Makita BHP459, BDF459 Technical Information

Models No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 11

BHP459

Cordless Hammer Driver Drill

Specification

Standard equipment

Optional accessories

Note: The standard equipment for the tool shown above may vary by country.

+ – bit 2-45 ........ 1

Belt clip .............. 1

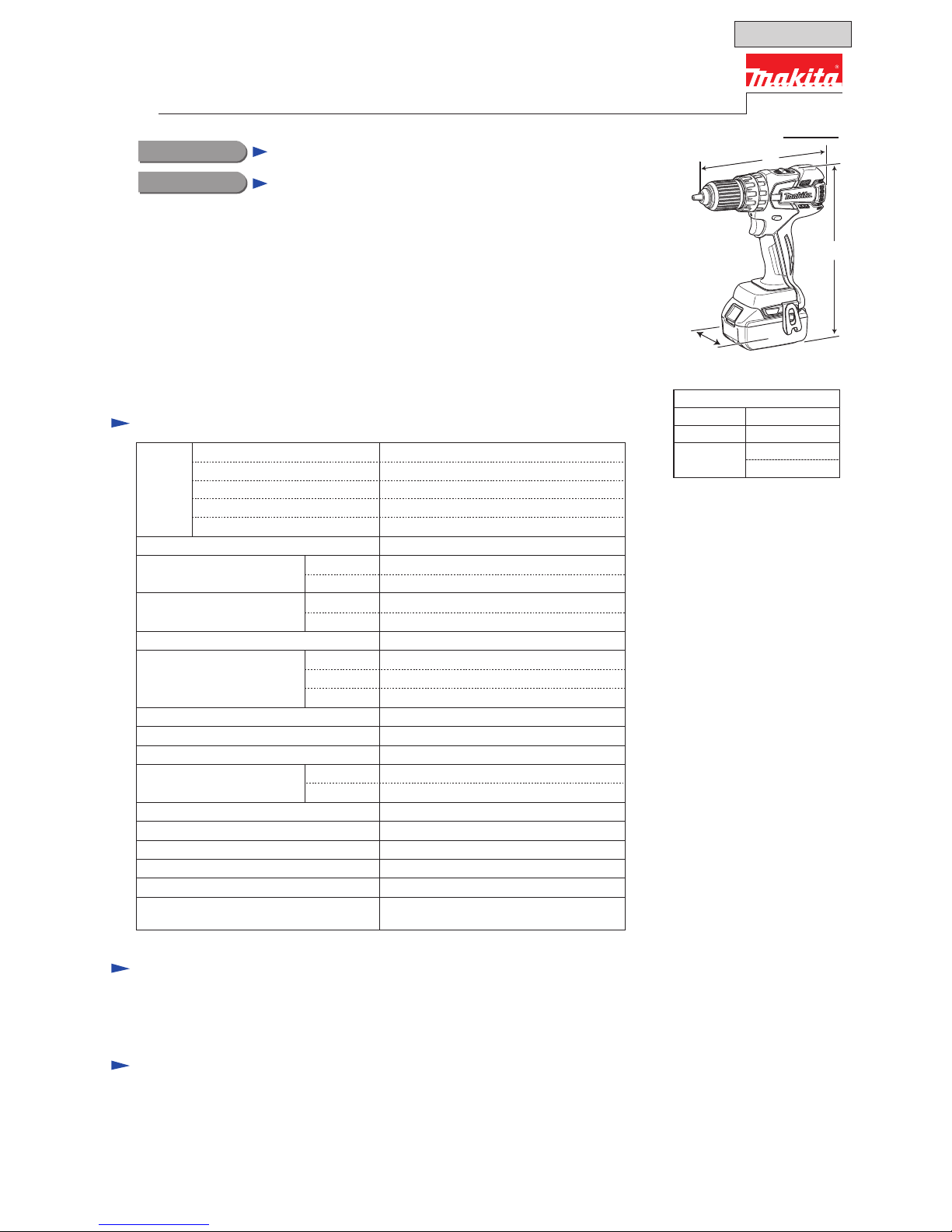

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

192 (7-9/16)

78 (3-1/16)

238 (9-3/8)*

2

256 (10-1/8)*3

*2: with Battery BL1815

*3: with Battery BL1830

Li-ion Battery BL1830

Li-ion Battery BL1815

Drill bits for wood

Drill bits for steel

Phillips bits

Fast charger DC18RA

(for USA, Canada, Guam, Panama, Colombia, Mexico)

Fast charger DC18RC

(for all countries except the countries above)

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

[Drawn above is the image

with BL1830.]

Battery

Capacity of drill chuck: mm (")

Capacity: mm (")

Max lock torque: N.m (in.lbs)

Electric brake

Variable speed control

Mechanical speed control

Reversing switch

Max fastening torque:

N.m (in.lbs)

Torque setting

Steel

Wood

Soft joint

Hard joint

No load speed: min-

1=rpm

Energy capacity: Wh

Voltage: V

Capacity: Ah

High

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

Low

Max output: W

24 (27*4)/ 54

Charging time (approx.): min.

Cell Li-ion

15/ 22 with DC18RC (DC18RA*1)

18

1.3 (1.5*

4)/ 3.0

Yes

Yes

Yes (2 speed)

Yes

Yes

1.5/ 1.7 (3.3/ 3.8)

13 (1/2)

38 (1-1/2)

16 stages + drill mode

Clutch torque setting: N.m (in.lbs)

1.0 - 5.0 (9 - 44)

45 (400)

25 (220)

45 (400)

0 - 1,500

0 - 400

1.5 (1/16) - 13 (1/2)

250

LED job light

T

ECHNICAL INFORMATION

Model BHP459 Cordless Hammer Driver Drill has been developed

specially for light to medium duty drilling and fastening applications.

This model is equipped with a basic BLDC motor (BrushLess DC motor) specially

designed to provide, above all, more work amount on a single full battery charge.

This product is powered by 18V-1.3(1.5*4)Ah/ 3.0Ah Li-ion batteries BL1815/ BL1830,

and available in the variations listed in the next page.

*

4 for some countries only

L

H

W

Impacts per minute:

min

ˉ¹=ipm

High

Low

0 - 22,500

0 - 6,000

Masonry 13 (1/2)

OFFICIAL USE

for ASC & Sales Shop

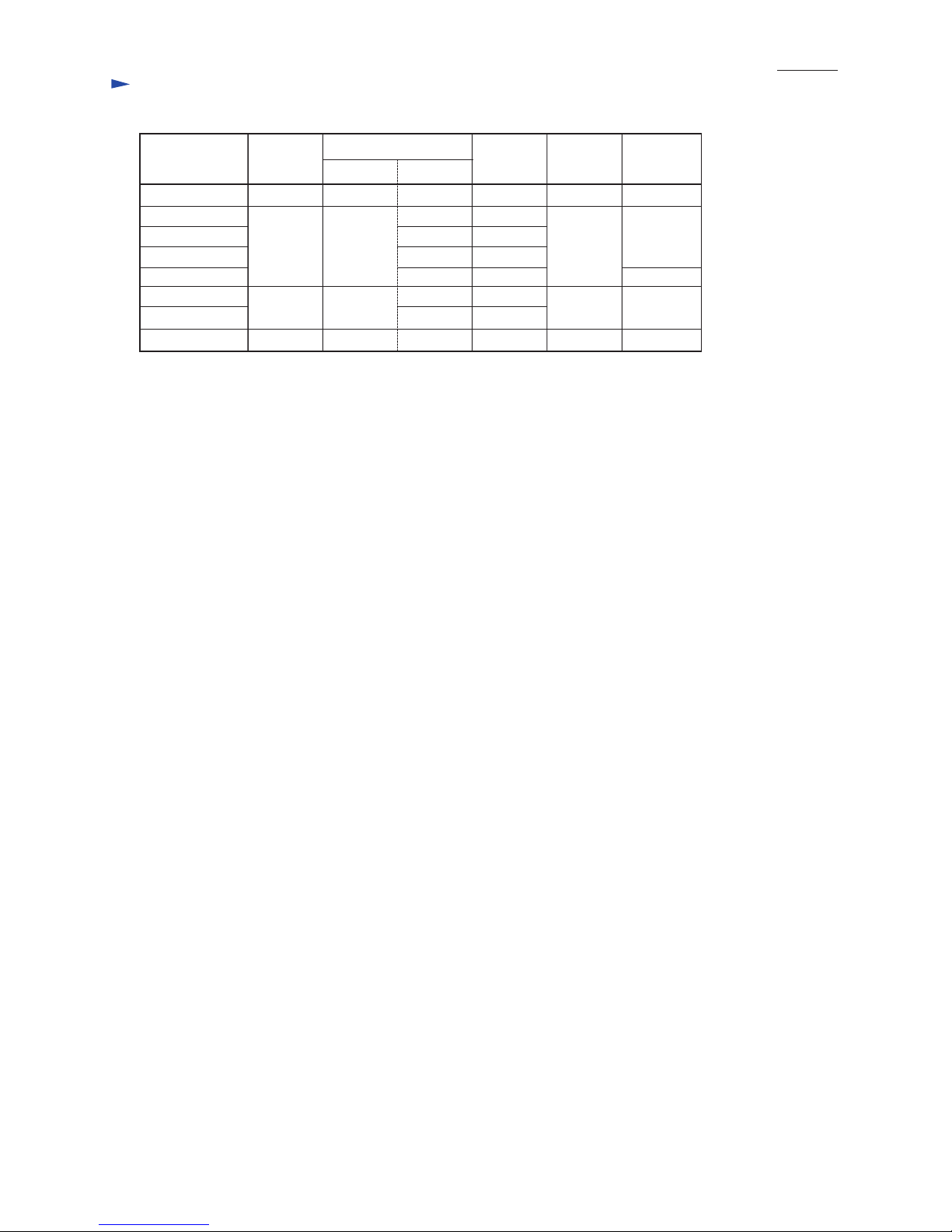

BHP459RFE

BHP459RF

Model No.

Type Quantity

Plastic

carrying

case

Battery

cover

Battery

No NoBHP459Z No

2 1

1 No

1 No

No

DC18RC

Charger

No

Yes

BL1830

BHP459RFE3

BHP459RH

BHP459RHE

BL1815 Yes

Yes

2 1

DC18RC

BHP459SHE 2 1DC18SD BL1815

BHP459

Housing

color

BHP459RFEW 2 1

Makita blue

Makita blue

Makita blue

White

Note: All models also include the accessories listed in "Standard equipment" of page 1.

3 2

Makita blue

Variation list

P 2/ 11

Repair

It is not required to lubricate the gear section because the portion is replaced as a factory- lubricated gear unit.

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Drill Chuck

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No. Description Use for

1R359 Drill chuck removing tool

[2] LUBRICATION

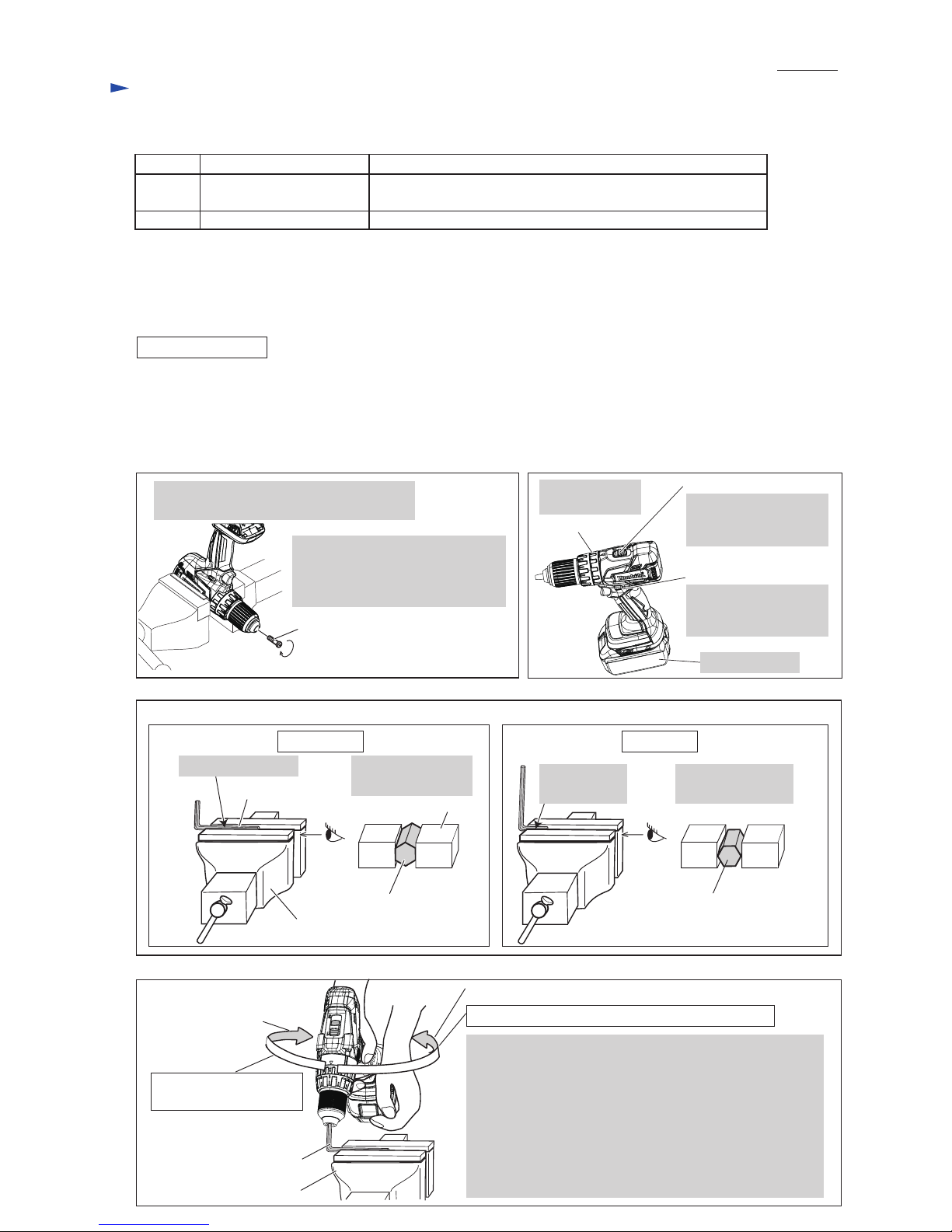

DISASSEMBLING

Hex wrench 10

(Use this tool if Drill chuck cannot be removed by the method of

described in “[3]-1 Drill chuck disassembling”.)

removing/ mounting Drill chuck

Fig. 1

M6x22 Flat head screw

(Left handed thread)

Note: It is required to remove Drill chuck when replacing Gear assembly, but you need not when replacing

the parts that are independent of Gear assembly.

(1) Remove M6x22 Flat head screw. (Fig. 1)

(2) Preset the machine. (Fig. 2) And set Hex wrench 10 to Vise. (Fig. 3)

(3) While holding Hex wrench 10 with Drill chuck firmly, remove Drill chuck from Gear assembly. (Fig. 4)

Fig. 2

Attach Battery.

F/R change lever

Set F/R Change lever

to Reverse (counter-

clockwise) rotation.

Set Speed change lever

to Low speed mode

designated with 1.

Speed change lever

Set Change ring

to Drill mode.

Change ring

Open Drill chuck fully and remove M6x22

Flat head screw by turning it clockwise.

CORRECT WRONG

Fig. 3

Fig. 4

Setting of Hex wrench10

Vise

Grip flat surfaces

of Hex wrench 10.

Hex wrench 10

Hex wrench 10,

viewed from side [A]

Vise

Hold the long end.

[A]

Do not hold edges

of Hex wrench 10.

Do not hold

the short end.

Hex wrench 10,

viewed from side [A]

Note: Use Impact driver to unscrew

M6x22 Flat head screw if it

could not be removed

manually.

[A]

Clockwise

Counterclockwise

Hex wrench 10

Vise

Clockwise*1 recoil force

of Machine

Note: The rotational direction is viewed from operator.

1. Hold Hex wrench 10 with Drill chuck and grip Machine.

Important:

Grip Machine tightly with both hands to provide

the sufficient counterclockwise*2 force against

clockwise*1 recoil force of Machine.

2. Pull Switch trigger slowly.

3. Spindle rotates counterclockwise*2 and consequently

Drill chuck is removed from spindle.

Counterclockwise*

2 force to be applied by operator

P 3/ 11

P 4/ 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Drill Chuck (cont.)

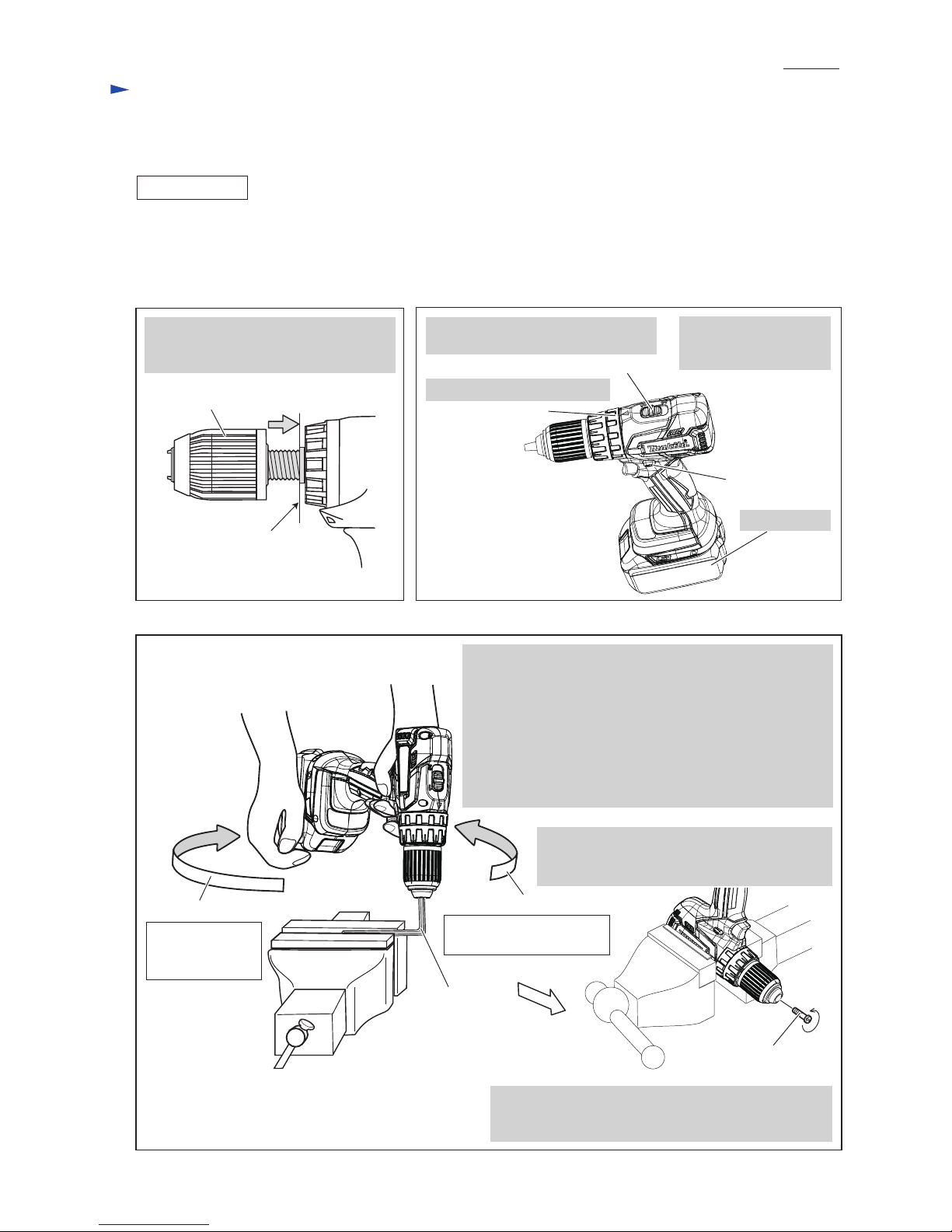

ASSEMBLING

Fig. 5

End of the threaded

portion of Spindle

Drill chuck

Fig. 6

Attach Battery.

F/R change lever

Set F/R Change lever

to Forward (clockwise)

rotation.

Set Speed change lever to Low speed

mode designated with 1.

Speed change lever

Set Change ring to Drill mode.

Change ring

Counterclockwise

Hex wrench 10

Fig. 7

Clockwise

4. Open Drill chuck fully, and tighten Drill chuck

with M6x22 Flat head screw by turning it

counterclockwise with Impact driver.

(1) Seat Drill chuck on Spindle. (Fig. 5)

(2) Set the machine to Drill mode, Low gear mode and Forward rotation mode. (Fig. 6)

(3) Set Hex wrench 10 to vise. (Refer to Fig. 3)

(4) Tighten Drill chuck. (Fig. 7)

M6x22 Flat head screw

(Left handed thread)

Turn Drill chuck clockwise by hand until

it is seated on the end of the threaded

portion of Spindle.

Note: Apply adhesive (ThreeBond 1342 or Loctite 242)

to threaded portion when re-using the removed

M6x22 Flat head screw.

Counterclockwise*

2 recoil

force of Machine

Note: The rotational direction is viewed from operator.

1. Hold Hex wrench 10 with Drill chuck and grip Machine.

Important: Grip Machine hard with both hands to provide

sufficient clockwise*1 force against

counterclockwise*2 recoil force of Machine.

2. Pull Switch trigger slowly to turn Spindle clockwise*1.

Note: Pull the Trigger so that Spindle’s rotating reaches full

speed in one second.

3. Drill chuck is tightened and consequently Spindle is locked.

Clockwise*

1 force

to be applied

by operator

Loading...

Loading...