Page 1

Four-Column Vehicle Lift

Trucklift

for passenger cars and vans up to max. gross weight of 8 t/10 t

Standard Operating Procedure

and User’s Manual

Englisch/English

D1 3602BA1-GB03

Page 2

Trucklift

DITION

E

Version 3 of the 22.10.1997 dated

D1 3602BA1-GB03

Software Version from 4.3

© MAHA GMBH & CO. KG.

All rights reserved. Any reproductions of this document, partial or complete, are only allowed

with prior consent of MAHA GmbH & Co. KG.

All rights reserved in cases of patent granting or registration of design.

The contents of this version have been checked with great care. However, errors cannot be fully

excluded. Please contact MAHA should you find errors of any kind.

Subject to technical change without notice.

These instructions are intended for users with previous technical knowledge in the field of

vehicle testing technology as well as basic computer knowledge and MS-Windows operating

system application.

Windows and Windows for Workgroups is a registered trademark of the Microsoft-Corporation.

ANUFACTURER

M

ERVICE

S

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

Hoyen 20

D-87490 Haldenwang/Allgäu

Telephone: 08374 / 585-0

Telefax: 08374/ 585-499

Internet: http://www.maha.de

e-mail: maha@maha.de

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

- Service dept. Hoyen 20

D-87490 Haldenwang/Allgäu

Hotline: 08374 / 585 + extension

260 for brake testers, test lanes

280 for lifting technology

290 for performance testers, exhaust and air condidioning service equipment

Service: 08374 / 585-110 bis - 113, - 115

Telefax: 08374 / 585-491

II

Page 3

Trucklift

ABLE OF CONTENTS

T

1 Safety Instructions....................................................................................................1

1.1 Safety Information..........................................................................................................................1

1.2 Further Information ........................................................................................................................2

1.3 Safety Features..............................................................................................................................2

1.4 Safety Guidelines...........................................................................................................................3

2 Description ................................................................................................................5

2.1 Usage, Applications .......................................................................................................................5

2.2 General View .................................................................................................................................5

2.3 Specifications.................................................................................................................................6

2.4 Noise Emissions ............................................................................................................................6

3 Installation.................................................................................................................7

3.1 General Information .......................................................................................................................7

3.2 Installation Location .......................................................................................................................7

3.3 Foundations ...................................................................................................................................8

4 Operation...................................................................................................................9

4.1 Controls..........................................................................................................................................9

4.2 Vehicle Tracks .............................................................................................................................10

4.3 Driving onto the Lift......................................................................................................................11

4.4 Lifting............................................................................................................................................12

4.5 Working on Raised Vehicles........................................................................................................12

4.6 Lowering ......................................................................................................................................13

4.7 Locking the Lift to Prevent Unauthorise d Oper ati on.................................................................... 13

5 Maintenance, Troubleshooting..............................................................................15

5.1 Maintenance ................................................................................................................................15

5.2 Repair Notes................................................................................................................................16

5.3 Troubleshooting Checklist ...........................................................................................................17

5.4 Lowering the Lift in the Event of a Power Failure ........................................................................19

6 Warranty, Service....................................................................................................21

6.1 Warranty ......................................................................................................................................21

6.2 Warranty Exclusion Clause..........................................................................................................21

6.3 Service.........................................................................................................................................22

III

Page 4

Trucklift

IV

Page 5

Trucklift

1 Safety Instructions

1.1 Safety Information

Safety Instructions are provided to warn about dangerous situations and to help avoid

injury to people.

The truck lift is only to be used for its

instructions!

trained authorized personnel

Only

Explosion protection!

The truck lift is not to be used in rooms liable to contain explosive mixtures!

lifts have no EX-protection!

The main power switch

In case of emergency, turn switch to 0-position.

Persons are not permitted in the da nger zone during lifting and lowering cycles.

Unauthorized persons

net load capacity

The

Persons may

Before repair-/maintenance-/set up work

tampering.

Secure the lift from unauthorized usage by

All work done on

electricians or service technicians only

Protect all parts of the machinery from humidity and moisture.

not climb

electrical parts

serves as

may not in any way be positioned underneath the

stated on the identification plate of the lift

on or be

intended purpose

may operate the truck lift.

Emergency-Off switch!

transported

of the equipment is to be carried out by

on the

turn off main switch and secure against

locking the main switch.

.

as described in the operating

may not be exceeded!

lift.

lifted vehicle

trained, qualified

Standard

!

D1 3602BA1-GB03 1

Page 6

Trucklift Safety Instructions

1.2 Further Information

At installation pay attention to the following:

Standard lifting platforms may not be operated in washing halls, rooms with high humidity or

outdoors! The lifting platform must be protected from any form of water splashing! Never

clean the lifting platform with high pressure cleaners or steam cleaners!

In rooms with very low ceilings it is recommended to install a ceiling light barrier. This can be

ordered from the manufacturer.

For safe operation pay attention to the following:

Read the standard operating procedures and user`s manual thoroughly!

accept and is not liable for any claims for damage or service costs incurred due to noncompliance with these operating instructions.

All official Accident Prevention Regulations must be thoroughly complied with!

Damages to

Keep the

Do not deposit any parts on the support arms or on the driving platform.

The

vehicle should be driven slowly onto the lifting platform

unnecessary strain on vehicle and lifting platform.

On

lifting platforms equipped with an axle jack

below the axle jack.

Balancing work

roll off the driving platform.

Pull the parking brake

All work done on impulse sensors and proximity switches should be carried out by

electricians.

low-lying vehicle parts

lifting platform

on the lift while the platform is being

and the

of the vehicle after entering the lifting platform.

are not covered by the warranty.

surrounding work area clean

pay close attention that no objects are

loaded

is forbidden. The vehicle may

.

to avoid putting any

MAHA will not

trained

1.3 Safety Features

The TRUCKLIFT is equipped with the following safety features:

Electronic lift synchronisation monitoring

and ensures that they are synchronised during lifting and lowering. If one carriage blocks all

the drive motors are switched off automatically.

Electronic bearing nut monitoring system

system only permits the unit to be moved to its lower starting position.

Bearing nut wear indicator

replaced.

Drive belt breakage safety system

automatically if a drive belt is defective.

Motor overload protection system

Catch nuts

The

main switch

switched off by turning the switch to position 0.

2 D1 3602BA1-GB03

, which support the load on the lift in the event of failure of the bearing nuts.

doubles as an

, lets you know in good time when the bearing nuts need to be

on all four columns. All motors are switched off

on all four columns.

emergency off switch

. This system monitors all the lifting carriages

on all four columns. If a bearing nut breaks the

. In an emergency, the unit can be

Page 7

Fehler! Verweisquelle konnte nicht gefunden werden. Trucklift

Adjustable guard rails

columns must be adjusted in such a way, that there is a clearance of approx. 150 mm

between the extension and the connection plates of the column. The adjustable guard rail

can be locked by tightening the M 8 screw.

around the lift and on the ramps. The

guard rails

on the four

150

Adjustable guard rails on all four columns

1.4 Safety Guidelines

The following points were taken into consideration at construction:

The safety regulations correspond with the prEN 1493.

The lifting platform meets the safety demands of the following guidelines:

- 89/392/EWG in connection with 91/368/EWG and 93/44/EWG EG-Maschinery Guidelines.

- 73/23/EWG EG-Low Voltage Guidelines

- 89/336/EWG EG-guidelines regarding electro-magnetic tolerance.

CE-Declaration of Conformity

The

Pay attention during operation:

The Accident Prevention Regulations of the country in which the lifting platform is being

operated apply.

The following guidelines apply within the European Union countries:

- 89/391/EWG Safety and Health Protection for the Employee.

- 89/654/EWG Safety and Health Protection in the Work Area.

- 89/655/EWG Safety and Health Protection when using Working Materials.

- 89/656/EWG Safety and Health Protetion when using personal Protective Clothing.

- 92/58/EWG Safety and/or Health Protection Identification at the Place of Work.

is attached to the Operating Instructions or Test Booklet.

EU-Guidelines are available from

DITR German Information Center for Technical Rules in DIN e.V.

10772 Berlin

D1 3602BA1-GB03 3

Page 8

Trucklift Safety Instructions

4 D1 3602BA1-GB03

Page 9

Trucklift

2 Description

2.1 Usage, Applications

The TRUCKLIFT 8 / TRUCKLIFT 10 is a device for lifting motor vehicles up to a maximum gross

weight of 8,000 kg / 10000 kg, with a maximum load of 6000 kg / 6600 kg permitted on any pair

of columns. The maximum lifting height of the unit is 2,1 m, making it easy to work on the

underside of the vehicle, even for taller staff members.

TRUCKLIFT is designed primarily for lifting vans. However, the vehicle tracks can easily be

adjusted for lifting normal cars as well.

The lift must be installed and prepared for operation by a properly trained technician.

Structural and technical alterations to the lift are prohibited.

Always observe the detailed operating and service instructions provided.

2.2 General View

4

Column

D1 3602BA1-GB03 5

is the control column.

Page 10

Trucklift Descriptions

2.3 Specifications

Max. rated load in t

Machine weight in kg

Column height HS in mm

Max. lifting height Ho in mm

Height above ground surface

Textmarke nicht definiert.

mm

Height to guard rail lower edge HB in

mm

Overall height HG in mm

Inside column width B

Max. horizontal clearance BM in mm

Overall width BG in mm

Inside track width B

Vehicle track width BB in mm

Column spacing LS in mm

Overall baseplate length LG in mm

Effective vehicle track length LF in

mm

8 10

1975

Fehler!

H

u in

in mm

L

E in mm

Trucklift 8 Trucklift 10

3500

2650

200

5810

5850

3200

2980

3800

1100 - 1640

617

6200

6510

5940

Overall length L in mm

Lifting period in s

Lifting travel in mm

Lifting speed in mm/s

Anchoring dowels

Concrete grade

Motor output

Voltage supply

Specifications subject to change without notice!

2.4 Noise Emissions

The noise emissions of the lift in the area occupied by the operating personnel are lower than

70 dB (A)

20 x UPAT

3 x 400 V + N + PE; 50 Hz

7800

54

1775

ca. 35

composite dowels

min. BN 25

4 x 2,2 kW

UKA 3 M 16

6 D1 3602BA1-GB03

Page 11

Trucklift

3 Installation

3.1 General Information

TRUCKLIFT is normally installed by the manufacturer's own trained technicians.

However, the lift can also be installed by the operator's own technical staff, provided that they

are

properly trained, with the necessary skills

experience in the proper use of

connections in accordance with the

composite dowels

VDE regulations

3.2 Installation Location

The lift can be installed in any suitable location. The only restriction is that the standard version

of the lift is not rated for use in rooms with

The installation location must be provided with the necessary power supply by the operator:

3~/N + PE 400/230 V, 50 Hz. The operator must also see to it that the power supply is protected

with a T35A circuit breaker in accordance with the VDE 0100 regulation.

. It is important that they should have

and the proper installation of the electrical

.

explosive atmospheres

The standard point for the power supply cable inlet to the lift is at the top in the control column.

However, the power supply cable can also be routed in through the hole provided in the

baseplate. In both variants, the cable must be protected with a suitable

The power supply cable must be connected to the terminals of the main switch in the control

console on the control column.

Before installation, suitable foundations conforming to the specifications of the manufacturer

MAHA must be provided. They must either be built specifically for installation of the unit, or the

operator must provide evidence that they conform to the specifications. The installation location

must be perfectly flat and level. If the foundations are installed in the open or in rooms where

winter weather conditions or frost can be expected, the foundations must be sunk down to

.

depth

cable support sleeve

.

frost

D1 3602BA1-GB03 7

Page 12

Trucklift Installation

3.3 Foundations

The concrete used for the foundations must be at least grade B25 and reinforced. Because of

the anchoring dowels used, the concrete base slab must also have a

200 mm

.

minimum thickness

of

The operator must provide evidence of the base slab load bearing capacity.

The foundations plan is also available from MAHA.

8 D1 3602BA1-GB03

Page 13

Trucklift

4 Operation

4.1 Controls

The TRUCKLIFT unit has four controls.

The

main switch

is used to turn the entire system on and

off, and also doubles as an emergency off switch.

The main switch must always be easily

accessible.

Its position should never be changed.

The

light switch

switch to the right to switch the

is identified by a light symbol. Turn this

on.

light

The

button is identified by an arrow pointing up. The

raise

lift stops moving immediately as soon as you release the

button. The lift also stops automatically when it reaches its

upper travel limit.

VorÖffnen des

Gerätes

Haupschalter

ausschalten!

Sicherheitsbestimmungen

Bedienung:

1

0

The

button is identified by an arrow pointing down.

lower

The lift stops moving immediately as soon as you release

the button. The lift also stops automatically when it reaches

its lower travel limit.

D1 3602BA1-GB03 9

Page 14

Trucklift Ôperation

4.2 Vehicle Tracks

The vehicle tracks can be moved laterally on the

crossbars to adjust the width to match the track width

of the vehicle to be lifted. Normally, you will only need

to adjust the left track.

Track to be adjusted

To adjust the track width, first remove the retaining

pins at the front and rear. Then move the track in the

desired direction by inserting a lever in the retaining

lug and levering against one of the holes in the

perforated section below. This must be done both at

the front and the rear, otherwise the track will not be

straight.

Adjusting the track

After adjusting the track position you must

secure it again with the retaining pins!

Front retaining pin

You do not have to adjust the other track, but you can

if you wish, for example in order to centre a vehicle

over a working pit. To do this, you must first unscrew

the retaining disks on the two retaining pins, and then

unscrew and remove the pins themselves. You can

then adjust the position of the track. Since this only

needs to be done once, no leverage aids are provided.

Fixed track"

After you have adjusted the track position you must

replace the retaining pins.

Retaining pin

10 D1 3602BA1-GB03

Page 15

Operation Trucklift

4.3 Driving onto the Lift

The control console is mounted on lifting column 1.

The main switch is on the side of the console. Turn

this switch to position 1 to turn on the power. The lift is

then ready for operation.

The main switch doubles as the

emergency off switch. In emergencies, simply turn

the switch to the 0 position to switch off the lift!

1

0

Remove all tools, chocks, stands etc. from the

working area of the lift.

Always make sure that the working area is

kept free of excessive dirt!

Lower the lift (see Lowering) until it stops

automatically in its starting position.

Drive the vehicle onto the lift tracks and stop so that it

is centred between the end columns.

The vehicle tracks of the lift must be

adjusted to match the track width of the

vehicle.

The actual gross weight of the vehicle should

never exceed the maximum rated load of 8 t.

1.

2.

= =

Secure the vehicle so that it can't roll away

(motor off, hand brake on, gear engaged,

chocks under the wheels).

D1 3602BA1-GB03 11

Page 16

Trucklift Ôperation

4.4 Lifting

You can lift the vehicle once it is properly positioned

on the lift and secured against rolling away. To start

the lift, press the '

' button. The lift stops as soon

###

as you release the button.

Nobody should ever be in the working area of

the lift while a vehicle is being lifted!

Whenever the lift is moved you should always

keep an eye on the load and everything used to keep

the load in place!

Lifting people and climbing on the lift or on the

vehicle when the lift is raised are all strictly prohibited!

You can now lift the vehicle to the desired height.

4.5 Working on Raised Vehicles

Sicherheitsbestimmungen

Bedienung:

Vor Öffnendes

Gerätes

Haupschalter

ausschalten!

Never place any items on the lift or the v ehicle

tracks!

Lifting people and climbing on the lift or on the

vehicle when the lift is raised are all strictly

prohibited!

Secure the vehicle so that it can't roll away

(motor off, hand brake on, gear engaged,

chocks under the wheels).

You can turn on the

by turning the light switch to

light

the right.

12 D1 3602BA1-GB03

Page 17

Operation Trucklift

4.6 Lowering

Sicherheitsbestimmungen

Before lowering, always make absolutely

sure that nobody is in the working area of the lift!

Remove all tools, chocks, stands etc. from the

working area of the lift.

Press the 'Ä' key until the platform is in its lowest

position. The lift stops automatically in its starting

position.

Bedienung:

Vor Öffnen des

Gerätes

Haupschalter

ausschalten!

4.7 Locking the Lift to Prevent Unauthorised Operation

When the lift is not being used you should

always lock it to prevent unauthorised operation!

To lock the main switch, first turn it to the 0 position.

Then press in the protruding pin and lock the switch in

this position with a padlock. This prevents

unauthorised operation of the lift.

1

0

D1 3602BA1-GB03 13

Page 18

Trucklift Ôperation

14 D1 3602BA1-GB03

Page 19

Trucklift

5 Maintenance, Troubleshooting

5.1 Maintenance

Regular maintenance is necessary to ensure reliable operation of the lift and a long service life.

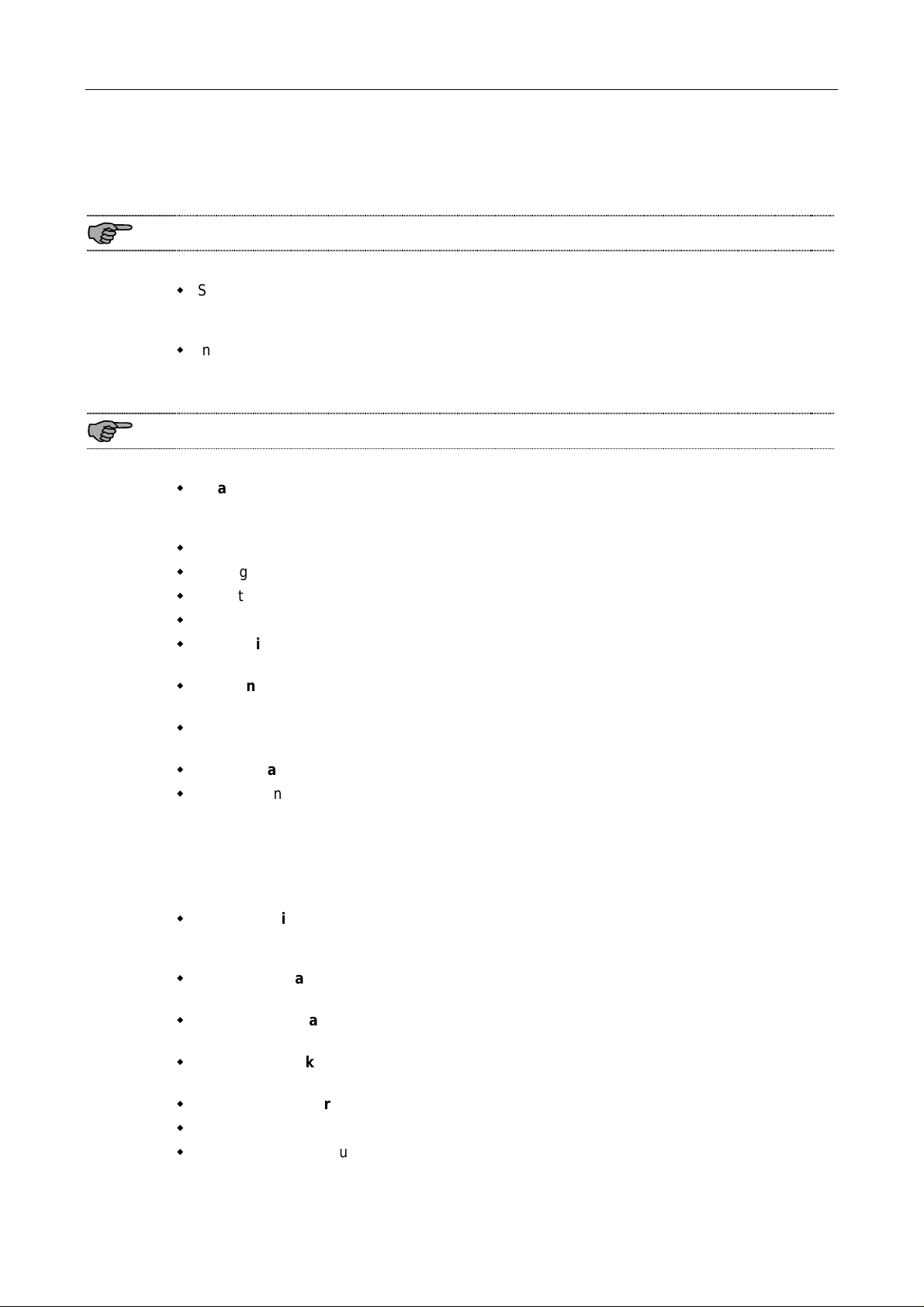

a) The support arm extension and the

support disc threading should be well

greased. It is recommended to use

lithium soap grease.

b) The oil level of the oil pan should be

checked quarterly. It is located on the

carriage slides behind the spindle

cover sheet. (see the upper part of the

diagram to the right) The pan should

have at least 5 mm of oil in it. If the oil

is not up to this level refill it. The neck

of the oil can be directly applied

through the brush cover of the column.

0-2mm

Use only

available from the manufacturer, order no.

360004.

D1 3602BA1-GB03 15

SAE 140

gear or the special oil

Page 20

Trucklift Maintenance, Troubleshooting

c) Wear and tear on the support nut must

be checked annually. Remove the

plastic cap from the spindle cover

sheet and move the carriage slides so

that the control drill holes lines up with

the window.

If there is no visible gap this is an

indicatioin that the support nut is worn

down beyond the permissable limit.

The support nut must be replaced. The

gap is approximately 2 mm. ex factory.

When the wear limit is reached the

lift must be shut down until the

bearing nuts have been replaced.

Lock the main switch to ensure that

nobody can use the machine .

5.2 Repair Notes

Only trained, skilled electricians are allowed to check impulse sensor and proximity

switches.

Immediately contact your MAHA dealer or the MAHA service center when there are problems

with impulse sensors or proximity switches.

Unskilled work on electrical parts of the lifting platform can be life threatening.

The main switch should be switched off and secured before any repair work or

malfunction troubleshooting is done on the lift!

Malfunctions due to unskilled repair or adjustment work are not covered by the warranty.

16 D1 3602BA1-GB03

Page 21

Maintenance, Troubleshooting Trucklift

5.3 Troubleshooting Checklist

The following checklist will help your service technicians to locate faults in the event of

problems.

Problem Possible cause Remedy

When lifting, lift stops of its

own accord at an arbitrary

height.

The LED on the circuit

board lights up (see ill. on

next page).

Lowering from this position

is possible.

When lowering, the lift

stops of its own accord at

an arbitrary height.

The LED on the circuit

board lights up (see ill. on

next page).

Lifting from this position is

possible.

Lift stops in the upper

position. After pressing the

RESET button followed by

the "Lower" button, all

motors activate briefly and

then stop.(see ill. on next

page)

a) Excessive load on the lift.

b) The distance between the

pulse encoder and the drive

pulley is too great.

a) The lift has run into an

obstacle, lifting out the

jackscrew.

b) The distance between

the pulse encoder and the

drive pulley is too

great.

No signals from the upper pulse

encoders.

a) Check whether the load

exceeds the rated maximum

lifting capacity. Check the

jackscrew lubrication and the

tension of the toothed drive

belt.

b) Check impulse encoder

distance (have it corrected, if

necessary).

Lifting should then be possible

again after lowering the lift by at

least 2 cm.

a) Remove the obstacle.

b) Check the upper pulse

encoder.

Lowering should then be

possible again after raising the

lift by at least 5 cm.

Check the upper pulse

encoders.

When the "Lift" button is

pressed the motors

activate again briefly and

then stop.

Pressing the buttons again

produces no further

reaction from the lift.

The red LED on the circuit

board lights up after about

5 seconds.(see ill. on next

page)

D1 3602BA1-GB03 17

Page 22

Trucklift Maintenance, Troubleshooting

Problem Possible cause Remedy

The lift stops at a height of

approx. 260 mm

(measured from the floor to

the lower edge of the

carriage).

The lift can only be

lowered from this position.

Further raising is not

possible.

The LED on the circuit

board blinks.(see ill. on

next page)

The lift stops at a height of

approx. 400 mm

(measured from the floor to

the lower edge of the

carriage).

The lift can only be

lowered from this position.

Further raising is not

possible.

a) The distance between the

catch nuts and the jackscrew

bearing nuts is too small.

b) A proximity switch is defective

or its setting is incorrect.

No signal pulse from the

switching cam on the frame or

the catch nut.

a) Check the wear of the bearing

nuts.

b) Check the distance between

the proximity switches and the

switching cams on the frame

and on the catch nuts .5 mm).

Check the proximity switches.

(Call MAHA-Service Dept.).

Check the distance between the

proximity switches and the

switching cams on the frame

and on the catch nuts.

The LED on the circuit

board blinks.(see ill. on

next page)

The lift can only be moved

to its lower starting

position.

Lifting is no longer

possible.

At the beginning of lifting

the lift stops and the power

supply circuit breaker trips.

Neither lifting nor lowering

are possible.

A bearing nut is broken and the

load is being borne by the catch

nut.

All motors are starting up

simultaneously. This causes a

voltage peak that trips the circuit

breaker

DIP switch 4 is set to "ON".(see

ill. on next page)

Have the bearing nut repaired.

Shut down the lift and

lock the main switch!

Change the setting of DIP switch

4 on the control PCB to

"OFF".(see ill. on next page).

This starts the motors in a

staggered sequence.

18 D1 3602BA1-GB03

Page 23

Maintenance, Troubleshooting Trucklift

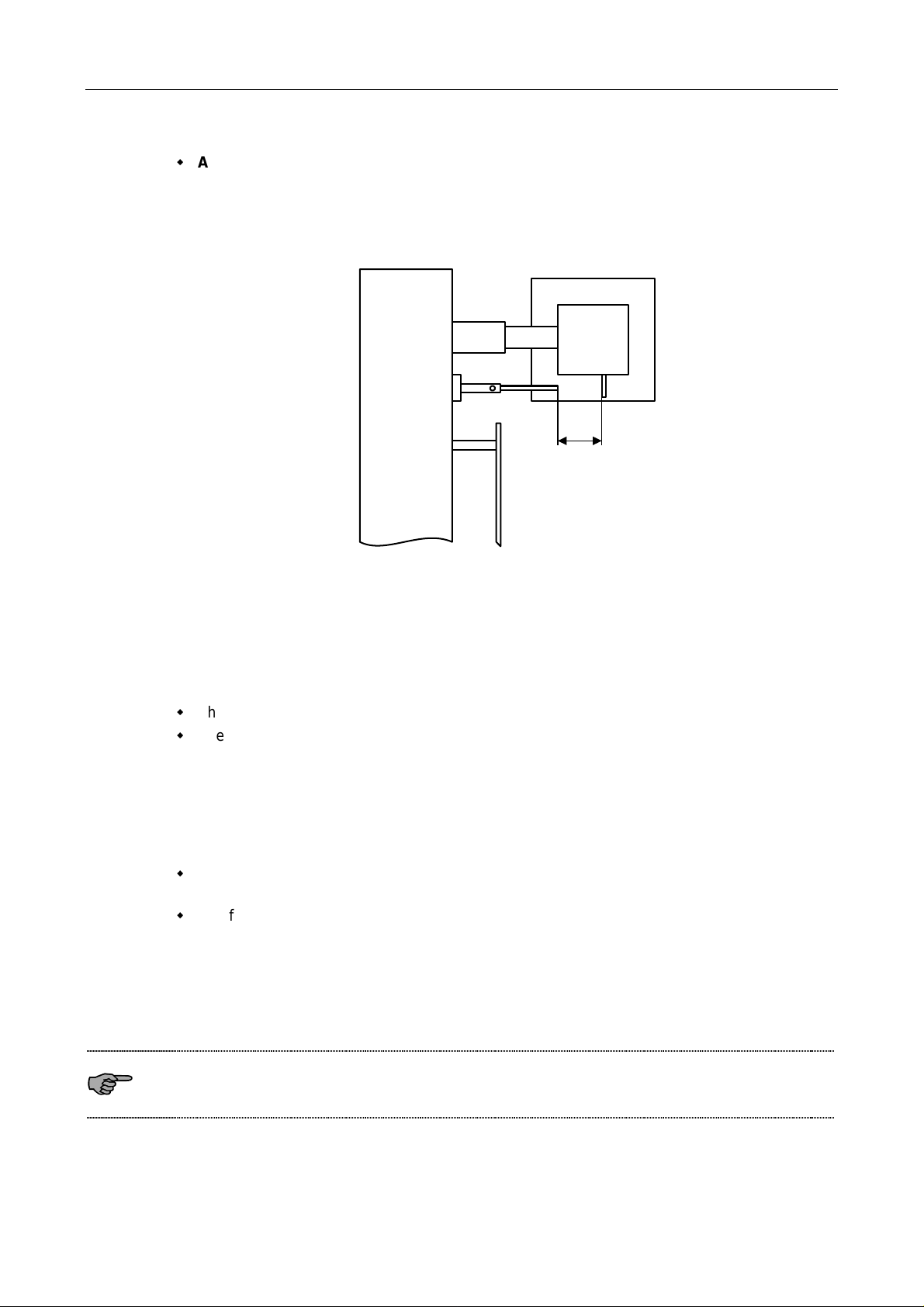

RESETDIP LED

Reset

LED

KEB

o63

470nJ

1234

ON

DIP

Ver.

Appl.

o63

470nJ

o63

470nJ

o63

470nJ

K3 K4

K1 K2

00

11

MK1

K7 K8

MK1

K5 K6

00

11

MK1

o63

470nJ

o63

470nJ

o63

470nJ

Q1

S2.2 S3.2

PE

18V 0,25A

VDE 0551 T 60/E

GERTH BV 4218-1

230V 50/60Hz

Control cabinet, opened Control PCB

5.4 Lowering the Lift in the Event of a Power Failure

Remove the motor cover hoods. Each spindle can be turned separately at the large drive

pulleys with a ratchet (nut size 36) to lower the carriages. When doing this, two persons should

lower the front column pair at the same time and then the back column pair.

As soon as the power returns, synchronise the carriages again by pressing "

down until all movement stops.

ERO

ERO

o63

470nJ

o63

470nJ

F1776-4223471 9220/

F1776-4223471 9220/

" and holding it

###

The height difference between the lateral column pair should never be more tha n 20 mm.

The height difference between the column pair in driving direction may not exceed 100

mm!

Important:

In the event of a power failure the lifting carriages should only be lowered!

D1 3602BA1-GB03 19

Page 24

Trucklift Maintenance, Troubleshooting

20 D1 3602BA1-GB03

Page 25

Trucklift

6 Warranty, Service

6.1 Warranty

Subject to the provisions of their General Terms and Conditions of Business, Maschinenbau

Haldenwang (MAHA) undertakes to repair or replace any defective components free of charge

during the warranty period if the product is sent to MAHA – either directly or through an

authorised MAHA dealer – or if the product is repaired or installed by authorised personnel.

This warranty is only provided for products installed by authorised personnel.

Damage resulting from improper alterations or grossly negligent damage to the product is

excluded from the warranty.

No warranty coverage for MAHA products can be provided without a fully completed Warranty

Registration Card and a Warranty Application, together with a completed and signed original

sale receipt showing the date of purchase and the serial number of the product. Proper regular

servicing is also a requirement for warranty coverage.

6.2 Warranty Exclusion Clause

All warranty coverage is subject to the condition that our products must be used properly for

their intended purpose, in accordance with the Installation and Maintenance Instructions and

Operating Instructions, including any subsequent operating and service information provided.

Normal functional wear and tear on vehicle components are excluded from the warranty. The

warranty does also not cover any damage to vehicles and/or our equipment or other products

caused by alterations to motor vehicles or other deviations of the motor vehicles from the series

model specifications.

D1 3602BA1-GB03 21

Page 26

Trucklift Warranty, Service

6.3 Service

MAHA has customer service offices in many countries all over the world. You can contact these

offices at any time to obtain answers to any questions you may have regarding MAHA products.

If your product needs repair you can always contact your dealer, or you can contact MAHA

directly. A charge will be made for repairs after the end of the warranty period.

You can reach our central customer service office at the address below:

MAHA Maschinenbau Haldenwang GmbH & Co. KG.

D-87490 Haldenwang/Allgäu

Telephone : 08374 / 585-0

Telefax : 08374 / 585-491

Internet : http://www.maha.de

E-Mail : maha@maha.de

22 D1 3602BA1-GB03

Loading...

Loading...