: Special repairing tool and Lubricant are not required.

DISASSEMBLING

(1) Separate Housing R and eight 4x18 Tapping screws from Housing L.

(2) Remove Baffle plate, Filter plate, Sponge sheet C and Motor complete as an assembled part. (Fig. 65)

Fig. 65

P 20/ 25

Motor complete

Note: Replacing Fan separately is not allowed.

ASSEMBLING

Assemble the components by reversing the disassembly procedure.

Guide plate, Cushion and four Rubber pins 4 are on not only Housing R but also Housing L, and therefore, be careful not

to drop their parts.

Fig. 66

Guide plate

Baffle plate

Sponge sheet C

Baffle plate

Cushion

Rubber pin 4 (4 pcs. on this side)

Rack B

Earth rubber

Page 21

P 21/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-10. Slide levers of Dust extraction system DX01, DX02

DISASSEMBLING

• Slide lever B on Housing L

Remove Rack B and Compression spring 3 in Housing L as drawn in Fig. 67, and then move Slide lever B toward

the upper direction like the arrow mark. (Fig. 67)

Fig. 67

Inside of Housing L

Housing L

Slide lever B

Compression spring 3

Rack B

Outside of Housing L

(viewed from the opposite)

Slotted screwdriver

Housing L

Arrow mark

on Slide lever B

• Slide lever A on Slide pipe

Remove Collector base A (DX01)/ B (DX02) from Slide pipe by releasing the hooks with a thin-slotted screwdriver,

and then separate Rack A, Compression spring 3, Stopper base and Slide lever A. (Fig. 68)

Fig. 68

Collector

base A/ B

1

3

Hooks to set in the holes

on sides of Slide pipe

Slide pipe

Stopper base

2

Slide lever A

Rack ACompression spring 3

Note: Remove Rack A, Compression spring 3 and Slide lever A

in the same way as mentioned in Fig. 67.

Page 22

P 22/ 25

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-11. Tips on repair of Dust extraction system DX01, DX02

DISASSEMBLING

• Hose 30 is not glued on the other parts, and therefore it is possible to remove Hose 30 from Collector base A (DX01)/

B (DX02) and Inner pipe. (Fig. 69)

When it is difficult to remove because of the tight contact, peel it with a thin-slotted screwdriver. (Fig. 69)

Fig. 69

Hose 30

Collector base A/ B

ASSEMBLING

• Hose 30 is not glued on the other parts, and therefore it is possible to remove Hose 30 from Collector base A (DX01)/

B (DX02) and Inner pipe. (Fig. 69)

When it is difficult to remove because of the tight contact, peel it with a thin-slotted screwdriver. (Fig. 69)

• When reassembling Collector base A/B and Inner pipe, keep a right angle between them.

In assembly of housing L to R and shrinkage of Hose 30, while turning the hose 30 counterclockwise, snap the hooks of

Collector base A/ B into the holes of Slide pipe as drawn in Fig. 70. (Reverse the step shown in Fig. 68.)

• While turning Hose 30 clockwise, adjust your desired positions of Hose, Collector base A/ B and Inner pipe each other.

The inner diameter of the spring of Hose is expanded, and consequently this way allows loose contact of Hose during

revolving.

Fig. 70

Page 23

Circuit diagram

Fig. D-1

Color index of lead wire’s sheath

Black Orange

White

Red Yellow

Blue

Brown

P 23/ 25

BHR242,

BHR243

Switch

Stator

Connector to Dust

extraction system

(DX01, DX02)

Orange mark

White mark

Fig. D-2

DX01,

DX02

Terminal

Controller

Black mark

Connector

to BHR242

and BHR243

Two hole type

Line filter (if used)

One hole type

Line filter ø10-30mm (if used)

Controller

DC motor

Red mark

Page 24

Wiring diagram

Fig. D-3

P 24/ 25

BHR242, BHR243

Connect Lead wires to Controller/ Terminal

with Flag receptacles as drawn below.

Flag receptacles

Black

lead wire

White

lead wire

Stator

Terminal

Rib A

Do not put any lead

wires on this boss.

Flag receptaclesController

Set Controller in place with Flag receptacles faced

as drawn above.

Rib B

Orange

lead wire

Connector

Black

lead wire

Red

lead wire

Controller

Slacks of Lead wires between Controller and

Connector/ Stator have to be placed over the line

extended from Rib D.

Rib D

Line extended from Rib D

Rib C

Lead wires to Connector and Stator lead wires

have to be routed between Rib A and Rib B.

Do not put Stator lead wires on Rib C.

Lead wires to Connector have to be routed

between Rib B and Rib D.

Terminal

Route the lead wires between Connector and Controller to the bottom of Housing L

so as not to rise on the top line of Rib C. Turn them back to set Connector in place.

Place the turned portion over the line extended from Rib D.

Line extended from Rib D

The bottom of Housing L

viewed from the upper side

Controller

Turned portion

Rib D

Rib C

Connector

Page 25

Wiring diagram (cont.)

Fig. D-4

Connector

P 25/ 25

DX01, DX02

Connector viewed from lead wire installation side

Connect Lead wires to Connector with

Flag receptacles as drawn below.

Connector

Black lead wire

Lead wires between Connector and Controller have to fixed

with these lead wire holders. Do not slack them between

the lead wire holders.

Put Lead wires between Connector and Controller into this groove.Put Lead wires between Connector and Controller into this groove.

Connect Lead wires to DC motor with

Flag receptacles as drawn below.

Red lead wire

White lead wire

Pass Lead wires through the holes of

Line filter one by one and place them

in the space between Ribs.

(Line filter is not used for some countries.)

DC motor

Black

Lead wire

Red

Lead wire

Set DC motor in place so that the red mark

faces to the bottom of DX01/ DX02.

Red mark

Put Lead wires between Connector and Controller into this groove.

DC motor

Pass Lead wires through the hole of

Line filter and place them here.

(Line filter is not used for some countries.)

Loading...

Loading...