Przenośna pilarka taśmowa

̚ךÞþ¹Þ˛Č=ÝšÞ²þ₣Þ˛Č=−¦Ý˛

2106

Portable Band Saw

Instruction Manual

Tragbare Bandsäge

Betriebsanleitung

Instrukcja obsługi

ÊÞ¹²×³ð¾¦ć=−þ=Ćð¹−ݳ˛²˛¾¦¦

1

2

3

12

4

6

7

5

8

34

10

8

9

7

13

12

7

10

14

9

8

56

15

13

7

78

2

16

7

910

9

17

18

19

11 12

20 21

13

3

ENGLISH

Explanation of general view

1. Switch trigger

2. Lock button

3. Speed change switch

4. Blade tightening lever

5. Protrusion

6. Bearing

7. Blade

8. Blade guide

9. Wheel

10. Blade guard

11. Pu sh

12. Hex wrench

13. Stopper plate

14. Bolt

15. Triangular rule

16. Cutting wax

17. Tire

18. Lip

19. Limit mark

20. Screwdriver

21. Brush holder cap

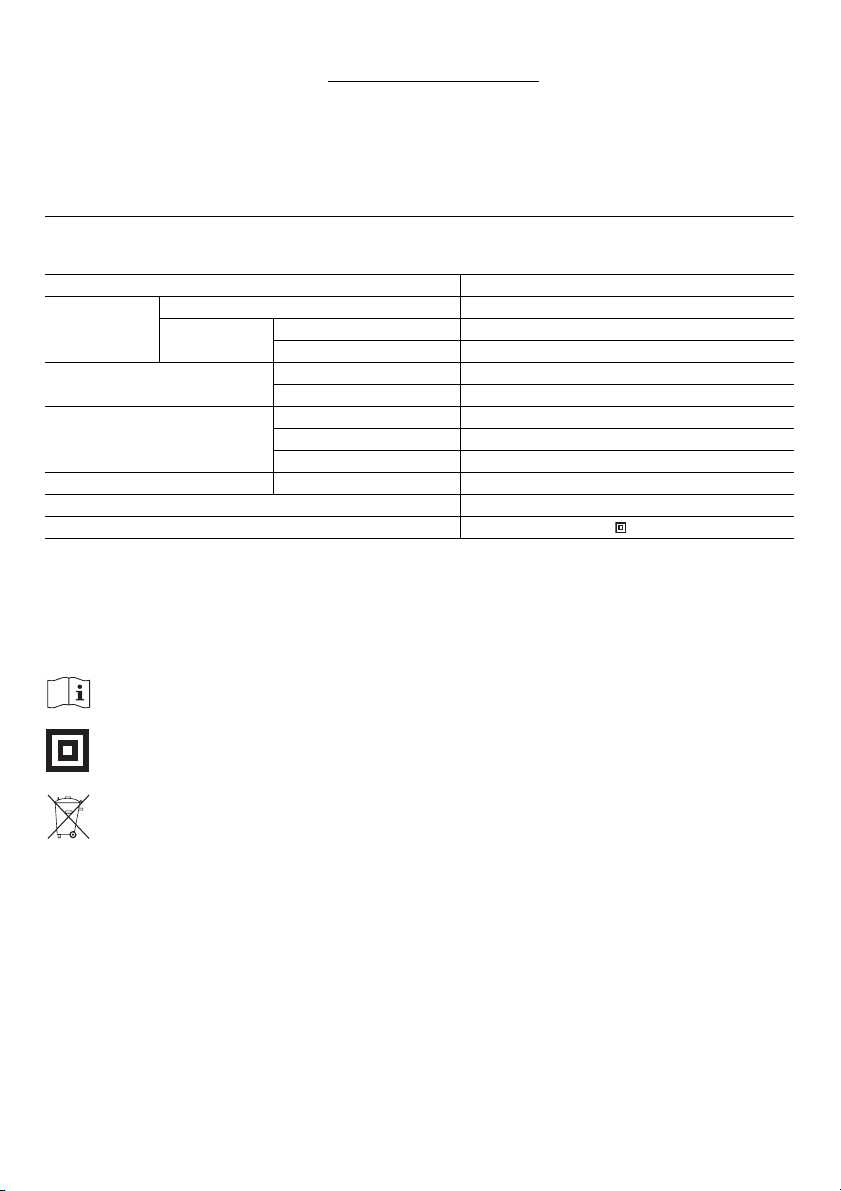

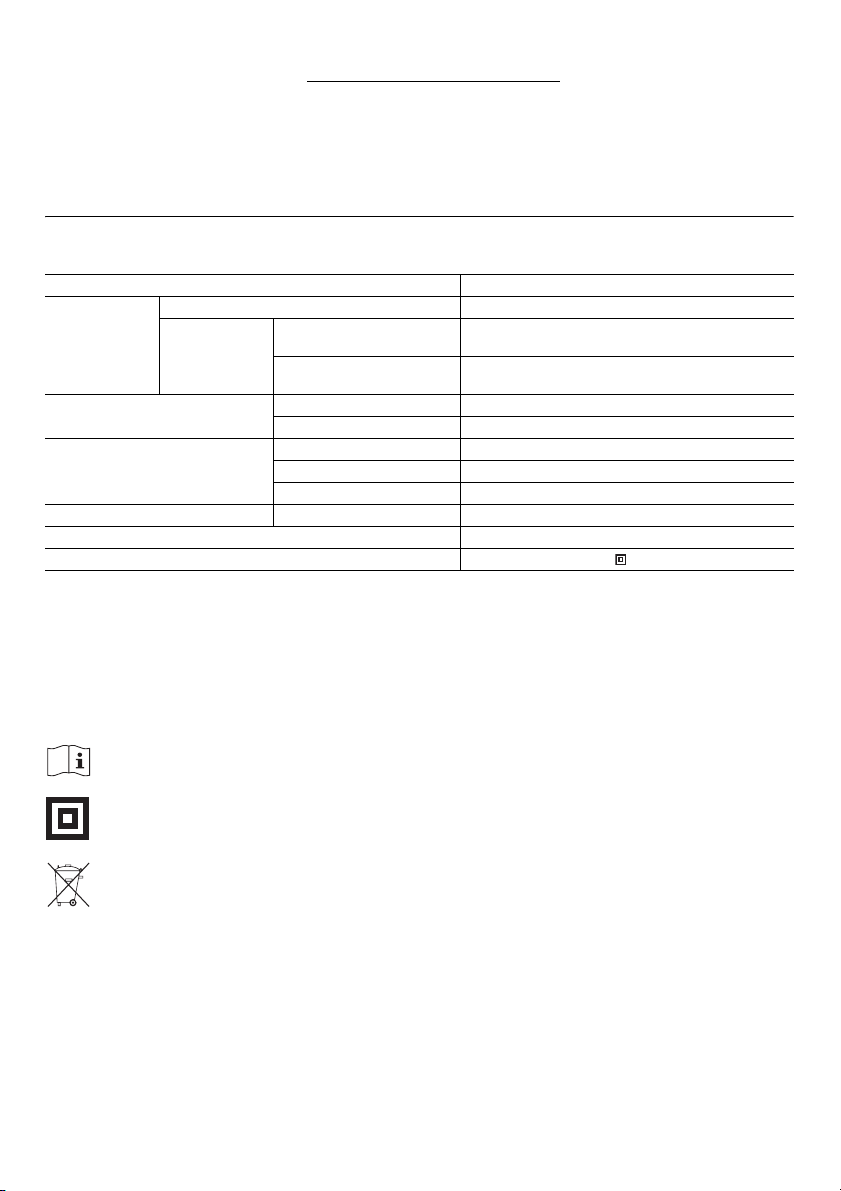

SPECIFICATIONS

Model 2106

Max. cutting

capacity

Blade speed (min

Overall dimensions H x W x L 235 mm x 230 mm x 500 mm

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

Symbols

The following show the symbols used for the tool. Be sure

that you understand their meaning before use.

............... Read instruction manual.

................ DOUBLE INSULATION

Blade size

Rectangular

workpiece

Round workpiece 115 mm dia.

Without optional stand 115 mm x 115 mm

With optional stand 75 mm x 110 mm

-1

)

Net weight 5.5 kg

Safety class /II

High 80 m

Low 60 m

Length 1,140 mm

Width 13 mm

Thickness 0.5 mm

Intended use

The tool is intended for cutting in wood, plastic and ferrous materials.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Only for EU countries

Do not dispose of electric equipment together with house-

hold waste material!

In observance of European Directive 2002/96/EC on

waste electrical and electronic equipment and its implementation in accordance with national law, electric equipment that have reached the end of their life must be

collected separately and returned to an environmentally

compatible recycling facility.

4

SAFETY INSTRUCTIONS

WARNING:

When using electric tools, basic safety precautions,

including the following, should always be followed to

reduce the risk of fire, electric shock and personal

injury. Read all these instructions before operating

this product and save these instructions.

For safe operations:

1. Keep work area clean.

Cluttered areas and benches invite injuries.

2. Consider work area environment.

Do not expose power tools to rain. Do not use power

tools in damp or wet locations. Keep work area well lit.

Do not use power tools where there is risk to cause

fire or explosion.

3. Guard against electric shock.

Avoid body contact with earthed or grounded surfaces

(e.g. pipes, radiators, ranges, refrigerators).

4. Keep children away.

Do not let visitors touch the tool or extension cord. All

visitors should be kept away from work area.

5. Store idle tools.

When not in use, tools should be stored in a dry, high

or locked up place, out of reach of children.

6. Do not force the tool.

It will do the job better and safer at the rate for which it

was intended.

7. Use the right tool.

Do not force small tools or attachments to do the job of

a heavy duty tool. Do not use tools for purposes not

intended; for example, do not use circular saws to cut

tree limbs or logs.

8. Dress properly.

Do not wear loose clothing or jewellery, they can be

caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

Wear protecting hair covering to contain long hair.

9. Use safety glasses and hearing protection.

Also use face or dust mask if the cutting operation is

dusty.

10. Connect dust extraction equipment.

If devices are provided for the connection of dust

extraction and collection facilities ensure these are

connected and properly used.

11. Do not abuse the cord.

Never carry the tool by the cord or yank it to disconnect it from the socket. Keep the cord away from heat,

oil and sharp edges.

12. Secure work.

Use clamps or a vice to hold the work. It is safer than

using your hand and it frees both hands to operate the

tool.

13. Do not overreach.

Keep proper footing and balance at all times.

14. Maintain tools with care.

Keep cutting tools sharp and clean for better and safer

performance. Follow instructions for lubrication and

changing accessories. Inspect tool cord periodically

and if damaged have it repaired by an authorized service facility. Inspect extension cords periodically and

replace, if damaged. Keep handles dry, clean and free

from oil and grease.

15. Disconnect tools.

When not in use, before servicing and when changing

accessories such as blades, bits and cutters.

16. Remove adjusting keys and wrenches.

Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool before

turning it on.

17. Avoid unintentional starting.

Do not carry a plugged-in tool with a finger on the

switch. Ensure switch is off when plugging in.

18. Use outdoor extension leads.

When tool is used outdoors, use only extension cords

intended for outdoor use.

19. Stay alert.

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

20. Check damaged parts.

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment of moving

parts, free running of moving parts, breakage of parts,

mounting and any other conditions that may affect its

operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service center unless otherwise indicated in this

instruction manual. Have defective switches replaced

by an authorized service facility. Do not use the tool if

the switch does not turn it on and off.

21. Warning.

The use of any accessory or attachment, other than

those recommended in this instruction manual or the

catalog, may present a risk of personal injury.

22. Have your tool repaired by a qualified person.

This electric tool is in accordance with the relevant

safety requirements. Repairs should only be carried

out by qualified persons using original spare parts,

otherwise this may result in considerable danger to

the user.

ADDITIONAL SAFETY RULES

FOR TOOL

1. Use only blades which are 1,140 mm long, 13 mm

wide, and 0.5 mm thick.

2. Check the blade carefully for cracks or damage

before operation. Replace cracked or damaged

blade immediately.

3. Secure the workpiece firmly. When cutting a bundle of workpieces, be sure that all workpieces are

secured together firmly before cutting.

4. Cutting workpieces covered with oil can cause the

blade to come off unexpectedly. Wipe off all

excess oil from workpieces before cutting.

5. Never use the cutting oil as a cutting lubricant.

Use only Makita cutting wax.

6. Do not wear gloves during operation.

7. Hold the tool firmly with both hands.

8. Keep hands away from rotating parts.

5

9. When cutting metal, be cautious of hot flying

chips.

10. Do not leave the tool running unattended.

11. Do not touch the blade or workpiece immediately

after operation; they are extremely hot and could

burn your skin.

SAVE THESE INSTRUCTIONS

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Switch action (Fig. 1)

CAUTION:

• Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

To start the tool, simply pull the switch trigger. Release the

switch trigger to stop.

For continuous operation, pull the switch trigger and then

push in the lock button.

To stop the tool from the locked position, pull the switch

trigger fully, then release it.

Speed change (Fig. 2)

To change the tool speed, press the “H” side of the speed

change switch for high speed or the “L” side for low

speed.

CAUTION:

• Do not use the speed change switch while the tool is

running. The tool may be damaged.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing or removing the blade

CAUTION:

• Oil on the blade can cause the blade to slip or come off

unexpectedly. Wipe off all excess oil with a cloth before

installing the blade.

• Use caution when handling the blade so that you are

not cut by the sharp edge of the blade teeth.

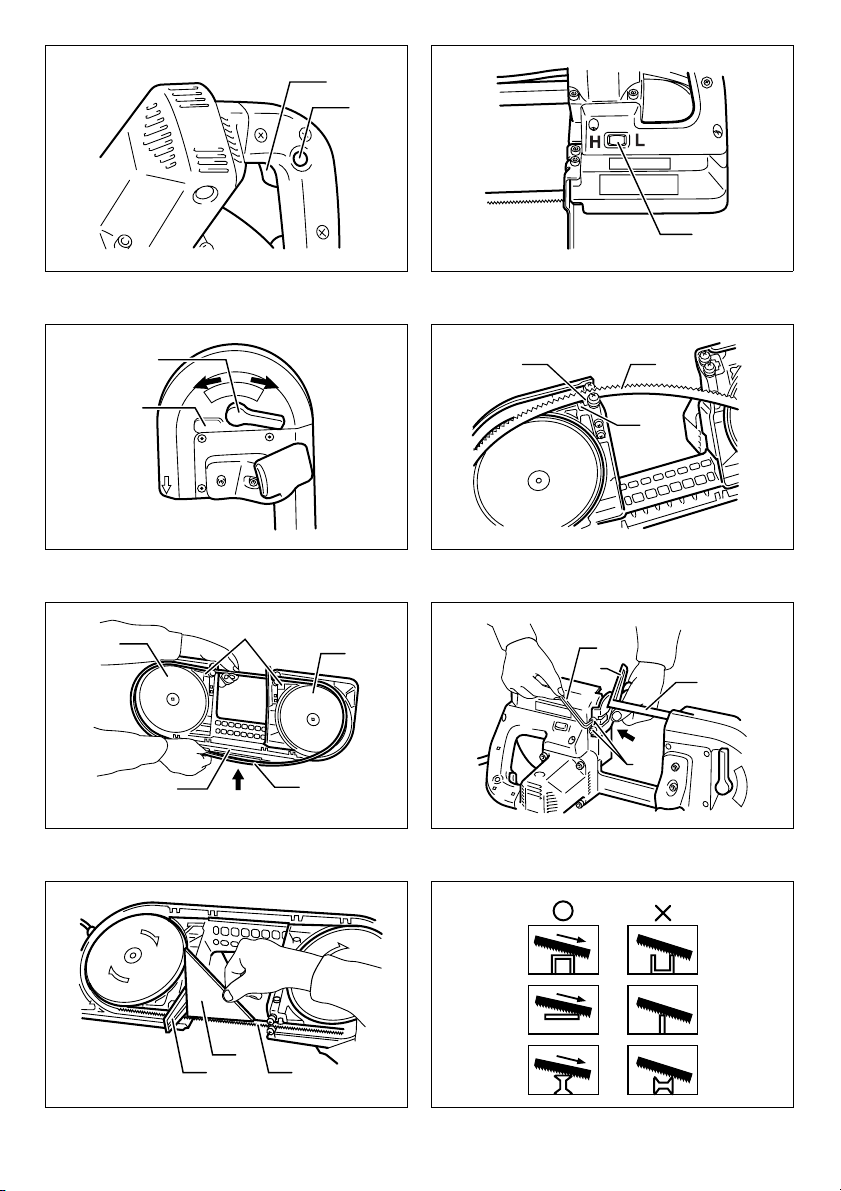

Turn the blade tightening lever clockwise until it hits

against the protrusion on the frame. Match the direction of

the arrow on the blade to that of the arrow on the wheels.

(Fig. 3)

Insert the blade between the bearings of one blade guide

first and then into the other blade guide. The blade back

should contact the bearings in the lower portion of the

blade guides. (Fig. 4)

Position the blade around the wheels and insert the other

side of the blade within the blade guard until the blade

back contacts the bottom of the blade guard.

Hold the blade in place and turn the blade-tightening lever

counterclockwise until it hits against the protrusion on the

frame. This places proper tension on the blade. Make

sure that the blade is correctly positioned within the blade

guard and around the wheels.

Start and stop the tool two or three times to make sure

that the blade runs properly on the wheels. (Fig. 5)

CAUTION:

• While making sure that the blade runs on the wheels

properly, keep your body away from the blade area.

To remove the blade, follow the installation procedure in

reverse.

CAUTION:

• When turning the blade tightening lever clockwise to

release the tension on the blade, the blade come off

unexpectedly. Be careful.

Installing stopper plate

This tool is shipped from the factory without the stopper

plate installed. Install the stopper plate as follows.

Install the stopper plate on the frame so that the blade can

run through the slot in the stopper plate. While pressing

the stopper plate against the frame, secure the stopper

plate with the bolts using the hex wrench. (Fig. 6)

Use the triangular rule to make sure that the side of the

blade is square with the side of the stopper plate. If not

square, loosen the bolts securing the stopper plate and

adjust the stopper plate accordingly. (Fig. 7)

OPERATION

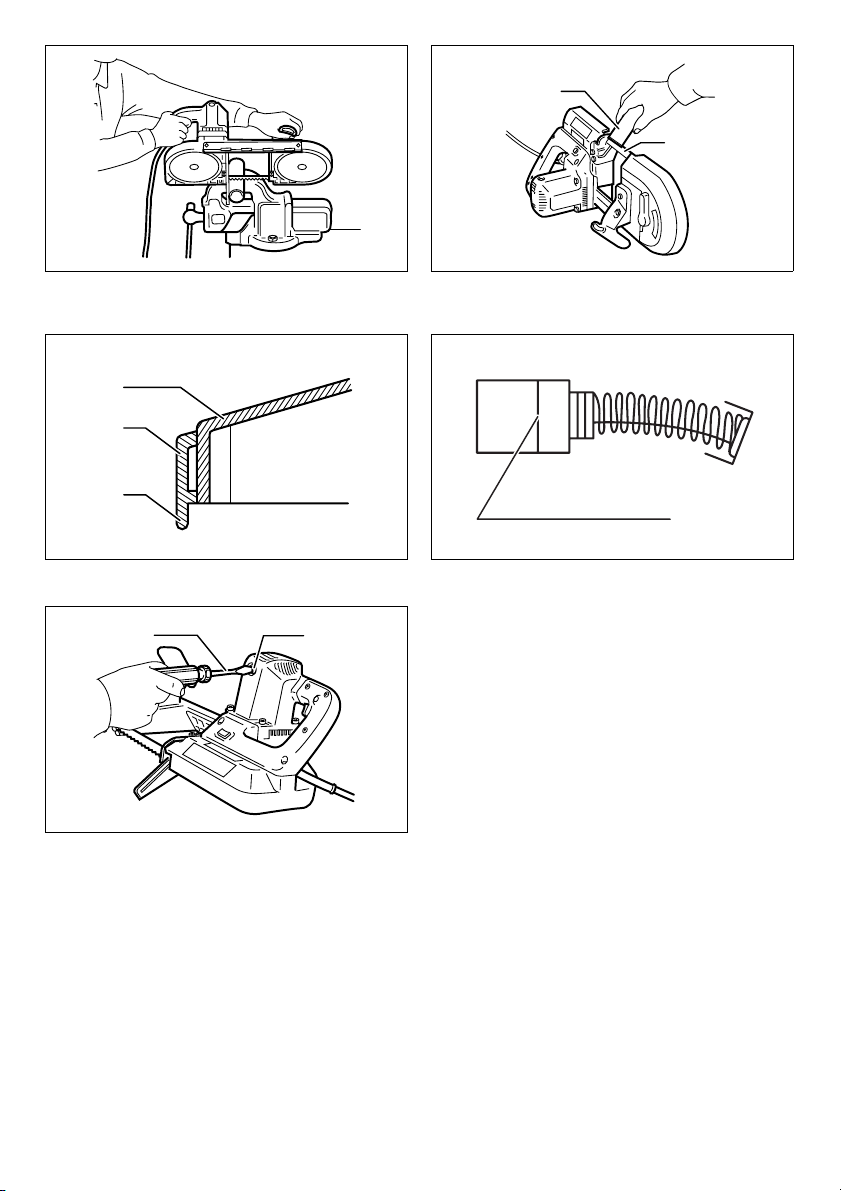

It is important to keep at least two teeth in the cut. Select

the proper cutting position for your workpiece by referring

to the figure. (Fig. 8)

Hold the tool as shown in the figure with the stopper plate

contacting the workpiece and the blade clear of the workpiece.

Turn the tool on and wait until the blade attains full speed.

Gently lower the blade into the cut. The weight of the tool

or slightly pressing the tool will supply adequate pressure

for the cutting. Do not force the tool.

As you reach the end of a cut, release pressure and, without actually raising the tool, lift it slightly so that it will not

fall against the workpiece. (Fig. 9)

CAUTION:

• Applying excessive pressure to the tool or twisting of

the blade may cause bevel cutting or damage to the

blade.

• When not using the tool for a long period of time,

remove the blade from the tool.

Cutting lubricant

When cutting metals, use Makita cutting wax as a cutting

lubricant. To apply the cutting wax to the blade teeth, start

6

the tool and cut in to the cutting wax as shown in the figure. (Fig. 10)

CAUTION:

• Never use cutting oil or apply excessive amount of wax

to the blade. It may cause the blade to slip or come off

unexpectedly.

• When cutting cast iron, do not use any cutting lubricant.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

Cleaning

After use, remove wax, chips and dust from the tool,

wheel tires and blade.

CAUTION:

• Never use solvents such as turpentine, gasoline, lacquer, etc. to clean plastic parts.

• Wax and chips on the tires may cause the blade to slip

and come off unexpectedly. Use a dry cloth to remove

wax and chips from the tires.

Replacing tires on wheels (Fig. 11)

When the blade slips or does not track properly because

of badly worn tires, or the lip of the tire on motor side gets

damaged, the tires should be replaced.

Replacing carbon brushes

Remove and check the carbon brushes regularly. Replace

when they wear down to the limit mark. Keep the carbon

brushes clean and free to slip in the holders. Both carbon

brushes should be replaced at the same time. Use only

identical carbon brushes. (Fig. 12)

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps. (Fig. 13)

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

For European countries only

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 92 dB (A)

sound power level: 105 dB (A)

– Wear ear protection. –

The typical weighted root mean square acceleration value

is not more than 2.5 m/s

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product

is in compliance with the following standards of standardized documents, HD400, EN50144, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336/EEC, 98/37/EC.

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes, Bucks MK15

8JD, ENGLAND

2

.

Yasuhiko Kanzaki CE 2005

Director

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Band saw blades

• Triangular rule

•Hex wrench 4

•Cutting wax

• Portable band saw stand

7

DEUTSCH

Erklärung der Gesamtdarstellung

1. Ein/Aus-Schalter

2. Arretiertaste

3. Drehzahlschalter

4. Sägeblatt-Spannhebel

5. Vorsprung

6. Lager

7. Sägeblatt

8. Blattführung

9. Rad

10. Blattschutz

11. Dr ück en

12. Sechskantschlüssel

13. Anschlagplatte

14. Bolzen

15. Einstelldreieck

16. Schneidwachs

17. Reifen

18. Lippe

19. Verschleißgrenze

20. Schraubendreher

21. Bürstenhalterkappe

TECHNISCHE ANGABEN

Modell 2106

Rundes Werkstück 115 mm Durchm.

Max. Schnitttiefe

Sägeblattgeschwindigkeit (min

Sägeblattgröße

Gesamtabmessungen H x B x L 235 mm x 230 mm x 500 mm

• Aufgrund unserer fortschreitenden Forschungen und Entwicklungen sind Änderungen an den hier wiedergegebenen

Angaben ohne Vorankündigung vorbehalten.

• Hinweis: Die Angaben können sich je nach Land unterscheiden.

Symbole

Im Folgenden sind die Symbole dargestellt, die im

Zusammenhang mit dem Werkzeug verwendet werden.

Es ist wichtig, dass Sie deren Bedeutung vor dem Einsatz

des Werkzeugs kennen.

....Lesen Sie die vorliegende Betriebsanleitung.

.....DOPPELISOLIERUNG

Rechteckiges

Werkstück

Nettogewicht 5,5 kg

Sicherheitsklasse /II

Ohne optional verwendbares

Mit optional verwendbarem

-1

)

Gestell

Gestell

Hoch 80 m

Niedrig 60 m

Länge 1.140 mm

Breite 13 mm

Stärke 0,5 mm

Vorgesehene Verwendung

Das Werkzeug wurde für das Sägen von Holz, Kunststoff

und Eisenmaterial entwickelt.

Stromversorgung

Das Gerät darf nur an Stromquellen mit der auf dem

Typenschild angegebenen Spannung und einphasigem

Wechselstrom betrieben werden. Aufgrund der

Doppelisolierung nach europäischem Standard kann es

auch an Steckdosen ohne Erdungskabel betrieben

werden.

115 mm x 115 mm

75 mm x 110 mm

Nur für EU-Länder

Werfen Sie Elektrowerkzeuge nicht in den Hausmüll!

Gemäss Europäischer Richtlinie 2002/96/EG über

Elektro- und Elektronik- Altgeräte und Umsetzung in

nationales Recht müssen verbrauchte Elektrowerkzeuge

getrennt gesammelt und einer umweltgerechten

Wiederverwertung zugeführt werden.

8

Loading...

Loading...