Makita 165 mm 5604R Instruction Manual

GB

Circular Saw Instruction Manual

F

Scie circulaire

Manuel d’instructions

D

Handkreissäge Betriebsanleitung

I

Sega circolare Istruzioni per l’uso

NL

Cirkelzaagmachine Gebruiksaanwijzing

E

Sierra circular Manual de instrucciones

P

Serra circular Manual de instruções

DK

Rundsav Brugsanvisning

S

Cirkelsåg Bruksanvisning

N

Sirkelsag Bruksanvisning

FIN

Pyörösaht Käyttöohje

GR ∆ισκοπρίονο Οδηγίες χρήσεως

165 mm 5604R

2

0

12

34

56

78

3

2

1

4

7

6

5

3

9

8

12

10

11

13

16

14

15

1 5 mm

_

17

18

18

21

20

19

23

22

910

11 12

13 14

15 16

4

24

2726

17 18

19 20

21

5

ENGLISH

Explanation of general view

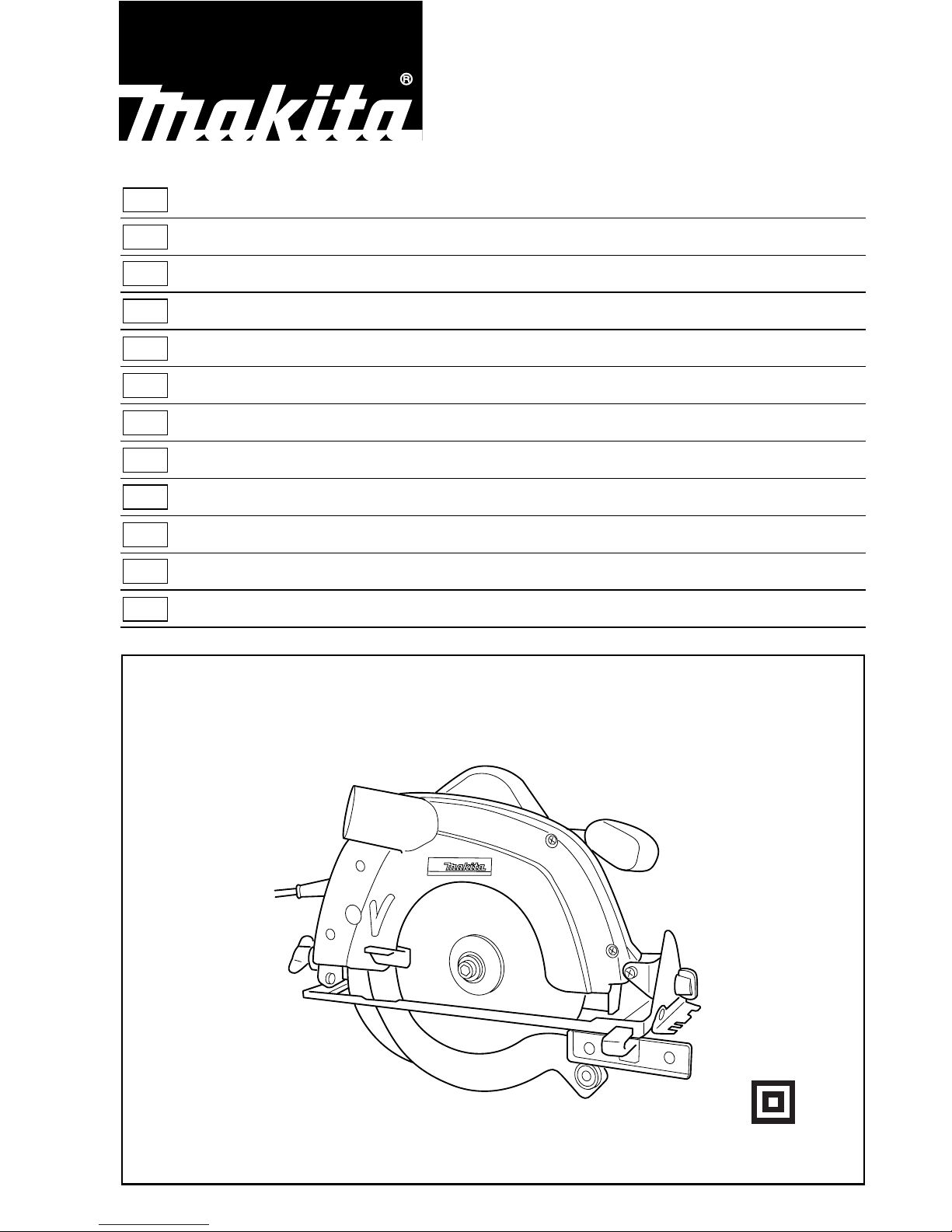

1 A typical illustration of proper

hand support, workpiece support, and supply cord routing (if

applicable).

2 To avoid kickback, do support

board or panel near the cut.

3 Don’t support board or panel

away from the cut.

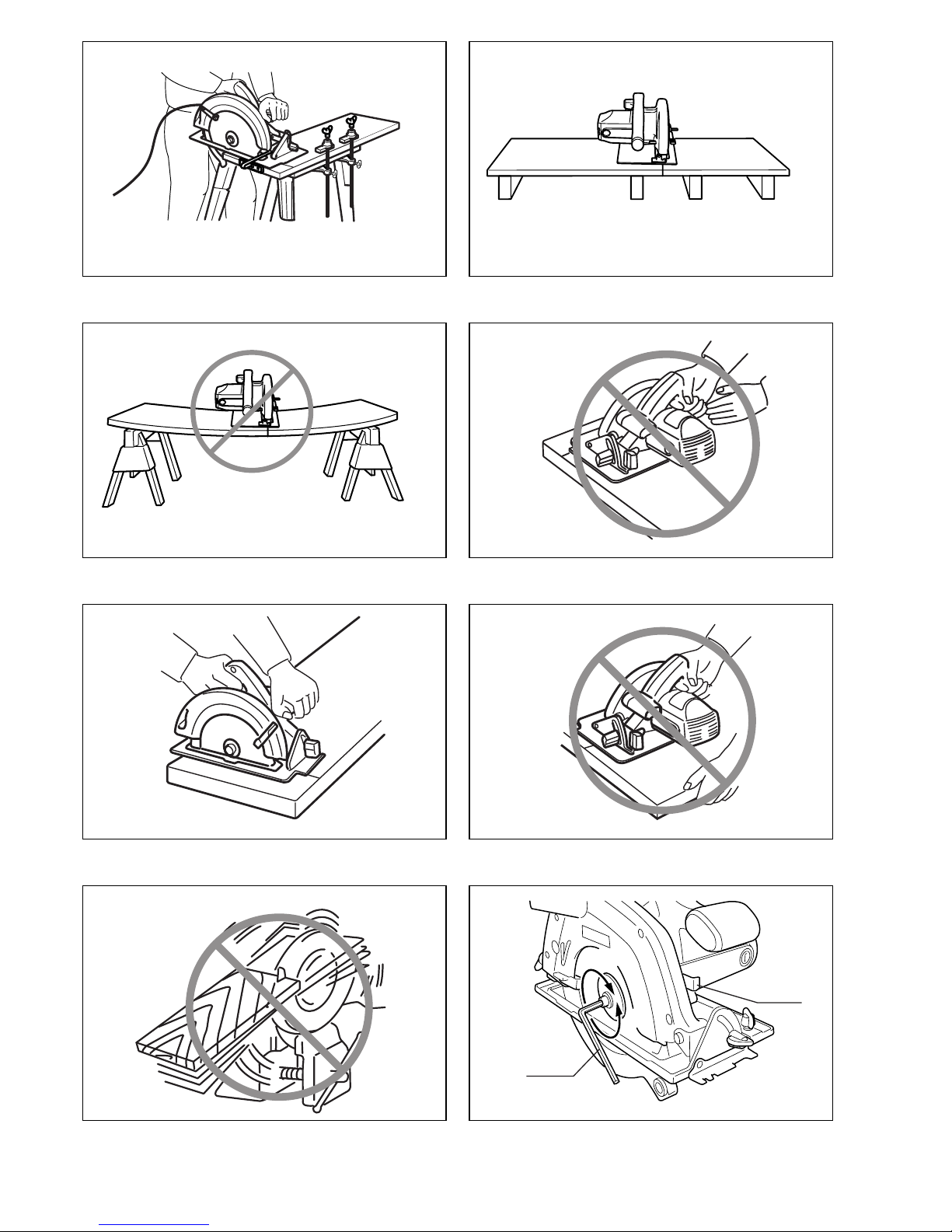

4 Hex wrench

5 Shaft lock

6Tighten

7 Loosen

8 Saw blade

9 Outer flange

10 Inner flange

11 Outer flange

12 Hex socket head bolt

13 Saw blade

14 Setting protuberances

15 Hex socket head bolt

(For adjusting riving knife)

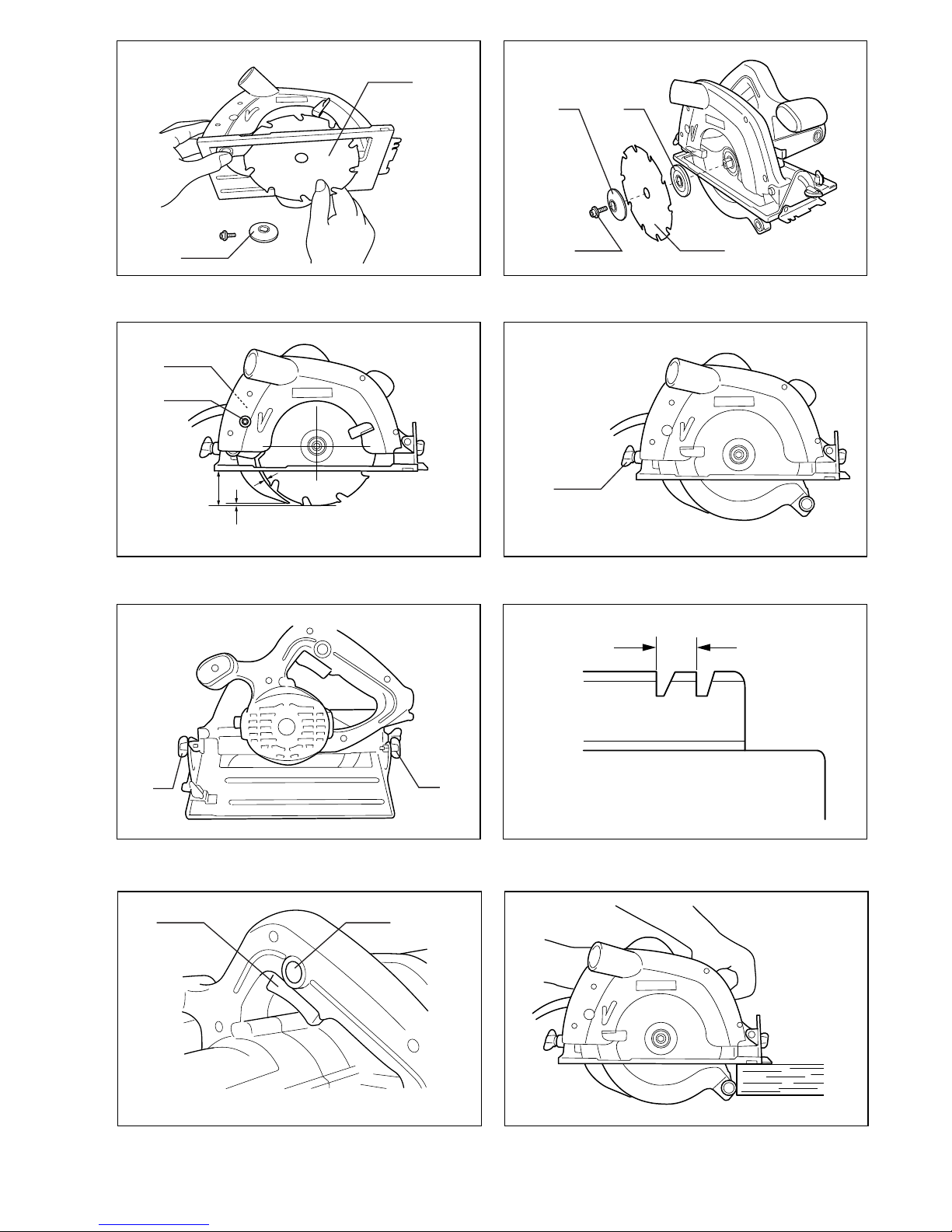

16 Cutting depth

17 Thumb nut

18 Thumb nut

19 For 45° bevel cuts

20 For straight cuts

21 Base plate

22 Lock-off button

23 Switch trigger

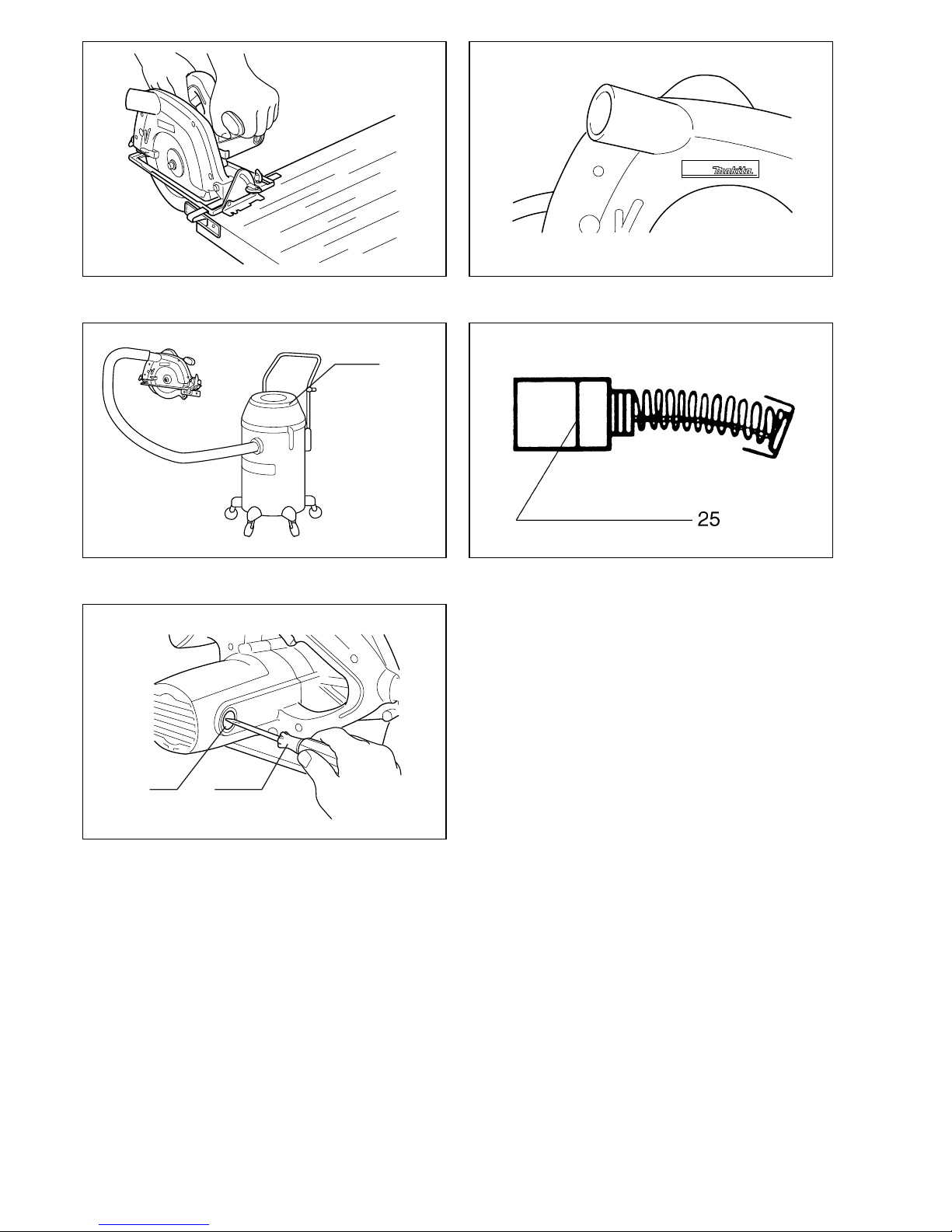

24 Vacuum cleaner

25 Limit mark

26 Brush holder cap

27 Screwdriver

SPECIFICATIONS

Model 5604R

Blade diameter ................................................... 165 mm

Max. cutting depth

At 90° ................................................................. 54 mm

At 45° ................................................................. 35 mm

No load speed (min

-1

) .............................................5,000

Overall length .....................................................320 mm

Net weight .............................................................. 3.6 kg

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for performing lengthways and

crossways straight cuts and miter cuts with angles to 45°

in wood while in firm contact with the workpiece.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

Safety hints

For your own safety, please refer to the enclosed safety

instructions.

SPECIFIC SAFETY RULES

GEB029-1

DO NOT let comfort or familiarity with product

(gained from repeated use) replace strict adherence

to circular saw safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious personal injury.

Danger:

1. Keep hands away from cutting area and the

blade. Keep your second hand on auxiliary handle, or motor housing. If both hands are holding

the saw, they cannot be cut by the blade.

2. Do not reach underneath the workpiece. The

guard cannot protect you from the blade below the

workpiece. Do not attempt to remove cut material

when blade is moving.

CAUTION: Blades coast after turn off. Wait until

blade stops before grasping cut material.

3. Adjust the cutting depth to the thickness of the

workpiece. Less than a full tooth of the blade teeth

should be visible below the workpiece.

4. Never hold piece being cut in your hands or

across your leg. Secure the workpiece to stable

platform. It is important to support the work properly

to minimize body exposure, blade binding, or loss of

control. (Fig. 1)

5. Hold power tool by insulated gripping surfaces

when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the

operator.

6. When ripping always use a rip fence or straight

edge guide. This improves the accuracy cut and

reduces the chance of blade binding.

7. Always use blades with correct size and shape

(diamond versus round) of arbour holes. Blades

that do not match the mounting hardware of the saw

will run eccentrically, causing loss of control.

8. Never use damaged or incorrect blade washers

or bolt. The blade washers and bolt were specially

designed for your saw, for optimum performance and

safety of operation.

9. Causes and Operator Prevention of Kickback:

– kickback is a sudden reaction to a pinched, bound

or misaligned saw blade, causing an uncontrolled

saw to lift up and out of the workpiece toward the

operator;

– when the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward the

operator;

– if the blade becomes twisted or misaligned in the

cut, the teeth at the back edge of the blade can dig

into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward the

operator.

Kickback is the result of saw misuse and/or incorrect

operating procedures or conditions and can be

avoided by taking proper precautions as given

below.

• Maintain a firm grip with both hands on the

saw and position your arms to resist kickback

forces. Position your body to either side of the

blade, but not in line with the blade. Kickback

could cause the saw to jump backwards, but kickback forces can be controlled by the operator, if

proper precautions are taken.

6

• When blade is binding, or when interrupting a

cut for any reason, release the trigger and hold

the saw motionless in the material until the

blade comes to a complete stop. Never attempt

to remove the saw from the work or pull the

saw backward while the blade is in motion or

kickback may occur. Investigate and take correc-

tive actions to eliminate the cause of blade binding.

• When restarting a saw in the workpiece, centre

the saw blade in the kerf and check that saw

teeth are not engaged into the material. If saw

blade is binding, it may walk up or kickback from

the workpiece as the saw is restarted.

• Support large panels to minimise the risk of

blade pinching and kickback. Large panels tend

to sag under their own weight. Supports must be

placed under the panel on both sides, near the line

of cut and near the edge of the panel.

• To minimize the risk of blade pinching and kickback. When cutting operation requires the resting

of the saw on the workpiece, the saw should be

rested on the larger portion and the smaller piece

cut off. (Fig. 2 & 3)

• Do not use dull or damaged blades. Unsharpened or improperly set blades produce narrow kerf

causing excessive friction, blade binding and kickback. Keep blade sharp and clean. Gum and wood

pitch hardened on blades slows saw and

increases potential for kickback. Keep blade clean

by first removing it from tool, then cleaning it with

gum and pitch remover, hot water or kerosene.

Never use gasoline.

• Blade depth and bevel adjusting locking levers

must be tight and secure before making cut. If

blade adjustment shifts while cutting, it may cause

binding and kickback.

• Use extra caution when making a “plunge cut”

into existing walls or other blind areas. The

protruding blade may cut objects that can cause

kickback. For plunge cuts, retract lower guard

using retracting handle.

• ALWAYS hold the tool firmly with both hands.

NEVER place your hand or fingers behind the

saw. If kickback occurs, the saw could easily jump

backwards over your hand, leading to serious personal injury. (Fig. 4)

• Never force the saw. Forcing the saw can

cause uneven cuts, loss of accuracy, and possible kickback. Push the saw forward at a speed

so that the blade cuts without slowing.

10. Check lower guard for proper closing before

each use. Do not operate the saw if lower guard

does not move freely and close instantly. Never

clamp or tie the lower guard into the open position. If saw is accidentally dropped, lower guard may

be bent. Raise the lower guard with the retracting

handle and make sure it moves freely and does not

touch the blade or any other part, in all angles and

depths of cut. To check lower guard, open lower

guard by hand, then release and watch guard closure. Also check to see that retracting handle does

not touch tool housing. Leaving blade exposed is

VERY DANGEROUS and can lead to serious personal injury.

11. Check the operation of the lower guard spring. If

the guard and the spring are not operating properly, they must be serviced before use. Lower

guard may operate sluggishly due to damaged

parts, gummy deposits, or a build-up of debris.

12. Lower guard should be retracted manually only

for special cuts such as “plunge cuts” and

“compound cuts.” Raise lower guard by retracting handle and as soon as blade enters the

material, the lower guard must be released. For

all other sawing, the lower guard should operate

automatically.

13. Always observe that the lower guard is covering

the blade before placing saw down on bench or

floor. An unprotected, coasting blade will cause the

saw to walk backwards, cutting whatever is in its

path. Be aware of the time it takes for the blade to

stop after switch is released. Before setting the tool

down after completing a cut, be sure that the lower

guard has closed and the blade has come to a complete stop.

14. Use the appropriate riving knife for the blade

being used. For the riving knife to work, it must be

thicker than the body of the blade but thinner than

the tooth set of the blade.

15. Adjust the riving knife as described in this

instruction manual. Incorrect spacing, positioning

and alignment can make the riving knife ineffective

in preventing kickback.

16. Always use the riving knife except when plunge

cutting. Riving knife must be replaced after plunge

cutting. Riving knife causes interference during

plunge cutting and can create kickback.

17. For the riving knife to work, it must be engaged

in the workpiece. The riving knife is ineffective in

preventing kickback during short cuts.

18. Do not operate the saw if riving knife is bent.

Even a light interference can slow the closing rate of

a guard.

19. Use extra caution when cutting damp wood,

pressure treated lumber, or wood containing

knots. Adjust speed of cut to maintain smooth

advancement of tool without decrease in blade

speed.

20. Avoid Cutting Nails. Inspect for and remove all

nails from lumber before cutting.

21. Place the wider portion of the saw base on that

part of the workpiece which is solidly supported,

not on the section that will fall off when the cut is

made. As examples, Fig. 5 illustrates the RIGHT

way to cut off the end of a board, and Fig. 6 the

WRONG way. If the workpiece is short or small,

clamp it down. DO NOT TRY TO HOLD SHORT

PIECES BY HAND! (Fig. 5 & 6)

22. Never attempt to saw with the circular saw held

upside down in a vise. This is extremely dangerous and can lead to serious accidents. (Fig. 7)

23. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation

and skin contact. Follow material supplier safety

data.

24. Do not stop the blades by lateral pressure on the

saw blade.

25. Always use blades recommended in this manual.

Do not use any abrasive wheels.

Loading...

Loading...