Page 1

GB

Cordless Driver Drill Instruction Manual

F

Perceuse-visseuse sans fil Manuel d’instructions

D

Akku-bohrschrauber Betriebsanleitung

I

Trapano-avvitatore a batteria Istruzioni per l’uso

NL

Snoerloze boor-schroevedraaier Gebruiksaanwijzing

E

Taladro-atornillador a batería Manual de instrucciones

P

Berbequim aparafusador a bateria Manual de instruções

DK

Akku bore-skruemaskine Brugsanvisning

S

Sladdlös borrmaskin/skruvdragare Bruksanvisning

N

Akku boreskrutrekker Bruksanvisning

SF

Akkuporakone Käyttöohje

GR Βιδοτρύπανο µε µπαταρία Οδηγίες χρήσεως

6204D

Page 2

1

2

2

3

4

12

6

5

7

8

34

9

10

12

11

13

9

14

15

16

56

18

17

19

20

78

2

Page 3

22

23

21

910

3

Page 4

ENGLISH

1Button

2 Battery cartridge

3 Charging light

4 Fast charger

5 Tighten

6Sleeve

7 Ring

8 Switch trigger

Explanation of general view

9 Reversing switch lever

10 A side

11 B side

12 Clockwise

13 Counterclockwise

14 Low speed

15 High speed

16 Speed change lever

17 Adjusting ring

18 Graduations

19 Drill marking

20 Pointer

21 Limit mark

22 Screwdriver

23 Brush holder cap

SPECIFICATIONS

Model 6204D

Capacities

Steel .................................................................. 10 mm

Wood ................................................................. 21 mm

Wood screw ....................................... 6.1 mm x 55 mm

Tool screw ........................................................... 6 mm

No load speed (min

High ............................................................... 0 – 1,100

Low ................................................................... 0 – 350

Overall length ..................................................... 197 mm

Net weight ............................................................. 1.5 kg

Rated voltage ................................................... D.C.9.6 V

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

–1

)

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. SAVE THESE INSTRUCTIONS — This manual

contains important safety and operating instructions for battery charger.

2. Before using battery charger, read all instruc-

tions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

3. CAUTION — To reduce risk of injury, charge only

MAKITA type rechargeable batteries. Other types

of batteries may burst causing personal injury

and damage.

4. Do not expose charger to rain or snow.

5. Use of an attachment not recommended or sold

by the battery charger manufacturer may result

in a risk of fire, electric shock, or injury to persons.

6. To reduce risk of damage to electric plug and

cord, pull by plug rather than cord when disconnecting charger.

7. Make sure cord is located so that it will not be

stepped on, tripped over, or otherwise subjected

to damage or stress.

8. Do not operate charger with damaged cord or

plug — replace them immediately.

9. Do not operate charger if it has received a sharp

blow, been dropped, or otherwise damaged in

any way; take it to a qualified serviceman.

ENC001-3

10. Do not disassemble charger or battery cartridge;

take it to a qualified serviceman when service or

repair is required. Incorrect reassembly may

result in a risk of electric shock or fire.

11. To reduce risk of electric shock, unplug charger

from outlet before attempting any maintenance

or cleaning. Turning off controls will not reduce

this risk.

12. The battery charger is not intended for use by

young children or infirm persons without supervision.

13. Young children should be supervised to ensure

that they do not play with the battery charger.

14. If operating time has become excessively

shorter, stop operating immediately. It may result

in a risk of overheating, possible burns and even

an explosion.

15. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

ADDITIONAL SAFETY RULES FOR CHARGER

& BATTERY CARTRIDGE

1. Do not charge Battery Cartridge when temperature is BELOW 10°C (50°F) or ABOVE 40°C

(104°F).

2. Do not attempt to use a step-up transformer, an

engine generator or DC power receptacle.

3. Do not allow anything to cover or clog the

charger vents.

4. Always cover the battery terminals with the battery cover when the battery cartridge is not

used.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

7. Do not incinerate the battery cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

8. Be careful not to drop, shake or strike battery.

4

Page 5

9. Do not charge inside a box or container of any

kind. The battery must be placed in a well ventilated area during charging.

ADDITIONAL SAFETY RULES FOR TOOL

1. Be aware that this tool is always in an operating

condition, because it does not have to be

plugged into an electrical outlet.

2. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and shock the operator.

3. Always be sure you have a firm footing.

4. Be sure no one is below when using the tool in

high locations.

5. Hole the tool firmly.

6. Keep hands away from rotating parts.

7. Do not leave the tool running. Operate the tool

only when hand-held.

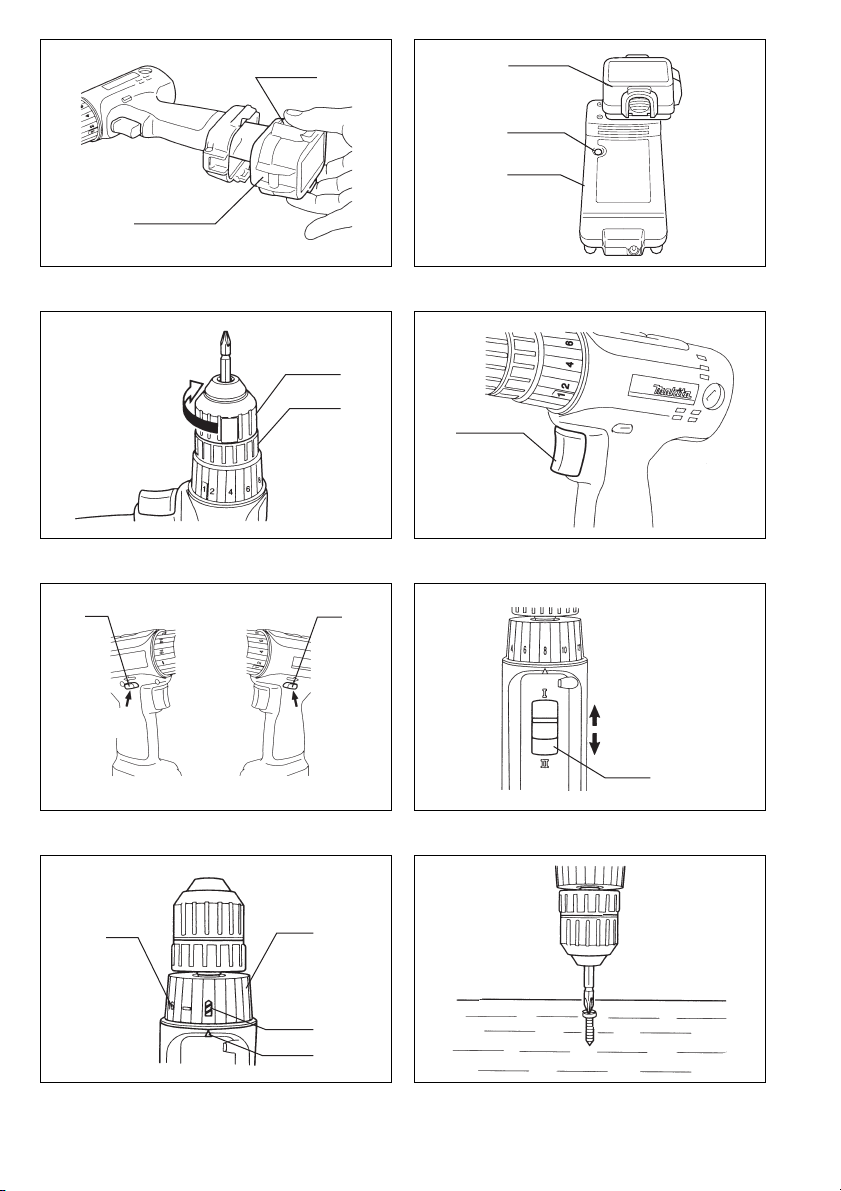

Charging (Fig. 2)

Plug the battery charger into the proper A/C voltage source. The charging light will flash in green color. Insert the battery cartridge so that the plus and minus terminals on the battery cartridge are on the same sides as their respective

markings on the battery charger. Insert the cartridge fully into the port so that it rests on the charger port floor. When

the battery cartridge is inserted, the charging light color will change from green to red and charging will begin. The

charging light will remain lit steadily during charging. When the charging light color changes from red to green, the

charging cycle is complete. The charging time is approximately one hour. If you leave the battery cartridge in the

charger after the charging cycle is complete, the charger will switch into its “trickle charge (maintenance charge)”

mode. After charging, unplug the charger from the power source. Refer to the table below for the charging time.

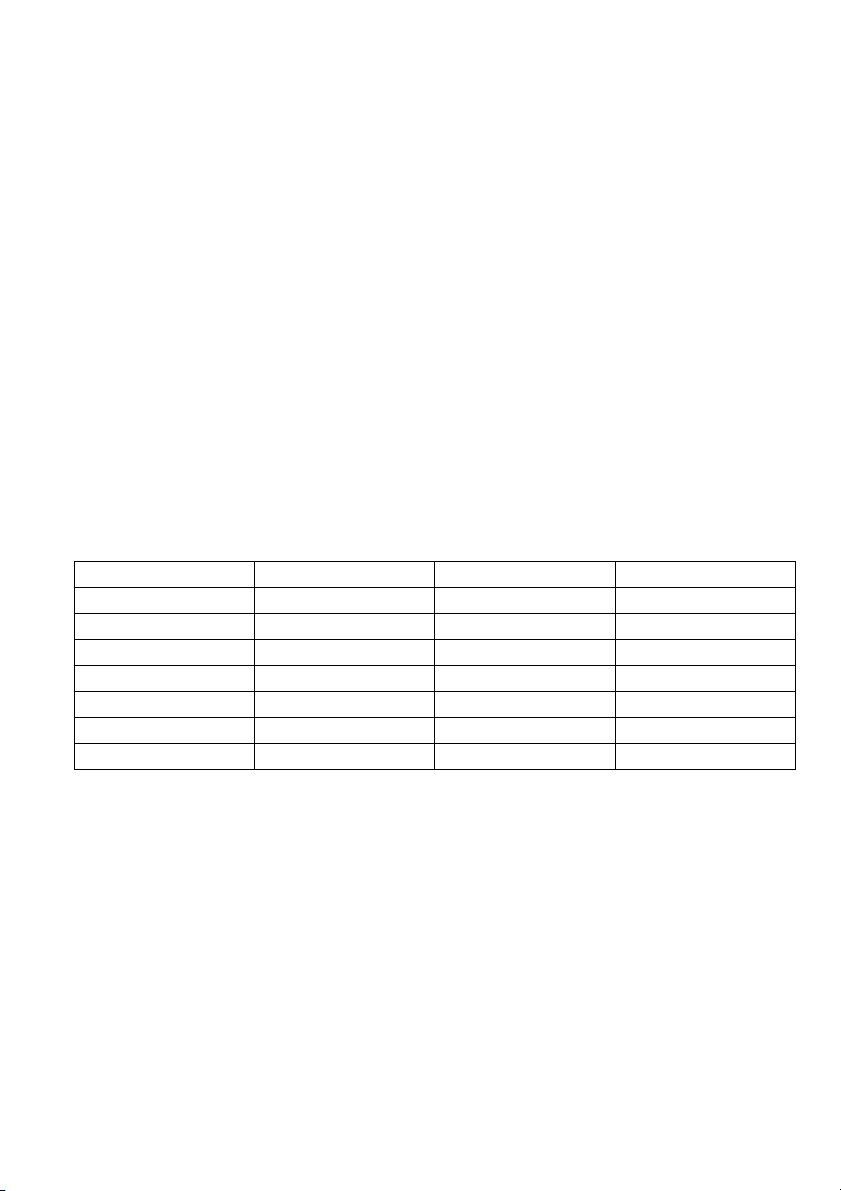

Battery type Capacity (Ah) Number of cells Charging time

9100 (Ni-cd) 1.3 8 Approx. 30 min.

9102 (Ni-cd) 2.0 8 Approx. 45 min.

9102A (Ni-cd) 2.0 8 Approx.45 min.

9122 (Ni-cd) 2.0 8 Approx. 45 min.

9133 (Ni-MH) 2.2 8 Approx. 50 min.

9134 (Ni-MH) 2.6 8 Approx. 60min.

9135 (Ni-MH) 3.0 8 Approx. 70min.

CAUTION:

• The fast charger is for charging Makita bettery cartrige. Never use it for other purposes or for other manufactor’s bat-

teries.

• When you charge a new battery cartridge or a battery cartridge which has not been used for a long period of time, it

may not accept a full charge. This is a normal condition and does not indicate a problem. You can recharge the battery cartridge fully after discharging it completely and recharging a couple of times.

• If you charge a battery cartridge from a just-operated tool or a battery cartridge which has been left in a location

exposed to direct sunlight or heat for a long time, the charging light may flash in red color. If this occurs, wait for a

while. Charging will begin after the battery cartridge cools. The battery cartridge will cool faster if you remove the

battery cartridge from the fast charger.

• If the charging light flashes alternately in green and red color, a problem exists and charging is not possible. The ter-

minals on the charger or battery cartridge are clogged with dust or the battery cartridge is worn out or damaged.

• If you wish to charge two battery cartridges, allow 15 minutes between chargings on the fast charger.

Trickle charge (Maintenance charge)

If you leave the battery cartridge in the charger to prevent spontaneous discharging after full charge, the charger will

switch into its “trickle charge (maintenance charge)” mode and keep the battery cartridge fresh and fully charged.

ENB022-1

8. Do not touch the drill bit or the workpiece immediately after operation; they may be extremely

hot and could burn your skin.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

Installing or removing battery cartridge (Fig. 1)

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the

tool while pressing the buttons on both sides of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

5

Page 6

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely discharged. Always stop tool operation and charge the battery

cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C – 40°C (50°F – 104°F).

Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when you do not use it for more than six months.

Installing or removing driver bit or drill bit (Fig. 3)

Important:

Always be sure that the tool is switched off and the battery cartridge is removed before installing or removing

the bit.

Hold the ring and turn the sleeve counterclockwise to

open the chuck jaws. Place the bit in the chuck as far as it

will go. Hold the ring firmly and turn the sleeve clockwise

to tighten the chuck.

To remove the bit, hold the ring and turn the sleeve counterclockwise.

Switch action (Fig. 4)

CAUTION:

Before inserting the battery cartridge into the tool, always

check to see that the switch trigger actuates properly and

returns to the “OFF” position when released.

To start the tool, simply pull the trigger. Tool speed is

increased by increasing pressure on the trigger. Release

the trigger to stop.

Reversing switch action (Fig. 5)

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the A

side for clockwise rotation or from the B side for counterclockwise rotation. When the switch lever is in the neutral

position, the switch trigger cannot be pulled.

Speed change (Fig. 6)

To change the speed, first switch off the tool and then

slide the speed change lever to the “ II ” side for high

speed or “ I ” side for low speed. Be sure that the speed

change lever is set to the correct position before operation. Use the right speed for your job.

CAUTION:

• Always set the speed change lever fully to the correct

position. If you operate the tool with the speed change

lever positioned half-way between the “ I ” side and “ II ”

side, the tool may be damaged.

• Do not use the speed change lever while the tool is run-

ning. The tool may be damaged.

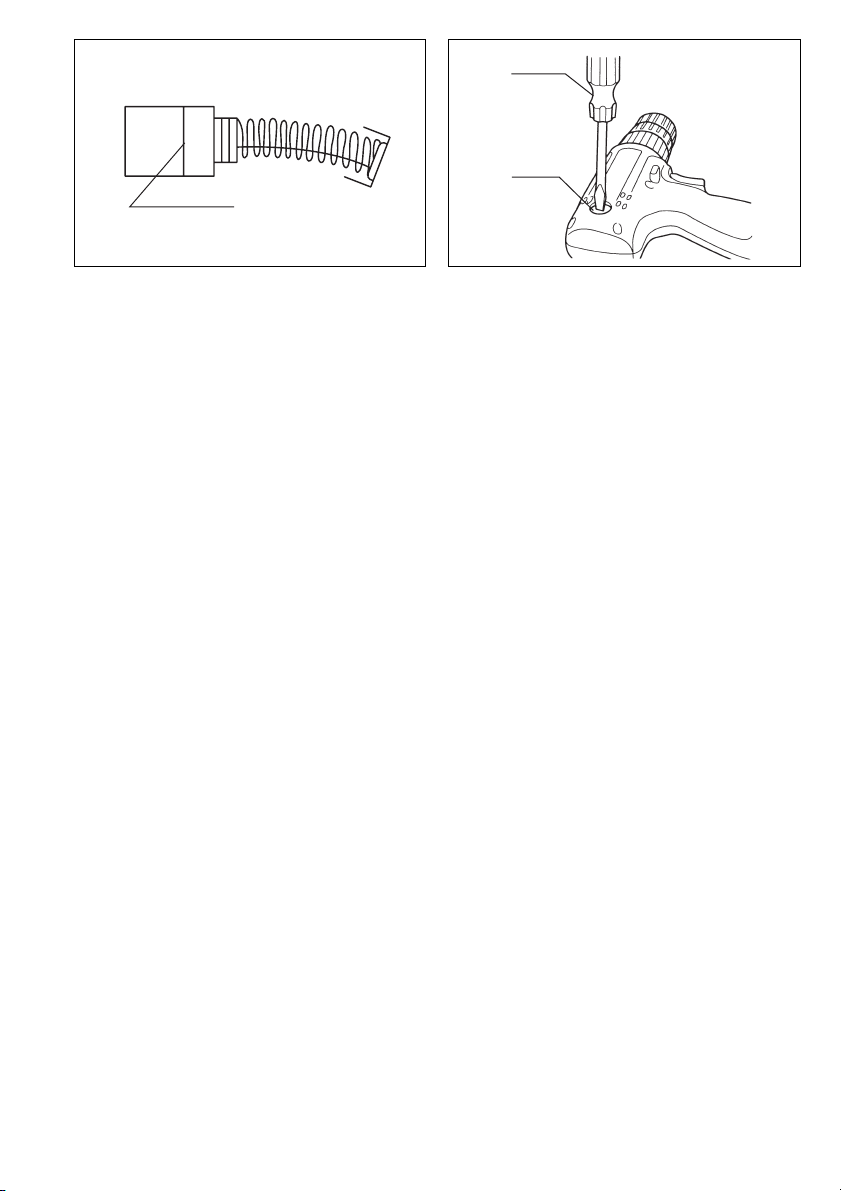

Adjusting the fastening torque (Fig. 7)

The fastening torque can be adjusted in 17 steps by turning the adjusting ring so that its graduations are aligned

with the pointer on the tool body. The fastening torque is

minimum when the number 1 is aligned with the pointer,

and maximum when the marking A is aligned with the

pointer.

The clutch will slip at various torque levels when set at

the number 1 to 16. The clutch is designed not to slip at

the A marking. Before actual operation, drive a trial

screw into your material or a piece of duplicate material

to determine which torque level is required for a particular application.

NOTE:

Do not operate the tool with the adjusting ring set

between the number 16 and the A marking. The tool may

be damaged.

Screwdriving operation (Fig. 8)

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the trigger as

soon as the clutch cuts in.

NOTE:

• Make sure that the driver bit is inserted straight in the

screw head, or the screw and/or bit may be damaged.

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting of the workpiece.

See the chart below.

Nominal diameter of

wood screw (mm)

3.1 2.0 – 2.2

3.5 2.2 – 2.5

3.8 2.5 – 2.8

4.5 2.9 – 3.2

4.8 3.1 – 3.4

5.1 3.3 – 3.6

5.5 3.6 – 3.9

5.8 4.0 – 4.2

6.1 4.2 – 4.4

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

Recommended size of

pilot hole (mm)

6

Page 7

Drilling operation

First, turn the adjusting ring so that the pointer on the tool

body points to the A marking. Then proceed as follows.

• Drilling in wood

When drilling in wood, best results are obtained with

wood drills equipped with a guide screw. The guide

screw makes drilling easier by pulling the bit into the

workpiece.

• Drilling in metal

To prevent the bit from slipping when starting a hole,

make an indentation with a centerpunch and hammer

at the point to be drilled. Place the point of the bit in the

indentation and start drilling. Use a cutting lubricant

when drilling metals. The exceptions are iron and brass

which should be drilled dry.

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool performance and shorten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole breakthrough. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and the battery cartridge is removed before carrying out any work on

the tool.

Replacement of carbon brushes (Fig. 9 & 10)

Replace carbon brushes when they are worn down to the

limit mark. Both identical carbon brushes should be

replaced at the same time.

To maintain product safety and reliability, repairs, maintenance or adjustment should be carried out by a Makita

Authorized Service Center.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

•Screw bits

• Rubber pad assembly

• Foam polishing pad 125

• Wool bonnet 100

• Various type of Makita genuine batteries and chargers

• Plastic carrying case

7

Page 8

NEDERLANDS

1 Knop

2 Accu

3 Oplaadlampje

4 Snellader

5 Vastdraaien

6Bus

7 Ring

8 Trekschakelaar

Verklaring van algemene gegevens

9 Omkeerschakelaar

10 Zijde A

11 Zijde B

12 Rechtse draairichting

13 Linkse draairichting

14 Laag toerental

15 Hoog toerental

16 Toerentalschakelaar

17 Stelring

18 Schaalverdelingen

19 Boormarkering

20 Wijzer

21 Limietaanduiding

22 Schroevendraaier

23 Dop van koolborstelhouder

TECHNISCHE GEGEVENS

Model 6204D

Capaciteiten

Staal ..................................................................10 mm

Hout ...................................................................21 mm

Houtschroef ....................................... 6,1 mm x 55 mm

Kolomschroef ....................................................... 6 mm

Toerental onbelast (min

Hoog .............................................................. 0 – 1 100

Laag ..................................................................0 – 350

Totale lengte .......................................................197 mm

Netto gewicht ......................................................... 1,5 kg

Nominale spanning ..........................................D.C. 9,6 V

• In verband met ononderbroken research en ontwikke-

ling behouden wij ons het recht voor bovenstaande

technische gegevens te wijzigen zonder voorafgaande

kennisgeving.

• Opmerking: De technische gegevens kunnen van land

tot land verschillen.

Veiligheidswenken

Voor uw veiligheid dient u de bijgevoegde Veiligheidsvoorschriften nauwkeurig op te volgen.

–1

)

BELANGRIJKE

VEILIGHEIDSVOORSCHRIFTEN VOOR

GEBRUIK VAN DE BATTERIJLADER EN HET

BATTERIJPAK

1. BEWAAR DEZE VOORSCHRIFTEN — In deze

gebruiksaanwijzing staan belangrijke veiligheids- en bedieningsvoorschriften betreffende

de batterijlader (snellader).

2. Lees alle voorschriften en waarschuwingen

betreffende (1) de batterijlader, (2) het batterijpak

en (3) het gereedschap aandachtig door alvorens de batterijlader in gebruik te nemen.

3. LET OP — Om het gevaar voor ongelukken te

verminderen, dient u met de snellader uitsluitend MAKITA oplaadbare batterijen te laden. Batterijen van andere merken kunnen gaan barsten

en hierdoor verwondingen of schade veroorzaken.

4. Stel de batterijlader niet bloot aan regen of

sneeuw.

5. Het gebruik van accessoires die niet door de

fabrikant van de batterijlader worden verkocht of

aanbevolen, kan brandgevaar, elektrische schok

of verwondingen veroorzaken.

6. Om de stekker en het netsnoer niet te beschadi-

gen, trekt u het netsnoer uit het stopkontakt

door de stekker vast te pakken.

7. Let op dat het snoer zodanig op de grond ligt,

dat niemand erop kan stappen of erover kan

struikelen en dat er niets op het snoer geplaatst

wordt.

8. Gebruik in geen geval de batterijlader als het

netsnoer of de stekker beschadigd is. Vervang

deze onmiddellijk.

9. Gebruik de batterijlader ook niet als deze gevallen is, aan een zware stoot heeft blootgestaan, of

als u vermoedt dat hij beschadigd is. Laat in

deze gevallen de batterijlader eerst nakijken.

10. Haal de batterijlader of het batterijpak niet uit

elkaar; laat eventuele servicebeurten of reparaties uitsluitend vakkundig uitvoeren. Het onjuist

opnieuw in elkaar zetten kan namelijk elektrische schok of brandgevaar opleveren.

11. Om gevaar voor elektrische schok te verminderen, trekt u de stekker uit het stopkontakt alvorens de batterijlader te reinigen of een

onderhoudsbeurt te geven. Door de batterijlader

alleen maar uit te schakelen, vermindert u dit

gevaar niet.

12. De acculader is niet bedoeld voor gebruik door

kleine kinderen of geestelijk gestoorden waarop

geen toezicht wordt gehouden.

13. Houd toezicht op kleine kinderen om te voorkomen dat ze met de acculader spelen.

14. Als de gebruiksduur van de accu bijzonder kort

geworden is, moet u het gebruik ervan onmiddellijk stopzetten omdat er anders gevaar is voor

oververhitting, brandwonden en zelfs een explosie.

15. Als er elektrolyt in uw ogen is terechtgekomen,

moet u deze spoelen met schoon water en

onmiddellijk de hulp van een dokter inroepen.

Elektrolyt in de ogen kan blindheid veroorzaken.

BIJGEVOEGDE

VEILIGHEIDSVOORSCHRIFTEN VOOR

GEBRUIK VAN DE BATTERIJLADER EN HET

BATTERIJPAK

1. Laad het batterijpak niet op als de temperatuur

LAGER is dan 10°C of HOGER dan 40°C.

2. Gebruik voor het laden nooit een step-up transformator, een dynamo of een gelijkstroombron.

3. Zorg dat de ventilatiegaten van de batterijlader

niet afgesloten worden of verstopt raken.

4. Bedek altijd de polen van de accu met het accudeksel wanneer u de accu niet gebruikt.

21

Page 9

5. Voorkom kortsluiting van het batterijpak:

(1) Raak de aansluitklemmen nooit aan met

geleidend materiaal.

(2) Bewaar het batterijpak niet op een plaats

waar ook andere metalen voorwerpen zoals

spijkers, munten e.d. worden bewaard.

(3) Stel het batterijpak niet bloot aan water of

regen.

Kortsluiting van het batterijpak kan leiden tot

een grote stroomafgifte, oververhitting, brandwonden of zelfs tot defecten.

6. Bewaar de batterijlader en het batterijpak niet in

plaatsen waar de temperatuur tot 50°C of hoger

kan op lopen.

7. Werp zwaar beschadigde of volledig uitgeputte

batterijpakken niet in het vuur, omdat een

gevaarlijke explosie er het gevolg van kan zijn.

8. Wees voorzichtig dat u het batterijpak niet laat

vallen en het niet aan schokken of stoten blootstelt.

9. Laad het batterijpak niet op in een kist, een container e.d. Om het batterijpak op te laden, dient u

dit in een goed geventileerde ruimte te plaatsen.

AANVULLENDE VEILIGHEIDSVOORSCHRIFT

EN VOOR HET GEREEDSCHAP

1. Denk eraan dat dit gereedschap altijd gebruiksklaar is, aangezien het niet hoeft te worden aangesloten op een stopcontact.

2. Houd het gereedschap bij de geïsoleerde handgrepen vast wanneer u boort op plaatsen waar

de boor op verborgen elektrische bedrading kan

stoten. Door contact met een onder spanning

staande draad zullen ook de niet-geïsoleerde

metalen delen van het gereedschap onder spanning komen te staan, zodat de gebruiker een

elektrische schok kan krijgen.

3. Zorg ervoor dat u altijd stevige steun voor de

voeten hebt.

4. Controleer of er zich niemand onder u bevindt

wanneer u het gereedschap op een hoge plaats

gaat gebruiken.

5. Houd het gereedschap stevig vast.

6. Houd uw handen uit de buurt van roterende

onderdelen.

7. Laat het gereedschap niet achter terwijl het nog

in bedrijf is. Laat het gereedschap alleen draaien

wanneer u het met beide handen vasthoudt.

8. Raak de boor of het werkstuk niet aan onmiddellijk na het gebruik; deze kunnen zeer heet zijn en

brandwonden veroorzaken.

BEWAAR DEZE VOORSCHRIFTEN.

BEDIENINGSVOORSCHRIFTEN

Installeren of verwijderen van de accu (Fig. 1)

• Schakel het gereedschap altijd uit alvorens de accu te

installeren of te verwijderen.

• Om de accu te verwijderen, neemt u deze uit het

gereedschap terwijl u de knoppen aan beide zijden van

de accu indrukt.

• Om de accu te installeren, past u de rug op de accu in

de groef in de behuizing van het gereedschap, en dan

schuift u de accu naar binnen. Schuif de accu zo ver

mogelijk erin, totdat deze met een klikgeluid vergrendelt. Indien u dit niet doet, kan de accu per ongeluk uit

het gereedschap vallen en uzelf of anderen verwonden.

• Als de accu moeilijk in de houder gaat, moet u niet pro-

beren hem met geweld erin te duwen. Indien de accu

er niet gemakkelijk ingaat, betekent dit dat u hem niet

op de juiste wijze erin steekt.

Laden (Fig. 2)

Sluit de acculader aan op een stopkontakt. Het laadcontrolelampje zal in groen knipperen. Schuif de accu zodanig in

de acculader dat de plus en min klemmen van de accu overeenkomen met de plus en min markeringen op de acculader. Schuif de accu zo ver mogelijk in de opening, zodat het op de bodem van de lader rust. Wanneer de accu helemaal erin zit, zal de kleur van het laadcontrolelampje veranderen van groen in rood en zal het laden beginnen. Tijdens

het laden zal het laadcontrolelampje blijven branden. Wanneer de kleur van het oplaadlampje verandert van rood in

groen, is het opladen voltooid. De oplaadtijd is ongeveer een uur. Wanneer u een volledig opgeladen accu in de lader

laat zitten, zal de lader overschakelen naar de “bijladen (handhaven van de lading)” stand. Trek de stekker van de

lader uit het stopkontakt nadat het laden is voltooid. Zie de onderstaande tabel voor de oplaadtijden.

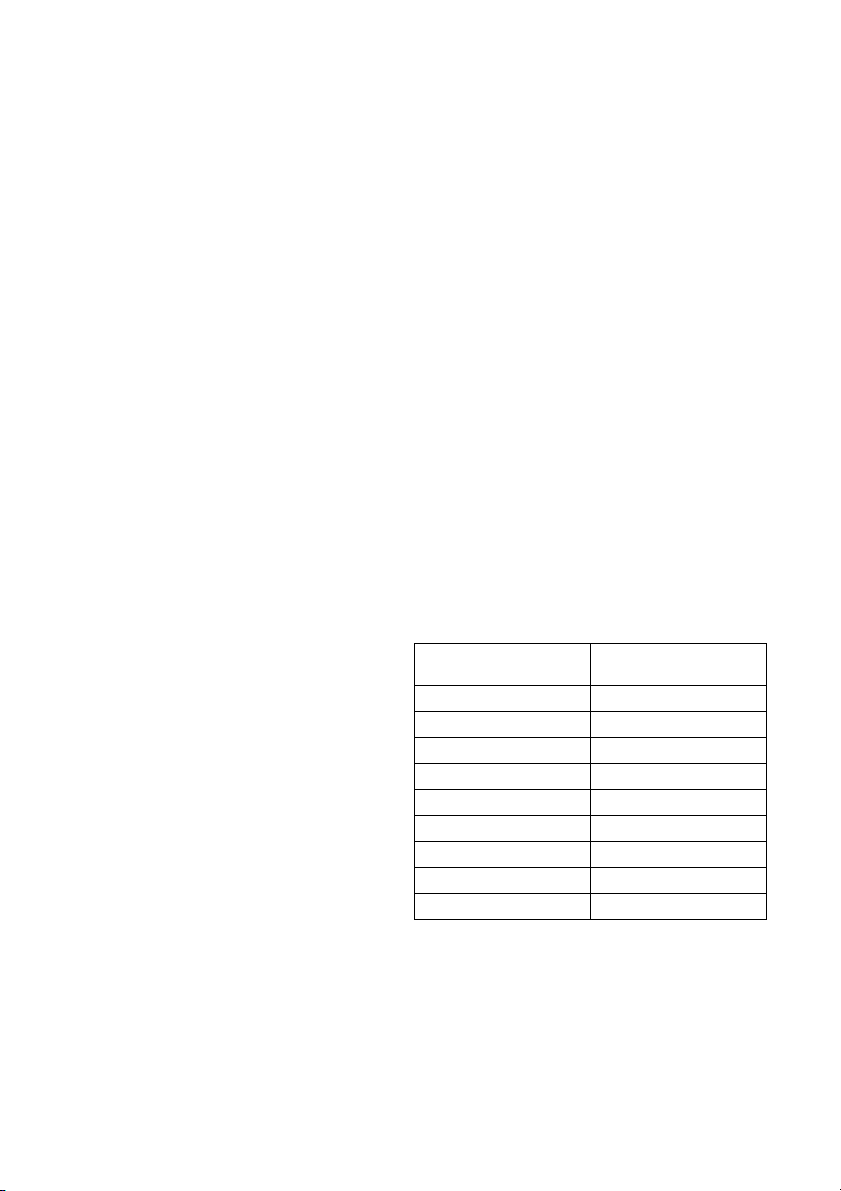

Accu type Capaciteit (Ah) Aantal cellen Oplaadtijd

9100 (Ni-cd) 1,3 8 ca. 30 min.

9102 (Ni-cd) 2,0 8 ca. 45 min.

9102A (Ni-cd) 2,0 8 ca.45 min.

9122 (Ni-cd) 2,0 8 ca. 45 min.

9133 (Ni-MH) 2,2 8 ca. 50min.

9134 (Ni-MH) 2,6 8 ca. 60min.

9135 (Ni-MH) 3,0 8 ca. 70min.

22

Page 10

LET OP:

• De snellader is uitsluitend bestemd voor het laden van Makita accu’s. Gebruik deze nooit voor andere doeleinden of

voor het laden van accu’s van andere fabrikanten.

• Een nieuwe accu of een accu die gedurende lange tijd niet werd gebruikt, kan eventueel niet volledig worden geladen. Dit is normaal en duidt niet op een defect. Nadat de accu een paar keer volledig is ontladen en herladen, kunt u

deze weer volledig laden.

• Wanneer u de accu van een zojuist gebruikt gereedschap laadt, of een accu die voor langere tijd aan direct zonlicht

of hitte werd blootgesteld, gebeurt het wel eens dat het oplaadlampje in rood knippert. Wacht in zo’n geval een tijdje.

Het laden zal beginnen nadat de accu is afgekoeld. De accu zal sneller afkoelen indien u deze van de snellader verwijdert.

• Indien het oplaadlampje afwisselend in groen en rood knippert, wijst dit op een probleem en is laden niet mogelijk.

De klemmen op de snellader of op de accu zijn vuil of de accu is versleten of beschadigd.

• Als u twee accu’s achtereen wilt laden, geef dan de snellader tussendoor 15 minuten rust.

Bijladen (Handhaven van de lading)

Wanneer u een volledig opgeladen accu in de lader laat zitten om spontaan ontladen te voorkomen, zal de lader overschakelen naar de “Bijladen (Handhaven van de lading)” stand waardoor de accu vers en in volledig opgeladen toestand wordt gehouden.

Wenken om een maximale levensduur van de accu te handhaven

1. Laad de accu op alvorens deze volledig is ontladen.

Stop het gebruik van het gereedschap en laad de accu op telkens wanneer u vaststelt dat het vermogen van het

gereedschap verminderd is.

2. Laad een volledig opgeladen accu nooit opnieuw op.

Wanneer u de accu te veel oplaadt, zal deze minder lang meegaan.

3. Laad de accu op bij een kamertemperatuur tussen 10°C en 40°C.

Laat een warme accu afkoelen alvorens deze op te laden.

4. Laad de nikkel-metaalhydride accu op wanneer u deze langer dan zes maanden niet gebruikt.

Installeren of verwijderen van de schroefbit of

boor (Fig. 3)

Belangrijk:

Controleer altijd of het gereedschap is uitgeschakeld en

de accu is verwijderd alvorens de boor te installeren of te

verwijderen.

Houd de ring vast en draai de bus naar links om de klauwen van de boorkop te openen. Steek de boor zo ver

mogelijk in de boorkop. Houd daarna de ring weer stevig

vast en draai de bus naar rechts om de boorkop vast te

zetten.

Om de boor te verwijderen, houdt u de ring vast en draait

u de bus naar links.

Werking van de trekschakelaar (Fig. 4)

LET OP:

Alvorens de accu in het gereedschap te plaatsen, moet u

altijd controleren of de trekschakelaar juist werkt en bij

het loslaten naar de “OFF” positie terugkeert.

Om het gereedschap in te schakelen, drukt u gewoon de

trekschakelaar in. Hoe dieper de trekschakelaar wordt

ingedrukt, hoe sneller het gereedschap draait. Om het

gereedschap uit te schakelen, de trekschakelaar loslaten.

Werking van de omkeerschakelaar (Fig. 5)

LET OP:

• Controleer altijd de draairichting alvorens het gereedschap te gebruiken.

• Verander de stand van de omkeerschakelaar alleen

nadat het gereedschap volledig tot stilstand is gekomen. Indien u de draairichting verandert terwijl de boor

nog draait, kan het gereedschap beschadigd raken.

• Zet de omkeerschakelaar altijd in de neutrale stand

wanneer u het gereedschap niet gebruikt.

Dit gereedschap heeft een omkeerschakelaar voor het

veranderen van de draairichting. Druk de omkeerschakelaar in vanaf zijde A voor rechtse draairichting, of vanaf

zijde B voor linkse draairichting. Wanneer deze schakelaar in de neutrale stand staat, kan de trekschakelaar niet

worden ingedrukt.

Veranderen van het toerental (Fig. 6)

Om het toerental te veranderen, schakelt u eerst het

gereedschap uit en dan schuift u de toerentalschakelaar

naar de “II” zijde voor hoog toerental, of naar de “I” zijde

voor laag toerental. Zorg ervoor dat de toerentalschakelaar in de juiste stand staat alvorens met het werk te

beginnen. Gebruik het toerental dat geschikt is voor uw

werk.

LET OP:

• Schuif de toerentalschakelaar altijd volledig naar de

juiste positie. Als u het gereedschap gebruikt met de

toerentalschakelaar halverwege tussen de “I” en “II”

posities, kan het gereedschap beschadigd raken.

• Verschuif de toerentalschakelaar niet terwijl het

gereedschap draait. Hierdoor kan het gereedschap

beschadigd raken.

Instellen van het draaimoment (Fig. 7)

Het draaimoment kan worden ingesteld in 17 stappen

door de stelring zodanig te draaien dat zijn schaalverdelingen overeenkomen met de wijzer op het huis van het

gereedschap. Het draaimoment is minimaal wanneer het

cijfer 1 met de wijzer overeenkomt, en is maximaal wanneer de A markering met de wijzer overeenkomt.

Wanneer de stelring op een cijfer van 1 tot 16 is ingesteld, zal de koppeling bij verschillende draaimomentniveaus slippen. De koppeling is ontworpen om niet te

slippen bij de A markering. Alvorens met het eigenlijke

werk te beginnen, moet u het geschikte draaimoment

bepalen door een proefschroef in uw werkstuk of in een

ander stuk van hetzelfde materiaal te schroeven.

23

Page 11

OPMERKING:

Gebruik het gereedschap niet met de stelring ingesteld

tussen het cijfer 16 en de A markering. Hierdoor kan het

gereedschap beschadigd raken.

Indraaien van schroeven (Fig. 8)

Plaats de punt van de schroefbit in de schroefkop en

oefen druk op het gereedschap uit. Begin met lage snelheid en voer dan de snelheid geleidelijk op. Laat de trekschakelaar los zodra de koppeling ingrijpt.

OPMERKING:

• Zorg ervoor dat u de schroefbit recht op de schroefkop

plaatst, aangezien anders de schroef en/of de schroefbit beschadigd kan worden.

• Wanneer u houtschroeven indraait, maak dan voorboorgaten in het hout. Dit vergemakkelijkt het inschroeven en voorkomt dat het hout splijt. Zie de

onderstaande tabel.

Nominale diameter van

houtschroef (mm)

3,1 2,0 – 2,2

3,5 2,2 – 2,5

3,8 2,5 – 2,8

4,5 2,9 – 3,2

4,8 3,1–3,4

5,1 3,3–3,6

5,5 3,6–3,9

5,8 4,0–4,2

6,1 4,2–4,4

• Indien het gereedschap ononderbroken wordt gebruikt

totdat de accu is ontladen, dient u het gereedschap

15 minuten te laten rusten alvorens met een nieuwe

accu verder te werken.

Aanbevolen diameter

van voorboorgat (mm)

Boren

Draai eerst de stelring zodat de wijzer op het gereedschap naar de A markering wijst. Ga dan als volgt te

werk.

• Boren in hout

Voor boren in hout krijgt u de beste resultaten met

houtboren die voorzien zijn van een geleideschroef.

Het boren gaat dan gemakkelijker aangezien de geleideschroef de boor in het hout trekt.

• Boren in metaal

Om te voorkomen dat de boor slipt wanneer u begint te

boren, moet u van te voren met een drevel een deukje

in het metaal slaan op de plaats waar u wilt boren.

Plaats vervolgens de boorpunt in het deukje en start

het boren. Gebruik altijd boorolie wanneer u in metaal

boort. De enige uitzonderingen zijn ijzer en koper die

droog geboord dienen te worden.

LET OP:

• Door overmatige druk op het gereedschap uit te oefenen verloopt het boren niet sneller. Integendeel, teveel

druk op het gereedschap zal alleen maar de boorpunt

beschadigen, de prestatie van het gereedschap verminderen en de gebruiksduur verkorten.

• Wanneer de boor uit het gaatje tevoorschijn komt,

wordt een enorme kracht uitgeoefend op het gereedschap en op de boor. Houd daarom het gereedschap

stevig vast en wees op uw hoede wanneer de boor

door het werkstuk begint te dringen.

• Wanneer de boor klemraakt, keert u met de omkeerschakelaar de draairichting om, om de boor uit het

gaatje te krijgen. Het gereedschap kan echter plotseling terugspringen indien u het niet stevig vasthoudt.

• Kleine werkstukken dient u altijd eerst vast te zetten in

een klemschroef of iets dergelijks.

• Indien het gereedschap ononderbroken wordt gebruikt

totdat de accu is ontladen, dient u het gereedschap

15 minuten te laten rusten alvorens met een nieuwe

accu verder te werken.

ONDERHOUD

LET OP:

Controleer altijd of het gereedschap is uitgeschakeld en

de accu is losgekoppeld vooraleer onderhoud uit te voeren aan het gereedschap.

Vervangen van koolborstels (Fig. 9 en 10)

Vervang de borstels wanneer ze tot aan de aangegeven

limiet zijn afgesleten. Beide koolborstels dienen tegelijkertijd te worden vervangen.

Opdat het gereedschap veilig en betrouwbaar blijft, dienen alle reparaties, onderhoud of afstellingen te worden

uitgevoerd bij een erkend Makita service centrum.

ACCESSOIRES

LET OP:

• Deze accessoires of hulpstukken worden aanbevolen

voor gebruik met het Makita gereedschap dat in deze

gebruiksaanwijzing is beschreven. Bij gebruik van

andere accessoires of hulpstukken bestaat er gevaar

voor persoonlijke verwonding. Gebruik de accessoires

of hulpstukken uitsluitend voor hun bestemde doel.

Raadpleeg het dichtstbijzijnde Makita Servicecentrum

voor verder advies of bijzonderheden omtrent deze

accessoires.

•Schroefbits

• Rubber steunschijf set

• Schuimrubber polijstkussen 125

• Wollen poetsschijf 100

• Diverse types originele Makita accu’s en acculaders

• Plastic draagkoffer

24

Page 12

ENGLISH

EC-DECLARATION OF CONFORMITY

The undersigned, Yasuhiko Kanzaki, authorized by

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan declares that this product

manufactured by Makita Corporation in Japan is in compliance with the following standards or standardized documents,

in accordance with Council Directives, 89/336/EEC and

98/37/EC.

(Serial No. : series production)

EN50260, EN55014

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Je soussigné, Yasuhiko Kanzaki, mandaté par Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi 446-8502

Japan, déclare que ce produit

fabriqué par Makita Corporation au Japon, est conformes

conformément aux Directives du Conseil, 89/336/CEE et

98/37/EG.

(No. de série: production en série)

aux normes ou aux documents normalisés suivants,

EN50260, EN55014

DEUTSCH

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki,

Bevollmächtigter von Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi 446-8502 Japan, daß dieses

von der Firma Makita Corporation in Japan hergestellte

Produkt

gemäß den Ratsdirektiven 89/336/EWG und 98/37/EG

mit den folgenden Normen bzw. Normendokumenten

übereinstimmen:

CE-KONFORMITÄTSERKLÄRUNG

(Serien-Nr.: Serienproduktion)

EN50260, EN55014.

ITALIANO

DICHIARAZIONE DI CONFORMITÀ

CON LE NORME DELLA COMUNITÀ EUROPEA

Il sottoscritto Yasuhiko Kanzaki, con l’autorizzazione

della Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan, dichiara che questo prodotto

(Numero di serie: Produzione in serie)

fabbricato dalla Makita Corporation in Giappone è conformi alle direttive europee riportate di seguito:

secondo le direttive del Consiglio 89/336/CEE e 98/37/CE.

EN50260, EN55014

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

De ondergetekende, Yasuhiko Kanzaki, gevolmachtigd

door Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo,

Aichi 446-8502 Japan verklaart dat dit produkt

vervaardigd door Makita Corporation in Japan voldoet

aan de volgende normen of genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad 89/

336/EEC en 98/37/EC.

(Serienr. : serieproduktie)

EN50260, EN55014

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

El abajo firmante, Yasuhiko Kanzaki, autorizado por

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, declara que este producto

(Número de serie: producción en serie)

fabricado por Makita Corporation en Japón cumple las

siguientes normas o documentos normalizados,

de acuerdo con las directivas comunitarias, 89/336/EEC

y 98/37/CE.

EN50260, EN55014

54

Yasuhiko Kanzaki

Director Amministratore

Directeur Directeur

Direktor Director

CE 98

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

Page 13

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

O abaixo assinado, Yasuhiko Kanzaki, autorizado pela

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, declara que este produto

(N. de série: produção em série)

fabricado pela Makita Corporation no Japão obedece às

seguintes normas ou documentos normalizados,

EN50260, EN55014

de acordo com as directivas 89/336/CEE e 98/37/CE do

Conselho.

DANSK

EU-DEKLARATION OM KONFORMITET

Undertegnede, Yasuhiko Kanzaki, med fuldmagt fra

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan, erklærer hermed, at dette produkt

fremstillet af Makita Corporation i Japan, er i overens-

(Løbenummer: serieproduktion)

stemmelse med de følgende standarder eller normsæt-

tende dokumenter,

EN50260, EN55014

i overensstemmelse med Rådets Direktiver, 89/336/EEC

og 98/37/EC.

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Undertecknad, Yasuhiko Kanzaki, auktoriserad av Makita

Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi 446-8502

Japan deklarerar att denna produkt

tillverkad av Makita Corporation i Japan, uppfyller kraven

i följande standard eller standardiserade dokument,

i enlighet med EG-direktiven 89/336/EEC och 98/37/EC.

(serienummer: serieproduktion)

EN50260, EN55014

NORSK

Undertegnede, Yasuhiko Kanzaki, med fullmakt fra

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan bekrefter herved at dette produktet

fabrikert av Makita Corporation, Japan, er i overensstemmelse med følgende standarder eller standardiserte

dokumenter:

i samsvar med Råds-direktivene, 89/336/EEC og 98/37/EC.

EUs SAMSVARS-ERKLÆRING

(Serienr. : serieproduksjon)

EN50260, EN55014,

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Makita Corporation, 3-11-8 Sumiyoshi-Cho, Anjo, Aichi

446-8502 Japan valtuuttamana allekirjoittanut, Yasuhiko

Kanzaki, vakuuttaa että tämä tämä tuote

valmistanut Makita Corporation Japanissa vastaa seu-

(Sarja nro : sarjan tuotantoa)

raavia standardeja tai stardardoituja asiakirjoja

neuvoston direktiivien 89/336/EEC ja 98/37/EC mukaisesti.

EN50260, EN55014

ΕΛΛΗΝΙΚΑ

Ο υπογράφων, Yasuhiko Kanzaki, εξουσιοδοτηµένος

απ την εταιρεία Makita Corporation, 3-11-8

Sumiyoshi-Cho, Anjo, Aichi 446-8502 Japan, δηλώνει

τι αυτ το προϊν

κατασκευασµένο απ την Εταιρεία Makita στην

Ιαπωνία, βρίσκεται σε συµφωνία µε τα ακλουθα

πρτυπα ή τυποποιηµένα έγγραφα,

σύµφωνα µε τις Οδηγίες του Συµβουλίου, 89/336/

EEC και 98/37/ΚE.

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

(Αύξων Αρ.: παραγωγή σειράς)

EN50260, EN55014

Yasuhiko Kanzaki

CE 98

Director Direktor

DirektørJohtaja

Direktör ∆ιευθυντής

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

55

Page 14

ENGLISH

EC-DECLARATION OF CONFORMITY

The undersigned, Yasuhiko Kanzaki, authorized by Kao

Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan declares that this battery charger

manufactured by Kao Lung Tamura Electronics Co., Ltd.

in Taiwan is in compliance with the following standards or

standardized documents,

in accordance with Council Directives, 73/23/EEC and

89/336/EEC.

(Serial No. : series production)

EN60335, EN55014, EN61000

FRANÇAISE

DÉCLARATION DE CONFORMITÉ CE

Je soussigné, Yasuhiko Kanzaki, mandaté par Kao Lung

Tamura Electronics Co., Ltd. No. 4 Industry 1st Street,

Ping Tung industry District Chiao Nan Li, Ping Tung City,

Taiwa n, d éclare que ce chargeur de batterie

fabriqué par Kao Lung Tamura Electronics Co., Ltd. au

Taiwan, est conformes aux normes ou aux documents

normalisés suivants,

conformément aux Directives du Conseil, 73/23/CEE et

89/336/CEE.

(No. de série: production en série)

EN60335, EN55014, EN61000

ITALIANO

DICHIARAZIONE DI CONFORMITÀ CON

LE NORME DELLA COMUNITÀ EUROPEA

Il sottoscritto Yasuhiko Kanzaki, con l’autorizzazione della

Kao Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan, dichiara che questo caricabatteria

(Numero di serie: Produzione in serie)

fabbricato dalla Kao Lung Tamura Electronics Co., Ltd. in

Ta iw a n è conformi alle direttive europee riportate di

seguito:

secondo le direttive del Consiglio 73/23/CEE e

89/336/CEE.

EN60335, EN55014, EN61000

NEDERLANDS

EG-VERKLARING VAN CONFORMITEIT

De ondergetekende, Yasuhiko Kanzaki, gevolmachtigd

door Kao Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st Street, Ping Tung Industry District Chiao Nan Li,

Ping Tung City, Taiwan verklaart dat dit accu-oplader

vervaardigd door Kao Lung Tamura Electronics Co., Ltd.

in Taiwan voldoet aan de volgende normen of genormaliseerde documenten,

in overeenstemming met de richtlijnen van de Raad

73/23/EEC en 89/336/EEC.

(Serienr. : serieproduktie)

EN60335, EN55014, EN61000

DEUTSCH

Hiermit erklärt der Unterzeichnete, Yasuhiko Kanzaki,

Bevollmächtigter von Kao Lung Tamura Electronics Co.,

Ltd. No. 4 Industry 1st Street, Ping Tung Industry District

Chiao Nan Li, Ping Tung City, Taiwan, daß dieses von der

Firma Kao Lung Tamura Electronics Co., Ltd. in Taiwan

hergestellte ladegerät

gemäß den Ratsdirektiven 73/23/EWG und 89/336/EWG

mit den folgenden Normen bzw. Normendokumenten

übereinstimmen:

CE-KONFORMITÄTSERKLÄRUNG

(Serien-Nr.: Serienproduktion)

EN60335, EN55014, EN61000.

Yasuhiko Kanzaki

Director Amministratore

Directeur Directeur

Direktor Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

56

ESPAÑOL

DECLARACIÓN DE CONFORMIDAD DE LA CE

El abajo firmante, Yasuhiko Kanzaki, autorizado por Kao

Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan, declara que este cargador de baterías

(Número de serie: producción en serie)

fabricado por Kao Lung Tamura Electronics Co., Ltd. en

Taiwan cumple las siguientes normas o documentos normalizados,

de acuerdo con las directivas comunitarias, 73/23/EEC y

89/336/EEC.

EN60335, EN55014, EN61000

CE 94

Page 15

PORTUGUÊS

DECLARAÇÃO DE CONFORMIDADE DA CE

O abaixo assinado, Yasuhiko Kanzaki, autorizado pela

Kao Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan, declara que este carregador de bateria

fabricado pela Kao Lung Tamura Electronics Co., Ltd. no

Taiwan obedece às seguintes normas ou documentos

normalizados,

de acordo com as directivas 73/23/CEE e 89/336/CEE

do Conselho.

(N. de série: produção em série)

EN60335, EN55014, EN61000

DANSK

EU-DEKLARATION OM KONFORMITET

Undertegnede, Yasuhiko Kanzaki, med fuldmagt fra Kao

Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan, erklærer hermed, at dette batteriopladeren

fremstillet af Kao Lung Tamura Electronics Co., Ltd. i

Taiwan, er i overensstemmelse med de følgende standarder eller normsættende dokumenter,

i overensstemmelse med Rådets Direktiver 73/23/EEC

og 89/336/EEC.

(Løbenummer: serieproduktion)

EN60335, EN55014, EN61000

SVENSKA

EG-DEKLARATION OM ÖVERENSSTÄMMELSE

Undertecknad, Yasuhiko Kanzaki, auktoriserad av Kao

Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan deklarerar att denna batteriladdaren

tillverkad av Kao Lung Tamura Electronics Co., Ltd. i

Taiwan, uppfyller kraven i följande standard eller standardiserade dokument,

i enlighet med EG-direktiven 73/23/EEC och 89/336/EEC.

(serienummer: serieproduktion)

EN60335, EN55014, EN61000

NORSK

Undertegnede, Yasuhiko Kanzaki, med fullmakt fra Kao

Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan bekrefter herved at dette batterilader

fabrikert av Kao Lung Tamura Electronics Co., Ltd., Taiwan, er i overensstemmelse med følgende standarder

eller standardiserte dokumenter:

i samsvar med Råds-direktivene, 73/23/EEC og

89/336/EEC.

EUs SAMSVARS-ERKLÆRING

(Serienr. : serieproduksjon)

EN60335, EN55014, EN61000,

SUOMI

VAKUUTUS EC-VASTAAVUUDESTA

Kao Lung Tamura Electronics Co., Ltd. No. 4 Industry 1st

Street, Ping Tung Industry District Chiao Nan Li, Ping

Tung City, Taiwan valtuuttamana allekirjoittanut, Yasuhiko

Kanzaki, vakuuttaa että tämä akkulaturi

valmistanut Kao Lung Tamura Electronics Co., Ltd. in

Taiwan vastaa seuraavia standardeja tai stardardoituja

asiakirjoja

neuvoston direktiivien 73/23/EEC ja 89/336/EEC mukaisesti.

(Sarja nro : sarjan tuotantoa)

EN60335, EN55014, EN61000

ΕΛΛΗΝΙΚΑ

Ο υπογράφων, Yasuhiko Kanzaki, εξουσιοδοτηµένος

απ την εταιρεία Kao Lung Tamura Electronics Co.,

Ltd. No. 4 Industry 1st Street, Ping Tung Industry

District Chiao Nan Li, Ping Tung City, Taiwan,

δηλώνει τι αυτ το φορτιστής µπαταρίας

κατασκευασµένο απ την Εταιρεία Kao Lung Tamura

Electronics Co., Ltd. στην Taiwan, βρίσκεται σε

συµφωνία µε τα ακλουθα πρτυπα ή τυποποιηµένα

έγγραφα,

σύµφωνα µε τις Οδηγίες του Συµβουλίου, 73/23/EEC

και 89/336/EEC.

∆ΗΛΩΣΗ ΣΥΜΜΟΡΦΩΣΗΣ ΕΚ

(Αύξων Αρ.: παραγωγή σειράς)

EN60335, EN55014, EN61000

Yasuhiko Kanzaki

Director Direktor

DirektørJohtaja

Direktör ∆ιευθυντής

CE 94

MAKITA INTERNATIONAL EUROPE LTD.

Bucks MK15 8JD, ENGLAND

Michigan Drive, Tongwell, Milton Keynes,

57

Page 16

ENGLISH

The typical A-weighted sound pressure level is not more than

70 dB (A).

The noise level under working may exceed 85dB (A).

The typical weighted root mean square acceleration value is

not more than 2.5 m/s

Noise and Vibration

– Wear ear protection. –

2

.

FRANÇAISE

Le niveau de pression sonore pondéré A type ne dépasse

pas 70 dB (A).

Le niveau de bruit en fonctionnement peut dépasser 85 dB (A).

L’accélération pondérée ne dépasse pas 2,5 m/s

Bruit et vibrations

– Porter des protecteurs anti-bruit. –

2

.

DEUTSCH

Geräusch- und Vibrationsentwicklung

Der typische A-bewertete Schalldruckpegel beträgt nicht

mehr als 70 dB (A).

Der Lärmpegel kann während des Betriebs 85 dB (A) überschreiten.

Der gewichtete Effektivwert der Beschleunigung beträgt nicht

mehr als 2,5 m/s

– Gehörschutz tragen. –

2

.

ITALIANO

Il livello di pressione sonora pesata secondo la curva A non

supera i 70 dB (A).

Il livello di rumore durante il lavoro potrebbe superare gli

85 dB (A).

Il valore quadratico medio di accellerazione non supera i

2

2,5 m/s

Rumore e vibrazione

– Indossare i paraorecchi. –

.

NEDERLANDS

Het typische A-gewogen geluidsdrukniveau is niet meer dan

70 dB (A).

Tijdens het werken kan het geluidsniveau 85 dB (A) overschrijden.

De typische gewogen effectieve versnellingswaarde is niet

meer dan 2,5 m/s

Geluidsniveau en trilling

– Draag oorbeschermers. –

2

.

ESPAÑOL

El nivel de presión sonora ponderada A no sobrepasa los

70 dB (A).

El nivel de ruido en condiciones de trabajo puede que sobrepase los 85 dB (A).

El valor ponderado de la aceleración no sobrepasa los 2,5 m/s2.

Ruido y vibración

– Póngase protectores en los oídos. –

PORTUGUÊS

O nível normal de pressão sonora A é inferior a 70 dB (A).

O nível de ruído durante o trabalho pode exceder 85 dB (A).

O valor médio da aceleração é inferior a 2,5 m/s

Ruído e vibração

– Utilize protectores para os ouvidos –

2

.

DANSK

Det typiske A-vægtede lydtryksniveau overstiger ikke 70 dB (A).

Støjniveauet under arbejde kan overstige 85dB (A).

Den vægtede effektive accelerationsværdi overstiger ikke

2

.

2,5 m/s

Lyd og vibration

– Bær høreværn. –

SVENSKA

Den typiska-A-vägda ljudtrycksnivån överstiger inte 70 dB (A).

Bullernivån under pågående arbete kan överstiga 85 dB (A).

Det typiskt vägda effektivvärdet för acceleration överstiger

inte 2,5 m/s

Buller och vibration

– Använd hörselskydd –

2

.

NORSK

Det vanlige A-belastede lydtrykksnivå overskrider ikke 70dB (A).

Under bruk kan støynivået overskride 85 dB (A).

Den vanlig belastede effektiv-verdi for akselerasjon overskrider ikke 2,5 m/s

Støy og vibrasjon

– Benytt hørselvern. –

2

.

SUOMI

Tyypillinen A-painotettu äänenpainetaso ei ylitä 70 dB (A).

Melutaso työpaikalla saattaa ylittää 85 dB (A).

Tyypillinen kiihtyvyyden painotettu tehollisarvo ei ylitä 2,5 m/s

Melutaso ja tärinä

– Käytä kuulosuojaimia. –

ΕΛΛΗΝΙΚΑ

Η τυπική Α-µετρούµενη ηχητική πίεση δεν ξεπερνά τα

70 dB (A).

Η ένταση ήχου υπο συνθήκες εργασίας µπορεί να

µπερβεί τα 85 dB (A).

Η τυπική αξία της µετρούµενης ρίζας του µέσου

τετραγώνου της επιτάχυνσης δεν ξεπερνά τα 2,5 m/s

Θ9ρυβος και κραδασµ9ς

– Φοράτε ωτοασπίδες. –

2

.

2

.

58

Page 17

59

Page 18

Makita Corporation

884179D990

Loading...

Loading...