Makita EBH341U, EBH341L, BH341U/EBH341L, EM2650UH, EM2651UH Original Instruction Manual

...

Petrol Brushcutter

EBH341U/EBH341L

Important:

Read this instruction manual carefully before putting the Petrol Brushcutter into operation and strictly observe

the safety regulations!

Preserve instruction manual carefully!

EBH341U EBH341L

ORIGINAL INSTRUCTION MANUAL

2

Thank you very much for purchasing the MAKITA Petrol Brushcutter. We are

pleased to recommend to you the MAKITA Petrol Brushcutter which is the

result of a long development programme and many years of knowledge and

experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the best

possible result from your MAKITA Petrol Brushcutter.

Table of Contents Page

Symbols .........................................................................2

Safety instructions .........................................................3

Technical data................................................................7

Designation of parts.......................................................8

Mounting of handle ........................................................9

Mounting of protector...................................................10

Mounting of cutter blade or nylon cutting head............ 11

Before start of operation .............................................. 12

Correct handling of machine........................................14

Points in operation and how to stop ............................14

Resharpening the cutting tool ......................................16

Servicing instructions...................................................18

Storage ........................................................................22

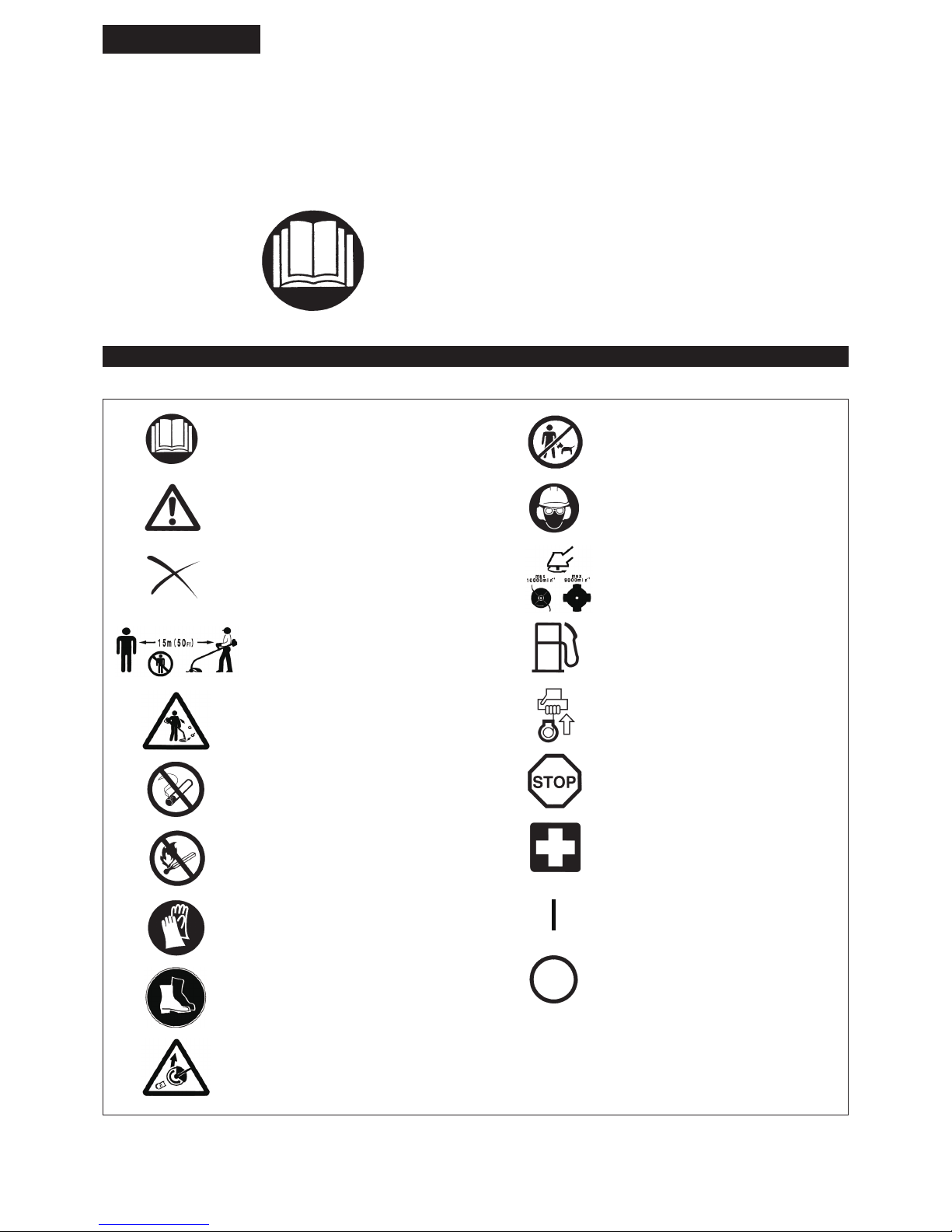

Take Particular care and attention!

Read instruction manual and follow

the warnings and safety precautions!

Forbidden!

No smoking!

No open ame!

Protective gloves must be worn!

Keep the area of operation clear of all

persons and pets!

Wear protective helmet, eye and ear

protection!

Engine-manual start

Top permissible tool speed

Emergency stop

ON/START

OFF/STOP

Flying object hazard!

Keep distance!

Kickback!

Fuel (Gasoline)

First Aid

You will note the following symbols when reading the instructions manual.

SYMBOLS

Wear sturdy boots with nonslip soles.

Steeltoed safety boots are recommended!

English

(Original instructions)

3

15 Meters

Diagrammatic gure

SAFETY INSTRUCTIONS

General Instructions

Read this instruction manual to become familiar with handling of the –

equipment. Users insufciently informed will risk danger to themselves as

well as others due to improper handling.

It is recommended only to lend the equipment to people who have proven to –

be experienced.

Always hand over the instruction manual.

First users should ask the dealer for basic instructions to familiarize oneself –

with the handling of brushcutters.

Children and young persons aged under 18 years must not be allowed to –

operate this equipment. Persons over the age of 16 years may however

use the device for the purpose of being trained while under supervision of a

qualied trainer.

Use with the utmost care and attention. –

Operate only if you are in good physical condition. Perform all work calmly –

and carefully. The user has to accept liability for others.

Never use this equipment after consumption of alcohol or drugs, or if feeling –

tired or ill.

National regulation can restrict the use of the machine. –

Intended use of the machine

This equipment is only intended for cutting grass, weeds, bushes, –

undergrowth. It should not be used for any other purpose such as edging or

hedge cutting as this may cause injury.

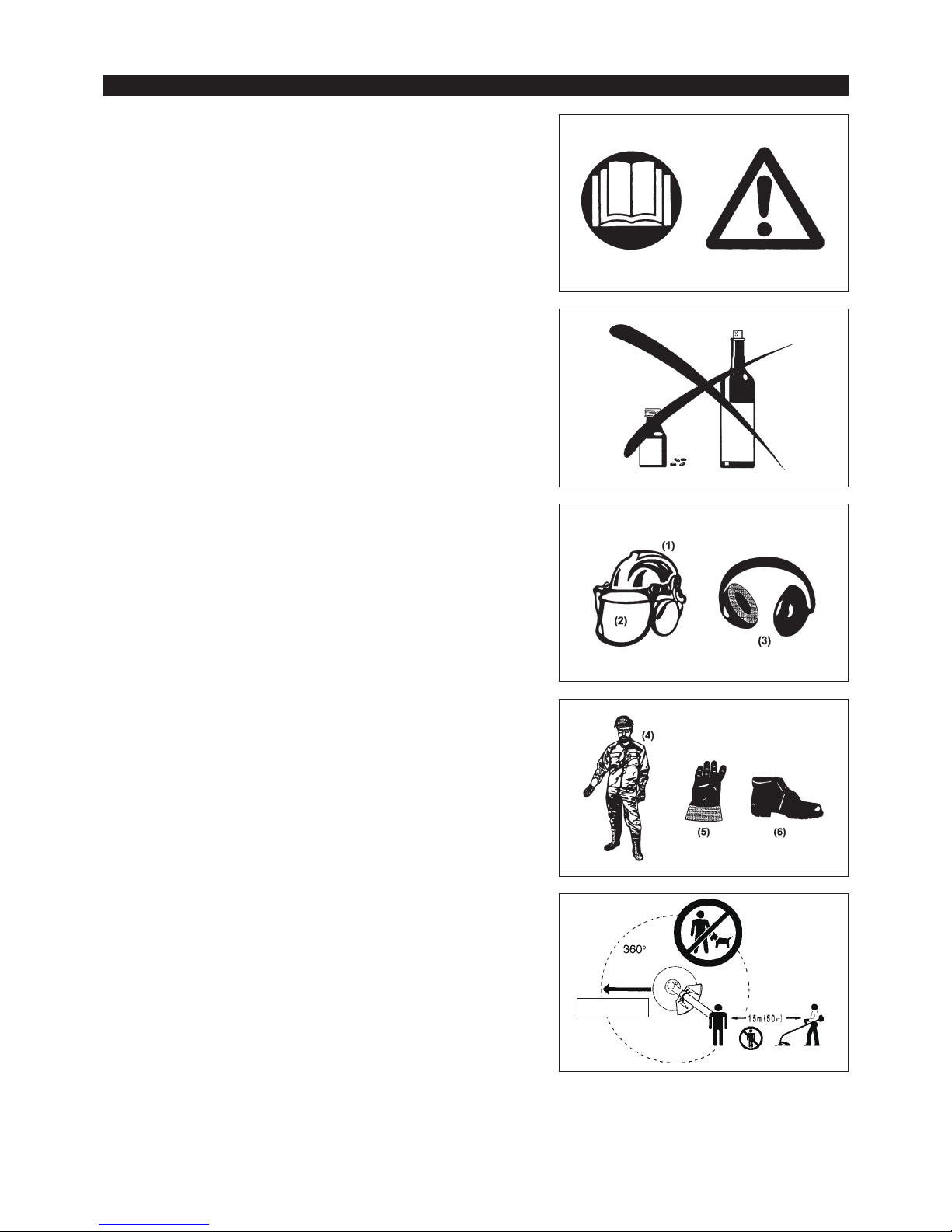

Personal protective equipment

The clothing worn should be functional and appropriate, i.e. it should be tight- –

tting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

In order to avoid either head-, eye-, hand-or foot injuries as well as to protect –

your hearing the following protective equipment and protective clothing must

be used during operation.

Always wear a helmet where there is a risk of falling objects. The protective –

helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

The visor (2) of the helmet (or alternatively goggles) protects the face from –

ying debris and stones. During operation always wear goggles, or a visor to

prevent eye injuries.

Wear adequate noise protection equipment to avoid hearing impairment (ear –

muffs (3), ear plugs etc.).

The work overalls (4) protect against ying stones and debris. –

We strongly recommend that the user wears work overalls.

Gloves (5) are part of the prescribed equipment and must always be worn –

during operation.

When using the equipment, always wear sturdy shoes (6) with a non-slip –

sole. This protects against injuries and ensures a good footing.

Starting up the brushcutter

Please make sure that there are no children or other people within a working –

range of 15 meters (50 ft), also pay attention to any animals in the working

vicinity.

Before use always check the equipment is safe for operation: –

Check the security of the cutting tool, the throttle lever for easy action and

check for proper functioning of the throttle lever lock.

Rotation of the cutting tool during idling speed is not allowed. Check with your –

dealer for adjustment if in doubt. Check for clean and dry handles and test

the function of the start/stop switch.

4

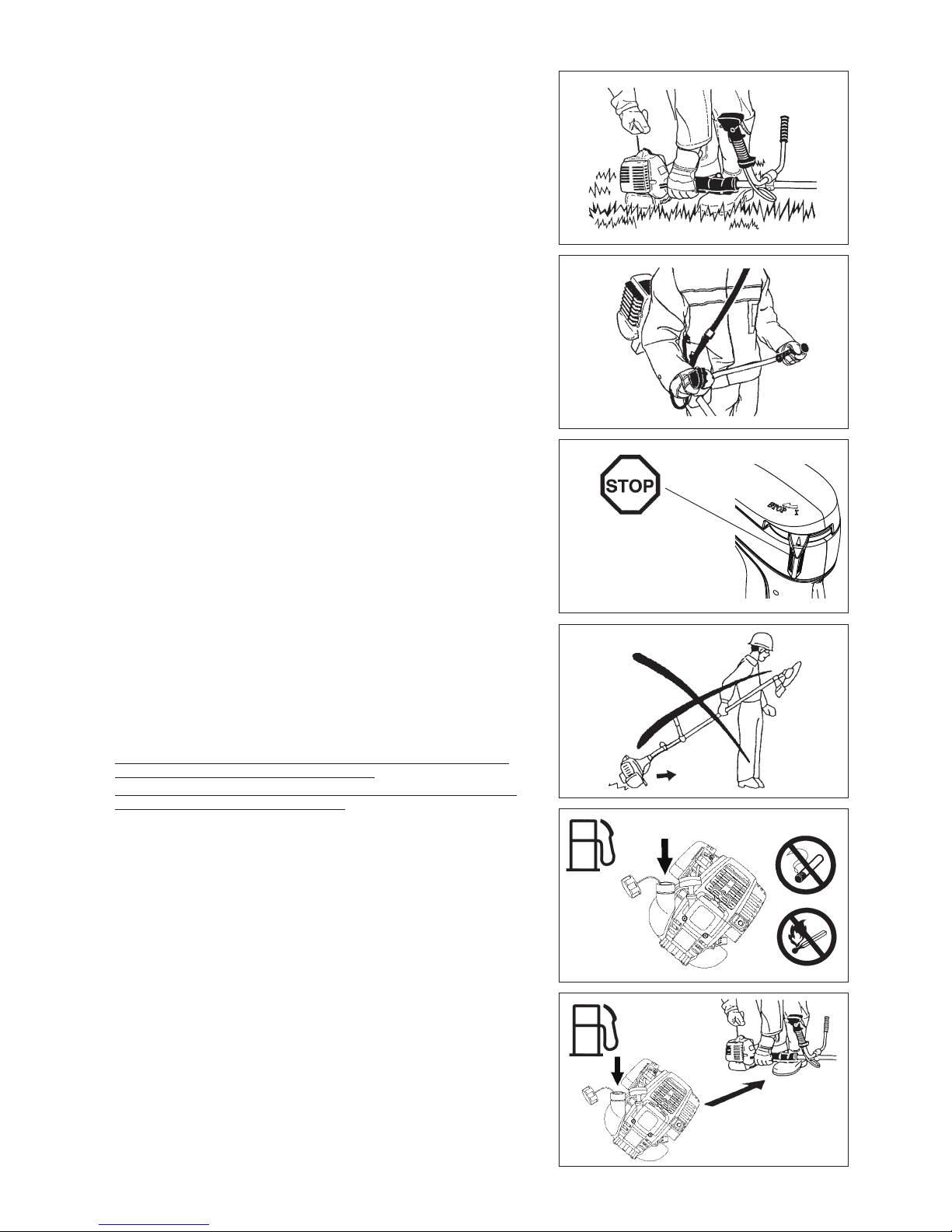

• Resting

• Transport

• Refuelling

• Maintenance

• Tool replacement

3 meters

Start the brushcutter only in accordance with the instructions.

Do not use any other methods for starting the engine! –

Use the brushcutter and the tools only for such applications as specied. –

Only start the engine, after the entire assembly is done. Operation of the –

device is only permitted after all the appropriate accessories are attached!

Before starting make sure that the cutting tool has no contact with hard –

objects such as branches, stones etc. as the cutting tool will revolve when

starting.

The engine is to be switched off immediately in case of any engine problems. –

Should the cutting tool hit stones or other hard objects, immediately switch off –

the engine and inspect the cutting tool.

Inspect the cutting tool at short regular intervals for damage (detection of –

hairline cracks by means of tapping-noise test).

If the equipment gets heavy impact or fall, check the condition before –

continuing work. Check the fuel system for fuel leakage and the controls

and safety devices for malfunction. If there is any damage or doubt, ask our

authorized service center for the inspection and repair.

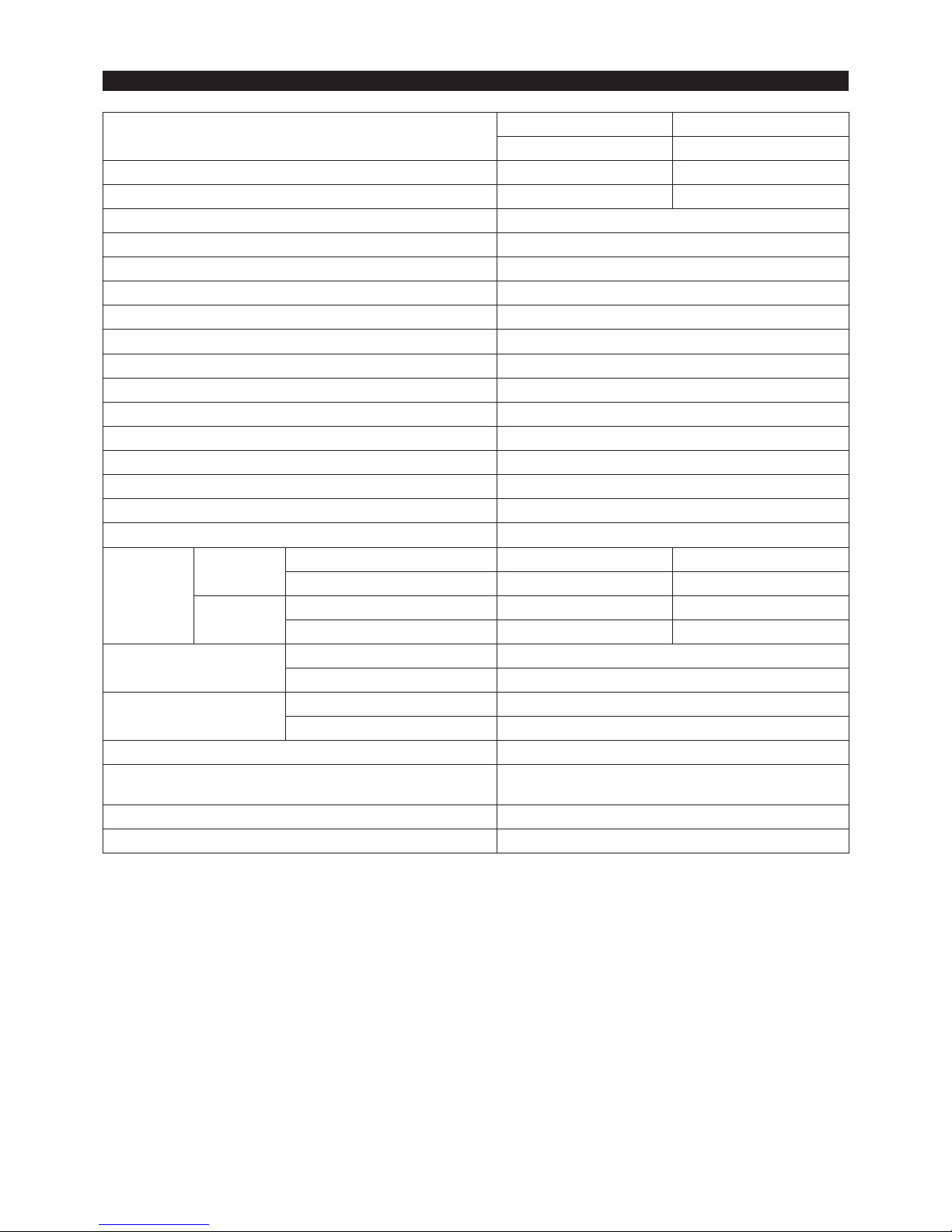

Operate the equipment only with the shoulder harness attached which is –

to be suitably adjusted before putting the brushcutter into operation. It is

essential to adjust the shoulder harness according to the user size to prevent

fatigue occurring during use. Never hold the cutter with one hand during use.

During operation always hold the brushcutter with both hands. –

Always ensure a safe footing.

Operate the equipment in such a manner as to avoid inhalation of the exhaust –

gases. Never run the engine in enclosed rooms (risk of gas poisoning).

Carbon monoxide is an odorless gas.

Switch off the engine when resting and when leaving the equipment –

unattended, and place it in a safe location to prevent danger to others or

damage to the machine.

Never put the hot brushcutter onto dry grass or onto any combustible –

materials.

Always install the approved cutting tool guard onto the equipment before –

starting the engine.

Otherwise contact with the cutting tool may cause serious injury.

All protective installations and guards supplied with the machine must be –

used during operation.

Never operate the engine with faulty exhaust mufer. –

Shut off the engine during transport. –

When transporting the equipment, always attach the cover to the cutting –

blade.

Ensure safe position of the equipment during car transportation to avoid fuel –

leakage.

When transporting, ensure that the fuel tank is completely empty. –

When unloading the equipment from the truck, never drop the Engine to the –

ground or this may severely damage the fuel tank.

Except in case of emergency, never drop or cast the equipment to the ground –

or this may severely damage the equipment.

Remember to lift the entire equipment from the ground when moving the –

equipment. Dragging the fuel tank is highly dangerous and will cause damage

and leakage of fuel, possibly causing re.

Refueling

Shut off the engine during refueling, keep away from open ames and do not –

smoke.

Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always –

wear protective gloves during refueling. Change and clean protective clothing

at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination –

(environmental protection). Clean the brushcutter immediately after fuel has

been spilt.

Avoid any fuel contact with your clothing. Change your clothing instantly if –

fuel has been spilt on it (to prevent clothing catching re).

Inspect the fuel cap at regular intervals making sure that it can be securely –

fastened and does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at –

least 3 meters away from the place of refueling).

Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of –

explosions).

Only transport and store fuel in approved containers. Make sure the fuel –

stored is not accessible to children.

5

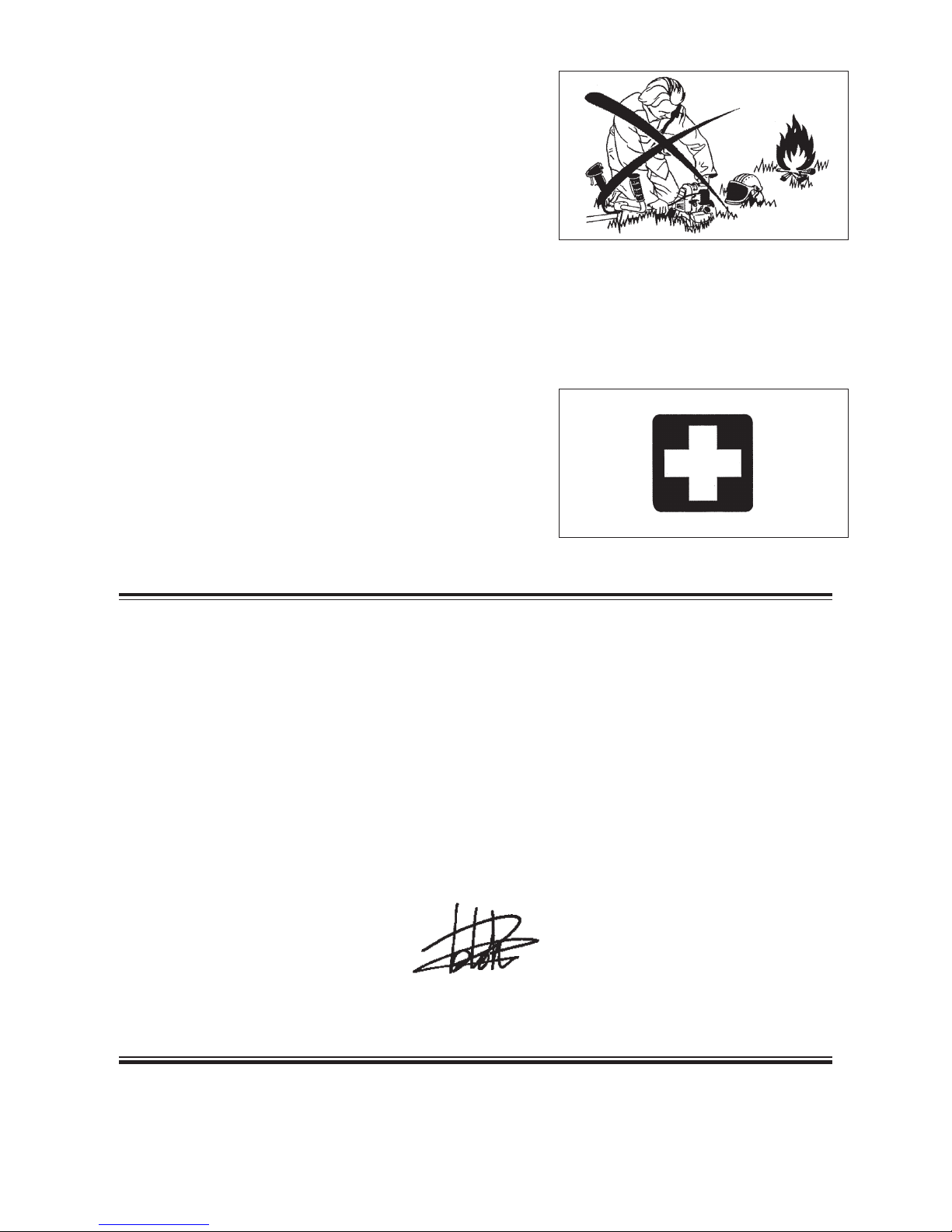

Caution:

Kickback

Diagrammatic

gure

Diagrammatic

gure

Method of operation

Only use in good light and visibility. During the winter season beware of –

slippery or wet areas, ice and snow (risk of slipping). Always ensure a safe

footing.

Never cut above waist height. –

Never stand on a ladder. –

Never climb up into trees to perform cutting operation. –

Never work on unstable surfaces. –

Remove sand, stones, nails etc. found within the working range. –

Foreign particles may damage the cutting tool and can cause dangerous

kick-backs.

Before commencing cutting, the cutting tool must have reached full working –

speed.

When using metal blades, swing the tool evenly in half-circle from right to left, –

like using a scythe.

If grass or branches get caught between the cutting tool and guard, always

stop the engine before cleaning. Otherwise unintentional blade rotation may

cause serious injury.

Take a rest to prevent loss of control caused by fatigue. We recommend to –

take a 10 to 20-minute rest every hour.

Cutting Tools

Use an applicable cutting tool for the job in hand. –

Nylon cutting heads (string trimmer heads) are suitable for trimming lawn

grass.

Metal blades are suitable for cutting weeds, high grasses, bushes, shrubs,

underwood, thicket, and the like.

Never use other blades including metal multi-piece pivoting chains and ail

blades. Otherwise serious injury may result.

When using metal blades, avoid “kickback” and always prepare for an –

accidental kickback. See the section “Kickback” and “Kickback prevention.”

Kickback (blade thrust)

Kickback (blade thrust) is a sudden reaction to a caught or bound cutting –

blade. Once it occurs, the equipment is thrown sideway or toward the

operator at great force and it may cause serious injury.

Kickback occurs particularly when applying the blade segment between 12 –

and 2 o’clock to solids, bushes and trees with 3 cm or larger diameter.

To avoid kickback: –

Apply the segment between 8 and 11 o’clock;•

Never apply the segment between 12 and 2 o’clock;•

Never apply the segment between 11 and 12 o’clock and between 2 and •

5 o’clock, unless the operator is well trained and experienced and does it at

his/her own risk;

Never use cutting blades close to solids, such as fences, walls, tree trunks •

and stones;

Never use cutting blades vertically, for such operations as edging and •

trimming hedges.

Vibration

People with poor circulation who are exposed to excessive vibration may –

experience injury to blood vessels or the nervous system. Vibration may

cause the following symptoms to occur in the ngers, hands or wrists: “Falling

asleep” (numbness), tingling, pain, stabbing sensation, alteration of skin color

or of the skin. If any of these symptoms occur, see a physician!

To reduce the risk of “white nger disease”, keep your hands warm during –

operation and well maintain the equipment and accessories.

Maintenance instructions

Have your equipment serviced by our authorized service center, always using –

only genuine replacement parts. Incorrect repair and poor maintenance can

shorten the life of the equipment and increase the risk of accidents.

The condition of the cutter, in particular of the cutting tool of the protective –

devices and also of the shoulder harness must be checked before

commencing work. Particular attention is to be paid to the cutting blades

which must be correctly sharpened.

Turn off the engine and remove spark plug connector when replacing or –

sharpening cutting tools, and also when cleaning the cutter or cutting tool.

6

Never straighten or weld damaged cutting tools.

Pay attention to the environment. Avoid unnecessary throttle operation for –

less pollution and noise emissions. Adjust the carburetor correctly.

Clean the equipment at regular intervals and check that all screws and nuts –

are well tightened.

Never service or store the equipment in the vicinity of naked ames. –

Always store the equipment in locked rooms and with an emptied fuel tank. –

When cleaning, servicing and storing the equipment, always attach the cover –

to the cutting blade.

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modications to the equipment as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other work is

to be done by an Authorized Service Agent. Use only genuine spare parts and accessories released and supplied by MAKITA.

Use of non-approved accessories and tools means increased risk of accidents.

MAKITA will not accept any liability for accidents or damage caused by the use of non-approved cutting tools and xing devices of cutting tools,

or accessories.

First Aid

In case of accident make sure that a rst-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the rst aid box.

When asking for help, please give the following

information:

Place of accident –

What happened –

Number of injured persons –

Kind of injuries –

Your name –

For European countries only

EC Declaration of Conformity

We Makita Corporation as the responsible manufacturer declare that the following Makita machine(s):

Designation of Machine: Petrol Brushcutter

Model No./ Type: EBH341U, EBH341L

Specications: see “TECHNICAL DATA” table

are of series production and

Conforms to the following European Directives:

2000/14/EC, 2006/42/EC

And are manufactured in accordance with the following standards or standardized documents:

EN ISO 11806-1

The technical documentation is kept by:

Makita International Europe Ltd., Technical Department,

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15 8JD, England

The conformity assessment procedure required by Directive 2000/14/EC was in Accordance with annex V.

Measured Sound Power Level: 109.7 dB

Guaranteed Sound Power Level: 111 dB

31. 8. 2009

Tomoyasu Kato

Director

Makita Corporation

3-11-8, Sumiyoshi-cho,

Anjo, Aichi, JAPAN

7

TECHNICAL DATA EBH341U, EBH341L

Model

EBH341U EBH341L

Bike handle Loop handle

Dimensions: length x width x height (without cutting blade) mm 1,810 x 620 x 500 1,810 x 330 x 275

Mass (without plastic guard and cutting blade) kg 7.1 6.7

Volume (fuel tank) L 0.65

Volume (oil tank) L 0.1

Engine displacement cm

3

33.5

Maximum engine performance ISO8893 kw 1.07 at 7,000 min

-1

Maximum rotational frequency of the spindle min

-1

6,850

Engine speed at recommended max. spindle rotational frequency min

-1

10,000

Fuel consumption at max. engine performance ISO8893 kg/h 0.458

Specic fuel consumption at max. engine performance g/kwh 426

Engine speed at idling min

-1

3,000

Clutch engagement speed min

-1

4,100

Carburetor (Diaphragm - carburetor) type WALBRO WYL

Ignition system type Solid state ignition

Spark plug type NGK CMR4A

Electrode gap mm 0.7 - 0.8

Vibration per

ISO 22867

Right handle

(Rear grip)

a

hv eq

m/s

2

3.3 6.1

Uncertainty K m/s

2

0.70 2.0

Left handle

(Front grip)

a

hv eq

m/s

2

2.5 7.4

Uncertainty K m/s

2

1.26 0.63

Sound pressure level average to

ISO 22868

L

PA eq

dBA 98.2

Uncertainty K dBA 2.1

Sound power level average to

ISO 22868

L

WA eq

dBA 106.7

Uncertainty K dBA 1.3

Fuel Automobile gasoline

Engine Oil

SAE 10W-30 oil of API Ciassication,

Class SF or higher (4-stroke engine for automobile)

Cutting tools (cutter blade dia.) mm 305 (with three blades)

Gear ratio 13/19

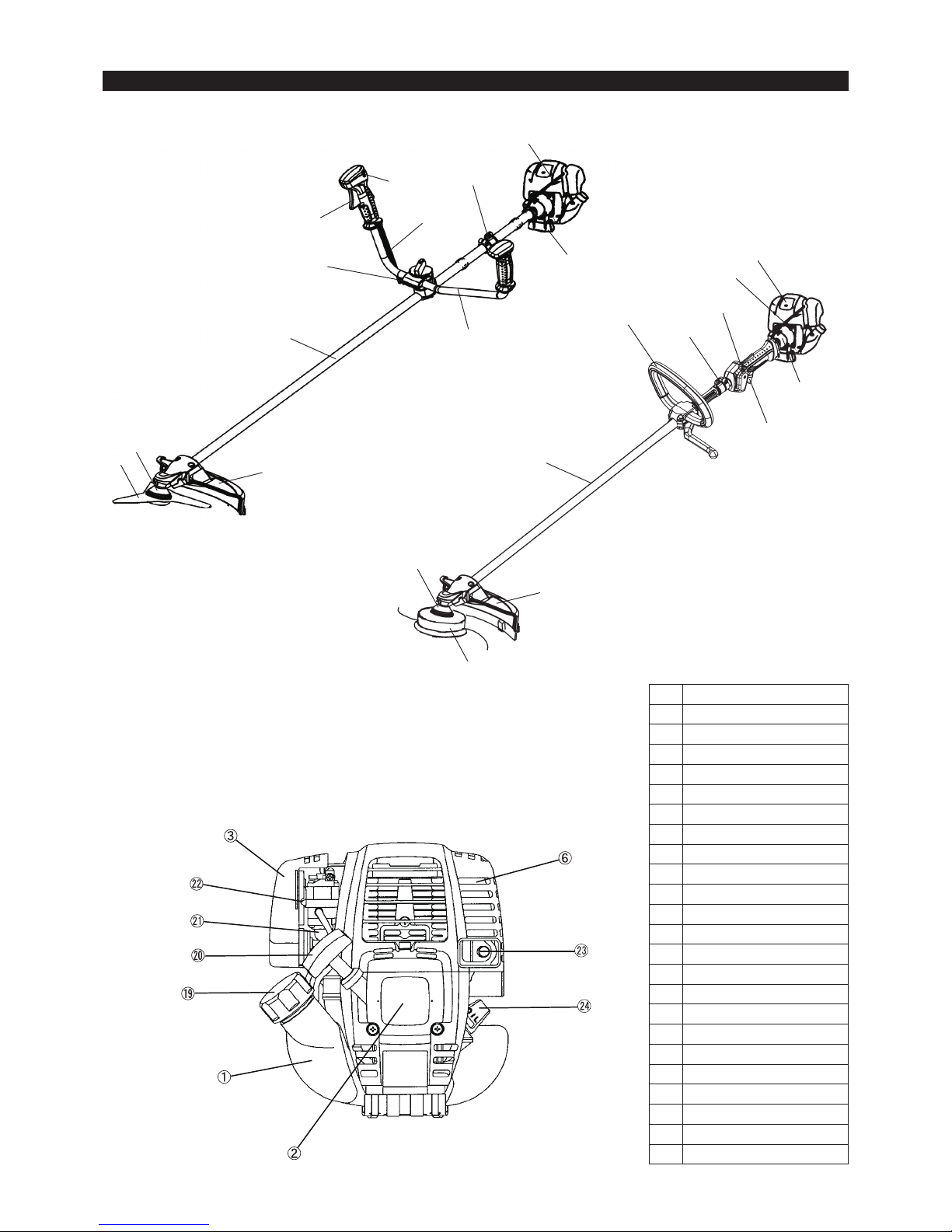

8

EBH341U

DESIGNATION OF PARTS

GB DESIGNATION OF PARTS

1 Fuel Tank

2 Rewind Starter

3 Air Cleaner

4 I-O Switch (on/off)

5 Spark Plug

6 Exhaust Mufer

7 Clutch Case

9 Hanger

10 Handle

11 Throttle Lever

12 Control Cable

13 Shaft

14 Protector (Cutting tool guard)

15 Gear Case/Head Case

16 Handle Holder

17 Cutter Blade

18 Nylon Cutting Head

19 Fuel Filler Cap

20 Starter Knob

21 Primer Pump

22 Choke Lever

23 Exhaust Pipe

24 Oil Gauge

④

⑤

⑰

⑦

⑪

⑩

⑫

⑭

⑯

⑮

⑬

⑨

EBH341L

⑤

⑫

⑦

⑪

④

⑨

⑩

⑬

⑱

⑭

⑮

9

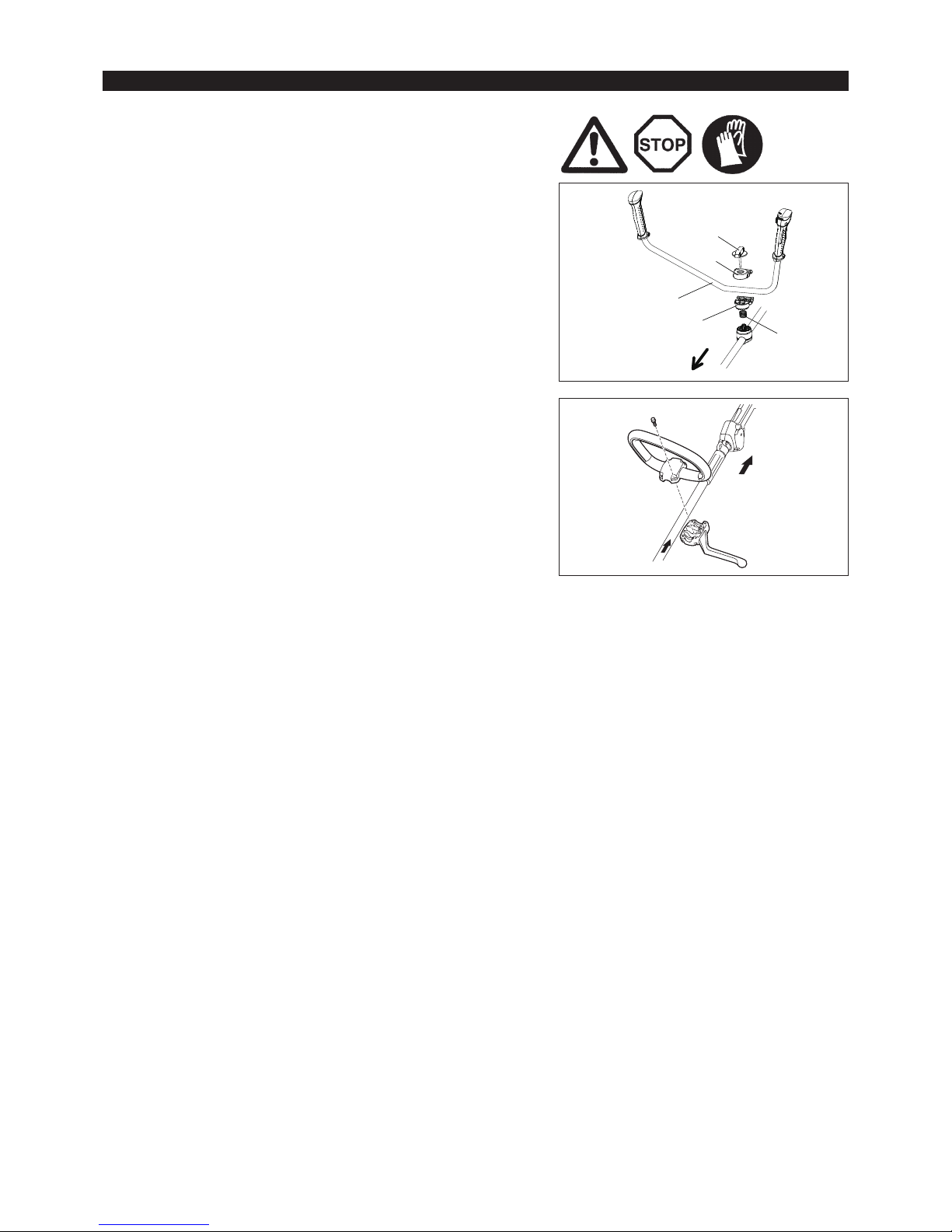

CAUTION: Before doing any work on the Petrol Brushcutter, always stop the

engine and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the Petrol Brushcutter only after having assembled it

completely.

For machines with bike handle models

– Loosen knob (1).

– Place handle (4) between handle clamp (2) and handle holder (3).

– Adjust handle (4) to an angle that provides a comfortable working position

and then secure by rmly hand-tightening knob (1).

CAUTION: Do not forget to mount spring (5).

MOUNTING OF HANDLE

(1)

(2)

(3)

(4)

(5)

Engine

Engine

For machines with loop handle

– Fix a barrier to the left side of the machine together with the handle for

operator protection.

– Make sure that the grip/barrier assembly is tted between the spacer and the

arrow mark.

WARNING: Do not remove or shrink the spacer. The spacer keeps a certain

distance between both hands. Setting the grip/barrier assembly

close to the other grip beyond the length of the spacer may cause

loss of control and serious personal injury.

Arrow mark

Loading...

Loading...