Page 1

INSTALLER / CONSUMER

SAFETY INFORMATION

PLEASE READ THIS

MANUAL BEFORE INSTALL-

ING AND USING APPLIANCE

IMPORTANT: Installation of natural

gas should be completed by a

qualified installer, service agency

or gas supplier.

WARNING: If the information in

this manual is not followed exactly, a fire or explosion may

result causing property damage,

personal injury or loss of life.

Vermont Castings GPF

Gas Patio Fire

Models: GPFMN, GPFMP

FOR YOUR SAFETY:

• Installation and service must be

performed by a qualified installer, service agency or the gas

supplier.

• Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

FOR YOUR SAFETY:

If you smell gas:

• Do not touch any electrical

switches

• Do not try to light any appliance.

Extinguish any open flame

• Do not use the phone in your build-

ing

• Immediately call your gas supplier

from a neighbor’s phone

4237

Homeowner’s Installation and

Operating Manual

• Follow your gas supplier’s instruc-

tions

• If you cannot reach your gas sup-

plier, call the fire department

WARNING: For outdoor use only!

WARNING:

Do not use for cooking!

INSTALLER: Do Not Discard This Manual

Leave for Homeowner

20004237 / 0901

1

Page 2

Vermont Castings GPF

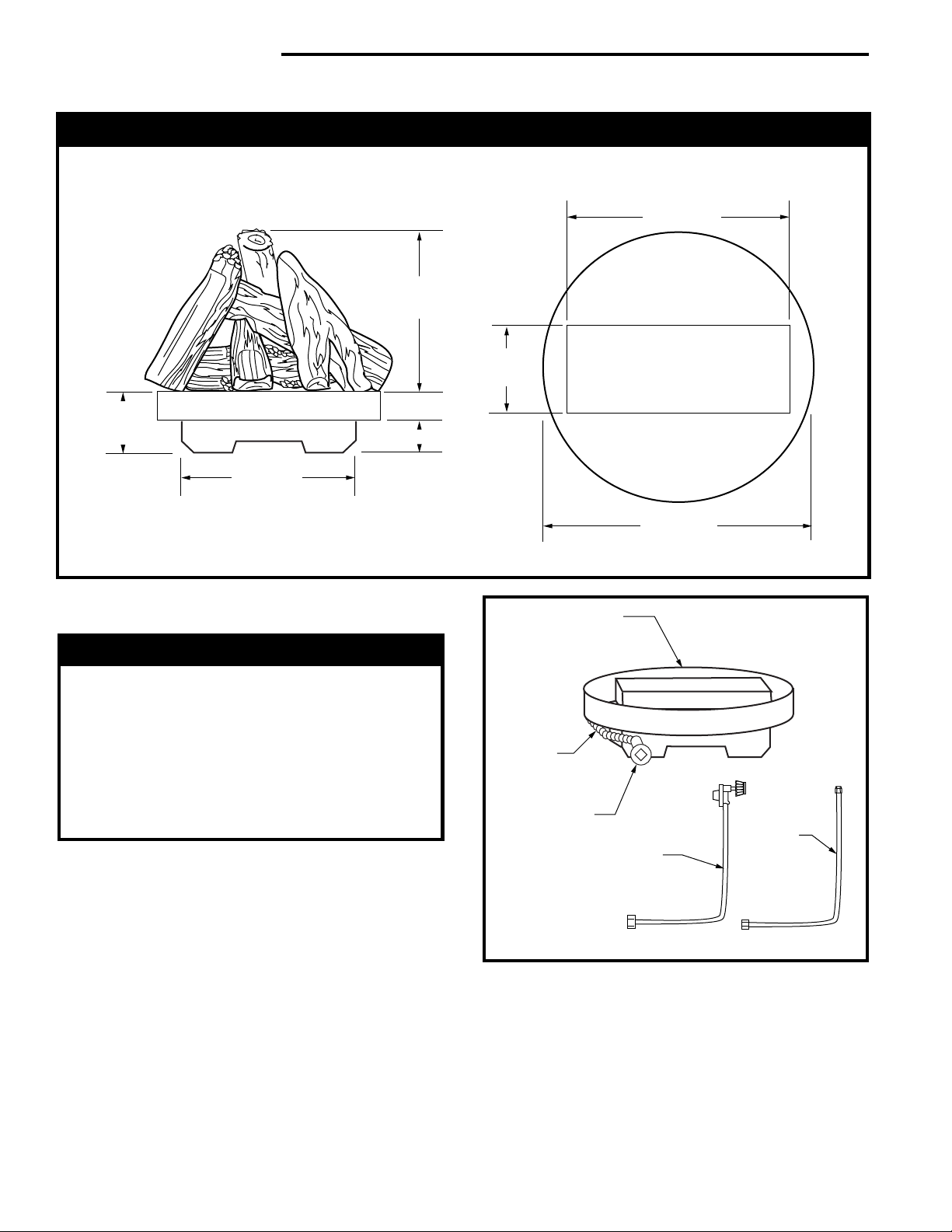

GPF Dimensions

11³⁄₈"

(289mm)

12"

(305mm)

5"

(127mm)

11¹⁄₂"

(292mm)

Fig. 1 Physical dimensions.

Table of Contents

Specifications ....................................................2

General Information ..........................................3

Assembly & Installation .....................................4

Log Placement .................................................. 7

Operation ..........................................................9

Maintenance.................................................... 10

Replacement Parts.......................................... 11

Accessories.....................................................12

3¹⁄₄"(83mm)

8¹⁄₄"

(210mm)

Burner Assembly

Flex Line

Valve

Propane

Regulator/Hose

Burner

16¹⁄₄"

(413mm)

4237

Natural

Hose

FP1129

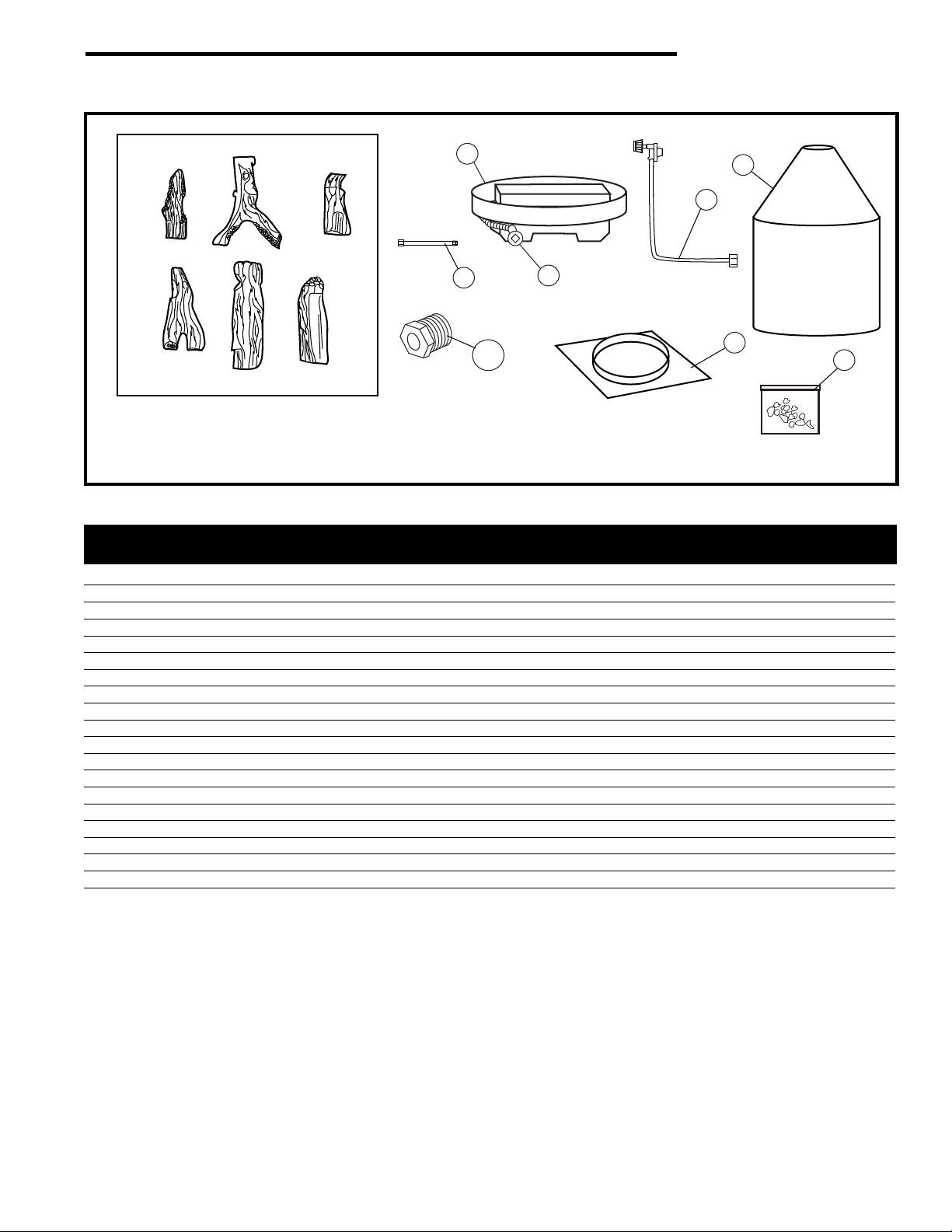

Fig. 2 GPF parts.

2

Page 3

General Information

Model GPF is a decorative gas log set for outdoor use

only . This appliance must not be used for cooking.

IMPORTANT: Read all instructions and warnings

carefully before starting installation. Failure to follow

these instructions may result in a possible fire hazard

and will void the warranty.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause injury or

property damage. Read the installation, operating and

maintenance instructions thoroughly before installing or

servicing this equipment.

WARNING: This appliance shall be used only outdoors

in a well-ventilated space and shall NOT be used inside

a building, garage or any other enclosed area.

WARNING: This log set must NOT be installed in an

unvented appliance.

WARNING: This unit is not for use with solid fuel.

NOTE: All new LP cylinders (and in many cases used

cylinders) may contain water, air or other contaminants,

and it is essential that these be removed before filling

the cylinder and placing into service. Water vapor

present in the gas vapor may cause the regulator to

“freeze up” and cause an interruption to the gas flow.

This interruption will cause the unit to shut down. To

prevent this form occurring it is essential that a

qualified individual ALWAYS purge a new tank

thoroughly before placing it into service. It is

recommended that cylinders that have not been used

for extended periods of time also be purged before use.

The installation must conform with Local Codes or, in

the absence of local codes, with the National Fuel Gas

Code ANSI Z223.1 or CSA-B149.1 Installation Code.

The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressure testing or the system at test pressures in

excess of 1/2 psig (3.5kPa).

This appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/

2 psig (3.5kPa).

The following clearances to combustible construction

must be maintained: Bottom - 0 inches (0mm), Sides

(all around) - 16 inches (406mm) and Top - (7 feet

(2.1m).

Always keep the appliance area clear and free from

combustible materials, gasoline and other flammable

vapors and liquids.

Vermont Castings GPF

Do not locate appliance where it can get excessively

wet. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the unit and to replace any part of

the control system and any gas control which has been

under water.

• Children and adults should be alerted to the hazards

of high surface temperatures and should stay away to

avoid burns or clothing ignition.

• Young children should be carefully supervised when

they are in the area of the appliance.

• Never leave unit unattended during operation.

• Clothing or other flammable materials should not be

hung from the appliance, or placed on or near the

appliance.

• Any guard or other protective device removed for

servicing the appliance must be replaced prior to

operating the appliance.

• Installation and repair should be done by a qualified

service person. The appliance should be inspected

before use and at least annually by a qualified service

person. More frequent cleaning may be required as

necessary. It is imperative the control compartment,

burners and circulating air passageways of the

appliance be kept clean.

• Inspect the fuel supply connection (including the hose

for LP models) before each use of the appliance.

• If it is evident there is excessive abrasion or wear, or

the hose is cut, it must be replaced prior to the

appliance being put into operation.

• The pressure regulator and hose assembly supplied

with LP models must be used. Replacement pressure

regulators and hose assemblies must be those

specified in this manual.

• The LP gas supply cylinder used with LP models must

be constructed and marked in accordance with the

specifications for LP gas cylinders of the U.S.

Department of Transportation (DOT).

• Cylinders must be stored outdoors in a well-ventilated

area out of reach of children. Disconnected cylinders

must have threaded valve plugs tightly installed and

must not be stored in a building, garage or any other

enclose area.

• Storage of this appliance indoors is permissible only

it has been disconnected from its fuel supply (natural

gas line or LP gas cylinder).

• The LP gas cylinder supply system must be arranged

for vapor withdrawal.

• The LP gas cylinder used must include a collar to

protect the cylinder valve.

• When an LP model is not in use, the LP gas must be

turned off at the supply cylinder.

3

Page 4

Vermont Castings GPF

Assembly and Installation

The logs and burner assembly are shipped together.

1. Remove the gas log set and burner assembly and

check for damage. DO NOT install damaged

components. The logs are fragile - handle with care.

2. Place the burner assembly on a flat, stable surface

in an outdoor location such as a patio or a deck.

This location must be adjacent to the gas supply line

(natural gas) or LP gas supply cylinder. NOTE:

Minimum clearances to combustibles must be

maintained.

Remember, you must have easy access to the gas

valve control knob AFTER the appliance is installed

and connected to the gas supply.

The ON/OFF Gas Valve is used to turn the burner

on and off.

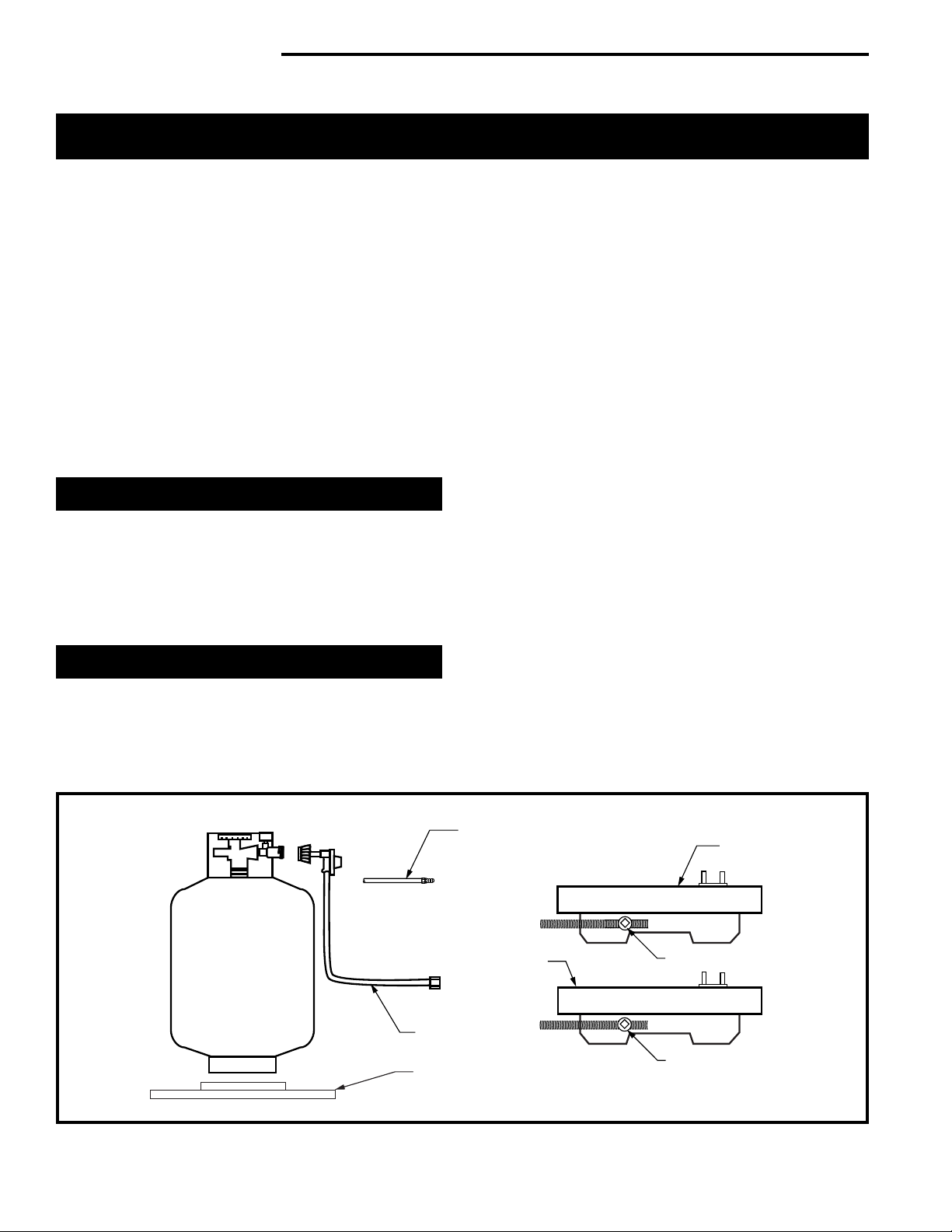

Natural Gas Models

Connect the incoming gas supply line to the on/off gas

valve of the appliance. (Fig. 3) Make certain ALL gas

connections are tight. Test for leaks. Use a 50/50

solution of liquid soap and water to test for leaks at gas

fittings and joints. Apply water/soap solution with a

brush only -

do not over apply. NEVER test with an

open flame.

LP Gas Models

1. Place cylinder base (provided with unit) on a level

surface.

2. Be sure to place cylinder in ring on base.

3. Make sure tank valve is in its full off position. (Turn

clockwise to stop)

4. Check tank valve features to ensure it has proper

external mating threads. (Tank valve Marked: USE

WITH TYPE 1)

5. Inspect hose shipped with the unit for damage.

Never attempt to use damaged or plugged

equipment. See your local LP Gas Dealer for

repairs.

6. After inspecting the LP hose shipped with the unit,

connect the end with the female fitting on the hose

to the male fitting on the on/off gas valve at the end

of the flex tube and make sure it is tight.

7. When connecting regulator assembly to the tank

valve, hand tighten nut clockwise to a positive stop.

DO NOT use a wrench to tighten. Use of a wrench

may damage quick closing coupling nut and result in

a hazardous condition. (Fig. 3)

8. Locate the hose out of pathways where people may

trip over it or in areas where the hose may be

subject to accidental damage.

9. Open tank valve fully (counterclockwise). Turn the

on/off valve at the unit slowly to the on position and

use a 50/50 solution of liquid soap and water to test

for leaks at gas fitting and joints. Apply water/soap

solution with a brush only - do not over apply.

NEVER test with an open flame. If a leak is found,

turn tank valve off and do not use the appliance until

repairs can be made by a local LP Gas Dealer. DO

NOT attempt to make repairs yourself.

10. Never attempt to use this appliance or any

components that have been damaged or exposed to

an accidental fire.

Fig. 3 Gas line connection.

4

Natural Gas Supply Line

Burner

Assembly

Propane

Regulator Hose

Cylinder Base

Burner Assembly

Valve

Valve

FP1130

Page 5

Vermont Castings GPF

Enclosures for LP Gas Supply Systems

If you build an enclosure for an LP gas cylinder, follow

these recommended specifications. You must also

follow local codes.

Enclosures for LP gas supply cylinders shall be

ventilated by openings at the level of the cylinder valve

and at floor level. The effectiveness of the opening(s)

for purposes of ventilation shall be determined with the

LP gas supply cylinder(s) in place. This shall be

accomplished by one of the following:

1. One side of the enclosure shall be completely open;

or

2. For an enclosure having four sides, a top and

bottom:

a. At least two ventilation openings at cylinder valve

level shall be provided in the side wall, equally sized,

spaced at 180 degrees (3.14 rad), and unobstructed.

Each opening shall have a total free area of not less

than 1/2 square inch per pound (3.2 sq. cm/kg) of

stored fuel capacity and not less than a total free

area of 10 square inches (64.5sq. cm).

b. Ventilation opening(s) shall be provided at floor level

and shall have a total free area of not less than 1/2

inch per pound (3.2 sq. cm/kg) of stored fuel

capacity and not less than a total free area of 10

square inches (64.5 sq. cm). If ventilation openings

at floor level are in a side wall, there shall be at least

two openings. The bottom of the openings shall be

at floor level and the upper edge no more than 5

inches (127mm) above the floor. The openings shall

be equally sized, spaced at 180 degrees (3.14 rad)

and unobstructed.

c. Every opening shall have minimum dimensions so

as to permit the entrance of a 1/8 inch (3.2mm)

diameter rod.

3. Cylinder valves shall be readily accessible for hand

operation. A door on the enclosure to gain access to

the cylinder valves is acceptable, provided it is

nonlocking and can be opened without the use of

tools.

4. There shall be a minimum clearance of 2 inches

(50.8 mm) between the lower surface of the floor of

the LP gas supply cylinder enclosure and the

ground.

5. The design of the enclosure shall be such that (1)

the LP gas supply cylinder(s) can be connected,

disconnected and the connections inspected and

tested outside the cylinder enclosure; and (2) those

connections which could be disturbed when

installing the cylinder(s) in the enclosure can be leak

tested inside the enclosure.

6. Be certain to mount or set the LP gas cylinder on a

flat stable surface and restrain it to prevent it from

tipping.

Purge the gas supply line of any trapped air prior to the

first firing of the unit.

WARNING: During the initial purging and

subsequent lightings, NEVER allow gas valve to

remain in the “Open” position without first placing

a burning match on the top of the burner.

Place the logs on the burner assembly. Refer to log

placement instructions.

Test fire the unit after referring to the SAFETY

INFORMATION and Lighting Instructions found on page

9.

CAUTION: Do not leave the burner on with the

cover on.

NOTE: Carbon (soot) may build up on the surface of

the logs with heavy use. This is more likely to occur

when using LP gas. The soot should be cleaned off the

surface of the logs periodically to prevent excessive

build up. To clean the logs, be sure the fire is out, the

gas supply is turned off and the logs are cool to the

touch. The soot can then be brushed off with a dry

bristle brush or cloth. Take care while cleaning the logs

as they can become damaged if mishandled. Care

should be taken to dispose of the soot and cleaning

materials properly. Keep away from clothing and

outdoor furniture.

5

Page 6

Vermont Castings GPF

Installation of GPF in Optional Villa Base

The Villa Base is designed as a decorative enhancement for use with the Gas Patio Fire.

Tools required: 7/16”, 3/4” and 11/16” wrenches, phillips

screwdriver.

Installation Instructions

1. Remove octagonal plate from shipping carton.

2. Remove base/Villa from shipping carton. Remove

four (4) 1/4-20 fasteners, four (4) nuts and eight (8)

washers that fasten the base to the Villa. Remove base.

Remove two (2) 1/4-20 x 1/2” fasteners, two (2) washers from cast valve panel. Set hardware aside. (Fig. 4)

6

Page 7

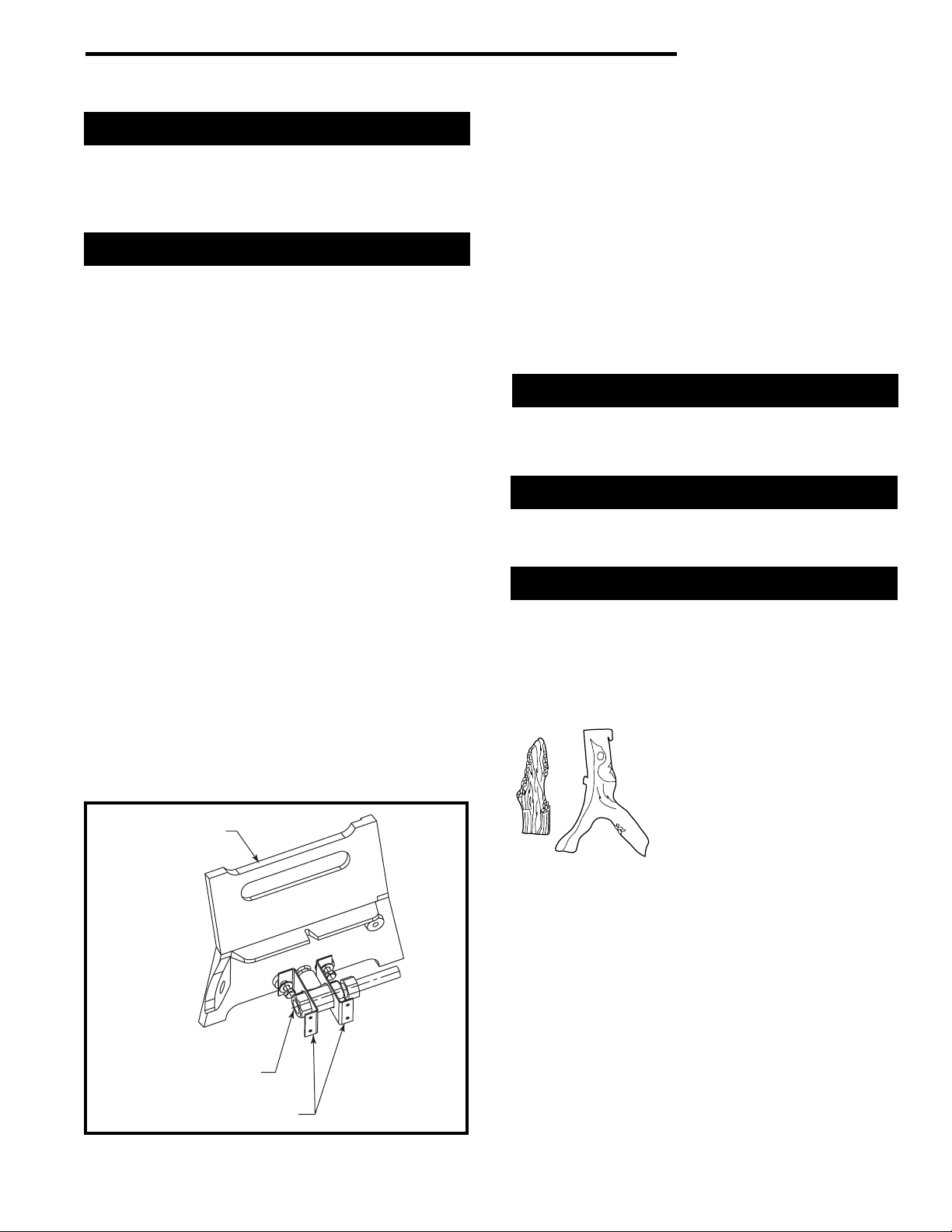

Installation of GPF in Optional Chalet Base

The Chalet Base is designed as a decorative enhancement for use with the Gas Patio Fire.

Tools required: 7/16”, 3/4” and 11/16” wrenches, phillips

screwdriver.

Installation Instructions

1. Remove Chalet Base assembly from shipping

carton. Remove two (2) 1/4-20 fasteners and two (2)

washers from the cast valve panel, set aside.

2. Remove decorative brass ring from the burner valve

on the GPF and discard. Remove the four (4) sheet

metal screws that hold the valve brackets to the burner

on the GPF and discard.

3. Disconnect the fuel supply line from the valve using

a 3/4” wrench. (Fig. 7) Using both the 3/4” and 11/16”

wrenches, remove the fuel supply line from the venturi

(tube secured to the bottom of the burner). Assemble

the valve and bracket assembly to the Chalet using the

1/4-20 x 1/2” fasteners and washers removed in Step 2.

Reconnect the fuel supply line to the valve and tighten.

Feed the fuel line from the gas supply through the fuel

line opening in the base. Place the octagonal mounting

plate on the Chalet. (Fig. 8) Orient the plate with the

long side of the rectangular opening parallel to the

valve panel. Pass the fuel line through the rectangular

opening and reconnect the fuel supply line to the

venturi on the GPF and tighten using the 3/4” and

11/16” wrenches.

6. Seat the octagonal plate on the Chalet. Pass the

GPF legs through the rectangular opening in the plate.

(Fig. 8)

7. Continue with volcanic rock and log placement on

page 8.

Vermont Castings GPF

Log & Volcanic Rock Placement

Remove logs from packaging and examine each for

damage. If any logs are damaged or missing, contact

your dealer. DO NOT install damaged logs.

Volcanic Rock Placement

Pour volcanic rock into outer ring and over burner.

Make sure the volcanic rock is level with the outer ring

and builds up to cover the burner.

Log Placement

1. Arrange logs on floor near burner according to

Figure 9. As shown in Figure 9, the bottom of the

logs will be toward the outside of the burner ring.

2. Use flex line as reference. Begin with line to your

left.

Cast Valve Panel

Valve

Valve Brackets

Fig. 7 Attach valve and brackets to cast valve brackets.

KT264

7

Page 8

Vermont Castings GPF

Log C4

Log C1

Fig. 13 Logs C3 & C4 placement.

Log C4

Log C2

Log C3

Log C5

Log C2

LG164a

Log C1

CAUTION

The logs are fragile. Use caution when placing

the cover on, or removing the cover from, the unit

to avoid damaging the logs.

8

Fig. 14 Log C5 placement.

Log C5

Log C4

Log C1

LG166a

Fig. 15 Log C6 placement.

Log C6

Log C3

LG165a

Log

C2

Page 9

Operation

Vermont Castings GPF

Upon completing the gas line connection, a small

amount of air will be in the lines. When first lighting the

burner, it will take a few minutes for the lines to purge

themselves of this air. Once the purging is complete,

the burner will light and operate as indicated in the

instruction manual. Subsequent lighting of the

appliance will not require such purging.

Lighting And Operating Instructions

FOR YOUR SAFETY READ BEFORE LIGHTING

WARNING:If you do not follow these instructions exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

A. This outdoor cooking appliance must be lit

manually. When lighting, follow these instructions exactly.

B. BEFORE LIGHTING smell all around the

appliance area for gas. Be sure to smell next to

the floor because some gas is heavier than air

and will settle on the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any fireplace

• Do not touch any electric switch

• Do not use any phone in your building

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

WARNING: Read and follow the Safety and Lighting

Instructions page in this manual and on labels on the

appliance. IF YOU DO NOT FOLLOW THESE

INSTRUCTIONS PRECISELY, A FIRE OR EXPLOSION

MAY RESULT AND YOU MAY BE SERIOUSLY

INJURED!

• If you cannot reach your gas supplier, call the

Fire Department

C. Use only your hand to push in or turn the gas

control knob. Never use tools. If the knob will not

push in or turn by hand, do not try to repair it, call

a qualified service technician. Applying force or

any attempted repair may result in a fire or

explosion.

D. Do not use this appliance if any part has been

under water. Immediately call a qualified service

technician to inspect the appliance and to replace

any part of the gas control which has been under

water.

Lighting Instructions

1. STOP! Read the safety information above.

2. Remove the cover.

3. Insert the “TEE” handle in the valve.

4. Place a burning match on top of burner in the middle

where ports are present. DO NOT HOLD THE

MATCH IN HAND.

• For Natural Gas unit, turn the “TEE” handle

slowly counterclockwise.

• For LP unit, turn valve on the LP tank

To Turn Off Gas To Heater

1. Turn the valve to the “OFF” position at the unit for

natural gas unit. For LP unit, turn the valve to the

“OFF” position, fully clockwise at the unit, then

turn the valve on the LP tank to the “OFF” position,

clockwise .

2. Replace the cover.

counterclockwise all the way and then turn the

“TEE” handle on the valve slowly

counterclockwise.

5. If the burner does not light before the match goes

out, immediately turn the gas valve to “OFF”.

6. Wait at least five (5) minutes to clear out any gas. If

you have unsuccessfully tried to light the burner,

wait longer. Then smell for gas, including near the

floor. If you smell gas, ST OP! Follow “B” in the safety

information above. If you do not smell gas, repeat step

4.

9

Page 10

Vermont Castings GPF

Maintenance

1. The appliance should be inspected before initial use

and inspected and cleaned at least annually by a

qualified field service person.

2. Tampering is DANGEROUS and voids all

warranties. Any component that is found to be faulty,

must be replaced with an approved component.

3. To obtain proper operation, it is imperative that the

burner flame characteristics are steady, not lifting or

floating. Check the burner flame patterns with Figure

13.

LG168

Fig. 16 GPF flame appearance.

4. Periodically remove the logs and examine the

burner. If dirty, clean with a soft brush. Also examine

the area around the burner air shutter. Any dirt or lint

in this area should be removed. This will ensure long

life and trouble free operation. When the appliance

is put back in service, check the burner flame

patterns with Figure 17. Reinstall the logs as shown

in the log placement instructions.

5. Periodically check the hose connecting the LP gas

cylinder to ensure it is not damaged in any way.

LG169

Fig. 17 Correct burner flame appearance.

High Elevation Installation

This U.L. listed gas appliance is tested and approved

for elevations form 0 to 2,000 feet in the US and from 0

to 4,500 feet in Canada.

When installing this appliance at an elevation above

2,000 feet (in the US), it may be necessary to decrease

the input rating by changing the existing burner orifice

to a smaller size. Input should be reduced four percent

(4%) for each 1,000 feet above sea level, unless the

heating value of the gas has been reduced, in which

case this general rule will not apply. To identify the

proper orifice size, check with the local gas utility.

When installing this fireplace at an elevation between

2,000 and 4,500 feet (in Canada), the input rating must

be reduced by ten percent (10%).

When installing this fireplace at an elevation above

4,500 feet (in Canada), check with local authorities.

Consult your local gas utility for assistance in

determining the proper orifice for your location.

10

Page 11

Vermont Castings GPF

1

ab

d

e

The Vermont Castings Majestic Products Company reserves the right to make changes in design, materials, specifications, prices and discontinue

colors and products at any time, without notice.

c

f

2

6

7a,b

5

4

3

9

8

4237

GPF

Item / Model Number Part Number

1. Complete Log Set 20004457

1a. Log C1 20004451

1b. Log C2 20004452

1c. Log C3 20004454

1d. Log C4 20004453

1e. Log C5 20004455

1f. Log C6 20004456

2. Burner Assy. 20003733

3. Hose/Regulator Assy. - LP 50000248

4. Cover 20004450

5. Dante Valve 20004482

6. Natural Supply Line 50000198

7a. Short Stem Orifice - Natural 20004497

7b. Short Stem Orifice - LP 20004498

8. Volcanic Rock 20000198

9. LP Gas Cylinder Base 20004578

10. LP Conversion Kit 20004752

11. NG Conversion Kit 20004753

Contact The Vermont Castings Majestic Products

Company with questions concerning prices and

policies covering replacement parts. Parts may be

ordered through your distributor or dealer.

You will need the following information when ordering

replacement parts:

• The appliance model number.

• The serial number.

• A description of the part.

Should you need additional information beyond what

your dealer can furnish, contact:

The Vermont Castings Majestic Products Company

410 Admiral Blvd.

Mississauga, Ontario

Canada L5T 2N6

11

Page 12

Vermont Castings GPF

Accessories

The following accessories for these appliances are available form your local Vermont Castings Majestic Products

Company distributor. Each accessory comes with a separate installation instruction for the particular appliance. Be

sure to read each instruction thoroughly before installing.

Description Model Number

Patio Fire Optional Safety Screen Kit PFOSK

Villa Patio Fire (Urn) Base PFCBUMB

Chalet Patio Fire (Octagonal) Base PFCBOMB

CAUTION: This appliance is a highly engineered system, and, as such, must be operated only with The

Vermont Castings Majestic Products Company approved components. If you use an unapproved component

to make any modifications, you may create a possible fire hazard and will void the Vermont Castings Majestic

Products Company warranty. In addition, such action may void the coverage provided by the owner’s

insurance.

12

Page 13

LIMITED WARRANTY & EXTENDED LIFE TIME PROTECTION

For Vermont Castings Gas Appliance Products*

BASIC WARRANTY:

The Vermont Castings, Majestic Products Company (hereinafter referred to

collectively as the "Company") warrants that your new Vermont Castings Gas

Appliance is free from manufacturing and material defects for a period of one

year from date of installation, subject to the following conditions and

limitations.

EXTENDED LIFE TIME WARRANTY:

The heat exchanger, combustion chamber and ceramic burner parts of every

*The Vermont Castings, Majestic Products Company products are warranted

for life to the original owner, subject to proof of purchase and the following

conditions and limitations:

1.

This new Vermont Castings product must be installed by a competent,

authorized service contractor. It must be installed and operated at all times in

accordance with the Installation and Operating instructions furnished with the

product. Any alteration, willful abuse, accident, or misuse of the product shall

nullify this warranty.

2.

This warranty is non-transferrable, and is made to the original owner, provided

that the purchase was made through an authorized supplier of the Company.

3.

This warranty is limited to the repair or replacement of part(s) found to be

defective in material or workmanship, provided that such part(s) have been

subjected to normal conditions of use and service, after said defect is confirmed

by the Company's inspection.

4.

The Company may, at its discretion, fully discharge all obligations with respect

to this warranty by refunding the wholesale price of the defective part(s).

5.

Any installation, labour, construction, transportation, or other related costs/

expenses arising from defective part(s), repair, replacement, or otherwise of

same, will not be covered by this warranty, nor shall the Company assume

responsibility for same. Further, the Company will not be responsible for any

incidental, indirect, or consequential damages, except as provided by law.

6.

All other warranties - expressed or implied - with respect to the product, its

components and accessories, or any obligations/liabilities on the part of the

Company are hereby expressly excluded.

7.

The Company neither assumes, nor authorizes any third party to assume, on

its behalf, any other liabilities with respect to the sale of this Vermont Castings

product.

8.

The warranties as outlined within this document do not apply to chimney

components or other non Vermont Castings accessories used in conjunction

with the installation of this product.

9.

The Company will not be responsible for . . .

a) Down drafts or spillage caused by environmental conditions such as near-

by trees, buildings, roof tops, hills, or mountains.

b) Inadequate ventilation or negative air pressure caused by mechanical

systems such as furnaces, fans, clothes dryers, etc.

10.

This warranty is void if:

a) The fireplace has been operated in atmospheres contaminated by chlorine,

fluorine or other damaging chemicals.

b) The fireplace is subjected to prolonged periods of dampness or

condensation.

c) Any damage to the fireplace, combustion chamber, heat exchanger or other

components due to water, or weather damage which is the result of, but

not limited to, improper chimney/venting installation.

d) Any alteration, willful abuse, accident, or misuse of the product.

Glass doors are not warranted for breakage due to misuse or accident.

Brass parts should be cleaned with lemon oil only. Brass cleaners cannot be used.

Mortar mix and masonry cleaners may corrode the brass finish. The Company will

not be responsible for, nor will it warrant any brass parts which are damaged by

external chemicals or down draft conditions.

1) Contact your supplier. Make sure you have your warranty, your sales receipt,

and the model/serial number of your Vermont Castings product.

2) DO NOT ATTEMPT TO DO ANY SERVICE WORK YOURSELF.

*The Vermont Castings, Majestic Products Company products

bearing this special Warranty Seal of Approval carry a

comprehensive Limited Lifetime Warranty . This includes the

Flame

Ceramic Burners, Heat Exchange System and Combustion

Chamber. All other parts are covered for one year.

410 Admiral Blvd.

Mississauga ON L5T 2N6

GLASS DOORS & BRASS PLATED PARTS

IF WARRANTY SERVICE IS NEEDED . . .

Insta-

Vermont Castings GPF

GARANTIE DE BASE:

The Vermont Castings, Majestic Products Company (aux présentes nommée

la "Société") garantit votre nouveau foyer au gaz Vermont Castings contre

tous défauts de fabrication et de matières premières pour une période d'un an

à compter de la date d'installation, sujet aux conditions et limitations suivantes.

GARANTIE A VIE PROLONGEE:

Les pièces de l'échangeur de chaleur, de la chambre à combustion et du brûleur

en céramique de tout produit *The Vermont Castings, Majestic Products

Company sont garanties pour la vie de l'acheteur d'origine, le tout sujet à une

preuve d'achat et aux conditions et limitations suivantes:

1.

Ce nouveau produit Vermont Castings doit être installé par un entrepreneur

de service autorisé et compétent. Il doit être installé et utilisé en tout temps

selon les instructions d'installation et de fonctionnement fournies avec le produit.

T oute altération, abus volontaire, accident ou mauvais usage du produit annulera

cette garantie.

2.

Cette garantie n'est pas transférable et est offerte à l'acheteur au détail d'origine,

à condition que l'achat soit effectué par l'entremise d'un détaillant autorisé de la

Société.

3.

Cette garantie est limitée à la réparation ou au remplacement de(des) pièce(s)

trouvée(s) défectueuse(s) en matières premières ou main-d'oeuvre, à condition

que lesdites pièces aient été sujettes aux conditions normales d'usage et de

service, après que ledit défaut a été confirmé par une inspection par la Société.

4.

La Société peut, à sa discrétion, se décharger entièrement de toutes obligations

se rapportant à cette garantie en remboursant le prix de gros de la(des) pièce(s)

défectueuse(s).

5.

Tous les frais/dépenses d'installation, de main-d'oeuvre, de construction, de

transport ou autres causés par une (des) pièce(s) défectueuse(s), une réparation,

un remplacement ou autre, ne seront pas couverts sous cette garantie, et la

Société n'assume aucune responsabilité pour ceux-ci. De plus, la Société ne

pourra être tenue responsable pour tous dommages fortuits ou indirects sauf la

ou prévu par la loi.

6.

Toutes autres garanties, exprimées ou sous-entendues, en ce qui a trait au

produit, ses composants et accessiores, ou toutes obligations/responsabilités

de la part de la Société sont aux présentes expressment excluses.

7.

La Société n'assume et n'autorise personne à assumer, en son nom, toutes

responsabilités en ce qui a trait à la vente de ce produit Vermont Castings.

8.

Les garanties, telles que décrites dans ce document, ne s'appliquent pas aux

compasants de cheminée ou aux autres accessoires non Vermont Castings

utilisés conjointement pour l'installation de ce produit.

9.

La Société n'encourrera aucune responsabilité pour . . .

a) Les refoulements de cheminées ou débordements causés par les conditions

environnementales comme par les arbres, les édifices, les toits, les côteaux

ou les montagnes adjacents.

b) Une ventilation inadéquate ou une pression d'air négative causée par des

systèmes mécaniques comme les fournaises, les ventilateurs, les

sécheuses, etc.

10.

Cette garantie est nulle si:

a) Le foyer a été utilisé dans une atmosphère contaminée par du chlore, du

fluor ou tous autres produits chimiques.

b) Le foyer est assujetti à de longues périodes d'humidité ou de condensation.

c) Des dommages sont causés au foyer, à la chambre de combustion. à

l'échangeur de chaleur ou aux autres composants par de l'eau ou par la

température qui est le résultat mais sans y être limité, d'une mauvaise

installation de cheminée/ventilation.

d) Toute altération, abus volontaire, accident ou mauvais usage du produit

annulera cette garantie.

Les portes en verre ne sont pas garanties contre le bris causé par un mauvais

usage ou un accident.

Les pièces en laiton devraient être nettoyées qu'avec de l'essence de citron. Les

nettoyeurs de laiton ne peuvent pas être utilisés. La Société ne sera pas responsable

pour, et ne garantit pas les pièces en laiton qui sont endommagées par des conditions

chimiques externes ou de refoulement.

1. Communiquez avec votre détaillant. Assurez-vous que vous avez votre garantie,

2. NE TENTEZ PAS D'EFFECTUER DES REPARATIONS VOUS-MEME.

*Les foyers à gaz The Vermont Castings, Majestic Products

Company portant ce scean d'approbatic de la garantie

spéciale sont couverts par une garantie limitée à vie. Celle- ci

inclue les brüleurs en céramique Insta-Flame, le'échangeur de

chaleur et la chambre à combustion. Toutes les autres

pièces sont couverte pour un an.

PORTES EN VERRE & PIECES PLAQUEES LAITON

SI UN SERVICE SOUS GARANTIE EST REQUIS . . .

votre reçu de caisse ainsi que le numéro de modèle/série de votre produit

Vermont Castings.

13

Page 14

Vermont Castings GPF

14

The Vermont Castings

Majestic Products Company

410 Admiral Blvd. • Mississauga, Ontario, Canada L5T 2N6 • 905-670-7777

www.majesticproducts.com • www.vermontcastings.com

© The Vermont Castings Majestic Products Company

Loading...

Loading...