Makita BHR240, BHR240SFE, BHR240SF, BHR240Z Technical Information

T

ECHNICAL INFORMATION

Models No.

BHR240

PRODUCT

P 1 / 14

Description

Cordless Rotary Hammer

CONCEPT AND MAIN APPLICATIONS

The cordless version of HR2453/HR2454 has been launched

with D-handle for operator's comfort.

These new products will be available in the following variations.

Model No.

BHR240SFE

BHR240SF

BHR240Z

The variations for USA, Canada, Mexico and Panama are as follows.

Model No.

BHR240

BHR240Z

Specification

No load speed : (min -1= rpm)

Blows per min, :(bpm=min -1)

Max. Output(W)

Voltage: V

Battery

Chuck Capacity: mm ( " )

Bit Shank

Capacity

: mm ( " )

Working

mode

Variable switch

Reverse switch

Clutch (Torque Limiter)

Electric Brake

Net Weight : kg (lbs)

Cell and Capacity

Charging Time

Rotation

Rotation + Hammering

Hammering

Battery

Type Quantity

BL1830

No No No

Battery

Type Quantity

BL1830

No No No

Steel

Wood

* Concrete

Charger

2

DC18RA

1

---

Charger

DC18RA

2

---

Li-ion 3.0 Ah

approx. 22 min. with DC18RA

26 (1-1/16)

18 (11/16)

3.0 (6.6) including Battery BL1830

carrying case

carrying case

0 - 1,100

0 - 4,000

10 (3/8)

SDS plus

13 (1/2)

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Plastic

Yes

Yes

Plastic

Yes

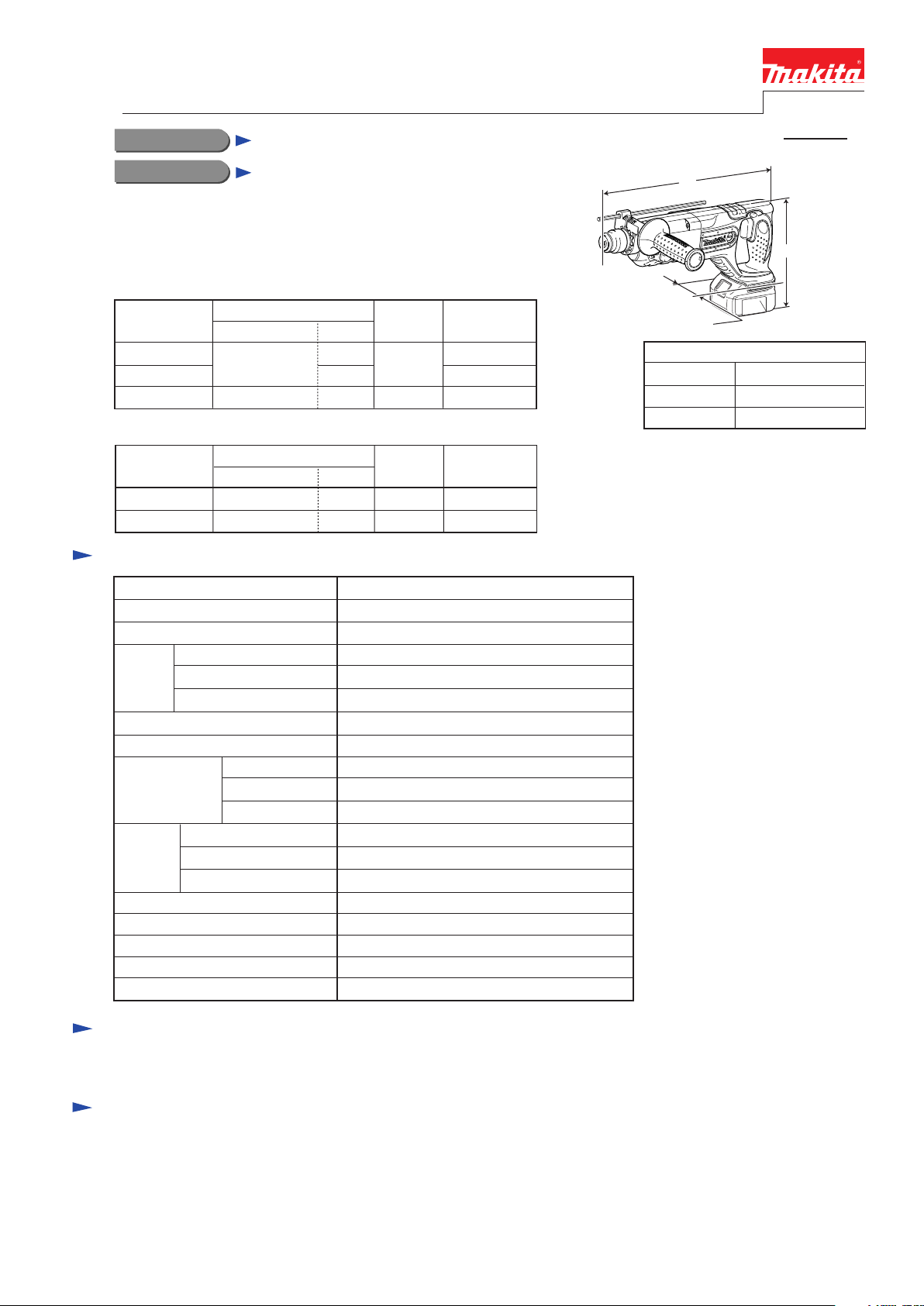

330

18

L

H

W

Dimensions: mm (")

Length (L)

Width (W)

Height (H)

* Concrete: 24 (7/8)

for North American Countries

410 (16-1/8)

78 (3-1/16)

206 (8-1/8)

Standard equipment

* Grip Assembly ................................... 1 set * Depth Gauge (Stopper Pole) .............. 1 pc.

Note: The standard equipment for the tool shown above may differ by country.

Optional accessories

* SDS-Plus bits

* Taper shank T.C.T bits

* Taper shank adapter

* Cotter

* Drill chuck assembly

* Chuck adapter

* Drill chuck S13

* Chuck key S13

* Keyless drill chuck

* Grip assembly

* Scraper Assembly

* Cold chisels

* Grooving chisels

* Scaling chisels

* Bull points

* Dust Cup

* Grease Vessel 30g

* Blow out bulb

* Safety goggle

* Dust extractor attachment

* Joint 25

* Charger DC18RA

* Charger DC18SC

* Charger DC24SA

* Charger DC24SC

* Battery BL1830

Repair

CAUTION: Remove the battery from the machine for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

Item No. Description Purpose

1R003

1R004 Retaining ring S pliers ST-2

1R023 Pipe ring Removing Helical gear 25

1R032 Bearing Setting Plate 8.2 Installing Helical gear 25

1R033 Bearing Setting Plate 10.2 Installing Helical gear 25

1R034 Bearing Setting Plate 12.2 Installing Helical gear 25

1R038 Armature holder 32 Fixing Tool holder

1R269 Bearing extractor Removing Ball bearing 608ZZ

1R281 Round bar arbor 7-50 Removing Ring 8

1R291 Retaining ring S and R pliers Removing Retaining ring S-7

1R306

Retaining ring S pliers ST-2N

Ring spring removing jig Removing Ring spring 29

Removing/ installing Ring spring 19

Removing/ installing Ring spring 29

Removing Helical gear 251R022 Bearing plate

Installing Needle bearing complete1R164 Ring spring setting tool A

Removing/ installing Ring spring 19 (for modular use with 1R003)1R212 Tip for retaining ring pliers

Installing Oil seal 251R232 Pipe 30

Removing Oil seal 251R252 Round bar for arbor

P 2 /14

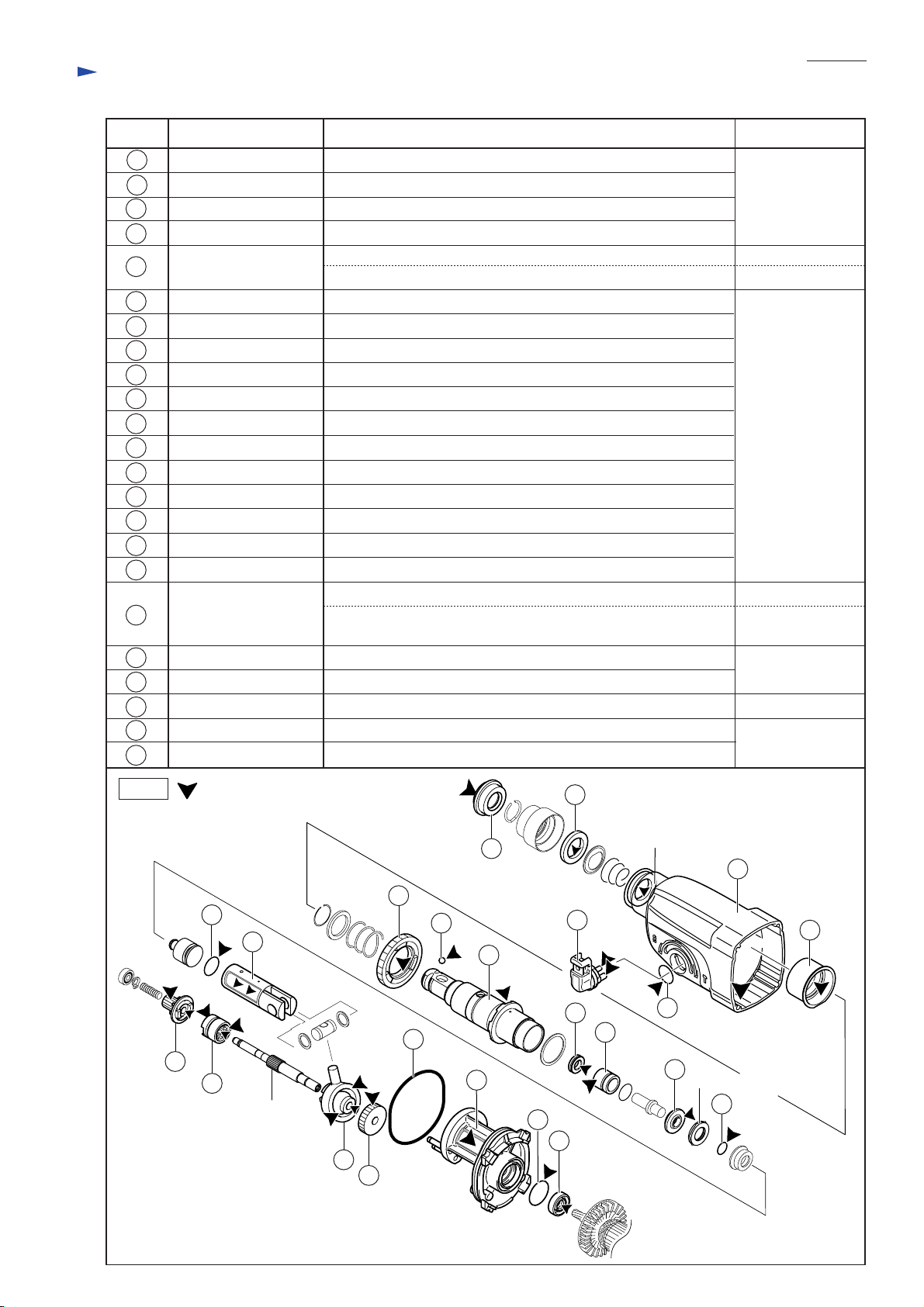

[2] LUBRICATION

Apply the following grease to the portions designated with the triangles to protect parts and product from unusual abrasion.

Item No. Description Portion to lubricate

29 Tool holder complete Whole inside surface

43

45

Flat washer 12 (2pcs)

44

50 Clutch cam

52

Fig. 1

Piston joint

Swash bearing 10 Pin portion that is inserted into 44 Piston joint

:Molybdenum disulfied grease

Whole surface

Whole surface

Groove

29

50

Piston cylinder

43

44

45

52

Repair

[2] -2. Makita Grease RB No.00

Item No. Amount to applyDescription Portion to lubricate

Cap 35 Inside surface that contacts hammer bit

1

Ring 21

4

13

17 Gear housing comp.

18

28

29 Tool holder comp.

31

35

42

52

65 Inner housing comp.

Change lever comp. Two pins

Needle bearing comp. Inside surface

Steel ball 7.0 Whole surface

X ring 9 Inner circumference

Ring 10 Surface that contacts Cushion ring 13

Piston cylinder Inside surface that contacts Striker

Swash bearing 10

Inner circumference that contacts Tool holder comp.

Whole surfaceO ring 1716

Gear room

Inner circumference of Oil seal

Inner circumference27 Spur gear 51

Face of cam and the surface that contacts Inner housing comp.

Surface that contacts Tool holder comp.32 Sleeve 9

Whole surface38 O ring 9

Whole surface41 O ring 16

Teeth portion and the inside surface that contacts Cam shaft49 Spur gear 10

Both faces of cam and the inside surface that contacts Cam shaft50 Clutch cam

Ball portion about 4g

Surface that contacts Helical gear 26 and the inside surface that

contacts Cam shaft

Teeth portion53 Helical gear 26

Whole surface48 O ring 63

Crank room where Piston cylinder thrusts

Whole surface66 O ring 24

Inner circumference that contacts Armature shaft67 Oil seal 8

P 3 /14

appropriate amount

about 17g

appropriate amount

appropriate amount

appropriate amount

appropriate amount

about 5g

appropriate amount

Fig. 2

:Makita grease RB No.00

41

42

49

50

Cam shaft

52

53

27

54

28

65

29

4

32

Oil seal

16

17

35

Cushion ring 13

38

18

1

13

31

66

67

Repair

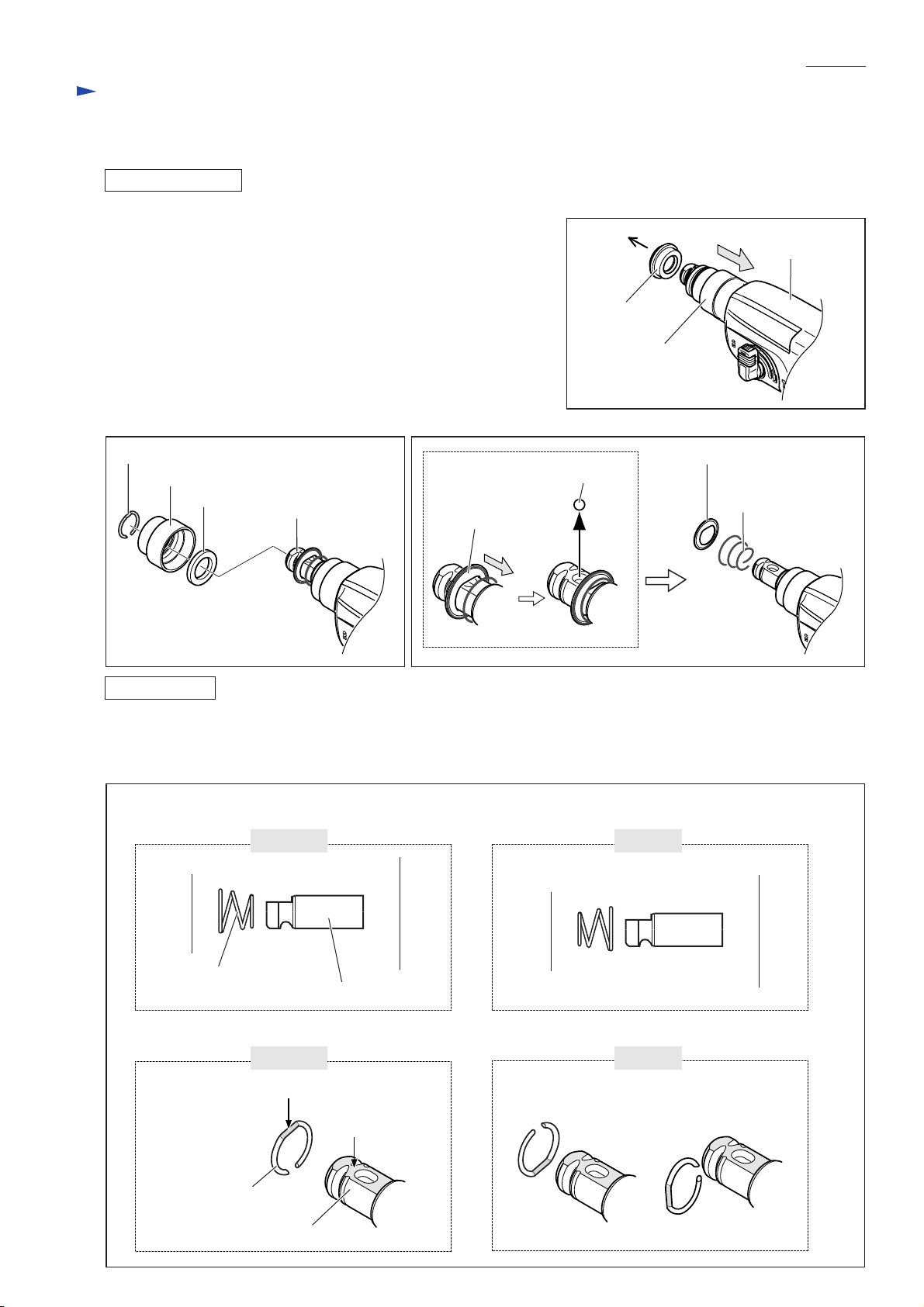

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Chuck Section

DISASSEMBLING

1) Slide Chuck cover in the direction of Gear housing.

Remove Cap 35 using hand and a slotted screwdriver (Fig. 3).

2) Remove Ring spring 19 from the groove on Tool holder complete

using 1R003 and 1R212. Remove Ring spring 19.

Chuck cover and Ring 21 can now be removed (Fig. 4).

3) Pushing Guide washer in the direction of Gear housing,

remove Steel ball 7.0 from the slot on Tool holder complete.

Remove Guide washer and Conical compression spring 21-29 (Fig. 5).

P 4 /14

Fig. 3

Gear housing

Cap 35

Chuck cover

Fig. 4

Ring spring 19

Chuck cover

Ring 21

ASSEMBLING

Do the reverse of the disassembling steps.

Note: Conical compression spring 21-29 and Ring spring 19 are not reversible when assembled to Tool holder complete.

Be sure to assemble as illustrated in Fig. 6.

Fig. 6

Conical compression spring 21-29

Tool holder complete

Correct

Fig. 5

Guide washer

Steel ball 7.0

Guide washer

Conical compression

spring 21-29

Wrong

Cap 35 side

Conical compression

spring 21-29

Ring spring 19

Ring spring 19

Tool holder complete

Tool holder complete

Correct

flat portion

Gear housing side

flat portion

Cap 35 side

Gear housing side

Wrong

Repair

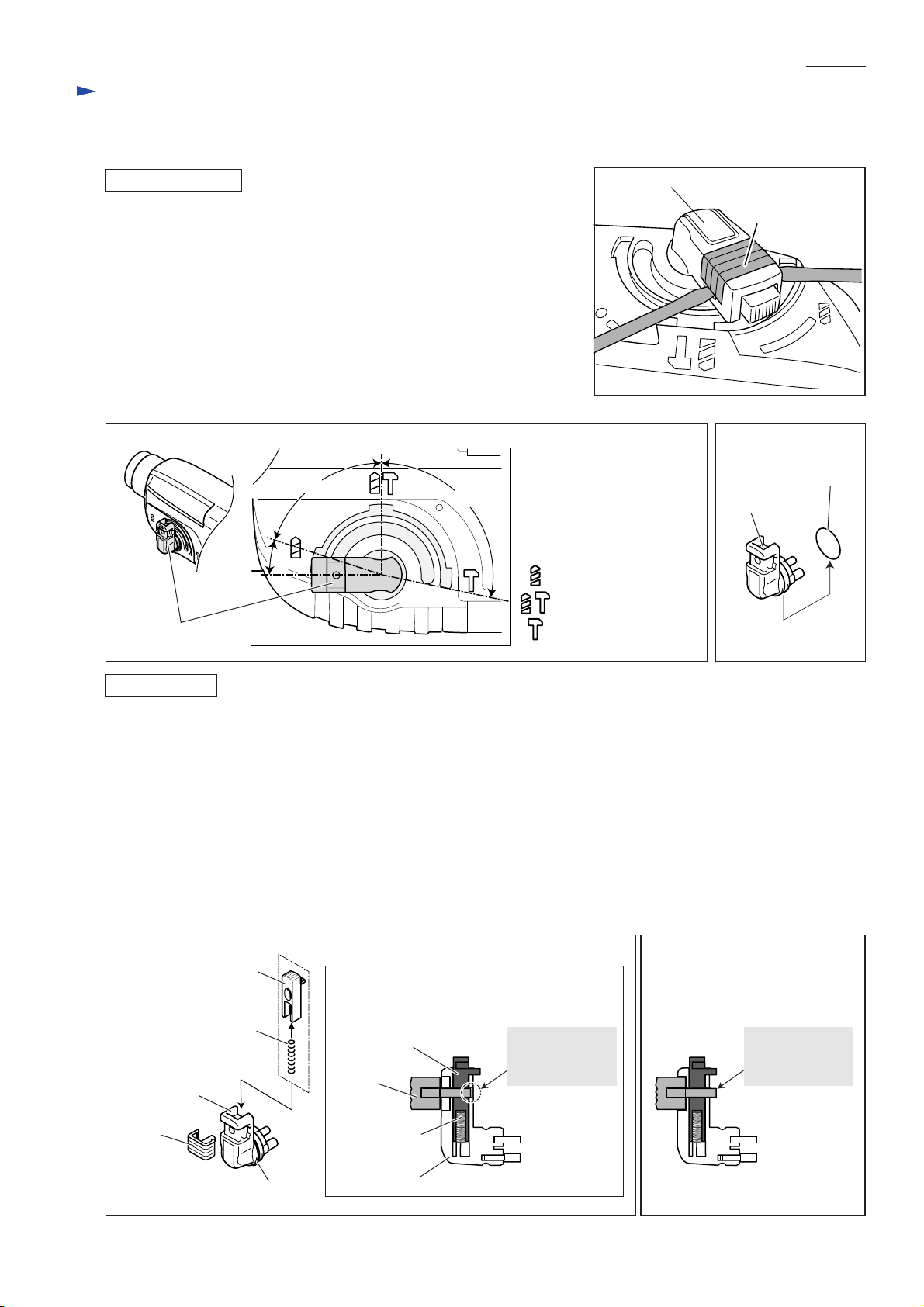

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Change Lever

P 5 /14

Fig. 7

DISASSEMBLING

1) Lever up Cap from Change lever using two slotted screwdrivers (Fig. 7).

Note: Lock button and Compression spring 3 will fly away in this step.

Be careful not to lose them.

2) Rotate Change lever fully in the direction of the drill mode position until

the lever is located within the area B (Fig. 8). Change lever can now be

pulled off. Remove O ring 17 from Change lever (Fig. 9).

Fig. 8 Fig. 9

C

A

Change lever

Change lever

B

= Drill mode

= Rotary hammer mode

Change lever

= Hammer mode

Cap

O ring 17

ASSEMBLING

1) Apply grease to O ring 17 and the pins of Change lever as described in page 3.

2) Put Compression spring 3 and Lock button in place on Change lever. Assemble Cap provisionally to Change lever

as illustrated in Fig. 10 in order to prevent the spring from popping out from Change lever.

Do not forget to assemble O ring 17 to Change lever in this step.

3) Place the provisionally assembled Change lever within the area A of Gear housing (Fig. 8), and insert into the Change

lever installation hole. Change lever cannot be inserted completely in this step.

4) Pushing Change lever against Gear housing, turn Change lever in the direction of the drill mode until it reaches the

area B where it can be completely inserted into the hole. If cannot be completely inserted, do this operation with

Lock button pressed.

5) Turn Change lever to the area C (Fig. 8). Assemble Cap completely to Change lever by pushing in the direction of

Gear housing (Fig. 11).

Fig. 10 Fig. 11

Lock button

Compression spring 3

Change lever

Cap

Cap provisionally

assembled to Change lever

Lock button

Cap

Compression

spring 3

not protruding

from the surface

of Change lever

Cap completely

assembled to Change lever

protruding

from the surface

of Change lever

O ring 17

Change lever

Loading...

Loading...