Makita 12 V 8413D, 18 V 8443D, 14.4 V 8433D Instruction Manual

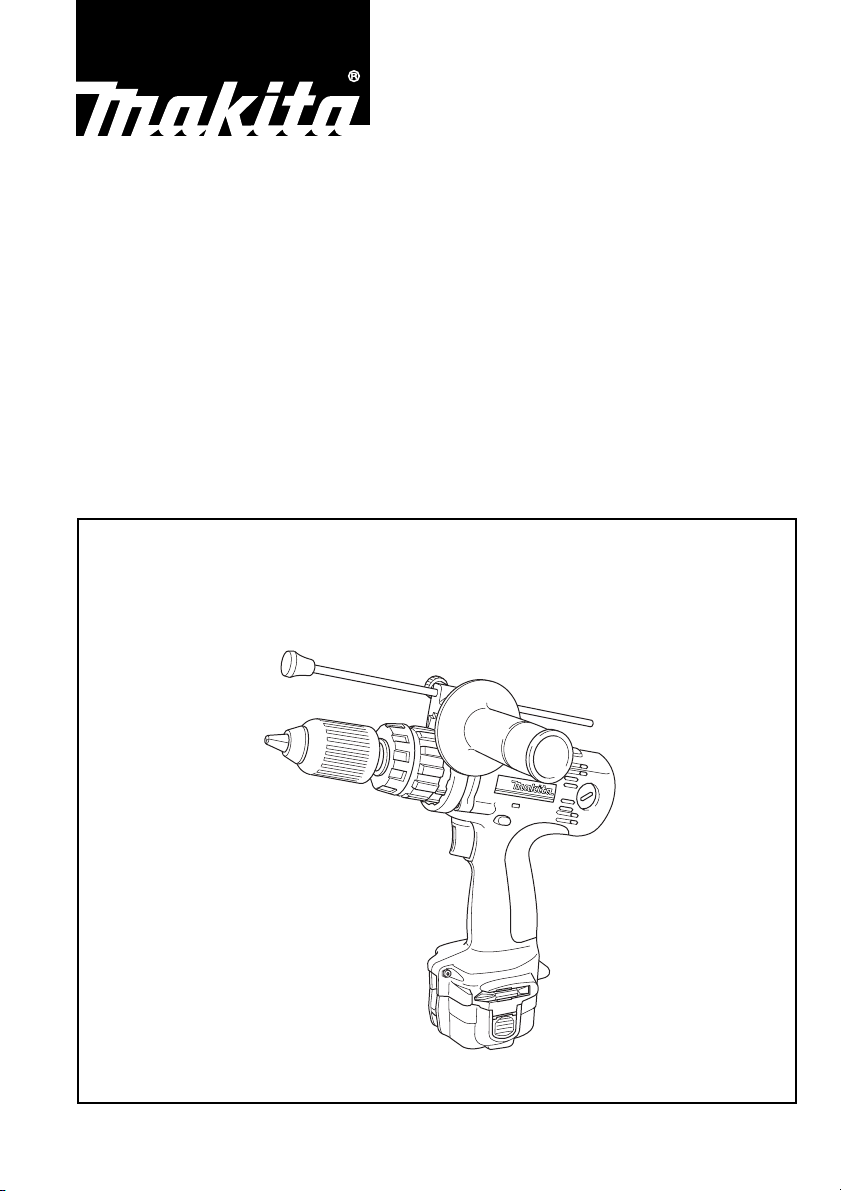

Cordless Percussion-Driver Drill

Instruction Manual

Akku-Schlagbohrschrauber

Betriebsanleitung

Bezprzewodowa udarowa wkrętarko-wiertarka

Instrukcja obsługi

Беспроводной бурильно-завинчивающий молоток

Инструкция по эксплуатации

12 V 8413D

14.4 V 8433D

18 V 8443D

1

3

2

12

4

4

9

5

7

8

6

10

11

34

12

10 12 14 16

13

14

15

13

56

16

17

18

19

78

2

20

21

24

22

23

16

25

910

11 12

26

27

13 14

29

30

15

28

3

Symbols

The following show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt

mit ihrer Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich

znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Indoor use only

❏ Nur für trockene Räume

Tylko do użytku w pomieszczeniach

❏

❏

Использование только внутри помещения

❏ Read instruction manual

❏ Bitte Betriebsanleitung lesen

Przeczytaj instrukcję obsługi

❏

❏

Прочитайте инструкцию по эксплуатации

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

PODWÓJNA IZOLACJA

❏

❏

ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ Ready to charge

Ladebereit

❏

❏

Gotowość do ładowania

❏

Готово для зарядки

❏ Charging

Akku wird geladen

❏

❏

Ładowanie

❏

Зарядка

❏ Charging complete

Laden beendet

❏

❏

Ładowanie zakończone

❏

Зарядка завершена

❏ Delay charge (too hot battery)

Ladungsverzögerung (Akku zu heiß)

❏

❏

Ładowanie opóźnione (zbyt ciepłe akumulatory)

❏

Задержка зарядки (слишком горячая батарея)

❏ Deffective battery

Akku defekt

❏

❏

Uszkodzony akumulator

❏

Дефектная батарея

4

❏ Do not short batteries

Schließen Sie die Kontakte nicht kurz. Brandgefahr!

❏

❏

Nie zwieraj akumulatorów

❏

Не закорачивайте батареи

❏ Always recycle batteries

❏ Verbrauchte Akkus stets dem Recycling zuführen

Zawsze kieruj akumulatory do odzysku

❏

❏

Всегда выбрасывайте батареи для рециркуляции

❏ Do not discard batteries into garbage can or the like

❏ Verbrauchte Akkus nicht in den Hausmüll werfen

Nigdy nie wyrzucaj akumulatorów do kosza na śmieci ani żadnego podobnego miejsca

❏

❏

Не выбрасывайте батареи в мусорный ящик или подобный контейнер

Note:

The recycling method may differ from country to country, or state (province) to state (province). Consult with

your nearest Makita Authorized Service Center or Distributor.

Achtung:

Die Art des Recycling kann von Land zu Land unterschiedlich sein. Bei Fragen wenden Sie sich an eine

autorisierte Werkstatt oder an den nächstgelegenen Makita-Kundendienst.

Uwaga:

Sposoby odzysku materiałów odpadowych mogą różnić się w poszczególnych krajach lub regionach (stanach). Poradź się najbliższego autoryzowanego punktu napraw lub dystrybutora firmy Makita.

Примечание:

Метод вторичной переработки может различаться в зависимости от страны или штата (провинции) .

Проконсультируйтесь с Вашим ближайшим уполномоченным центром по техобслуживанию Мakita или

дистрибьютером.

5

ENGLISH

Explanation of general view

1 Push button

2 Battery cartridge

3 Switch trigger

4 Reversing switch lever

5 A side

6 B side

7 Clockwise

8 Counterclockwise

9 Low speed

10 High speed

SPECIFICATIONS

Model 8413D 8433D 8443D

Capacities

Concrete ......................................................13 mm 14 mm 16 mm

Steel ............................................................13 mm 13 mm 13 mm

Wood ...........................................................30 mm 36 mm 38 mm

Wood screw .................................................6 mm x 75mm 6 mm x 75 mm 10 mm x 90 mm

Machine screw ............................................6 mm 6 mm 6 mm

No load speed (min

High .............................................................0 – 1,300 0 – 1,300 0 – 1,400

Low .............................................................. 0 – 400 0– 400 0 – 450

Blows per minute

High .............................................................0 – 19,500 0 – 19,500 0 – 21,000

Low .............................................................. 0 – 6,000 0 – 6,000 0 – 6,750

Overall length .................................................267 mm 267mm 267 mm

Net weight (with battery cartridge) .................2.3 kg 2.4 kg 2.6 kg

Rated voltage .................................................D.C.12 V D.C. 14.4 V D.C. 18 V

-1

)

11 Speed change lever

12 Action mode changing ring

13 Arrow

14 Adjusting ring

15 Graduations

16 Tighten

17 Sleeve

18 Bit

19 Bit holder

20 Grip base

21 Teeth

22 Side grip

23 Loosen

24 Depth rod

25 Thumb screw

26 Screw

27 Set plate

28 Limit mark

29 Brush holder cap

30 Screwdriver

• Due to our continuing program of research and devel-

opment, the specifications herein are subject to change

without notice.

• Note: Specifications may differ from country to country.

Intended use

The tool is intended for impact drilling in brick, concrete

and stone as well as for drilling without impact in wood,

metal, ceramic and plastic.

SAFETY INSTRUCTIONS

WARNING! When using battery operated tools basic

safety precautions, including the following, should

be followed to reduce the risk of fire, leaking batteries and personal injury: Read these instructions

before operating this product and save these instructions.

For safe operation:

1. Keep work area clean

– Cluttered areas and benches invite injuries.

2. Consider the work environment

– Do not expose the tool to rain. Keep work area well

lit. Do not use tools in the presence of flammable

liquids or gases.

3. Keep children away

– Do not let visitors touch the tool. Keep visitors

away from work area.

ENA002-1

6

4. Store batteries or idle tools

– When not in use, tools and batteries should be

stored separately in a dry, high or locked up place,

out of reach of children.

– Ensure that battery terminals cannot be shorted by

other metal parts such as screws, nails, etc.

5. Do not force the tool

– It will do the job better and safer at the rate for

which it was intended.

6. Use the right tool

– Do not force small tools or attachments to do the

job of a heavy duty tools. Do not use tools for purposes not intended.

7. Dress properly

– Do not wear loose clothing or jewellery, they can

be caught in moving parts. Non-skid footwear is

recommended when working outdoors. Wear protecting hair covering to contain long hair.

8. Use protective equipment

– Use safety glasses and if the cutting operation is

dusty, a face or dust mask.

9. Connect dust extraction equipment

– If devices are provided for the connection of dust

extraction and collection ensure these are connected and properly used.

10. Do not abuse the supply cord (if fitted)

– Never carry the tool by the cord or yank it to dis-

connect from the socket. Keep the cord away from

heat, oil and sharp edges.

11. Secure the work

– Use clamps or a vice to hold the work. It is safer

than using your hand and it frees both hands to

operate the tool.

12. Do not over-reach

– Keep proper footing and balance at all times.

13. Maintain tools with care

– Keep cutting tools sharp and clean for better and

safer performance. Follow instructions for lubrication and changing accessories. Inspect tool cords

periodically and if damaged have repaired by an

authorized service facility.

14. Disconnect tools

– Where the design permits, disconnect the tool

from its battery pack when not in use, before servicing and when changing accessories such as

blades, bits and cutters.

15. Remove adjusting keys and wrenches

– Form the habit of checking to see that keys and

adjusting wrenches are removed from the tool

before turning it on.

16. Avoid unintentional starting

– Do not carry the tool with a finger on the switch.

17. Stay alert

– Watch what you are doing. Use common sense.

Do not operate the tool when you are tired.

18. Check damaged parts

– Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of moving parts, free running of moving par ts, breakage

of parts, mounting and any other condition that

may affect its operation. A guard or other part that

is damaged should be properly repaired or

replaced by an authorized service facility unless

otherwise indicated in this instruction manual.

Have defective switches replaced by an authorized

service facility. Do not use the tool if the switch

does not turn it on and off.

19. Warning

– The use of any accessory or attachment, other

than recommended in this instruction manual or

the catalog, may present a risk of personal injury.

– Ensure that the battery pack is correct for the tool.

– Ensure that the outside surface of battery pack or

tool is clean and dry before plugging into charger.

– Ensure that batteries are charged using the cor-

rect charger recommended by the manufacturer.

Incorrect use may result in a risk of electric shock,

overheating or leakage of corrosive liquid from the

battery.

20. Have your tool repaired by a qualified person

– This tool is constructed in accordance with the rel-

evant safety requirements. Repairs should only be

carried out by qualified persons using original

spare parts, otherwise this may result in consider-

able danger to the user.

21. Disposal of battery

– Ensure battery is disposed of safety as instructed

by the manufacturer.

IMPORTANT SAFETY INSTRUCTIONS FOR

CHARGER & BATTERY CARTRIDGE

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Always cover the batter y terminals with the battery cover when the battery cartridge is not

used.

6. Do not short the battery cartridge:

(1) Do not touch the terminals with any conduc-

tive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a breakdown.

7. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

8. Do not incinerate the battery cartridge even if it

is severely damaged or is completely worn out.

The battery cartridge can explode in a fire.

9. Be careful not to drop or strike battery.

ENC004-1

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room temperature at 10°C – 40°C (50°F – 104°F). Let a hot battery cartridge cool down before charging it.

4. Charge the Nickel Metal Hydride battery cartridge when you do not use it for more than six

months.

ADDITIONAL SAFETY RULES

1. Be aware that this tool is always in an operating

condition, because it does not have to be

plugged into an electrical outlet.

2. Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring. Contact with a “live”

wire will also make exposed metal parts of the

tool “live” and shock the operator.

3. Always be sure you have a firm footing.

4. Be sure no one is below when using the tool in

high locations.

ENB022-1

7

5. Hold the tool firmly.

6. Keep hands away from rotating parts.

7. Do not leave the tool running. Operate the tool

only when hand-held.

8. Do not touch the drill bit or the workpiece immediately after operation; they may be extremely

hot and could burn your skin.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

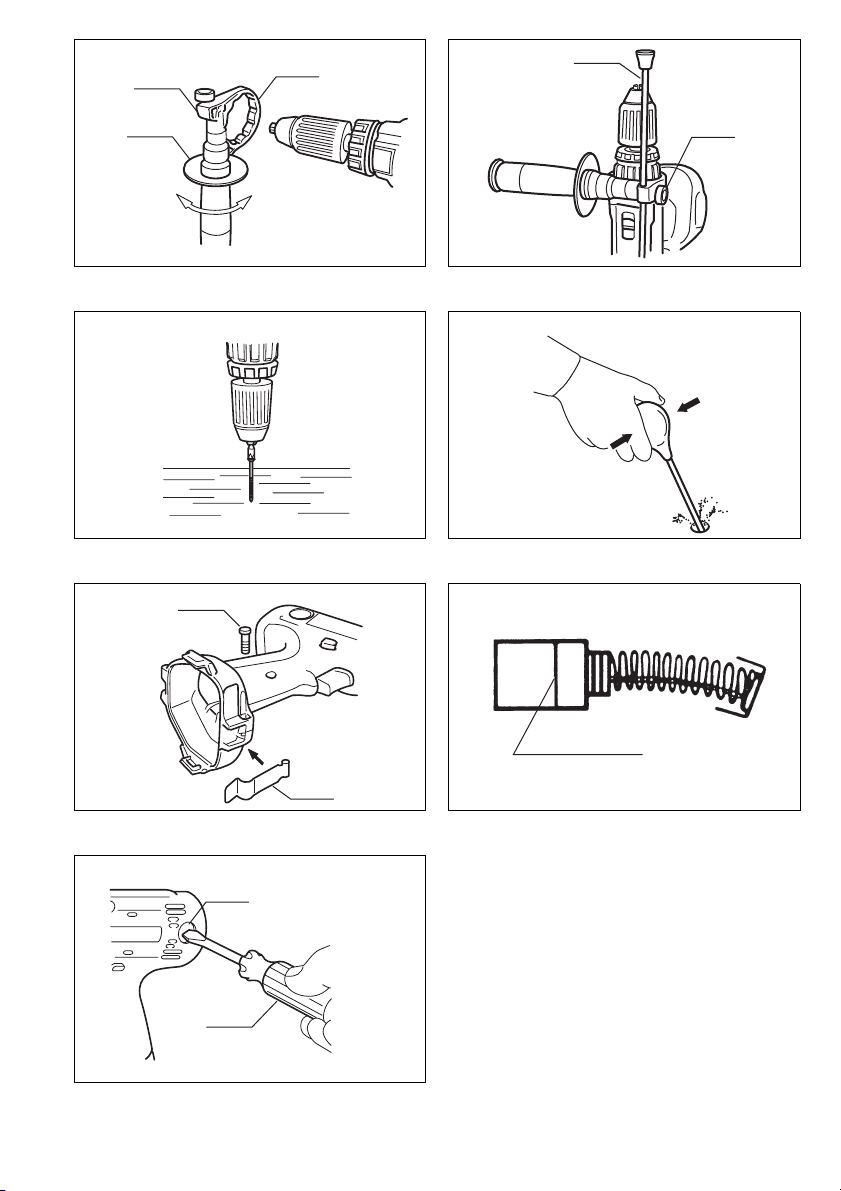

Installing or removing battery cartridge (Fig. 1)

• Always switch off the tool before insertion or removal of

the battery car tridge.

• To remove the battery cartridge, withdraw it from the

tool while pressing the buttons on both sides of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If not, it may accidentally fall out

of the tool, causing injury to you or someone around

you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

Switch action (Fig. 2)

CAUTION:

Before inserting the battery cartridge into the tool, always

check to see that the switch trigger actuates properly and

returns to the “OFF” position when released.

To start the tool, simply pull the trigger. tool speed is

increased by increasing pressure on the trigger. Release

the trigger to stop.

Reversing switch action (Fig. 3)

CAUTION:

• Always check the direction of rotation before operation.

• Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

• When not operating the tool, always set the reversing

switch lever to the neutral position.

This tool has a reversing switch to change the direction of

rotation. Depress the reversing switch lever from the A

side for clockwise rotation or from the B side for counterclockwise rotation. When the switch lever is in the neutral

position, the switch trigger cannot be pulled.

Speed change (Fig. 4)

To change the speed, first switch off the tool and then

slide the speed change lever to the “ II ” side for high

speed or “ I ” side for low speed. Be sure that the speed

change lever is set to the correct position before operation. Use the right speed for your job.

CAUTION:

• Always set the speed change lever fully to the correct

position. If you operate the tool with the speed change

lever positioned half-way between the “ I ” side and “ II ”

side, the tool may be damaged.

• Do not use the speed change lever while the tool is running. The tool may be damaged.

Selecting the action mode (Fig. 5)

This tool employs an action mode changing ring. Select

one of the three modes suitable for your work needs by

using this ring. For rotation only, turn the ring so that the

arrow on the tool body points toward the M mark on the

ring. For rotation with hammering, turn the ring so that

the arrow points toward the X on the ring. For rotation

with clutch, turn the ring so that the arrow points toward

the U mark on the ring.

CAUTION:

Always set the ring correctly to your desired mode mark.

If you operate the tool with the ring positioned half-way

between the mode marks, the tool may be damaged.

Adjusting the fastening torque (Fig. 6)

The fastening torque can be adjusted in 16 steps by turning the adjusting ring so that its graduations are aligned

with the arrow on the tool body. The fastening torque is

minimum when the number 1 is aligned with the arrow,

and maximum when thenumber 16 is aligned with the

arrow.

Before actual operation, drive a trial screw into your

material or a piece of duplicate material to determine

which torque level is required for a particular application.

Installing or removing driver bit or drill bit

(Fig.7 & 8)

Important:

Always be sure that the tool is switched off and the battery cartridge is removed before installing or removing

the bit.

Turn the sleeve counterclockwise to open the chuck jaws.

Place the bit in the chuck as far as it will go. Turn the

sleeve clockwise to tighten the chuck. To remove the bit,

turn the sleeve counterclockwise.

When not using the driver bit, keep it in the bit holders.

Bits 45 mm long can be kept there.

Side grip (auxiliary handle) (Fig. 9)

Always use the side grip to ensure operating safety.

Install the side grip so that the teeth on the grip fit in

between the protrusions on the tool barrel. Then tighten

the grip by turning clockwise at the desired position. It

may be swung 360° so as to be secured at any position.

Adjustable depth rod (Fig. 10)

The adjustable depth rod is used to drill holes of uniform

depth. Loosen the thumb screw, set to desired position,

then tighten the thumb screw.

8

Screwdriving operation (Fig. 11)

First, turn the action mode changing ring so that the

arrow on the tool body points to the U marking. Adjust

the adjusting ring to the proper torque level for your work.

Then proceed as follows.

Place the point of the driver bit in the screw head and

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the trigger as

soon as the clutch cuts in.

NOTE:

• Make sure that the driver bit is inser ted straight in the

screw head, or the screw and/or bit may be damaged.

• When driving wood screws, predrill pilot holes to make

driving easier and to prevent splitting of the workpiece.

See the chart below.

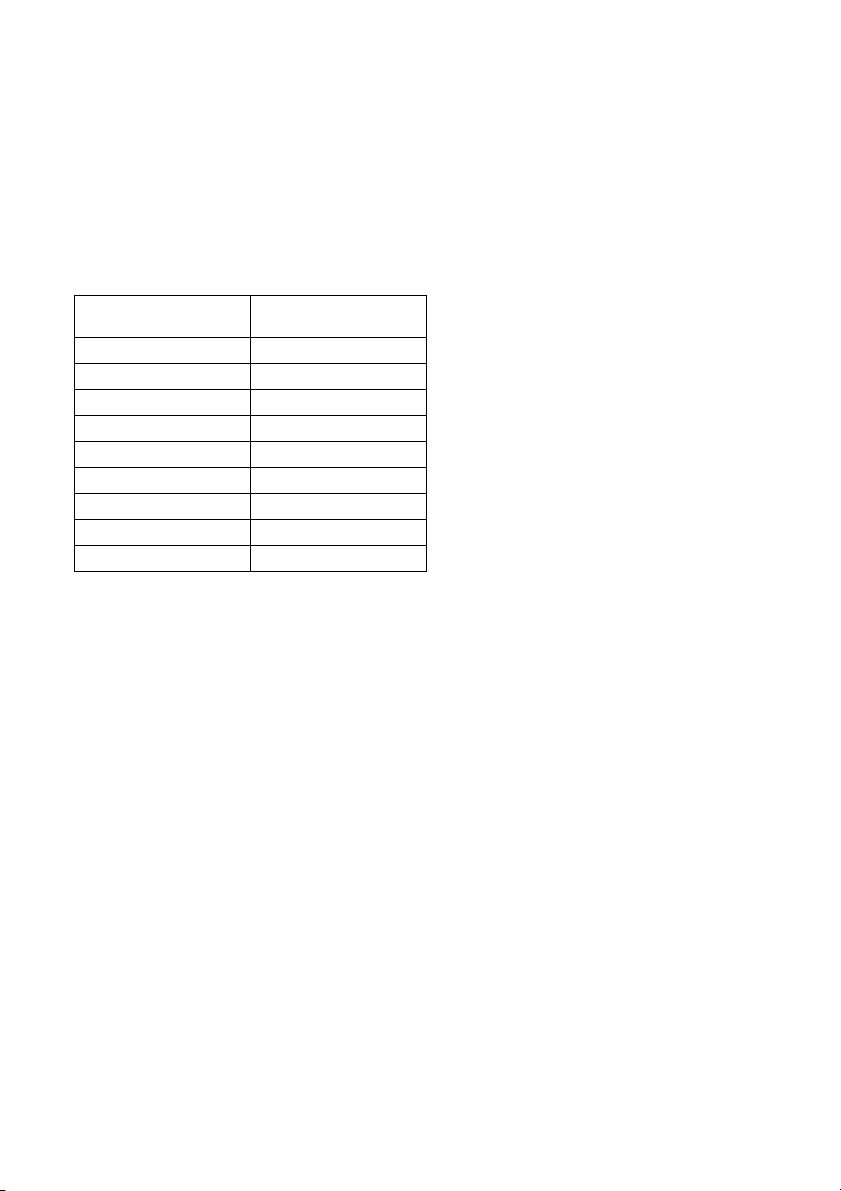

Nominal diameter

of wood screw (mm)

3.1 2.0–2.2

3.5 2.2–2.5

3.8 2.5–2.8

4.5 2.9–3.2

4.8 3.1–3.4

5.1 3.3–3.6

5.5 3.6–3.9

5.8 4.0–4.2

6.1 4.2–4.4

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

Drilling operation

First, turn the action mode changing ring so that the

arrow on the tool body points to the M marking. The

adjusting ring can be aligned in any torque levels for this

operation. Then proceed as follows.

• Drilling in wood

When drilling in wood, best results are obtained with

wood drills equipped with a guide screw. The guide

screw makes drilling easier by pulling the bit into the

workpiece.

• Drilling in metal

To prevent the bit from slipping when starting a hole,

make an indentation with a centerpunch and hammer

at the point to be drilled. Place the point of the bit in the

indentation and start drilling. Use a cutting lubricant

when drilling metals. The exceptions are iron and brass

which should be drilled dry.

Recommended size

of pilot hole (mm)

CAUTION:

• Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool performance and shor ten the service life of the tool.

• There is a tremendous force exerted on the tool/bit at

the time of hole breakthrough. Hold the tool firmly and

exert care when the bit begins to break through the

workpiece.

• A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back out.

However, the tool may back out abruptly if you do not

hold it firmly.

• Always secure small workpieces in a vise or similar

hold-down device.

• If the tool is operated continuously until the battery cartridge has discharged, allow the tool to rest for 15 minutes before proceeding with a fresh battery.

Hammer drilling operation

First, turn the action mode changing ring so that the

arrow on the tool body points to the X marking. The

adjusting ring can be aligned in any torque levels for this

operation. Position the bit at the desired location for the

hole, then pull the trigger. Do not force the tool. Light

pressure gives best results. Keep the tool in position and

prevent it from slipping away from the hole. Do not apply

more pressure when the hole becomes clogged with

chips or particles. Instead, run the tool at an idle, then

remove the bit partially from the hole. By repeating this

several times, the hole will be cleaned out and normal

drilling may be resumed.

CAUTION:

There is a tremendous and sudden twisting force exerted

on the tool/bit at the time of hole breakthrough, when the

hole becomes clogged with chips and par ticles, or when

striking reinforcing rods embedded in the concrete.

Always use the side grip (auxiliary handle) and firmly

hold the tool by both side grip and switch handle during

operations. Failure to do so may result in the loss of control of the tool and potentially severe injury.

Blow-out bulb (Fig. 12)

Use the blow-out bulb to clean out the hole.

Installing set plate (Fig. 13)

For 8413D

Always install the set plate when using battery cartridges

1200, 1202 or 1202A. Install the set plate on the tool with

the screw provided.

9

Loading...

Loading...