Page 1

IW4 WB / WBV

IW7 WB / WBV

Roller Brake Tester

for vans and trucks up to 13t / 18t axle load

Standard Operating Procedures

and User’s Manual

English

D1 0412BA1-GB04

Page 2

IW4/IW7 WB/WBV

EDITION

Version 4 of the operations manual dated 2005-08-08

D1 0412BA1 GB04

Software Version 1.43

Software Version 1.44 / MB

Software Version 1.45 / Portugal

Software Version 1.46 / Deutschland

Software Version 1.48 / Hongkong

© MAHA GMBH & CO. KG.

All rights reserved. Any reproductions of this document, partial or complete, are only allowed

with prior consent of MAHA GmbH & Co. KG.

All rights reserved in cases of patent granting or registration of design.

The contents of this version have been checked with great care. However, errors cannot be fully

excluded. Please contact MAHA should you find errors of any kind.

Subject to technical change without notice.

These instructions are intended for users with previous technical knowledge in the field of

vehicle testing technology as well as basic computer knowledge and MS-Windows operating

system application.

Windows and Windows for Workgroups is a registered trademark of the Microsoft-Corporation.

MANUFACTURER

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

Hoyen 20

D-87490 Haldenwang/Allgäu

Telephone: 08374 / 585-0

Telefax: 08374/ 585-499

Internet: http://www.maha.de

e-mail: maha@maha.de

SERVICE

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

- Service dept. Hoyen 20

D-87490 Haldenwang/Allgäu

Hotline: 0180 56242 + extension

60 for brake testers, test lanes

80 for lifting technology

90 for performance testers, exhaust and air conditioning service equipment

Service: 0180 5624250

Telefax: 0180 5624255

II D1 0412BA1-GB04

Page 3

IW4/IW7 WB/WBV

TABLE OF CONTENTS

1 Description.................................................................................................................1

1.1 Introduction.....................................................................................................................................1

1.2 General Information about Brake Testing......................................................................................1

1.2.1

Vehicle with a Driven Axle ..............................................................................................2

1.2.2

4-Wheel Drive Vehicle....................................................................................................2

1.3 Technical Data ...............................................................................................................................5

1.3.1

Electrical Data.................................................................................................................5

1.3.2

Mechanical Data.............................................................................................................6

1.3.3

Electronic........................................................................................................................7

1.4 Standard Equipment IW4/IW7 WB/WBV (4WD) ...........................................................................7

1.5 Noise Emission ..............................................................................................................................7

1.6 Equipment IW7 MB Version...........................................................................................................8

2 Safety..........................................................................................................................9

2.1 Introduction.....................................................................................................................................9

2.2 Safety Regulations for Commissioning ........................................................................................10

2.3 Safety Regulations during Operation ...........................................................................................10

2.4 Safety Regulations for Service Work ...........................................................................................10

2.5 Attention.......................................................................................................................................11

2.6 Further Information.......................................................................................................................11

2.7 Combination with Accessories .....................................................................................................11

2.8 Exchange of Parts........................................................................................................................11

2.9 Safety Features............................................................................................................................12

2.9.1

Lockable Main Switch...................................................................................................12

2.9.2

Sensor Rollers (Brake Tester)......................................................................................12

2.9.3

Pit Safety (Option).........................................................................................................12

2.9.4

Warning and Information Labels...................................................................................12

3 Operations ...............................................................................................................13

3.1 Symbol Description ......................................................................................................................13

3.2 IW7 Equipment Variations............................................................................................................16

3.3 IW4 Equipment Variations............................................................................................................19

3.4 Preparations for a Brake Test......................................................................................................22

3.5 Running a Brake Test ..................................................................................................................22

3.5.1

Determining the Roller Resistance ...............................................................................23

3.5.2

Ovality Test (optional)...................................................................................................23

3.5.3

Maximum Brake Force Test .........................................................................................24

3.6 Imbalance Display (Optional).......................................................................................................25

3.7 Special Features on Test Stands with MB Mode .........................................................................25

3.8 Special Points about the Portugal-Mode......................................................................................26

3.9 Special Points about the Sweden Mode.......................................................................................26

3.10 Special Points about the Hongkong Mode...................................................................................27

4 Maintenance, Error Codes......................................................................................29

4.1 Maintenance of the Roller Set......................................................................................................29

4.2 Description of Error Codes...........................................................................................................30

4.3 General Error Codes....................................................................................................................30

4.4 Additional Defect Codes on 4-Wheel Drive Test Stands .............................................................32

4.5 Installation and Dismantling of the Test Stand.............................................................................32

D1 0412BA1-GB04 III

Page 4

IW4/IW7 WB/WBV

IV D1 0412BA1-GB04

Page 5

IW4/IW7 WB/WBV Description

1 Description

1.1 Introduction

The IW4/IW7 WB/WBV (4WD) belong to the group of roller brake testers.

This class includes two different measuring methods to record brake forces:

! the testing of drive torque or

! the testing of drive power.

The former is applied in the MAHA IW4/IW7 WB/WBV (4WD) brake tester. The

IW4/IW7 WB/WBV (4WD) consists of a proven roller set and an open-ended electronic system

based on a processor board with an integral operating system.

The standard test stand may be expanded to a complete test line by using the MAHA

accessories.

1.2 General Information about Brake Testing

To avoid skidding it is important that the brake forces of the individual wheels of one axle are the

same. Just as important is the minimum brake torque for each individual wheel, so that when

braking no vehicle brake is overburdened. Consequently, each wheel is tested individually on the

brake tester.

For measuring the brake force, a static and a dynamic method are available. Using the static

method the force necessary to rotate a wheel which is positioned on a plate, with applied brakes

is determined. The dynamic method is more practice orientated - whereby the wheel is brought

up to a predetermined RPM by the motor driven roller set and then the brakes are applied. A

sensor roller measures the wheel revolutions. A comparison of the drive roller RPM to the

sensor roller RPM determines how large the slippage is. For safety reasons, all MAHA brake

testers automatically interrupt the brake test at a slippage of approximately 30%.

The measurement principle is the same for both methods of testing. The drive motor is

supported in a rotary fashion (motor housing not supported); without any additional support, the

drive shaft and the housing would counter rotate when under load, depending on the force

distribution. The additional support consists of a flexible beam, on which the housing rests. The

steel beam bends corresponding to the torque produced by the motor, which the beam resists.

The torque is zero at the beginning of the static test. With the dynamic test method, the torque is

just high enough to set the drive rollers with the vehicle wheel in motion with the brakes not

applied.

A strain gauge is mounted on the transverse beam which converts the brake force into a usable

electrical value.

For the IW4/IW7 WB/WBV (4WD)) brake tester the dynamic test method is used. This method

ensures the most accurate measurement. There is simply no alternative for 4 wheel drive brake

testing.

D1 0412BA1-GB04 1

Page 6

Description IW4/IW7 WB/WBV

1.2.1 Vehicle with a Driven Axle

Drive the wheel axle to be tested onto the roller set. This will push both sensors rollers down

which measure the RPM of the wheels. Now both drive motors of the roller set will slowly

accelerated to nominal speed turning both vehicle wheels forward. When the drive motors have

reached nominal speed a comparison is made between the nominal drive roller speed and the

sensor roller speed in order to be able, at any time, to switch off the drive motors when a

slippage of 30% is exceeded. (This is to protect the drive motors against overload and the tires

against excessive wear.)

The READY indicator will light up, signaling that the test rig is ready to start the brake test.

During brake tests the vehicle is decelerated to a point, that at least one sensor roller exceeds

30% slippage and the drive motors are switched off.

1.2.2 4-Wheel Drive Vehicle

On non-permanent 4-wheel drive vehicles the brakes are tested with the 4-wheel drive switched

off, just like vehicles with only one drive axle.

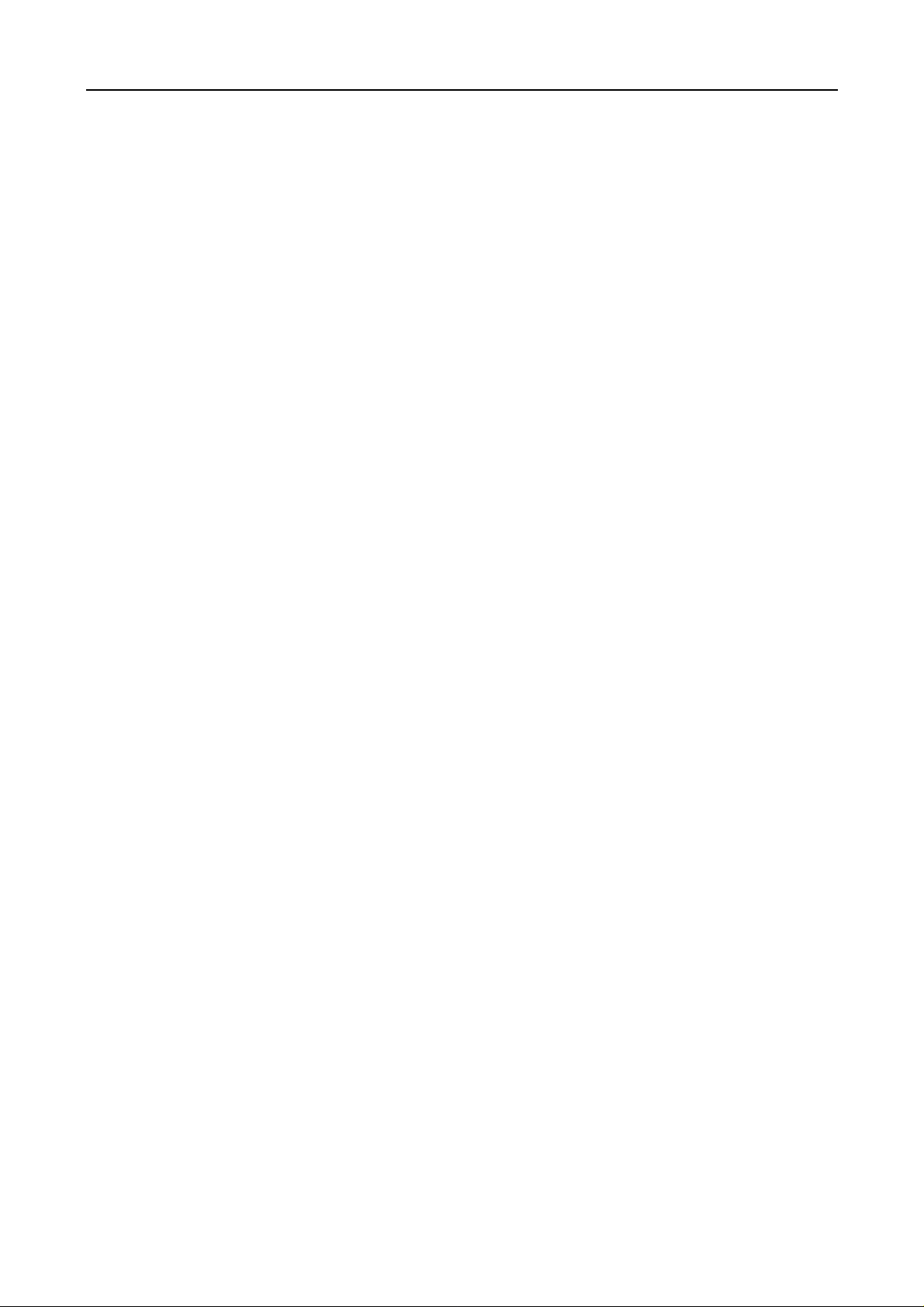

Principle of 4 Wheel Drive

On 4-wheel drive vehicles the torque applied to the drive shaft is evenly distributed to all four

wheels, i.e. a quarter of the total torque will be applied to each wheel. The same applies for the

brake torques that arise when braking. When testing 4 wheel drive vehicles it must therefore be

ensured that no brake torque will be transferred from one vehicle wheel to the other. This is

accomplished if no torque is applied to the drive shaft of the differential during the brake test.

The following example will explain this in detail:

In order to simulate a defective brake, one brake is disabled. Now only one brake of the axle to

be tested is enabled. If the brake test is done on a standard test stand where the torque is not

eliminated from the drive shaft, the same force applies to the strain gauges of both drive motors,

i.e. the same brake torque will be indicated. This would lead to the false assumption that the

brakes are fully intact. If the test was conducted correctly, no brake torque would be indicated for

the wheel with the disabled brake and the actual brake torque applied to the other wheel would

appear.

If both wheels of the axle to be tested are rotating forward during the brake test, the vehicle will

be lifted out of the test rig, as torque is transferred by the drive shaft to the wheels of the other

vehicle axle. To prevent this, the wheels counter rotate with the same RPM, one vehicle wheel is

driven in forward direction and the other wheel in reverse direction. This eliminates the torque

built-up in the differential against the drive shaft and transmission of torque to the other vehicle

axle.

2 D1 0412BA1-GB04

Page 7

IW4/IW7 WB/WBV Description

As the brake characteristics depend on the rotating direction of the wheels (the brake linings and

brake drums are ground in forward direction), only the brake torque of the wheel rotating in

forward direction is measured. For this reason, the brake test has to be done separately for each

wheel.

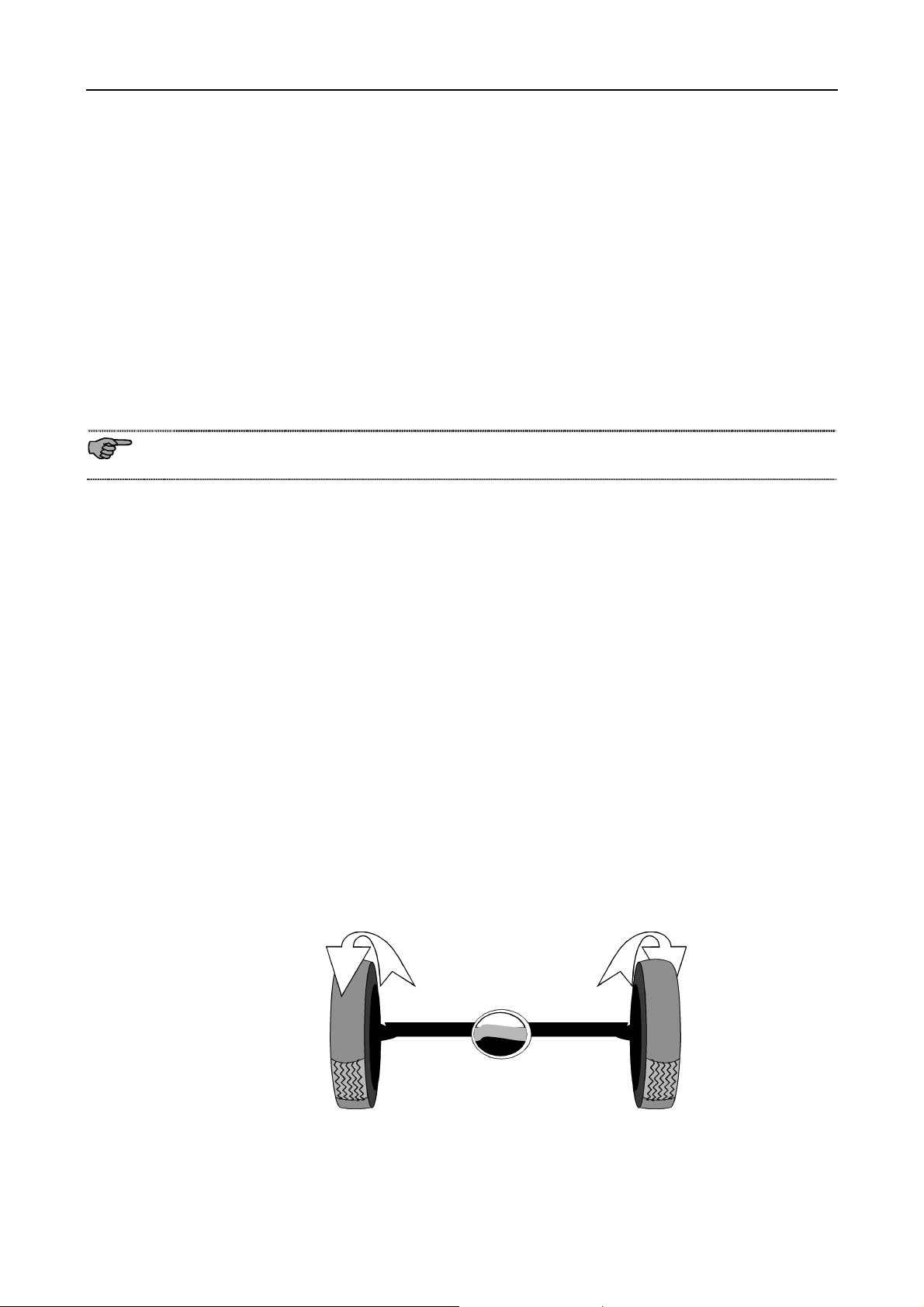

In order to obtain a reliable comparision between the brake forces of both wheels of the same

axle, the same pedal force will have to be applied at the brake test of the left and right wheel. To

accomplish this, a pedal force meter can be connected to the vehicle's brake pedal.

It is also possible to measure the current pressure Pm of the hydraulic brake by means of a

pressure sensor.

Testing of various 4-wheel drive types

There are three different types of 4-wheel drives:

a) Disengageable drive shaft leading to the differential

b) Visco-clutch (VC) in the drive shaft leading to the differential

c) Rigid drive shaft between the differentials

a) Disengageable drive shaft leading to the differential

On vehicles equipped with non-permanent 4-wheel drive, the brakes are tested with the 4-wheel

drive switched off, just like vehicles with only one drive axle.

b) Visco-clutch (VC) in the drive shaft leading to the differential

There are two different Visco-clutch types. The soft Visco clutch has a higher torsibility

(viscosity) than the hard Visco clutch, therefore no torque is transferred to the other wheels

when the drive shaft rotation is low.

D1 0412BA1-GB04 3

Page 8

Description IW4/IW7 WB/WBV

As described above, brake tests on 4-wheel drive vehicles are feasible if both wheels on the

same axle counter-rotate at the same speed. As, in practice, the circumference of the left and

right wheel is not exactly the same due to different tire tread depths and uneven tire pressure,

the RPM of the two drive motors is normally different. Therefore the drive motors must control

their speed in order to obtain the same RPM for both wheels.

Approximately the same speed of the roller set drive motors will be sufficient for a 4-wheel drive

vehicle having a soft VISCO clutch in the drive shaft as no brake torque is transferred by the

VISCO clutch when the drive shaft rotation is low. Therefore the speed control of the drive

motors alone will be sufficient in this case.

Contrary to the above, when testing the brakes of 4-wheel drive vehicle having a hard VISCO

clutch in the drive shaft both wheels on the same axle must rotate synchronously during the

brake test, as the clutch viscosity is so low that even the slowest rotation of the drive shaft will

transfer brake torque to the other wheels through the VISCO clutch.

c) Rigid drive shaft between the differentials

To perform a brake test on a 4-wheel drive vehicle having a rigid drive shaft, the wheel rotations

must be exactly controlled in such a way that no brake torque can be transferred by the drive

shaft.

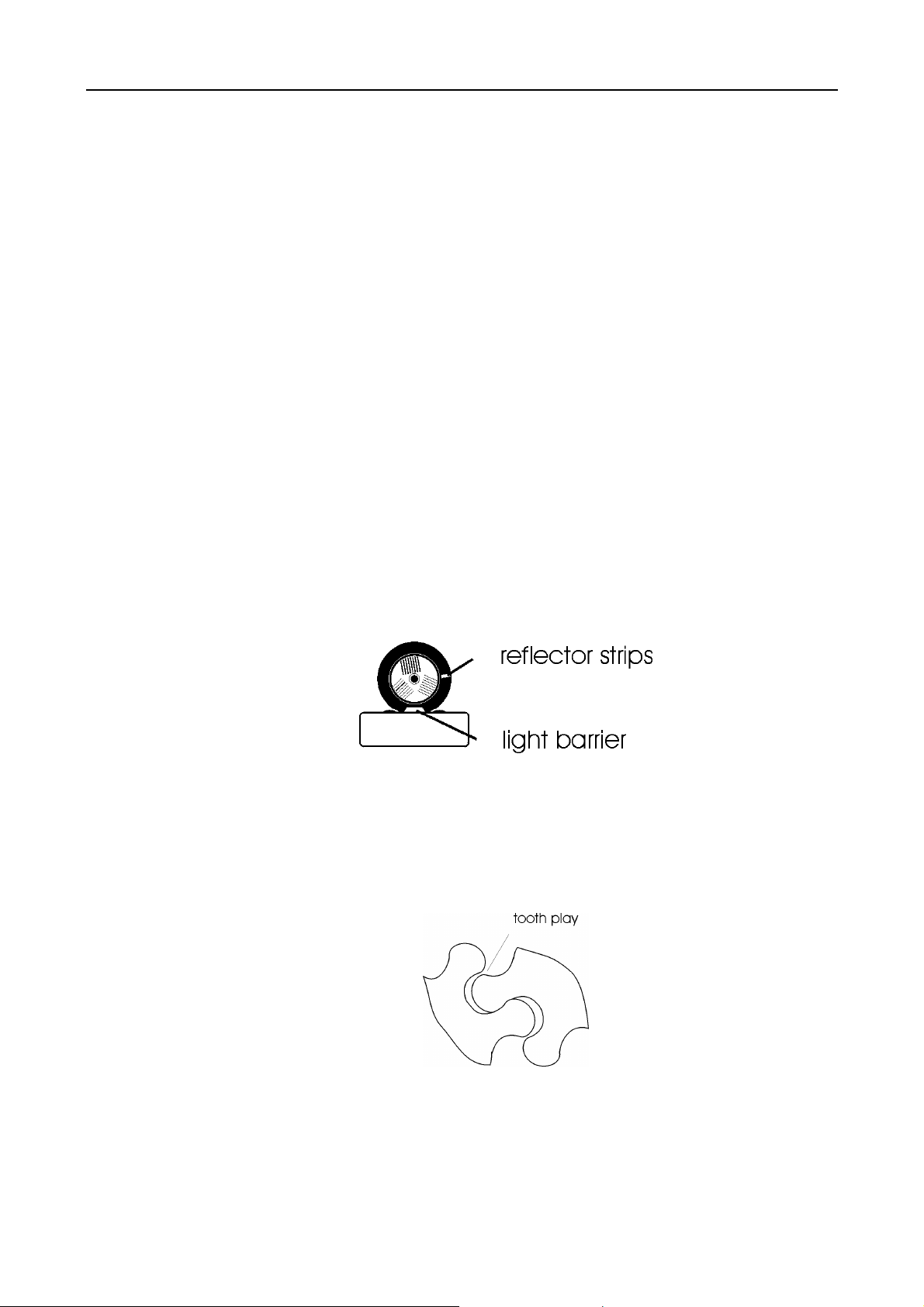

Controlling the synchroneous rotation of the wheels

In order to control synchronous rotation of the wheels, reflector strips are fastened to the sides

of the wheels which trigger a signal via two photo-electric cells, mounted on the side of the roller

set.

On vehicles equipped with a rigid drive shaft or with a hard Visco clutch the wheels cannot be

individually turned. If one vehicle wheel is turned forward in the roller set, the other wheel (on the

same axle) will be turning backwards in a synchronous manner. If one wheel is turned slowly in

forward or backward direction, one will note that the other wheel starts turning with a little delay.

This slight delay in following the other wheel to turn is caused by the gear play (backslash of

teeth) inside of the differential.

To perform a brake test on a 4-wheel drive vehicle having a rigid drive shaft, the wheel rotation

must be controlled in such a way that no brake torque can be transferred by the drive shaft. This

is achieved by staying within the gear play of the differential during the brake test. The

differential will be in a "balance" state.

4 D1 0412BA1-GB04

Page 9

IW4/IW7 WB/WBV Description

To be able to effectively use this, the exact backlash of teeth is assessed in a learning mode:

Initially the left drive motor will be switched on to accelerate the left vehicle wheel to nominal

speed. As the right drive motor is switched off and thus running free, the left wheel is dragging

the right wheel along. The flanks of a tooth in the differential touch each other on one side. Now

the first limit position of gear play is measured by the reflector strips and the photo electric cells.

The procedure is now reversed, the left drive motor of the roller set is switched off and the right

vehicle wheel is accelerated to nominal speed. This time the left wheel is dragged along and in

the differential the flanks of teeth touch each other on the opposite side. The second limit

position of the gear play will now be measured. Out of the two measured limit positions the

center of gear play is calculated. This "center of gear play" is used to control the rotation of

wheels during the brake test.

During the brake test, both drive motors are accelerated to a speed where the "center of gear

play" is reached. One vehicle wheel will rotate forward, the other in opposite direction. As soon

as the nominal speed is reached by both wheels, and no brake torque is being transferred to the

drive shaft, brake testing may be started.

As with standard vehicles the drive motors will be switched off if excessive slip occurs.

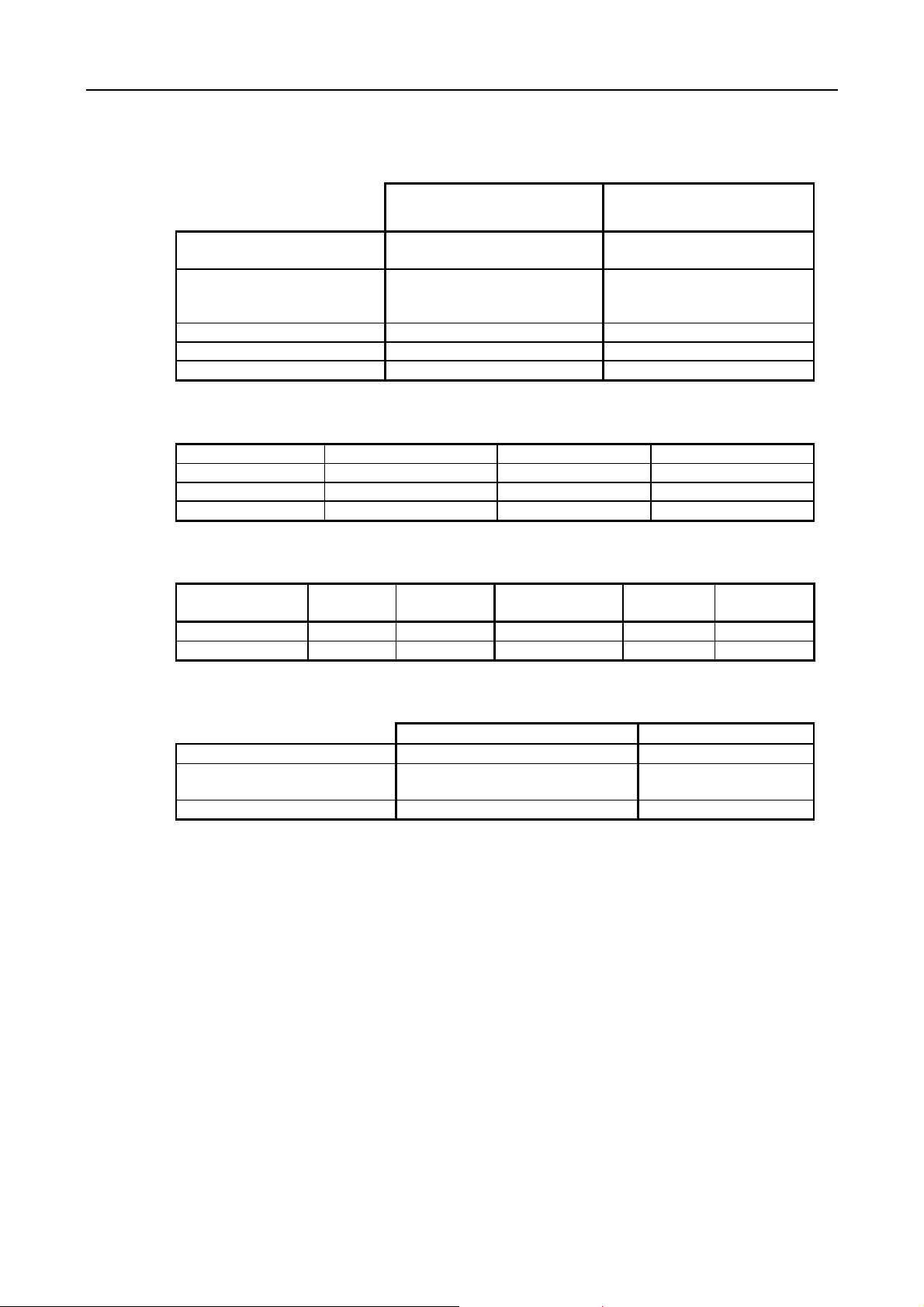

1.3 Technical Data

1.3.1 Electrical Data

IW7

Voltage supply 400 V, 3 Phases, 50 Hz 400 V, 3 Phases, 50 Hz

Special voltage 230 V, 3 Phases, 50 Hz 230 V, 3 Phases, 50 Hz

Motor drive capacity

IW7/1 2 x 7,5 kW IW4/1 2 x 7.5 kW

IW7/2 2 x 11 kW IW4/2 2 x 9 kW

IW7/3 2 x 11 kW

IW7/4 2 x 7,5 kW

Star delta starters for motors with IW7/1 E, IW7/2 E, IW4/1 E and IW4/2 E

Dahlander-control system for IW7/3 E and IW7/4 E

Main switch fuse Main switch fuse with special voltage

IW7/1 and IW7/4 50 A slow IW4 (4 wheel drive) 63 A slow

IW4/1 35 A slow IW7 (4 wheel drive) 100 A slow

IW4/2 50 A slow

IW7/2 and IW7/3 63 A slow

Only trained electricians or authorized service technicians are allowed to carry out work on

electrical parts of the brake tester. (Control box, roller set, etc.)

(4 wheel drive)

IW4

(4 wheel drive)

D1 0412BA1-GB04 5

Page 10

Description IW4/IW7 WB/WBV

1.3.2 Mechanical Data

Axle load (Standard) roller

set, closed, self-supporting

Track ( e.g. Roller set No. 2) min.= 200 mm

max.=track min.+2200 mm

Roller diameter 265 mm 202 mm

Roller axle separation 475 mm 430 mm

Dimensions roller set (HxWxL) 700x1142x1427 mm (HxWxL) 500x1043x1225mm

Test speed

IW7/1 3 km/h IW4/1 2.3 km/h

IW7/2 3 km/h IW4/2 2.3 km/h

IW7/3 3 km/h and 6 km/h

IW7/4 3 km/h and 6 km/h

Roller friction coeffic ients

Steel IW7

(4 wd)

Dry ca. 0.9 ca. 0.9 dry ca. 0.9 ca. 0.9

Wet ca. 0.9 ca. 0.7 wet ca. 0.9 ca. 0.9

IW4

(4 wd)

IW7

(4 wd)

max. 18 t max. 13 t

max.=track min.+2200 mm

Plastic IW7

(4 wd)

IW4

(4 wd)

min.= 200 mm

IW4

(4 wd)

Display range depending on model

IW7 (4 wd) IW4 (4 wd)

small measuring range 2 x 0-6 kN (optional 2 x 0-8 kN) 2 x 0-7,5 kN

large measuring range 2 x 0-30 kN

(optional 2 x 0-40 kN)

Diameter Analog display 350 mm 350 mm

Display accuracy > 2%

Measuring accuracy > 1%

Operating temperature -10°C to +40°C

Double pressure pneumatic gauge

Pressure gauge dial diameter 200 mm

2 x 0-30 kN

6 D1 0412BA1-GB04

Page 11

IW4/IW7 WB/WBV Description

1.3.3 Electronic

Processor PCB with operating system

EEPROM for variable system configuration

6 Slots for system expansion

Serial interface RS 232

Connection for LCD-Display

Subject to technical alterations without notice!

Only trained electricians or authorized service technicians are allowed to carry out work on

electrical parts of the brake tester. (Control box, roller set, etc.)

1.4 Standard Equipment IW4/IW7 WB/WBV (4WD)

IW4 (4WD): Roller set no.1 or no.2

IW7 (4WD): Roller set no.2

Single wheel mode

Delayed automatic switch on

Automatic switch-off after exiting the roller set

Automatic slip switch-off including pointer stop and automatic re-start

Electronic strain gauge

Lockable main switch

RS 232 Interface

Optional:

Weighing system; static (2 pressure cells) or dynamic (4 pressure cells)

Standard equipment subject to change without notice.

Standard equipment of the c urrent price list apply.

In addition to the standard versions, Maschinenbau Haldenwang (MAHA) offers various expansion possibilities which

are listed in the current pric e l i st.

1.5 Noise Emission

The noise emission value created when the tester is in operation is less than 70dB(A) in the

work area of the operational personnel.

D1 0412BA1-GB04 7

Page 12

Description IW4/IW7 WB/WBV

1.6 Equipment IW7 MB Version

! The roller brake testers equippped with the Mercedes-Benz-Program differ in several aspects

from the standard version:

! Sticker indicating MB-recognition and month and year of production

! Optical acknowledgement of the slip shut-off via 2 lamps below the display instruments

! Manual- and automatic operation

! Remote control

! Key switch / Emergency-Off switch on the front side of the display panel (optionally available

for inspection pit)

! Counter for hours of operation

! Calibration possibilities using push button in control cabinet while drive motors running

! Possible to install roller set using MAHA-adapter set in MB-standard pit

! Running rollers made of grooved steel with sanding or synthetic coating

! Additional malfunction-release button with integrated malfunction lamp

8 D1 0412BA1-GB04

Page 13

IW4/IW7 WB/WBV Safety

2 Safety

2.1 Introduction

Before commissioning the machinery please read the operating instructions carefully and

thoroughly and comply with the instructions. The instruction manual should always be

conveniently stored to be readily accessible at all times.

Injury to persons incurred due to non-compliance with these operating instructions is not covered

by the product liability laws.

MAHA will not accept and is not liable for any claims for damage to the test stand and/or vehicle

or service costs incurred due to non-compliance with these operating instructions.

Warning means that instructions that are not complied with or incompletely complied

with can endanger persons.

Attention means that instructions that are not complied with or incompletely complied

with can lead to equipment damage.

Notes provide additional information.

Safety information is provided to warn about dangerous situations and help prevent damage to

equipment and injury to persons. For your own safety it is imperative that all safety regulations

included in these instruction be carefully observed.

Carefully observe all national and international safety and health regulations. Every user is

responsible for observing all regulations which apply to his workplace and is obliged to integrate

any new regulations that may be initiated.

D1 0412BA1-GB04 9

Page 14

Safety IW4/IW7 WB/WBV

2.2 Safety Regulations for Commissioning

! The test stand may only be commissioned by MAHA service technicians or those authorized

by MAHA as service partners.

! All electrical parts of the testing machinery must be protected from moisture and humidity.

! The test stand may not be installed or operated in exlpsion endangered rooms or wash halls.

2.3 Safety Regulations during Operation

! The MAHA test stand may only be used and operated for its intended purpose and within its

stated performance limits.

! The MAHA test stand may only be operated by trained, authorized personnel. The test lane

and the surrounding work area must be kept clean.

! The test stand must be switched off when not in use and the main switch secured against

tampering with a padlock.

! No persons are allowed in the MAHA test stand danger zone. Rotating or moving parts are

dangerous. (e.g. test stand rollers)

! In case of emergency turn the main switch (the Emergency-Off switch) to 0.

! Running vehicle engines represent potential carbon monoxide poisoning. The operator/owner

is responsible for providing sufficient air ventilation.

2.4 Safety Regulations for Service Work

! Service work such as installation, maintenance or repair work on the MAHA test lane

Eurosystem may only be done by MAHA service technicians or authorized service partner

technicians.

! All work done on electrical parts of the equipment is to be carried out by trained, qualified

electricians.

! Before doing any repair / maintenance / set up work turn off the main switch and secure it

against tampering.

10 D1 0412BA1-GB04

Page 15

IW4/IW7 WB/WBV Safety

2.5 Attention

! When the vehicle is on the brake tester roller set with the driven axle, exit the roller set only

when the roller drive is running. Exiting when the roller drive is not on can destroy the electric

motors due to extreme acceleration of the rollers.

! The brake tester may not be operated without a functioning slip monitoring. Otherwise there

is risk of tire damage.

! Never start a vehicle engine using the roller set drive. This can lead to equipment damage.

! No vehicle with a rigid 4-wheel drive may be tested on the brake tester with a standard roller

set. This can lead to damage to both vehicle and test lane. Please ask your MAHA service

representative for more information.

2.6 Further Information

! 4 wheel drive vehicles cannot be tested using the standard roller set. Erroneous tests will be

the result.

A special 4 wheel drive control is necessary. Please ask your MAHA service representative

for more information.

! Avoid unnecessary strain on vehicle and test stand.

Drive the vehicle slowly onto the test stand.

Pay attention that the vehicle has sufficient ground clearance.

2.7 Combination with Accessories

The test stand may only be operated with accessories which MAHA has provided or approved.

This applies especially for every accessory with electrical and/or mechanical connections to the

MAHA test stand.

2.8 Exchange of Parts

Only genuine MAHA spare parts may be used to guarantee reliable functioning and thereby the

safety of the MAHA test stand. Original MAHA spare parts are manufactured under the highest

quality standards.

D1 0412BA1-GB04 11

Page 16

Safety IW4/IW7 WB/WBV

2.9 Safety Features

The safety features are to be inspected regularly by an authorized service technician.

(recommended interval: 12 months). Official guidelines should be followed at all times.

The test stand may not

be operated when the safety features are defective.

2.9.1 Lockable Main Switch

Serves as normal On and Off switch for the test stand as well as an EMER OFF switch.

The switch can be secured against unauthorized switch on by using a padlock.

2.9.2 Sensor Rollers (Brake Tester)

Both sensor rollers must be pressed to start the roller brake tester.

The RPM difference between sensor rollers and test stand roller determines the slip. If the

preset slip is reached the roller drive switches off.

2.9.3 Pit Safe ty (Option)

Light barrier or infrared movement sensor. Prevents the test stand from starting up when

persons are in the pit.

2.9.4 Warning and Information Labels

Warning and information labels are attached to the MAHA test stand. The labels may not be

changed or removed. Unreadable labels must be replaced.

12 D1 0412BA1-GB04

Page 17

IW4/IW7 WB/WBV Operations

3 Operations

3.1 Symbol Description

These symbols describe the signal lamps and operational elements which are located on the

front of the test stand. Various switches are optional and may not be available.

Symbol Description

Ready

When this lamp is lit, the brake pedal may be operated (and/or

Hand brake) .

Power ON

When this lamp is lit the test stand is ready for operation.

Automatic/Malfunction

Standard test stand: The red malfunction lamp is located on

the left of this symbol. To the right is the Power-On button.

Test stand with MB-Mode: The green lamp indicates that the test

rig is in automatic operation.

Zero point-Potentiometer

Using the zero-point potentiometer on the right hand side of the

test rig the pointers on the analog-display can be adjusted. In

order to do this, the Power-On button must be pressed while the

potentiometer is being turned.

D1 0412BA1-GB04 13

Page 18

Operations IW4/IW7 WB/WBV

Optional (Various switches are optional and are not necessarily available)

Symbol Explanation

Remote Control

If using the RCF 30 this lamp is lit to indicate that there is contact

with the pressure converters. If using the Tele-BPS II, a lit lamp

indicates that contact has been established with the remote

control. A blinking lamp indicates that a pressed button on the

remote control has been confirmed.

Driving Direction Display (Only with 4 wd test stands)

The lit up arrow indicates which wheel is turning in driving

direction.

Roller Heating

When the rotary switch is turned to the right -> Roller heating is

ON. The switch is lit up green.

Pit Safety Device

Red lamp is lit up continually:

The pit safety device has been triggered and the test stand has

been completely switched off. Investigate the reason for the pit

safety activation and correct the problem before the test stand is

put into operation again. To restore operation the green button

must be pushed.

Red lamp is blinking:

The pit safety system - model GSL - is defective.

The blinking of the lamp with pit safety system GSL means that

once the malfunction has been corrected, the pit safety must be

reinstated.

Graphic

This lamp will light up after pressing the Graphic button on the

remote control. Within 12 seconds after test begin the graphic

drawing will take place

Brake Force Application Limiter (optionally available

Lights up when the brakes have been applied too quickly.

Malfunction Lamp and Release Button (MB-Mode)

The red defect lamp lights up when a malfunction occurs. (Error

code via pointer, s. Chap. 4). To confirm press the release button.

Manual (MB-Mode)

When this lamp is lit the test stand is in manual mode.

14 D1 0412BA1-GB04

Page 19

IW4/IW7 WB/WBV Operations

Optional (various switches are optional and not necessarily available)

Symbol Description

Driving Direction Reverse

Use the reversing switch to reverse the driving direction of the

rollers. It is possible then to drive onto the test stand from 2

directions.

Speed Switch-Over

The testing speed of the rollers can be switched over from 3 km/h

to 6 km/h. (only possible with IW7E /3, or IW7E /4).

Slip Switch-Off Control (MB-Mode)

The green lamp on the display lights up on the side on which the

slip occurs first

'Unoccupied'-Simulation for Weight Simulator

When the rotary switch is set to position 1 the test stand is in "

inactive" mode to facilitate safe operation of the weight simulator.

Turn the rotary switch to 0 to re-activate the test stand.

Manual Measurement Range Switch-Over

The large measurement range is always activated when the

motors are turned on on test stands not equipped with load cell or

remote control. For safety reasons, however, the smaller

passenger car slip switch-off value has been selected as a presetting. The switch-over to the higher truck slippage value only

takes place when the brake force exceeds 5 kN. If the test should

be conducted using the truck slip value even with small brake

values, use this button to switch directly over to the truck slip

value. When a passenger car is driven onto the test rollers the

small measurement range can be selected using this switch.

Single Wheel Switch

A selector switch has been installed for single wheel tests for test

stands without remote control.

Position 0: both rollers start up

Position L: only the left-hand roller starts up

Position R: only the right-hand roller starts up

If the selector switch is set to 0 after the single wheel

measurement is completed the rollers will start up

automatically when occupied!

Weight Transfer Switch (Portugal-Mode)

A selection switch is built into test lanes with shock absorber

testers for the weight measurement.

Position A: Weight of the axle (for TRK) is measured via the

brake tester (internal scale).

Position B: Weight of the axle (for CARS) is measured via the

shock absorber tester (external scale) and transferred to the

brake tester.

D1 0412BA1-GB04 15

Page 20

Operations IW4/IW7 WB/WBV

3.2 IW7 Equipment Variations

The following pages offer diagrams of the different equipment variations available for the IW7.

The suggestions are in no way binding and can vary. See the current price list for available

equpiment accessories.

Fig. 3-1: IW7 (4 wd) Standard equipment i wth optional accessories

A POWER-ON lamp

B Main switch

C Single wheel switch

D Adjustment screw rotary foot

E "Malfunction" lamp; "Mains-On" button

F Data printer "PRINTCOM" (optional)

G Control-Lamp "Remote control"

H Zero-point potentiometer

I "Ready" lamp

J Differential display (optional)

K Manometer pressure gauge

16 D1 0412BA1-GB04

Page 21

IW4/IW7 WB/WBV Operations

Fig: IW7 4-wheel drive version with o p ti o n al accesso ri es, side slip tester display and operator guidance

A POWER-ON lamp

B Main switch

C 4WD switch driving direction display

(optional)

D Adjustment screw rotary foot

E Pit security (optional)

F Roller heating (optional)

G "Malfunction" lamp; "Mains-On" button

H Data printer "PRINTCOM" (optional)

I Control-Lamp "Remote control"

J Zero-point potentiometer

K Data printer "MINC" (optional)

L "Ready" lamp

M "Graphic" lamp (optional)

N Differential display (optional)

O "Application limiter" lamp (optional)

P Manometer pressure gauge

Q "Operator guidance" LED or LCD (optional)

R Minc side-slip tester display (optional)

The display console can be ordered either with LED or LCD display for operator guidance,

pressure display, wheel weights and deceleration.

D1 0412BA1-GB04 17

Page 22

Operations IW4/IW7 WB/WBV

Fig. 3-3: IW 7 (4 wd) Mercedes Benz-version

A EMERGENCY-OFF switch

B Main switch

C "Malfunction" lamp; "Unlock" button

D Adjustment screw rotary foot

E "Automatic" button; "Manual" button

F Cable remote control single-wheel mode

G Data printer "PRINTCOM" (optional)

H Control-Lamp "Remote control"

I Zero-point potentiometer

J "Ready" lamp

K Slip switch-off right/left control lamps

L Differential display (optional)

M Manometer pressure gauge

N POWER-ON lamp

18 D1 0412BA1-GB04

Page 23

IW4/IW7 WB/WBV Operations

3.3 IW4 Equipment Variations

The following pages offer diagrams of the different equipment variations available for the IW4

The suggestions are in no way binding and can vary. See the current price list for available

equipment accessories.

Fig. 3-4: IW 4 exp ansion step 1

A POWER-ON lamp

B Manometer pressure gauge

C Main switch

D Adjustment screw rotary foot

E Single-wheel switch

F "Malfunction" lamp; "Power-On" button

G Measuring range switch-over

H READY display

D1 0412BA1-GB04 19

Page 24

Operations IW4/IW7 WB/WBV

Fig. 3-5: IW 4 exp ansion level 2

A POWER-ON indication

B Double pressure manometer and digital

weight display of the wheel weight

C Main switch

D Adjustment screw rotary foot

E Operator guidance display

F READY display

G Measuring range switch-over

H "Remote control" lamp

I MALFUNCTION lamp, POWER-ON lamp

20 D1 0412BA1-GB04

Page 25

IW4/IW7 WB/WBV Operations

Fig. 3-6: IW 4 exp ansion level 3

A POWER-ON lamp

B Double pressure manometer and digital

weight display of the wheel weight

C Main switch

D Adjustment screw rotary foot

E Operator guidance display

F READY display

G Measuring range switch-over

H "Remote control" lamp

I MALFUNCTION lamp, POWER-ON lamp

D1 0412BA1-GB04 21

Page 26

Operations IW4/IW7 WB/WBV

3.4 Preparations for a Brake Test

The procedures described here are for normal operation of 4 wheel drive test stands. (4 wheel

drive switch to position "0"). There is a seperate description available for the 4 wheel drive

test. (See Tele-BPS II + RCF 30 operating manual).

If the test stand is equipped with an internal scale no weight may burden the roller set when the

test stand is switched on. Otherwise the weighing electronic will store this switch on weight as an

Offset value and the measurement will be distorted.

! Enable main switch

The needle of the display will complete an offset balance and return to zero.

! Press POWER ON key

Press POWER ON button or the '*' key on the remote control.

The white POWER ON lamp should now be lit up. The needles will again adjust and return to

zero. The test stand is now ready for operation!!

On test stands without a PC-console but equipped with a DIN A4-printer which is offline or

defective, the message "Printer defective (ONLINE?)" will appear after switch-on. If the test

should be carried out without the printer, the printer can be de-activated by pressing the Power

On button again.

! Select the measuring range (optional)

If the test stand is equipped with a manual measurement range button, use it to select the

desired measurement range. The integrated green lamp will light up when the large

measurement range is selected.

! Conduct a single-wheel test (optional)

Test stand which are not equipped with a remote control have a single wheel switch which

facilitates single wheel testing. Depending on the test stand version the Power-On key must

be pressed after a single wheel test.

The rollers will start up automatically after a single wheel test when the switch has been re-set to

the 0 position.

3.5 Running a Brake Test

The manufacturer does not accept any liability claims for damage to low lying vehicle parts.

Drive first axle to be tested onto the roller set switch into idle. After the delayed start-up, the

motors will be started individually. Should the motors switch off again immediately, the start-up

monitor has been triggered to protect your vehicle and/or its tires against damage. One or both

wheels may be jammed (seized bearings, jammed brake pads, etc.).

22 D1 0412BA1-GB04

Page 27

IW4/IW7 WB/WBV Operations

3.5.1 Determining the Roller Resistance

Before the brake pedal is applied, check needles for roller resistance. The roller resistance can

have various values depending on vehicle type and load:

Car ca. 0,1 bis 0,6 kN

Truck ca. 0,5 bis 4,0 kN

The left-hand roller resistance should be approximately the same as the right-hand resistance. If

large differences exist, a bearing might be faulty or a brake be jammed.

If the roller resistance of one or both wheels is so excessive that tire damage by the rollers may

be anticipated or if the brake pedal has already been depressed, the start-up monitor will be

triggered when the wheel is started, immediately switching the test stand off.

3.5.2 Ovality Test (optional)

The ovality test serves to determine the quality of the brakes. "Ovality" defines faulty concentric

running of a wheel, e.g. out of round due to brake drum or disk brake deformation.

After the motors have started, wait until the yellow READY lamp lights up. The brake test can

now be started.

Apply moderate force to the brake pedal

Apply moderate force to the brake pedal - approx. half of the max. brake

force (switch-off value) and maintain brake force constant for at least one

wheel revolution. The needles in the display will show the ovality value.

The difference between the maximum and minimum display value of the

needle is ovaIity in kN.

! Press Ovality key

If a remote control is being used for testing, the ovality key must remain pressed

for one entire wheel revolution. The ovality is automatically stored with the brake

values.

Ovality Measurement

Fig. 3-7: The ovality measurement

The ovality value should not exceed 20% of the constant brake force. This value only represents

a suggested guideline and is not based on any legal regulation.

D1 0412BA1-GB04 23

Page 28

Operations IW4/IW7 WB/WBV

3.5.3 Maximum Brake Force Test

On test stands with brake force application limiter (optional), the motors switch

off automatically if the brake pedal was depressed too fast, and/or the brake

force application limiter warning lamp lights up. In this case the vehicle must

be braked until the wheels block or, if this is not possible, the vehicle must exit

the roller set. Once the Ready-lamp lights up after the roller set is re-occupied

the brake force application limiter warning lamp will extinguish. Now the

test can be repeated. Make sure that braking is done slowly and constantly.

! Depress brake pedal completely.

Depress brake pedal slowly and evenly.

! Observe the instruments on the display panel

Observe the pointer instruments on the display cabinet. The pointers of the brake forces

should move forward corresponding to the applied pedal force.

! Terminate the measurement

As soon as one wheel has reached a slip of 30%, both rollers will be switched off. Now the

maximum brake force has been reached. This value will be displayed by the needles until the

motors are restarted (needle stop). Should the motor not switch off inspite of maximum pedal

force, the brake force reached at maximum pedal force is the maximum brake force.

On test stands equipped with a brake force application limiter (optional) the red "Application

limiter" lamp will be lit if the brake pedal is depressed too fast. In this case the test will have to be

repeated.

The ratio of maximum brake force of the service brake to the weight of the vehicle should not be

less than the legally permissable min. brake force!

Never drive a driven axle from the roller set unless both motors are running and the yellow

ready lamp is lit. This could lead to serious damage to the electrical and mechanical system of

the test stand!

Brake Test

Fig. 3-8: Running a Brake Test

24 D1 0412BA1-GB04

Page 29

IW4/IW7 WB/WBV Operations

3.6 Imbalance Display (Optional)

! Imbalance display

The imbalance display will show the

difference between the right-hand and lefthand brake force in percentage (%). The

imbalance display will be activated when a

pre-set total brake force is reached.

The brake force difference should not

exceed the legal permissable value.

! Testing in the large measuring range

If a vehicle is tested using the large measurement range (measurement range switch-over on

the remote control or on the test stand) it can happen that the necessary trigger value to

activate the imbalance display is not reached because the attained brake forces were not

high enough. In this case, there will be no imbalance display.

3.7 Special Features on Test Stands with MB M ode

Selection of the operating mode

Test stands with MB-Mode are equipped with an operational selector switch making it possible

to switch between:

• "Automatic" :

• "Manual" :

control. Observe the green lamp which indicates in which operational mode the test stand is.

the rollers will start up automatically after the switch-on time delay.and

the rollers are started one after the other manually by using the remote

The green lamp will extinguish if the pit safety system is triggered.

Switching on the unoccupied test stand

The "Automatic" operational mode is started by turning on the main switch while the test stand is

unoccupied. Use the selector switch to switch to "Manual" operation.

Switching on the occupied test stand

The "Manual" operational m ode is started by turning on the main switch while the test stand is

occupied. The test stand can only be switched to "Automatic" operational mode when it is

unoccupied.

Acknowledging malfunctions

Test stands with MB-Mode are also equipped with a malfunction button. If problems occur during

operation, the malfunction lamp will light up. Certain problems can be ack nowledged by pressing

the malfunction button. (see defect codes).

If the trouble occurs while the test stand is occupied, it immediately switches to "Manual"

operation.

D1 0412BA1-GB04 25

Page 30

Operations IW4/IW7 WB/WBV

3.8 Special Points about the Portugal-Mode

Select weight transfer

Test stands with the Portugal-Mode are equipped with a selection switch

with which the weight transfer can be selected. (in unoccupied test

stand) :

Position A: Weight of the axle (for TRK) is measured via the brake tester

(internal scale).

Position B: Weight of the axle (for Car) is measured via the shock

absorber tester (external scale) and transferred to the brake tester.

3.9 Special Points about the Sweden Mode

The Pseudo 4 wheel drive measurement can be done using the special rotation direction

reverse on test stands with the Sweden mode.

Test Procedure:

1. In unoccupied test stand press the key combination SHIFT + D on the remote control to

activate the rotation direction reverse and/or manual operation.

Following message appears on the display:

2. Confirm the rotational direction reverse with

the *-key on the remote control.

Deactivate the rotational direction reverse

again using the #-key on the remote control.

3. Drive onto the test stand.

Following message appears on the display:

4. Press the left Motor-On key of the remote

control.

Both motors start simultaneously, counter clockwise. The selected side rotates in a forward

direction.

Conduct the measurement.

If slip is reached the motors switch off.

If slip is not reached , the motors must be switched off using the Motor Off key on the remote

control.

* = J A # =

L I = V O R W

L I = V O R W

D R E H

D R E H

D R E H

K E H R

N E I N

K E H R

K E H R

Ä R T S

Ä R T S

The right side is measured after the left hand

side.

Following message appears on the display:

5. Press the right Motor On key on the remote

control.

Both motors start up simultaneously, counter clockwise. The selected side rotates in the forward

direction.

Conduct the measurement.

If slip is reached the motors switch off.

If slip is not reached , the motors must be switched off using the Motor Off key on the remote

control.

6. After the motors have switched off the measurement values are shown on the display.

Store the measurement value using the appropriate key combination. (see the operating

manual of the remote control).

26 D1 0412BA1-GB04

R E = V O R W

D R E H

K E H R

Ä R T S

Page 31

IW4/IW7 WB/WBV Operations

After exiting the roller set and storing of the measurement values the rotational direction reverse

is immediately deactivated. The test stand is in the Automatic mode again.

3.10 Special Points about the Hongkong Mode

Test stands with the Hongkong mode one side will continue to measure even once the other

side has switched off via slip. The other wheel will be blocked at a later point in time due to the

pedal force being raised.

Test Procedure

Switch on the test stand and and wait for ready-to-test.

1 Drive onto the rollers.

2 Rollers start up.

3 Brake slowly until one roller side has reached slip.

Either the left or right hand side will switch off.

The respective pointer falls back to zero.

4 Slowly continue to brake until the other roller side has reached slip.

Either the left or right hand side will switch off.

The respective pointer stops and the other pointer shows the first brake value.

Slip is too small:

The roller does not switch off.

Release the brake.

Store the max. value using the corresponding key combination on the remote control.

D1 0412BA1-GB04 27

Page 32

Operations IW4/IW7 WB/WBV

28 D1 0412BA1-GB04

Page 33

IW4/IW7 WB/WBV Maintenance, Error Codes

4 Maintenance, Error Codes

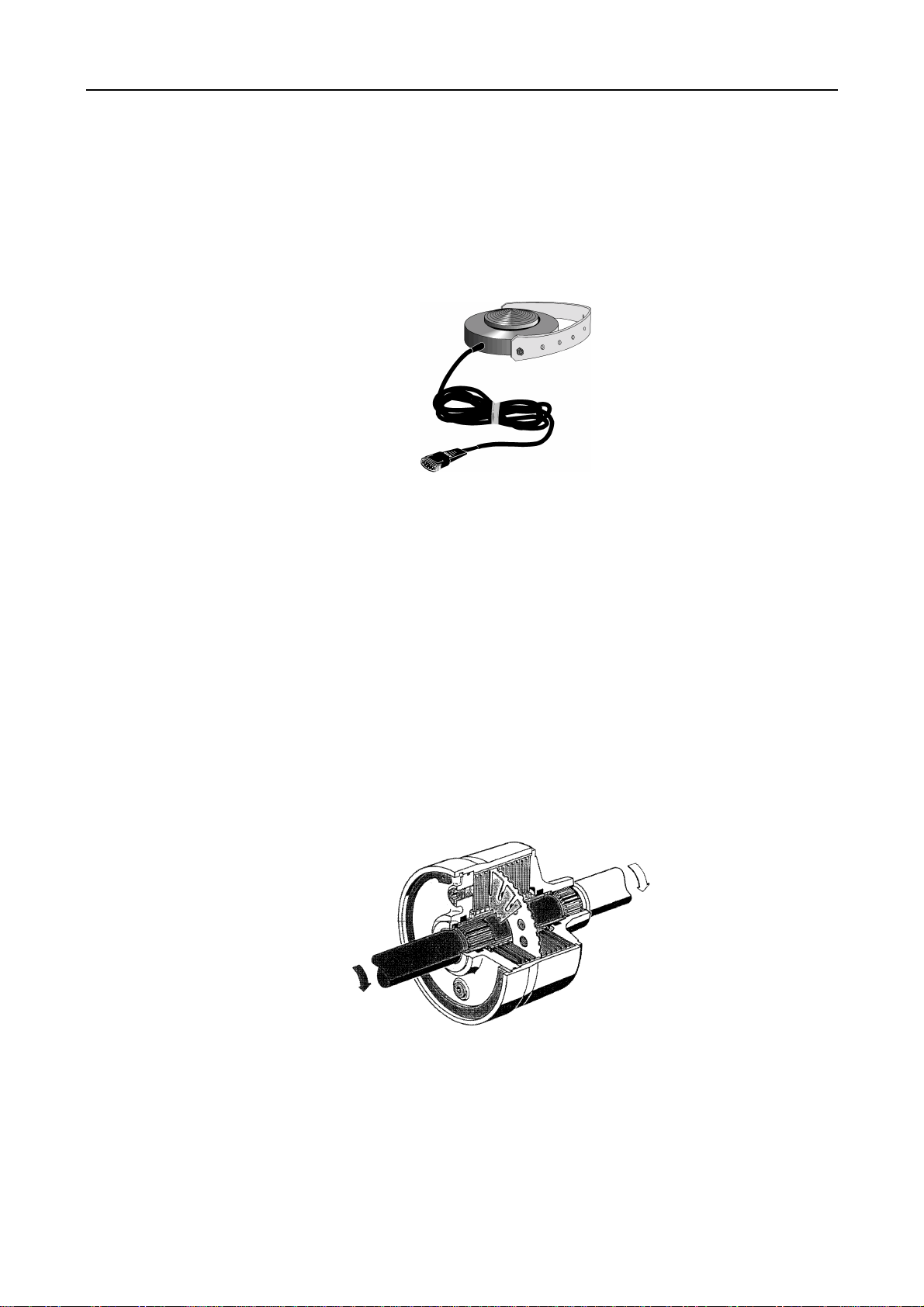

4.1 Maintenance of the Roller Set

The roller set should be inspected and serviced every 200 operating hours or once every 12

months, whichever comes first. The inspection should include a thorough check of the anchoring

of the roller set as well as all fasteners and screws. The chain tension must be checked for the

first time 14 days after initial commissioning and afterwards inspected on a monthly basis.

Fig. 4-1: Maintenance points on the roller set

! Remove the lateral cover plates of the roller set. Now grease the chain (1) along its entire

length well with a universal type lubricant (turn the rollers manually)

! The chain should have a slack of about 5 mm in either direction. If the chain does not have

enough tension, loosen the attachment screws (a). Turn the tension screw (b) until proper

tension is achieved. When this is completed re-tighten the attachment screws (a) and check

the chain slack again.

! The sensor roller hinges (2) must be regularly greased or oiled every 200 operating hours or

at least once a year.

D1 0412BA1-GB04 29

Page 34

Maintenance, Error Codes IW4/IW7 WB/WBV

4.2 Description of Error Codes

When problems occur with the operation of the IW4/IW7 WB/WBV (4WD) a "defect code" will

appear. This code can be read on the pointer of the small measurement range. All defect codes

(except 33) can be acknowledged using the POWER ON key or the '*' key on the remote

control.

E.g. defect code 32 will appear as follows:

3 kN on the left hand display

2 kN on the right-hand display

Fig.. 4-2: Analog display of an error code

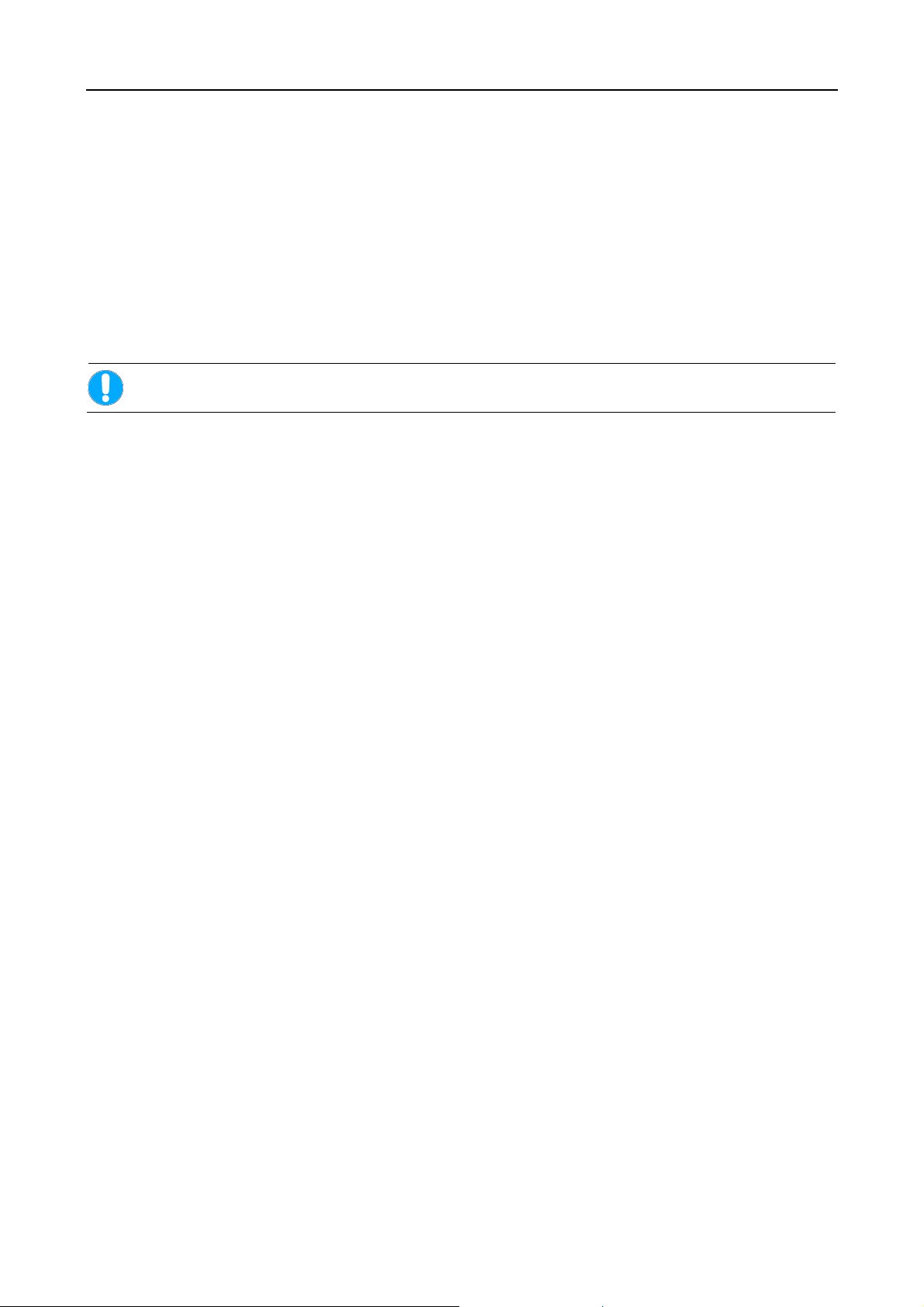

4.3 General Error Codes

Error Code Description Remedy

20

21

22

32 *) Left-hand proximity switch is defective

34 *) Right-hand proximity switch is defective

Right-hand motor protection switch is

set to 'Aus'/'OFF'

Left-hand motor protection switch is set

to 'Aus'/'Off'

Right and left-hand protection switch is

set to 'Aus'/'Off'

or

connection to the printed circuit board

of the test stand is disturbed

or

connection to the printed circuit board

of the test stand is disturbed

*) Error Codes 32 and 34:

Error messages can be acknowledged with the 'Power ON' key. Afterwards the pointers of

the analog display got to zero and the test stand is ready for testing again. Pay attention

that the exit assistance is no longer activated and that no slip monitoring takes place on

the defective side!

Press right-hand and/or left-hand motor

protection switch again. Switch main switch off

and then on again and press Power-On button.

Contact the MAHA-Service Dept.

ATTENTION ! Possible damage to the motors.

Check proximity switch to make sure switch

distance and connections have proper contact.

Contact MAHA-Service Dept.

ATTENTION ! Exit support is out of order!

Check proximity switch to make sure switch

distance and connections have proper contact

ATTENTION ! Exit support is out of order!

30 D1 0412BA1-GB04

Page 35

IW4/IW7 WB/WBV Maintenance, Error Codes

Defect Code Description Remedy

33 Both proximity switches are defective

or

not properly connected to the PCB of

the test stand

Selector switch 'Driving Direction

Reverse' (optional) is set on position 0.

Fuse of phase L2 and/or L3 has blown

out.

Switch for speed switch over is set to

Position 0 (optional)

40 Zero point adjustment is defective Re-adjust zero. While the Power-On button is

41

42

Only the left-hand sensor roller is

pressed down

Only the right-hand sensor roller is

pressed down

Check proximity switch to make sure switch

distance and connections have proper contact.

ATTENTION !Exit support is out of order! *)

Drive vehicle out of the rollers and set selector

switch 'Driving Direc tion Reverse' to position

'1' or '2' .

Switch test stand off and exchange fuses.

ATTENTION ! If the defect occurs a second

time do not operate the test stand any longer

and notify the customer service dept.

immediately!

pressed the defective zero point can be readjusted.

ATTENTION! Testing can be resumed after

pressing the Power-On key but the attained

measurement values will not be exact based on

the zero point deviation

If this defect occurs after the test stand has

been switched on :

it is highly likely that a sensor roller switch is

defective..

If this defect occurs when a vehicle drives onto

the rollers:

it is possible that the vehicle is not positioned

properly on the rollers and only one sensor

roller is pressed.

Re-position the vehicle and its axles and press

the Power-On key or the * key on the remote

control.

ATTENTION! Use extreme caution when

doing this! Customer service should be notified

immediately when sensor roller defects occur!

D1 0412BA1-GB04 31

Page 36

Maintenance, Error Codes IW4/IW7 WB/WBV

A

4.4 Additional Defect Codes on 4-Wheel Drive Test Stands

Slow blinking of the malfunction lamp:

reflector strips on the left-hand side

of the wheel.

Rapid blinking of the malfunction lamp:

strips on the right-hand side of the

wheel.

Rapid/slow blinking of the malfunction lamp:

strips on either side of the wheel.

The error messages will also appear on the analogue display and on the display.

Defect code Description Remedy

43 Moreg defective (general) Notify the service dept!

44

45

46

There is no signal from the left-hand

light barrier

No signal from the right-hand light

barrier

No signal from either light barrier

ttach reflector strips or position them correctly.

It is possible that the light barrier is defective.

In addition to the defect code the red defect

lamp is blinking:

slowly ⇒ left

fast ⇒ right

fast-slow ⇒ both

The program detects no

The program detects no reflector

The program detects no reflector

4.5 Installation and Dismantling of the Test Stand

The installation or modification of the roller set should only be carried out by the manufacturer's

trained authorized personnel or other qualified technicians to avoid any problems with

adjustments or settings. (This applies in particular to installed weighing systems.)

Operational malfunctions caused by unqualified installation or alteration work done on the test

32 D1 0412BA1-GB04

stand are not covered by the warranty. This regulation applies to the normal warranty period

also.

Page 37

Page 38

Page 39

Qualitätsnachweis

für Montage- und Servicearbeiten

Diesem Qualitätsnachweis liegen die Montage-, Kalibrier- und Servicean-

Bitte beachten

leitungen sowie die betreffenden Protokolle für die einzelnen Produkte gemäß

den Herstellerangaben bzw. den jeweils gültigen Richtlinien zugrunde.

Kundenanschrift

Firma

Ansprechpartner

Straße

PLZ, Ort

Telefon / Fax

Markenvertretung

Installation, Inbetriebnahme & Nachfolgeservice

Produkte

Typ: Seriennummer:

Bitte beachten

Firmenstempel

Raum für weitere Geräte Seite 2

Liste fortgeführt auf Seite 2

Bestätigung

Ort, Datum

Unterschrift Kunde

mit Firmenstempel

Raum für

Bemerkungen

Einweisung durchgeführt

Bedienungsanleitung erhalten

(Die CE-Konformitätserklärung befindet sich auf der letzten Seite)

Wir bestätigen hiermit die ordnungsgemäße Übergabe und die ordentliche

Ausführung der Servicearbeiten für die aufgeführten Geräte.

Ort, Datum

Unterschrift

Servicetechniker

Raum für

Bemerkungen

Die Firma MAHA als Hersteller der Produkte übernimmt Garantie- oder

Bitte beachten

Produkthaftungsansprüche nur bei ordentlich ausgefülltem Protokoll. Das

Protokoll ist innerhalb 2 Wochen nach Inbetriebnahme der Geräte an den

Bitte beachten

Hersteller zu schicken.

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

Hoyen 20 87490 Haldenwang Germany

Tel. +49 (0) 8374 585-0 Fax +49 (0) 8374 585-499 Internet: www.maha.de E-mail: maha@maha.de

10150600/1

Page 40

Installation, Inbetriebnahme & Nachfolgeservice

Produkte

Typ: Seriennummer:

10150600/2

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

Hoyen 20 87490 Haldenwang Germany

Tel. +49 (0) 8374 585-0 Fax +49 (0) 8374 585-499 Internet: www.maha.de E-mail: maha@maha.de

Page 41

Loading...

Loading...