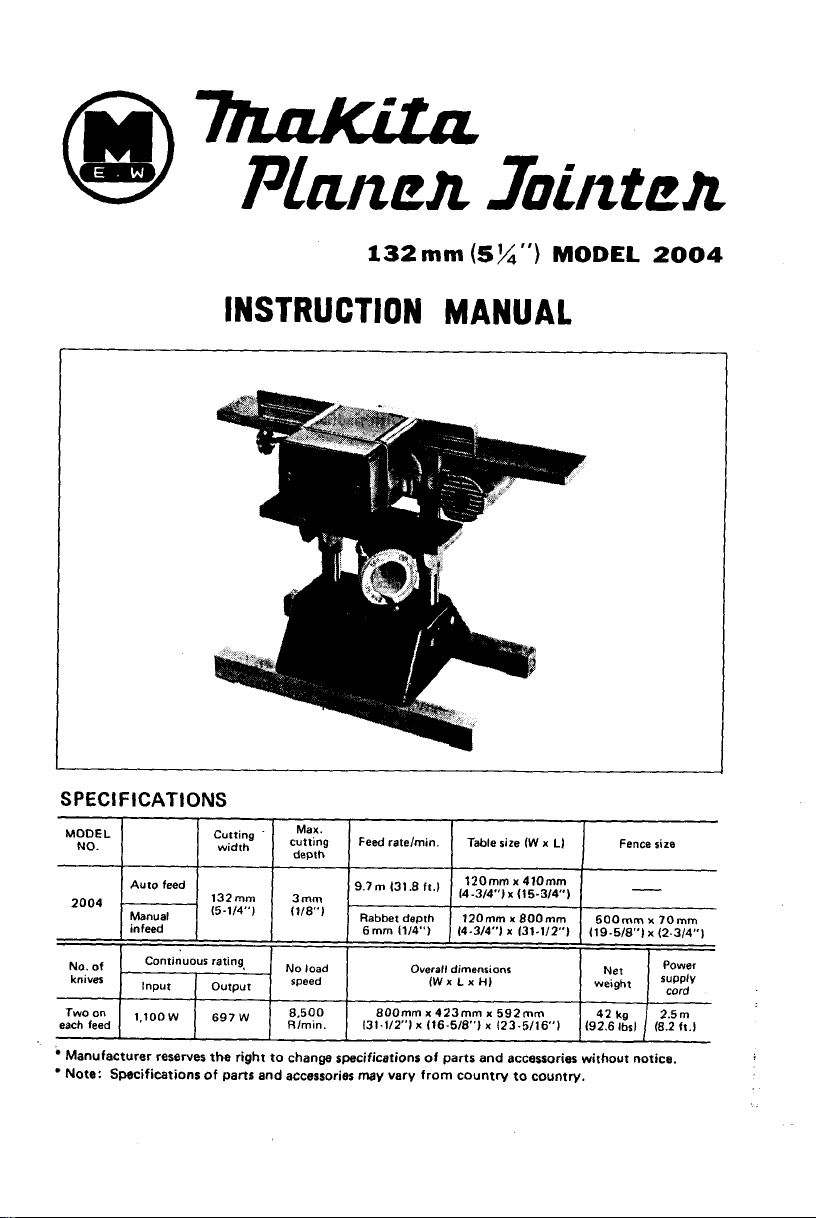

Page 1

132

mm

(5%")

MODEL

2004

MODEL

NO.

2004

No,

of

knives

Two

on

each feed

INSTRUCTION

width - czkg Feed ratelmin. Table size fW

Auto feed

~

Manual f5-1/4")

infeed

Continuour rating,

Input

'''0°

132" 3mm

Output

697

MANUAL

x

x

410"

x

8OOmm

x

131-1/2"1

L)

depth

9.7m

131'8ft') (4.3/4")~(15.3/4")

f118")

No

speed fWx

8.500 800mm

R/min. 131.1/2") X (16-5/8") x 123.5/16') (92.6

Rabbet depth l2Omm

6mm

1114"l

load Overall dimensions Power

120"

1444")

Lx

HI

x

423" x 592"

Fence size

-

500" x 70"

119-5/8") x (2-3/4")

ws"$),

42

kg

lbsl

SUPPk

cord

2.5m

18.2

ft.)

Page 2

BEFORE CONNECTING YOUR TOOL

TO

A

POWER SOURCE

Be

sure

you

have

read

all

GENERAL POWER TOOL SAFETY RULES

GENERAL SAFETY PRECAUTIONS

1.

KEEP GUARDS IN PLACE and

2.

REMOVE ADJUSTING KEYS AND WRENCHES.

that keys and adjusting wrenches are removed from tool before turning

3.

KEEP WORK AREA CLEAN. Cluttered areas

4.

AVOID DANGEROUS ENVIRONMENT. Don't

locations. Keep work

5.

KEEP CHILDREN AWAY. All visitors should

6.

MAKE WORKSHOP KID PROOF

ing starter keys.

7.

DON'T FORCE TOOL.

was designed.

8.

USE

RIGHT

TOOL. Don't force tool or attachment to do a job

for.

9.

WEAR PROPER APPAREL. No loose clothing or jewelry to get caught

parts. Rubberjoled footwear

10.

USE SAFETY GLASSES. Also

11.

SECURE WORK. Use clamps or a vise to hold work when practical.

using your hand and

12.

DON'T OVERREACH. Keep proper footing and balance

13.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

performance. Follow instructions for lubricating and changing accessories.

14.

DISCONNECT TOOLS before servicing; when changing accessories such

blades.

15.

AVOID ACCIDENTAL STARTING. Make sure switch

plugging in.

16.

USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The use

17.

NEVER STAND ON TOOL. Serious injury could occur

the cutting tool

18.

CHECK DAMAGED PARTS.

is

damaged should be carefully checked to ensure that

that

and perform

of moving parts, breakage of

affect

paired or replaced.

19.

PROPER GROUNDING. These tools should be grounded while in

the

operator from electric shock.

its

its

operation. A guard or other part that

area

it

frees both hands to operate

is

accidentally contacted.

intended function - check for alignment

in

working order.

Form habit of checking to

and

benches invite accidents.

use

power tools in damp or wet

well

lit.

-With

It

will do

the

is

recommended for best footing.

use

face or dust mask

be

kept

safe

padlocks, master switch-, or by remov-

job

better and safer

if

cutting operation

tool.

of

improper accessories may cause hazards.

Before further use of

parts,

mounting, and any other conditions that

the

tool, a guard or other part

is

damaged should

it

distance from work area.

at

the rate for which

it

was not designed

It's

at

all

times.

is

in

off

position before

if

the

tool

is

tipped or

is

will operate properly

of

moving

parts,

be

properly

use

to protect

see

on.

in

moving

is

dusty.

safer than

safest

as

cutter

binding

may

re-

it

if

Page 3

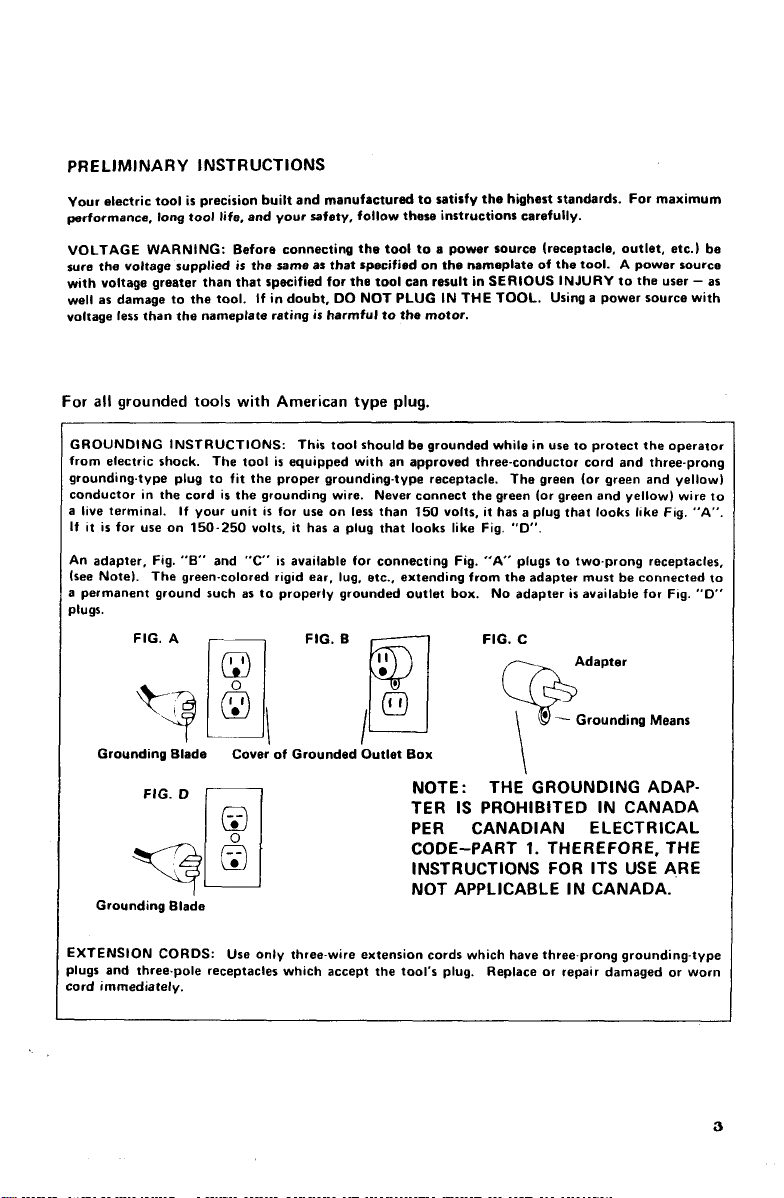

PRE

LlMl NAR

Your electric tool

performance,

VOLTAGE WARNING: Before connecting the tool to

sure the voltage supplied

with voltage greater than that specified for

well as damage to the tool. If

voltage

less

For

all

Y I NSTR UCTl ONS

is

precision built and manufactured

long

tool life, and your safety, follow these instructions carefully.

is

than the nameplate rating

grounded

tools

with

the same as that specified

in

doubt,

DO

is

harmful

the

tool can result

NOT PLUG

to

the motor.

American type plug.

to

satisfy the highest standards. For maximum

a

power source (receptacle, outlet, etc.) be

on

the nameplate of the tool.

in

SERIOUS INJURY to the user - as

IN

THE TOOL. Using a power source with

A power source

GROUNDING INSTRUCTIONS: This tool should be grounded while

from electric shock. The tool

grounding-type plug to fit the proper grounding-type receptacle. The green (or green and yellow)

conductor

a live terminal. If your unit

It

An adapter, Fig. "B" and

(see Note). The green-colored rigid ear, lug, etc., extending from the adapter must be connected to

a permanent ground such as to properly grounded outlet box.

plugs.

in

the

it

is

for ure on

Grounding Blade

FIG.

cord

150-250

D

is

equipped with an approved three-conductor cord and threeprong

is

the grounding wire. Never connect the green (or green and yellow) wire to

is

for use

on

volts, it has a plug that

"C'

is

available for connecting Fig.

Cover' of Grounded Outlet Box

less than

150

looks

volts,

like Fig.

NOTE: THE GROUNDING ADAP-

IS

TER

PER

CANADIAN ELECTRICAL

CODE-PART

in

use to protect

it

has a plug that looks like Fig.

"D".

"A'

plugs to two-prong receptacles,

No adapter

is

the

operator

available for Fig.

\

PROHIBITED IN CANADA

1.

THEREFORE, THE

"A".

"D"

INSTRUCTIONS FOR ITS USE ARE

Grounding Blade

EXTENSION

plugs and three-pole receptacles which accept the tool's plug.

:ord immediately.

CORDS:

Use

only three-wire extension cords which have three-prong grounding-type

NOT APPLICABLE IN CANADA.

Replace or repair damaged or worn

3

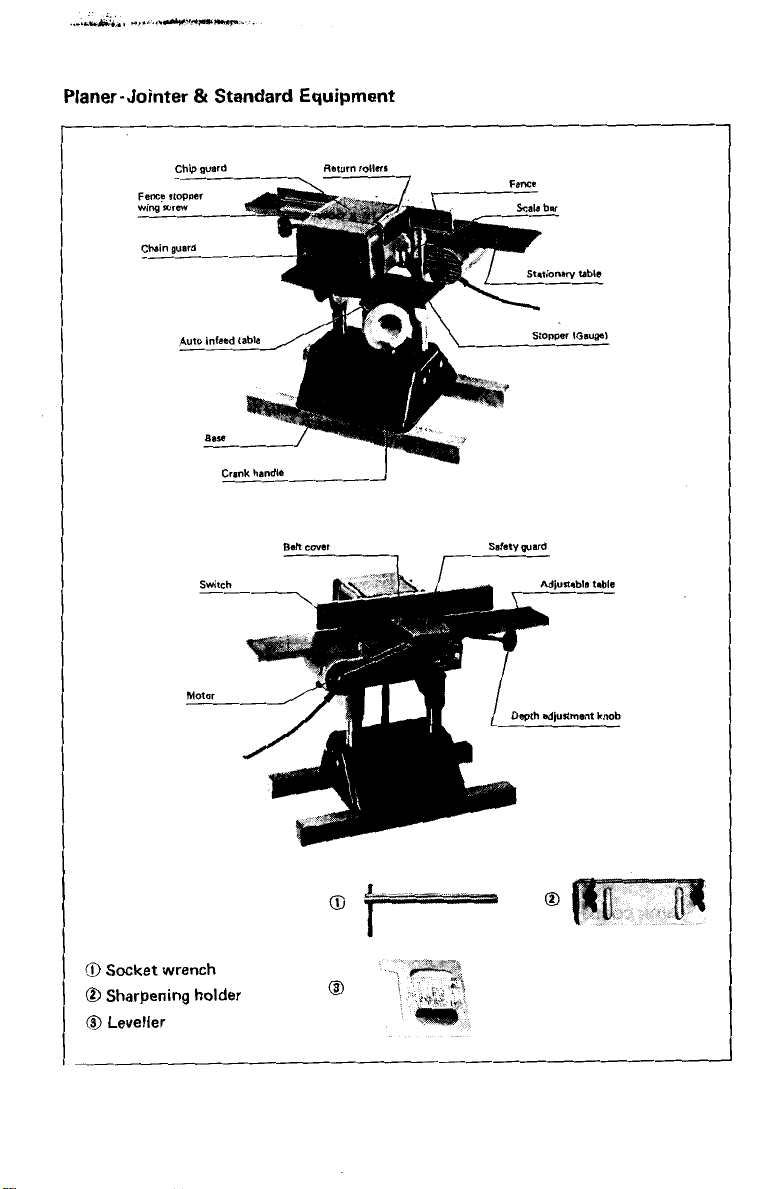

Page 4

0

Socket wrench

0

Sharpening holder

@

Leveller

Crank

handle

Belt

cover

------lI

0

I

safety

guard

I

Page 5

Special Precautions with Planer- Jointer

a.

Jointing Operations

Do

not perform jointing operations on material shorter than

narrower than

b.

Planing Operations

Do

not perform planing operations on material shorter than

narrower than

5-1/4

inches

c.

Maintain the proper relationships of infeed and outfeed table surfaces and cutter head

knife path.

d. Support the workpiece adequately

the work

e.

Do

not back the work toward the infeed table.

f.

Do

not attempt to perform an abnormal or little-used operation without study and the

use

of

adequate holddown/push blocks, jigs, fixtures, stops, etc.

HOW

TO

I

Forthe Planer

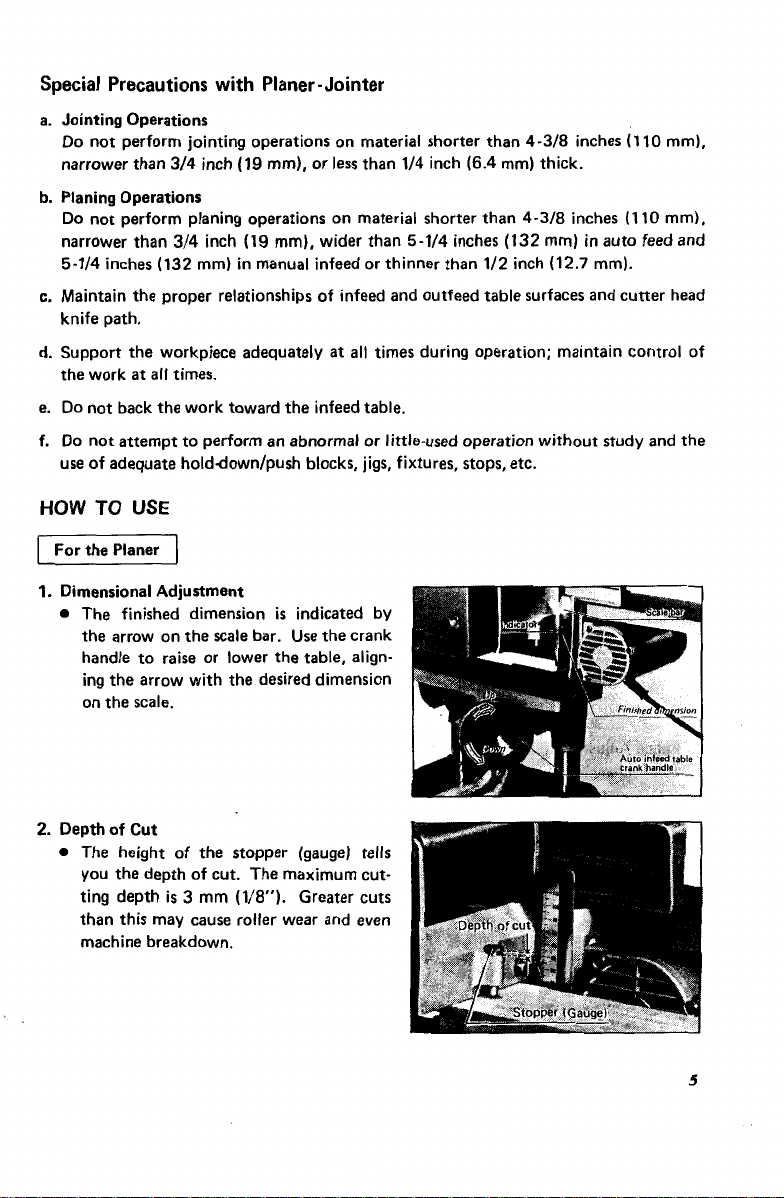

1.

Dimensional Adjustment

0

The finished dimension

the arrow on the scale bar.

handle to raise or lower the table, aligning the arrow with the desired dimension

on the scale.

(132

at

all

USE

314

inch

(19

mm), or

3/4

inch

(19

mm) in manual infeed or thinner than

times.

less

than

mm), wider than

at

all

times during operation; maintain control of

1/4

5-1/4

1

is

indicated by

Use

the crank

inch

inches

(6.4

1/2

4-3/8

mm) thick.

4-3/8

(132

mm)

inch

(12.7

inches

(110

inches

(110

in auto feed and

mm).

mm),

mm),

2.

Depth

of

Cut

0

The height

you the depth of cut. The maximum cutting depth

than this may cause roller wear and even

machine breakdown.

of

the stopper (gaugej

is

3

mm

(1/8").

tells

Greater cuts

5

Page 6

3.

Return

Cut stock can be easily returned by means

of

the rollers on top.

4.

Support long stock

of

a

cut to prevent gouging

faces.

1.

The depth of cut

scale.

Turn the knob to the right to increase

cutting depth and to the left to decrease

Maximum cutting depth: 3 mm

at

the beginning and end

or

rough end sur-

is

indicated in mm on the

(1/8").

it.

2.

Fence Adjustment

When changing the fence setting for rabbet

cuts and the like, loosen the fence stopper

wing

screw

and move the fence to the de-

sired position; then secure the wing screw.

Page 7

I

Cutter Replacement

First,

unplug the planer-jointer from the power source.

1.

Removal

Auto infeed table (Planer): First, left off the chip cover (guard).

0

Manual feed table (Jointer): Remove cover (guard) after taking off safety cover

I

(guard) bolt.

Planer

Jointer

Page 8

2.

Installation

0

Hold the belt steady by hand and insert

the cutter between the leaf spring and the

drum

so

that the blade protrudes slightly

above the table surface.

3.

Cutter Height

Adjustment

Make the drum stationary before performing the adjustment

drum locking lever

so

by

that

pressing in the

from the stopper; then fasten the drum

in place by inserting the end of the lever

into the drum concave (grooved) portion.

it

is

released

Lever to lock

drum in place

I'

Press

Lever

to

lock

I

drum

Page 9

After hooking the lever for drum locking onto the stopper, secure the hex bolts hold-

ing down the blade holder:

0

After

all

bolts have been secured, check your cutter height agian.

a

total

of

8

on the planer arid jointer sides, respectively.

MAINTENANCE

0

Remove the chain guard and lubricate the

chain with machine oil.

Oil the sliding support parts, moving parts

you

and feed screw portions whenever

it

necessary.

think

CARBON

0

BRUSH

REPLACEMENT

Replace carbon brushes when they wear

down to about

6

mm

(1/4")

or sparking will

occur. Both brushes should be changed

the same time.

at

L

I_-----

!

9

Page 10

0

To

replace carbon brushes, use

screwdriver equipped to remove

cap on

the

motor housing.

brush.

HOW

TO USE THE SHARPENING HOLDER

0

First, loosen the 2 wing nuts on the holder

and insert blades Aand

so

that they contact side C and

Then tighten wing nuts.

0

Immerse dressing stone in water .Jr 2 or

minutes before sharpening. Iiold the holder

so

that

blades both contact the dressing

stone for simultaneous sharpening

same angle.

B

as

the

the

Then

replace

in figure

D.

(-1

minus

holder

at

right,

at

the

the

Wing

nut

-w

3

IO

I

Page 11

0

Replacement blades

Width

(mm)

136 15-3/8"1

136 (5-3/8'1

*

Material

.

. .

Tungsten-Carbide

Dressing

stone

Part

No.

741801-4

Part

No.

155334-7

0

Sharpening holder

Part

No.

123006.2

Pait

No.

731013-7

731203-2

t

Socket

Part

wrench

No.

782203-5

I

Page 12

132mm(5%")

Model

2004

PLANER

JOINTER

2

c

Page 13

Page 14

14

-

$,M

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

19

30

31

32

33

34

35

36

I7

38

39

40

41

42

43

44

45

46

47

48

19

50

51

52

53

54

55

26

>l

MA

2

3

4

5

6

7

8

9

1

#

PART NO.

*

154260-7

164510-2

231098-8

924206-5

91 13094

3230

14.5

253312-2

152 146-9

271 244-1

9511 19.7

321131.5

2537980

91 1316-7

341498-5

2537980

321 135-7

8154384

812120-6

311104.2

953106-2

2539226

941301-6

341497-7

951 157.9

231048.3

921661-2

951 101.6

251609-3

941151.9

1631294

23

1537-8

911256.9

341808.8

2575574

91 11262

315111-1

151130-1

156576-6

921556-9

5

1064

31

911226.8

911226-8

33

1105.8

311451-5

951281-8

164509.7

155331-3

9112014

3211462

25301 1

91 1221-8

2315360

951101-6

30-9

1631

9111042

3415054

321531-5

-

'LkM

$Fo

DEYRlPTlON

1

Ru1I.r

1

Chip

Cover

Compression

Spring

1

T

Screw

1

2

P

H

Screw

1

SfOP!m

T

Washer 12

A

R.

2

Rullor

1

1

I

1

2

1

1

1

1

1

2

4

1

1

1

2

1

1

1

1

1

1

1

1

1

1

4

1

1

1

3

1

3

3

2

1

4

1

1

2

1

1

6

1

1

1

1

1

1

4

-

26

Knob

60

Spring Pin

Screw

M14

F Washer 13

P

H

Scrm

Screw

Holder

F Warher 13

GWOe

Name

Plate

Scab

Plate

P

H

Screw

Rivet

0

C

Warher 12

F

Washer 12

Slide

Plate

Spring

Pin

Compression

H

Boll M12x40

Sprmg Pin

H F H

F

flasher

Blade

Cover

Torsion

P

H

Screw

Bel,

cover

Sleeve

6

P

H

Screw

8ear,ng

Frame

Motor

Housing

E436538

3132060

H

801,

Cover

Motor

P

H

Screw

P

ti

Screw

Column

Bed

Spr,ng

Pl"

Bare

Guide

P

H

Erew

Bush

5

F

Washer

P

H

Screw

Torsion

Spring

Pin

Lock

Lever

P

H

Screv,

Indicator

ti]8olt M10x20 (With Washer1

6

M5x10

M6.10 IWifh Washer1

4-24

M6x14 IWothWarhorl

M4x6 IWith Washer1

-

5

5-16

Spring

13

4-10

Bolt

M6x17

6

Spring

17

M5x35 IWilh Washer1

M4x16 IWith Waihsrl

BO"

IWith Brush

x

2

and

n

Set

x

M10x35 <With Washer1

Scrcv

21

M5x18 IWith Washer1

M5x18 IWith Warherl

8-55

M5x8 IWith Warherl

6

M5x16 (With Washer1

Spring

13

4-10

M4x16 (With Washer)

Holder

M5x8

PART NO. DESCRIPTION

MA<

NE

-

801

102

103

I04

-

58

59

60

61

62

63

64

65

66

67

60

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

04

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

00

05

06

07

08

09

10

11

12

13

-

3114484

921571-3

2531340

321132.3

2544001.2

221317.0

2533114

9112268

951 1163

341499.3

2533114

2533148

911226.8

3415004

951116.3

271025-3

271607-1

9112014

321133-1

254001-2

961055-9

221317.0

961055-9

911261.6

911271-3

341509-6

257556-6

9

1 124 1.2

4112014

253011-6

9312026

911216-1

341515-1

156575-8

91 1221-8

231535-2

257555-8

25301

257556-6

251609-3

341510 1

342486

731013 7

2216584

21 1256-2

341507-0

161074-7

311106-8

341507.0

211256.2

222074

225053.0

31

>11106.1

141506-2

513340-2

19CS.2

1

4

4

I

1

1

1

3

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

1

1

4

1

1

1.6

1

1

16

4

5

4

4

1

1

1

1

8

1

1

3

1

1

2

1

1

1

-

Column

Supporter

H.

Boll M10x50 IWilh Washer1

F.Wmher 11

Screw

MZO

Woadrvll

Key

Straqht

T.

P.

Sprinp Pin

Screw

T.

T.Warhcr 15

P.

Handle

Spring

Handle

Knob

P.

Handle

Woadrulf

Retaining

Straight

Retaining

P.

P.

Chsn

Sleeve

P

P. H Screw

F.Washer

H.

P.

Chip

GM

P

Torsion

Sleeve

F.

Sleeve

n.

Drum

Blade

Planer

Helical

Ball

Washer 17

Drum

P H Screw

Washer 17

Ball

V-Pulley

Poly

P.

Ball

Warher 12

ARMATURE ASSEMBLY

Items

100

4

Bsvsl

Gear

Washer 10

H.

Screw

Holdor

Waher 10

H.

Screw

20

H

Screw

n.

~crm

H.

Screw

Cover

H.

Screw

Nu1

n.

S~W

Guide

nousan9

H.

Screw

Washer

F. H 8011 ~6x17

Cover

Holder

Blade

Bearing

Bearing

V-Belt

H.

Screw

Bearing

115. 116. 117. 118. 119& 1201

v.

16

M5x18 IWnh Washed

4-20

M5x18 IWtth Washed

Supporter

Pin

4-20

120

M5x8 IWith WYherl

Shall

Key

4

Ring

S-15

Bevel

Gear

16

Ring

S-15

~5x40

M5x50 IWilh Wesherl

6

M5x25 IWlth Washer1

M5rB IWith Washer)

6

M5

~5x14

cover

M5x16 IWilh Washer1

Spring

13

5

6

6

135

136

Gear

15

6203LLB

M4x8

IWtthWsharl

.

6203LLB

6-41.5

IR1

6-504

M5xSO

(With Werherl

6201LL8

IAsnembled

I

Page 15

'k;M

MACHINE

114

115

116

117

118

119

im

121

122

123

124

125

126

127

128

129

130

-

PART

i13342-8

141025.7

L13051-6

111066-7

~31270-2

1630024

301002-1

5431504

643153.8

6436504

263005-3

5233W.6

523302-2

222073-5

3415046

6521609

645006-7

i41066-6

651750-6

6517514

582505.8

682503.2

-

NO.

"!&

DESCRIPTION

11s

v.

zm

v.

220

v.

230

V.

Fan

92

1

O"llSs.l

1

Ball

Bearing

1

CDmDr&On

1

Rubber

1

Insulation Washer

2

Carbon

2

CB-150

CB-153

2

Holder

RuMar

1

FIELD

1

(With

100

v.

115

V. - 130V.

200

v.

220

v.

230

v.

1

V-Pulley

1

Switch

1

Inwl~tion

1

Noire

1

CORD

(Airembled

Black-White (With Plug)

Blask.Whm IWilh French

~ikk.Whi(e IWithoUl

uL

&

UL

B

SEV

SAA

Draka

Itahan

Spanish

Switch

1

Double

Double

Cord

1

For

BIeck

Lsted

Oraka

For

Spanish.

-

-

1mv.

-

250

10

8200LLB

Rn

4

Brush

For

CaD

Pin

6

ASSEMBLY

Garter

-

2WV.

6-20

Protector

Washer

Suppm1.0r

ASSEMBLY

Cord.

CSA Listed

CSA Listed

Listed

(With

Listed

(With

Tyoe

Tyw

Pole

Pole

Guard

White. Blur

ISJT

B

Cord

V

SWlnl

11

1WV.

Spring

654020-2)

(LI

Plug

ISJT

ISJ

Plug1

IW+th Plug1

Plus1

(With

Plum1

(With

Plug1

IWilh

Squared

SJ

Type).

lial+an

B

IL

Card

Tyw

Plug1

TVD~

Type

Brwn.

SEV

SAA

Guard)

Plug)

With

Plug)

Wifh Plug)

Wsrhcrl

UL

B

Lasted

Listed

Card

CSA

&

M"

131

I32

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

I63

ACCI

400

401

402

403

404

405

406

-

687620.7

687609-1

911216-1

253748-5

221661-5

3211344

253797.2

221513.0

257065.5

9422514

931503-2

253180-3

221660.7

221657-6

256093.7

256092-9

253180

256092-9

253180-3

221659.2

9112234

32 1205.2

1-1

21425

231262- 1

162096-0

256093.7

221513.0

257065-5

942251-8

931503.2

2255

1 1-6

25~180.3

2216568

256092

j0UlES

-

123006

934301

2410096

3128465

2519203

1551'539

7822035

820001

1

1

For

Csosda

p

n

&raw

2

I

F WeshCr 12

Helicd

1

S~liodle

1

F

Wmhm 14

1

Sprocket

1

Ring

10

1

5

Wahcr 10

1

H

Nul

1

F

Warhcr 10

1

Helical

1

HcIIF~I

1

P,"

4

1

P,"

4

1

F

Washer

1

3

Pl"

4

1

1

F

Washer 10

Heileal

1

P

H

Screw

8

4

Metal Holder

Plant

Braring

4

~ompre~ion

3

Roller

2

PI"

4

2

iprochet

2

9mg

10

2

P

Wmher 10

2

H

Nut

2

Cham 35-44

I

F

Washer

1

neilcai

1

P,"

1

2

1

1

2

1

1

1

4

SH~RPENING

lA%$emblcd

W

Nut

PreSIure

Sharpeomg

C

S

N

Leveller

Socket

TOO1

care

9

2

3

2

I

M5r14 (With Washer)

Gear

76

8

M10

Gem

67

Gear

12

10

n ear

61

M5x16 IWNh Washer)

17

Soring

8

'

M10

10

GW

12

HOLDER

Items

400.401.402 5 4031

M6

Plale

Holder

Bolt

M6r30

Wrench 9

~

14

ASSEMBLY

Page 16

&24?c&k-*ud.

Anjo,

Aichi,

hp8n

PRINTED IN JAPAN

1979-9-1.000 N

c

1

Loading...

Loading...