Page 1

4326

4327

4328

4329

Jig Saw

Instruction Manual

Stichsäge

Betriebsanleitung

Piła włośnica

Instrukcja obsługi

Лобзик

Инструкция по эксплуатации

Page 2

2

1

3

12

4

5

6

7

34

10

6

7

8

9

56

8

9

11

7

6

12

13

78

2

Page 3

14

12

910

7

6

12

11 12

7

6

12

13 14

15

16

17

15 16

3

Page 4

19

13

18

17 18

21

20

19 20

21

6

23

7

20

20

19

7

22

6

20

19

24

22

20

25

21 22

21

24

23

25

20

23 24

4

19

20

Page 5

21

20

25 26

26

27

29

28

26

27 28

28

5

Page 6

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werde n für die Masch ine verwendet. Mache n Sie sich vor der Benutzung unbe dingt mit ihrer

Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Bedienungsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ Only for EU countries

Do not dispose of electric equipment together with household waste material!

In observance of European Di rective 2002/96/EC on waste elec trical an d electron ic equipment and

its implementation in accorda nce with national law, electric eq uipmen t that have reache d the end of

their life must be collected separately and returned to an environmentally compatible recycling facility.

❏ Nur für EU-Länder

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäß Europäischer Richtlinie 2002/96/EG über Elektro- und Elektronik-Altgeräte und Umsetzung in

nationales Recht mü ssen verbrau c ht e E le ktrowe r kzeuge g etr en nt ge sam mel t u nd ei n er um wel tge rechten Wiederverwertung zugeführt werden.

❏ Dotyczy tylko państw UE

Nie wyrzucaj urządzeń elektrycznych wraz z odpadami z gospodarstwa domowego!

Zgodnie z Europejską Dyrektywą 2002/96/WE w sprawie zużytego sprzętu elektrotechnicznego i

elektronicznego oraz dostosowaniem jej do prawa krajowego, zużyte urządzenia elektryczne należy

posegregować i zutylizować w sposób przyjazny dla środowiska.

❏ Только для стран ЕС

Не выкидывайте электрическое оборудование вместе с бытовым мусором!

В соответствии с европейской директивой 2002/96/EC об утилизацияи старого

электрического и электронного оборудования и её применения в соответствии с местными

законами электрическое оборудование, бывшее в эксплуатации, должно утилизовываться

отдельно безопасным для окружающей среды способом.

6

Page 7

ENGLISH

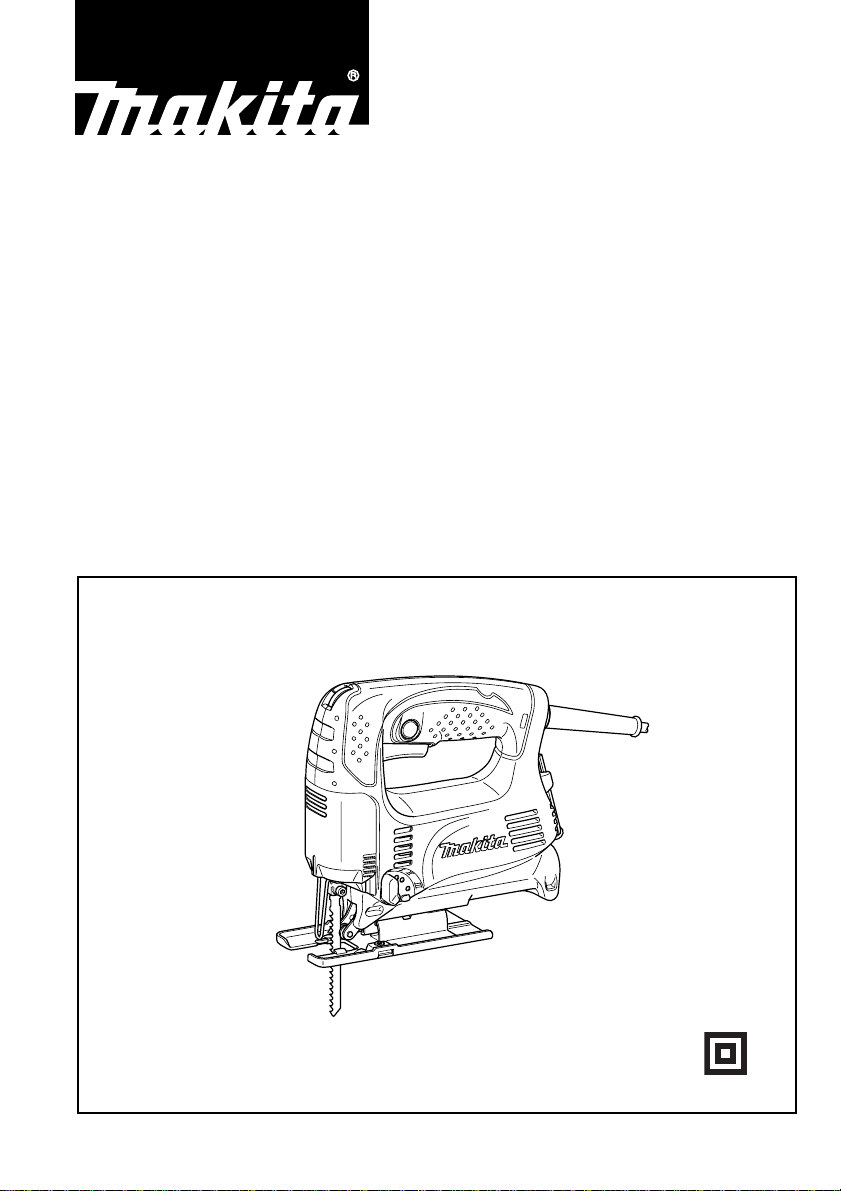

Explanation of general view

1 Cutting action changing lever

2 Switch trigger

3 Lock button

4 Speed adjusting dial

5 Blade holder

6Bolt

7Hex wrench

8Blade

9 Roller

10 Hook

SPECIFICATION

Model 4326 4327 4328 4329

Length of stroke 18 mm 18 mm 18 mm 18 mm

Blade type B type

Max. cutting

capacities

Strokes per minute (min

Overall length

Net weig ht

Safety class /II

• Due to our continuing programme of research and

development, the specifications herein are subject to

change without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intende d for the sawing of wood, pla stic and

metal materials. As a result of the extensive accessor y

and saw blade program, the tool can be used for many

purposes and is very well suite d for curved or circular

cuts.

Power suppl y

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply.

They are double-insulated in accor dance with European

Standard and can, therefore, also be us ed from sockets

without earth wire.

Wood 65 mm 65 mm 65 mm 65 mm

Mild steel 6 mm 6 mm 6 mm 6 mm

–1

) 3,100 500 – 3,100 500 – 3,100 500 – 3,100

General Power Tool Safety Warnings

WARNING! Read all safety warnings and all instructions. Failure to follo w the warnings and instructions may

result in electric shock, fire and/or serious injury.

Save all warnings and

instructions for future reference.

11 Retainer

12 Base

13 Dust cover

14 Cutting line

15 Edge

16 Graduation

17 S ta rting hole

18 Hose

19 Steel base type

20 Rip fence (Guide rule)

217 mm

(Steel base type)

223 mm

(Aluminum base type)

1,8 kg

(Steel base type)

1,9 kg

(Aluminum base type)

21 Aluminum base type

22 Guide facing

23 Fence guide

24 Threaded knob

25 Pin

26 Anti-splintering device

27 Protrusions

28 Aluminum base

29 Cover plate

217 mm

(Steel base type)

223 mm

(Aluminum base type)

1,8 kg

(Steel base type)

1,9 kg

(Aluminum base type)

Work area safety

1. Keep work area clean and well lit. Cluttered a nd

dark areas invite accidents.

2. Do not operat e power tools in explosive atmospheres, such as i n the presence of fl ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

3. Keep children and bystanders away while o perating a power tool. Distractions can cause you to

lose control.

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. The re is an increased r isk of electr ic

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edg es or

moving parts. Damaged or entangled cords

increase the risk of electric shock.

217 mm 223 mm

1,8 kg 1,9 kg

7

Page 8

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

9. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter (GFCI) protected supply. Use of an GFCI

reduces the risk of electric shock.

Personal safety

10. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influenc e of drugs, alc ohol or medi cation. A

moment of inattention while operating power tools

may result in serious personal injury.

11. Use personal protective equipment. Always wear

eye protection. Protective equ ipment such as dus t

mask, non-skid safety shoes, hard hat, or heari ng

protection used for appropriate conditions will

reduce personal injuries.

12. Prevent unintentional starting. Ensure the

switch is in the off-position before con n ect ing to

power source and/ or batt ery pa ck, pickin g up or

carrying the tool. Carrying power tools with your

finger on the switch or energising power too ls that

have the switch on invites accidents.

13. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

14. Do not overreach. Keep proper footing and balance at all times. T his enabl es bette r contr ol of the

power tool in unexpected situations.

15. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewellery

or long hair can be caught i n moving parts.

16. If devices are provided for the connection of

dust extraction and c ollection facilities, ensure

these are conne cted and properly used. Use o f

dust collection can reduce dust-related hazards.

Power tool use and care

17. Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the j ob better and safer at the rate for

which it was designed.

18. Do not use th e powe r to ol if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is da ngerou s and mu st be

repaired.

19. Disconnect the plug from the power source and/

or the battery pack from the power tool before

making any adjustm ents, chan ging ac cessor ies,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

20. Store idle power tools out of the reach of children and do not allow p ersons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

21. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired befo re us e. Many accidents are caused by

poorly maintained power tools.

22. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

23. Use the power tool, accessories and tool bits

etc. in accordanc e with these instructions, t aking into account t he working c onditions and the

work to be performed. Use of the power tool for

operations different from th ose i nte nde d co uld r esu lt

in a hazardous situation.

SERVICE

24. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensu re that the safety of the power

tool is maintained.

25. Follow instruction for lubrica ting and changing

accessories.

26. Keep handles dry, clean and free from oil and

grease.

SPECIFIC SAFETY RULES

GEB016-1

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence to jig saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious

personal injury.

1. Hold power tools by insulated gripping surfaces when performing an operation where

the cutting tool may contact hidden wiring or

its own cord.

exposed metal par ts of th e tool "li ve" and shock the

operator.

2. Use clamps or another practical way to

secure and support the workpiece to a stable

platform.

body leaves it unstable and may lead to loss of control.

3. Always use safety glasses or goggles. Ordinary eye or sun glasses are NOT safety

glasses.

4. Avoid cutt ing nails. Inspect workpiece for any

nails and remove them before operation.

5. Do not cut oversize workpiece.

6. Check for the proper clearance beyond the

workpiece before cutting so that the blade

will not strike the floor, workbench, etc.

7. Hold the tool firml y.

8. Make sure the blade is not contacting the

workpiece before th e swit ch is tu r n ed on.

9. Keep hands away from moving parts.

10. Do not leave the tool running. Operate the

tool only when hand-held.

11. Always switch off and wait for the blade to

come to a complete stop before removing the

blade from the workpiece.

12. Do not touch the blade or the workpiece

immediately after operation; they may be

extremely hot and could burn your skin.

13. Do not operate the tool at no-load unnecessarily.

Contact with a "live" wire will make

Holding the work by han d o r ag ainst your

8

Page 9

14. Some material contains chemi cals w hic h m a y

be toxic. Take caution to prevent dust inhalation and skin contact. Follow material supplier safety data.

WARNING:

MISUSE or failure to follow the safety rules stated

in this instruction manual may cause serious

personal injury.

15. Always use the correct dust mask/respirator

for the material and appl ication you are working with.

SAVE THESE INSTRUCTIONS.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and unplugged before adjusting or checking function on the tool.

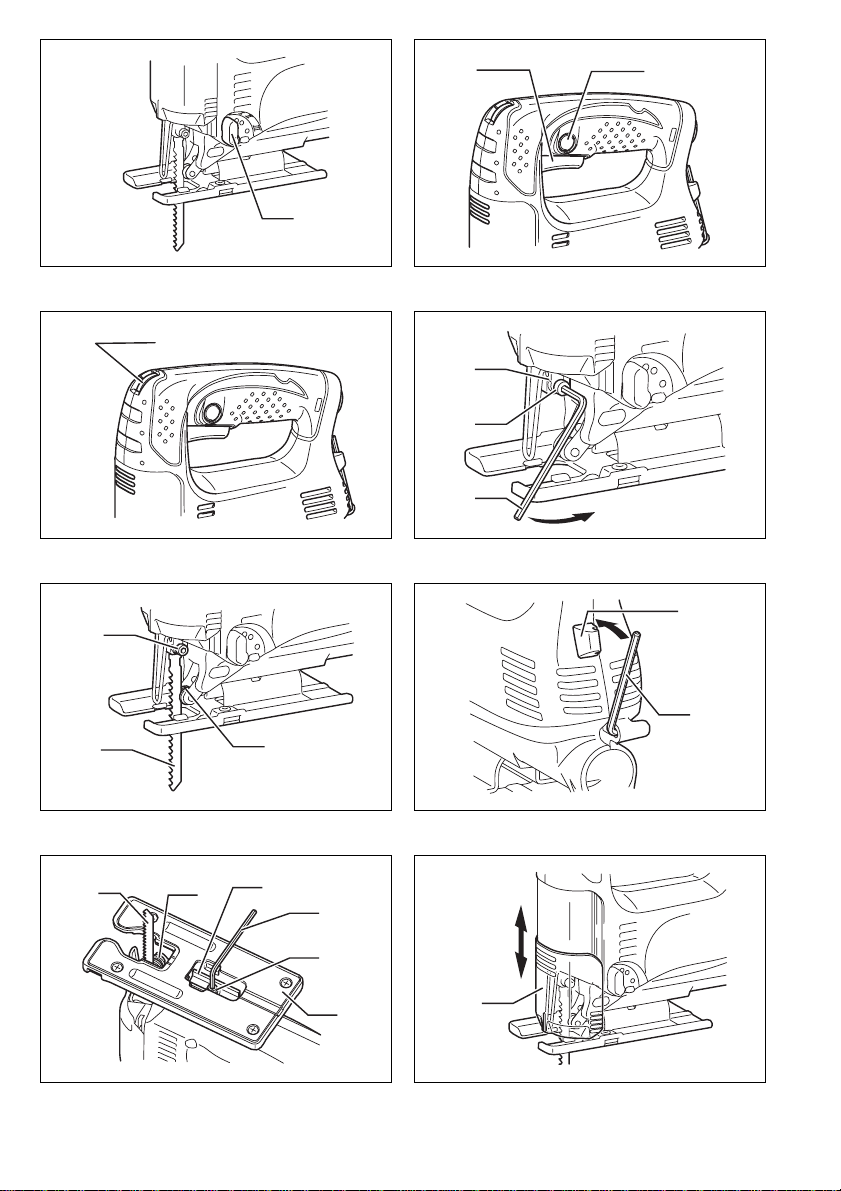

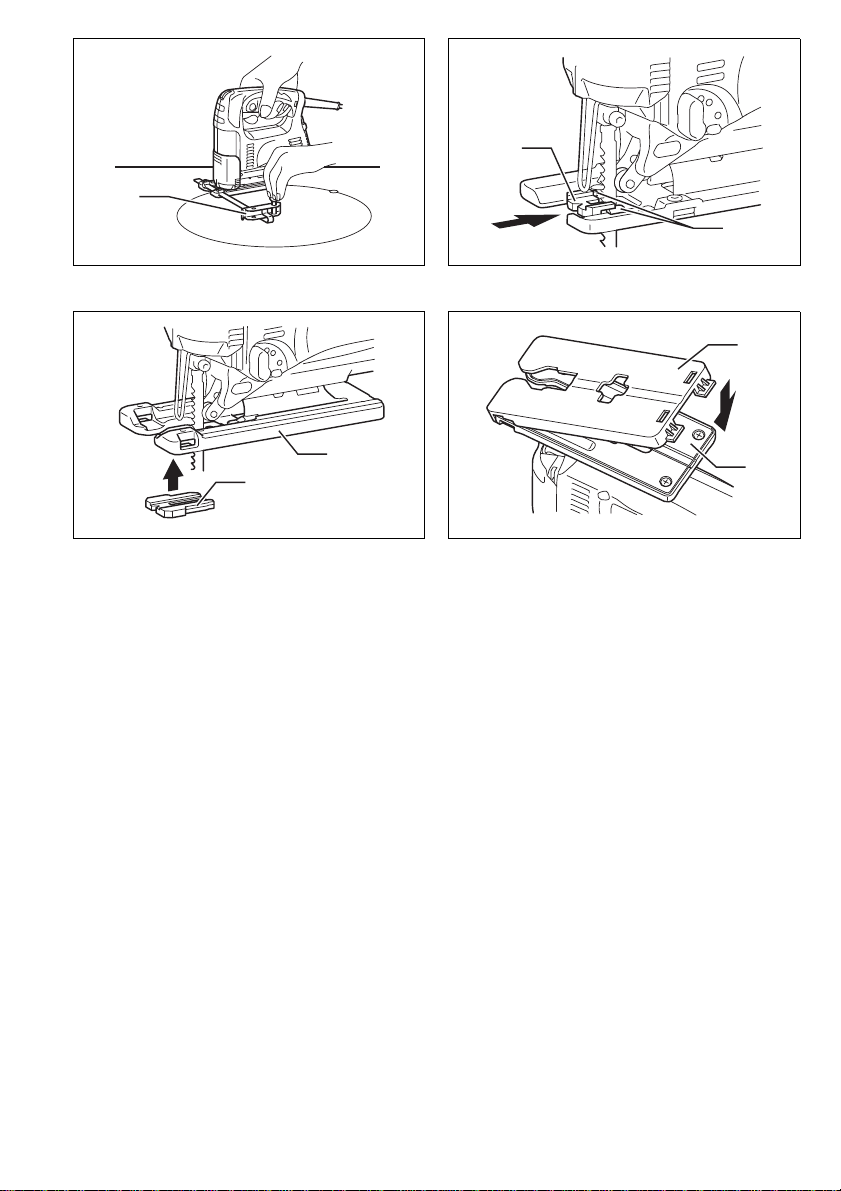

Selecting the cutting action (For models 4328/4329 ) (F ig. 1)

This tool can be operated with an orbital or a straight line (up and down) cutting actio n. The orbital cutting action

thrusts the blade forward on the cutting stroke and greatly increases cutting speed.

To change the cutting action, just turn the cutting action changing lever to the d esired cutti ng action position.

Refer to the table to select the appropriate cutting action.

Position Cutting action Applications

0 Straight line cutting action

I Small orbit cutting action For cutting mild steel, aluminum and hard wood.

II Medium orbit cutting action

III Large orbit cutting action For fa st cutting in wood and plywood.

Switch action (Fig. 2)

CAUTION:

• Before plugging in the tool , always check to see that

the switch trigger actu ates properly a nd returns to the

“OFF” position when released.

To start the tool, simply pull the switch trigg er. Release

the switch trigger to stop.

For continuous operation, pull the switch trigger and then

push in the lock button.

To stop the tool from the locked position, pull the switch

trigger fully, then release it.

Speed adjusting dial (F or models 4327/432 8/4329)

(Fig. 3)

The tool speed can be inf initely adjusted between 500

and 3,100 strokes per minute by turning the adjusting

dial. Higher speed is ob tained when th e dial is turn ed in

the direction of number 6; lower speed is obtained when

it is turned in the direction of number 1.

Refer to the table to select the proper speed for the workpiece to be cut. However, the appropriate sp eed m ay differ with the type or thickness of the workpiece. In

general, higher speeds w ill allow you to cut workpieces

faster but the service life of the blade will be reduced.

For cutting mild steel, stainless steel and plastics.

For clean cuts in wood and plywood.

For cutting wood and plywood.

For fast cutting in aluminum and mild steel.

Wor kpiece to be cut Number on adjusting dial

Wood 5 – 6

Mild steel 3 – 6

Stainless steel 3 – 4

Aluminum 3 – 6

Plastics 1 – 4

CAUTION:

• If the tool is o perated con tinuously at l ow speeds for a

long time, the motor will get overloaded and heated up.

• The speed adjusting dial can be turned only as far as 6

and back to 1. Do not force i t past 6 or 1, or the speed

adjusting function may no longer work.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

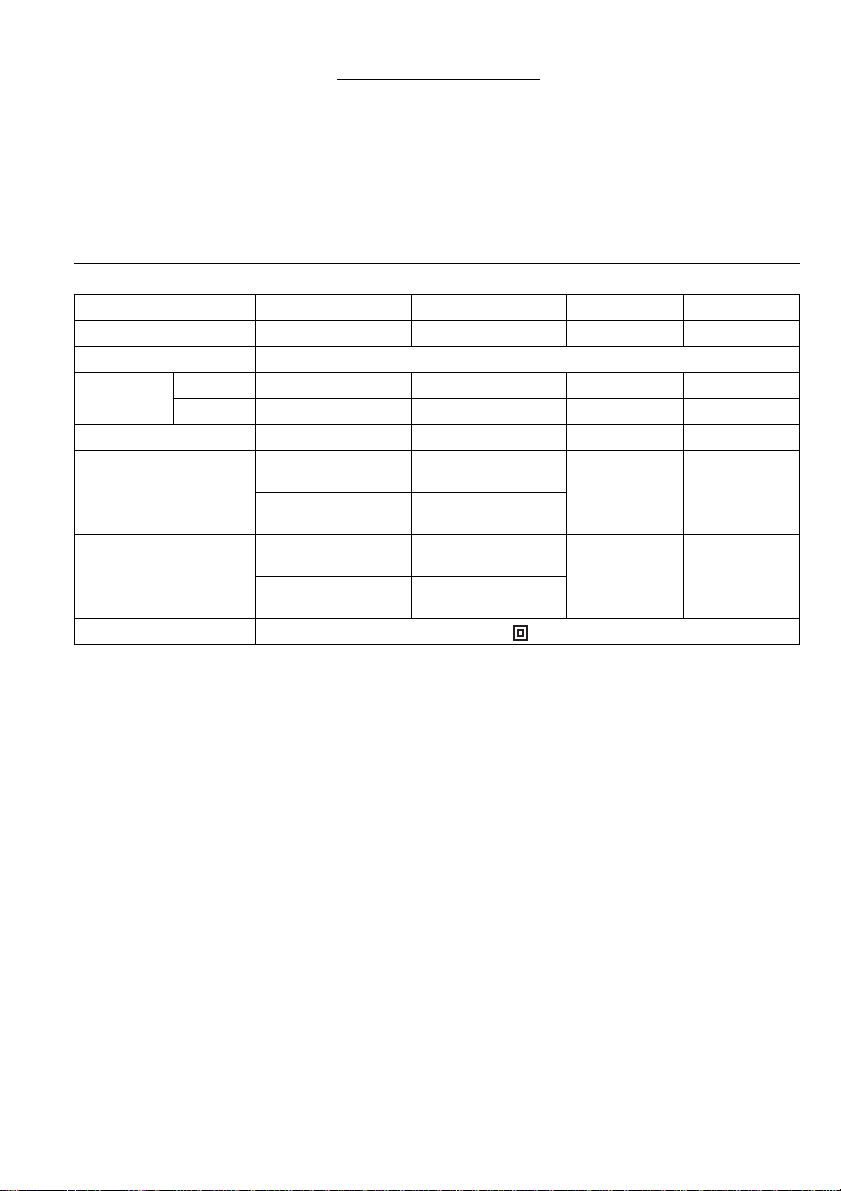

Installing or r em ovi ng saw blade (Fig. 4 & 5)

CAUTION:

• Always clean out all chips or foreign matter adh er in g to

the blade and/or blade holder. Failure to do so may

cause insufficient tighte ning of the blad e, resulting in a

serious personal injury.

9

Page 10

• Do not touch th e blade or the workpiece immedi ately

after operation; they may be extremely h ot and could

burn your skin.

• Alway s se c ur e the blade firmly. In s uff i c ie nt t igh t en i ng of

the blade may cause blade bre akage or serious personal injury.

• Use only B type blades. Using blades other than B type

blades causes insufficient tightening of the blade,

resulting in a serious personal injury.

To install the blade, lo osen the bo lt counterclockwis e on

the blade holder with the hex wrench.

With the blade teeth facing forward, insert the blade into

the blade holder as far as it will go. Make sure that the

back edge of the blade fits into the roller. Then tighten the

bolt clockwise to secure the blade.

To remove the blade, follow the installation procedure in

reverse.

NOTE:

• Occasionally lubricate the roller.

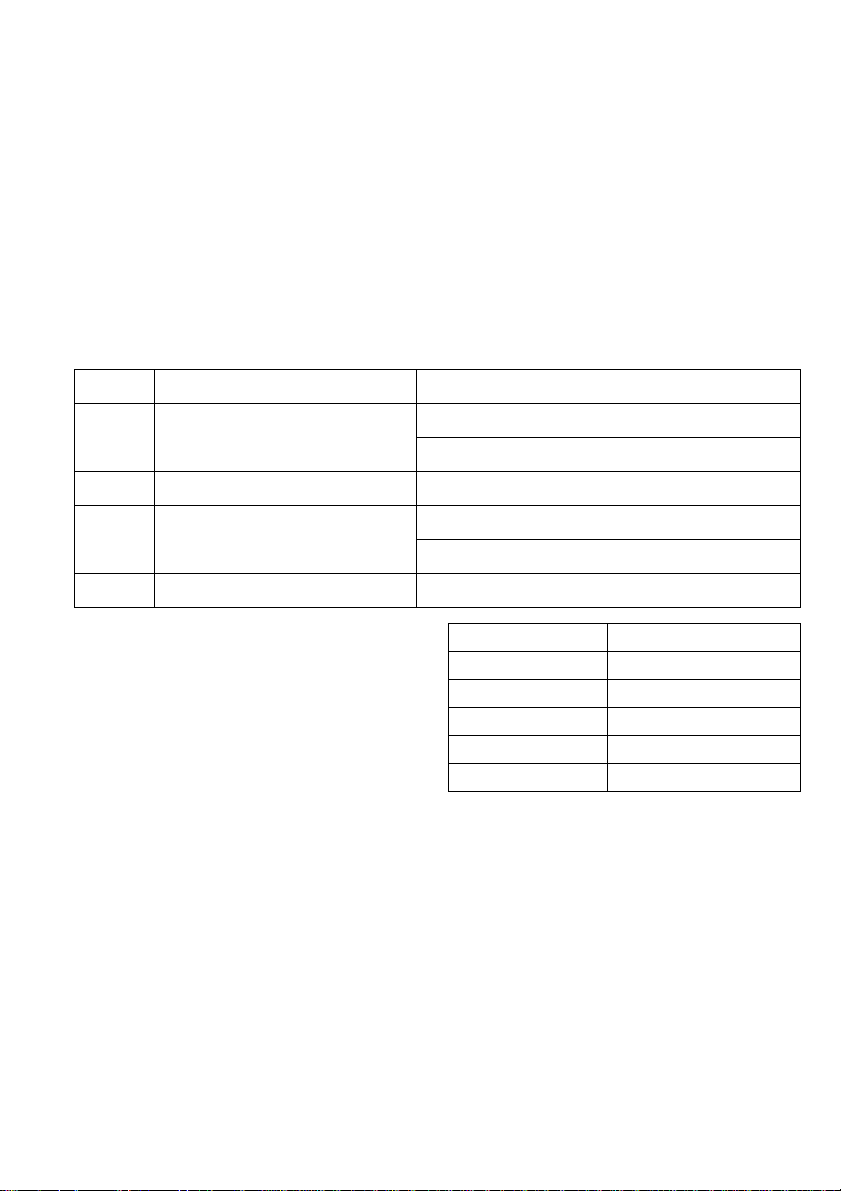

Hex wrench storage (Fig . 6)

When not in use, store the h ex wrench as shown in the

figure to keep it from being lost.

Adjusting roller (For models 4326/4327) (Fig.7)

Loosen the bolt on th e ba ck of the too l base w ith the hex

wrench. Move the retai ner so t hat the roller c ontacts the

blade lightly. Then tighten the bolt to secure the tool base

and the retainer.

NOTE:

• Occasionally lubricate the roller.

Dust cover (Fig.8)

CAUTION:

• Always wear safety goggles even when operating the

tool with the dust cover lowered.

Lower the dust cover to prevent chips from flying. However, when making bevel cuts, raise it all the way.

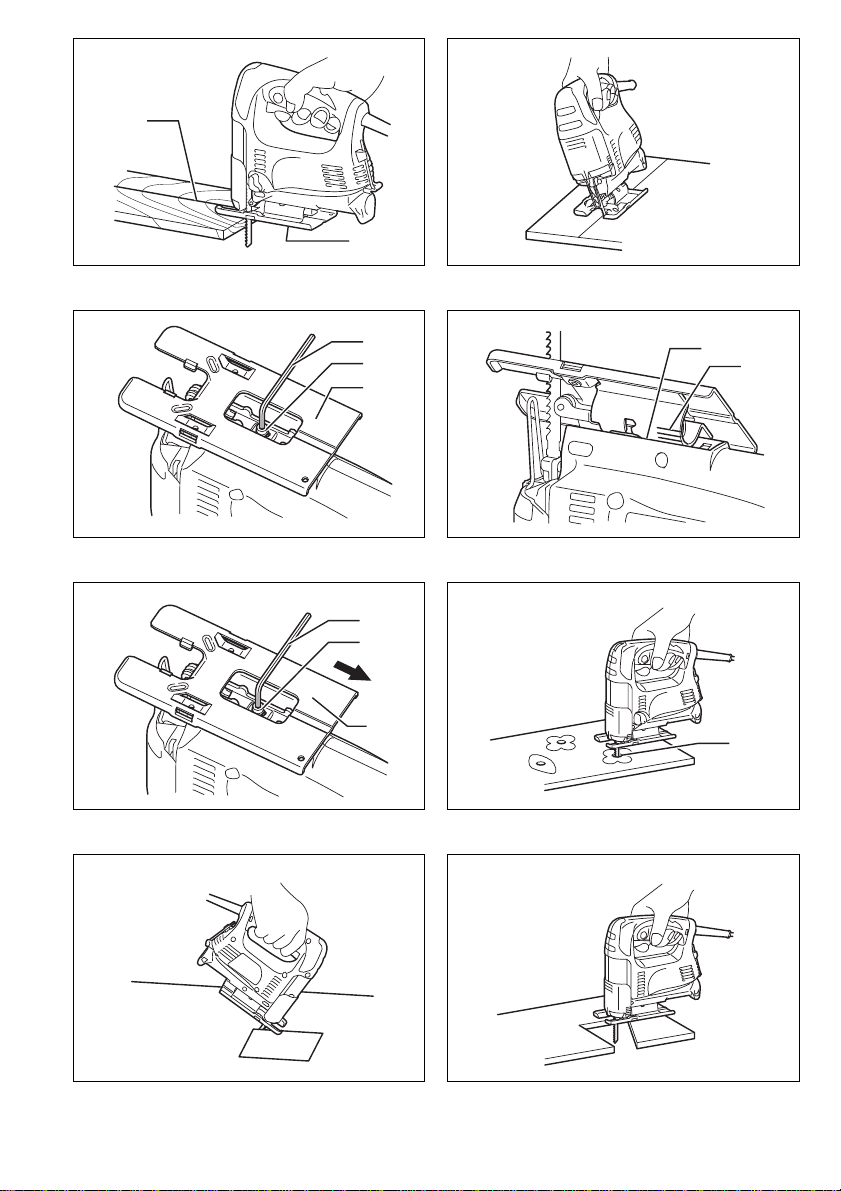

OPERATION

CAUTION:

• Always hold the base flush with the wor kpiece. Failure

to do so may cause blade breakage, resulting in a ser i ous injury.

• Advance the tool very slowly w hen cutting curves or

scrolling. Forcing the tool may cause a slanted cutting

surface and blade breakage.

Turn the tool on without the blade making any contact

and wait until the blade attains ful l speed. Then rest the

tool base flat on the w orkpiece and gentl y move the tool

forward along the previously marked cutting line. (Fig. 9)

Bevel cutting

CAUTION:

• Always be sure that the tool is switched off and

unplugged before tilting the tool base.

• Raise the dust cover all the way before making bevel

cuts.

With the base tilted, you can make bevel cuts at any

angle between 0° and 45° (left or right). (Fig. 10)

Loosen the bolt on t he back of the base with the hex

wrench. Move the tool base so that the bolt is positioned

in the center of the cross-shaped slot in the base.

(Fig. 11)

Tilt the base until the desired bevel angle is obtained.

The edge of the moto r housi ng in dicates th e bevel angle

by graduations. Then tig hte n the bo lt to secure the b ase.

(Fig. 12)

Front flush cuts (Fig. 13)

Loosen the bolt on the back of the tool base with the hex

wrench, and slide the base all the way back. Then tighten

the bolt to secure the tool base.

Cutouts

Cutouts can be made with either of two methods A or B.

A) Boring a starting hole

For internal cutouts without a lead-in cut from an

edge, pre-drill a starting hole 12 mm or more in diameter. Insert the blade int o this hole to star t your cut.

(Fig. 14)

B) Plunge cutting

You need not bore a starting h ole or make a lead- in

cut if you carefully do as follows.

1. Tilt the tool up on the front edge of th e base with

the blade point positioned just above the workpiece surface. (Fig. 15)

2. Apply pressure to the tool so that the fron t ed ge o f

the base will not move when you switch on the tool

and gently lower the back end of the tool slowly.

3. As the blade pierces the workpiece, slowly lower

the base of the tool d own ont o the workp iece surface.

4. Complete the cut in the normal manner.

Finishing edges (Fig. 16)

To trim edges or make dimensional adjustments, run the

blade lightly along the cut edges.

Metal cutting

Always use a suitable coolant (cutting oil) when cutting

metal. Failure to do so will cause significant blade wear.

The underside of th e workpiece c an be greased ins tead

of using a coolant.

Dust extraction (Fig.17)

Clean cutting operations can be performed by connecting

this tool to a Makita vacuum cleaner. Insert the hose of

the vacuum cleaner int o the hole at the r ear of the tool.

Lower the dust cover before operation.

NOTE:

• Dust extraction cannot be performed when making

bevel cuts.

Rip fence (optional ac cessory)

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing accessories.

1) Straight cuts (Fig. 18, 19, 20 & 21)

When repeatedly cut ting widths of 160 mm or less,

use of the rip fence will assure fast, clean, straight

cuts.

To install, insert the rip fence into the rectangular hole

on the side of the tool base with the fence guide facing down. Slide the rip fence to the desir ed cutting

width position, then tighten the bolt to secure it.

10

Page 11

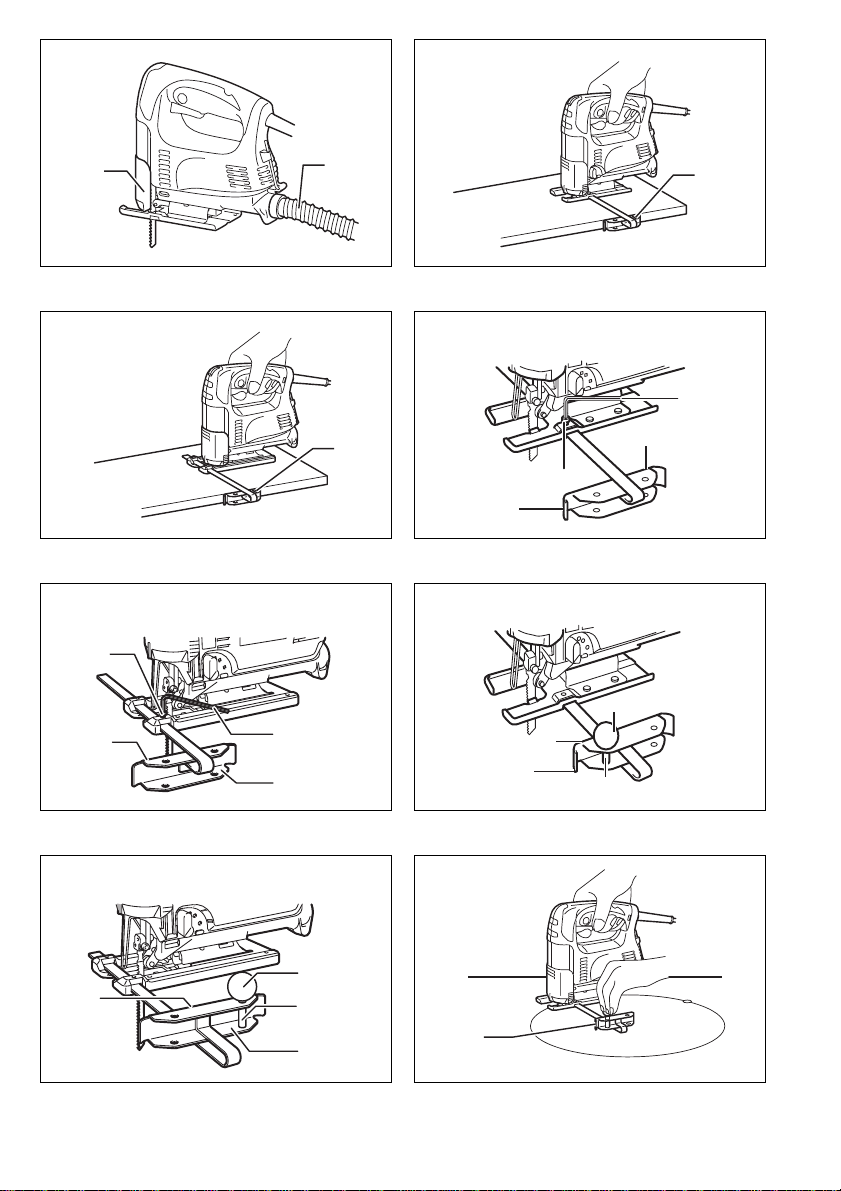

2) Circular cuts (Fig. 22, 23, 24 & 25)

When cutting circles or arcs of 170 mm or less in

radius, install the rip fence as follows.

Insert the r ip fence into the rectangular hole on the

side of the tool base with the fence guide facing up.

Insert the circ ular guide pin through e ither of th e two

holes on the fence guide. Screw the th readed knob

onto the pin to secure the pin.

Now slide the rip fence to the desired cutting radius,

and tighten the bolt t o secure it in plac e. Then move

the tool base all the way forward.

NOTE:

• Always use blades No. B-17, B-18, B-26 or B-27

when cutting circles or arcs.

Anti-splintering device for steel base (opti o nal

accessory) (Fig. 26)

For splinter-free cuts, the anti-splinterin g device can be

used. To in sta l l t he an t i-s p li n te ring device, mo ve the base

all the way forward and insert it be tween the two protr usions of the base.

NOTE:

• The anti-splinter ing device canno t be use d when m aking bevel cuts.

Anti-splintering device for aluminum base

(optional accessory) (Fig. 27)

For splinter-free cuts, the anti-splinterin g device can be

used. To install the anti-splinterin g device, move the tool

base all the way forward and fit it from the back of tool

base. When you use the cover plate, install the anti-splintering device onto the cover plate.

CAUTION:

• The anti-splinter ing device canno t be use d when m aking bevel cuts.

Cover plate for aluminum base (optional

accessory) (Fig. 28)

Use the cover plate when cutting decorative veneers,

plastics, etc. It protects sensitive or delicate surfaces

from damage. Fit it on the back of the tool base.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

To maintain product SAFET Y and RE LIABILIT Y, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by Makita Authorized Service Centers, always using Makita

replacement parts.

ACCESSORIES

CAUTION:

• These accessorie s or attachments are reco mmended

for use with your Makita tool specifie d in this manual.

The use of any other accessories or attachments might

present a risk of injur y t o persons. O nly use acce ssor y

or attachm ent for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Jig saw blades

• Hex wrench 3

• Rip fence (guide rule) set

• Anti-splintering device

• Hose (For vacuum cleaner)

• Cover plate (For aluminum base type)

4326, 4327

Model;

For European countries only

Noise

The typical A-weighted noise level determined according

to EN60745-2-11:

Sound pressure level (L

Sound power level (L

Uncertainty (K): 3 dB (A)

Wear ear protection.

pA): 86 dB (A)

wA): 97 dB (A)

Vibration

The vibration total value (tri-axial vector sum) determined

according to EN60745-2-1 1:

Work mode: cutting chipboard

Vibration emission (a

Uncertainty (K): 1.5 m/s

Work mode: cutting sheet metal

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,CW

h,CM

): 5 m/s

2

): 4,5 m/s

2

2

2

Model; 4328, 4329

For European countries only

Noise

The typical A-weighted noise level determined according

to EN60745-2-11:

Sound pressure level (L

Uncertainty (K): 3 dB (A)

pA): 83 dB (A)

The noise level under working may exceed 85 dB (A).

Wear ear protection.

Vibration

The vibration total value (tri-axial vector sum) determined

according to EN60745-2-1 1:

Work mode: cutting chipboard

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,CW

Work mode: cutting sheet metal

Vibration emission (a

Uncertainty (K): 1.5 m/s

h,CM

): 7 m/s

2

): 5 m/s

2

2

2

11

Page 12

EC-DECLARATION OF CONFORMITY

Model; 4326, 4327, 4328, 4329

We declare under our sole responsibility that this product

ENH101-8

is in compliance with the following standards of

standardized documents;

EN60745, EN55014, EN61000

in accordance with Council Directives, 2004/108/EC and

98/37/EC.

Tomoyasu Kato

CE 2007

Director

Responsible Manufacturer:

Makita Corporation

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Authorized Representative in Europe:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD , ENGLAND

12

Page 13

DEUTSCH

Übersicht

1 Schnittbewegung-Umschalthebel

2 Schalter

3 Schalterarretierung

4 Hubzahl-Stellrad

5 Sägeblattaufnahme

6 Schraube

7 Inbusschlüssel

8 Sägeblatt

9 Führungsrolle

10 Haken

11 Klemmstück

TECHNISCHE DATEN

Modell 4326 4327 4328 4329

Hubhöhe 18 mm 18 mm 18 mm 18 mm

Sägeblatttyp Typ B

Maximale

Schnitttiefe

Hubzahl pro Minute (min

Gesamtlänge

Nettogewicht

Sicherheitsklasse /II

• Wir behalten uns vor, Änderungen im Zuge der Entwicklung und des technischen Fortsch ritts ohne vorherige Ankündigung vorzunehmen.

• Hinweis: Die technische n Daten können von Land zu

Land abweichen.

Vorgesehene Verwendung

Diese Maschine ist für das Sägen von Holz, Kunststoff

und Metall vorgesehen. Dank des umfangreichen Zubehör- und Sägeblattprogramms kann die Maschine für

viele Zwecke eingesetzt werden und eignet sich ideal für

Bogen- oder Kreisschnitte.

Netzanschluß

Die Maschine darf nu r a n di e au f d em Typenschild angegebene Netzspannung angeschlossen werden und

arbeitet nur mit Einphasen-Wechselspannung. Sie ist

entsprechend den Europäischen Richtlinien doppelt

schutzisolier t und kann daher auch an Steckdosen ohne

Erdanschluß betrieben werden.

Holz 65 mm 65 mm 65 mm 65 mm

Weichstahl 6 mm 6 mm 6 mm 6 mm

–1

) 3100 500 – 3 100 500 – 3 100 500 – 3 100

(Typ mit Stahl-Grundplatte)

(Typ mit Stahl-Grundplatte)

12 Grundplatte

13 Schutzhaube

14 Schnittlin ie

15 Kante

16 Teilstriche

17 Vorbohrung

18 Schlauch

19 Typ mit Stahl-Grundplatte

20 Parallelanschlag

(führungslinealsatz)

21 Typ mit Aluminium-Grundplatte

217 mm

223 mm

(Typ mit

Aluminium-Grundplatte)

1,8 kg

1,9 kg

(Typ mit

Aluminium-Grundplatte)

22 Führungsfläche

23 Anschlagführung

24 Gewindeknopf

25 Stift

26 Spanreißschutz

27 Führungsschiene

28 Aluminium-Grundplatte

29 Gleitplatte

217 mm

(Typ mit Stahl-Grundplatte)

223 mm

(Typ mit

Aluminium-Grundplatte)

(Typ mit Stahl-Grundplatte)

1,8 kg

1,9 kg

(Typ mit

Aluminium-Grundplatte)

217 mm 223 mm

1,8 kg 1,9 kg

Allgemeine Sicherheitswarnungen für

Elektrowerkzeuge

WARNUNG! Lesen Sie alle Sicherheitswarnungen

und Anweisungen durch. Eine Missachtung der unten

aufgeführten Warnungen und Anweisungen kann zu

einem elektrischen Schlag, Brand und/oder schweren

Verletzungen führen.

Bewahren Sie alle Warnungen und

Anweisungen für spätere Bezugnahme

auf.

Sicherheit im Arbeitsbereich

1. Halten Sie den Arbeitsbereich sauber und gut

beleuchtet. Unaufgeräumte und dunkle Bereiche

führen zu Unfällen.

2. Betreiben Sie E lek trowerkzeuge nicht in exp lo siven Umgebungen, wie z.B. in Gegenwart von

brennbaren Flüssigkeiten, Gasen oder Staub.

Elektrowerkzeuge erzeugen Fun ken, die den Staub

oder die Dämpfe entzünden können.

3. Halten Sie Kinder und Umstehende während der

Benutzung eines Elektrowerkzeugs vom Arbeitsbereich fern. Ablenkungen können dazu führen,

dass Sie die Kontrolle verlieren.

13

Page 14

Elektrische Sicherheit

4. Der Stecker des Elektrowerkzeugs muss an die

Steckdose angepa sst sein. Der Stecker darf auf

keinen Fall in irgendeiner F orm abgeän dert we rden. Verwenden Sie keine Adapterstecker mit

geerdeten Elektrowerkzeugen. Vorschriftsmäßige

Stecker und passende Steckdosen reduzieren die

Stromschlaggefahr.

5. Vermeiden Sie Körperkontakt mit geerdeten

Gegenständen (z.B. Rohre, Kühler, Herde, Kühlschränke). Es besteht erhö hte Stromschlaggefahr,

falls Ihr Körper Erdkontakt hat.

6. Setzen Sie Elektrowerkzeuge keinem Regen

oder Nässe aus. Wasser, das in ein Elektr owerk-

zeug eindringt, erhöht die Stromschlaggefahr.

7. Behandeln Sie das Kabel sorgfältig. Benutzen

Sie das Kabel nie mals zum Tragen, Ziehen od er

Abtrennen des Elektrowerkzeugs. Halten Sie das

Kabel von Hitze, Öl, scharfen Kanten oder

beweglichen Teilen fern. Ein beschädigtes oder

verheddertes Kabel erhöht die Stromschlaggefahr.

8. Wenn Sie ein Elektrowerkzeug im Freien betreiben, verwenden Sie ein für Freiluftbenutzung

geeignetes Verlängeru ngskabel. Die Verwendung

eines für Freiluftbenutzung g eeigne ten K abels re duziert die Stromschlaggefahr.

9. Lässt sich der Einsatz eines Elektrowerkzeugs in

feuchter Umgebung nicht vermeiden, verwenden

Sie eine Stromquelle, die mit einem Fehlerstr omSchutzschalter (GFCI) geschützt ist. Der GFCI

verringert die Gefahr eines elektrischen Schlags.

Persönliche Sicherheit

10. Bleiben Sie wachsam, und lassen Sie beim

Umgang mit einem Elektrowerkzeug Vorsicht

und gesunden Me ns c h enverstan d wa lt e n. B e n ut zen Sie keine Ele ktrowerkzeu ge , wen n S ie mü de

sind oder unter dem Einfluss von Drogen, Alkohol oder Medikamenten stehen. Ein Augenblick

der Unachtsamkeit während der Benutzung von

Elektrowerkzeugen kann zu schwere n Verletzungen

führen.

11. Benutzen Sie Schutzausrüstung. Tragen Sie

stets eine Schutzbrille. Sachgemäßer Gebrauch

von Schutzausrüstung (z. B. Staubmaske, rutschfeste Sicherheitsschuhe, Helm und Gehörschutz)

trägt zu einer Reduzierung der Verletzungsgefahr

bei.

12. Unbeabsichtigtes Einschalten verhüten. Vergewissern Sie s ich, da ss sich de r E in- Aus- Schalt er

in der Aus-Stellung befindet, bevor Sie die

Stromquelle und/oder den Akku anschließen

bzw. die Maschine aufheben oder tragen. Das

Tragen von Elektrowerkzeugen mit dem Fi nger am

Ein-Aus-Schalter oder das Anschließen bei ein geschaltetem Ein-Aus-Schalter führt zu Unfällen.

13. Etwaige Einste ll- oder Schraubensch lüssel sind

vor dem Einschalten des Elektrowerkzeugs zu

entfernen. Ein Schrauben- oder Einstellschlüssel,

der auf ei nem r o ti e r en den Teil des El ek tr o werkzeugs

stecken gelassen wird, kann zu einer Verletzung

führen.

14. Übernehmen S ie sich n icht . Achten S ie stets auf

sicheren Stand und gute Balance. Sie haben

dann in unerwarteten Situationen e ine be sser e Kontrolle über das Elektrowerkzeug.

15. Achten Sie auf zweckmäßige Kleidung. Tragen

Sie keine lose Kleidung oder Schmuck. Halten

Sie Haare, Kleidung und Handschuhe von

beweglichen Teilen fern. Lose Kleidung, Schmuck

oder langes Haar ka nn sich in beweglichen Teilen

verfangen.

16. Wenn Anschlussvorrichtungen für Staubabsaug- und S taubsammelgeräte vorhan den sind,

sollten diese montiert u nd sachgere cht verwendet werden. Die Verwendung von Staubsammelvor-

richtungen kann d urch Staub verursa chte Gefahren

reduzieren.

Gebrauch und Pflege von Elektrowerkzeugen

17. Setzen Sie Elektrowerkzeuge keiner Gewaltanwendung aus. Verwenden Sie d as kor rekt e E lektrowerkzeug für Ihre Anwendung. Ein korrektes

Elektrowerkzeug verrichtet die anstehende Arbeit

bei sachgemäßer Handhabung besser und sicherer.

18. Benutzen S ie das Elektrowerkzeug ni cht, wenn

es sich nicht mit dem Ein- Aus-Schalter ein- und

ausschalten läss t. Ein Elektrowerkzeug, das ni cht

auf die Schalterbetätigung reagiert, ist gefährlich

und muss repariert werden.

19. Trennen Sie den Stecker von der Stromquelle

und/oder den Akku vom Elektrowerkzeug, bevor

Sie Einstellungen durchführen, Zubehör auswechseln oder d as Elektrowerkz eug lager n. Sol-

che vorbeugenden Sicherheitsmaßnahmen

reduzieren die Gefahr eines versehentlichen Einschaltens des Elektrowerkzeugs.

20. Bewahren Sie unbenutzte Elektrowerkzeuge

außer Reichweite von Kindern auf, und lassen

Sie nicht zu, dass Personen, di e nicht mit dem

Elektrowerkzeug od er diesen Anweis ungen vertraut sind, das E lektrowerkzeug benutz en. Elek-

trowerkzeuge in den Hände n unerfahren er Benu tzer

sind gefährlich.

21. Pflegen Sie Elektrowerkzeuge. Überprüfen Sie

Elektrowerkzeuge auf Fehlausrichtung oder

Schleifen beweglicher Teile, Beschädigung von

Teilen und andere Zustände, die ihren Betrieb

beeinträchtigen können. Lassen Sie das Elektrowerkzeug bei Beschädigung vor der Benutzung

reparieren. Viele Unfälle werden durch schlecht

gewartete Elektrowerkzeuge verursacht.

22. Halten Sie Schneidwerkzeuge scharf und sauber. Gut instand gehaltene Schneidwerkzeuge mit

scharfen Schneiden sind weniger anfällig für Klemmen und lassen sich leichter handhaben.

23. Benutzen Sie das Elektrowerkzeug, das Zubehör,

die Einsatzwerkzeuge usw. gemäß diesen

Anweisungen, und berücksichtigen Sie stets die

Arbeitsbedingungen und die anstehende Arbeit.

Unsachgemäßer Gebrauch des Elektrowerkzeugs

kann zu einer Gefahrensituation führen.

Wartung

24. Lassen Sie Ihr Elektrowerkzeug nur unter Verwendung ident ischer Ersat zteile von e inem qu alifizierten Wartungstechniker warten. Dadurch

wird die Aufrechterhaltung der Sich erheit des Elektrowerkzeugs gewährleistet.

25. Befolgen Sie die Anweisungen für die Schmierung und den Austausch von Zubehör .

26. Halten Sie Gri ffe trocken, saub er und fre i von Öl

und Fett.

14

Page 15

SPEZIELLE SICHERHEITSREGELN

Lassen Sie sich NICHT durch Bequemlichkeit oder

Vertrautheit mit dem Produkt (durch wiederholten

Gebrauch erworben) von de r strikten Ei nhaltung de r

Sicherheitsrege ln für die Stichsäge abh alten. Wenn

Sie dieses Elektrowerkzeug auf unsichere oder

unsachgemäße Weise benutzen, können Sie schwere

Verletzungen erleiden.

1. Halten Sie Elektrowerkzeuge nur an den isolierten Griffflächen, wenn Sie Arbeiten ausführen,

bei denen die Gefahr besteht, dass verborgene

Kabel oder das eigene Kabel kontaktiert werden.

Bei Kontakt mit einem stromfüh renden Kabel werden die freiliegenden Metallteile der Maschine ebenfalls stromführend, so dass der Benutzer einen

elektrischen Schlag erleiden kann.

2. Verwenden Sie Klemmen oder eine andere praktische Methode, um das Werkstück auf einer stabilen Unterlage zu sichern und abzustützen.

Wenn Sie das Werkstück nur von Ha nd oder gegen

Ihren Körper halten, befindet es sich in einer instabilen Lage, die zum Verlust der Kontrolle führen kann.

3. Tragen Sie stets eine Sicherheits- oder Schutzbrille. Eine gewöhnliche Brille oder Sonn enbrille

ist KEIN Ersatz für eine Sicherheitsbrille.

4. Schneiden Sie keine Nägel durch. Untersuchen

Sie das Werkstück auf Näg el, und entferne n Sie

diese vor der Bearbeitung.

5. Schneiden Sie keine übergroßen Werkstücke.

6. Vergewissern Sie sich vor dem Sägen, dass

genügend Freiraum hinter dem Werkstück vorhanden ist, damit das Sägeblatt nicht gegen eine

harte Oberfläche, wie Fußboden, Werkbank

usw., stößt.

7. Halten Sie die Maschine sicher in der Hand.

8. Achten Sie stets darauf, daß das Sägeblatt nicht

das Werkstück berühr t, bevor die Stich säge ei ngeschaltet wird.

9. Halten Sie während de s Betriebs die Hände von

den sich bewegenden Teilen der Maschine fern.

10. Die Maschine nicht im eing eschalteten Zustand

aus der Hand legen. Die Benutzung ist nur in

handgehaltener Weise vorgesehen.

11. Das Sägeblatt erst d ann vom Werkstück entfernen, nachdem die Maschine abgeschaltet wurde

und das Sägeblatt zum St ill sta nd geko mme n i st.

12. Berühren Sie weder Sägeblatt noch Werkstück

unmittelbar nach dem Schneiden; beide können

sehr heiß sein un d Verbrennungen verursach en .

13. Lassen Sie das Werkzeug nicht u nnötig im Le erlauf laufen.

14. Manche Materialien können giftige Chemikali en

enthalten. Treffen Sie Vorsichtsmaßnahmen, um

das Einatmen von Arbeitsstaub und Hautkontakt

zu verhüten. Befolgen Sie die Sicherheitsdaten

des Materialherste llers .

15. Verwenden Sie stets die korrekte Staubschutzoder Atemmaske für das jeweilige Material und

die Anwendung.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

WARNUNG:

MISSBRAUCH oder Missachtung de r Sicherhei tsvorschriften in dieser Anleitung können schwere Verletzungen verursachen.

FUNKTIONSBESCHREIBUNG

VORSICHT:

• Vergewissern Sie sich vor jeder Einstellung oder Funktio nsprüf ung de r Masch ine stet s, dass sie au sgescha ltet u nd

vom Stromnetz getrennt ist.

Wahl der Schnittbewegung (Für Modelle 4328/4329) (Abb. 1)

Diese Maschine kann mit Pendelhub oder Linearhub (ge rade Auf-Ab-Bewegung) betrieben werden. Bei Pendelhub

wird das Sägeblatt im Schnitthub vorwärts geschoben, wodurch erheblich höhere Schnittgeschwindigkeiten mögl ich

sind.

Zum Umschalten der Sch nittbewegung drehen Sie einfach den Umschalthebel auf di e Positi on der gewünschten

Schnittbewegung.

Wählen Sie die geeignete Schnittbewegung anhand der Tabelle aus.

Position Schnittbewegung Anwendungen

0 Geradlinige Schnittbewegung

I Kleiner Pendelhub Zum Schneiden von Weichstahl, Aluminium und Hartholz.

II Mittlerer Pendelhub

III Großer Pendelhub Für schnelles Schneiden von Holz und Sperrholz.

Zum Schneiden von Weichstahl, Edelstahl und Kunststoff.

Für saubere Schnitte in Holz und Sperrholz.

Zum Schneiden von Holz und Sperrholz.

Für schnelles Schneiden von Aluminium und Weichstahl.

15

Page 16

Schalterfunktion (Abb. 2)

VORSICHT:

• Überprüfen Sie vor dem Anschließen der Maschine an

das Stromnetz stets, o b der Schal ter ordnun gsgemäßfunktionier t und beim Loslas sen in die “AUS” -Stellung

zurückkehrt.

Zum Einschalten der Maschine einfach den Schalter drücken. Zum Ausschalten den Schalter loslassen.

Für Dauerbetrieb den Schalter drücken, und dann die

Schalterarretierung hineindrücken.

Zum Ausrasten der Schalterarretierung den Elektronikschalter ganz hineindrücken und dann loslassen.

Hubzahl-Stellrad (Für Modelle 4327/4328/4329)

(Abb. 3)

Die Hubzahl kann durch Drehen des Hubzahl-Stellrads

zwischen 500 und 3.100 Hüben pro Minute eingestellt

werden. Auf dem Hubzah l-Stellrad sin d die Positionen 1

(niedrigste Hubzahl) bis 6 (höchste Hubzahl) markiert.

Hinweise auf die richtige, werkstoffgerechte Hubzahl entnehmen Sie der Tabelle. Die geeignete Hubzahl kann

jedoch je nach Art und Dicke des Werkstücks unterschiedlich sein. Höhere Hubzahlen ermöglichen im allgemeinen schnelleres Sägen von Werkstücken, bewirken

aber auch eine Verkürzung der Lebensd auer des S ägeblatts.

Werkstoff Hubzahl-Einstellung

Holz 5– 6

Weichstahl 3 – 6

Edelstahl 3 – 4

Aluminium 3 – 6

Kunststoff 1– 4

VORSICHT:

• Wird die Maschine üb er längere Zeitspannen im Dauerbetrieb mit niedriger Drehzahl betrieben, wird der

Motor überlastet und überhitzt.

• Das Hubzahl-Stel lrad läßt sich nur bis zur Position 6

vor- und bis zur Position 1 zurückdrehen. Drehen Sie

es nicht gewaltsam über die Position 6 oder 1 hinaus,

weil sonst eine genaue Einstellung der Hubzahl nich t

mehr möglich ist.

MONTAGE

VORSICHT:

• Vergewissern Sie sich vor der Ausführung von Arbeiten

an der Maschine stets, dass sie ausgeschaltet und vom

Stromnetz getrennt ist.

Montage/Demontage des Sägeblatts

(Abb. 4 u. 5)

VORSICHT:

• Säubern Sie Sägeblatt und/oder Sägeblatthalter stets

von anhaftenden Spänen oder Fremdkörpern. Anderenfalls besteht die Gefahr, daß das Sägeblatt nicht

richtig sitzt, was zu schweren Verletzungen führen

kann.

• Vermeiden Sie eine Berührung des Sägeblatts oder

des Werkstücks unmittelbar nach der Bearbeitung, weil

sie dann noch se hr heiß sind und Hautverb rennungen

verursachen können.

• Ziehen Sie das Sägeblatt stets fest an. Unzureichendes Anziehen des Sägeblatts kann zu Sägeblattb ruch

oder schweren Körperverletzungen führen.

• Verwenden Sie nur Sägeblätter d es Typs B. D ie Verwendung von anderen Sägeblättern außer solchen des

Typs B verursacht unzureichende Befestigung des

Sägeblatts, was zu schweren Körpe rverletzungen führen kann.

Zum Montieren des Säge blatts die Schraube am Sägeblatthalter mit dem Inbusschlüsse l durch Drehen entgegen dem Uhrzeigersinn lösen.

Das Sägeblatt mit den Zähnen nach vorn weisend bis

zum Anschlag in den Sägeblatthal ter einführen. Vergewissern Sie sich, dass die Hi nterkante des Sägeblatts in

der Rolle sitzt. Dann d ie Schraube zur Sicherung des

Sägeblatts im Uhrzeigersinn festziehen.

Zum Demontieren des Sägeblatts ist das Montageverfahren umgekehrt anzuwen den .

HINWEIS:

• Schmieren Sie die Führungsrolle von Zeit zu Zeit.

Inbusschlüssel-Aufbewahrung (Abb. 6)

Der Inbusschlüssel kann a n d er in der Abbildung ge zeigten Stelle aufbewahrt werden, damit er nicht verloren

geht.

Einstellen der Führungsrolle

(Für Modelle 4326/4327) (Abb.7)

Lösen Sie die Schraube auf der Rückseite der Grundplatte mit dem Innensechskantschlüssel. Verschieben

Sie das Klemmstück, so daß die Rolle das Sägeblatt

leicht berührt. Ziehen Sie dann die Schraube zur Befestigung von Grundplatte und Klemmstück an.

HINWEIS:

• Die Führungsrolle von Zeit zu Zeit schmieren.

Schutzhaube (Abb.8)

VORSICHT:

• Tragen Sie stets eine Schutzbrille, wenn Sie die Stichsäge mit abgesenkter Schutzhaube betreiben.

Senken Sie die Sch utzhaube ab, um Herausfliege n von

Spänen zu verhüten. Zum Ausführen von Gehrungsschnitten muß sie jedoch ganz angehoben werden.

BETRIEB

VORSICHT:

• Setzen Sie die Grundp latte der Stichsäge stets flach

auf das Werkstück auf. Anderenfalls besteht die Gefahr

eines Sägeblattbruchs, was zu schwer en Verletzungen

führen kann.

• Schieben Sie die Maschine beim Kurvenschneiden

oder Dekupieren sehr langsam vor. Gewaltsames Vorschieben der Masch i ne kann zu einer schiefen Schni ttfläche oder Sägeblattbruch führen.

Schalten Sie die Maschin e ein, ohne das s das Sägeblatt

Kontakt hat, und warten Sie, bis sie ihre volle Hubzahl

erreicht. Setzen Sie die Gr undplatte flach auf d as Werkstück, und bewegen Sie die Maschine entlang der vorher

markierten Schnittlinie sachte vorwärts. (Abb. 9)

Gehrungsschnitte

VORSICHT:

• Vergewissern Sie sich vor dem Kippen der Gru ndp l atte

stets, daß die Maschine ausg eschaltet und vom Netz

getrennt ist.

16

Page 17

• Heben Sie die Schut zhau be bei G ehrungsschnitten bis

zum Anschlag.

Durch Neigen der Grundplatte kön nen Gehr ung sschnitte

in jedem Winkel zwischen 0° und 45° (links oder rechts)

ausgeführt werde n. (Abb. 10)

Lösen Sie die Schraube an der Rückseite de r Grundplatte mit dem Inbusschlüssel. Verschieben Sie die

Grundplatte so, daß sich die Innensechskantschraube in

der Mitte des Kreuzsch litzes in der Gru ndplatte befind et.

(Abb. 11)

Neigen Sie die Gr undplatte, bis der gew ünschte Winkel

erreicht ist. Die Kant e des Motorge häuses kennzeichnet

den Neigungswinkel mit Teilstrichen. Dann die Schraube

zur Befestigung der Grundplatte festziehen. (Abb. 12)

Randnahe Schnitte (Abb. 13)

Lösen Sie die Innensechskantschraube an der Unterseite der Maschine und schieben Sie die Gru nd platt e bis

zum Anschlag zurück. Ziehen Sie anschließend die

Innensechskantschraube zur Befestigung der Grundplatte wi eder an.

Ausschnitte

Es gibt zwei Möglichkeiten, Ausschnitte durchzuführen:

A) Vorbohren

Bei Innenausschnitten o hne Zuführschnitt von einer

Kante aus machen Sie eine Vorbohrung von ca.

12 mm D urc hm esse r. Das Sägeblatt i n d iese Öffnung

einführen und mit dem Sägen beginnen. (Abb. 14)

B) Tauchschnitte

Um Schnitte ohne Vorbohren oder Zuführschni tt auszuführen, gehen Sie wie folgt vor:

1. Die Stichsäge auf der Vorderkante der Grundplatte

kippen, so daß d ie Sägeblattspitze dicht über d er

Oberfläche des Werkstücks liegt. (Abb. 15)

2. Druck auf die Stichsäge ausüben, damit die Vorderkante der Grundplatte nicht verrutscht, wenn

die Stichsäge einges chaltet und das hintere Ende

langsam abgesenkt wird.

3. Sobald das Sägeblatt in das Werkstück ei ndringt,

die Grundplatte langsam auf die Oberfläche des

Werkstücks absenken.

4. Den Schnitt in gewohnter Weise beenden.

Bearbeitung von Kanten (Abb. 16)

Um Kanten nachzuarbei ten oder Maßkorrekt uren vorzunehmen, das Säge blatt leicht an den Sc hnittkanten entlangführen.

Schneiden von Metall

Beim Schneiden von Metall stets ein geeignetes Kühlmittel (Schneidöl) verwenden. Nichtbeachtung verursacht

erheblichen Verschleiß des Sägeblatts. Anstelle von

Kühlmittel kann au ch die U n ter seite d es Werkstü cks ei ngefettet werden.

Staubabsaugung (Abb.17)

Durch den Anschluß dies er Maschine an ein A bsauggerät wird staubarmes Arbeiten ermöglicht. Schließ en Sie

den Schlauch eines Absaugg erätes an den Absaugst utzen an. Senken Sie die Schutzhaube vor dem Betrieb ab.

HINWEIS:

• Bei Gehrungsschnitten ist keine Staubabsaugung möglich.

Parallelanschlag (Sonderzubehör)

VORSICHT:

• Vergewissern Sie sich vor dem Montieren oder Demontieren von Zubehör stets, daß die Maschine ausgeschaltet und vom Netz getrennt ist.

1) Gerade Schnitte (Abb. 18, 19, 20 u. 21)

Bei wiederholtem Sc hneiden von Breiten kl einer als

160 mm gewährleistet der Parallelanschlag

schnelle, saubere und gerade Schnitte.

Führen Sie den Parallelanschlag in d ie rechteckige

Öffnung an der Seite der Grundplatte ein, so daß die

Anschlagführun g nach unte n gerich tet ist. Schieb en

Sie den Parallelanschlag zur Position der gewünschten Schnittbreite, und zi ehe n Si e da nn die S chrau be

zur Befestigung an.

2) Kreisschnitte (Abb. 22, 23, 24 u. 25)

Um Kreis- oder Bogenschnitte von weniger als

170 mm Radius durch zuführen, montieren Sie d en

Parallelanschlag wie folgt.

Führen Sie den Parallelanschlag in d ie rechteckige

Öffnung an der Seite der Grundplatte ein, so daß die

Anschlagführung nach oben gerichtet ist. Setzen Sie

den Dorn des Kreisschneiders in eine der beiden

Bohrungen in de r Anschlagf ührung ein, und sic hern

Sie ihn mit dem Gewindeknopf.

Schieben Sie nun den Parallelanschlag zu dem

gewünschten Schnittradius, und ziehen Sie die

Schraube zur Befestigung an. Schieben Sie dann

die Grundplatte der Maschine ganz nach vorn.

HINWEIS:

• Verwenden Sie stets die Sägeblätter Nr. B-17, B18, B-26 oder B -27 für kreis- oder boge nförmige

Schnitte.

Splitterschutz für Stahl-Grundplatte

(Sonderzubehör) (Abb. 26)

Für splitterfreie Schni tte kann der Sp litterschu tz verwendet werden. Zum Montieren des Splitterschutzes die

Grundplatte gan z nach vorn schieben, und die Vorrichtung zwischen die zwei Vorsprünge der Grundplatte einführen.

HINWEIS:

• Bei der Durchführ ung von Neigungssc hnitten ka nn der

Splitterschutz nicht verwendet werden.

Splitterschutz für Aluminium-Grundplatte

(Sonderzubehör) (Abb. 27)

Um splitterfreie Schni tte auszuführen, empfi ehlt sich die

Verwendung des Spanreißschutzes. Schieben Sie die

Grundplatte bis z um Anschlag nach vo rne, und montieren Sie den Spanreißschutz von der Unterseite der

Grundplatte. Wenn Sie die Gleitplatte verwenden, montieren Sie den Spanreißschutz auf die Gleitplatte.

VORSICHT:

• Bei Gehrungsschnitten ka nn der Spanreißschutz nicht

verwendet werden.

Abdeckplatte für Aluminium-Grundplatte

(Sonderzubehör) (Abb. 28)

Verwenden Sie die Gleitplatte zu m Sc hneiden von de korativen Furnieren, Kunststoffen usw. Sie schützt empfindliche oder feine Oberflächen vor Beschädi gung. Passen

Sie die Gleitplatte auf die Unterseite der Grundplatte.

17

Page 18

WARTUNG

VORSICHT:

• Denken Sie vor der Durchführung von Überprüfungen

oder Wartungsarbeit en stets daran , die Maschine auszuschalten und vom Stromnetz zu trennen.

Um die SICHERHEIT und ZUVERLÄSSIGKEIT dieses

Produkts aufrechtzu erhalten, sollten Rep araturen, Überprüfung und Austausch der Kohlebürsten und andere

Wartungs- oder E instellarb eiten nur von Maki ta-Kundendienstzentren unter ausschließlicher Verwendung von

Makita-Original ersa tzte il en ausg efü hrt werden.

ZUBEHÖR

VORSICHT:

• Die folgenden Zubeh örteile oder Vorrichtungen wer den

für den Einsatz mit der in dieser Anleitung besc hrie benen Makita-Maschine empfohlen. Die Verwendung

anderer Zubehörteile oder Vorrichtungen kann eine

Verletzungsgefahr darstellen. Verwenden Sie Zubehörteile oder Vorrichtungen nur für ihren vorgesehenen

Zweck.

Wenn Sie weitere Einzelheiten bezüglich dieser Zubehörteile benö tige n, wenden Si e sich bitte a n Ihre Ma kitaKundendienststelle.

• Sägeblatt

• Inbusschlüssel 3

• Parallelanschlagsatz (führungslinealsatz)

• Spanreißschutz

• Schlauch (Für Staubsauger)

• Gleitplatte (Für Typ mit Aluminium-Grundplatte)

Modell; 4326, 4327

Nur für europäische Länder

Geräusch

Typischer A-bewerte ter Geräuschpegel ermittelt g emäß

EN60745-2-11:

Schalldruckpegel (L

Schalleistungspegel (L

pA): 86 dB (A)

wA): 97 dB (A)

Ungewissheit (K): 3 dB (A)

Gehörschutz tragen.

Vibration

Vibrationsgesamtwert (Drei-Achsen-Vektorsumme)

ermittelt gemäß EN60745-2-11:

Arbeitsmodus: Schneiden von Spanplatten

Vibrationsemission (a

Ungewissheit (K): 1,5 m/s

h,CW

Arbeitsmodus: Schneiden von Blechen

Vibrationsemission (a

Ungewissheit (K): 1,5 m/s

h,CM

): 5 m/s

2

): 4,5 m/s

2

2

2

Modell; 4328, 4329

Nur für europäische Länder

Geräusch

Typischer A-bewerte ter Geräuschpegel ermittel t gemäß

EN60745-2-11:

Schalldruckpegel (L

Ungewissheit (K): 3 dB (A)

pA): 83 dB (A)

Der Lärmpegel kann während des Betriebs 85 dB (A)

überschreiten.

Gehörschutz tragen.

Vibration

Vibrationsgesamtwert (Drei-Achsen- Vektorsumme)

ermittelt gemäß EN60745-2-11:

Arbeitsmodus: Schneiden von Spanplatten

Vibrationsemission (a

Ungewissheit (K): 1,5 m/s

Arbeitsmodus: Schneiden von Bleche n

Vibrationsemission (a

Ungewissheit (K): 1,5 m/s

h,CW

h,CM

): 7 m/s

2

): 5 m/s

2

2

2

CE-KONFORMITÄTSERKLÄRUNG

Modell; 4326, 4327, 4328, 4329

Hiermit erklärt wir unter unserer alleinigen

Verantwortung, daß dieses Produkt gemäß den

ENH101-8

Ratsdirektiven 2004/108/EG und 98/37/EG mit den

folgenden Normen von Normendokumenten

übereinstimmen:

EN60745, EN55014, EN61000.

Tomoyasu Kato

CE 2007

Direktor

Verantwortlicher Hersteller:

Makita Corporation

3-11-8, Sumiyoshi-cho, Anjo, Aichi, JAPAN

Autorisierte Vertretung in Europa:

Makita International Europe Ltd.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

18

Page 19

POLSKI

Wyjaśnienia dotyczące urządzenia i jego użycia

1 Dźwignia zmiany sposobu

cięcia

2 Spust włącznika

3 Przycisk pracy ciągłej

4 Pokrętło regulacji prędkości

5 Uchwyt brzeszczotu

6Śruba

7 Klucz sześciokątny

8 Brzeszczot

9 Wałek

10 Haczyk

11 Ustalacz

12 Podstawa

13 Pokrywa przeciwpyłowa

14 Linia cięcia

15 Brzeg

16 Skala

17 Otwór początkowy

18 Wąż

19 Typ ze stalową podstawą

20 Prowadnica

(wyposażenie dodatkowe)

21 Typ z aluminiową podstawą

22 Osłona prowadnicy

23 Wodzik prowadnicy

24 Nagwintowana gałka

25 Przetyczka

26 Urządzenie antyodpryskowe

27 Występy

28 Aluminiowa podstawa

29 Płyta ochronna

DANE TECHNICZNE

Model 4326 4327 4328 4329

Długość przesuwu 18 mm 18 mm 18 mm 18 mm

Typ brzeszczotu Typ B

Maksymalna

zdolność cięcia

Liczba uderzeń na minutę (min

Całkowita długość

Ciężar netto

Klasa bezpieczeństwa /II

• Ze względu na prowadzony program udoskonaleń i

badań, podane dane techniczne mogą zostać

zmienione bez uprzedzenia.

• Uwaga: Dane techniczne mogą się różnić w zależności

od kraju.

Przeznaczenie

Urządzenie jest przeznaczone do cięcia drewna, plastiku

i metalu. Dzięki wielu funkcjom elementów wyposażenia

i samej wyrzynarki urządzenie może być używane do

wielu celów i znakomicie nadaje się do wycięć

krzywoliniowych lub po okręgu.

Zasilanie

Urządzenie to powinno być podłączone tylko do źródła

zasilania o takim samym napięciu jak pokazano na

tabliczce znamionowej i może być używane tylko dla

zmiennego prądu jednofazowego. Zgodnie ze

standardami Unii Europejskiej zastosowano podwójną

izolację i dlatego też możliwe jest zasilanie z gniazda bez

uziemienia.

Drewno 65 mm 65 mm 65 mm 65 mm

Stal miękka 6 mm 6 mm 6 mm 6 mm

–1

) 3100 500 – 3100 500 – 3100 500 – 3100

217 mm

(Typ ze stalową

podstawą)

223 mm

(Typ ze aluminiową

podstawą)

1,8 kg

(Typ ze stalową

podstawą)

1,9 kg

(Typ ze aluminiową

podstawą)

217 mm

(Typ ze stalową

podstawą)

223 mm

(Typ ze aluminiową

podstawą)

1,8 kg

(Typ ze stalową

podstawą)

1,9 kg

(Typ ze aluminiową

podstawą)

217 mm 223 mm

1,8 kg 1,9 kg

Ogólne ostrzeżenia dotyczące

bezpieczeństwa dla urządzenia

zasilanego prądem

OSTRZEŻENIE! Przeczytaj wszystkie ostrzeżenia

dotyczące bezpieczeństwa i wszystkie instrukcje.

Niestosowanie się do ostrzeżeń i instrukcji może

doprowadzić do porażenia prądem, pożaru lub

poważnych obrażeń.

Zachowaj wszystkie ostrzeżenia i

instrukcje do wykorzystania w przyszłości.

Bezpieczeństwo miejsca pracy

1. Miejsce pracy powinno być uporządkowane i

dobrze oświetlone. Nieuporządkowane i ciemne

miejsca sprzyjają wypadkom.

2. Nie używaj urządzeń zasilanych prądem w

miejscach, gdzie w powietrzu znajdują się

substancje wybuchowe, np. w pobliżu palnych

płynów, gazów lub pyłów. Urządzenia zasilane

prądem wytwarzają iskry, które mogą zapalić pyły

lub opary.

19

Page 20

3. Podczas pracy z urządzeniem zasilanym prądem

dzieci i osoby postronne powinny znajdować się

z dala. Rozproszenie może doprowadzić do utraty

panowania.

Bezpieczeństwo elektryczne

4. Wtyczki urządzeń zasilanych prądem muszą

pasować do gniazdek. Nigdy nie przerabiaj

wtyczki w żaden sposób. Dla urządzeń

zasilanych prądem z uziemieniem nie używaj

żadnych adapterów wtyczek. Nie przerabiane

wtyczki i pasujące do nich gniazdka zmniejszają

niebezpieczeństwo porażenia prądem.

5. Unikaj dotykania ciałem uziemionych

powierzchni, takich jak rury, kaloryfery, grzejniki

i lodówki. Kiedy ciało jest uziemione,

niebezpieczeństwo porażenia prądem jest większe.

6. Nie narażaj urządzeń zasilanych prądem na

deszcz lub wilgoć. Dostanie się wody do wnętrza

urządzenia zasilanego prądem może zwiększyć

niebezpieczeństwo porażenia prądem.

7. Obchodź się starannie z przewodem. Nigdy nie

używaj go do przenoszenia, przeciągania lub

odłączania od zasilania urządzenia zasilanego

prądem. Trzymaj przewód z dala od źródeł

ciepła, oleju ostrych krawędzi i ruchomych

części. Uszkodzone lub splątane przewody

zwiększają niebezpieczeństwo porażenia prądem.

8. Podczas używania urządzenia zasilanego

prądem na zewnątrz korzystaj z przedłużacza

przeznaczonego do użytku na zewnątrz.

Korzystania z przedłużacza przeznaczonego do

użytku na zewnątrz zmniejsza niebezpieczeństwo

porażenia prądem.

9. Jeżeli nie możesz uniknąć używania urządzenia

zasilanego prądem w mokrym miejscu, korzystaj

ze zwarciowego przerywacza obwodu.

Korzystanie ze zwarciowego przerywacza obwodu

ogranicza niebezpieczeństwo porażenia prądem.

Bezpieczeństwo osobiste

10. Podczas pracy z urządzeniem zasilanym prądem

zachowuj czujność, uważaj, co robisz, i

zachowuj zdrowy rozsądek. Nie używaj

urządzeń zasilanych prądem, kiedy jesteś

zmęczony lub pod wpływem narkotyków,

alkoholu lub lekarstw. Chwila nieuwagi podczas

obsługi urządzenia zasilanego prądem może

doprowadzić do poważnych obrażeń.

11. Używaj osobistego wyposażenia ochronnego.

Zawsze zakładaj osłonę oczu. Wyposażenia

ochronne, takie jak maska przeciwpyłowa, obuwie z

podeszwą antypoślizgową, kask lub osłona uszu,

używane w wymagających tego sytuacjach, może

zapobiec obrażeniom osobistym.

12. Unikaj przypadkowego włączenia urządzenia.

Przed podłączeniem do źródła zasilania lub

zestawu akumulatorowego, podnoszeniem lub

przenoszeniem urządzenia upewnij się, czy

włącznik znajduje się w położeniu wyłączonym.

Przenoszenie urządzenia z palcem na włączniku lub

podłączanie do zasilania z włączonym włącznikiem

prowokuje wypadki.

13. Przed włączeniem urządzenia zasilanego

prądem zdejmij z niego wszelkie klucze do

regulacji. Pozostawienie klucza założonego na

obracającą się część urządzenia zasilanego prądem

może spowodować obrażenia.

14. Nie pochylaj się zbyt silnie. Przez cały czas stój

pewnie i w równowadze. Pozwala to na lepsze

panowanie nad urządzeniem zasilanym prądem w

nieoczekiwanych sytuacjach.

15. Ubieraj się właściwie. Nie zakładaj luźnych

rzeczy lub biżuterii. Trzymaj włosy, ubranie i

rękawice z dala od ruchomych części. Luźne

ubranie, biżuteria i długie włosy mogą zaplątać się

w ruchome części.

16. Jeżeli posiadasz urządzenia do podłączenia

wyciągów pyłu, upewnij się, czy są one

podłączone i prawidłowo używane. Korzystanie z

wyciągów pyłu może ograniczyć zagrożenia

powodowane przez pył.

Korzystanie i dbanie o urządzenia zasilane prądem

17. Nie przeciążaj urządzeń zasilanych prądem.

Korzystaj z urządzeń przeznaczonych do

wykonywania danej pracy. Właściwe urządzenie

zasilane prądem wykona pracę lepiej i bezpieczniej,

kiedy będzie używane w tempie, na jakie zostało

zaprojektowane.

18. Nie używaj urządzenia zasilanego prądem, jeżeli

nie można go włączyć i wyłączyć włącznikiem.

Wszelkie urządzenia zasilane prądem, których nie

można kontrolować włącznikiem są niebezpieczne i

muszą być naprawione.

19. Przed wykonywaniem wszelkich regulacji,

wymianą wyposażenia lub przechowywaniem

urządzenia zasilanego prądem odłącz wtyczkę

od źródła zasilania lub odłącz akumulator. Ta ki

środek zapobiegawczy zmniejsza

niebezpieczeństwo przypadkowego uruchomienia

urządzenia.

20. Przechowuj nie używane urządzenia zasilane

prądem poza zasięgiem dzieci i nie pozwalaj,

aby obsługiwały je osoby nie zaznajomione z

nimi lub niniejszą instrukcją obsługi. Urządzenia

zasilane prądem w rękach nie przeszkolonych osób

są niebezpieczne.

21. Konserwuj urządzenia zasilane prądem.

Sprawdzaj, czy ruchome części są prawidłowo

ustawione i nie blokują się, czy części nie są

pęknięte i czy nie zachodzą inne warunki

mogące mieć wpływ na pracę urządzenia

zasilanego prądem. Jeżeli urządzenie zasilane

prądem będzie uszkodzone, napraw je przed

użyciem. Źle utrzymane urządzenia zasilane

prądem powodują wiele wypadków.

22. Urządzenia tnące powinny być czyste i

naostrzone. Właściwie utrzymane urządzenia tnące

z naostrzonymi ostrzami nie zakleszczają się tak

łatwo i można nad nimi łatwiej panować.

23. Używaj wyposażenia, końcówek roboczych itp.

urządzeń zasilanych prądem zgodnie z niniejszą

instrukcją obsługi, biorąc pod uwagę warunki

pracy i wykonywane zadanie. Używanie urządzeń

zasilanych prądem do prac, do których nie są one

przeznaczone, może doprowadzić do

niebezpiecznych sytuacji.

Serwis

24. Serwis urządzeń zasilanych prądem powinien

być wykonywany przez wykwalifikowane osoby i

przy użyciu wyłącznie jednakowych części

zamiennych. Zapewni to zachowanie

bezpieczeństwa pracy z urządzeniem zasilanym

prądem.

20

Page 21

25. Postępuj zgodnie z zaleceniami dotyczącymi

smarowania i wymiany wyposażenia.

26. Uchwyty powinny być suche, czyste i nie pokryte

olejem lub smarem.

SZCZEGÓŁOWE ZASADY BEZPIECZEŃSTWA

NIE pozwól, aby poczucie pewności i znajomości

urządzenia (uzyskane w wyniku wielokrotnego

używania) zastąpiły ścisłe przestrzeganie zasad

bezpiecznej pracy z wyrzynarką. Jeżeli to urządzenie

zasilane prądem będzie używane w sposób

niebezpieczny lub nieprawidłowy, może dojść do

poważnych obrażeń.

1. Podczas wykonywania prac, w trakcie których

urządzenie tnące może zetknąć się z ukrytymi

przewodami elektrycznymi lub własnym kablem,

trzymaj urządzenie zasilane prądem za

izolowane powierzchnie uchwytu. Zetknięcie się

z przewodem elektrycznym pod napięciem może

spowodować, że odsłonięte metalowe części

urządzenia znajdą się również pod napięciem,

co może doprowadzić do porażenia prądem

operatora.

2. Używaj zacisków lub innych sposobów, aby

przymocować i podeprzeć obrabiany przedmiot

na stabilnej podstawie. Jeżeli obrabiany

przedmiot będzie trzymany ręką lub

przeciskanie ciałem, będzie on niestabilny i

może dojść do utraty kontroli nad nim.

3. Zawsze używaj okularów ochronnych lub gogli.

Zwykłe okulary lub okulary słoneczne NIE są

okularami ochronnymi.

4. Unikaj przecinania gwoździ. Przed

przystąpieniem do pracy sprawdź obrabiany

przedmiot i usuń wszystkie gwoździe.

5. Nie przecinaj zbyt dużych przedmiotów.

6. Przed przecinaniem sprawdź, czy pod

obrabianym przedmiotem znajduje się wolna

przestrzeń, aby brzeszczot nie uderzył w

podłogę, stół warsztatowy itp.

7. Trzymaj urządzenie pewnie.

8. Upewnij się, czy przewód nie znajduje się na

drodze ani na linii cięcia.

9. Trzymaj ręce z daleka od ruchomych części.

10. Nie oddalaj się od pracującego urządzenia.

Obsługuj urządzenie tylko wtedy, gdy trzymasz

je w ręce.

11. Przed wyjęciem brzeszczotu z przecinanego

przedmiotu zawsze wyłącz urządzenie i

zaczekaj, aż brzeszczot zatrzyma się całkowicie.

12. Nie dotykaj brzeszczotu ani przecinanego

przedmiotu natychmiast po wycinaniu; mogą

one być bardzo gorące i poparzyć skórę.

13. Nie uruchamiaj urządzenia bez potrzeby bez

obciążenia.

14. Niektóre materiały zawierają związki chemiczne,

które mogą być trujące. Podejmij środki

ostrożności, aby zapobiec wdychaniu pyłu i ich

kontaktowi ze skórą. Stosuj się do środków

bezpieczeństwa podanych przez producenta.

15. Zawsze używaj maski przeciwpyłowej/

respiratora właściwego dla obrabianego

materiału i wykonywanej pracy.

ZACHOWAJ TĘ INSTRUKCJĘ.

OPIS DZIAŁANIA

OSTRZEŻENIE:

• Przed regulacją lub sprawdzaniem działania urządzenia zawsze upewnij się, czy jest ono wyłączone i odłączone od

zasilania.

Wybór sposobu cięcia (Dla modeli 4328/4329) (Rys. 1)

Urządzenie może ciąć wzdłuż okręgu lub linii prostej (do góry i dołu). W trakcie cięcia wzdłuż okręgu, podczas

przesuwu brzeszczot jest również wysuwany do przodu, co bardzo zwiększa prędkość cięcia.

Aby zmienić sposób cięcia, obróć dźwignię zmiany sposobu cięcia do położenia odpowiadającego żądanemu

sposobowi.

Zapoznaj się z tabelą, aby wybrać właściwy sposób cięcia.

Położenie Sposób cięcia Zastosowanie

0 Cięcie wzdłuż linii prostej

I Cięcie wzdłuż łuku o małym promieniu Do cięcia stali miękkiej, aluminium i twardego drewna.

II Cięcie wzdłuż łuku o średnim promieniu

III Cięcie wzdłuż łuku o dużym promieniu Do szybkiego cięcia drewna i sklejki.

Do cięcia stali miękkiej, nierdzewnej i plastiku

Do równego cięcia drewna i sklejki.

Do cięcia drewna i sklejki.

Do szybkiego cięcia aluminium i stali miękkiej.

Działanie włącznika (Rys. 2)

OSTRZEŻENIE:

• Przed podłączeniem urządzenia do zasilania zawsze sprawdź, czy spust włącznika działa poprawnie i powraca do

położenia “OFF” po zwolnieniu.

Aby włączyć urządzenie, pociągnij za spust włącznika. Aby je zatrzymać, zwolnij spust.

W celu uzyskania pracy ciągłej pociągnij za spust, a następnie wciśnij przycisk pracy ciągłej.

Aby zatrzymać urządzenie pracujące w sposób ciągły, pociągnij do końca za spust, a następnie zwolnij go.

21

Page 22

Pokrętło regulacji prędkości

(Dla modeli 4327/4328/4329) (Rys. 3)

Prędkość urządzenia może być dowolnie regulowana

pomiędzy 500 a 3100 przesuwów na minutę poprzez

obracanie pokrętłem regulacyjnym. Wyższą prędkość

uzyskuje się obracając pokrętło w stronę liczby 6; niższą

prędkość obracając je w stronę liczby 1.

Aby wybrać właściwą prędkość dla przecinanego

przedmiotu, posłuż się poniższą tabelą. Właściwa

prędkość może jednak różnić się w zależności od

rodzaju i grubości przecinanego przedmiotu. Ogólnie

mówiąc, wyższe prędkości pozwalają na szybsze cięcie,

ale skracają żywotność brzeszczotu.

Przecinany przedmiot

Drewno 5– 6

Stal miękka 3– 6

Stal nier dzewna 3–4

Aluminium 3– 6

Plastik 1–4

OSTRZEŻENIE:

• Jeżeli urządzenie będzie pracowało z niską prędkością

przez dłuższy czas, silnik może zostać przeciążony i

przegrzany.

• Pokrętło regulacji prędkości może być obracane tylko

do 6 i z powrotem do 1. Nie obracaj go na siłę poza 6

lub 1, ponieważ funkcja regulacji prędkości może

przestać działać.

Liczba na pokrętle

regulacyjnym

SKŁADANIE

OSTRZEŻENIE:

• Przed przystąpieniem do jakiejkolwiek pracy nad

urządzeniem zawsze upewnij się, czy jest ono

wyłączone i odłączone od zasilania.

Zakładanie lub wyjmowanie brzeszczotu

(Rys. 4 i 5)

OSTRZEŻENIE:

• Zawsze oczyść wióry i ciała obce przylegające do

brzeszczotu i jego uchwytu. Niestosowanie się do tego

zalecenia może doprowadzić do niewystarczającego

zamocowania brzeszczotu i poważnego zranienia.

• Nie dotykaj brzeszczotu ani przecinanego przedmiotu

natychmiast po przecinaniu; mogą one być bardzo

gorące i poparzyć skórę.

• Zawsze zamocuj pewnie brzeszczot. Niewystarczające

dokręcenie brzeszczotu może spowodować jego

pęknięcie lub poważne obrażenia osobiste.

• Używaj wyłącznie brzeszczotów typu B. Używanie

brzeszczotów innych niż typu B powoduje

niewystarczające dokręcenie brzeszczotu i prowadzi

do poważnych obrażeń osobistych.

Aby założyć brzeszczot, odkręć śrubę na uchwycie

brzeszczotu przeciwnie do ruchu wskazówek zegara

kluczem sześciokątnym.

Włóż brzeszczot do uchwytu brzeszczotu najgłębiej jak

to jest możliwe i tak, aby zęby były zwrócone do przodu.

Sprawdź, czy grzbiet brzeszczotu wszedł w wałek.

Następnie zakręć śrubę zgodnie z ruchem wskazówek

zegara, aby zamocować brzeszczot.

Aby zdjąć brzeszczot, wykonaj procedurę zakładania w

odwrotnej kolejności.

UWAGA:

• Smaruj wałek od czasu do czasu.

Przechowywanie klucza sześciokątnego (Rys. 6)

Kiedy nie używasz klucza sześciokątnego, przechowuj

go w sposób pokazany na rysunku, aby nie zgubić go.

Regulacja wałka (Dla modeli 4326/4327) (Rys. 7)

Odkręć kluczem sześciokątnym śrubę z tyłu podstawy

urządzenia. Przesuń ustalacz tak, aby wałek stykał się

lekko z brzeszczotem. Następnie zakręć śrubę, aby

zamocować podstawę urządzenia i ustalacz.

UWAGA:

• Smaruj wałek od czasu do czasu.

Pokrywa przeciwpyłowa (Rys. 8)

OSTRZEŻENIE:

• Zawsze noś okulary ochronne, nawet kiedy

obsługujesz urządzenie z obniżoną pokrywą

przeciwpyłową.

Obniż pokrywę przeciwpyłową, aby zapobiec

odskakiwaniu wiórów. Jednak podczas wykonywania

ciąć ukośnych podnieś ją całkowicie.

POSTĘPOWANIE

OSTRZEŻENIE:

• Zawsze utrzymuj podstawę urządzenia na równi z

powierzchnią przecinanego przedmiotu.

Niestosowanie się do tego zalecenia może

spowodować złamanie brzeszczotu, prowadząc do

poważnego zranienia.

• Podczas wycinania krzywych i spiral, przesuwaj

urządzenie do przodu bardzo wolno. Wywieranie

silnego nacisku na urządzenie może dać w rezultacie

ukośną powierzchnię cięcia i spowodować pęknięcie

brzeszczotu.

Włącz urządzenie trzymając je tak, aby brzeszczot nie

stykał się z obrabianym przedmiotem i zaczekaj, aż

osiągnie on pełną prędkość. Następnie ustaw podstawę

urządzenia płasko na przecinanym przedmiocie i

delikatnie przesuwaj urządzenie do przodu wzdłuż

uprzednio zaznaczonej linii cięcia. (Rys. 9)

Cięcie ukośne

OSTRZEŻENIE:

• Przed pochylaniem podstawy urządzenia zawsze

upewnij się, czy jest ono wyłączone i odłączone od

zasilania.

• Przed cięciem ukośnym pod kątem pionowym podnieś

całkowicie osłonę przeciwpyłową.

Dzięki pochyleniu podstawy urządzenia można

wykonywać cięcie ukośne pod dowolnym kątem

pionowym od 0˚ do 45˚ (w prawo lub w lewo).

(Rys. 10)

Odkręć śrubę na grzbiecie podstawy kluczem

sześciokątnym. Przesuń podstawę tak, aby śruba

znalazła się w środku krzyżowej szczeliny w podstawie.

(Rys. 11)

Pochyl podstawę, aż osiągnie ona żądany kąt pionowy.

Kąt cięcia ukośnego jest pokazany na skali na brzegu

obudowy silnika. Następnie zakręć śrubę, aby

zamocować podstawę. (Rys. 12)

22

Page 23

Cięcia na powierzchni przedniej (Rys. 13)

Odkręć śrubę na grzbiecie podstawy urządzenia

kluczem sześciokątnym, a następnie przesuń podstawę

do końca do tyłu. Następnie zakręć śrubę, aby

zamocować podstawę.

Wycięcia

Wycięcia mogą być wykonywane jedną z dwóch metod

A lub B.

A) Wiercenie otworu początkowego

W celu wykonywania wycięć wewnętrznych, bez

początkowego cięcia rozpoczynającego się od

brzegu, wywierć najpierw otwór początkowy o

średnicy ponad 12 mm. Aby rozpocząć wycinanie,

włóż brzeszczot do tego otworu i chwyć pewnie

urządzenie. (Rys. 14)

B) Wycinanie z zagłębianiem

Jeżeli postępujesz dokładnie według poniższych

wskazówek, nie musisz wiercić otworu

początkowego ani robić początkowego cięcia.

1. Pochyl urządzenie do przodu, opierając je na

przednim brzegu podstawy, z wierzchołkiem

brzeszczotu tuż nad powierzchnią obrabianego

przedmiotu. (Rys.15)

2. Naciśnij silnie na urządzenie, aby przedni brzeg

podstawy nie przesunął się, kiedy włączysz

urządzenie, a następnie delikatnie i powoli obniż

tył urządzenia.

3. Kiedy brzeszczot będzie wycinał otwór w

obrabianym przedmiocie, powoli obniżaj

podstawę urządzenia do powierzchni obrabianego

przedmiotu.

4. Zakończ wycinanie w normalny sposób.

Wykańczanie brzegów (Rys.16)

W celu przycinania brzegów lub nieznacznego

przycinania do wymiarów, przesuwaj brzeszczot lekko

wzdłuż brzegów cięcia.

Cięcie metalu

Podczas cięcia metalu zawsze używaj odpowiedniego

chłodziwa (cieczy chłodząco-smarującej).

Niestosowanie się do tego zalecenia powoduje szybkie

zużycie brzeszczotu. Zamiast używania chłodziwa,

można nasmarować spodnią część obrabianego

przedmiotu.

Wyciąganie pyłu (Rys. 17)

Podłączając urządzenie do odkurzacza Makita, można

uzyskać czyste cięcie. Włóż wąż odkurzacza do otworu

z tyłu urządzenia. Przed przystąpieniem do pracy obniż

pokrywę przeciwpyłową.

UWAGA:

• Nie można wyciągać pyłu podczas cięcia pod kątem

pionowym.

Prowadnica (wyposażenie dodatkowe)

OSTRZEŻENIE:

• Przed zakładaniem lub zdejmowaniem wyposażenia

zawsze upewnij się, czy urządzenie jest wyłączone i

odłączone od zasilania.

1) Cięcie proste (Rys. 18, 19, 20 i 21)

Podczas wielokrotnego przycinania przedmiotów o

szerokości 160 mm lub mniejszej, stosowanie

prowadnicy zapewnia szybkie, równe i proste cięcie.

Aby założyć prowadnicę, włóż ją do prostokątnego

otworu z boku podstawy urządzenia wodzikiem

skierowanym w dół. Przesuń prowadnicę do żądanej

szerokości cięcia, a następnie zakręć śrubę, aby ją

zamocować.

2) Cięcie wzdłuż okręgu (Rys. 22, 23, 24 i 25)

Podczas wycinania okręgów lub łuków o promieniu

170 mm lub mniejszym, załóż prowadnicę w

następujący sposób.

Włóż prowadnicę do prostokątnego otworu z boku

podstawy urządzenia wodzikiem skierowanym w

górę. Przełóż szpilę prowadnicy do okręgów przez

jeden z dwóch otworów w wodziku. Nakręć

nagwintowaną gałkę na szpilę, aby ją zamocować.

Następnie przesuń prowadnicę do żądanego

promienia cięcia i zakręć śrubę, aby unieruchomić ją

w tym miejscu. Przesuń wtedy podstawę urządzenia

do końca do przodu.

UWAGA:

• Podczas wycinania okręgów lub łuków zawsze

używaj brzeszczotów nr B-17, B-18, B-26 lub

B-27.

Urządzenie antyodpryskowe dla stalowej

podstawy (wyposażenie dodatkowe) (Rys. 26)

Aby uzyskać cięcie bez odprysków, można skorzystać z

urządzenia antyodpryskowego. Aby założyć urządzenie

antyodpryskowe, przesuń podstawę całkowicie do

przodu i włóż urządzenie pomiędzy dwa występy w

podstawie.

UWAGA:

• Urządzenia antyodpryskowego nie można używać