Makita 4334 User Manual

INSTRUCTION MANUAL

MANUEL D'INSTRUCTION

MANUAL DE INSTRUCCIONES

Cordless Jig Saw

Scie sauteuse sans fil

Sierra caladora inalámbrica

4334D

002701

WARNING:

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

AVERTISSEMENT:

Pour votre propre sécurité, prière de lire attentivement avant l’utilisation.

GARDER CES INSTRUCTIONS POUR RÉFÉRENCE ULTÉRIEURE.

ADVERTENCIA:

Para su seguridad personal, LEA DETENIDAMENTE este manual antes de usar la herramienta.

GUARDE ESTAS INSTRUCCIONES PARA FUTURA REFERENCIA.

ENGLISH

SPECIFICATIONS

Model 4334D

Length of stroke 26 mm (1”)

Wood 135 mm (5-5/16”)

Max. cutting capacities

Strokes per minute 500 - 2,800/min

Overall length 281 mm (11”)

Net weight 3.4 kg (7.5 lbs)

Rated voltage D.C. 18V

Standard battery cartridge 1822, 1833, 1834, 1835

• Due to our continuing programme of research and development, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Mild steel 10 mm (3/8”)

Aluminum 20 mm (13/16”)

GENERAL SAFETY RULES

USA003-2

(FOR ALL BATTERY OPERATED TOOLS)

WARNING:

Read and understand all instructions.

Failure to follow all instructions listed below,

may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

1. Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

2. Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

4. A battery operated tool with integral batteries or

a separate battery pack must be recharged only

with the specified charger for the battery. A

charger that may be suitable for one type of battery

may create a risk of fire when used with another battery.

5. Use battery operated tool only with specifically

designated battery pack. Use of any other batter-

ies may create a risk of fire.

Personal Safety

6. Stay alert, watch what you are doing, and use

common sense when operating a power tool. Do

not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inat-

tention while operating power tools may result in

serious personal injury.

7. Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving parts.

8. Avoid accidental starting. Be sure switch is in

the locked or off position before inserting battery pack. Carrying tools with your finger on the

switch or inserting the battery pack into a tool with

the switch on invites accidents.

9. Remove adjusting keys or wrenches before turning the tool on. A wrench or a key that is left

attached to a rotating part of the tool may result in

personal injury.

10. Do not overreach. Keep proper footing and balance at all times. Proper footing and balance

enable better control of the tool in unexpected situations.

11. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

2

Tool Use and Care

12. Use clamps or other practical way to secure and

support the workpiece to a stable platform. Hold-

ing the work by hand or against your body is unstable and may lead to loss of control.

13. Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

14. Do not use tool if switch does not turn it on or

off. A tool that cannot be controlled with the switch is

dangerous and must be repaired.

15. Disconnect battery pack from tool or place the

switch in the locked or off position before making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

16. Store idle tools out of reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

17. When battery pack is not in use, keep it away

from other metal objects like: paper clips, coins,

keys, nails, screws, or other small metal objects

that can make a connection from one terminal to

another. Shorting the battery terminals together

may cause sparks, burns, or a fire.

18. Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools with

sharp cutting edge are less likely to bind and are

easier to control.

19. Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

20. Use only accessories that are recommended by

the manufacturer for your model. Accessories

that may be suitable for one tool may create a risk of

injury when used on another tool.

SERVICE

21. Tool service must be performed only by qualified

repair personnel. Service or maintenance per-

formed by unqualified personnel may result in a risk

of injury.

22. When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unau-

thorized parts or failure to follow Maintenance

instructions may create a risk of shock or injury.

ADDITIONAL SAFETY RULES

USB030-2

DO NOT let comfort or familiarity with

product (gained from repeated use)

replace strict adherence to cordless jig

saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer

serious personal injury.

1. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will make exposed metal parts of the tool

“live” and shock the operator.

2. Be aware that this tool is always in an operating

condition, because it does not have to be

plugged into an electrical outlet.

3. Always use safety glasses or goggles. Ordinary

eye or sun glasses are NOT safety glasses.

4. Avoid cutting nails. Inspect for and remove all

nails from the workpiece before operation.

5. Do not cut hollow pipe.

6. Do not cut oversize workpiece.

7. Check for the proper clearance beneath the

workpiece before cutting so that the blade will

not strike the floor, workbench, etc.

8. Hold the tool firmly.

9. Check the blade is not contacting the workpiece

before the switch is turned on.

10. Keep hands away from moving parts.

11. Do not leave the tool running. Operate the tool

only when hand-held.

12. Always switch off and wait for the blade to come

to a complete stop before removing the blade

from the workpiece.

13. Do not touch the blade or the workpiece immediately after operation; they may be extremely hot

and could burn your skin.

14. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

SAVE THESE INSTRUCTIONS

WARNING:

MISUSE or failure to follow the safety

rules stated in this instruction manual

may cause serious personal injury.

3

SYMBOLS

The followings show the symbols used for tool.

V............................volts

.......................direct current

.......................no load speed

.../min....................revolutions or reciprocation per

minute

USD301-1

IMPORTANT SAFETY

INSTRUCTIONS FOR BATTERY

CARTRIDGE

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Always cover the battery terminals with the battery cover when the battery cartridge is not

used.

6. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as nails,

coins, etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

7. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

8. Do not incinerate the battery cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

9. Be careful not to drop or strike battery.

ENC004-1

SAVE THESE INSTRUCTIONS

Tips for maintaining maximum battery

life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C - 40°C (50°F - 104°F). Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when you do not use it for more than six

months.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

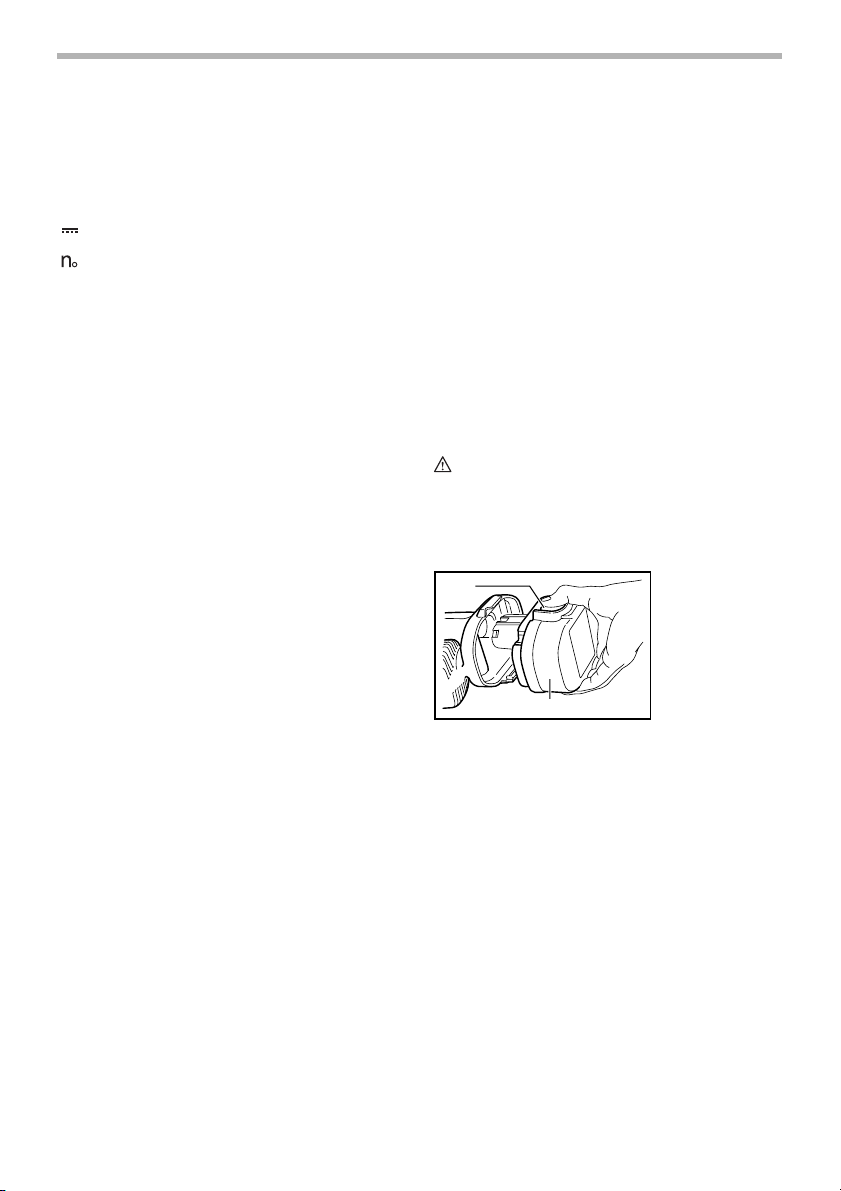

Installing or removing battery cartridge

1

2

• Always switch off the tool before insertion or

removal of the battery cartridge.

• To remove the battery cartridge, withdraw it from

the tool while pressing the buttons on both sides of

the cartridge.

• To insert the battery cartridge, align the tongue on

the battery cartridge with the groove in the housing

and slip it into place. Always insert it all the way

until it locks in place with a little click. If not, it may

accidentally fall out of the tool, causing injury to you

or someone around you.

• Do not use force when inserting the battery

cartridge. If the cartridge does not slide in easily, it

is not being inserted correctly.

002703

1. Button

2. Battery cartridge

4

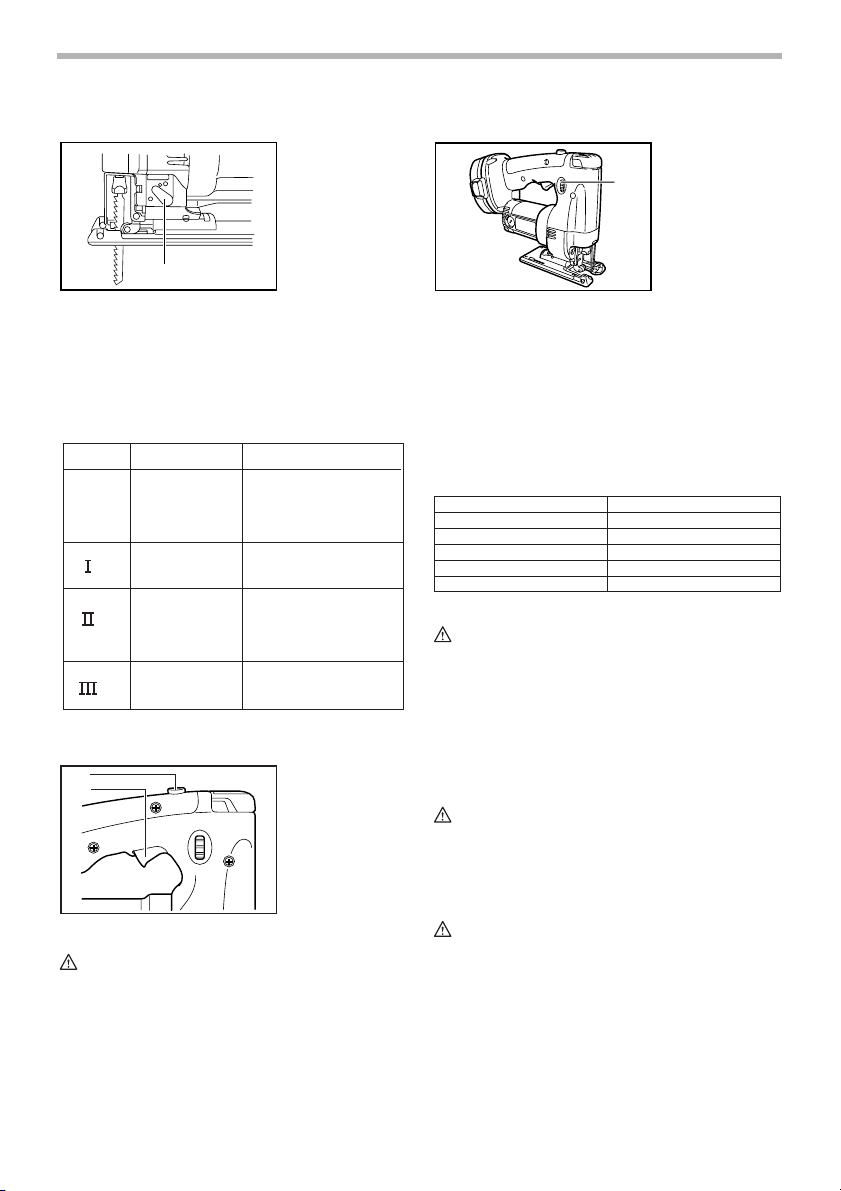

Selecting the cutting action

002706

1

1. Cutting action

changing lever

Speed adjusting dial

002712

1

1. Speed adjusting dial

This tool can be operated with an orbital or a straight line

(up and down) cutting action. The orbital cutting action

thrusts the blade forward on the cutting stroke and

greatly increases cutting speed.

To change the cutting action, just turn the cutting action

changing lever to the desired cutting action position.

Refer to the table to select the appropriate cutting action.

Position Cutting action Applications

For cutting mild steel,

stainless steel and plastics.

For clean cuts in wood

and plywood.

For cutting mild steel,

aluminum and hard wood.

For cutting wood and

plywood.

For fast cutting in

aluminum and mild steel.

For fast cutting in

wood and plywood.

002709

1. Lock-off button

2. Switch trigger

0

Switch action

1

2

Straight line

cutting action

Small orbit

cutting action

Medium orbit

cutting action

Large orbit

cutting action

006376

The tool speed can be infinitely adjusted between 500

and 2,800 strokes per minute by turning the adjusting

dial. Higher speed is obtained when the dial is turned in

the direction of number 5; lower speed is obtained when

it is turned in the direction of number 1.

Refer to the table to select the proper speed for the workpiece to be cut. However, the appropriate speed may differ with the type or thickness of the workpiece. In

general, higher speeds will allow you to cut workpieces

faster but the service life of the blade will be reduced.

Workpiece to be cut Number on adjusting dial

Wood 3 - 5

Mild steel 3 - 5

Stainless steel 3 - 4

Aluminum 2 - 3

Plastics 1 - 4

006378

CAUTION:

• If the tool is operated continuously at low speeds for

a long time, the motor will get overloaded and

heated up.

• The speed adjusting dial can be turned only as far

as 5 and back to 1. Do not force it past 5 or 1, or the

speed adjusting function may no longer work.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out

any work on the tool.

Installing or removing saw blade

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the switch trigger actuates

properly and returns to the “OFF” position when

released.

To prevent the switch trigger from being accidentally

pulled, a lock-off button is provided.

To start the tool, push in the lock-off button and pull the

switch trigger. Release the switch trigger to stop.

CAUTION:

• Always clean out all chips or foreign matter

adhering to the blade and/or blade holder. Failure to

do so may cause insufficient tightening of the blade,

resulting in a serious personal injury.

• Do not touch the blade or the workpiece

immediately after operation; they may be extremely

hot and could burn your skin.

• Always secure the blade firmly. Insufficient

tightening of the blade may cause blade breakage

or serious personal injury.

5

INSTALLATION

1. Push the blade installing lever in the (1) direction to

release it.

(1)

002719

1. Blade installing

lever

1

5. With the blade held against the blade holder, rotate

the blade installing lever in the (5) direction until it

stops.

(5)

1

002722

1. Blade installing

lever

2. Blade

2

2. Pull the blade installing lever in the (2) direction

until it stops with a little click. If you have difficulty

pulling it out, try to do so while moving it back and

forth in the (3) direction.

3. Rotate the blade installing lever in the (4) direction

until the clamp protrudes 5 - 7 mm from the blade

holder.

(3)

(2)

002720

(4)

CAUTION:

• If you rotate the blade installing lever excessively,

the clamp will also rotate and finally come off. In

this case, re-install it properly as lately described in

’’Installing clamp’’.

4. With the blade teeth facing forward, insert the blade

into the blade holder as far as it will go. Make sure

that the back edge of the blade fits properly into the

groove of the roller.

002721

1. Blade holder

1

2

3

2. Clamp

3. Slot

4. Roller

5. Blade

6. With the blade installing lever held in this position,

push it in the (6) direction. Then rotate the blade

installing lever to its original position.

1

(6)

002723

1. Blade installing

lever

Removal

1. Push the blade installing lever in the (1) direction to

release it.

002719

1. Blade installing

(1)

lever

1

2. Pull the blade installing lever in the (2) direction

until it stops with a little click. If you have difficulty

pulling it out, try to do so while moving it back and

forth in the (3) direction.

3. Rotate the blade installing lever in the (4) direction

and remove the blade.

002720

4

5

(3)

(2)

(4)

6

4. Rotate the blade installing lever in the (5) direction

until it stops.

1

(5)

5. With the blade installing lever held in this position,

push it in the (6) direction. Then rotate the blade

installing lever to its original position.

1

(6)

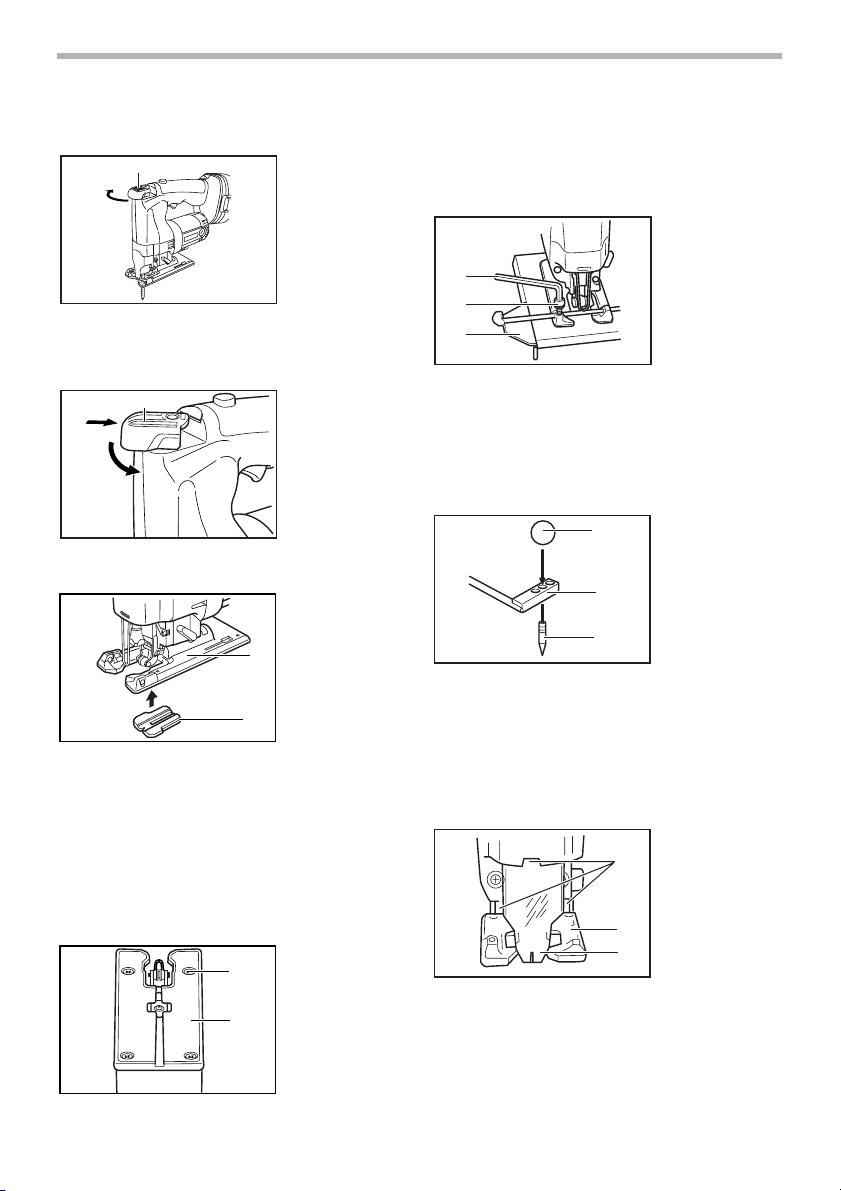

Anti-splintering device

002724

1. Blade installing

lever

002723

1. Blade installing

lever

002734

1. Base

2. Anti-splintering

device

1

Use the plastic base plate when cutting decorative

veneers, plastics, etc. It protects sensitive surfaces from

damage. To replace the base plate, remove the four

screws.

Rip fence (optional accessory)

002738

1. Hex wrench

2. Bolt

1

3. Rip fence

(Guide rule)

2

3

When cutting widths of under 150 mm (5 - 29/32”)

repeatedly, use of the rip fence (guide rule) will assure

fast, clean, straight cuts. To install it, loosen the bolt on

the front of the base. Slip in the rip fence and secure the

bolt.

Circular guide (optional accessory)

002739

1

1. Threaded knob

2. Circular guide

3. Pin

2

3

2

For splinter-free cuts, the anti-splintering device can be

used. To install the anti-splintering device, move the base

all the way forward and fit it into the base from the back of

base.

NOTE:

• The anti-splintering device cannot be used when

making bevel cuts.

Plastic base plate (optional accessory)

002736

1

1. Screw

2. Plastic base

plate

2

Use of the circular guide insures clean, smooth cutting of

circles under 200 mm (7 - 7/8”) in radius. Insert the pin

through the center hole and secure it with the threaded

knob. Move the base of the tool forward fully. Then install

the circular guide on the base in the same manner as the

rip fence (guide rule).

Vacuum head (optional accessory)

002740

1. Notches

2. Base

1

3. Plastic cover

2

3

The vacuum head is recommended to perform clean cutting operations. Install the plastic cover on the tool by fitting it into the notches in the tool.

To attach the vacuum head on the tool, insert the hooks

of the vacuum head into the hole in the base. The vac-

7

uum head can be installed on either left or right side of

the base.

1

002741

1. Vacuum head

2. Base

2

002742

Then connect a Makita vacuum cleaner to the vacuum

head.

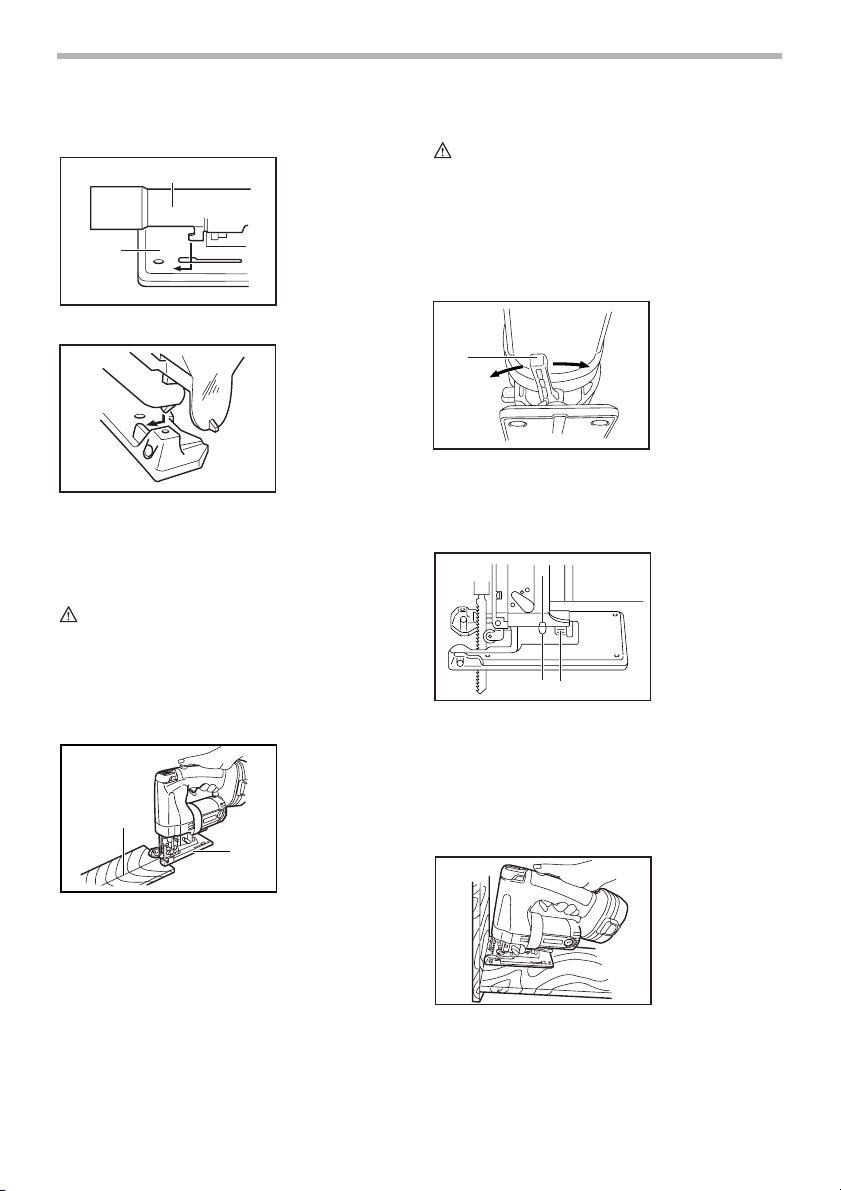

OPERATION

CAUTION:

• Always hold the base flush with the workpiece.

Failure to do so may cause blade breakage,

resulting in a serious injury.

• Advance the tool very slowly when cutting curves or

scrolling. Forcing the tool may cause a slanted

cutting surface and blade breakage.

1

002745

1. Cutting line

2. Base

2

Bevel cutting

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before tilting the base.

With the base tilted, you can make bevel cuts at any

angle between 0° and 45° (left or right).

Loosen the base securing lever and move the base so

that the dent mark in the motor housing is aligned with

the slot in the base.

1

Tilt the base until the desired bevel angle is obtained.

The edge of the motor housing indicates the bevel angle

by graduations. Then tighten the base securing lever to

secure the base.

1

23

NOTE:

• Always remove the plastic cover (chip shield) from

the tool when you make bevel cuts using an

optional rip fence (guide rule) or circular guide.

Front flush cuts

002754

1. Base securing

lever

002755

1. Dent mark

2. Slot

3. Graduation

002759

Turn the tool on without the blade making any contact

and wait until the blade attains full speed. Then rest the

base flat on the workpiece and gently move the tool forward along the previously marked cutting line.

NOTE:

• If the tool is operated continuously until the battery

cartridge has discharged, allow the tool to rest for

15 minutes before proceeding with a fresh battery.

Loosen the base securing lever and slide the base all the

way back. Then tighten the base securing lever to secure

the base.

8

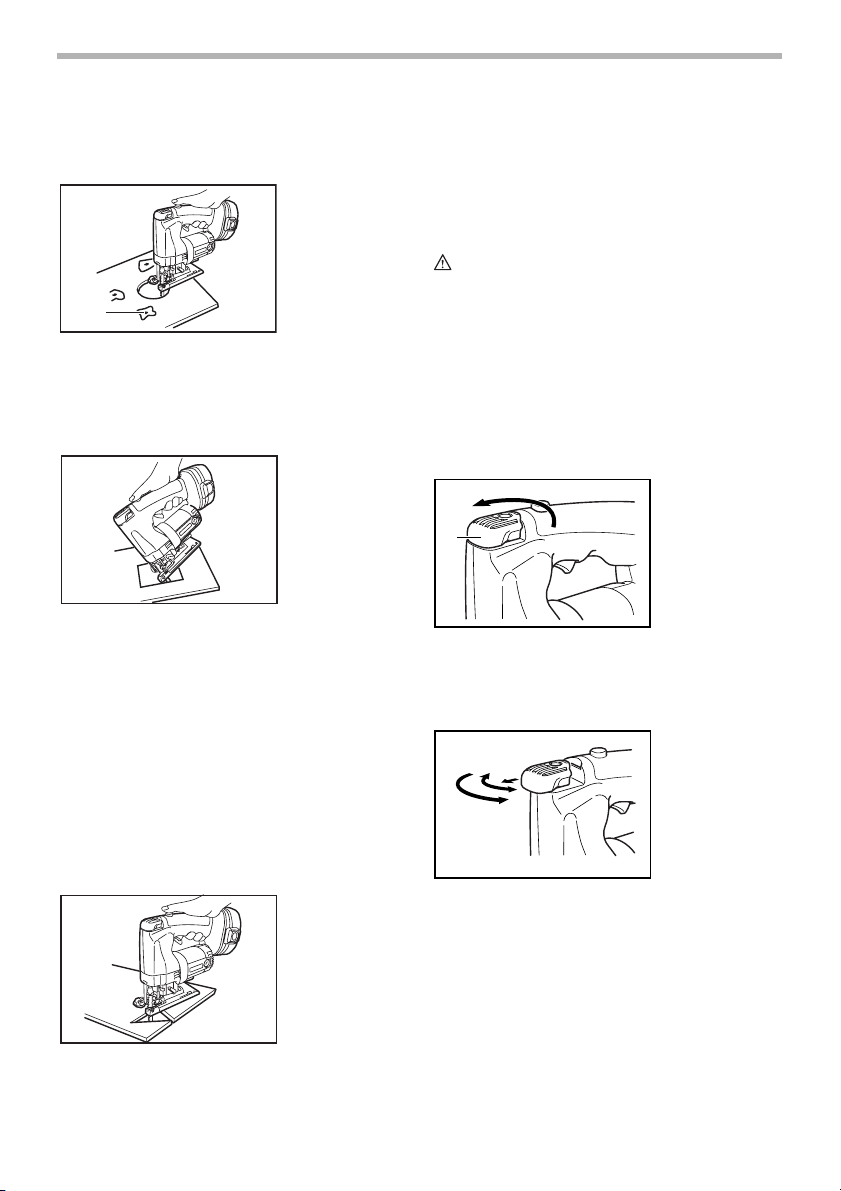

Cutouts

Cutouts can be made with either of two methods A or B.

A) Boring a starting hole:

1

For internal cutouts without a lead-in cut from an

edge, pre-drill a starting hole 12 mm (1/2”) or more

in diameter. Insert the blade into this hole to start

your cut.

B) Plunge cutting:

You need not bore a starting hole or make a lead-in

cut if you carefully do as follows.

(1) Tilt the tool up on the front edge of the base

with the blade point positioned just above the

workpiece surface.

(2) Apply pressure to the tool so that the front

edge of the base will not move when you

switch on the tool and gently lower the back

end of the tool slowly.

(3) As the blade pierces the workpiece, slowly

lower the base of the tool down onto the

workpiece surface.

(4) Complete the cut in the normal manner.

Finishing edges

002765

1. Starting hole

002766

002770

Metal cutting

Always use a suitable coolant (cutting oil) when cutting

metal. Failure to do so will cause significant blade wear.

The underside of the workpiece can be greased instead

of using a coolant.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

Cleaning clamp on blade holder

If chips or foreign matter get into the clamp on the blade

holder, clean out the clamp after removing it from the

blade holder.

Removing clamp

1. Push the blade installing lever in the (1) direction to

release it.

(1)

1

2. Pull the blade installing lever in the (2) direction

until it stops with a little click. If you have difficulty

pulling it out, try to do so while moving it back and

forth in the (3) direction.

(3)

(2)

(4)

002719

1. Blade installing

lever

002720

To trim edges or make dimensional adjustments, run the

blade lightly along the cut edges.

9

3. Rotate the blade installing lever in the (4) direction

until it stops. The clamp will protrude from the blade

holder.

002993

1. Blade holder

1

2. Clamp

2

4. Remove the clamp from the blade holder while

rotating the clamp in the (5) direction.

1

002781

1. Blade holder

2. Clamp

CAUTION:

• Do not rotate the clamp more than one full turn

when inserting in into the blade holder. If you do so,

the blade may not be tightened firmly.

3. Grasp the clamp with your fingers so that it will not

turn, then rotate the blade installing lever in the (7)

direction until it stops. The clamp will go in the

blade holder.

1

(7)

002784

1. Blade installing

lever

2

(5)

Installing clamp

1. Make sure that the blade installing lever has been

rotated in the (4) direction until it stops.

002782

(4)

2. Insert the clamp into the blade holder while rotating

it in the (6) direction one quarter to one full turn so

that its slot will face forward.

1

002783

1. Blade holder

2. Clamp

2

(6)

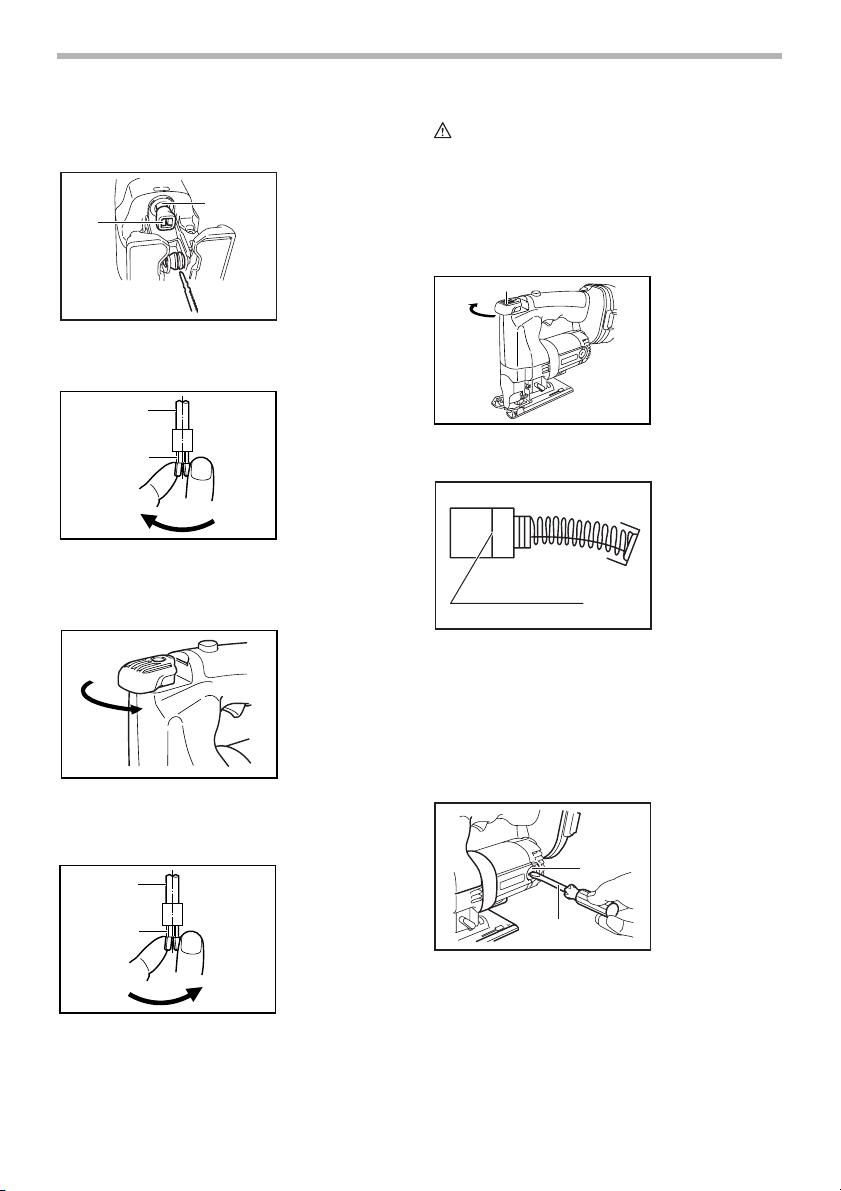

Replacing carbon brushes

001145

1. Limit mark

1

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

002786

1. Brush holder

cap

2. Screwdriver

1

2

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers,

always using Makita replacement parts.

10

EN0001-1

Ni-Cd

Recycling the Battery

The only way to dispose of a Makita battery is to recycle

it. The law prohibits any other method of disposal.

To recycle the battery:

1. Remove the battery from the tool.

2. a) Take the battery to your nearest Makita Fac-

Call your nearest Makita Service Center or Distributor to

determine the location that provides Makita battery recycling. See your local Yellow Pages under “Tools-Electric”.

ACCESSORIES

• These accessories or attachments are

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Jig saw blades

• Hex wrench 3

• Rip fence (guide rule) set

• Circular guide set

• Plastic base plate

• Plastic cover

• Anti-splintering device

• Vacuum head

• Hose (For vacuum cleaner)

• Various type of Makita genuine batteries and

tory Service Center

or

b) Take the battery to your nearest Makita

Authorized Service Center or Distributor that

has been designated as a Makita battery

recycling location.

CAUTION:

recommended for use with your Makita tool

specified in this manual. The use of any other

accessories or attachments might present a risk of

injury to persons. Only use accessory or

attachment for its stated purpose.

chargers

MAKITA LIMITED ONE YEAR WARRANTY

EN0006-1

Warranty Policy

Every Makita tool is thoroughly inspected and tested

before leaving the factory. It is warranted to be free of

defects from workmanship and materials for the period of

ONE YEAR from the date of original purchase. Should

any trouble develop during this one year period, return

the COMPLETE tool, freight prepaid, to one of Makita’s

Factory or Authorized Service Centers. If inspection

shows the trouble is caused by defective workmanship or

material, Makita will repair (or at our option, replace)

without charge.

This Warranty does not apply where:

• repairs have been made or attempted by others:

• repairs are required because of normal wear and

tear:

• the tool has been abused, misused or improperly

maintained:

• alterations have been made to the tool.

IN NO EVENT SHALL MAKITA BE LIABLE FOR ANY

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES FROM THE SALE OR USE OF THE PRODUCT.

THIS DISCLAIMER APPLIES BOTH DURING AND

AFTER THE TERM OF THIS WARRANTY.

MAKITA DISCLAIMS LIABILITY FOR ANY IMPLIED

WARRANTIES, INCLUDING IMPLIED WARRANTIES

OF “MERCHANTABILITY” AND “FITNESS FOR A SPECIFIC PURPOSE,” AFTER THE ONE YEAR TERM OF

THIS WARRANTY.

This Warranty gives you specific legal rights, and you

may also have other rights which vary from state to state.

Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. Some states do

not allow limitation on how long an implied warranty lasts,

so the above limitation may not apply to you.

11

Loading...

Loading...